Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Calibration and Verification of Measuring Equipment interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Calibration and Verification of Measuring Equipment Interview

Q 1. Explain the difference between calibration and verification.

Calibration and verification are both crucial for ensuring the accuracy of measuring equipment, but they differ in their scope and purpose. Think of it like this: calibration is adjusting a measuring instrument to a known standard, while verification is confirming that the instrument is performing within its specified tolerances.

- Calibration: Involves comparing a measuring instrument’s readings to a traceable standard and adjusting it to meet predefined tolerances. It aims to minimize measurement errors and ensures accurate readings. For example, calibrating a pressure gauge involves comparing its readings to a known accurate pressure source and adjusting it if necessary.

- Verification: Checks if the measuring instrument is still performing within its specified accuracy limits after a period of use or after an event like a repair. Verification doesn’t necessarily involve adjustment. It confirms whether the equipment is suitable for continued use without requiring recalibration. Imagine checking your bathroom scale to confirm it’s still accurate after moving it.

In essence, calibration corrects the instrument, while verification confirms its accuracy.

Q 2. What is traceability in calibration?

Traceability in calibration means establishing an unbroken chain of comparisons to national or international standards. It ensures that the measurements made are reliable and comparable globally. Imagine a pyramid: at the top is a national standard maintained by a metrology institute; lower levels consist of calibration labs and the instruments they calibrate. Each calibration step is documented, showing the instrument’s accuracy relative to the standards above it.

This chain of documentation provides confidence that the measurements are reliable and not subject to random variations. For example, if a thermometer is calibrated, its certificate should trace back to a national standard, proving its accuracy is dependable.

Q 3. Describe the process of calibrating a digital multimeter.

Calibrating a digital multimeter (DMM) involves verifying its accuracy in measuring voltage, current, and resistance against known standards. This typically requires a calibration setup that includes precision voltage sources, current sources, and resistance standards.

- Preparation: Gather the DMM, calibration standards (with traceable certificates), calibration leads, and the DMM’s specifications.

- Voltage Calibration: Use a precision voltage source to apply known voltages to the DMM’s input and record the DMM’s reading. Compare the DMM’s reading to the known value from the precision source for several voltage levels (e.g., 1V, 10V, 100V). This helps identify any systematic or random errors.

- Current Calibration: Similarly, apply known currents using a precision current source and record the DMM’s readings for different current levels. Note any deviations.

- Resistance Calibration: Use precision resistance standards and measure their values using the DMM’s resistance function. Compare readings with the known values.

- Analysis: Analyze the measured data and compare deviations against the DMM’s specifications. Calculate the error for each measurement point.

- Documentation: Document all measurements, comparisons, and any adjustments made. Create a calibration certificate.

Note: Some DMMs have self-calibration features, but external calibration with traceable standards is still necessary for ensuring long-term accuracy.

Q 4. What are the different types of calibration standards?

Calibration standards come in various forms depending on the measured quantity:

- Primary Standards: These are the highest level of accuracy, directly linked to fundamental physical constants. They’re typically found in national metrology institutes and are rarely used outside these institutions. An example would be a primary standard for resistance using the quantum Hall effect.

- Secondary Standards: Calibrated against primary standards and used to calibrate other instruments. They provide a link between primary standards and working standards.

- Working Standards: Used for the daily calibration of measuring instruments. They are calibrated against secondary standards.

The choice of standard depends on the required accuracy and the application. For example, a simple workshop might use a working standard, while a laboratory requiring high accuracy would use secondary standards.

Q 5. How do you determine the uncertainty of a measurement?

Determining the uncertainty of a measurement involves considering all potential sources of error and their contributions. This is a crucial step in ensuring reliable results.

Uncertainty is expressed as a range around the measured value, indicating the confidence level in the result. For example, a measurement of 10.0 ± 0.1 indicates a value between 9.9 and 10.1 with a certain level of confidence. The calculation involves considering factors such as:

- Resolution of the Instrument: The smallest division on the instrument scale contributes to uncertainty.

- Calibration Uncertainty: The uncertainty associated with the calibration of the measuring instrument.

- Environmental Factors: Temperature, humidity, and pressure can affect measurements.

- Operator Error: Human error in reading the instrument or making measurements.

Standard statistical methods are used to combine these uncertainties to provide an overall uncertainty estimate for the measurement.

Q 6. What is a calibration certificate and what information does it contain?

