The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Cat5 Cable Splicing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Cat5 Cable Splicing Interview

Q 1. Explain the difference between Cat5 and Cat5e cabling.

Cat5 and Cat5e cables are both twisted-pair cables used for Ethernet networking, but Cat5e offers significant improvements in performance. The key difference lies in their ability to handle higher frequencies and thus, faster data transmission speeds. Cat5 supports speeds up to 100 Mbps, while Cat5e supports speeds up to 1 Gbps. This improvement is largely due to stricter specifications on crosstalk (interference between pairs) in Cat5e. Think of it like this: Cat5 is a decent highway, but Cat5e is a wider, better-maintained highway capable of handling much more traffic without congestion.

In practical terms, while Cat5 might suffice for older networks or low-bandwidth applications, Cat5e is the recommended standard for modern networks to ensure reliable Gigabit Ethernet speeds. Choosing Cat5e ensures future-proofing your network infrastructure.

Q 2. Describe the process of terminating a Cat5 cable using a punch-down tool.

Terminating a Cat5 cable with a punch-down tool involves connecting the individual wires within the cable to the terminals on a keystone jack or patch panel. It’s a precise process requiring careful attention to detail. Here’s a step-by-step guide:

- Strip the cable: Carefully remove the outer sheath of the Cat5 cable, exposing about an inch of the twisted pairs. Avoid nicking the individual wires.

- Untwist and straighten: Gently untwist the pairs, ensuring each wire is straight and of equal length.

- Arrange according to standard: Arrange the wires according to either the 568A or 568B standard (explained in the next answer). Consistency is crucial.

- Insert into jack: Insert the wires into the appropriate slots of the keystone jack.

- Punch down: Using a punch-down tool, firmly punch down each wire into the jack, ensuring a secure connection. A poorly punched-down wire can lead to connection problems.

- Test the connection: After terminating, test the connection with a cable tester to ensure proper continuity and signal quality.

Remember, practice makes perfect! Start with a few spare cables to get comfortable with the process before working on critical network connections.

Q 3. What is the significance of the 568A and 568B wiring standards?

The 568A and 568B wiring standards define the color-coded arrangement of wires within a Cat5 cable. Both standards achieve the same end result – a functional network connection – but they differ in the order of the color pairs. This is crucial because consistency is key. Using different standards at either end of the cable will cause signal problems and network failures.

568A: Orange-White, Orange, Green-White, Blue, Blue-White, Green, Brown-White, Brown

568B: Green-White, Green, Orange-White, Blue, Blue-White, Orange, Brown-White, Brown

In practice, you need to use the same standard at both ends of the cable (either A-A or B-B). Mixing standards will create a mismatch that prevents proper communication.

Q 4. How do you identify a faulty Cat5 cable?

Identifying a faulty Cat5 cable often involves a combination of visual inspection and testing. Visual inspection might reveal obvious damage like cuts, kinks, or poorly terminated ends. However, many faults are not visible and require specialized testing equipment.

- Cable tester: A cable tester is the most effective tool. It checks for continuity (whether a complete electrical path exists), shorts (unintended connections between wires), and open circuits (breaks in the wire). A tester will pinpoint the exact location of the fault.

- Network testing tools: Network testing tools can identify problems beyond basic continuity. These tools can test for signal attenuation (signal weakening) and crosstalk, providing more detailed diagnostics.

- Troubleshooting the network: If the cable is part of a larger network, systematically checking different components (routers, switches, computers) can help isolate the problem. A faulty cable might manifest as intermittent connectivity or slow speeds.

In a real-world scenario, I’ve encountered a seemingly good cable that was causing intermittent internet drops. The cable tester revealed a loose connection at one of the punch-down points—a problem easily solved by re-punching the wire.

Q 5. What tools are essential for Cat5 cable splicing?

Essential tools for Cat5 cable splicing include:

- Cable stripper: For removing the outer jacket of the cable without damaging the internal wires.

- Wire cutters/diagonal cutters: For precisely cutting the wires to length.

- Punch-down tool: For connecting the wires to keystone jacks or patch panels.

- Crimping tool: For securing RJ45 connectors onto the ends of cables.

- Cable tester: For verifying the integrity of the connection after splicing or termination.

- Measuring tape: To cut the cable at the proper length.

- RJ45 connectors: The plugs that connect the cables to network devices.

Having a good quality set of these tools will ensure accurate and reliable cable splicing.

Q 6. Explain the importance of proper cable management.

Proper cable management is vital for several reasons: It ensures optimal network performance, improves safety, and simplifies troubleshooting and maintenance. Poorly managed cables can lead to signal degradation (due to interference), tripping hazards, and difficulty in identifying individual cables during maintenance.

