The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Car Sealing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Car Sealing Interview

Q 1. Explain the different types of car sealants available.

Car sealants come in various forms, each offering unique properties and protection levels. Think of them like different sunscreens – some offer basic protection, while others provide more robust defense.

- Wax: A traditional sealant, wax provides a relatively short-lived protective layer (lasting a few weeks) that enhances gloss and water beading. It’s easy to apply but requires more frequent reapplication.

- Sealant (synthetic): Synthetic sealants offer longer-lasting protection (several months) than wax, providing enhanced water resistance and UV protection. They’re generally easier to apply than ceramic coatings.

- Ceramic Coating: These are the top-tier protection, offering years of durability and extreme hydrophobic properties. They create a very hard, chemically bonded layer that resists scratches, stains, and UV damage. Application is more complex and requires specialized products.

- Paint Protection Film (PPF): Unlike the others, PPF is a clear urethane film applied to the paint surface, acting as a sacrificial layer that absorbs impacts and prevents scratches. It offers the highest level of protection but is the most expensive option and requires professional installation.

The choice depends on your budget, desired longevity, and the level of protection you need. A weekend warrior might opt for wax, while someone wanting maximum protection would choose a ceramic coating or PPF.

Q 2. Describe the process of applying a ceramic coating.

Applying a ceramic coating is a meticulous multi-step process requiring attention to detail and a clean environment. Think of it like painting a miniature masterpiece – any flaws will be magnified.

- Preparation: This is crucial. The surface needs to be flawlessly clean, free of contaminants like dust, dirt, and swirl marks. This typically involves a multi-stage wash, clay bar treatment, and potentially paint correction to remove imperfections.

- Degreasing: A specialized degreaser removes any remaining oils or waxes, ensuring optimal adhesion of the ceramic coating.

- Application: The ceramic coating is applied in thin, even layers using a designated applicator pad. This often involves sectioning the vehicle to ensure even coverage and prevent drying.

- Curing: The coating needs time to cure, typically several hours or even days, to achieve maximum hardness and durability. The curing time and environment are crucial for proper bonding.

- Inspection and Finishing: After curing, the surface is inspected for any imperfections. A final wipe-down removes any excess coating and leaves a flawless finish.

Proper training and high-quality products are essential for successful ceramic coating application. Attempting this without sufficient experience can lead to an uneven or flawed finish.

Q 3. What are the benefits of using paint protection film?

Paint Protection Film (PPF) is like an invisible shield for your car’s paint. It’s a clear, flexible urethane film that protects against various hazards.

- Rock Chip Protection: PPF absorbs impacts from road debris, preventing chips and scratches on the paint.

- Scratch Resistance: It acts as a sacrificial layer, taking the brunt of minor scratches, preserving the original paint’s condition.

- UV Protection: PPF shields the paint from harmful UV rays, reducing fading and deterioration.

- Self-Healing Properties: Some PPF films have self-healing capabilities, where minor scratches can disappear with heat.

- Enhanced Paint Value: By preserving the paint’s original condition, PPF can increase the resale value of the vehicle.

Imagine a superhero cape for your car’s paint – that’s PPF in a nutshell. It’s especially beneficial for vehicles driven in harsh environments or those prone to minor scrapes.

Q 4. How do you prepare a car’s surface before applying a sealant?

Surface preparation is the most critical step in car sealing. A poorly prepared surface will result in a subpar finish, regardless of the quality of the sealant.

- Washing: Start with a thorough two-bucket wash, using a dedicated wash mitt and grit guard to prevent scratches.

- Decontamination: Remove embedded contaminants like tar, tree sap, and iron particles using a dedicated iron remover and/or clay bar. This ensures a smooth surface for optimal sealant adhesion.

- Drying: Dry the car thoroughly using a high-quality microfiber drying towel. Air drying can leave water spots.

- Panel Wiping: Wipe down each panel with an isopropyl alcohol solution to remove any remaining residue and ensure a perfectly clean surface.