A calibration certificate is a formal document that verifies that a measuring instrument has been calibrated against traceable standards. It’s essential proof of the instrument’s accuracy within a specified period.

The certificate typically contains:

- Instrument Identification: Make, model, and serial number of the instrument.

- Calibration Date: Date when the calibration was performed.

- Calibration Standards: Identification of the standards used for calibration.

- Measurement Results: The measured values, uncertainties, and deviations from the expected values.

- Calibration Intervals: Recommended frequency of future calibrations.

- Expiry Date: Date when the calibration is no longer valid.

- Accreditation Information (if applicable): Information about the accreditation of the calibration laboratory.

The calibration certificate is crucial for maintaining the integrity of measurement data and ensuring compliance with regulations.

Q 7. Explain the concept of measurement error and its sources.

Measurement error is the difference between the measured value and the true value of the quantity being measured. It’s inevitable, but understanding its sources is key to minimizing it.

Sources of measurement error include:

- Systematic Errors: These are consistent and repeatable errors due to factors like instrument bias, incorrect calibration, or environmental conditions. For example, a consistently inaccurate scale.

- Random Errors: These are unpredictable and vary from one measurement to another. For example, small variations in readings due to fluctuations in ambient conditions or operator variations.

- Gross Errors: These are human errors, such as misreading the instrument, incorrect operation, or data entry mistakes.

Minimizing measurement errors requires careful instrument selection, proper calibration procedures, controlled environmental conditions, and thorough operator training. Understanding the sources of error and their magnitudes allows for a more accurate assessment of measurement results.

Q 8. How do you handle out-of-tolerance measurements?

Handling out-of-tolerance measurements requires a systematic approach. First, we must verify the result. Was there a procedural error? Was the equipment malfunctioning? A repeat measurement is crucial. If the out-of-tolerance result is confirmed, the instrument is deemed out of calibration. This doesn’t automatically mean the instrument is broken; it simply means its measurements are no longer within the acceptable tolerance limits.

Next, we initiate a corrective action. This might involve cleaning the instrument, adjusting settings, or performing minor repairs. If the problem persists, a more extensive repair or recalibration by a qualified technician might be necessary. The affected measurements must be investigated. Were any decisions made based on these inaccurate readings? If so, we must assess the potential impact and determine if remedial actions are needed. Finally, thorough documentation is essential, including details of the out-of-tolerance result, the corrective actions, and the subsequent verification results. This entire process is crucial for maintaining data integrity and ensuring the reliability of future measurements.

For instance, imagine a laboratory using a balance for weighing samples. If a balance consistently weighs samples 0.1g heavier than the true value, that’s out of tolerance. We’d investigate (check calibration weights, cleanliness), recalibrate if needed, and review any potentially affected previous results.

Q 9. What is the importance of maintaining calibration records?

Maintaining accurate calibration records is paramount for several reasons. Firstly, it provides irrefutable proof of compliance with relevant standards and regulations. This is essential for audits and demonstrating adherence to quality management systems like ISO 9001 or ISO 17025. Secondly, it enables efficient tracking of instrument performance over time. By reviewing calibration data, we can identify trends, predict potential failures, and schedule preventative maintenance. Thirdly, comprehensive records are crucial for tracing the accuracy of past measurements. If a dispute arises about a measurement’s validity, calibration records offer clear evidence to support or refute claims. Finally, these records facilitate improved efficiency. They clearly indicate when an instrument is due for its next calibration, minimizing downtime and ensuring uninterrupted workflow.

Imagine a pharmaceutical company – their calibration records are not merely paperwork; they are vital proof that their manufacturing processes adhere to stringent quality standards, ensuring patient safety. Poorly maintained records could lead to costly recalls or regulatory issues.

Q 10. Describe different calibration methods (e.g., comparison, substitution).

Calibration methods broadly fall into two categories: comparison and substitution. In the comparison method, the instrument under test (IUT) is compared directly with a known standard of higher accuracy (a reference standard). The difference between the IUT’s reading and the standard’s reading reveals the IUT’s error. This method is relatively simple and commonly used for calibrating instruments like thermometers, voltmeters, and pressure gauges.

The substitution method involves replacing the IUT with the known standard in the same measurement setup. This technique minimizes the effect of systematic errors from the measurement system itself, enhancing accuracy. It’s particularly suitable for calibrating instruments where the measurement system’s influence is significant, like mass balances or force gauges.

