Preparation is the key to success in any interview. In this post, we’ll explore crucial Capping Machine Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Capping Machine Operation Interview

Q 1. What are the different types of capping machines?

Capping machines are categorized based on their capping method and production capacity. The primary types include:

- Rotary Capping Machines: These are high-speed machines that use a rotating turret to apply caps to containers moving along a conveyor belt. They’re ideal for high-volume production lines.

- Linear Capping Machines: These machines use a linear arrangement of capping heads, processing containers one by one. They are generally slower than rotary machines but offer greater flexibility for different container shapes and sizes.

- Chuck Capping Machines: These machines utilize chucks that grip and tighten the caps onto containers. They are effective for a wide range of cap styles and offer excellent control over torque application.

- Continuous Motion Capping Machines: These machines allow for continuous container movement throughout the capping process. They’re excellent for smooth, high-speed operation and minimizing stoppages.

- Intermittent Motion Capping Machines: This type stops and holds the container briefly during the capping process. This method is beneficial for delicate containers or challenging cap types.

The choice of machine depends on factors like production volume, container type, cap style, and budget.

Q 2. Explain the capping process step-by-step.

The capping process generally follows these steps:

- Container Infeed: Containers are fed into the machine via a conveyor system or other infeed mechanism. This ensures consistent and controlled flow.

- Orientation: The machine orients the containers to ensure the cap is applied correctly. This might involve using mechanical guides or sensors.

- Capping: The capping head applies the cap to the container, utilizing various mechanisms such as screwing, crimping, or pressing depending on the cap and machine type. Precise torque control is essential here.

- Inspection (Optional): Some machines include integrated inspection systems to verify proper cap application and detect any defects like loose caps or missing caps.

- Outfeed: Capped containers are transported out of the machine via a conveyor system or other outfeed mechanism.

Variations exist depending on the specific machine and cap type. For example, a screw-cap machine uses a rotating head to screw the cap onto the container, while a crimp-cap machine uses a press to crimp the cap onto the container.

Q 3. How do you identify and troubleshoot common capping machine malfunctions?

Troubleshooting involves a systematic approach. I’d first visually inspect the machine for obvious issues like jams, damaged parts, or loose connections. Then:

- Low Capping Efficiency/Loose Caps: Check for inadequate torque, worn capping heads, improper container orientation, or incorrect cap placement.

- Capping Head Damage: Examine for wear and tear on the capping heads. Replacing or repairing damaged components is crucial for maintaining capping quality.

- Machine Jamming: Investigate container jams caused by incorrect container placement, faulty feed mechanisms or container defects.

- Inconsistent Torque: Check the torque settings and calibration. This often involves using a torque wrench to verify accurate torque application.

- Electrical Problems: Check for faulty wiring, blown fuses, or issues with the machine’s control system.

Maintaining detailed operational logs and preventive maintenance schedules helps to identify and prevent malfunctions.

Q 4. Describe your experience with different capping machine mechanisms (e.g., screw-cap, crimp-cap, etc.).

My experience encompasses various capping mechanisms. I’ve worked extensively with screw-cap machines, which require precise torque control to prevent over-tightening or under-tightening. I’ve also operated crimp-cap machines, understanding the importance of consistent pressure for a secure seal. I’m familiar with press-on caps and induction sealers used for specific applications. My experience also includes adjusting the machine settings for each cap type and container material, optimizing the process for each unique situation. I’ve worked with machines handling glass bottles, plastic containers, and metal cans, adapting to the distinct characteristics of each.

Q 5. What safety precautions do you follow while operating a capping machine?

Safety is paramount. Before operation, I always ensure:

- Lockout/Tagout Procedures: The machine is properly locked out and tagged out during maintenance or repairs to prevent accidental starts.

- Personal Protective Equipment (PPE): I wear appropriate PPE, including safety glasses, gloves, and hearing protection to mitigate potential hazards.

- Machine Guards: All safety guards are in place and functioning correctly to prevent accidental contact with moving parts.

- Regular Inspections: I conduct regular inspections of the machine for any signs of wear and tear, damage or malfunction before starting operations.

- Emergency Stop: I’m familiar with the location and operation of the emergency stop button.

I also follow all company safety protocols and regularly participate in safety training.

Q 6. How do you ensure the quality of the capping process?

Ensuring capping quality involves a multi-faceted approach:

- Visual Inspection: Regularly inspect capped containers for any signs of improperly applied caps, such as loose caps, tilted caps or missing caps.

- Torque Monitoring: Maintain consistent torque settings within specified tolerances. Regular calibration of the torque measuring devices is essential.

- Leak Testing: Conduct periodic leak tests to ensure the caps provide an adequate seal. This is especially crucial for liquid products.

- Preventive Maintenance: Regular scheduled maintenance prevents malfunctions and ensures the machine is operating optimally.

By implementing these measures, we minimize defective products and maintain consistent high quality.

Q 7. What are the key performance indicators (KPIs) for a capping machine?

Key Performance Indicators (KPIs) for a capping machine include:

- Output/Throughput: The number of containers capped per minute or hour. This reflects the efficiency of the machine.

- Capping Efficiency: The percentage of correctly capped containers. This is a key indicator of quality.

- Torque Consistency: The variability in torque applied to the caps. Consistent torque ensures consistent sealing and prevents damage.

- Downtime: The amount of time the machine is not operating. Minimizing downtime improves overall productivity.

- Mean Time Between Failures (MTBF): The average time between machine failures, indicating reliability.

- Total Productive Maintenance (TPM): A measure of proactive maintenance activities which reduce unexpected downtime and extend machine lifespan.

Monitoring these KPIs allows for continuous improvement of the capping process and optimization of machine performance.

Q 8. How do you maintain and perform preventative maintenance on a capping machine?