Think of it as preparing a canvas before painting a masterpiece. A clean, smooth surface is paramount for a professional finish.

Q 5. What are the common challenges encountered during car sealing?

Several challenges can arise during car sealing, requiring experience and problem-solving skills.

- Dust and Contaminants: Dust or other airborne particles settling on the surface during application can ruin the final finish.

- Uneven Application: Applying the sealant unevenly will result in an inconsistent glossy finish.

- Environmental Conditions: High humidity or direct sunlight can affect the curing process and the final appearance.

- Improper Product Use: Using the wrong product or failing to follow instructions will lead to less-than-optimal results.

- Difficult-to-Reach Areas: Applying sealant to tight corners and crevices requires patience and specialized tools.

Addressing these issues requires careful planning, meticulous attention to detail, and the right tools and environment.

Q 6. How do you handle difficult-to-reach areas during application?

Reaching difficult areas requires using specialized tools and techniques. Think of it like a surgeon using specialized instruments for precision.

- Applicator Pads: Using smaller applicator pads enables better control and access to tight spaces.

- Detailing Brushes: Detailing brushes are essential for reaching deep crevices and tight corners.

- Microfiber Towels: Small microfiber towels allow for precise wiping and buffing in hard-to-reach areas.

- Patience and Precision: Take your time and be precise to avoid leaving streaks or uneven coverage.

It’s important to remember that thoroughness is key. Don’t rush these areas, as imperfections will be noticeable.

Q 7. What are the safety precautions involved in using car sealants?

Safety is paramount when working with car sealants. Always follow these precautions:

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes.

- Eye Protection: Wear safety glasses to protect your eyes from splashes.

- Gloves: Wear gloves to protect your skin from the chemicals in the sealants.

- Product Labels: Always read and follow the manufacturer’s instructions carefully.

- Disposal: Dispose of used materials properly according to local regulations.

Treating car sealants with respect will minimize any potential hazards. Remember, safety first!

Q 8. How do you determine the correct amount of sealant to use?

Determining the correct amount of sealant is crucial for effective protection and avoiding mess. It’s not about using a lot; it’s about using enough for complete, even coverage. The manufacturer’s instructions on the sealant bottle are your best guide. They usually specify application methods (e.g., thin coats, beading, etc.) and the recommended quantity per panel or area. Think of it like painting – multiple thin coats are far superior to one thick, gloopy coat. For example, a typical car might require around 3-6 ounces of sealant depending on its size and the specific product used. You might need more if you’re applying multiple layers, or dealing with a particularly porous surface. Always perform a test application on a less visible area first to gauge the required amount and the sealant’s performance.

Q 9. What are the signs of a poorly applied sealant?

Signs of a poorly applied sealant are often visible and can compromise protection. Uneven coverage, where some areas are thick while others are thin, is a classic indicator. This often shows up as streaks or blotches after the sealant cures. Runoff, where sealant drips or pools, suggests excessive application or improper prep. A milky or hazy appearance can mean the sealant wasn’t properly buffed out, leaving residue on the clear coat. Another important sign is a lack of beading after a water test. If the water doesn’t bead properly, this shows the sealant hasn’t adhered correctly or may not be providing adequate water repellency. Finally, premature degradation (the sealant losing its shine or protection much faster than expected) suggests poor application, inappropriate product selection, or neglect of aftercare.

Q 10. How do you ensure even coverage during application?

Achieving even coverage is paramount for optimal results. Start by thoroughly cleaning and prepping the car surface. This involves washing, decontaminating (clay barring), and then drying it meticulously. Apply the sealant using a quality applicator pad or microfiber cloth, working in small sections. Use gentle, overlapping strokes to ensure complete coverage without leaving any gaps. Use a consistent amount of pressure; too much can push the sealant too thin, and too little might result in patchy areas. The ‘less is more’ approach is particularly relevant here. It’s better to apply several thin coats than a single thick coat. Once applied, you can use a microfiber detailing towel to buff and spread the sealant to achieve a perfect finish. Always work in a cool, shaded area to prevent premature drying.

