Are you ready to stand out in your next interview? Understanding and preparing for Cat5 Cable Installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Cat5 Cable Installation Interview

Q 1. Explain the difference between Cat5, Cat5e, and Cat6 cables.

Cat5, Cat5e, and Cat6 are all twisted-pair Ethernet cables used for networking, but they differ in their bandwidth capabilities and performance. Think of them like different models of cars – all get you from point A to point B, but some are faster and more efficient.

- Cat5: The older standard, Cat5 supports speeds up to 100 Mbps. Its construction is less stringent than later versions, leading to more signal interference.

- Cat5e (enhanced): An improvement over Cat5, Cat5e supports speeds up to 1 Gbps (Gigabit Ethernet). It uses improved twisting techniques and stricter manufacturing standards to reduce crosstalk and improve signal integrity. This is the most commonly used standard in many existing installations.

- Cat6: Designed for higher bandwidth applications, Cat6 supports speeds up to 10 Gbps. It incorporates even stricter manufacturing tolerances and features larger, thicker conductors along with improved shielding to minimize signal interference and enable transmission of higher data rates. You’ll often find Cat6 in high-performance networks or installations where future-proofing is essential.

In short: Cat5e offers a good balance of performance and cost, while Cat6 is the go-to choice for high-speed needs. Cat5 is largely outdated for new installations.

Q 2. What is the maximum cable length for Cat5e before signal degradation becomes significant?

The maximum recommended cable length for Cat5e before significant signal degradation occurs is 100 meters (approximately 328 feet). Beyond this length, you’ll start seeing a noticeable decrease in data transmission speed and reliability, leading to connection drops and data loss. Think of it like a water pipe – the longer the pipe, the more pressure is lost.

While you *might* get a connection beyond 100 meters, it won’t be stable or reliable. It’s crucial to stick to the recommended length for optimal performance. If you need to span a greater distance, you’ll need to use repeaters or switches to extend the network.

Q 3. Describe the process of terminating a Cat5 cable using a punch-down tool.

Terminating a Cat5 cable using a punch-down tool involves connecting the wires to a keystone jack or patch panel. It’s a precise process; even a slight misalignment can affect performance. Here’s a step-by-step guide:

- Strip the cable: Carefully remove about 1 inch of the outer jacket, exposing the individual wires.

- Untwist and arrange the wires: Separate the wire pairs and arrange them according to the TIA/EIA 568A or 568B standard (choose one consistently throughout your installation). The color codes for each standard differ; there are plenty of images of these online, and consistency is key.

- Punch down the wires: Insert the wires into the designated slots of the keystone jack or patch panel, ensuring proper alignment. Use a punch-down tool to firmly crimp the wires into place, cutting off the excess.

- Verify the connection: After punching down all eight wires, visually check for any loose or improperly connected wires. Using a cable tester (discussed below) provides verification.

Remember to always use the correct punch-down tool for your keystone jack or patch panel type. Improper termination can result in connectivity issues, data loss, or complete network failure. Think of it like properly crimping a terminal on a car battery – if you don’t, you’ll have a bad connection.

Q 4. What is the purpose of a keystone jack?

A keystone jack is a modular connector used to terminate Cat5 cables. Think of it as the ‘plug socket’ for your ethernet cable. It provides an easy way to connect and disconnect cables within a structured cabling system. It’s then typically plugged into a faceplate for easy access and a professional finish.

Keystone jacks facilitate easy cable management and allow for quick replacements or rearrangements. They allow for modularity, allowing you to swap out jacks for other uses (e.g., telephone, data, audio) within the same system.

Q 5. How do you test Cat5 cable continuity and identify shorts or opens?

Testing Cat5 cable continuity and identifying shorts or opens requires a cable tester. These devices use electrical signals to check for connectivity problems. A good tester will check:

- Continuity: Verify that a continuous path exists between each wire and its corresponding terminal on the other end. Think of it like testing a circuit to ensure it’s fully wired.

- Shorts: Detect any unintended connections between different wire pairs. This means two wires might be touching inside the jacket.