Other methods, such as in-situ calibration (calibrating equipment while in its operational environment) and remote calibration (using remote data acquisition to calibrate equipment), are also used depending on the specific instrument and its application. The choice of method depends on the instrument’s type, accuracy requirements, and the available resources.

Q 11. What is a calibration interval and how is it determined?

The calibration interval is the time period between successive calibrations of a measuring instrument. It’s not a fixed value but depends on several factors, primarily the instrument’s stability, its usage frequency, the severity of its application, and the environmental conditions it operates under. A highly stable instrument used infrequently in a controlled environment might have a longer interval, while a less stable instrument used frequently in harsh conditions requires more frequent calibration.

Determining the interval often involves a risk assessment. The potential consequences of an inaccurate measurement are considered. For critical applications where measurement errors could be costly or dangerous, shorter intervals are preferred. Manufacturers’ recommendations also guide this decision, though they often act as starting points rather than rigid rules. The calibration interval might be adjusted based on observations from calibration history. If an instrument consistently shows minimal drift over several calibration cycles, the interval might be extended, subject to approval.

For example, a laboratory thermometer used for routine checks might have a yearly interval, while a high-precision thermometer used for critical experiments might be calibrated every three or six months.

Q 12. Explain the significance of ISO 17025 in calibration laboratories.

ISO 17025, or General requirements for the competence of testing and calibration laboratories, is an internationally recognized standard that outlines the requirements for the operation of competent calibration laboratories. It ensures the quality and reliability of calibration services worldwide. Achieving ISO 17025 accreditation demonstrates a laboratory’s commitment to technical competence, management systems, and the delivery of traceable and reliable results.

The standard addresses many aspects, including personnel competency, method validation, equipment maintenance, traceability to national standards, uncertainty assessment, and quality management systems. Accreditation under ISO 17025 provides increased confidence in a laboratory’s calibration results, as it ensures that the processes used meet stringent international standards. Clients can trust the accuracy and reliability of the calibration data they receive from an accredited laboratory.

In essence, ISO 17025 provides a framework for ensuring the quality of calibration services, fostering international recognition and trust among organizations worldwide.

Q 13. How do you select the appropriate calibration equipment and methods?

Selecting appropriate calibration equipment and methods requires careful consideration. The first step is defining the measurement requirements. What are the accuracy, precision, and resolution needs? The selected equipment must meet or exceed these requirements. Next, the type of instrument to be calibrated plays a crucial role. Different instruments require different calibration methods and equipment. A digital multimeter would require a different calibration setup than a pressure transducer.

The traceability of the calibration equipment to national or international standards is paramount. This ensures that the calibration results are reliable and comparable across different laboratories. The environmental conditions during calibration must also be controlled and documented, as they can influence measurement results. Finally, the cost and availability of equipment and methods need to be considered. It is essential to select an approach that is both technically sound and economically feasible.

For example, if a company needs to calibrate high-precision balances, they’ll need a high-accuracy mass standard and a sophisticated calibration procedure. Using less accurate equipment would compromise the quality of the calibration and the subsequent measurements.

Q 14. What are the key performance indicators (KPIs) for a calibration lab?

Key Performance Indicators (KPIs) for a calibration laboratory help assess its efficiency and effectiveness. These typically include metrics related to turnaround time (how quickly calibrations are completed), on-time delivery (meeting scheduled calibration deadlines), and customer satisfaction (feedback from clients about their experience). Calibration accuracy, measured by the number of out-of-tolerance results and the overall uncertainty of measurements, is a critical KPI. Equipment utilization (percentage of time equipment is actively used for calibration) and cost per calibration are important for financial performance monitoring.

Accreditation status and compliance with ISO standards are crucial KPIs, reflecting the laboratory’s commitment to quality. Monitoring these KPIs enables continuous improvement by identifying areas for improvement and optimizing processes for better efficiency and accuracy. For example, a high percentage of out-of-tolerance results might indicate a need for better training or improved equipment maintenance procedures.

Q 15. Describe your experience with different types of measuring equipment.

My experience encompasses a wide range of measuring equipment, from simple instruments like calipers and micrometers to sophisticated devices such as pressure transducers, temperature sensors, and spectral analyzers. I’ve worked extensively with electrical test equipment like multimeters, oscilloscopes, and signal generators, as well as mechanical instruments such as balances, torque wrenches, and dimensional gauges. Each instrument presents unique calibration challenges, demanding a thorough understanding of its operating principles and potential sources of error. For instance, calibrating a micrometer requires a different approach than calibrating a complex automated measuring system. I’ve handled equipment used across various industries including manufacturing, pharmaceuticals, and aerospace, adapting my approach based on the specific requirements and regulatory standards of each.