Effective cable management involves:

- Using cable ties or straps: To bundle cables neatly and prevent tangling.

- Employing cable trays or raceways: For organizing cables, protecting them from damage and improving aesthetics.

- Labeling cables clearly: To easily identify individual cables and their purpose.

- Avoiding sharp bends or kinks: Which can damage the cables and compromise signal integrity.

Think of it like organizing a closet – properly managing your cables makes everything easier to find and keeps things running smoothly.

Q 7. How do you test Cat5 cable continuity and signal quality?

Testing Cat5 cable continuity and signal quality is done using a cable tester. These devices come in various forms, from simple continuity testers to advanced network analyzers. A basic continuity tester will show whether there is a continuous path between the wires and whether there are shorts or open circuits. More sophisticated testers can measure signal attenuation (signal loss) and crosstalk (interference between wire pairs).

The process typically involves connecting the tester to both ends of the cable and then reading the results displayed on the tester. The results will typically indicate whether the cable is good, and if not, indicate which wire(s) is the source of the problem. Identifying and resolving a faulty cable quickly is a crucial skill for any network technician.

Q 8. What are the common causes of Cat5 cable failures?

Cat5 cable failures can stem from a variety of issues, impacting network performance and connectivity. Common culprits include physical damage, such as cuts, crushing, or excessive bending, which can break internal wires. Improper termination, where the RJ45 connector isn’t properly crimped onto the wires, leads to poor signal transmission. Environmental factors, like extreme temperatures or moisture, can cause corrosion and degradation of the cable’s internal conductors, affecting signal integrity. Poor installation practices, such as sharp bends or excessive strain relief, weaken the cable, making it prone to breakage. Finally, electromagnetic interference (EMI) from nearby devices can disrupt the signals carried within the cable, leading to intermittent connectivity problems or data loss.

Think of it like a water pipe: a cracked pipe (physical damage) will leak, a poorly connected faucet (bad termination) will drip, and rust build-up (corrosion) will restrict water flow, all resulting in reduced water pressure (signal strength). Addressing these issues involves careful handling, proper termination techniques, and sometimes replacing damaged sections of the cable.

Q 9. Describe the process of crimping a RJ45 connector.

Crimping an RJ45 connector is a precise process requiring the right tools and techniques. First, you carefully strip the outer jacket of the Cat5 cable, exposing about an inch of the twisted pairs. Then, carefully untwist the pairs and arrange them according to the T568A or T568B standard (it’s crucial to be consistent!). The chosen standard dictates the order of the color-coded wires within the connector. Next, insert the wires into the RJ45 connector, ensuring they reach the end and are straight. Finally, use a crimping tool to firmly press the connector onto the wires, creating a secure connection. This process requires sufficient pressure to reliably connect the wires and prevent signal loss.

Imagine it like carefully threading a needle: each wire needs to be in its designated place. A poorly crimped connector can lead to loose connections, resulting in intermittent connectivity or data loss. Always inspect the crimp carefully to ensure it’s securely attached before plugging the cable in. A bad crimp is often visually apparent.

Q 10. What is the difference between stranded and solid core Cat5 cable?

The key difference between stranded and solid core Cat5 cable lies in the structure of the individual conductors. Stranded core cable uses multiple thin copper strands twisted together, offering greater flexibility and making it ideal for applications requiring frequent movement, such as connecting devices within a home or office. Solid core cable, on the other hand, uses a single, solid copper conductor, resulting in a more rigid cable better suited for fixed installations where flexibility isn’t crucial. It typically provides slightly better signal transmission but is less resistant to repeated bending and flexing.

Think of it as the difference between a rope (stranded) and a solid rod (solid). The rope is more flexible and can be bent easily without breaking, whereas the rod is stiffer but can easily snap if bent too forcefully. Choosing the right cable type depends on the specific needs of the application.

Q 11. Explain the importance of grounding in Cat5 cabling.

Grounding in Cat5 cabling is critical for minimizing electromagnetic interference (EMI) and preventing electrical surges that could damage network equipment. A properly grounded Cat5 system provides a low-impedance path for electrical currents, preventing unwanted noise from entering the network and protecting the sensitive electronics from voltage spikes. This is especially crucial in environments with significant electrical noise, protecting both the equipment and the data transmission.

Grounding acts as a safety net, diverting potentially harmful electrical currents away from sensitive equipment. Imagine it like a lightning rod, protecting a building from a lightning strike. A poorly grounded or ungrounded system can lead to data corruption, equipment failure, and even electrical shocks.

Q 12. What safety precautions should be taken when working with Cat5 cables?

