Are you ready to stand out in your next interview? Understanding and preparing for Calibration and Gage Management interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Calibration and Gage Management Interview

Q 1. Explain the difference between calibration and verification.

Calibration and verification are often confused, but they are distinct processes. Think of it like this: calibration is like taking your car to a mechanic for a tune-up – it’s a precise adjustment to ensure your instrument is measuring accurately against a known standard. Verification, on the other hand, is like a quick check-up – it confirms the instrument is still within acceptable limits, without necessarily making adjustments.

More formally, calibration involves comparing a measuring instrument’s readings to a traceable standard and adjusting the instrument to meet specified accuracy requirements. This process typically generates a calibration certificate detailing the results. Verification simply confirms that the instrument’s performance is still within its specified tolerances, often using a simpler procedure. It might involve checking a few points on the instrument’s range against a known standard without detailed adjustments. If the verification fails, then a full calibration is needed.

Example: A digital thermometer is calibrated by comparing its readings to a known-accurate temperature standard (like a calibrated liquid-in-glass thermometer) across its operating range. Verification might involve simply checking the thermometer against a known ice bath (0°C) and boiling water (100°C) to ensure readings fall within an acceptable tolerance.

Q 2. Describe the process of a Gage Repeatability and Reproducibility (GR&R) study.

A Gage Repeatability and Reproducibility (GR&R) study determines the variability within a measurement system. It separates the variation caused by the instrument (repeatability) from the variation caused by different operators using the instrument (reproducibility). This helps understand if the measurement system is capable of providing consistent and accurate results.

The process typically involves:

- Selecting parts: Choose a representative sample of parts covering the expected range of measurement values.

- Operators: Involve all operators who will use the gage in the study.

- Measurements: Each operator measures each part multiple times (e.g., 2-3 times). This provides multiple readings for each part-operator combination.

- Data analysis: Statistical software (e.g., Minitab) is used to analyze the data and calculate repeatability (variation within an operator) and reproducibility (variation between operators). The results usually quantify the percentage of total variation attributable to each source (gage, operator, and part-to-part variation).

- Assessment: The study determines whether the measurement system is adequate for its intended use. Acceptable limits are often based on a percentage of total variation, with a commonly accepted target of less than 30% gage variation.

Example: A GR&R study on a micrometer used to measure the thickness of a metal sheet. The results might show that 15% of the total variation is due to the micrometer’s repeatability, 5% to reproducibility among operators, and 80% to actual variation in sheet thickness. This suggests a good measurement system as most of the variation is inherent in the parts, not the measurement instrument or operators.

Q 3. What are the key elements of a successful calibration program?

A successful calibration program requires several key elements working in concert. Think of it as a well-oiled machine; each part is critical for optimal performance.

- Documented Procedures: Clear, documented procedures for calibration activities including frequency, methods, acceptance criteria, and corrective actions.

- Traceable Standards: Using calibration standards that can be traced back to national or international standards organizations (e.g., NIST, ISO).

- Qualified Personnel: Employing trained and competent personnel to perform calibrations.

- Calibration Equipment: Utilizing appropriate calibration equipment that is itself regularly calibrated.

- Control of Calibration Records: Maintaining accurate and organized records of calibration results, including certificates and instrument history.

- Regular Audits and Reviews: Periodic audits and reviews of the program to ensure compliance and effectiveness.

- Corrective Actions: Establishing a process for addressing instruments that fail calibration.

- Management Commitment: Commitment from upper management to support the calibration program financially and organizationally.

Without a robust system covering these aspects, the integrity of your measurements and ultimately, the quality of your products or services, can be compromised.

Q 4. How do you determine the appropriate calibration interval for a measuring instrument?

Determining the appropriate calibration interval is a crucial aspect of gage management. It balances the cost of calibration with the risk of using an out-of-calibration instrument. There’s no one-size-fits-all answer, as the interval depends on several factors:

- Instrument Type: Some instruments are inherently more stable than others.

- Usage Frequency: Instruments used frequently are more prone to wear and tear.

- Environmental Conditions: Harsh environments (high temperature, humidity, vibration) can affect instrument stability.