Q 11. Explain the difference between a sealant and a wax.

Sealants and waxes are both used to protect a car’s paint, but they differ significantly in their composition, longevity, and protection level. Wax is typically a natural or synthetic product that forms a thin layer over the paint, providing a cosmetic shine and a degree of protection. It’s relatively easy to apply and remove, but it usually only lasts a few weeks. Sealants, on the other hand, are chemically formulated to bond with the clear coat, creating a durable, protective barrier that lasts significantly longer—typically several months. They offer stronger protection against UV rays, environmental contaminants, and light scratches. Imagine wax as sunscreen: it provides temporary protection. A sealant is more like a long-lasting raincoat – offering more substantial and sustained protection.

Q 12. What are the different types of paint protection film?

Paint Protection Film (PPF) comes in various types, primarily differing in their material and thickness. The most common is polyurethane (PU) film, known for its durability and self-healing properties. This means minor scratches can often disappear with heat from sunlight. There are also thermoplastic urethane (TPU) films, often marketed as being more flexible and easier to install on complex car surfaces. Ceramic-coated PPF combines the protection of PPF with the added hydrophobic properties of a ceramic coating, offering superior protection and shine. The thickness of PPF also varies; thicker films generally offer better protection but can be more difficult to install. Finally, different PPF films also vary in their level of gloss or matte finish. Choosing the right type depends on factors like budget, desired level of protection, and ease of installation.

Q 13. How long does a typical car sealant last?

The longevity of a car sealant depends greatly on factors like the type of sealant, application technique, environmental conditions, and the frequency of washing and maintenance. High-quality sealants can last anywhere from 3 to 12 months or even longer. However, factors such as frequent exposure to harsh weather, acidic rain, or bird droppings can decrease the lifespan of the sealant. This is why regular maintenance is very important. A good rule of thumb is to inspect the sealant’s performance every few months through a water beading test. If beading becomes inconsistent or the sealant starts to look dull or hazy, it’s time to reapply.

Q 14. How do you maintain the sealant after application?

Maintaining a sealant after application is crucial to maximizing its lifespan and protection. Avoid harsh chemicals and abrasive cleaners, opting for pH-neutral car washes. Regular washing (at least every 2 weeks) removes contaminants and prevents buildup. After washing, always dry the car thoroughly, using a high-quality microfiber drying towel to prevent water spots. Avoid washing your car in direct sunlight. Consider using a quick detailer spray between washes to remove light dirt and dust, restoring shine, and maintaining the sealant’s hydrophobic properties. Periodically inspect the sealant for any signs of wear or degradation, and reapply when necessary. Remember, preventative measures are key for maintaining the effectiveness of your car sealant.

Q 15. What are the environmental factors that affect sealant longevity?

Sealant longevity is significantly impacted by environmental factors. Think of it like this: a sealant is a protective layer, and just like your skin needs protection from the sun and harsh weather, so does your car’s sealant.

- UV Radiation: Prolonged exposure to sunlight’s ultraviolet rays degrades the sealant’s chemical structure, causing it to break down and lose its protective properties. This leads to fading and cracking.

- Temperature Fluctuations: Extreme temperature changes, especially frequent cycles of freezing and thawing, can cause stress on the sealant, leading to cracking and peeling. Imagine a rubber band stretched and released repeatedly – eventually it loses its elasticity.

- Moisture and Humidity: Constant exposure to moisture can weaken the sealant’s bond with the car’s paint, leading to premature failure. Think of leaving a sticker on a window during rain – the water can get under and weaken the adhesive.

- Chemical Exposure: Contact with chemicals like bird droppings, tree sap, or industrial pollutants can damage the sealant’s protective layer. These substances can etch the surface and weaken the sealant.

- Washing and Cleaning: Aggressive washing techniques or the use of harsh chemicals can prematurely strip the sealant. A gentle wash with a pH-neutral car wash soap is always recommended.