Safety when working with Cat5 cables is paramount. Always disconnect power to network devices before working with cables to prevent electrical shock. Use appropriate tools, such as a cable cutter and crimping tool, to avoid accidental injuries. Wear safety glasses to protect your eyes from flying debris during cutting or stripping. Never force a connector, as this can damage the cable or the connector. Be mindful of potential hazards in your environment, such as sharp objects or exposed electrical wiring. Work in a well-lit area to improve visibility and reduce the risk of accidents.

Safety precautions are like wearing a seatbelt while driving: it’s a small effort that can prevent serious consequences.

Q 13. How does cable length affect signal performance?

Cable length significantly impacts signal performance. As the length increases, signal strength degrades, and signal attenuation (loss of signal strength) becomes more pronounced. Excessive cable length can lead to data loss, slower speeds, and increased errors. This is because the signal loses energy as it travels through the cable. Cat5 cable has limitations on the maximum recommended length (usually 100 meters for 100BASE-TX), exceeding which might render the connection unusable. This distance is standardized to ensure reliable data transmission. Shortening the cable or employing signal repeaters/amplifiers is necessary to maintain performance when longer distances are needed.

Think of it as a water hose: the further the water has to travel, the weaker the pressure becomes at the end. Similarly, the longer the Cat5 cable, the weaker the signal becomes at the receiving end.

Q 14. What is near-end crosstalk (NEXT) and how does it relate to Cat5 cable?

Near-end crosstalk (NEXT) is a type of signal interference that occurs in twisted-pair cabling, including Cat5. It refers to the unwanted signal coupling from one pair of wires in the cable to adjacent pairs at the same end of the cable. This unwanted signal can interfere with the intended signal, leading to data corruption or transmission errors. The level of NEXT is a crucial factor in determining the overall performance of Cat5 cable; lower NEXT values indicate better performance and reduced interference.

Imagine several water pipes running close to each other; if the water pressure in one pipe is high enough, it could affect the pressure in the adjacent pipes. NEXT is similar, the signal on one pair of wires can affect neighboring wire pairs, interfering with the data transmission.

Q 15. Describe your experience with different types of cable connectors.

My experience with Cat5 cable connectors spans a wide range, encompassing various types crucial for reliable network installations. The most common are RJ45 connectors, used to terminate Cat5 cables into modular jacks or patch panels. I’m proficient in crimping these connectors using various tools, ensuring proper wire pairing according to the TIA/EIA 568A or 568B standards. Beyond RJ45, I’ve worked with other connectors like those used in fiber optic cable splicing (though not directly Cat5), which requires specialized tools and techniques. I also have experience with various types of keystone jacks – the modular components that house the RJ45 connector within a patch panel or wall plate, ensuring compatibility with different wall-plate styles and aesthetics.

For example, in a recent project, we used shielded RJ45 connectors in areas with high electromagnetic interference (EMI) to ensure signal integrity. Proper connector selection is crucial to avoid signal loss or crosstalk, and I always choose connectors appropriate for the environment and application. I understand the importance of consistent crimping and testing to guarantee reliable connections.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot intermittent network connectivity issues related to Cat5 cabling?

Troubleshooting intermittent network connectivity issues in Cat5 cabling requires a systematic approach. My first step involves identifying the affected devices and the extent of the problem. Is it a single device or multiple devices experiencing connectivity issues? Does the problem occur consistently or intermittently?

Next, I visually inspect the cables for any signs of physical damage, such as kinks, cuts, or loose connections. I use a cable tester to check for continuity, shorts, and wire-pair issues. Intermittent problems often point to a loose connection, a corroded connector, or a faulty cable somewhere along the run. Sometimes, the problem isn’t even with the cable itself, but rather with a poorly terminated connector, a faulty port on a switch or router, or even environmental factors.

My troubleshooting strategy includes:

- Visual Inspection: Carefully examine the entire cable run, connectors, and wall plates.

- Cable Testing: Use a cable tester to verify continuity, shorts, and wire pairs.

- Connector Inspection: Check connectors for damage or corrosion, carefully resitting any connectors that are loose.

- Testing at different points: Replace a suspected section of cable with a working one to isolate the fault.

- Check Network devices: Ensure that the switches, routers and network cards are properly configured and working.

For example, I once diagnosed an intermittent connection problem as a loose connector inside a wall plate after several hours of testing, highlighting the importance of thorough and systematic troubleshooting. I always document my findings and the steps taken to resolve the issue, aiding future maintenance.

Q 17. What are the common standards and regulations for Cat5 cable installation?

Cat5 cable installation adheres to several crucial standards and regulations designed to guarantee performance, safety, and long-term reliability. The most prominent are TIA/EIA 568 and ISO/IEC 11801. These standards define cabling specifications, testing procedures, and installation best practices. They ensure consistent performance across different manufacturers and installations, preventing compatibility issues.

