Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Cargo Loading/Unloading interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Cargo Loading/Unloading Interview

Q 1. Describe your experience with different types of cargo handling equipment.

My experience encompasses a wide range of cargo handling equipment, from basic hand tools to sophisticated automated systems. I’m proficient with forklifts (both sit-down and stand-up), reach trucks, order pickers, and various types of cranes, including overhead cranes and mobile harbor cranes. I’ve also worked extensively with conveyor systems, pallet jacks, and specialized equipment like container handlers and side loaders. Understanding the capabilities and limitations of each piece of equipment is crucial for efficient and safe operations. For instance, I know the weight capacity of each forklift model I’ve operated, ensuring I never overload it, which could lead to accidents or damage. Similarly, I’m well-versed in the safety protocols for operating each machine, including pre-operational checks and emergency procedures.

For example, while working at a large distribution center, I was responsible for training new employees on the safe operation of forklifts. I created a comprehensive training program that included both theoretical instruction and hands-on practice, focusing on elements such as weight distribution, maneuvering in tight spaces, and recognizing and avoiding potential hazards. My experience with diverse equipment types allows me to adapt quickly to different work environments and optimize the loading/unloading process based on the available resources.

Q 2. Explain the process of securing cargo for transport.

Securing cargo is paramount to preventing damage and ensuring safety during transport. The process involves several key steps, starting with a thorough assessment of the cargo itself – its weight, dimensions, fragility, and any special handling requirements. Next, we select appropriate securing methods, such as using straps, chains, or nets. The choice depends on the type of cargo and the mode of transport. For example, fragile items might need cushioning and bracing, while heavy machinery requires robust chains and possibly additional support structures. Proper weight distribution is crucial to prevent instability and shifting during transit. This often means strategically placing heavier items lower in the stack and distributing weight evenly across the transport vehicle. Finally, we document the securing process, including the type of equipment used, its placement, and any specific notes on potential challenges. This documentation serves as a crucial record in case of any incidents or damage claims.

Imagine transporting a shipment of glass panels. We wouldn’t simply stack them on top of each other. Instead, we would carefully wrap each panel individually with protective material, use appropriate padding between the layers, and secure the entire stack with specialized straps to prevent shifting or breakage. This meticulous approach ensures the cargo reaches its destination safely and undamaged.

Q 3. How do you ensure the safety of yourself and others during loading/unloading operations?

Safety is my top priority. I strictly adhere to all safety regulations and company policies during loading and unloading operations. This begins with wearing appropriate personal protective equipment (PPE), which includes safety shoes, high-visibility vests, and safety gloves. Before starting any task, I thoroughly inspect the work area, identifying and eliminating potential hazards like uneven ground, obstructions, or damaged equipment. I always communicate clearly with my colleagues and drivers to coordinate movements and avoid collisions. When operating machinery, I follow all established procedures, including pre-operational checks and regular maintenance inspections. I also maintain a clean and organized workspace, removing debris and unused materials to prevent accidents. Furthermore, I regularly participate in safety training and actively contribute to identifying and mitigating potential hazards in the workplace.

One instance involved noticing a small crack in a forklift’s mast during a pre-operational check. Instead of ignoring it, I reported it immediately, preventing a potentially serious accident. My proactive approach to safety has prevented several near-miss incidents, creating a safer work environment for everyone.

Q 4. What are the common hazards associated with cargo handling, and how do you mitigate them?

Cargo handling involves numerous hazards, including:

- Musculoskeletal injuries: Lifting heavy objects improperly can lead to strains, sprains, and back problems.

- Crushes and impacts: Being struck by falling cargo or caught between equipment can cause severe injuries.

- Slips, trips, and falls: Uneven surfaces, spills, and poor lighting can lead to falls.

- Exposure to hazardous materials: Certain cargo may contain chemicals or substances that pose health risks.

- Equipment malfunctions: Faulty equipment can lead to accidents.

Mitigation involves implementing strict safety procedures, providing adequate training, using appropriate PPE, conducting regular equipment inspections, and establishing clear communication protocols. For instance, using lifting aids and following proper lifting techniques minimizes musculoskeletal injuries. Implementing a robust safety management system, including regular audits and safety meetings, helps maintain a safe working environment. Furthermore, employing risk assessment methodologies allows for proactive hazard identification and control measures, minimizing the probability of accidents.

Q 5. Describe your experience with inventory management in a warehouse setting.

My experience with inventory management in warehouse settings includes using various systems, from manual inventory tracking to sophisticated Warehouse Management Systems (WMS). I’m proficient in cycle counting, stock rotation (FIFO/LIFO), and managing inventory discrepancies. I’ve participated in inventory audits, ensuring accuracy and identifying areas for improvement. Understanding inventory levels is critical for efficient operations, allowing us to optimize storage space and ensure sufficient stock to meet demand. I’m also experienced with using barcode scanners and RFID technology for efficient inventory tracking and management. This experience enables effective forecasting and minimizes stockouts or overstocking, contributing to cost savings and streamlined logistics.