- Example: In a pharmaceutical setting, I calibrated highly sensitive balances used for weighing active pharmaceutical ingredients, ensuring accuracy to the milligram level, which is critical for drug formulation and patient safety.

- Example: In an aerospace environment, I was involved in the calibration of pressure transducers used in flight control systems, a task demanding meticulous attention to detail and stringent adherence to safety protocols.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the integrity of calibration standards?

Maintaining the integrity of calibration standards is paramount. These standards are the foundation upon which all other measurements are based; their accuracy directly impacts the accuracy of all calibrated equipment. We achieve this through a multi-layered approach:

- Traceability: All our standards are traceable to national or international standards organizations (like NIST in the US or similar bodies globally), ensuring a clear and unbroken chain of comparison to the most fundamental units of measurement. This traceability is documented in detailed calibration certificates.

- Regular Calibration: Calibration standards themselves need to be calibrated periodically according to their specified uncertainty and usage frequency. This often involves sending them to a higher-level calibration laboratory for verification.

- Environmental Control: Standards are stored and handled in controlled environments to minimize the impact of factors like temperature, humidity, and vibration, which can affect their stability and accuracy. Think of it like keeping a finely tuned instrument in optimal conditions.

- Proper Handling: Careful handling and maintenance practices are crucial. This includes avoiding damage, contamination, and misuse of the standards.

- Regular Inspection: Visual inspection for damage or signs of wear is carried out regularly, as well as functional checks to ensure the standards are performing as expected.

Imagine a pyramid; the national standards are at the peak, and all other calibrations are built upon them. Maintaining the integrity of this pyramid requires diligent care at every level.

Q 17. What is the role of statistical process control (SPC) in calibration?

Statistical Process Control (SPC) plays a vital role in calibration by providing a structured approach to monitoring the calibration process itself. It helps us identify trends and variations in the measurements, ensuring that the calibration process is consistent and reliable over time. We use control charts (like Shewhart charts or CUSUM charts) to plot calibration data. These charts allow us to:

- Detect Out-of-Control Conditions: Quickly identify when the calibration process is exhibiting unusual variations or drifts, indicating potential problems with the equipment, the calibration process, or even the standards themselves. This allows for prompt corrective actions.

- Monitor Stability: Assess the long-term stability and consistency of the calibration process. Consistent data points within the control limits suggest a stable and reliable process.

- Improve Process Capability: By analyzing the control charts, we can identify areas for improvement in the calibration process, leading to reduced variability and increased confidence in the calibration results.

For example, if we consistently see measurements drifting above or below the target value, it may indicate a problem with the calibration equipment or a need for recalibration of the standards. SPC helps us move beyond just individual measurements to understand the overall behavior of the calibration process.

Q 18. Explain your understanding of Good Calibration Practices (GCP).

Good Calibration Practices (GCP) encompass a comprehensive set of guidelines and procedures that ensure the accuracy, traceability, and reliability of calibration processes. Key aspects of GCP include:

- Documented Procedures: Detailed, documented procedures for each calibration process, including step-by-step instructions, acceptance criteria, and record-keeping requirements. Think of it as a recipe for ensuring consistent results.

- Qualified Personnel: Calibration technicians should be properly trained and competent in the use of the equipment and the application of calibration procedures. Regular competency assessments are essential.

- Traceable Standards: As discussed earlier, calibration standards must be traceable to national or international standards.

- Equipment Maintenance: Regular maintenance of calibration equipment is vital to ensure its continued performance and accuracy. This is like keeping your car tuned up for optimal performance.

- Environmental Control: Maintaining a suitable environment during the calibration process is crucial to minimize errors.

- Data Management: Rigorous data management, including secure storage and retrieval of calibration records, is essential for audit trails and traceability.

- Regular Audits: Regular internal and external audits are crucial to ensure compliance with established GCPs and identify areas for improvement.

Adherence to GCP is critical for ensuring the quality and reliability of measurements across any industry, particularly those under stringent regulatory oversight like pharmaceuticals or aerospace.

Q 19. How do you manage calibration workloads and priorities?