- Past Calibration History: Consistent results over time suggest a longer interval might be acceptable.

- Instrument Criticality: Instruments used for critical measurements require more frequent calibration.

- Manufacturer Recommendations: Manufacturers often provide guidelines on recommended calibration intervals.

- Regulatory Requirements: Some industries have regulations mandating specific calibration frequencies.

A risk assessment is usually conducted to determine the appropriate interval. It considers the potential impact of inaccurate measurements, cost of calibration, and frequency of instrument usage. A combination of manufacturer recommendations, past performance, and a risk assessment helps determine the appropriate calibration cycle. It’s an iterative process, and intervals are often reviewed and adjusted over time based on experience and data.

Q 5. What are the different types of calibration standards?

Calibration standards are crucial for ensuring accurate measurements. These standards are themselves calibrated to higher-level standards, creating a chain of traceability. Different types exist, categorized primarily by their metrological properties:

- Primary Standards: These are the highest-level standards maintained by national metrology institutes (e.g., NIST). They define the units of measurement.

- Secondary Standards: Calibrated against primary standards, these are used to calibrate working standards and instruments in laboratories and on the shop floor.

- Working Standards: Used directly to calibrate instruments. They are frequently checked against secondary or other working standards to maintain accuracy.

- Reference Standards: High accuracy standards used for comparison and verification, but not necessarily used for direct calibration adjustments.

The choice of standard depends on the accuracy requirements of the instrument being calibrated. For high-precision instruments, traceability to primary standards is essential, while lower-precision instruments might only require comparison to working standards.

Q 6. Explain the concept of traceability in calibration.

Traceability in calibration ensures that the results obtained from a calibration can be linked back to a known standard. It’s like following a breadcrumb trail to the source. This unbroken chain of comparisons, from the instrument being calibrated all the way to a national or international standard, builds confidence in the accuracy and reliability of the measurement.

It’s crucial for several reasons:

- Confidence in Measurements: Traceability ensures that measurements are consistent and comparable across different locations and organizations.

- Compliance with Standards: Many industries require traceable calibrations to comply with regulations and quality standards (e.g., ISO 9000, ISO 17025).

- Legal Defense: In case of disputes, traceable calibration records provide strong evidence supporting the accuracy of measurements.

Traceability is typically documented in a calibration certificate, showing the steps involved in linking the instrument’s calibration to a national standard. This often involves a documented chain of custody, showing when and how the standards involved were themselves calibrated.

Q 7. What is the purpose of a calibration certificate?

A calibration certificate is a formal record providing evidence that a measuring instrument has been calibrated against a traceable standard. It’s the essential proof that your instrument is accurate and reliable, and is similar to a passport for your equipment. Think of it as a certificate of good health for your measuring instrument.

A typical calibration certificate includes:

- Instrument identification: Unique identifier of the instrument being calibrated.

- Calibration date: Date when the calibration was performed.

- Calibration procedures: Description of the procedures used during the calibration.

- Standards used: Identification of the traceable standards used for comparison.

- Calibration results: Detailed results of the calibration, showing any adjustments made.

- Uncertainty of measurement: An estimate of the possible error associated with the calibration.

- Calibration expiry date: Date when the calibration is no longer valid.

- Accreditation details (if applicable): Information on the accreditation of the calibration laboratory (e.g., ISO 17025).

Calibration certificates are vital for demonstrating compliance, supporting quality management systems, and ensuring the accuracy of measurements for both internal and external stakeholders.

Q 8. How do you handle out-of-tolerance measuring instruments?

When a measuring instrument falls outside its tolerance limits – meaning its measurements are no longer reliable enough – it’s considered out-of-tolerance. The first step is to immediately remove it from service to prevent inaccurate measurements and potential product defects. We then investigate the cause. This could be anything from normal wear and tear to a sudden impact. Next, the instrument is sent for recalibration or repair by a qualified technician. A detailed record is kept, including the date of discovery, the out-of-tolerance readings, the corrective action taken, and the date it was returned to service after verification. For example, if a micrometer used for critical dimension measurement on engine parts is found out-of-tolerance, it will be tagged “Out of Calibration”, immediately taken out of use, and sent to the calibration lab. After recalibration and confirmation of accuracy, only then is it put back into service.