- Opens: Identify broken wires or incomplete connections.

The cable tester will typically display a visual indication (such as lights) showing the status of each wire pair. If there’s a short or open, the tester will indicate the affected wire pair. If your lights don’t match or show inconsistencies with the known color-coding, there’s a problem that needs further investigation. Without a good cable test, you’re only guessing.

Q 6. What are the common cable testing tools used for Cat5 installation?

Common cable testing tools used for Cat5 installation include:

- Cable testers: These range from simple continuity testers to sophisticated units that test for shorts, opens, and miswires, often providing visual indicators, and sometimes even lengths of wire.

- Tone generators and probes: Used to trace cables within a wall or ceiling. This is especially helpful for finding the other end of a long cable run.

- Multimeters: While not specifically designed for Cat5 testing, multimeters can help verify continuity and detect shorts or opens in a pinch.

The choice of tool depends on the complexity of the installation and the level of testing required. For simple home installations, a basic cable tester might suffice. For larger commercial installations, more sophisticated equipment will be needed to quickly resolve potential issues.

Q 7. Explain the importance of proper cable labeling and documentation.

Proper cable labeling and documentation are essential for efficient troubleshooting and future modifications. Imagine trying to fix a complex piece of equipment without a wiring diagram – it would be a nightmare.

Clear labels on cables and patch panels help identify each connection quickly. Comprehensive documentation, including cable runs, connection points, and equipment locations, simplifies future maintenance and upgrades. Without this documentation, even a small change could lead to significant downtime and frustration. You could easily spend hours tracing cables if you lack proper labeling and documentation.

Good practice involves using a consistent labeling system (e.g., room number, location, port number). This ensures that everyone involved understands the network layout and can easily troubleshoot problems. This is key for any large installation, helping anyone understand the cabling without extensive prior knowledge.

Q 8. What safety precautions should be taken during Cat5 cable installation?

Safety is paramount during Cat5 cable installation. Think of it like working with electricity – a little carelessness can have big consequences. Here’s a breakdown of essential precautions:

- Power Down: Always de-energize any electrical circuits before working near them. A stray wire could easily cause a short circuit and damage equipment or injure you.

- Personal Protective Equipment (PPE): Wear safety glasses to protect your eyes from flying debris when cutting or stripping cables. Work gloves prevent cuts and abrasions from the sharp cable ends.

- Proper Tools: Using the correct tools—like a punch-down tool and cable crimper—not only ensures a quality connection but also minimizes the risk of injury. Improper tools can lead to pinched fingers or damaged cables.

- Working at Heights: If installing cables overhead or in high places, use appropriate fall protection equipment, such as harnesses and safety lines. Don’t take any unnecessary risks.

- Awareness of Surroundings: Pay attention to your surroundings to avoid tripping hazards, especially when working in confined spaces or on ladders.

- Proper Disposal: Dispose of cable scraps and other waste materials responsibly, adhering to local regulations.

Remember, a safe work environment is a productive work environment. Prioritizing safety not only protects you but ensures a smooth and efficient installation process.

Q 9. Describe the different types of cable connectors used with Cat5 cabling.

Cat5 cabling uses several connector types, each serving a specific purpose. The most common is the RJ45 connector. Think of this as the ‘plug’ that fits into your network device. These connectors are typically modular and require crimping to attach securely to the cable.

Beyond RJ45 connectors, you might also encounter:

- Pre-terminated cables: These cables come with RJ45 connectors already attached, saving time and effort, especially for shorter runs.

- Patch panels: Patch panels are used to organize and terminate multiple cables in a centralized location, often found in server rooms.

- Keystones: Keystones are small RJ45 connectors that fit into patch panels or wall plates. They allow for a modular approach to network connections.

The choice of connector depends on the specific application and overall network design.

Q 10. How do you manage cable slack during installation?

Managing cable slack is crucial for preventing strain on connections and ensuring network stability. Imagine a phone line constantly being pulled taut—it’s likely to break! Here’s how to manage slack:

- Excess Cable Storage: Leave extra cable length – usually a few extra feet – to allow for future changes or repairs. This excess cable should be neatly coiled and secured, not just left dangling.