Managing calibration workloads and priorities requires a well-defined system. I typically use a combination of techniques:

- Calibration Schedule: A prioritized schedule based on equipment criticality, frequency of use, and regulatory requirements. Instruments used in critical processes (e.g., safety systems) receive higher priority.

- Work Order System: A formal work order system to track calibration requests, assign tasks, and monitor progress. This ensures no requests are overlooked.

- Software Tools: Calibration management software helps automate scheduling, tracking, and reporting, providing a centralized view of the calibration workload. This aids in prioritization based on due dates and criticality.

- Resource Allocation: Effective resource allocation, considering the number of technicians and available equipment, is vital to meeting deadlines and managing capacity.

- Risk Assessment: Prioritizing instruments based on their potential impact on safety and product quality. A critical instrument requiring calibration will be prioritized over a non-critical one.

By combining these approaches, I ensure that critical equipment is calibrated on time and that the entire calibration process runs smoothly and efficiently.

Q 20. Describe your experience with calibration software and databases.

I have extensive experience using various calibration software and databases. These systems are crucial for managing the entire calibration process efficiently and accurately. I’ve worked with both standalone software packages and integrated systems within larger enterprise resource planning (ERP) platforms. These systems typically include functionalities for:

- Instrument Tracking: Managing instrument details, calibration history, and maintenance records.

- Scheduling: Automating the scheduling of calibrations based on due dates and priorities.

- Work Order Management: Creating and managing work orders, tracking progress, and assigning tasks to technicians.

- Reporting: Generating various reports, including calibration certificates, compliance reports, and performance summaries.

- Data Analysis: Analyzing calibration data to identify trends and potential issues.

Example: I used a particular software to manage over 500 instruments, generating automated reports for audits and ensuring compliance with ISO 17025 standards.

Q 21. What are the common problems encountered during calibration?

Common problems encountered during calibration include:

- Equipment Malfunctions: Equipment may malfunction during the calibration process, requiring troubleshooting and repair before calibration can continue.

- Calibration Standard Issues: Problems with calibration standards, such as damage, drift, or incorrect traceability, can affect the accuracy of the calibration.

- Environmental Factors: Uncontrolled environmental conditions (temperature, humidity, vibration) can introduce errors into the calibration process.

- Technician Errors: Human error, such as incorrect procedures, misreading measurements, or faulty data entry, is a common source of problems.

- Outdated Procedures: Using outdated or incomplete calibration procedures can lead to inaccurate results.

- Lack of Traceability: Inability to trace the calibration back to national or international standards.

- Software/Hardware Incompatibility: Calibration software or hardware may be incompatible with the instrument being calibrated.

Effective problem-solving involves a systematic approach, including thorough investigation, root-cause analysis, and implementation of corrective actions to prevent recurrence. For example, if repeated errors are identified with a particular technician, additional training might be required.

Q 22. How do you troubleshoot equipment malfunctions related to calibration?

Troubleshooting equipment malfunctions after a calibration attempt requires a systematic approach. It begins with reviewing the calibration certificate to understand the expected performance. Then, we move to a visual inspection, checking for obvious issues like loose connections, damaged cables, or physical obstructions. If these checks don’t reveal the problem, I move on to more advanced steps. For example, if we’re calibrating a pressure gauge, I might use a known good pressure source to isolate whether the issue lies with the gauge itself, the pressure source, or the connecting tubing. I would also consult the equipment’s manual for troubleshooting guides and potential error codes. Documenting every step and observation is critical for effective troubleshooting and preventative maintenance. For instance, if a temperature sensor consistently reads low, I might check its calibration history for trends indicating a gradual drift or investigate potential environmental factors influencing its reading, such as proximity to heat sources.

In complex situations, I might utilize diagnostic tools like multimeters or signal generators to perform further checks and tests. For example, I might check the sensor’s output signal across a range of inputs to see if the issue is a linear drift or some other more complex non-linearity. The whole process is focused on identifying the root cause, not just masking the symptom.

Q 23. What safety precautions do you follow during calibration procedures?

Safety is paramount during calibration procedures. Before starting any work, I always ensure the equipment is turned off and disconnected from power sources whenever possible. I follow the specific safety guidelines outlined in the equipment’s manual and any relevant safety data sheets (SDS) for materials involved. This might involve wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, or lab coats, to protect myself from hazards like electrical shocks, chemical splashes, or sharp objects. Working in a well-lit and organized workspace reduces the risk of accidents. I would also make sure that there are no tripping hazards present, such as loose cords or cables, and that sufficient ventilation is provided. A risk assessment should be conducted prior to starting calibration activities to identify and mitigate potential hazards. When working with high-voltage equipment, for example, I would ensure that appropriate lockout/tagout procedures are in place to prevent accidental energization. After the calibration process is finished, I also verify that all equipment is safely turned off, stored correctly, and any hazardous materials are disposed of according to regulations. Following established safety protocols ensures a safe and efficient calibration process.