In a previous role, I implemented a new barcode scanning system, which reduced inventory discrepancies by 15% and streamlined the picking and packing process significantly. This demonstrated my ability to leverage technology to improve efficiency and accuracy.

Q 6. How do you prioritize tasks during peak loading/unloading periods?

During peak periods, prioritization is key. I utilize a combination of strategies, including:

- Urgency and Importance Matrix: Categorizing tasks based on urgency and importance allows for focusing on high-priority items first.

- First-In, First-Out (FIFO): Processing orders based on their arrival time ensures fairness and prevents delays.

- Communication and Coordination: Maintaining constant communication with the team and supervisors helps identify bottlenecks and reassign tasks as needed.

- Flexibility and Adaptability: Being willing to adjust plans based on unforeseen circumstances is crucial during peak times.

For example, during a busy holiday season, we might prioritize orders with tight deadlines or those containing perishable goods. Clear communication among the team ensures that everyone understands the priorities and works collaboratively to meet the demands.

Q 7. Explain your understanding of weight distribution and its importance in cargo loading.

Understanding weight distribution is crucial for safe and efficient cargo loading. Improper weight distribution can lead to instability, shifting during transit, and even vehicle damage or accidents. The goal is to distribute the weight evenly across the load-bearing surface, ensuring the center of gravity is kept low and centrally located. This often involves strategically placing heavier items lower in the stack and distributing weight evenly across the transport vehicle. In some cases, specialized equipment or techniques might be needed to secure unevenly weighted loads. For example, we may use blocking and bracing to prevent shifting of heavy equipment. The consequences of poor weight distribution can be serious, including vehicle rollovers, cargo damage, and potential injuries. Therefore, I am particularly meticulous about this aspect of cargo handling.

Imagine loading a truck with bricks. Simply stacking them all in one corner would create an unstable and dangerous situation. Distributing the weight evenly across the truck bed and securing the load properly ensures safe and efficient transportation. My experience ensures that I approach each loading scenario with a careful assessment of weight distribution to minimize risks and ensure safe delivery.

Q 8. How do you handle damaged or defective cargo?

Handling damaged or defective cargo begins with immediate identification and documentation. Upon noticing damage, I meticulously document the extent of the damage, including photographic evidence, and note the condition of the packaging. This documentation is crucial for insurance claims and to inform the appropriate parties (shipper, consignee, and transportation company) about the situation.

Next, I segregate the damaged cargo to prevent further damage or contamination to other goods. Depending on the nature and extent of the damage, we might attempt to salvage the cargo, for instance, if it’s minor damage to outer packaging and the contents are unharmed. If the damage is significant, rendering the cargo unusable, it is disposed of according to regulations. For hazardous materials, specialized disposal procedures are strictly adhered to. Throughout this process, accurate record-keeping is maintained, detailing the actions taken, the parties involved and the final disposition of the damaged goods. I’ve had experience with damaged shipments ranging from minor dents on boxes to complete destruction of sensitive electronics; in each instance, diligent documentation and proper handling were critical in managing the issue efficiently and minimizing financial losses.

Q 9. What is your experience with using handheld scanners for inventory tracking?

I have extensive experience using handheld scanners for inventory tracking, significantly improving efficiency and accuracy in our cargo loading and unloading operations. We primarily use barcode and RFID scanners. For instance, when receiving a shipment, I scan each pallet or individual item to verify against the manifest. This real-time tracking eliminates manual data entry, reduces human error, and allows us to quickly identify any discrepancies between the declared shipment and the actual cargo. The data from these scans are then integrated with our warehouse management system (WMS), generating real-time reports on inventory levels, location of goods, and tracking progress throughout the entire handling process. Using scanners has been instrumental in optimizing our workflow, minimizing stock losses, and providing timely, accurate information to our clients.

Q 10. Describe your knowledge of different types of cargo (e.g., hazardous materials, oversized goods).

My knowledge of cargo types is extensive and encompasses various categories, each demanding unique handling and safety measures. This includes:

- Hazardous Materials (Hazmat): I’m proficient in handling various classes of hazardous materials, understanding their specific regulations (e.g., IMDG Code for sea freight, IATA regulations for air freight), proper labeling, segregation, and emergency response procedures. I’m familiar with the use of placards, safety data sheets (SDS), and emergency response plans. I’ve personally handled shipments containing flammable liquids, corrosive chemicals, and radioactive materials.

- Oversized Goods: Experience includes loading and unloading oversized or heavy-lift cargo requiring specialized equipment and rigging techniques. This includes careful planning of the loading sequence, securing the cargo to prevent shifting during transit, and coordinating with crane operators and other specialists.