- Cable Ties and Straps: Secure cables using cable ties or straps to walls or other structures, keeping them organized and preventing them from becoming entangled.

- Cable Management Systems: Use cable trays, raceways, or conduit systems for larger installations to keep cables neatly organized and protected from damage.

- Avoid Sharp Bends: Sharp bends can damage the cable and compromise network performance. Keep bends gentle and gradual.

- Wall Plates and Patch Panels: Utilize wall plates and patch panels to consolidate cables and prevent messy bundles.

Proper slack management extends the life of your cabling and simplifies troubleshooting.

Q 11. What is TIA/EIA 568-A and 568-B wiring standards?

TIA/EIA 568-A and 568-B are widely accepted standards that define the wiring scheme for twisted-pair cabling, ensuring consistent and reliable network connectivity. These standards specify the order of color-coded wires within the connector. Think of it as a recipe for connecting your cables—follow it exactly, and your network works perfectly. Deviating from the standard can lead to connection issues.

Q 12. Explain the difference between T568A and T568B wiring schemes.

TIA/EIA 568-A and 568-B are two different wiring schemes that specify the pin-out of the RJ45 connector. While both achieve the same outcome, the order of the wire colors differs. This difference doesn’t impact the functionality of a single connection but consistency across your network is crucial. It’s important to use the same standard (either 568A or 568B) consistently across your entire network. Mixing standards can lead to connectivity problems.

Here’s a comparison:

- 568A:

Orange/White, Orange, Green/White, Blue, Blue/White, Green, Brown/White, Brown - 568B:

Green/White, Green, Orange/White, Blue, Blue/White, Orange, Brown/White, Brown

Choosing between A and B is largely a matter of convention and consistency; it’s usually recommended to stick to one standard for a particular installation.

Q 13. How do you troubleshoot a faulty Cat5 cable connection?

Troubleshooting a faulty Cat5 cable connection involves a systematic approach. Think of it like detective work—you need to gather clues to find the culprit. Here’s a step-by-step guide:

- Visual Inspection: Start with a thorough visual inspection of the cable and connectors. Look for any signs of damage, such as bent pins, broken wires, or loose connections.

- Check Connections: Ensure the RJ45 connectors are securely plugged into the network devices and patch panels. A loose connection is often the simplest cause.

- Test with a Cable Tester: Use a cable tester to check for continuity and wire pairing. This tool will quickly identify shorts, opens, or miswires.

- Check Network Devices: Ensure the network devices (switches, routers, computers) are properly configured and functioning correctly.

- Try a Different Cable: To isolate the problem, try a known-good cable to rule out the cable as the fault.

- Check for Interference: Electromagnetic interference can disrupt signals. Check for sources of interference nearby.

By systematically checking each component, you’ll quickly pinpoint the source of the problem.

Q 14. What is the impact of incorrect cable termination on network performance?

Incorrect cable termination directly impacts network performance. It’s like a leaky pipe; if the connection isn’t tight, the signal is weakened or lost completely. The results can range from minor slowdowns to complete network outages.

- Reduced Bandwidth: Incorrect wiring can restrict the bandwidth, leading to slow data transfer speeds.

- Signal Degradation: Mismatched or poorly terminated cables lead to signal loss, resulting in dropped packets and unreliable connections.

- Intermittent Connectivity: A loose or improperly crimped connector can result in intermittent connectivity issues. The connection might work for a while, then drop out unexpectedly.

- Data Errors: Incorrect wiring can introduce data errors, leading to corrupted files and data loss.

- Network Instability: Ultimately, incorrect cable termination contributes to an unstable network, leading to frustrating performance issues and downtime.

Ensuring proper termination is crucial for maintaining optimal network performance and reliability.

Q 15. What are some common causes of network connectivity issues related to Cat5 cabling?