Q 24. Explain your understanding of different uncertainty analysis methods.

Uncertainty analysis is crucial for quantifying the reliability of calibration results. I’m familiar with several methods, including those based on the Guide to the Expression of Uncertainty in Measurement (GUM). This guide provides a framework for determining measurement uncertainty by combining different sources of uncertainty. These sources could include calibration standards’ uncertainties, the resolution of the measuring instrument, environmental conditions, and operator influences. For instance, If we’re calibrating a digital multimeter, uncertainties might arise from its inherent resolution, the uncertainty of the calibration standard, and environmental temperature fluctuations. The GUM approach typically involves calculating the standard uncertainty (Type A and Type B) for each source and then combining them using root-sum-of-squares to get the overall combined uncertainty.

Another common approach involves Monte Carlo simulations. This method uses statistical modelling to account for uncertainty propagation. It uses repeated random sampling of input variables to simulate multiple outcomes and estimate the distribution of the output. This provides a better understanding of the uncertainty distribution instead of just the standard deviation. Each method’s suitability depends on the specific calibration task and the available data. The choice will involve considering both the complexity of the measurement and the level of precision required.

Q 25. How do you document calibration procedures and results?

Calibration documentation is essential for traceability and compliance. It’s typically done through a calibration certificate or report. This document must be clear, unambiguous and easy to understand for anyone who may refer to it. A well-structured calibration certificate includes details such as the equipment identification number, the date of calibration, the calibration standards used (with their traceability information), the test results, the uncertainty statements, and the signature of the calibration technician. I typically use a template which complies with ISO 17025 standards to ensure consistency and completeness. This ensures the certificate can be readily compared to previous certificates and provides evidence of compliance with established standards. I store the certificates in a secure and organized manner, either physically or electronically in a database with version control. Electronic records management systems are increasingly used to track certificates digitally, improving accessibility and traceability. A unique identification number helps to track the history of each device calibrated. For example, I’d track a specific temperature probe by giving it a unique ID and then entering data about its calibrations, including deviations from specified values.

Q 26. Describe your experience with internal audits related to calibration.

My experience with internal audits concerning calibration involves reviewing calibration procedures, records, and equipment performance data to ensure compliance with ISO 17025, relevant industry standards, and company policies. This includes checking that calibration procedures are documented, readily available, and followed consistently. I also look for evidence that the equipment used for calibration is itself calibrated and traceable to national or international standards. Audits include assessing the effectiveness of the calibration management system (CMS), including the processes for scheduling, performing, and reporting calibration results, investigating non-conformances, and ensuring corrective and preventative actions are taken where necessary. During audits, I usually create a checklist of criteria to be reviewed to ensure a thorough and objective evaluation. In one instance, during an internal audit, we discovered a gap in the documentation of calibration procedures for a specific type of pressure sensor. The corrective action involved updating the procedure documentation and providing additional training for technicians involved in the calibration of this type of sensor.

Q 27. What is your experience with different calibration techniques for different types of sensors?

Calibration techniques vary considerably depending on the type of sensor. For example, calibrating a thermocouple involves comparing its readings to a known standard reference thermometer over a range of temperatures. This might involve using a temperature bath or furnace that provides a stable and controlled temperature environment. For pressure sensors, I typically utilize a high-accuracy pressure source (like a piston gauge) to apply known pressures and compare the sensor’s readings. Calibration of a flow meter might necessitate using a calibrated flow standard, such as a master flow meter or a gravimetric method, to determine the flow rate accurately. In each case, the calibration method must be appropriate for the sensor’s operating range and accuracy specifications. For example, I would not use a low-accuracy pressure source to calibrate a high-precision pressure sensor. For each sensor type, I would select appropriate calibration equipment, consider environmental factors that may influence readings, and account for associated uncertainties. In addition, some sensors might require specialized calibration equipment or software. For instance, optical sensors may require specialized light sources and detectors for calibration.

Q 28. How would you approach a calibration assignment with limited resources?