- Refrigerated Cargo (Perishables): I am adept at handling temperature-sensitive goods, ensuring proper temperature monitoring and chain of custody throughout the handling process. Understanding the importance of maintaining consistent temperatures for pharmaceuticals, food products and other perishable goods.

- General Cargo: This covers a wide range of goods, from packaged consumer products to industrial equipment, each needing careful handling to minimize damage during transportation.

Understanding these cargo types is paramount for ensuring safe and efficient handling, complying with relevant regulations, and preventing damage or accidents.

Q 11. How do you ensure compliance with safety regulations during loading/unloading?

Safety is my top priority. Ensuring compliance with safety regulations during loading and unloading involves a multi-faceted approach.

- Pre-shift inspections: We start with a thorough check of the loading area, equipment, and the cargo itself for any potential hazards. This includes verifying the proper functioning of forklifts, ensuring clear pathways, and checking for any damage to the loading dock.

- Personal Protective Equipment (PPE): All personnel involved must wear appropriate PPE, such as safety boots, high-visibility vests, and gloves, depending on the cargo and the tasks involved.

- Safe lifting techniques: We strictly adhere to safe lifting practices, using appropriate lifting equipment and techniques to prevent injuries to personnel. Proper training and certification for equipment operation is mandatory.

- Securing the cargo: Cargo must be correctly secured to prevent shifting or falling during transit. We employ appropriate methods like strapping, blocking, and bracing, depending on the type of cargo and mode of transport.

- Following established procedures: We follow strict procedures and checklists for loading and unloading operations, ensuring consistency and mitigating risks.

Regular safety training and refresher courses keep everyone updated on best practices and changes in regulations. Moreover, reporting and investigating any near misses or accidents are key components in maintaining a safe work environment.

Q 12. How familiar are you with different types of loading docks and their features?

My experience encompasses various loading dock types, each with unique features and operational considerations:

- Level docks: These offer easy access to trailers and provide a level surface for loading and unloading. They are most efficient for loading and unloading using forklifts and conveyors.

- Ramp docks: Require the use of ramps to bridge the gap between the dock and the trailer. This requires more manual handling and carries a greater risk of slips, trips, and falls. Careful consideration of ramp angle and condition is necessary.

- Pit docks: These are docks recessed into the ground, allowing trucks to back directly into the dock. Suitable for heavy-duty equipment, but require more maintenance to ensure safety.

The choice of loading dock type depends on the type of cargo, volume of goods handled, and budget constraints. Understanding these features is crucial to selecting the most efficient and safest system for any given situation.

Q 13. Explain your experience with using different types of forklifts (e.g., sit-down, stand-up, reach truck).

I am proficient in operating various types of forklifts, including sit-down, stand-up, and reach trucks. Each type is suited for different tasks and environments.

- Sit-down forklifts: Provide greater stability and are ideal for heavy lifting and long-distance transport within the warehouse. They are more comfortable for extended use.

- Stand-up forklifts: Offer greater maneuverability in tight spaces and are suitable for lighter loads and shorter distances. Their compact design is beneficial in narrow aisles.

- Reach trucks: Are designed for high-stacking applications in narrow aisles, with the ability to lift pallets to considerable heights. Their design allows for efficient use of vertical space in warehouses.

My experience involves not only operating these forklifts but also conducting regular safety checks and understanding their limitations. Safety training and certification are a must before operating any forklift. I’ve used each type to address specific challenges in various warehouse environments, selecting the right equipment based on the task’s demands.

Q 14. How do you maintain accurate records of cargo received and dispatched?

Maintaining accurate records of cargo is crucial for efficient operations and legal compliance. We use a combination of manual and automated systems to ensure accuracy and traceability.

- Bills of Lading (BOLs): These documents are the foundation of our record-keeping, detailing the shipment’s origin, destination, contents, and parties involved. We meticulously verify each BOL against the actual cargo received.

- Warehouse Management System (WMS): Our WMS integrates data from handheld scanners, facilitating real-time inventory tracking, location management, and automated report generation. This eliminates manual data entry, reducing errors and providing immediate visibility into inventory status.

- Spreadsheets and Databases: We use spreadsheets and databases to maintain supplementary records, including detailed information about damaged goods, special handling requirements, and any other relevant data. These records provide a comprehensive history for each shipment.

All records are meticulously maintained and regularly audited to ensure data integrity. These systems are not just for compliance; they help us streamline our operations, respond efficiently to customer inquiries, and conduct effective inventory management, ultimately enhancing efficiency and client satisfaction.

Q 15. Describe your experience with loading and unloading containers.