Network connectivity issues stemming from Cat5 cabling often originate from seemingly small problems. Think of it like a water pipe – a tiny leak can disrupt the entire flow. Common culprits include:

- Crimping Errors: Incorrectly crimped RJ45 connectors are a leading cause. A poorly crimped connector leads to loose or broken wires, resulting in intermittent or no connectivity. Imagine trying to force a square peg into a round hole – it just won’t work properly.

- Broken or Damaged Cables: Physical damage to the cable itself, such as cuts, bends, or kinks, can interrupt the signal. This is like a kink in your garden hose; the water flow is restricted.

- Cable Length Limitations: Exceeding the maximum recommended cable length can significantly weaken the signal, leading to slow speeds and dropouts. This is akin to trying to send a message across a vast distance with a weak radio signal – the message is likely to be lost or distorted.

- Incorrect Wiring: Using the wrong wiring standard (e.g., T568A vs. T568B, and inconsistent use across a network) creates incompatibility issues. Think of it like trying to connect different types of electrical plugs – it won’t fit.

- Electromagnetic Interference (EMI): Nearby electrical devices can introduce interference that disrupts the signal. This is like static on a radio – it interferes with the clean transmission.

- Dirty or Damaged Ports: Dust and debris accumulated in the ports on network equipment can also hinder connectivity. A simple cleaning can often solve this easily overlooked problem.

Troubleshooting these issues usually involves visual inspection of the cables and connectors, testing with a cable tester, and checking for signal strength at various points in the network.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different cable management techniques.

My experience encompasses various cable management techniques, all aimed at ensuring network reliability, safety, and aesthetics. I’ve worked with:

- Cable Ties and Straps: A common and effective method for bundling cables neatly, especially for larger installations. It’s important to avoid over-tightening to prevent cable damage. Think of it as organizing your spaghetti – you need to keep it contained but not crush it.

- Cable Trays and Racks: These provide structured support for larger cable runs, improving organization and airflow. This is like having designated shelves for your books instead of just piling them on the floor.

- Labeling and Documentation: This is crucial for maintainability and troubleshooting. Clearly labeled cables make identifying and tracing them much easier, preventing hours of searching later. Think of it like a well-organized library – easy to find what you need.

- Wall Mounts and Raceway Systems: These solutions keep cables off the floor and protect them from damage. This is like having designated pathways for traffic so everything moves smoothly.

The choice of technique depends on the scale and complexity of the installation. For a small home network, cable ties might suffice. For a large office, cable trays and racks are essential.

Q 17. How do you handle cable routing in tight spaces or challenging environments?

Routing cables in tight spaces or challenging environments requires careful planning and the use of specialized tools and techniques. I’ve encountered many such situations, from cramped server rooms to running cables through walls and ceilings. Key strategies include:

- Flexible Cables: Using more flexible cable types allows for easier maneuvering in tight spaces.

- Fish Tape or Rods: These tools are invaluable for pulling cables through conduits, walls, and ceilings, especially in hard-to-reach areas.

- Cable Management Accessories: Small, adaptable accessories like cable clips, corner protectors and flexible conduits help to navigate obstacles and keep cables organized.

- Planning and Pre-Routing: Carefully planning the route beforehand using diagrams and measurements minimizes surprises and rework.

- Careful Bending Radii: Excessive bending can damage the cables, so maintaining proper bending radii is vital.

Safety is paramount in these situations. Always follow safety regulations and use appropriate personal protective equipment (PPE) when working with tools and in potentially hazardous environments.

Q 18. What is your experience with fiber optic cabling?

While my primary expertise lies in Cat5 cabling, I possess a working knowledge of fiber optic cabling. I understand the principles of fiber optic transmission, its advantages (higher bandwidth, longer distances), and the specialized tools and techniques required for its installation. I’m familiar with different fiber types (single-mode, multi-mode), connectors (SC, ST, LC), and testing equipment. While I haven’t extensively installed fiber optic cables independently, I have assisted experienced technicians and understand the safety precautions necessary when handling this type of cabling. It’s a more delicate process requiring more specialized equipment and training, which I am willing to pursue further if needed.

Q 19. Describe your experience with different types of network topologies.