Preventative maintenance on a capping machine is crucial for ensuring consistent performance and minimizing downtime. It’s like regularly servicing your car – you catch small issues before they become major problems. My approach involves a structured schedule encompassing daily, weekly, and monthly checks.

- Daily Checks: This includes visually inspecting the capping heads for wear and tear, checking the cap feed system for jams or blockages, and lubricating moving parts like the chuck and spindle. I also monitor the capping torque and make minor adjustments as needed. Think of this as a quick ‘health check’ before each shift.

- Weekly Checks: More in-depth checks are performed weekly. This includes a thorough cleaning of the machine, including removal of accumulated debris. I also check the air pressure and perform a more comprehensive lubrication of all moving parts. This is like a more thorough car wash and oil check.

- Monthly Checks: Monthly maintenance involves a more extensive inspection. I check the wear on the capping heads and replace them if necessary. I also examine the PLC program for any errors or anomalies and perform a full system calibration. Think of this as a comprehensive service at a garage.

Documentation is key! I meticulously record all maintenance activities, including date, time, parts replaced, and any issues identified. This helps track machine performance and predict potential failures.

Q 9. How do you handle a machine malfunction during production?

Machine malfunction during production is a serious issue requiring a swift and methodical response. My approach follows a structured troubleshooting methodology:

- Safety First: Immediately shut down the machine and ensure the safety of all personnel. This is paramount.

- Identify the Problem: Pinpoint the specific issue – is it a capping failure, a jam, or a power issue? Carefully observe the machine’s behavior and listen for unusual noises.

- Check the Obvious: Check the power supply, air pressure, and cap feed system for any obvious problems. Sometimes the solution is simpler than anticipated.

- Consult Documentation: Refer to the machine’s operating manual and maintenance logs. This will help diagnose the problem more efficiently. Past records can often pinpoint recurring issues.

- Systematic Troubleshooting: If the problem is not readily apparent, systematically check each component of the capping machine, one by one, to isolate the fault. This is like following a detective trail of clues.

- PLC Diagnostics: Utilize the PLC programming to diagnose any issues related to the control system. Error codes and logs can provide invaluable clues.

- Seek Assistance if Necessary: If the problem remains unresolved, contact a qualified technician or the machine’s manufacturer for assistance.

Once the problem is identified and resolved, I document the issue, the troubleshooting steps taken, and the solution implemented. This prevents future occurrences.

Q 10. What are the common causes of capping failures?

Capping failures can stem from several sources. They are often linked to improper torque, faulty components, or material inconsistencies.

- Insufficient or Excessive Torque: Incorrectly set torque can lead to loose caps or crushed containers. This requires careful adjustment using torque measuring tools.

- Worn Capping Heads: Over time, capping heads wear down, reducing their ability to apply consistent torque. Regular inspection and timely replacement are vital.

- Faulty Chucks and Spindles: These components are crucial for proper cap placement and application. Damage or wear can compromise the capping process.

- Cap Feed System Issues: Problems with the cap feeder, such as jams or misalignment, can lead to inconsistent capping or failures.

- Container Issues: Deformed or damaged containers can interfere with the capping process, leading to failures. This can also indicate a problem upstream in the production line.

- Air Pressure Issues: In pneumatic capping machines, insufficient or inconsistent air pressure can affect the capping torque and lead to inconsistent results.

Identifying the root cause requires a methodical approach, combining visual inspection, torque measurement, and careful observation of the entire process.

Q 11. Explain your experience with PLC programming related to capping machines.

I have extensive experience with PLC programming in the context of capping machine operation, particularly using Allen-Bradley PLCs. My expertise encompasses programming, troubleshooting, and modifying existing PLC programs to optimize machine performance and address specific issues.

For instance, I’ve developed programs to monitor capping torque in real-time, triggering alarms if it falls outside predefined parameters. I’ve also programmed functions to automatically adjust capping torque based on container size and material. This ensures consistent capping even with changes in production runs.

//Example Code Snippet (Illustrative): //Check Torque Value IF TorqueValue < MinimumTorque THEN ActivateAlarm; ReduceProductionSpeed; ENDIF;

Troubleshooting PLC programs involves using diagnostic tools to identify errors, analyze fault codes, and make necessary corrections. I'm adept at using ladder logic to modify existing programs and add new functionalities as needed. For example, I implemented a program to track production statistics, such as caps applied per minute and rejection rate, providing valuable data for process improvement.

Q 12. How do you adjust capping torque?

Adjusting capping torque is a critical aspect of capping machine operation. It requires precision and understanding of the machine's specifications. The method varies based on the type of capping machine, but generally involves accessing a control panel or software interface.

Many machines have a dedicated torque adjustment dial or setting in the PLC. This dial or setting is typically calibrated in Newton-meters (Nm) or inch-pounds (in-lb). The precise adjustment is crucial; using a torque wrench is very useful to measure that the torque is applied correctly. Too little torque results in loose caps, whereas excessive torque can damage containers and even lead to machine damage. For instance, glass containers require considerably less torque than plastic ones.

The correct torque setting is typically determined through testing and experimentation to find the optimal balance between secure capping and preventing damage. It's common to start with a manufacturer's recommended setting and then fine-tune based on real-world results and feedback from quality control.

Q 13. How do you identify and resolve torque inconsistencies?

Torque inconsistencies are a common problem leading to capping failures. Addressing them requires a systematic approach.

- Identify the Variation: Use a torque wrench to measure the torque at various points in the capping cycle. Note any significant deviations from the set value.

- Check the Capping Heads: Inspect the capping heads for wear, damage, or misalignment. Worn or damaged heads are a primary cause of inconsistent torque.

- Examine the Chuck and Spindle: Verify the proper functioning and alignment of the chuck and spindle. Any damage or misalignment will affect torque application.

- Evaluate the Cap Feed System: Ensure that the caps are being fed consistently and without obstructions. Irregular cap feeding can lead to inconsistent torque.