Q 9. What are the common sources of measurement error?

Measurement errors are inevitable, but understanding their sources helps minimize their impact. Common sources include:

- Environmental Factors: Temperature, humidity, and vibration can all affect instrument readings. For instance, a steel ruler will expand slightly in higher temperatures, leading to inaccurate measurements.

- Instrument Wear and Tear: Regular use can lead to wear, damage, or misalignment. A worn-out caliper might give consistently incorrect readings.

- Operator Error: Incorrect techniques, parallax errors (misaligned eye position when reading a scale), or misinterpretations of readings can introduce significant errors. For instance, not using the correct measuring technique could result in inaccurate measurement.

- Calibration Drift: Over time, even well-maintained instruments can drift from their calibrated values. This is why regular calibration checks are crucial.

- Improper Handling and Storage: Incorrect handling or storage can cause damage. Dropping a precision instrument can obviously cause damage, but even improper storage can contribute to inaccuracies.

Understanding these sources allows us to implement preventative measures, such as controlled environments, proper training, and rigorous calibration schedules.

Q 10. Describe your experience with different calibration methods (e.g., comparison, substitution).

I have extensive experience with various calibration methods. Comparison calibration is the most common; it involves comparing the instrument to a known standard. For example, we might compare a digital thermometer to a traceable standard thermometer. This is simple and cost-effective for many instruments. Substitution calibration involves replacing the standard with the instrument under test in the same measuring system. It is often used for instruments where direct comparison isn’t feasible. This method ensures that the system’s influence is eliminated. In some cases, we use functional calibration, where we check the instrument’s performance against established specifications using traceable standards. Think of calibrating a pressure gauge by applying known pressures and comparing the readings. The method selection depends on the instrument type, its precision, and the available standards. Each calibration is documented meticulously, tracing the accuracy to national or international standards.

Q 11. How do you manage calibration records and data?

Calibration records are critical for maintaining compliance and demonstrating traceability. We use a robust system combining physical and electronic records. Each instrument has a unique identification number, and all calibration activities are recorded in a detailed log, including dates, results, and any corrective actions. Electronic databases are used to maintain this information, allowing for easy searching and reporting. This data is regularly audited to confirm accuracy and completeness. We follow a specific filing system to ensure easy retrieval of physical records when needed. This comprehensive approach facilitates seamless tracking of calibration history, ensuring instrument accuracy and preventing any potential disruptions caused by inaccurate measurements.

Q 12. What software or systems are you familiar with for managing calibration?

I am proficient with several calibration management software systems including CMMS (Computerized Maintenance Management Systems), specifically those with robust calibration modules. These systems allow for automated scheduling of calibrations, tracking of assets, and generating reports. I’m also experienced using dedicated calibration software packages that provide advanced features like uncertainty analysis and compliance reports. My familiarity also extends to using spreadsheets (e.g., Excel) for managing simpler calibration programs. The choice of software depends on the complexity and scale of the calibration program.

Q 13. Explain the concept of measurement uncertainty.

Measurement uncertainty quantifies the doubt surrounding a measurement result. It’s essentially the range within which the true value likely lies. It’s not just about instrument error; it encompasses all sources of uncertainty, including environmental factors, operator skill, and the calibration method’s limitations. For example, if a scale measures a weight as 100g ± 0.5g, the uncertainty is ±0.5g. This means we’re 95% confident that the true weight lies between 99.5g and 100.5g. Understanding and reporting measurement uncertainty is vital for reliable data analysis and informed decision-making, especially in regulated industries.

Q 14. How do you ensure the accuracy and reliability of calibration results?

Ensuring accuracy and reliability involves a multi-faceted approach:

- Traceable Standards: Our calibration standards are traceable to national or international standards, providing a verifiable chain of custody for accuracy.

- Regular Calibration: Instruments are calibrated according to predefined schedules based on their criticality and usage frequency. This ensures that any drift is identified and corrected before it impacts measurements.

- Qualified Personnel: All personnel involved in calibration are properly trained and competent in using the equipment and interpreting results.

- Environmental Controls: Where necessary, we use controlled environments to minimize the impact of environmental factors on measurements.