My experience with network topologies is extensive. I’m familiar with the advantages and disadvantages of different topologies and how they impact network performance and design. I’ve worked with:

- Star Topology: The most common topology in modern networks, characterized by a central hub or switch connecting all devices. It offers high reliability and scalability.

- Bus Topology: A simpler topology where all devices are connected to a single cable. Less common now due to its vulnerability to single points of failure.

- Ring Topology: A topology where devices are connected in a closed loop. Data travels in one direction around the ring.

- Mesh Topology: A robust topology with multiple paths between devices, offering high redundancy and fault tolerance.

Understanding the topology is essential for effective cable management and troubleshooting. For example, a problem in a star topology is usually isolated to a single device or cable, while a problem in a bus topology could affect the entire network.

Q 20. How familiar are you with network patch panels?

I’m highly familiar with network patch panels. These are essential components for organizing and managing network cables. I understand their purpose in providing a centralized point of connection for cables, facilitating easy cable management and troubleshooting. I’m experienced in:

- Patch Panel Installation: Proper mounting and securing of the patch panel in a rack.

- Cable Termination: Correctly terminating cables onto the patch panel using appropriate punches and tools. This is crucial for ensuring good connectivity.

- Patch Cable Management: Organizing and labeling patch cables to maintain a neat and efficient setup.

- Troubleshooting: Identifying and resolving connectivity problems related to the patch panel.

Think of a patch panel as a highly organized switchboard for your network. Its proper installation and management are key to the smooth operation of the entire system.

Q 21. Explain your understanding of cable shielding and its importance.

Cable shielding is a critical aspect of Cat5 cable installation, particularly in environments with high levels of electromagnetic interference (EMI). Shielding protects the signal from external interference, ensuring reliable data transmission. This is like wrapping a delicate gift in protective bubble wrap – it safeguards the contents from damage.

Shielding typically consists of a metallic layer (foil or braid) wrapped around the cable’s conductors. This layer acts as a barrier, preventing EMI from affecting the signal. The effectiveness of shielding depends on factors like the type of shielding, the quality of the installation (proper grounding), and the level of EMI present.

In environments with high EMI, such as industrial settings or areas with numerous electrical devices, shielded cables are essential for reliable network performance. Unshielded cables are more susceptible to interference, leading to slow speeds, data loss, and connectivity problems. Choosing the right shielding type and ensuring proper grounding practices are crucial aspects of ensuring a stable and reliable network.

Q 22. What is your experience with various cable pulling methods?

My experience encompasses a wide range of cable pulling methods, chosen based on the specific environment and cable length. For shorter runs, I typically use hand pulling techniques, ensuring careful handling to avoid damage. This often involves using a fish tape to guide the cable through conduits or walls. For longer runs or difficult-to-access areas, I utilize power pulling equipment, such as a cable pulling machine, always adhering to the manufacturer’s safety guidelines. This might involve using lubricants to reduce friction and prevent damage to the cable. I’ve also employed pneumatic systems for extremely long or challenging installations. For example, in a recent project involving a large office building, we used a combination of hand pulling and a powered winch to efficiently install hundreds of meters of Cat5 cable through various floor levels.

The choice of method always considers factors such as cable type, conduit material, distance, and potential obstacles. Safety is paramount; I always inspect the path before pulling to avoid damaging the cable or causing injury.

Q 23. How do you ensure compliance with relevant safety standards during installation?

Safety is my top priority. I strictly adhere to OSHA (Occupational Safety and Health Administration) and NEC (National Electrical Code) standards. This includes using appropriate Personal Protective Equipment (PPE), such as safety glasses, gloves, and appropriate footwear, at all times. Before starting any installation, I conduct a thorough site survey to identify and mitigate potential hazards, such as energized lines or overhead obstructions. Proper grounding and bonding techniques are always employed to prevent electrical shocks. I’m also trained in lockout/tagout procedures to ensure the safety of myself and others working nearby when dealing with power sources. For instance, I recently worked on a project where we needed to install cables near an active electrical panel. We followed strict lockout/tagout procedures before proceeding, ensuring the power was completely isolated before we began work.