- Check Air Pressure (if applicable): For pneumatic cappers, fluctuations in air pressure can impact torque. Maintain consistent air pressure as specified by the manufacturer.

- Analyze PLC Data: Review the PLC's data logs for any irregularities in the torque control system. This might highlight problems with the control circuitry.

- Review Container Quality: Ensure that containers are uniform and free from defects. Irregular container shapes or defects can contribute to inconsistent torque.

Addressing torque inconsistencies often requires a combination of adjustments and maintenance. After making adjustments, it is crucial to retest the torque using a wrench and re-calibrate to confirm the changes improved the consistency.

Q 14. What is your experience with different types of container materials?

My experience encompasses a wide range of container materials, including glass, plastic (PET, HDPE, PP), and metal (aluminum, tin). Each material requires a different capping approach due to variations in their physical properties and sensitivities.

- Glass: Glass containers are delicate and require careful torque adjustment to avoid breakage. Over-torquing can easily shatter the bottle, whereas insufficient torque leads to leaks.

- Plastic (PET, HDPE, PP): Plastic containers are more resilient, allowing for a wider range of torque. However, excessive torque can still crush or deform them. Different plastic types also have different levels of stiffness, which affects the optimal capping torque.

- Metal (Aluminum, Tin): Metal containers often require higher torque than plastic or glass. However, excessive torque can damage the metal and affect the sealing integrity.

Understanding the unique properties of each material is crucial for optimizing the capping process and preventing damage or leaks. This understanding directly impacts the torque settings and sometimes even the choice of capping heads. I can adapt machine settings and maintenance protocols to accommodate different materials in a manufacturing environment.

Q 15. How do you handle different cap sizes and types on one machine?

Most modern capping machines are designed to handle a range of cap sizes and types. This is typically achieved through a combination of adjustable components and interchangeable parts. Think of it like a versatile toolbox – you have the main tool (the capping machine) and a set of attachments (different parts) to adapt it to various jobs.

- Adjustable Clamps/Chucks: Many machines utilize adjustable clamps or chucks that can be tightened or loosened to accommodate caps of different diameters. These are usually simple to adjust, often with a handwheel or lever.

- Interchangeable Starwheels/Cappers: The starwheels (or other capping mechanisms) are the parts that actually grip and apply the caps. These are often interchangeable, meaning you can quickly swap them out for ones designed for a specific cap size or type (e.g., screw-on caps versus snap-on caps). The changeover usually involves removing a few screws or fasteners.

- Programmable Settings: Advanced capping machines have programmable settings that allow you to input the specific dimensions and type of cap, automatically adjusting the machine's parameters for optimal performance. This eliminates the need for manual adjustments in many cases.

For example, in one previous role, I regularly handled a changeover from 28mm screw-on caps to 38mm snap-on caps on a high-speed capping line. This involved switching out the starwheels and adjusting the clamping pressure via the machine's control panel. The entire process took about 15 minutes, ensuring minimal downtime.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini's guide. Showcase your unique qualifications and achievements effectively.

- Don't miss out on holiday savings! Build your dream resume with ResumeGemini's ATS optimized templates.

Q 16. What is your experience with high-speed capping machines?

I have extensive experience operating high-speed capping machines, working with models capable of processing hundreds or even thousands of containers per minute. This experience involves a deep understanding of the delicate balance between speed and accuracy. Operating at high speed requires meticulous attention to detail, proactive maintenance, and a keen eye for potential issues.

Key aspects of my experience include:

- Understanding Machine Limitations: High-speed operation pushes the machine's limits. I understand the importance of monitoring vibration, noise levels, and temperature to identify potential problems before they lead to a malfunction or damage.

- Preventive Maintenance: Regular preventative maintenance is crucial for maintaining high-speed performance. This includes frequent lubrication, inspections of wearing parts, and prompt replacement of components showing signs of wear.

- Quality Control: At these speeds, even minor inconsistencies can lead to significant quality issues. I am experienced in implementing and maintaining robust quality control checks throughout the capping process, often incorporating in-line inspection systems.

For instance, I worked on a line using a high-speed rotary capper that processed over 1000 bottles per minute. By diligently adhering to a precise preventative maintenance schedule and implementing a thorough quality control protocol, we maintained a remarkably low rejection rate of less than 0.5%.

Q 17. Describe your experience with cleaning and sanitizing capping machines.

Cleaning and sanitizing capping machines are critical for maintaining product safety and hygiene. This process involves a meticulous approach, typically following strict Standard Operating Procedures (SOPs) established by the company and regulatory bodies.

My experience covers:

- Disassembly and Cleaning: This often involves disassembling accessible parts of the machine (following safety procedures!), using appropriate cleaning agents (often food-grade solutions) and brushes to remove residue, dirt, and contaminants. Particular attention is paid to areas where product and cap contact occurs.

- Sanitization: After cleaning, I follow up with sanitization, typically using approved sanitizing solutions. This ensures the elimination of harmful microorganisms that could contaminate the product.

- Drying and Reassembly: Thorough drying is crucial to prevent the growth of bacteria and to ensure the smooth operation of the machine after reassembly. All parts are carefully inspected before reassembly to avoid any potential damage.

- Documentation: Maintaining detailed records of cleaning and sanitization procedures is essential for traceability and compliance with hygiene regulations. I meticulously document all steps of the cleaning and sanitization process.

I recall a situation where a minor sanitation oversight caused a product recall. This reinforced the importance of thorough and meticulous cleaning and sanitation. The incident highlighted the value of standardized procedures and comprehensive documentation.

Q 18. How do you ensure proper lubrication of a capping machine?

Proper lubrication is essential for the smooth and efficient operation of a capping machine. Insufficient lubrication can lead to increased friction, premature wear, and ultimately, machine failure. Over-lubrication can also be problematic, leading to product contamination or messy operation.

My approach involves:

- Identifying Lubrication Points: I meticulously identify all lubrication points specified in the machine's manual. These are typically bearings, gears, and other moving parts that experience significant friction.