- Record Keeping: Meticulous record-keeping ensures traceability and allows for ongoing monitoring of instrument performance.

- Regular Audits: Our calibration processes undergo regular audits to identify and correct any shortcomings in the system.

By implementing this comprehensive quality control system, we maintain the integrity of our calibration results and ensure the accuracy and reliability of all measurements.

Q 15. What is your experience with different types of measuring instruments (e.g., calipers, micrometers, CMMs)?

My experience encompasses a wide range of measuring instruments, crucial for ensuring accuracy in various manufacturing and quality control processes. I’m proficient in using and calibrating instruments like:

- Vernier Calipers: I’ve extensively used calipers for precise linear measurements, understanding their limitations and proper techniques to minimize errors like parallax. For instance, I once identified a consistent 0.02mm offset in a set of calipers during a routine calibration, highlighting the importance of regular checks.

- Micrometers: Micrometers provide even higher precision than calipers. I’m experienced in using both outside and inside micrometers, understanding the proper techniques for accurate readings and the impact of factors like temperature and operator technique on measurement accuracy. I’ve trained numerous technicians on proper micrometer usage and preventative maintenance.

- Coordinate Measuring Machines (CMMs): CMMs are essential for complex 3D measurements. My experience includes programming CMMs using various software packages, analyzing measurement data, and troubleshooting issues. I’ve used CMMs to inspect intricate parts, identifying deviations from CAD models and contributing to process improvements.

Beyond these, my expertise extends to other instruments such as dial indicators, height gauges, and optical comparators, showcasing a broad understanding of metrology principles across diverse applications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with statistical process control (SPC) in calibration.

Statistical Process Control (SPC) is fundamental to effective calibration management. I use SPC charts, particularly control charts like X-bar and R charts, to monitor the stability of measurement processes and identify trends that might indicate instrument drift or other issues.

For example, I regularly track the calibration data of our critical micrometers using an X-bar and R chart. This allows me to visually see if the measurements are staying within acceptable control limits. If I observe a pattern of increasing measurements or a sudden shift outside of control limits, I investigate further, which might involve recalibrating the instrument, investigating the measurement process itself, or even identifying operator-related issues.

This proactive approach helps to prevent inaccurate measurements and maintain consistent product quality. Moreover, SPC data provides evidence to demonstrate compliance to regulatory requirements and internal quality systems.

Q 17. How do you identify and mitigate risks associated with calibration?

Risk mitigation in calibration focuses on preventing inaccurate measurements that can lead to costly product defects or even safety hazards. My approach involves a multi-faceted strategy:

- Risk Assessment: I regularly assess calibration processes, identifying potential sources of error, such as environmental factors (temperature, humidity), instrument wear and tear, and operator skill levels. This is often done through Failure Mode and Effects Analysis (FMEA).

- Calibration Schedule: A well-defined calibration schedule based on instrument criticality, usage frequency, and manufacturer recommendations is crucial. High-precision instruments are calibrated more frequently than those with lower precision.

- Preventative Maintenance: I emphasize preventative maintenance to extend instrument lifespan and reduce the likelihood of failure. This includes regular cleaning, lubrication, and visual inspections.

- Training and Competency: Ensuring that calibration personnel are properly trained and competent to operate and maintain instruments is vital. This reduces human error and ensures consistent results.

- Traceability: Maintaining a clear chain of traceability, linking calibrations back to national or international standards, is paramount for demonstrating accuracy and compliance.

By addressing these risk areas proactively, we can minimize the probability of inaccurate measurements and maintain the integrity of our calibration program.

Q 18. What are the regulatory requirements for calibration in your industry?

Regulatory requirements for calibration vary depending on the industry and the nature of the products being manufactured. In many industries, adherence to ISO 17025 (General requirements for the competence of testing and calibration laboratories) is considered best practice. This standard outlines rigorous requirements for managing quality, personnel competence, and ensuring the reliability of calibration results.

Furthermore, specific industry regulations might exist depending on the product. For example, in medical device manufacturing, adherence to FDA guidelines is crucial, requiring rigorous calibration protocols and documentation. In aerospace, stringent requirements often exist related to traceability and accuracy to ensure flight safety. I always stay abreast of current regulations relevant to our industry and ensure that our calibration processes comply fully.