Q 24. Describe your experience with troubleshooting and repairing network connectivity issues.

Troubleshooting network connectivity issues is a significant part of my role. My approach is systematic, starting with visual inspection of the cabling for physical damage such as cuts, kinks, or loose connections. I use cable testers to verify continuity and identify shorts or opens. If the problem isn’t immediately apparent, I then use network diagnostic tools like a packet analyzer to check data flow and identify bottlenecks or network segments with connectivity problems. I’ve successfully resolved numerous connectivity issues ranging from simple bad terminations to more complex problems involving faulty switches or router configurations. For example, I once identified a faulty patch panel causing intermittent connectivity problems in a large server room by systematically testing each port.

My experience includes diagnosing and repairing issues related to incorrect wiring (e.g., twisted pair issues), faulty jacks, and problems stemming from incorrect network device configurations. I’m proficient in using various testing tools, enabling me to isolate the source of the problem quickly and efficiently. This often involves documenting the troubleshooting steps and solutions to ensure future reference and prevent recurrence.

Q 25. What tools and equipment are essential for Cat5 cable installation?

Essential tools for Cat5 cable installation include:

- Cable stripper/cutter: For neatly removing the outer sheath and individual wire insulation.

- Crimping tool: To securely connect the wires to RJ45 connectors.

- Punch down tool: For terminating cables in patch panels.

- Cable tester: To verify connectivity and identify faults.

- RJ45 connectors: The modular plugs that attach to the end of the cable.

- Fish tape or cable puller: For guiding cables through conduits.

- Measuring tape: For accurate cable length measurement.

- Wire strippers: For removing insulation without damaging the conductors.

- Multi-meter: To check continuity and voltage.

The specific tools used might vary based on the project requirements, but these are fundamental for efficient and reliable installations.

Q 26. What is your experience with high-speed data transmission over Cat5 cabling?

Cat5 cable, while not designed for Gigabit Ethernet speeds, can support it with appropriate infrastructure and careful installation. However, Cat5e and Cat6 are recommended for optimal performance and reliability. I have extensive experience working with Cat5 cabling in various applications, including small office networks and even legacy systems where upgrading to newer standards isn’t feasible. My experience involves understanding the limitations of Cat5, specifically its susceptibility to crosstalk and signal attenuation at higher speeds and longer distances. I’ve successfully implemented strategies to minimize these issues, such as using shorter cable lengths and employing proper termination techniques.

Understanding the bandwidth limitations of Cat5 is crucial. While it can technically carry Gigabit Ethernet data, performance can degrade significantly over longer distances or in noisy environments. It’s imperative to account for these factors during the planning phase of a project.

Q 27. How do you ensure network security during Cat5 cable installation?

Network security during Cat5 cable installation primarily focuses on preventing unauthorized access to the network. This starts with securing the physical cabling itself, which means protecting against tampering and ensuring only authorized personnel have access to the wiring closets and cable runs. Proper labeling of cables and documentation is essential for tracking and managing network components. During the installation process, I always ensure that the cable runs are protected from unauthorized access, and that only trained professionals handle the wiring and connections. I’ve been involved in projects requiring additional physical security measures such as locked cabinets for network equipment.

While Cat5 cable installation itself doesn’t directly address the higher-level network security (firewalls, intrusion detection), protecting the physical infrastructure is the foundation for a secure network. Any vulnerabilities in the physical cabling can create entry points for malicious activities.

Q 28. Explain your experience working with different types of network devices (routers, switches, etc.)

My experience with network devices is extensive. I’m comfortable working with various types of routers, switches, and other network equipment, including both managed and unmanaged devices. I understand the differences between various switching technologies (e.g., layer 2 vs layer 3) and can configure basic network settings on most commonly used devices. I’ve worked with Cisco, Netgear, and HP networking equipment, among others. I understand how to connect and configure these devices effectively for optimal performance within various network topologies.