Approaching a calibration assignment with limited resources requires careful planning and prioritization. First, I would identify the most critical equipment needing calibration based on its impact on product quality, safety, or regulatory compliance. Prioritize calibration of equipment most likely to have impact if failing or inaccurate. I would then look for opportunities to optimize resource utilization, such as sharing calibration equipment across departments or using less expensive, but still appropriate, calibration standards when possible. I might also explore more efficient calibration methodologies to reduce time and costs. For example, I might use software tools to automate data collection and analysis. It might be more cost-effective to contract out the calibration of specialized or rarely used equipment instead of purchasing expensive calibration equipment. Maintaining comprehensive records and proper documentation will be vital to prove compliance despite limited resources. Effective communication with stakeholders is essential to manage expectations and ensure that the calibration program remains effective within the limitations. If the resources are severely constrained, a risk assessment may reveal that not all equipment requires calibration immediately, and some may be postponed until resources become available.

Key Topics to Learn for Calibration and Verification of Measuring Equipment Interview

- Measurement Uncertainty: Understanding and calculating uncertainty in measurement results, including sources of error and their propagation.

- Calibration Methods: Familiarize yourself with various calibration techniques (e.g., direct comparison, substitution, interpolation) and their applications to different types of equipment.

- Traceability and Standards: Grasp the concept of traceability to national and international standards and its importance in ensuring measurement validity.

- Calibration Certificates and Reports: Understanding the structure and interpretation of calibration certificates and the importance of accurate documentation.

- Verification Procedures: Differentiate between calibration and verification, and understand the processes involved in verifying the performance of measuring equipment.

- Types of Measuring Equipment: Gain proficiency in the calibration and verification of various equipment types, including dimensional measuring instruments, temperature sensors, pressure gauges, and balances.

- Statistical Process Control (SPC): Understanding the application of SPC principles to monitor measurement system performance and identify potential issues.

- Troubleshooting and Problem-Solving: Develop your skills in identifying and resolving common issues encountered during calibration and verification processes.

- Calibration Software and Databases: Familiarity with calibration management software and databases for tracking and managing calibration schedules and results.

- Regulatory Compliance: Understanding relevant industry standards and regulations related to calibration and verification.