Q 19. Explain the concept of a calibration laboratory’s accreditation.

Accreditation for a calibration laboratory, typically granted by a nationally recognized accreditation body (like A2LA in the US or UKAS in the UK), demonstrates that the laboratory operates according to internationally recognized standards, such as ISO 17025. This provides a level of confidence to customers that the calibrations performed are traceable, accurate, and reliable.

Accreditation involves a thorough audit of the laboratory’s procedures, equipment, personnel, and quality management system. Achieving accreditation signifies that the laboratory meets the stringent requirements for technical competence and operational integrity, making it a trustworthy partner for calibration needs. Choosing an accredited lab ensures the highest level of quality and assurance for your calibration needs.

Q 20. How do you ensure the competency of calibration personnel?

Ensuring the competency of calibration personnel is crucial for maintaining the accuracy and reliability of our calibration processes. My approach involves a multi-pronged strategy:

- Initial Training: All personnel receive comprehensive training on the relevant calibration techniques, instrument operation, and safety procedures. This might include classroom training, hands-on practice, and shadowing of experienced technicians.

- Ongoing Training: Continuous professional development is encouraged through workshops, online courses, and participation in industry conferences to stay updated on best practices and technological advancements.

- Performance Monitoring: Regular performance monitoring through internal audits, interlaboratory comparisons, and analysis of calibration data helps identify areas where additional training or improvement might be needed.

- Certification: Where applicable, personnel are encouraged to obtain relevant certifications to demonstrate expertise and proficiency in specific calibration areas.

- Documentation: Maintaining meticulous records of all training and competency assessments is essential for demonstrating compliance with quality management systems and regulatory requirements.

This comprehensive approach ensures that our personnel are equipped with the skills and knowledge to perform accurate and reliable calibrations consistently.

Q 21. Describe your experience with root cause analysis of calibration discrepancies.

Root cause analysis of calibration discrepancies is crucial for preventing future errors and improving the overall calibration process. I typically employ a structured approach, such as the 5 Whys technique or a Fishbone diagram (Ishikawa diagram), to systematically investigate the causes of discrepancies.

For example, if a micrometer consistently shows a bias, I wouldn’t simply adjust the instrument. I would systematically investigate potential root causes, such as:

- Instrument wear: Is there visible damage or wear to the measuring surfaces?

- Environmental factors: Are temperature fluctuations affecting the accuracy?

- Operator error: Are the calibration procedures being followed consistently and correctly?

- Calibration standards: Are the reference standards used for calibration properly traceable and accurate?

By systematically investigating each of these, I can identify the root cause, implement corrective actions, and prevent similar discrepancies in the future. This data is then documented and used to continually improve our calibration processes.

Q 22. How do you manage calibration workload and prioritize tasks?

Managing calibration workload effectively requires a structured approach. I typically begin by creating a comprehensive calibration schedule, considering factors like equipment criticality, manufacturer recommendations, and regulatory requirements. This schedule is often managed using a computerized maintenance management system (CMMS). Prioritization is key; I use a risk-based approach, assigning higher priority to instruments impacting product quality, safety, or regulatory compliance. For example, instruments used in final product inspection would be prioritized over those used in less critical processes. I also employ techniques like workload leveling, strategically scheduling calibrations to avoid peak periods and ensure consistent workflow. Regular review and adjustment of the schedule are crucial to adapt to changing business needs and equipment additions.

- Criticality Ranking: Assign a criticality level to each instrument based on its impact on the product or process.

- CMMS Utilization: Leverage a CMMS to track calibration due dates, generate reports, and manage work orders.

- Workload Leveling: Distribute calibration tasks evenly throughout the year to avoid bottlenecks.

Q 23. Explain your understanding of different calibration methods for different types of equipment.