This experience extends to troubleshooting issues with these devices. For example, I recently diagnosed and resolved a network outage caused by a faulty switch port by identifying the failed component and replacing it with a working one. Understanding the interoperability of different network devices is key to effective installation and maintenance of a robust network infrastructure.

Key Topics to Learn for Cat5 Cable Installation Interview

- Understanding Cat5e and Cat6 Cable Standards: Differences in bandwidth, application, and performance characteristics.

- Cable Termination Techniques: Mastering the 568A and 568B wiring standards, including proper crimping and testing procedures.

- Troubleshooting Common Cable Issues: Diagnosing problems like poor connections, signal attenuation, and crosstalk using testing equipment.

- Practical Application in Network Infrastructure: Understanding the role of Cat5 cables in building network infrastructure, including patch panels, jacks, and routers.

- Safety Precautions and Best Practices: Following safety protocols while working with electrical equipment and adhering to industry standards.

- Punch Down Techniques and Patch Panel Management: Efficient and organized methods for managing cables within a patch panel.

- Testing and Verification Methods: Using cable testers to verify proper connectivity and identify potential faults.

- Cable Management and Organization: Understanding the importance of proper cable routing and labeling for efficient network maintenance.

- Understanding Network Topologies: How Cat5 cable installation relates to different network topologies like star, bus, and ring.

- Fiber Optic Cable Basics (Optional): A basic understanding of fiber optic cables and their advantages over copper cabling, especially in high-bandwidth applications.