Next Steps

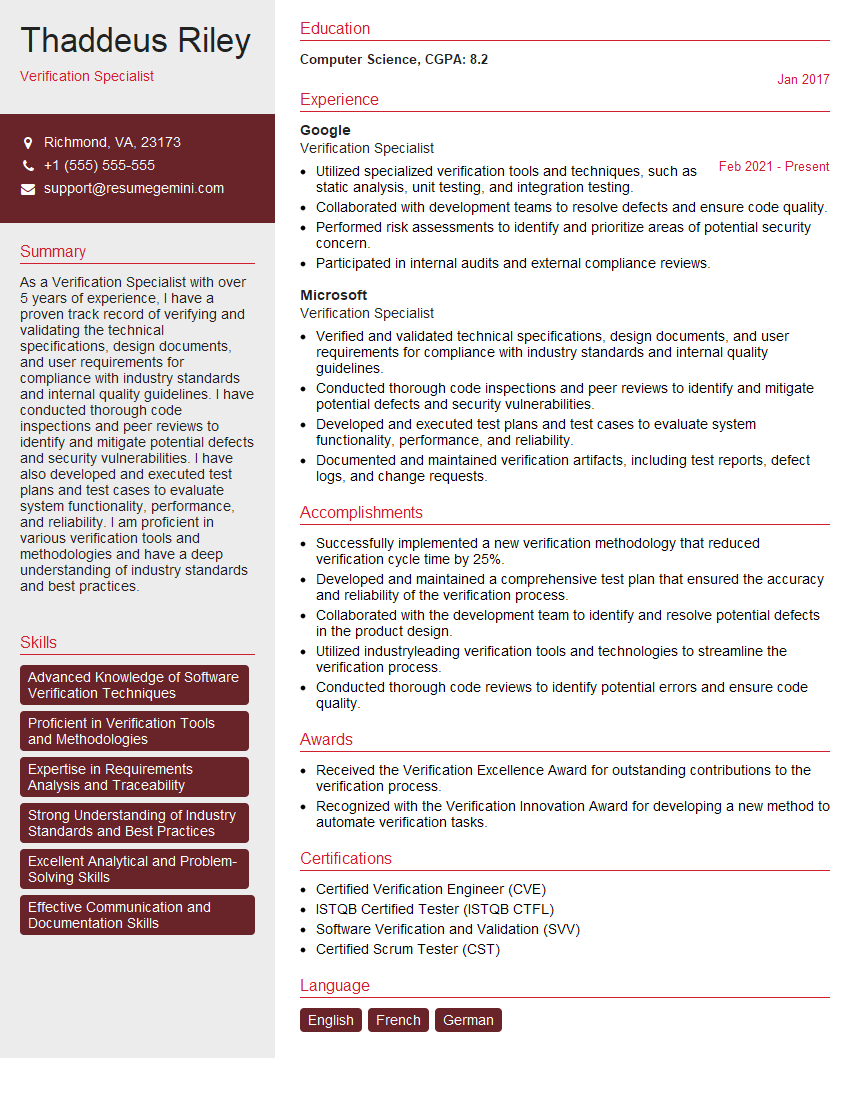

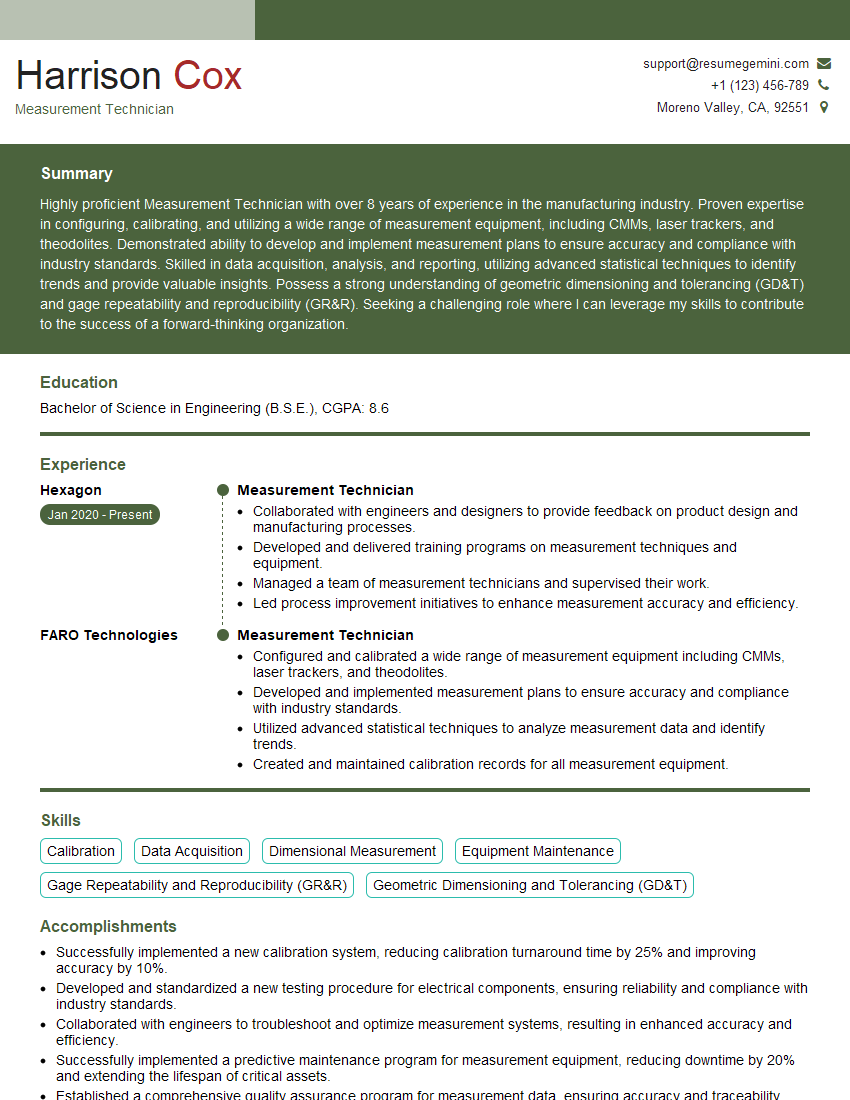

Mastering Calibration and Verification of Measuring Equipment opens doors to exciting career advancements in quality control, manufacturing, and various technical fields. A strong understanding of these principles significantly enhances your value to potential employers. To maximize your job prospects, create an ATS-friendly resume that clearly highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Calibration and Verification of Measuring Equipment to guide you in crafting a winning application. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good