Understanding these factors allows for better sealant selection and application, ultimately maximizing its lifespan.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you deal with imperfections on the car’s surface before sealing?

Preparing the car’s surface is crucial for a long-lasting and effective sealant application. Think of it like prepping a wall before painting – you wouldn’t paint over cracks or loose plaster.

- Washing and Drying: The first step is a thorough wash using a high-quality car wash soap to remove dirt, grime, and contaminants. Drying with a microfiber towel is vital to avoid water spots.

- Clay Bar Treatment (Optional but Recommended): A clay bar treatment helps remove embedded contaminants that washing alone cannot remove. This leaves the surface incredibly smooth, allowing for better sealant adhesion.

- Defect Correction: Depending on the condition of the paint, this may involve polishing or compounding to remove scratches, swirl marks, and other imperfections. The goal is to achieve a smooth, defect-free surface for optimal sealant performance.

- Degreasing (Optional): A degreasing step can ensure removal of any lingering waxes or polishes, further improving adhesion. This step is crucial if the car has recently been waxed.

By properly preparing the surface, you ensure that the sealant adheres effectively, providing maximum protection and a glossy finish.

Q 17. What are the different tools and equipment used in car sealing?

The tools and equipment used in car sealing vary depending on the desired level of precision and the complexity of the job. However, some essentials include:

- Microfiber Towels: For washing, drying, and applying sealant.

- Wash Mitt or Sponge: For washing the car’s surface effectively.

- Buckets: At least two buckets – one for soapy water and one for rinsing.

- Clay Bar Kit: For removing embedded contaminants.

- Polishing Machine (Optional): For removing swirl marks and scratches.

- Applicator Pads: For applying sealant evenly.

- Sealant: The sealant itself, of course! The type of sealant dictates its application method and necessary equipment.

- Detailing Spray (Optional): To lubricate the clay bar and provide lubrication during polishing.

For more advanced jobs, you might also use tools like paint thickness gauges to ensure you’re not removing too much clear coat during the correction process.

Q 18. Describe your experience with different brands of sealants.

I have extensive experience with various sealant brands, each possessing unique characteristics. Some popular brands include:

- Chemical Guys: Known for a wide range of sealants with varying levels of durability and gloss.

- Optimum Polymer Technologies (OPT): Renowned for their high-quality, long-lasting sealants.

- Griot’s Garage: Offers excellent sealants that are relatively easy to use.

- Meguiar’s: Provides a good balance between performance and price.

My experience has shown that the best sealant choice depends on the specific needs of the car and the customer’s preferences. For example, a car that’s primarily garaged might benefit from a sealant with high gloss but moderate durability, while a car that spends a lot of time outdoors requires a more durable, UV-resistant sealant.

Q 19. How do you remove old sealant before applying a new one?

Removing old sealant is essential before applying a new one to ensure proper adhesion. Think of it like removing old wallpaper before putting up new wallpaper – you want a clean, bare surface to work with.

The method depends on the type of sealant and its age. Sometimes, a thorough wash with a degreaser is sufficient. In other cases, a more aggressive approach may be required. For stubborn sealants, I often use a combination of:

- Strong Degreaser: Applied liberally to the surface and allowed to dwell for the recommended time.

- Microfiber Towels: Used to wipe away the degreaser and the loosened sealant.

- Paint Cleaning Clay: If needed, a clay bar can help further refine the surface and remove any remaining residue.

After the removal process, a final wash and thorough drying is essential before applying the new sealant.

Q 20. What are your knowledge of various sealant application techniques?

Sealant application techniques can vary depending on the product used, but the goal is always consistent: even, thin application to maximize coverage and durability. Methods include:

- Spray Application: The sealant is sprayed onto an applicator pad and then applied to the car’s surface in thin, overlapping sections. This is common with spray-on sealants.

- Wipe-On Application: A small amount of sealant is applied directly to a microfiber applicator pad and then spread evenly across the surface in thin coats. This method works for both spray and liquid sealants.