Next Steps

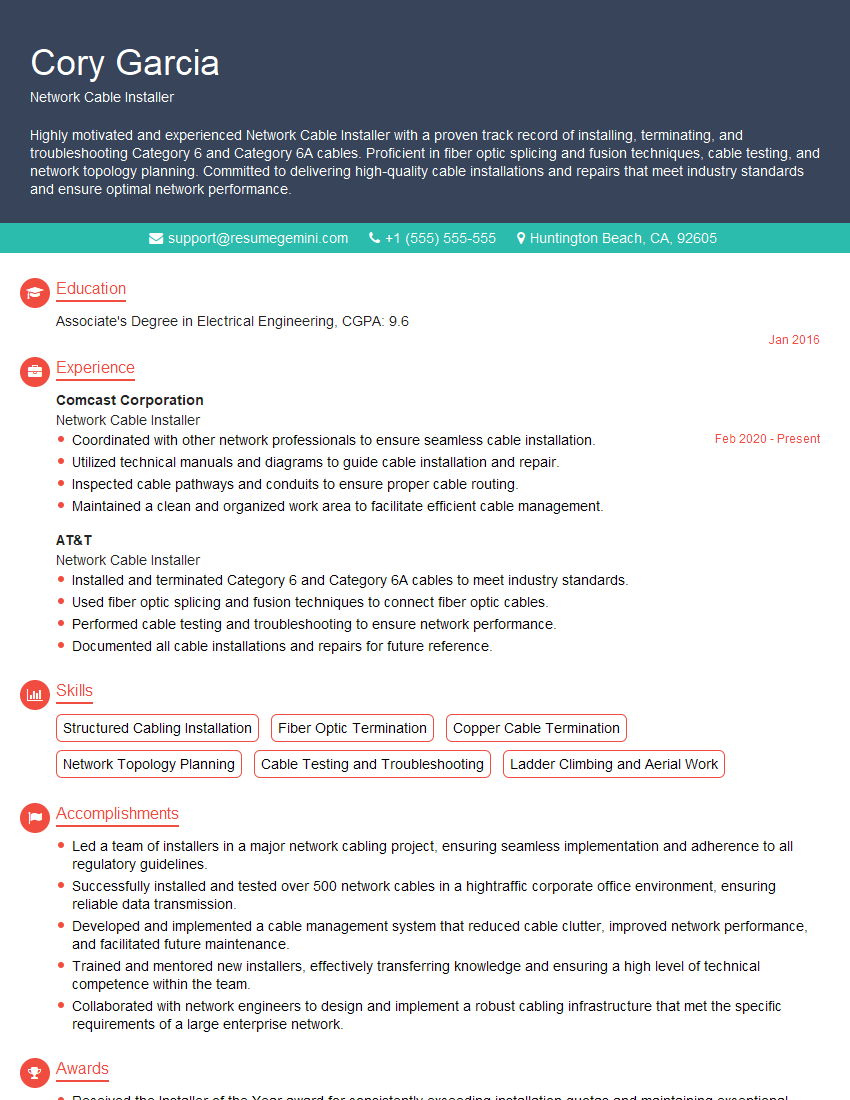

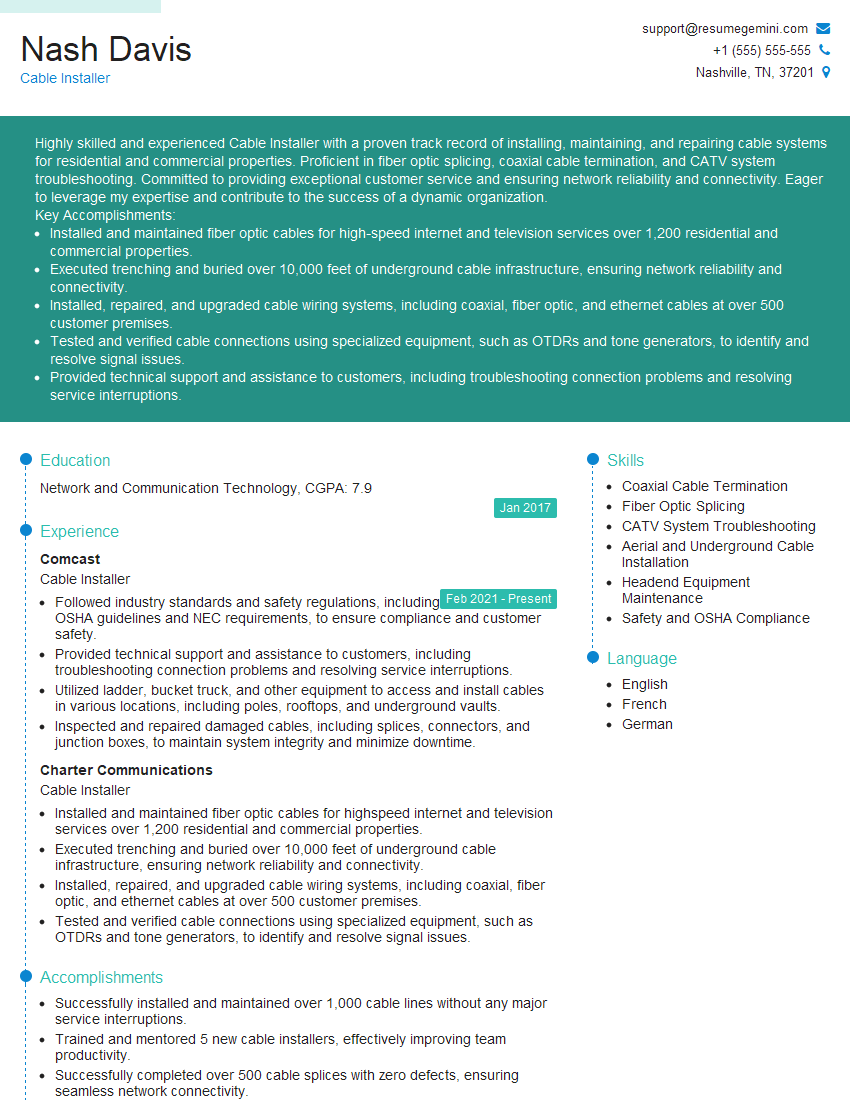

Mastering Cat5 cable installation opens doors to exciting opportunities in networking and telecommunications, offering excellent career growth potential. A well-crafted resume is crucial for showcasing your skills to potential employers. Creating an ATS-friendly resume increases your chances of getting noticed by recruiters. We highly recommend using ResumeGemini to build a professional and effective resume that highlights your Cat5 cable installation expertise. Examples of resumes tailored to Cat5 Cable Installation are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good