Calibration methods vary greatly depending on the type of equipment. For simple instruments like thermometers, a comparison calibration against a traceable standard is usually sufficient. This involves comparing readings from the instrument under test to a known accurate standard under controlled conditions. More complex equipment, like pressure gauges or electronic balances, might require a multi-point calibration, where readings are compared at several points across the instrument’s range. For sophisticated instruments such as spectral analyzers or oscilloscopes, a full functional calibration, involving multiple tests and adjustments, may be necessary. The chosen method always conforms to the manufacturer’s specifications and relevant standards. Traceability to national or international standards is crucial to ensure accuracy and consistency.

- Comparison Calibration: Comparing readings against a traceable standard.

- Multi-Point Calibration: Comparing readings at multiple points across the instrument’s range.

- Functional Calibration: Performing multiple tests and adjustments to verify functionality.

Q 24. Describe a time you had to troubleshoot a complex calibration problem.

In a previous role, we experienced unexpected drift in a high-precision spectrophotometer, leading to inconsistent readings. Initial troubleshooting focused on environmental factors like temperature and humidity fluctuations, which were ruled out after careful monitoring. We then investigated the instrument’s internal components, checking for loose connections, damaged sensors, and software glitches. After a thorough examination, we discovered a minor leak in the reference cell, affecting the instrument’s zero point. This leak, invisible to the naked eye, was detected through a pressure test. Once the leak was repaired and the instrument recalibrated, the accuracy was restored. This experience highlighted the importance of systematic troubleshooting, combining environmental checks, internal component inspection, and utilizing specialized tests to isolate the root cause of calibration problems.

Q 25. How do you ensure the proper storage and handling of calibrated instruments?

Proper storage and handling are crucial for maintaining the accuracy of calibrated instruments. I always follow a strict protocol, ensuring instruments are stored in designated areas with controlled environmental conditions. This often includes temperature and humidity control to minimize the effects of environmental factors on instrument performance. Instruments are stored in protective cases or enclosures to prevent damage during storage and handling. Additionally, a robust system for tracking instrument location and condition is vital, often facilitated by a CMMS. Regular cleaning and inspection are implemented based on instrument type and frequency of use to prevent contamination or damage. This prevents unexpected downtime and ensures the continued reliability of the measurements.

Q 26. What is your experience with preventative maintenance of measuring instruments?

Preventative maintenance is integral to ensuring the longevity and accuracy of measuring instruments. My experience involves developing and implementing preventative maintenance schedules based on manufacturer recommendations, instrument type, and usage frequency. This includes regular cleaning, lubrication, and inspection of mechanical parts, as well as software updates and functional checks for electronic instruments. For example, regularly cleaning a micrometer’s anvil and spindle prevents debris from affecting measurements. Conducting routine checks on a digital multimeter’s battery and fuses prevents unexpected failures during critical measurements. Detailed records are meticulously maintained to document all preventative maintenance activities, ensuring traceability and compliance with relevant standards. This proactive approach reduces downtime, extends instrument lifespan, and ensures the highest level of measurement accuracy.

Q 27. Describe your familiarity with ISO 9001 and its relevance to calibration.

ISO 9001 is an internationally recognized quality management system standard, and calibration plays a significant role in ensuring compliance. The standard emphasizes the need for documented procedures for calibration, traceable standards, and competent personnel. Calibration activities are critical to demonstrating the control and monitoring of measuring equipment, ensuring the accuracy and reliability of test and measurement results. My experience involves working within ISO 9001 frameworks, ensuring all calibration processes are documented, controlled, and auditable. This includes the development and implementation of calibration procedures, maintenance of calibration records, and participation in internal and external audits. The focus is on maintaining a quality system where calibrated equipment ensures product consistency and quality.

Q 28. How do you communicate calibration results to stakeholders?

Communicating calibration results effectively is paramount. I use a variety of methods depending on the audience and the complexity of the information. For routine calibrations, a simple pass/fail report with any necessary adjustments noted suffices. For complex calibrations or when significant deviations are found, a more detailed report is generated, including data plots, statistical analyses, and recommendations for corrective actions. This information is disseminated through various channels, including email, reports integrated within the CMMS, or presentations to relevant stakeholders. Clear and concise communication is vital; technical jargon is avoided unless the audience has the necessary background. The focus is on conveying the information in a way that is easily understood and actionable, facilitating informed decisions and prompt corrective actions if needed.