Beyond these core standards, other regulations apply based on location and context. This may include building codes related to cable routing and fire safety, as well as regulations regarding grounding and electromagnetic interference (EMI). For instance, in certain environments, plenum-rated cables are mandated to ensure fire safety. These regulations influence cable selection, routing, and installation methods. Failure to comply with relevant regulations can result in safety hazards or performance issues.

Adhering to these standards and regulations is crucial for ensuring a stable and efficient network. I prioritize compliance to avoid issues and maintain the integrity of the network infrastructure.

Q 18. Explain the concept of attenuation in Cat5 cabling.

Attenuation in Cat5 cabling refers to the reduction in signal strength as it travels along the cable. This is a natural phenomenon caused by the inherent resistance of the copper conductors and dielectric materials. The longer the cable, the greater the attenuation. Higher frequencies also experience greater attenuation. This loss of signal strength can lead to reduced data transmission speed, increased error rates, and ultimately, network connectivity problems if it is excessive.

Attenuation is measured in decibels (dB) per unit of length, such as dB/100m. Cat5 cable specifications define acceptable attenuation limits to ensure network performance. Exceeding these limits suggests potential problems, like damaged cabling, poorly terminated connectors, or excessive cable length. Understanding and mitigating attenuation is critical for designing reliable networks and choosing appropriate cable lengths.

For example, if a long cable run experiences unacceptable attenuation, signal boosters or repeaters might be necessary to compensate for the signal loss. Proper cable selection, mindful routing, and avoidance of excessive bends are all crucial in minimizing attenuation.

Q 19. How do you handle situations where cable damage is discovered during installation?

Discovering cable damage during installation necessitates a careful and methodical response prioritizing safety and network integrity. My first step is to thoroughly assess the extent of the damage, identifying the location and nature of the problem (e.g., cut, crush, fraying). Safety is paramount: If the cable damage involves exposed wires or poses a risk, I will immediately halt work and address the safety concern before proceeding.

Depending on the extent of the damage, several actions are possible:

- Minor Damage: For minor issues like small cuts or minor kinks in the cable jacket, sometimes a protective sleeve can be used to prevent further damage.

- Significant Damage: If the damage is more significant, including wire breaks or severe crushing, replacing the damaged section of the cable is usually necessary. This involves cutting out the damaged area and carefully splicing in a new section of cable, adhering strictly to the relevant cabling standards. Splicing should be done with the appropriate tools and connectors, ensuring proper wire pairing and termination. This also involves testing after the repair.

- Extensive Damage: In cases of extensive damage or if multiple cables are affected, a complete rerouting or replacement of the cable run might be required. This will depend on the location of the damage and the overall network architecture.

Following any repair, thorough testing is essential to ensure that the cable meets specifications and is free from shorts or opens. Proper documentation of the repair, including the location, type of damage, and steps taken, is crucial for future troubleshooting.

Q 20. What is the difference between TIA/EIA 568 and ISO/IEC 11801 standards?

Both TIA/EIA 568 and ISO/IEC 11801 are widely recognized standards for structured cabling, including Cat5 cable installation, but they have some key differences. TIA/EIA 568 is a North American standard developed by the Telecommunications Industry Association and Electronic Industries Alliance. ISO/IEC 11801 is an international standard established by the International Organization for Standardization and the International Electrotechnical Commission.

While both standards aim to provide guidelines for high-quality cabling installations, they differ in several aspects:

- Scope: TIA/EIA 568 focuses more on the commercial building environment, while ISO/IEC 11801 has a broader scope, encompassing various applications including industrial and residential settings.

- Testing Requirements: The testing procedures and requirements outlined in each standard have some variations, although they both cover essential parameters like attenuation and return loss.

- Cable Specifications: The specific cable types and their performance parameters might have slight variations between the two standards.

In practice, many installations try to meet both standards to ensure broader compatibility and interoperability. Understanding these subtle differences is crucial for proper cable selection and compliance with relevant regulations in a given region or project.

Q 21. Explain your experience working with different types of cabling infrastructure.

My experience with cabling infrastructure extends beyond Cat5 to encompass various types, including Cat6, Cat6A, and fiber optic cabling. I’m familiar with different cabling topologies, such as star, bus, and ring configurations, and I understand the strengths and weaknesses of each. I’ve worked on installations in diverse settings, from small offices to large data centers. This includes understanding the nuances of installing cables in various environments, including raised floors, ceilings, and walls, taking into account factors such as cable management, grounding, and fire safety.