- Using Appropriate Lubricants: I use only lubricants specifically recommended for the machine and its components. The type of lubricant is crucial – using the wrong lubricant can damage the machine or contaminate the product.

- Applying Lubricant Correctly: I carefully apply the lubricant in the correct amounts to avoid over-lubrication. Excessive lubricant can attract contaminants and lead to operational issues.

- Regular Lubrication Schedule: I maintain a regular lubrication schedule, typically according to the manufacturer's recommendations or established company protocols.

For instance, in a previous role, I implemented a lubrication schedule that reduced machine downtime by 15% and extended the lifespan of key components.

Q 19. What is your experience with changeovers on a capping machine?

Changeovers on a capping machine refer to the process of switching from one cap size or type to another. This involves adjusting various components to accommodate the new cap dimensions and type. Efficiency in this process is critical for minimizing downtime.

My experience in changeovers includes:

- Following Established Procedures: I adhere to documented procedures, ensuring all steps are followed meticulously. This reduces errors and minimizes downtime.

- Pre-Planning: Before starting a changeover, I carefully plan the process, ensuring I have all the necessary parts and tools readily available. This includes properly labeling and storing previously used components.

- Safety First: Safety is paramount. I always ensure the machine is locked out and tagged out before beginning any changeover work. This protects both the equipment and personnel.

- Testing and Verification: After the changeover, I thoroughly test the machine with a small batch of containers to ensure it's properly functioning and producing quality capped products before resuming full production.

In one instance, I optimized a changeover procedure, reducing the downtime by 20% through a combination of better pre-planning and streamlining the adjustment steps.

Q 20. How do you troubleshoot a machine jam?

Machine jams are a common occurrence in capping operations, often caused by issues such as incorrect cap orientation, damaged caps, container misalignment, or insufficient lubrication. Troubleshooting involves a systematic approach.

My troubleshooting steps typically include:

- Safety First: Always turn off and lock out the machine before attempting any troubleshooting.

- Visual Inspection: Carefully inspect the capping area for any obvious obstructions or damaged parts. Look at the feed mechanisms, starwheels, and the capping head.

- Check Cap Orientation: Ensure the caps are feeding correctly and are properly oriented for capping. A hopper jam or incorrect cap alignment is a frequent culprit.

- Check Container Alignment: Verify that containers are properly aligned on the conveyor belt, preventing misalignment and jams.

- Inspect Starwheels: Check starwheels for wear and tear, or foreign objects. Worn or damaged starwheels cannot reliably grip and apply the caps.

- Check Lubrication: Verify that the machine is properly lubricated. Insufficient lubrication is a common cause of jams, especially in high-speed machines.

I once solved a recurring jam issue by identifying a small piece of debris lodged in the capping mechanism that was consistently causing interruptions. The systematic approach I use helps to solve the problem quickly and efficiently.

Q 21. How do you deal with material waste during the capping process?

Material waste during the capping process can stem from various sources, including damaged or improperly oriented caps, container jams, and spillage. Minimizing waste is crucial for both economic and environmental reasons.

My strategies to minimize waste include:

- Preventive Maintenance: Regular maintenance, especially lubrication and inspection of key components, helps to reduce jams and breakage, minimizing waste.

- Quality Control: Implementing robust quality control checks throughout the process helps to identify and address issues before they lead to significant waste. This includes regular inspections of incoming materials.

- Operator Training: Well-trained operators are less likely to make mistakes that lead to jams and waste. Proper training and SOPs are crucial.

- Process Optimization: Continuously reviewing and optimizing the capping process can identify areas for improvement in terms of efficiency and waste reduction. This may involve adjustments to speed or feed mechanisms.

- Waste Management: Implementing proper waste segregation and disposal procedures can help reduce environmental impact and potentially enable the recovery of reusable materials.

In one instance, I implemented a system for collecting and reusing slightly damaged caps, reducing waste by 10%.

Q 22. What is your experience with different types of capping heads?

My experience encompasses a wide range of capping heads, from simple chuck-type cappers to sophisticated rotary and inline systems. I'm proficient with various capping mechanisms, including screw-on, press-on, and crimp-on heads. For example, I've extensively worked with chuck-type heads for smaller containers, which are reliable and easy to maintain but may be slower for high-volume production. In contrast, my experience with rotary capping machines allows for significantly higher throughput. These machines are more complex, often requiring precise adjustments for optimal capping torque and speed. I'm also familiar with different head materials, including stainless steel, aluminum, and plastics, each suited to specific product and production needs. I understand the intricacies of head changeovers, including the alignment and adjustment processes critical for preventing damage to containers and caps. Finally, my experience also includes troubleshooting issues related to capping head wear and tear, and recommending necessary replacements or repairs to ensure consistent and efficient performance.

Q 23. Explain your understanding of capping machine efficiency and optimization.

Capping machine efficiency is paramount for maximizing output and minimizing downtime. It's not just about speed; it's about achieving the perfect balance between speed, torque, and the prevention of defective caps. Optimization involves analyzing several key metrics. This includes capping speed, which should be balanced with the need to avoid damaging caps or containers. We also need to consider capping torque – the right amount of force to ensure a secure closure without damaging the container. Finally, a crucial element of optimization is minimizing downtime due to changeovers, maintenance, or malfunctions. In a recent project, we improved our line efficiency by 15% by optimizing capping torque based on data analysis and implementing a preventative maintenance schedule. This involved using sensors to monitor capping pressure and adjusting settings accordingly, thereby reducing faulty closures and production delays. This kind of continuous improvement process helps refine machine parameters to maintain consistent, high-quality capping.

Q 24. How familiar are you with the safety regulations related to capping machine operation?