My experience in loading and unloading containers spans over eight years, encompassing various cargo types, from delicate electronics to heavy machinery. I’m proficient in using various equipment, including forklifts, reach stackers, and cranes, adhering strictly to safety protocols. I’ve handled both standard 20-foot and 40-foot containers, as well as specialized containers requiring specific handling techniques. For example, I once managed the loading of a shipment of oversized wind turbine components, requiring careful planning and coordination with the crane operator and securing crew to prevent damage and ensure safe placement within the container.

My expertise extends to understanding container weight distribution and securing cargo to prevent shifting during transit. This involves using appropriate lashing materials and techniques, ensuring compliance with international shipping regulations. I’ve also developed a keen eye for identifying potential damage to containers before and after loading/unloading, ensuring prompt reporting and mitigation of potential issues. This is crucial in minimizing potential losses for the shipping company.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and report potential safety hazards in the workplace?

Identifying and reporting safety hazards is paramount in our industry. My approach involves a proactive, systematic process. Firstly, I conduct a thorough pre-operation inspection of the work area, checking for potential hazards like uneven ground, damaged equipment, unsecured cargo, or obstructed walkways. I also look for signs of potential weather-related hazards such as strong winds or rain. Secondly, I actively observe the work being performed and colleagues’ behavior, looking for unsafe practices or near misses. Thirdly, I communicate any observed hazards immediately to my supervisor and team using appropriate reporting channels, sometimes including photographic evidence, which can be especially helpful with damaged equipment or cargo.

For example, during the unloading of a container of chemicals, I noticed a leak in one of the drums. I immediately reported it, halting the operation until the leak was secured and the area properly ventilated. This prevented potential exposure to hazardous materials and ensured the safety of the team.

Q 17. Explain your experience with working in a fast-paced environment.

I thrive in fast-paced environments. My experience in busy ports and logistics hubs has equipped me with the ability to handle high-volume operations under tight deadlines. I manage pressure effectively by prioritizing tasks, delegating responsibilities when appropriate, and staying organized. This includes clear communication with team members to ensure everyone is on the same page and aware of the objectives. I find that breaking down large tasks into smaller, manageable steps helps maintain focus and efficiency even under significant time constraints. The use of checklists and pre-planned operational procedures also significantly improves efficiency.

During peak season, we often have multiple vessels arriving simultaneously, requiring rapid turnaround times. I’ve consistently met these challenges by efficiently coordinating my team, effectively managing resources, and ensuring the smooth flow of operations.

Q 18. How do you work effectively as part of a team?

Effective teamwork is essential in cargo handling. I actively participate in team discussions, providing input and sharing my expertise to achieve common goals. I believe in open communication, ensuring that all team members are informed and understand their roles and responsibilities. I also respect diverse perspectives and actively listen to my colleagues’ suggestions, fostering a collaborative environment where everyone feels valued and can contribute effectively. I often take the initiative to assist colleagues who might need help, promoting a supportive team dynamic.

For instance, when a particularly heavy piece of equipment needed to be loaded, I coordinated with my team, assigning roles based on individual strengths and ensuring proper safety measures were in place. This teamwork resulted in a safe and efficient loading operation.

Q 19. How do you adapt to changes in work schedules or priorities?

Adaptability is key in this industry. I’m comfortable with fluctuating work schedules and changes in priorities. I maintain flexibility by staying organized, using efficient time management techniques, and proactively communicating with supervisors to understand any changes in plans. I prioritize tasks based on urgency and importance, ensuring that critical operations are always addressed promptly. This includes being able to quickly re-prioritize tasks based on the needs of the client or changes in shipping schedules. The use of digital communication tools and tracking systems helps immensely in managing changes effectively.

I recall an instance where a container ship arrived unexpectedly early. I quickly adapted my schedule, coordinating with the team to rearrange operations and ensure the timely unloading of the vessel without compromising safety standards.

Q 20. Describe your problem-solving skills related to cargo loading/unloading issues.

Problem-solving is a daily part of this job. My approach involves a systematic process: First, I identify the problem clearly; second, I gather relevant information; third, I analyze the situation to identify potential causes; fourth, I develop and evaluate possible solutions; and finally, I implement the chosen solution and monitor its effectiveness. I utilize my experience and knowledge of cargo handling procedures to effectively analyze the problem. Additionally, I consult resources like manuals, guidelines, and experienced colleagues when needed.

For example, I once encountered a problem where a container’s door wouldn’t open properly. I systematically investigated the issue, identifying a jammed locking mechanism. I then consulted the container’s manual, identifying the proper procedure to fix the problem safely and efficiently, successfully resolving the situation and preventing delays.

Q 21. How do you handle discrepancies between shipment documentation and actual cargo?