I’ve been involved in projects that required working with different types of patch panels, wall plates, and other hardware components essential for proper cable organization and termination. I’m experienced in using a range of tools, from simple punch-down tools to sophisticated cable testers and OTDRs (Optical Time-Domain Reflectometers) for fiber optic installations. This diverse experience helps me ensure the design and installation of high-performance, reliable network infrastructures that meet the specific demands of the environment. I prioritize cable management best practices to guarantee ease of maintenance and upgrades in the future.

Q 22. How do you ensure proper cable labeling and documentation?

Proper cable labeling and documentation are crucial for maintainability and troubleshooting. Think of it like a detailed map for your network. Without it, finding a specific cable in a complex system becomes a nightmare.

My approach involves a multi-step process:

- Pre-installation Planning: Before any cabling begins, I create a detailed network diagram showing the location of each cable and its connection points. This plan serves as the foundation for my labeling system.

- Consistent Labeling System: I use a consistent labeling system throughout the project. This typically includes a unique identifier (e.g., a sequential number), location information (e.g., room number, rack number), and connection points (e.g., switch port, device port). I use durable, weatherproof labels that are clearly legible.

- Label Placement: Labels are attached at both ends of each cable, as well as at any intermediate connection points. I ensure labels are securely affixed and won’t be easily damaged or obscured.

- Digital Documentation: I maintain a digital record of the labeling scheme, often in a spreadsheet or database. This document cross-references the physical labels with the network diagram, providing a complete and searchable inventory of the cabling system. The digital documentation is also crucial if physical labels become damaged or illegible.

This comprehensive approach ensures traceability and simplifies future maintenance or troubleshooting tasks.

Q 23. Describe your experience with various cable testing equipment.

I have extensive experience with various cable testing equipment, ranging from basic cable testers to sophisticated network analyzers. Choosing the right tool depends on the specific task at hand.

- Basic Cable Testers: These identify wire pairs, shorts, opens, and miswires. They’re essential for initial verification of cable integrity after termination.

- Time Domain Reflectometers (TDRs): TDRs pinpoint cable faults such as breaks, kinks, or water ingress by measuring signal reflections. They’re invaluable for diagnosing intermittent connection problems.

- Cable Certifiers: These go beyond basic testing to certify the cable meets specific standards (like TIA/EIA 568) for bandwidth and performance. They provide detailed reports on attenuation, return loss, and near-end crosstalk, crucial for high-speed networks.

- Network Analyzers: These sophisticated tools perform more comprehensive network testing, including identifying bottlenecks, packet loss, and other network-related issues. While not strictly for cable testing, they’re crucial for complete network troubleshooting.

My expertise lies in using the right tool for the job. For example, a basic cable tester might suffice for verifying a simple patch cable, while a certifier would be needed for a critical high-speed backbone run. I also understand the limitations of each device and can interpret the results accurately to pinpoint and resolve problems.

Q 24. What are the limitations of Cat5 cabling compared to newer technologies (Cat6, Cat6a)?

Cat5 cabling, while still functional in many applications, has limitations compared to Cat6 and Cat6a. Think of it like comparing a bicycle to a motorcycle and then a sports car – each has increasing capabilities.

- Bandwidth Limitations: Cat5 cabling supports up to 100 MHz bandwidth, limiting its capacity for higher-speed data transmission. Cat6 and Cat6a support significantly higher bandwidths (250 MHz and 500 MHz respectively), allowing for faster Gigabit Ethernet and even 10 Gigabit Ethernet in the case of Cat6a.

- Crosstalk: Cat5 is more susceptible to crosstalk – interference between adjacent pairs within the cable. Cat6 and Cat6a utilize improved design features (e.g., better twisting, alien crosstalk reduction) to minimize this interference, ensuring signal integrity at higher speeds.

- Distance Limitations: While distance limitations aren’t as strictly defined as bandwidth, higher speeds over longer distances become increasingly challenging with Cat5 due to signal attenuation. Cat6 and Cat6a offer better signal integrity over longer runs.

In summary, Cat5 is suitable for lower-speed applications, but for demanding high-speed networks requiring greater bandwidth and distance, Cat6 and Cat6a are far superior.

Q 25. Explain your troubleshooting methodology for identifying problems in a Cat5 network.

My troubleshooting methodology follows a structured approach, eliminating possibilities systematically. It’s like solving a mystery, using clues to narrow down the culprit.

- Visual Inspection: I begin with a thorough visual inspection of all cables and connections, looking for any obvious signs of damage, loose connections, or incorrect termination.

- Basic Cable Testing: I use a cable tester to identify any shorts, opens, or miswires in the cabling. This often quickly reveals the problem.

- Advanced Testing (if necessary): If the basic testing doesn’t reveal the issue, I use more advanced tools such as TDRs or cable certifiers to pinpoint the location and nature of the fault.