- Two-Bucket Method: Using this method during the washing stage ensures clean wash water and prevents the introduction of contaminants onto the surface. This improves the longevity of the application.

Regardless of the technique, careful attention to detail and even application are crucial for achieving a flawless and long-lasting sealant application.

Q 21. How do you deal with customer complaints related to sealant application?

Customer complaints regarding sealant application are handled with professionalism and a focus on resolution. My approach involves:

- Active Listening: I carefully listen to the customer’s concerns, taking notes and asking clarifying questions.

- Visual Inspection: I thoroughly inspect the work to identify the source of the complaint. This may involve close examination under different lighting conditions.

- Problem Identification: I determine the cause of the issue – was it a problem with application, sealant degradation, or an external factor?

- Solution Proposal: Depending on the issue, I may propose a reapplication, partial correction, or a suitable compensation plan.

- Follow-up: After implementing the solution, I follow up with the customer to ensure they are satisfied with the outcome.

Transparency and proactive communication are key to resolving customer complaints effectively. It’s always better to address the issue swiftly and professionally, maintaining a positive customer relationship.

Q 22. What are your methods for quality control during the sealing process?

Quality control in car sealing is paramount. It’s a multi-step process ensuring a flawless, long-lasting finish. My methods begin with a meticulous pre-sealing inspection, checking for existing damage like scratches, swirl marks, or imperfections in the paint. This is followed by a thorough cleaning using high-quality detailing products, ensuring the surface is completely free of contaminants. During the application of the sealant itself, I meticulously monitor the evenness of coverage, avoiding runs or drips. After application, a careful inspection ensures complete coverage and absence of any imperfections. Finally, I conduct a post-sealing inspection under various lighting conditions to evaluate the final gloss and smoothness. I regularly calibrate my equipment and maintain detailed records of each job, including the products used and the client’s feedback to continually improve my process and identify any potential issues.

For example, if I notice a slight imperfection after the sealant has cured, I might carefully use a detailing clay bar to gently lift the imperfection before applying a final polishing. This attention to detail ensures consistent high-quality results.

Q 23. Describe your experience with different types of car surfaces (e.g., clear coat, matte paint).

My experience encompasses a wide range of car surfaces. Clear coats, while common, require a different approach compared to matte finishes. Clear coats are typically harder and more durable, allowing for more aggressive polishing before sealing to enhance gloss and remove imperfections. The sealant itself needs to be chosen carefully to complement the clear coat’s properties and avoid damaging it. Matte finishes, however, are more delicate. They require gentler techniques during preparation and application of sealants to avoid altering their texture. The choice of sealant is crucial; some sealants might negatively affect the matte finish’s unique look and feel. I always tailor my approach to the specific type of paint or surface I’m working with, making sure to use appropriate products and techniques to achieve the best possible result while preserving the integrity of the car’s finish.

For instance, on a classic car with a fragile original paint, I’d employ a much more conservative approach than on a new car with a modern clear coat. I might opt for a water-based sealant and avoid any harsh chemicals to prevent damage to the original paint.

Q 24. Explain your understanding of the chemical properties of various sealants.

Understanding the chemical properties of sealants is critical for successful application. Sealants broadly fall into categories like waxes, synthetic sealants, and ceramic coatings. Waxes are naturally derived, offering relatively short-term protection but often providing a warm, deep gloss. Synthetic sealants are polymer-based and provide longer-lasting protection, offering a balance between protection and ease of application. Ceramic coatings are the most durable, offering exceptional protection and gloss but are often more complex to apply. Each sealant has different chemical properties influencing its durability, gloss, and hydrophobic properties (water repellency). Some are solvent-based, others are water-based, affecting both their application and environmental impact.

For example, a sealant’s hardness (measured by its Shore hardness) indicates its resistance to scratching. Its hydrophobic properties determine its ability to repel water and dirt, influencing its self-cleaning capabilities. Knowing these properties allows me to choose the appropriate sealant for the car’s finish, its usage conditions, and the client’s desired level of protection and gloss.