Key Topics to Learn for Calibration and Gage Management Interview

- Calibration Standards and Traceability: Understanding the hierarchy of standards, calibration certificates, and the importance of maintaining unbroken traceability to national or international standards. Practical application: Explaining how to interpret a calibration certificate and identify potential discrepancies.

- Measurement Uncertainty and Error Analysis: Grasping the concepts of accuracy, precision, repeatability, and reproducibility. Practical application: Describing methods for minimizing measurement uncertainty and performing error analysis on measurement data.

- Calibration Methods and Techniques: Familiarity with various calibration methods (e.g., comparison, substitution, direct calibration) and their appropriate application based on the type of measuring equipment. Practical application: Explaining the selection process for a suitable calibration method for a specific instrument.

- Gage R&R Studies (Gauge Repeatability and Reproducibility): Understanding the purpose and execution of Gage R&R studies to assess the variability in measurement systems. Practical application: Interpreting the results of a Gage R&R study and identifying areas for improvement in measurement processes.

- Calibration Scheduling and Management: Developing and implementing effective calibration schedules based on instrument criticality, manufacturer recommendations, and regulatory requirements. Practical application: Discussing strategies for optimizing calibration schedules and minimizing downtime.

- Calibration Software and Databases: Experience with calibration management software for tracking calibration records, generating reports, and managing calibration assets. Practical application: Discussing the advantages and disadvantages of different calibration software solutions.

- Statistical Process Control (SPC) in Calibration: Applying SPC techniques to monitor the performance of measurement systems and identify trends or patterns. Practical application: Interpreting control charts used in calibration monitoring.

- Regulatory Compliance (ISO 9001, ISO 17025): Understanding the relevant regulatory requirements related to calibration and measurement. Practical application: Explaining how calibration processes ensure compliance with industry standards.