Discrepancies between shipment documentation and actual cargo are addressed meticulously. Upon noticing a discrepancy, I first verify the information by cross-referencing all available documentation, including the bill of lading, packing list, and any other relevant shipping documents. I then conduct a thorough physical check of the cargo to confirm the discrepancy. Once confirmed, I document the discrepancy thoroughly, detailing the nature of the discrepancy, the quantity involved, and any potential causes. This documented information is then reported to my supervisor and the relevant stakeholders, such as the shipping company or the customs authorities, according to established procedures.

For instance, if the documentation indicated 100 boxes of electronics but only 98 were physically present, I would document this discrepancy, take photos, and report it immediately to ensure investigation and appropriate actions are taken to track down the missing items.

Q 22. Describe your experience with using warehouse management systems (WMS).

Warehouse Management Systems (WMS) are the backbone of efficient cargo handling. My experience spans over five years, utilizing WMS software to manage inventory, track shipments, optimize storage space, and streamline the entire loading/unloading process. I’ve worked with both cloud-based and on-premise systems, including examples such as SAP EWM and NetSuite WMS. I’m proficient in using these systems to generate reports on inventory levels, track goods throughout the warehouse, and assign optimal locations for storage based on factors like product weight, size, and required access frequency. For instance, in my previous role, implementing a new WMS resulted in a 15% reduction in order fulfillment time and a 10% decrease in warehouse space utilization through better organization and bin optimization. I am also skilled in integrating WMS with other enterprise resource planning (ERP) systems, ensuring seamless data flow across different departments.

Q 23. What is your understanding of different loading techniques (e.g., block stacking, palletizing)?

Different loading techniques are crucial for optimizing space and ensuring cargo safety. Block stacking involves arranging cargo uniformly in blocks, often used for homogeneous items like boxes of similar size. It’s simple but can be less space-efficient than other methods. Palletizing, on the other hand, is significantly more efficient. It involves placing goods onto pallets – standardized platforms – for easy handling by forklifts or other equipment. This allows for better stacking, increased stability, and reduced risk of damage. Beyond these, I’m familiar with methods like container loading (optimizing the arrangement of goods within shipping containers), bulk loading (for loose materials like grain), and unit loading, where larger pre-assembled units (e.g., crates) are moved as a single entity. The choice of technique depends on factors like cargo type, size, weight, destination, and available equipment. For instance, delicate items would be carefully palletized and secured, while bulk materials require different handling procedures.

Q 24. How do you ensure cargo is loaded in accordance with weight limits and regulations?

Adhering to weight limits and regulations is paramount for safety and legal compliance. Before loading, I meticulously check the weight of each item and its specified maximum stack height. I use load charts and weight distribution calculations to ensure the weight is evenly distributed and doesn’t exceed the limits of the vehicle or storage structure. I also carefully consider center of gravity to prevent imbalance and potential tipping. This involves cross-referencing weight information from the Bill of Lading or shipping manifest with the physical weight measurements. Furthermore, I’m familiar with all relevant regulations pertaining to dangerous goods, hazardous materials, and weight limitations specified by transportation authorities. Any deviation requires immediate reporting and corrective action. I would never compromise safety for speed. For example, if a load exceeds the weight limit, we would plan for a second delivery instead of overloading the vehicle. This meticulous approach safeguards the cargo, vehicle, and personnel involved.

Q 25. Explain your understanding of Bill of Ladings and other shipping documents.

Bills of Lading (B/Ls) are crucial shipping documents acting as contracts between shippers and carriers, detailing the terms of shipment. They serve as proof of ownership and evidence of the cargo’s description, quantity, weight, origin, destination, and other key details. They are legally binding contracts and are essential for customs clearance and insurance claims. Beyond B/Ls, I’m familiar with other crucial documents like commercial invoices (detailing the cost of goods), packing lists (listing the contents of each package), certificates of origin (verifying the origin of goods), and various customs forms. Understanding these documents is vital for accurate cargo handling and ensuring smooth, compliant transportation. Discrepancies between the documentation and the actual cargo require thorough investigation and resolution before proceeding with loading or unloading.

Q 26. How do you maintain a clean and organized work area?

Maintaining a clean and organized workspace is critical for efficiency and safety. This is achieved through a structured system of 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). We regularly sort through materials, discarding unnecessary items and properly storing essential ones. Equipment is kept in designated areas, pathways are kept clear, and all spills or debris are immediately cleaned. We maintain regular cleaning schedules and designate responsibilities for upkeep. This organized approach minimizes the risk of accidents, reduces search time for materials, and facilitates smooth workflow. A clean and organized environment boosts morale and professionalism, making the workplace safer and more efficient for everyone.

Q 27. What are your salary expectations for this position?

My salary expectations for this position are in the range of $65,000 to $75,000 per year, depending on the benefits package and the overall responsibilities. This is based on my experience, skills, and the current market rate for similar roles in this region. I am confident my contributions will greatly benefit your organization, and I am open to discussing this further.