Q 25. How do you address swirl marks or scratches before sealing?

Addressing swirl marks and scratches before sealing is essential to achieve a perfect finish. This involves a multi-step process starting with thorough washing and drying. Next, I use a clay bar to remove embedded contaminants that can contribute to the appearance of scratches. Then, I employ various levels of polishing, starting with a coarser compound to address deeper scratches and gradually moving to finer polishes to refine the surface and remove swirl marks. The choice of compounds and polishes depends on the severity of the damage and the type of paint. I always test in an inconspicuous area first to ensure compatibility. The final step before sealing involves a thorough cleaning to remove any polishing residue.

Think of it like preparing a canvas before painting a masterpiece. The smoother and cleaner the surface, the better the final result will be. Using the right tools and techniques at this stage can significantly improve the final appearance of the sealed car.

Q 26. How do you price your car sealing services?

Pricing my car sealing services is based on several factors, including the size of the vehicle, the type of sealant used, the level of preparation required (e.g., correction of swirl marks or scratches), and the overall complexity of the job. I offer various packages to cater to different budgets and needs, ranging from basic sealants to advanced ceramic coatings. I provide detailed quotes upfront, outlining all the included services and materials. My pricing is competitive yet reflects the quality of my work and the premium materials I use. I find that transparency in pricing helps build trust with clients.

For example, a compact car requiring only a basic sealant will be priced differently than a large SUV needing extensive scratch correction and a high-end ceramic coating. I’m always happy to discuss different options with clients to find a solution that fits their needs and budget.

Q 27. What are your knowledge of current industry trends in car sealing?

The car sealing industry is constantly evolving. Currently, there’s a growing trend towards eco-friendly, water-based sealants, reflecting increased environmental awareness. There’s also a strong focus on advanced ceramic coatings, offering longer-lasting protection and superior gloss. These coatings often incorporate self-healing technologies, meaning minor scratches can disappear with exposure to heat. Furthermore, the incorporation of technology, such as UV protection and enhanced hydrophobic properties, is another significant trend. Keeping abreast of these developments allows me to offer my clients the most advanced and effective sealing solutions available.

For instance, I recently invested in training on a new type of ceramic coating that offers exceptional durability and ease of application, allowing me to offer a superior service to my clients.

Q 28. Describe a time you had to troubleshoot a problem during a car sealing job.

During a recent job, I encountered a situation where a newly applied ceramic coating showed inconsistent gloss. After careful inspection, I found that the problem stemmed from uneven surface preparation. Some areas had not been properly polished, leaving microscopic imperfections that affected the final gloss of the coating. To resolve this, I carefully re-polished the affected areas using finer polishing compounds, paying close attention to ensuring even pressure and movement. I then re-applied the ceramic coating to those sections, carefully ensuring even application. This meticulous attention to detail solved the problem, and the final result met my high standards. This experience highlighted the importance of a thorough and even pre-sealing preparation for achieving consistent results, even with premium products.

This experience reinforced the importance of methodical problem-solving and careful attention to detail at every stage of the process. I now have a more refined process for checking surface preparation to avoid such issues in the future.

Key Topics to Learn for Car Sealing Interview

- Sealant Types and Properties: Understanding the different types of sealants (e.g., polyurethane, silicone, butyl), their chemical properties, and their suitability for various applications (windshields, body panels, etc.).

- Application Techniques: Mastering proper sealant application methods, including surface preparation, dispensing techniques, and tooling for optimal adhesion and durability. This includes understanding the importance of proper surface cleaning and drying.

- Adhesion and Bonding Principles: Grasping the fundamental principles of adhesion and how various factors (surface cleanliness, temperature, sealant type) impact the bond strength and longevity of the seal.

- Troubleshooting Common Issues: Developing problem-solving skills to identify and address common sealing issues such as leaks, poor adhesion, and sealant failure. This includes understanding the causes of these issues and how to prevent them.