- Network Diagnostics: If the problem persists, I utilize network diagnostic tools to identify whether the issue lies within the network itself, rather than the cabling. This involves checking switch ports, network configuration, and other network components.

- Systematic Elimination: I work through each potential problem area systematically, eliminating possibilities one by one. This ensures I don’t overlook any potential causes.

This process, combined with my experience and understanding of network technologies, allows me to efficiently and accurately identify and resolve Cat5 network problems.

Q 26. How do you ensure that the cable installation adheres to building codes and regulations?

Adherence to building codes and regulations is paramount. Ignoring these can lead to safety hazards, project delays, and legal issues. It’s like building a house – you wouldn’t skip the foundation.

My approach involves:

- Familiarization with Local Codes: Before starting any project, I thoroughly review all relevant building codes and regulations, including those related to fire safety, electrical codes, and accessibility standards. These vary by location, so understanding the specifics is crucial.

- Proper Cable Routing: I ensure that all cables are routed safely and neatly, avoiding hazards and adhering to regulations on cable bundling, cable tray placement, and cable labeling requirements.

- Fire Safety Measures: I use fire-resistant materials and techniques where required to minimize the risk of fire spread. This might include using plenum-rated cables in air handling spaces.

- Documentation and Permits: I maintain detailed documentation of the cabling installation, including adherence to codes and regulations. If required, I obtain necessary permits before starting the work.

By strictly adhering to these procedures, I ensure that the Cat5 cable installation meets all relevant building codes and regulations, resulting in a safe, compliant, and functional network.

Q 27. Describe a challenging Cat5 cabling project you completed and how you overcame the obstacles.

One challenging project involved installing Cat5 cabling in a historic building with limited access and intricate architectural features. The building’s age posed significant obstacles; think of it as navigating a maze with hidden passages.

The obstacles included:

- Difficult Access: Narrow corridors, restricted spaces, and fragile historical structures made cable routing extremely challenging.

- Existing Infrastructure: The building contained old and often inconsistent infrastructure, necessitating careful coordination to avoid conflicts with existing systems.

- Aesthetic Concerns: The building’s historical significance required preserving its aesthetic integrity, meaning that cable installation had to be unobtrusive.

To overcome these challenges, we:

- Developed a Detailed Plan: We meticulously planned the cable routes, taking into account all access points and potential obstacles. This involved extensive site surveys and careful coordination with building management.

- Used Specialized Tools and Techniques: We utilized small, flexible cables and employed specialized techniques to negotiate tight spaces and minimize damage to the building’s structure.

- Prioritized Preservation: We took extreme care to avoid damaging historical features. This included using specialized tools and methods that minimized disruption to the building.

- Close Collaboration: We maintained constant communication and collaboration with all stakeholders throughout the project to address any concerns promptly.

Through careful planning, meticulous execution, and a collaborative approach, we successfully completed the project, delivering a functional Cat5 network while preserving the building’s historical integrity.

Key Topics to Learn for Cat5 Cable Splicing Interview

- Understanding Cat5e and Cat6 Cable Standards: Know the differences, applications, and performance characteristics of these common cable types. This includes understanding bandwidth capabilities and distance limitations.

- Cable Preparation Techniques: Mastering proper stripping, cutting, and cleaning techniques is crucial for reliable connections. Practice different methods and understand why precision is paramount.

- Punch Down Techniques: Become proficient in using a punch-down tool on both 110 and Krone blocks. Understand the color codes and wiring schemes (T568A and T568B) and their implications.

- Crimping RJ45 Connectors: Learn the correct crimping techniques to ensure reliable and consistent connections. Understand common crimping errors and how to troubleshoot them.

- Testing and Troubleshooting: Familiarize yourself with cable testers and their functionalities. Practice identifying and resolving common cabling issues, such as shorts, opens, and miswires.

- Understanding Cable Management Best Practices: Demonstrate knowledge of proper cable labeling, bundling, and routing techniques for a professional and efficient installation.

- Safety Precautions and Regulations: Highlight your awareness of safety procedures related to working with electrical equipment and adhering to relevant industry standards.

- Practical Applications: Be prepared to discuss real-world scenarios where your Cat5 cable splicing skills were utilized, emphasizing problem-solving and efficient execution.