Safety is my top priority. I'm deeply familiar with OSHA regulations and industry best practices regarding capping machine operation. This includes the proper use of lockout/tagout procedures during maintenance, ensuring all guarding is in place to prevent injuries from moving parts, and adhering to strict protocols for handling potentially hazardous materials. For instance, I’ve implemented and enforced training programs for all operators on safe machine operation, emphasizing the importance of personal protective equipment (PPE), emergency shutdown procedures, and hazard recognition. I understand the importance of regular machine inspections and the implications of non-compliance, which can lead to serious accidents and production disruptions. My experience includes conducting thorough risk assessments to identify and mitigate potential hazards associated with specific capping machines and production lines.

Q 25. Describe your problem-solving approach when facing a capping machine issue.

My problem-solving approach is systematic and data-driven. When encountering a capping machine issue, I follow a structured methodology. First, I conduct a thorough assessment, carefully observing the issue and gathering information such as error messages, production rates, and the type of defects. Then, I analyze this data to pinpoint the probable cause. This might involve checking cap alignment, torque settings, or examining the condition of capping heads for wear or damage. If the issue is more complex, I might use diagnostic tools, schematics, and troubleshooting guides. Once I identify the root cause, I develop and implement a solution, ensuring it’s both effective and safe. Finally, I document the problem, the solution, and any preventative measures to prevent future occurrences. For example, I once resolved a recurring issue of inconsistent capping torque by identifying a worn-out chuck in the capping head and promptly replacing it with a new part. This proactive approach ensures minimal downtime and maintains consistent production quality.

Q 26. How do you document maintenance procedures and repairs?

I maintain meticulous documentation of all maintenance procedures and repairs using a combination of digital and physical records. I use a computerized maintenance management system (CMMS) to track all work orders, spare parts inventory, and scheduled maintenance. The CMMS system allows us to track the history of each machine component and the time of repair, enabling more accurate preventative maintenance schedules. Additionally, I keep physical logs detailing maintenance performed, including date, time, specifics of the work done, parts replaced, and any observations made. This dual system approach ensures both accessibility and backup for critical maintenance information. Clear, concise documentation is vital for regulatory compliance and for troubleshooting future issues. For example, I consistently document all lubrication schedules, ensuring all machines are well-maintained and are operating at peak efficiency, minimizing downtime.

Q 27. How do you communicate effectively with your team during a machine issue?

Effective communication is essential during a machine issue. My approach involves clearly and concisely communicating the problem, its potential impact on production, and the steps I am taking to resolve it. I utilize a combination of verbal and written communication, using clear, non-technical language where appropriate. During a recent incident, I used a whiteboard to outline the troubleshooting steps and keep everyone updated on our progress, fostering collaborative problem-solving. This ensures that everyone is on the same page, understands the severity of the issue, and can assist as needed. Open communication prevents misunderstandings and encourages proactive collaboration, ensuring a rapid and effective resolution.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and expertise in capping machine operation. Considering my proven track record of improving efficiency, reducing downtime, and ensuring consistent production quality, I am seeking a competitive compensation package that reflects my value to the company. I am open to discussing specific figures after learning more about the details of the role and the company's compensation structure.

Key Topics to Learn for Capping Machine Operation Interview

- Machine Setup and Operation: Understanding the different types of capping machines, their components, and the proper procedures for setup, operation, and shutdown. This includes pre-operational checks and safety procedures.

- Troubleshooting and Maintenance: Identifying common malfunctions, performing basic troubleshooting, and knowing when to escalate issues to maintenance personnel. Practical experience with preventative maintenance tasks will be highly valuable.

- Quality Control and Assurance: Understanding the importance of consistent capping, identifying defects (loose caps, damaged caps, etc.), and implementing corrective actions to maintain product quality. This includes familiarity with quality control metrics and documentation.

- Safety Regulations and Procedures: Demonstrating a thorough understanding of all relevant safety regulations, including lockout/tagout procedures, personal protective equipment (PPE) requirements, and safe operating practices.

- Production Efficiency and Optimization: Understanding how to maximize capping machine output while maintaining quality. This involves knowledge of speed adjustments, feed mechanisms, and potential bottlenecks in the process.

- Cleaning and Sanitation: Understanding proper cleaning and sanitation procedures to maintain hygiene standards and prevent contamination. Knowledge of relevant cleaning agents and their proper usage is crucial.

- Material Handling and Storage: Safe and efficient handling of caps and containers, including proper storage to prevent damage and spoilage.