- Health and Safety Regulations: Familiarity with relevant health and safety regulations and procedures related to handling sealants and working in automotive environments (e.g., proper ventilation, personal protective equipment).

- Industry Best Practices: Understanding and adhering to industry best practices for car sealing to ensure high-quality, long-lasting results. This could include knowledge of specific industry standards or certifications.

- Quality Control and Inspection: Developing skills in inspecting sealed areas for defects and ensuring that the work meets quality standards. This includes understanding various inspection techniques.

Next Steps

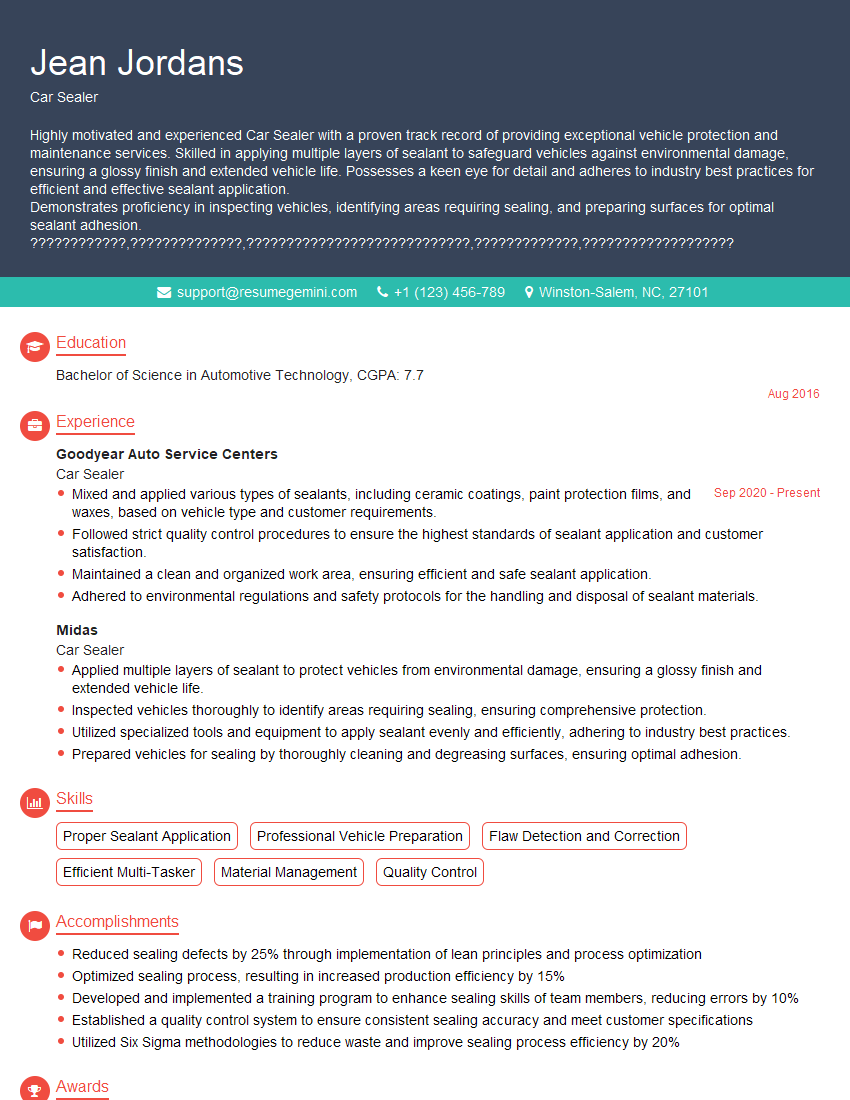

Mastering car sealing techniques opens doors to exciting career opportunities in the automotive industry, offering excellent prospects for growth and specialization. A strong understanding of the technical aspects, combined with a well-crafted resume, significantly increases your chances of securing your desired role. To make your application stand out, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the automotive industry. Examples of resumes specifically tailored for Car Sealing professionals are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good