Next Steps

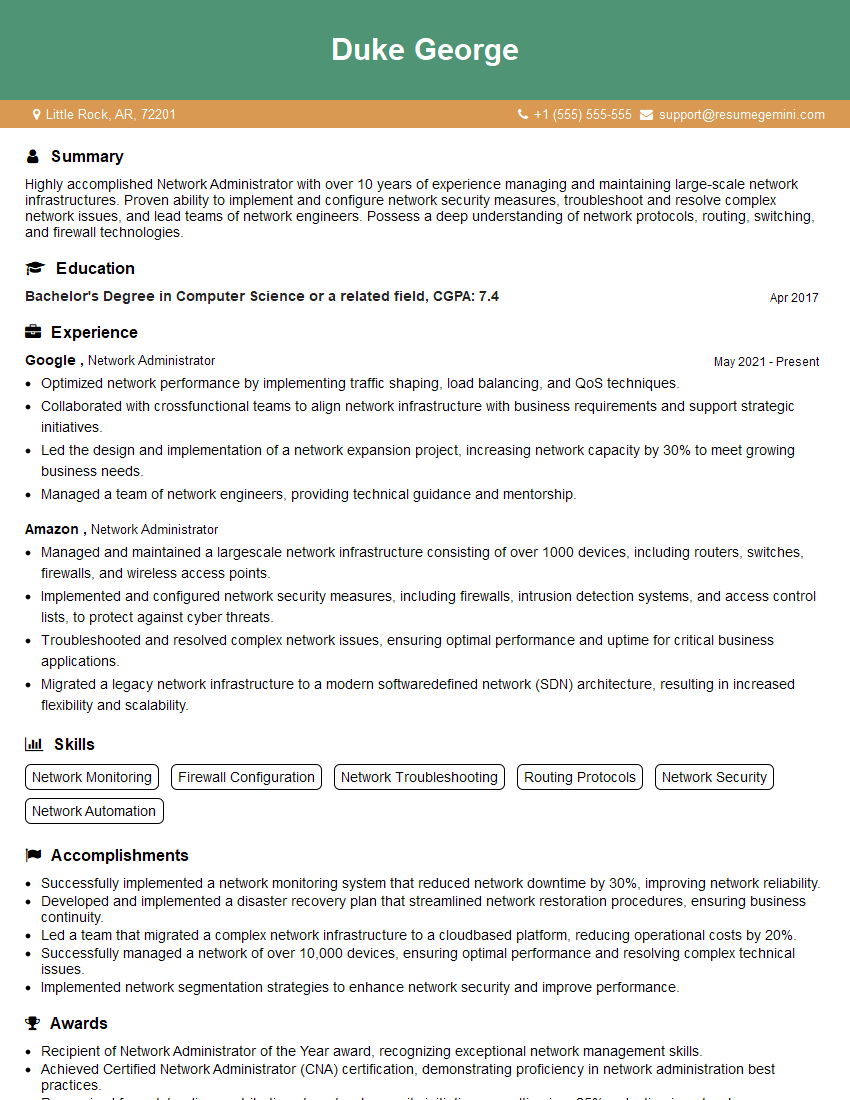

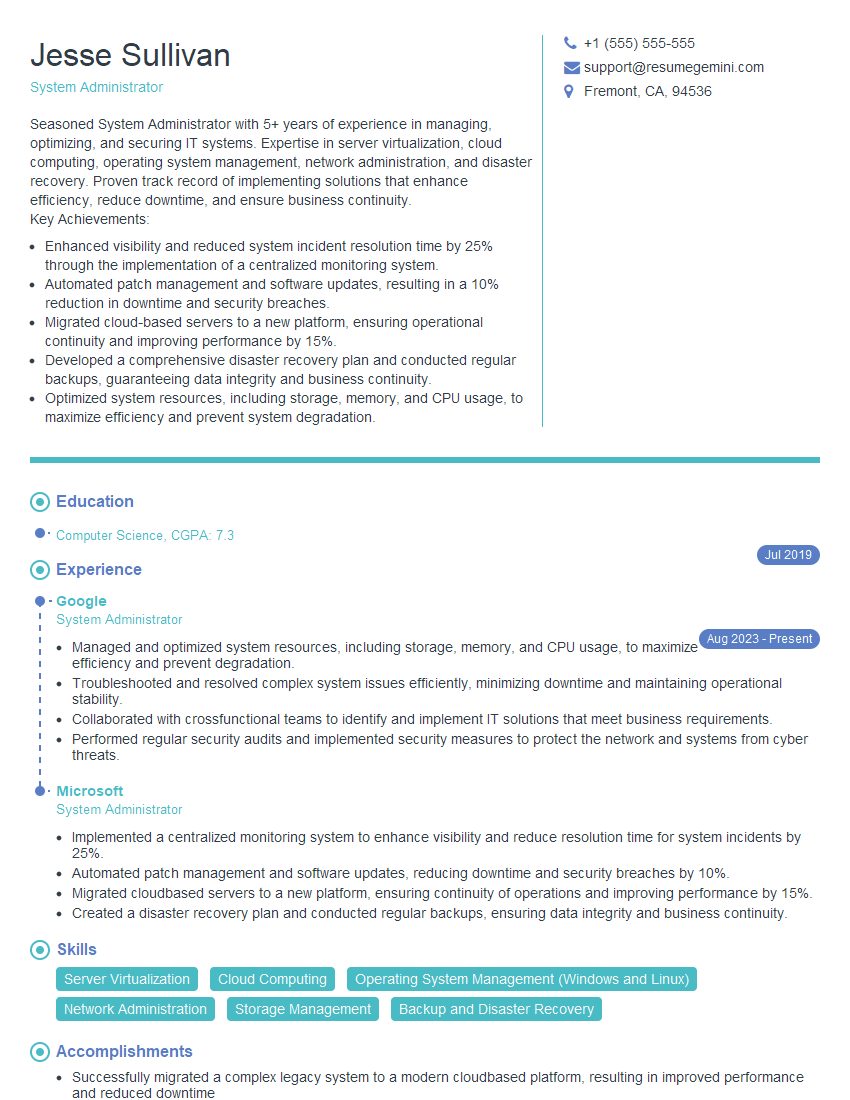

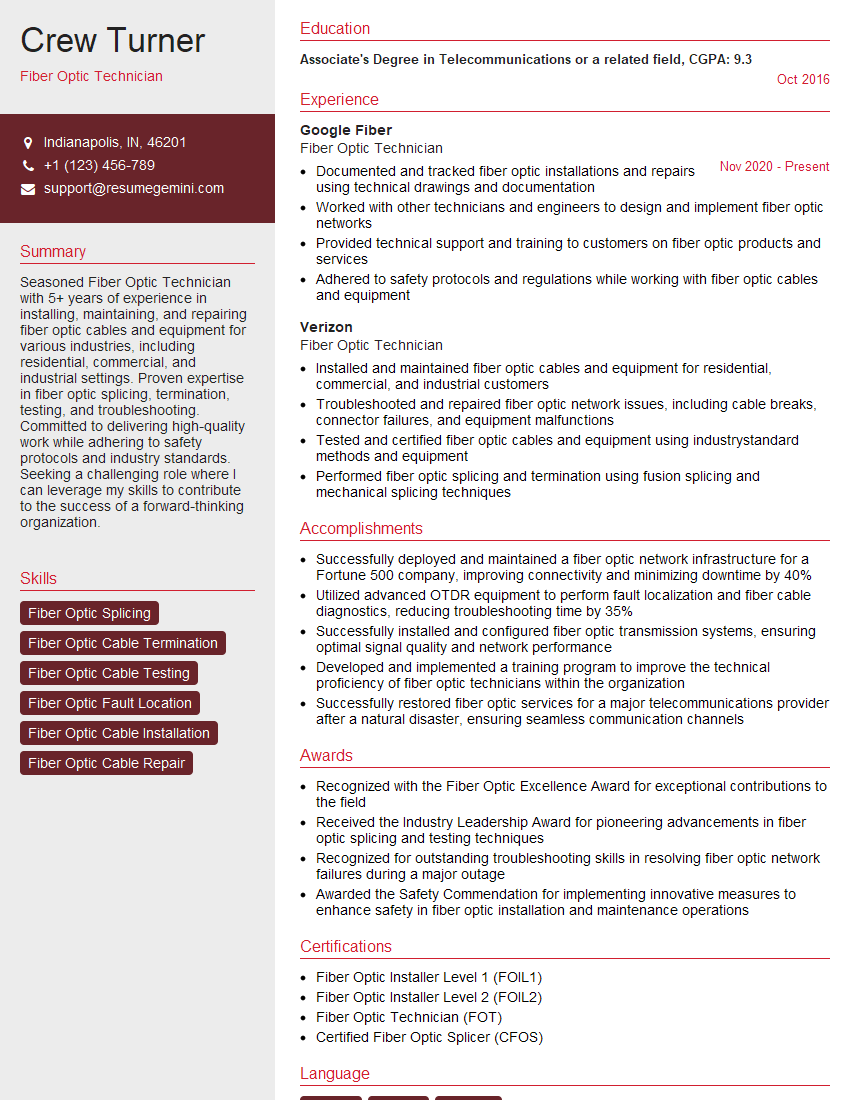

Mastering Cat5 cable splicing opens doors to numerous opportunities in networking, telecommunications, and IT infrastructure. A strong understanding of these skills is highly valued by employers, leading to career advancement and increased earning potential. To stand out, create an ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, designed to get noticed by recruiters. Examples of resumes tailored to Cat5 Cable Splicing are available to guide you through the process, ensuring your qualifications shine.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good