Key Topics to Learn for Cargo Loading/Unloading Interview

- Safety Regulations and Procedures: Understanding and adhering to all relevant safety regulations, including those related to hazardous materials, weight limits, and equipment operation. Practical application: Describe your experience with pre-shift safety checks and hazard identification.

- Cargo Handling Techniques: Mastering proper techniques for handling different types of cargo, considering weight, size, fragility, and stability. Practical application: Explain your experience with securing cargo using different methods (strapping, bracing, etc.) and minimizing damage risk.

- Equipment Operation and Maintenance: Familiarity with various loading and unloading equipment (forklifts, cranes, conveyor belts), including their safe and efficient operation and basic maintenance. Practical application: Describe your experience operating specific equipment and performing routine maintenance checks.

- Inventory Management and Tracking: Understanding the importance of accurate inventory tracking throughout the loading and unloading process, minimizing losses and ensuring efficient operations. Practical application: Describe methods you’ve used to verify cargo counts and identify discrepancies.

- Logistics and Planning: Knowledge of efficient loading and unloading strategies to optimize space utilization, minimize turnaround time, and manage resources effectively. Practical application: Discuss your experience in planning and executing loading/unloading operations for different cargo types and vessel sizes.

- Problem-Solving and Decision-Making: Ability to identify and resolve potential issues during the loading/unloading process, adapting to unexpected challenges and ensuring smooth workflow. Practical application: Describe a challenging situation you faced and how you successfully resolved it.