Next Steps

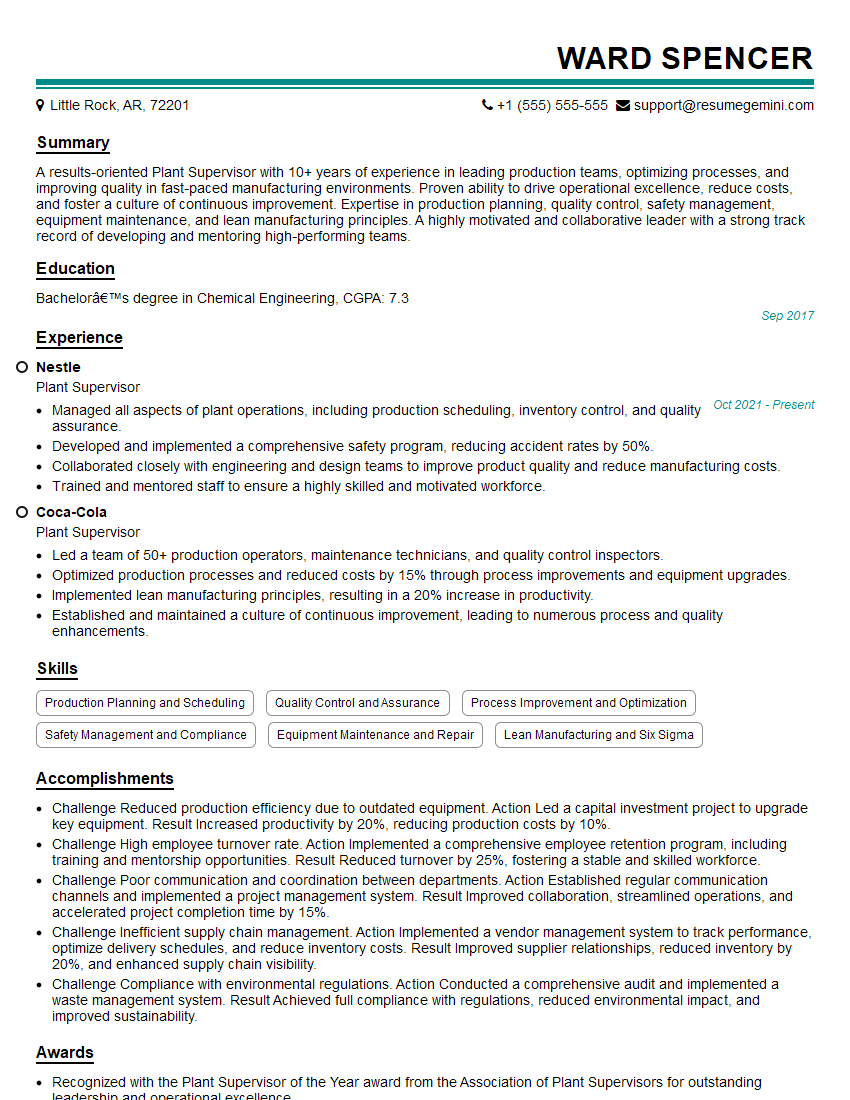

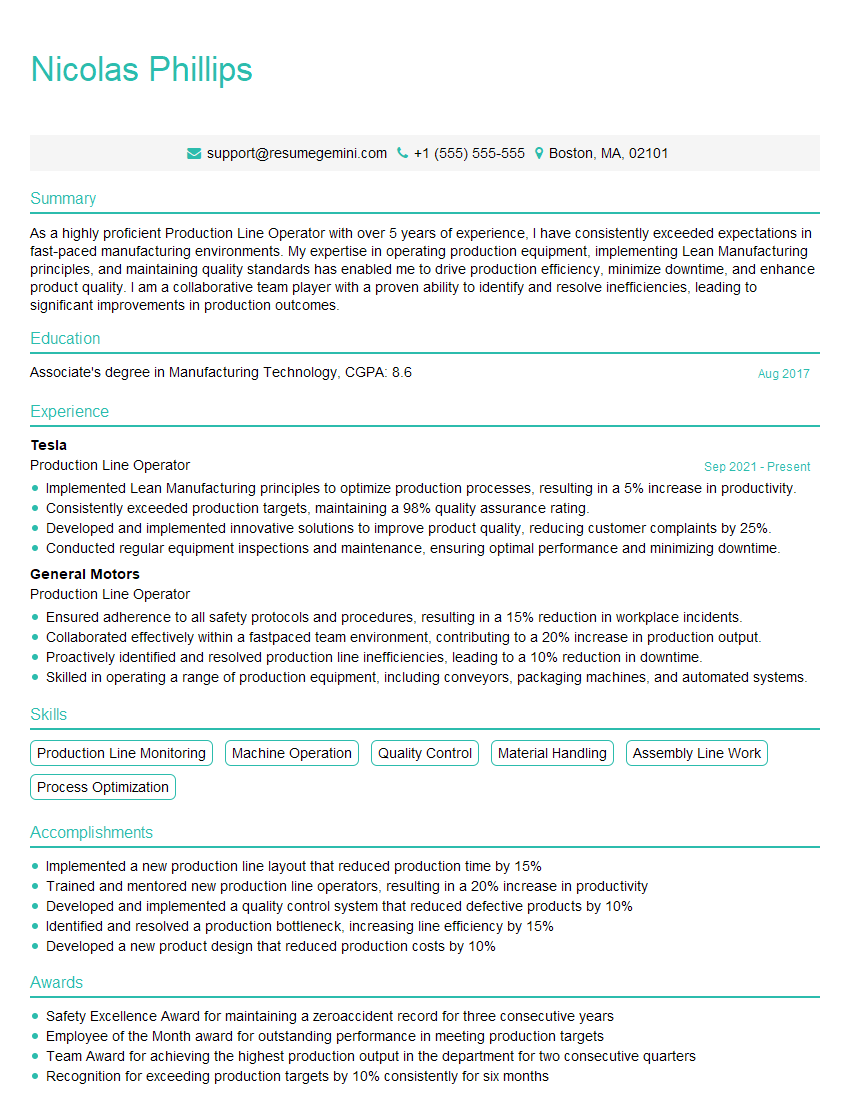

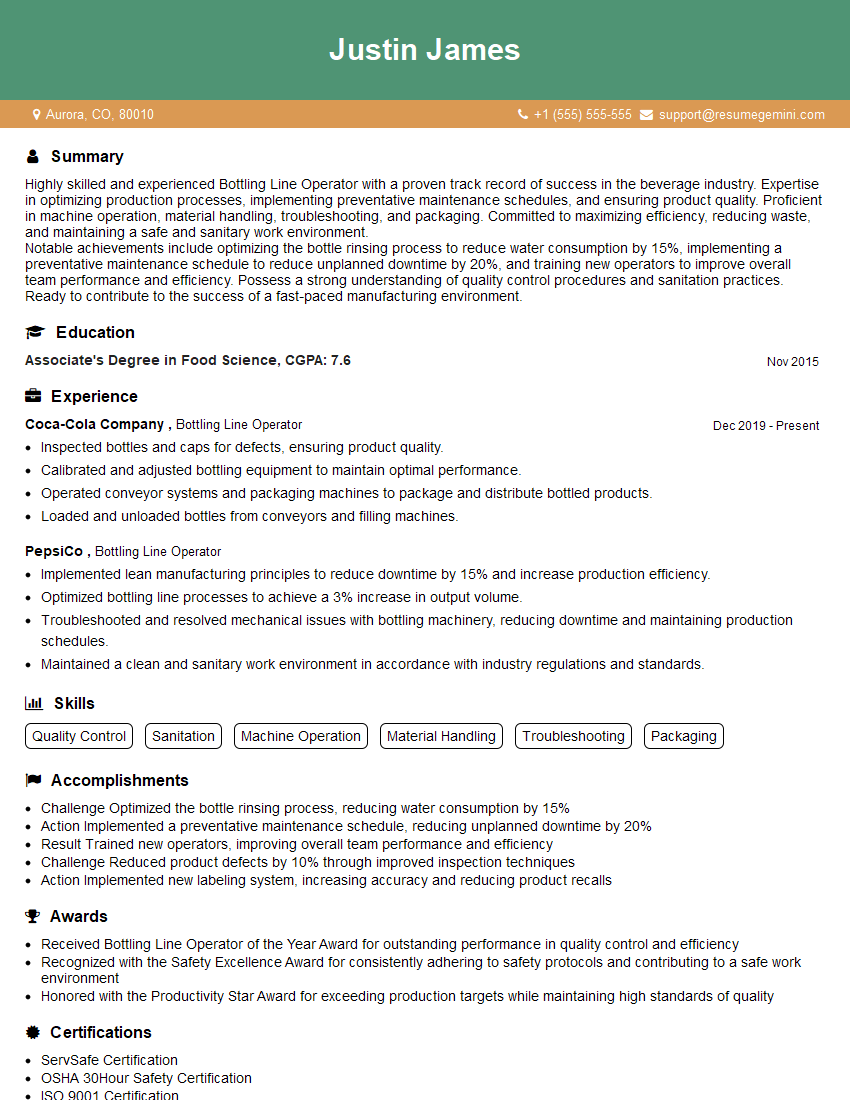

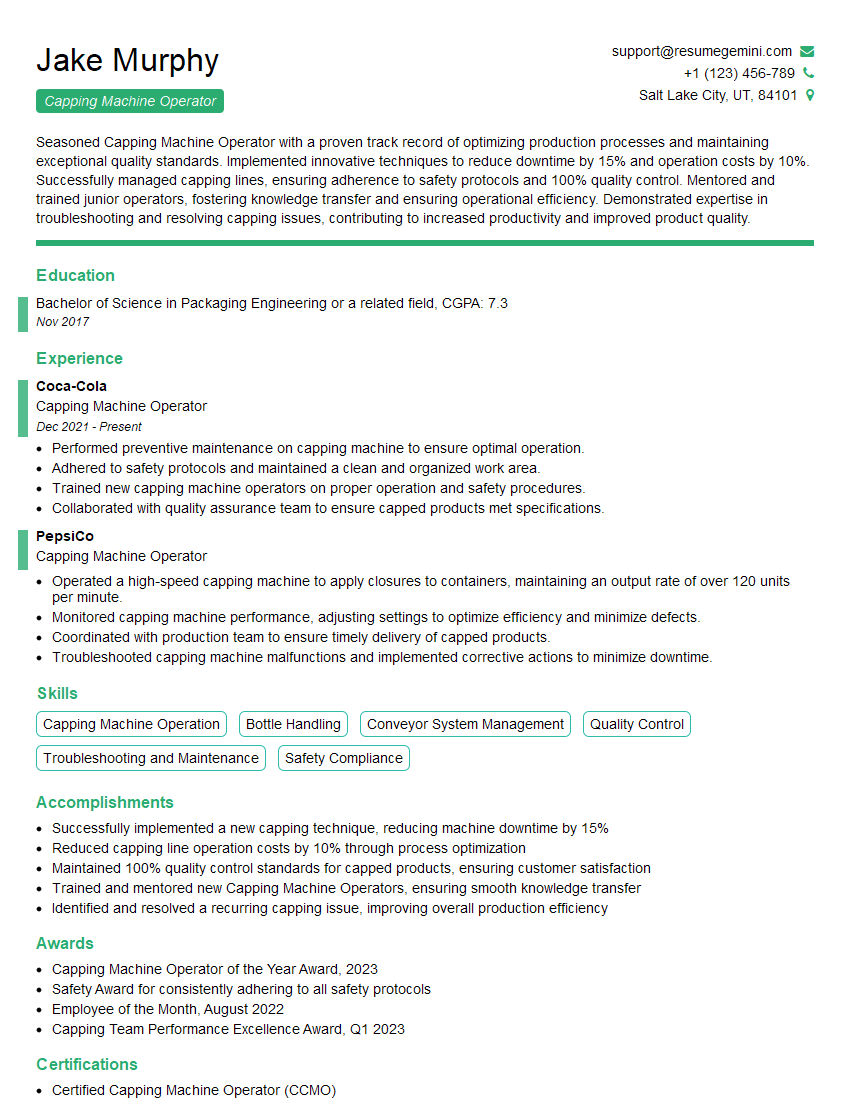

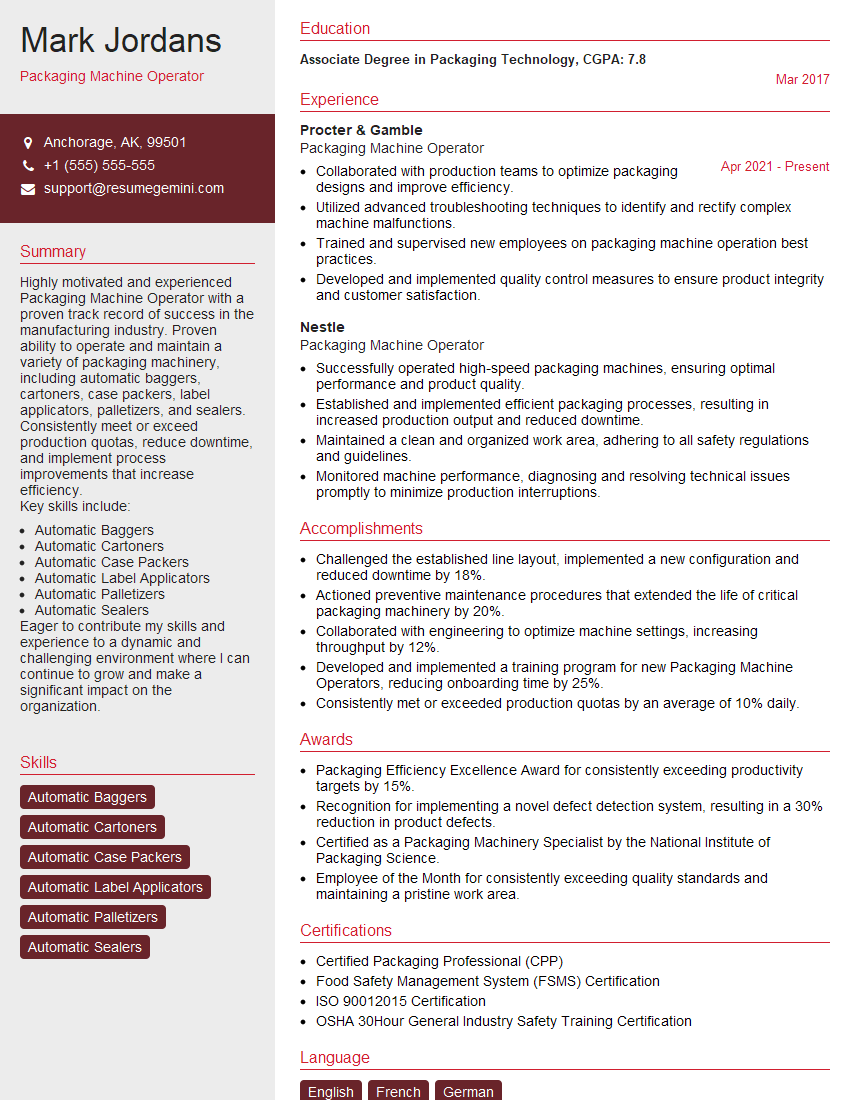

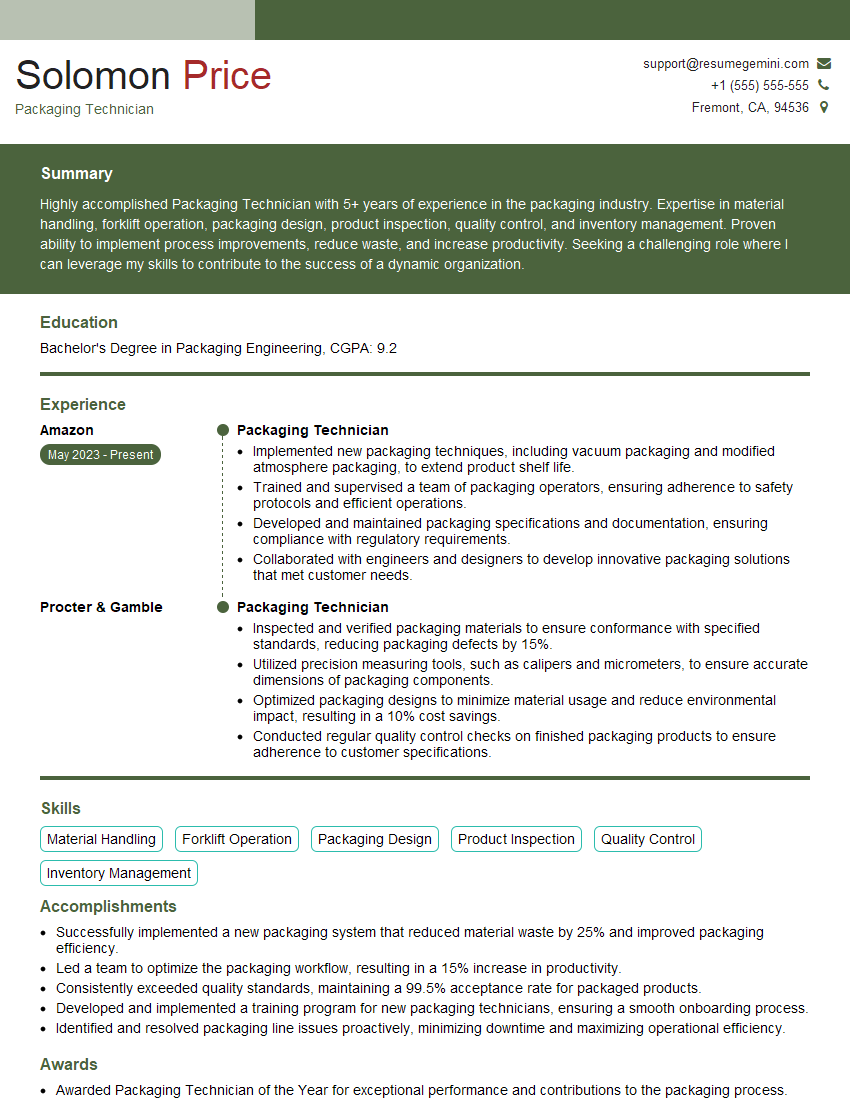

Mastering capping machine operation opens doors to a rewarding career with excellent growth potential within manufacturing and related industries. Your expertise in this crucial role will be highly sought after, leading to increased responsibility and earning potential. To maximize your job prospects, it's essential to have a resume that clearly showcases your skills and experience. An ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. We strongly encourage you to use ResumeGemini, a trusted resource for building professional and effective resumes. ResumeGemini provides examples of resumes tailored to Capping Machine Operation to help you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good