Next Steps

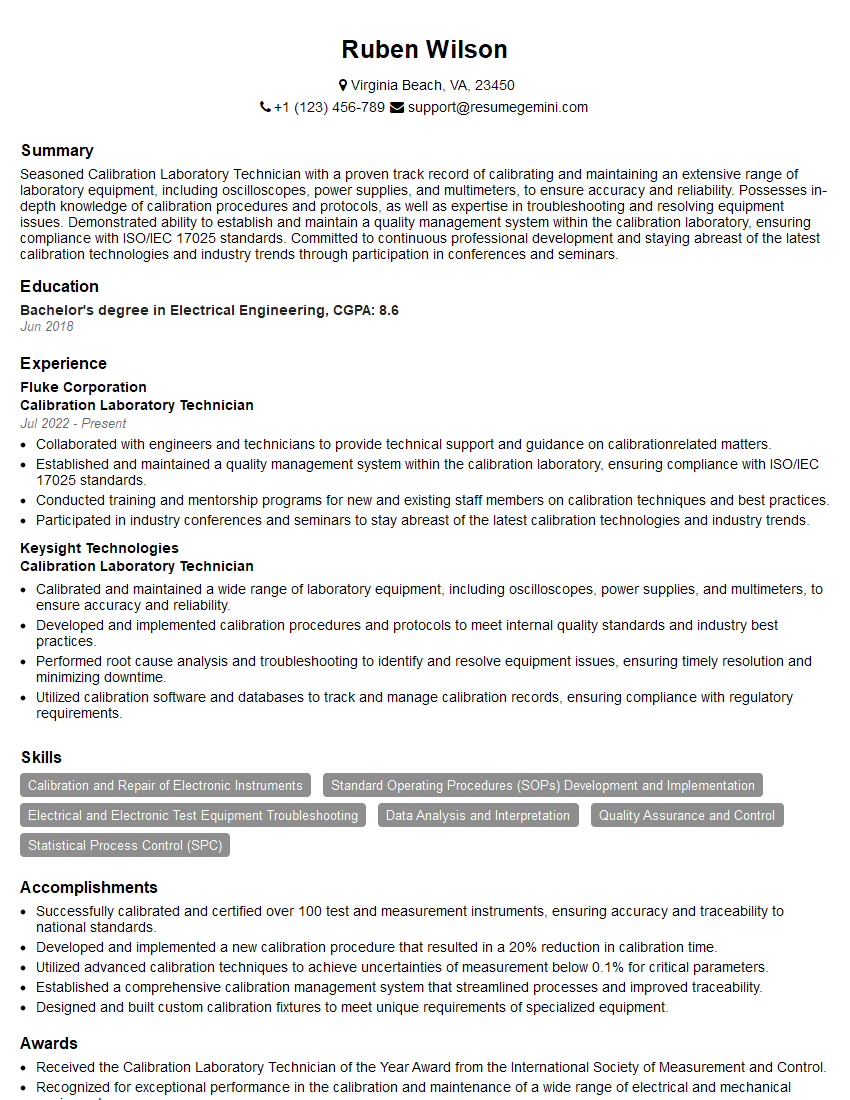

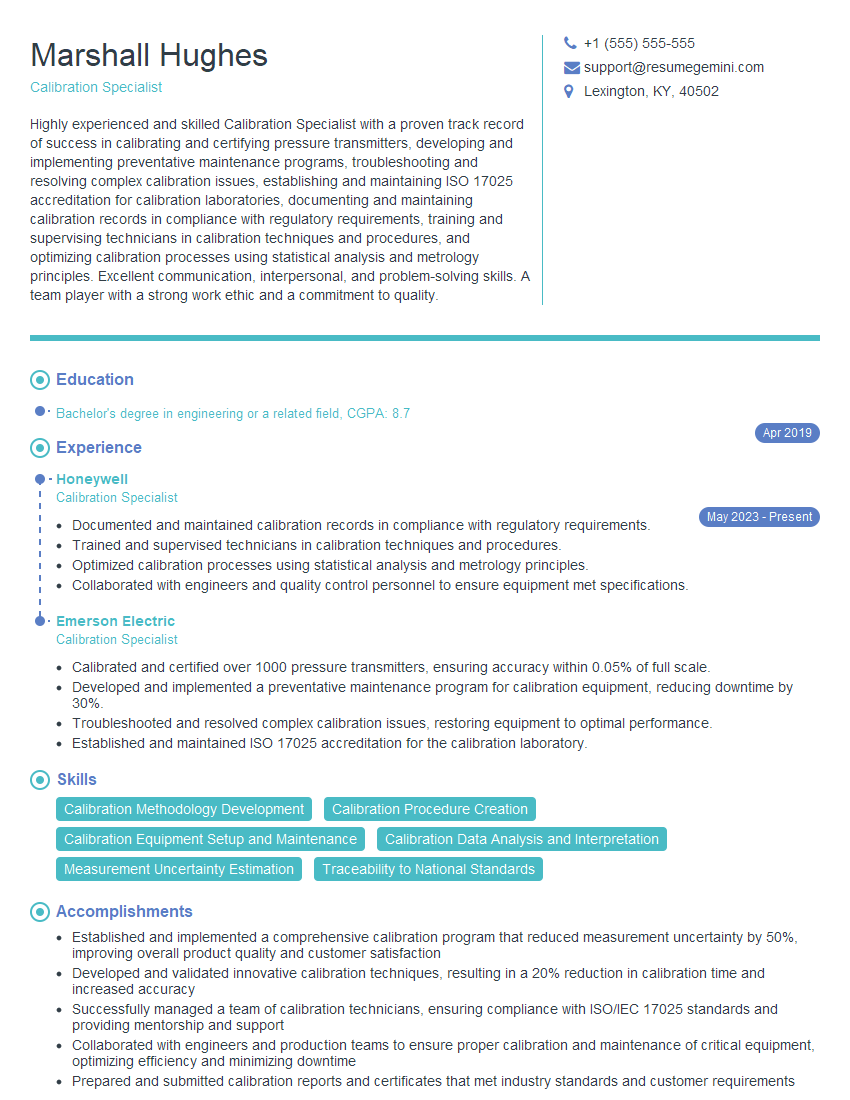

Mastering Calibration and Gage Management is crucial for career advancement in many technical fields, opening doors to leadership roles and specialized expertise. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the specific requirements of Calibration and Gage Management positions. Examples of resumes specifically designed for this field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good