Next Steps

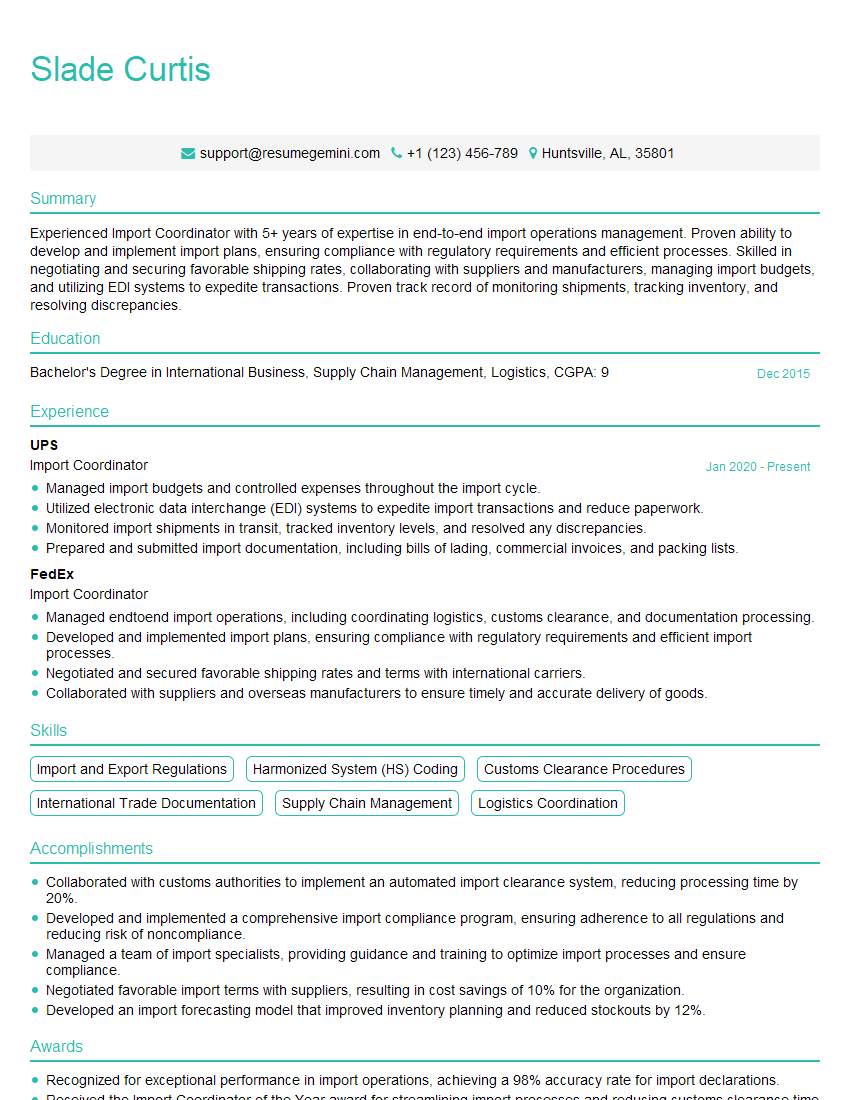

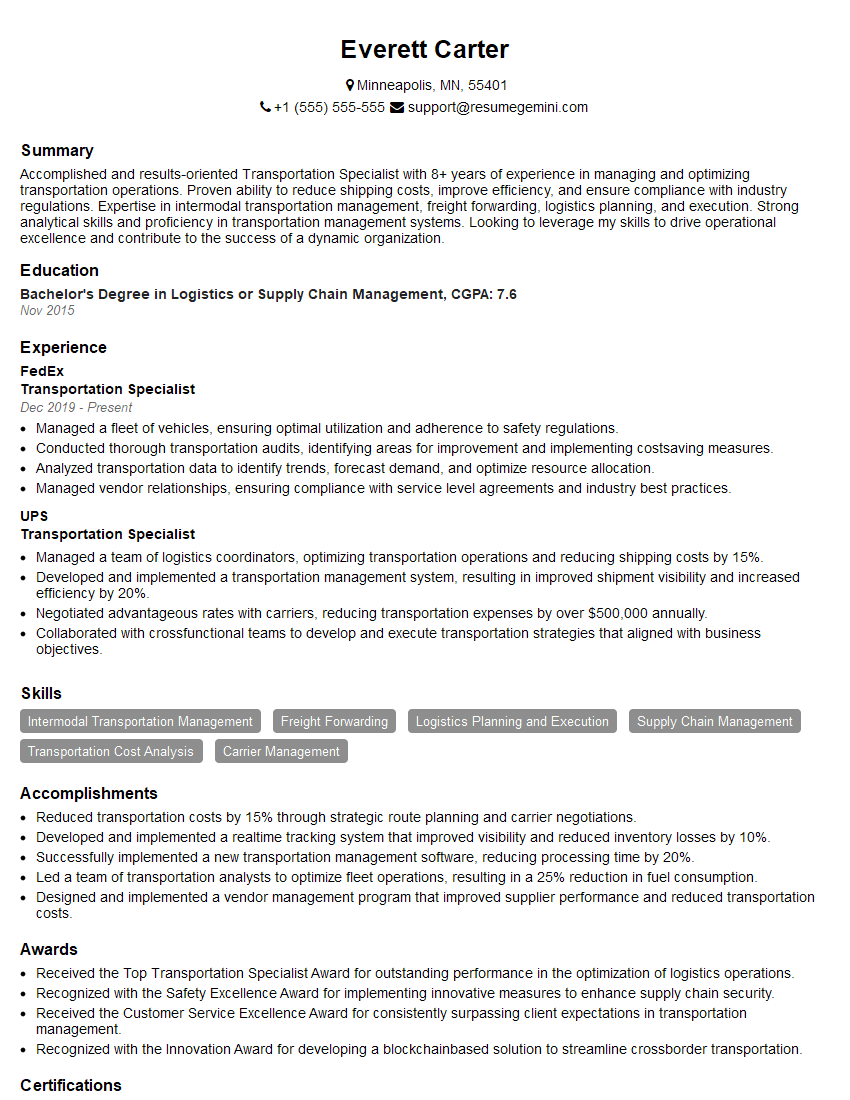

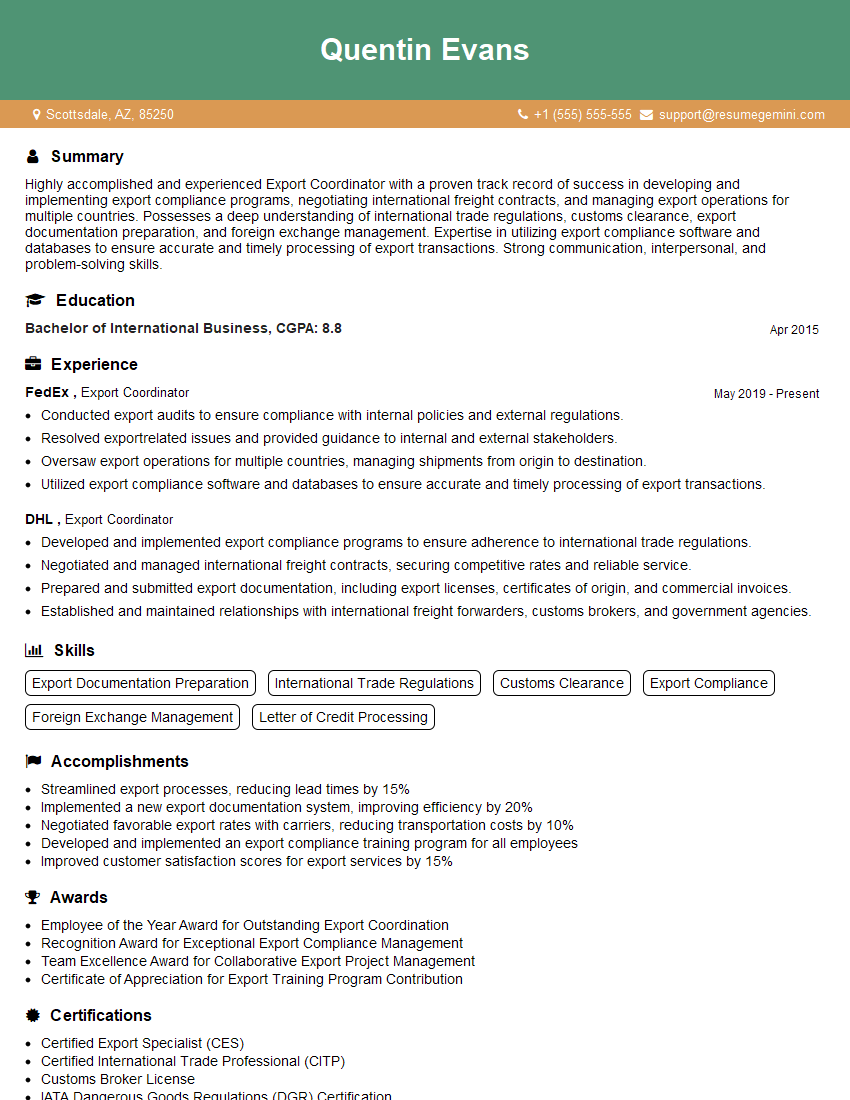

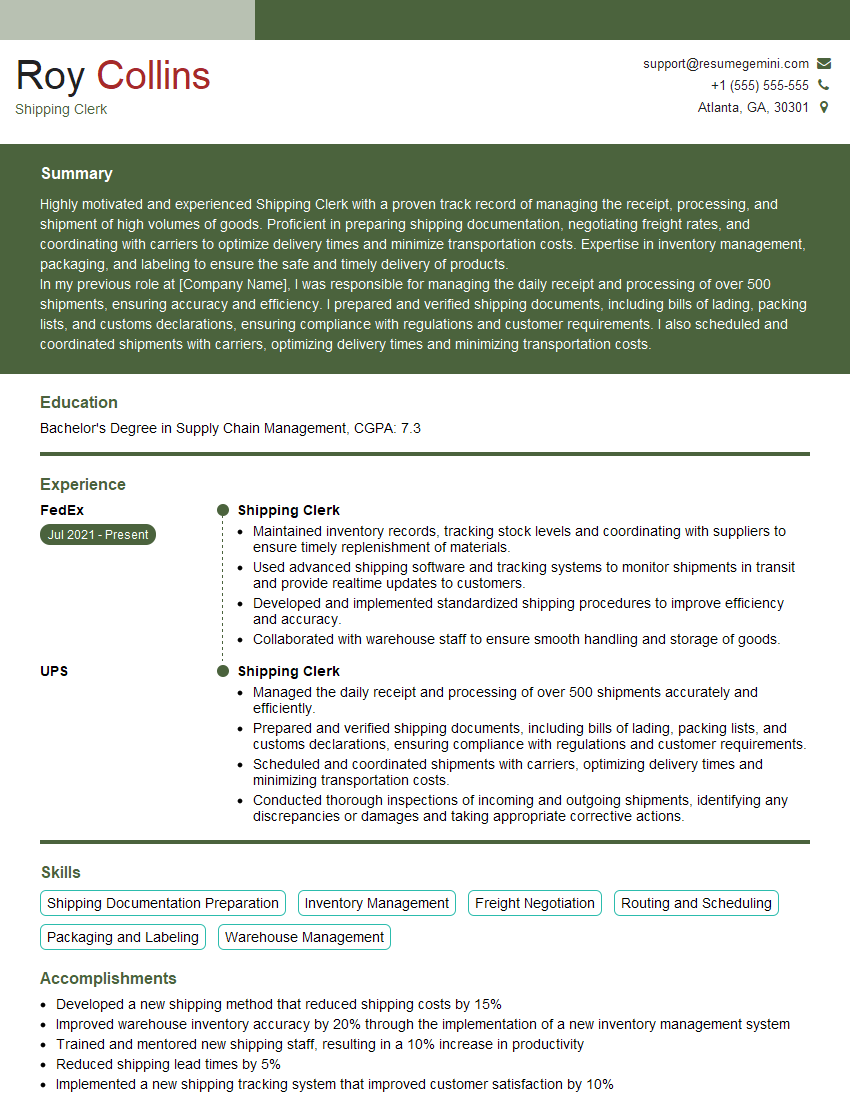

Mastering cargo loading and unloading is crucial for a successful and rewarding career in logistics and transportation. It opens doors to specialized roles and opportunities for advancement. To stand out to potential employers, a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you craft a compelling resume that showcases your skills and experience effectively. Examples of resumes tailored to Cargo Loading/Unloading professionals are available to help you get started. Invest time in perfecting your resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good