Preparation is the key to success in any interview. In this post, we’ll explore crucial Certified Six Sigma Black Belt (CSSBB) interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Certified Six Sigma Black Belt (CSSBB) Interview

Q 1. Explain the DMAIC methodology.

DMAIC is a data-driven methodology used in Six Sigma to improve processes. It’s an acronym for Define, Measure, Analyze, Improve, and Control. Think of it as a structured roadmap for systematically identifying and eliminating defects in any process, from manufacturing a product to handling customer service requests. It provides a framework for moving from a problem statement to a sustainable solution.

Q 2. Describe the five phases of DMAIC.

The five phases of DMAIC are:

- Define: Clearly define the project goals, scope, and customer requirements. This involves identifying the problem, setting measurable goals, and defining the project’s boundaries. For example, if the project aims to reduce customer wait times in a call center, this phase would detail the target wait time reduction and the specific call center locations involved.

- Measure: Gather data to understand the current process performance. This involves identifying key performance indicators (KPIs), collecting baseline data, and documenting the current process flow. For the call center example, this would involve measuring the current average wait times, call abandonment rates, and agent handling times.

- Analyze: Analyze the collected data to identify the root causes of the problem. This involves using statistical tools like process capability analysis, regression analysis, and Pareto charts to pinpoint the key factors contributing to the issue. In the call center scenario, analysis might reveal that insufficient staffing during peak hours is a major contributor to long wait times.

- Improve: Implement solutions to address the root causes identified in the analysis phase. This involves developing and testing potential solutions, selecting the best option, and implementing changes to the process. For the call center, improvements could include adjusting staffing schedules, implementing a call-back system, or improving agent training.

- Control: Monitor the improved process to ensure that the gains are sustained over time. This involves establishing control charts, implementing ongoing monitoring procedures, and making adjustments as needed to maintain performance. The call center would use control charts to track wait times post-improvement, ensuring the changes made continue to deliver the desired results.

Q 3. What are the key tools used in each phase of DMAIC?

The key tools used in each DMAIC phase vary but some common examples include:

- Define: SIPOC (Suppliers, Inputs, Process, Outputs, Customers), Project Charter, Voice of the Customer (VOC)

- Measure: Check Sheets, Data Collection Plan, Measurement System Analysis (MSA), Process Maps

- Analyze: Pareto Charts, Fishbone Diagrams (Ishikawa diagrams), Root Cause Analysis (5 Whys, Fault Tree Analysis), Regression Analysis, Hypothesis Testing

- Improve: Design of Experiments (DOE), Kaizen Events, Poka-Yoke (error-proofing), Value Stream Mapping

- Control: Control Charts (X-bar and R, p-chart, c-chart), Run Charts, Standard Operating Procedures (SOPs), Control Plans

Q 4. How do you define a project scope using Six Sigma principles?

Defining a project scope in Six Sigma involves a structured approach ensuring the project is focused, manageable, and delivers measurable results. It starts with clearly defining the problem statement, which should be specific, measurable, achievable, relevant, and time-bound (SMART). Then, we identify the boundaries of the project – what is included and, critically, what is excluded. This involves identifying:

- Objectives: What specific improvements are we aiming for (e.g., reduce defect rate by 15%).

- Metrics: How will success be measured (e.g., defect rate, cycle time, customer satisfaction)?

- Deliverables: What tangible outputs are expected (e.g., revised process map, new training materials)?

- Timeline: What is the project’s start and end date?

- Resources: What personnel, budget, and tools are needed?

- Limitations: What are the constraints on the project (e.g., budget, access to data)?

Using a Project Charter formally documents these aspects, ensuring everyone involved understands the project’s goals and boundaries. For instance, a project to improve order fulfillment might specifically focus on reducing errors in the picking process, excluding issues related to delivery logistics.

Q 5. Explain the concept of a control chart and its uses.

A control chart is a graphical tool used to monitor process performance over time. It plots data points representing process measurements against time, displaying the process’s central tendency and variability. The chart also includes control limits – upper and lower bounds calculated statistically. Points falling outside these limits signal potential process instability or special causes of variation requiring investigation. Imagine a doctor regularly monitoring a patient’s blood pressure: a control chart provides a similar visual representation of process health, enabling timely intervention if it drifts out of acceptable ranges.

Q 6. What are the different types of control charts and when would you use each?

Several types of control charts exist, each suited to different data types:

- X-bar and R chart: Used for continuous data (e.g., weight, temperature, length), measuring the average (X-bar) and range (R) of subgroups of data. Useful for monitoring variables that can take on any value within a given range.

- p-chart: Used for attribute data representing the proportion of nonconforming units (e.g., defect rate). Shows the percentage of defective items in a sample. Good for monitoring the fraction of defective units in a process.

- c-chart: Used for attribute data counting the number of defects per unit (e.g., scratches on a surface). Tracks the number of defects found in a sample. Useful when the number of defects per unit is of interest.

- u-chart: Similar to a c-chart but accounts for varying sample sizes. Used when the number of defects per unit is of interest but the sample size varies.

The choice depends on the type of data being monitored. For example, a p-chart would be appropriate for tracking the percentage of defective products in a manufacturing line, while an X-bar and R chart would be suitable for monitoring the average weight of filled packages.

Q 7. Describe the process of conducting a root cause analysis.

Root cause analysis (RCA) is a systematic process for identifying the underlying causes of a problem, not just its symptoms. The goal is to address the root issues to prevent recurrence. Several methods can be used:

- 5 Whys: A simple but effective technique that involves repeatedly asking “why” to drill down to the root cause. For instance, if a machine malfunctions, we might ask: Why did it malfunction? (Lack of lubrication). Why wasn’t it lubricated? (Maintenance schedule not followed). Why wasn’t the schedule followed? (Insufficient training for maintenance personnel). Why was there insufficient training? (Budget constraints).

- Fishbone Diagram (Ishikawa Diagram): A visual tool that categorizes potential causes into major areas (e.g., people, machines, methods, materials, environment). Brainstorming sessions are typically used to populate each category with potential causes. This helps to visualize and systematically explore all possible contributing factors.

- Fault Tree Analysis (FTA): A top-down approach that starts with the undesired event (the problem) and works backward to identify contributing factors. It uses Boolean logic to represent the relationship between causes. More suitable for complex problems requiring a detailed analysis of failure modes.

Regardless of the chosen method, RCA requires a data-driven approach, thorough investigation, and collaboration among involved parties to ensure all contributing factors are considered. After identifying the root cause(s), effective countermeasures need to be designed and implemented to resolve the issue permanently.

Q 8. What are the common root cause analysis tools?

Root cause analysis (RCA) is crucial in Six Sigma for identifying the underlying reasons for defects or problems. Several tools help achieve this. The choice depends on the situation and available data.

- Fishbone Diagram (Ishikawa Diagram): This visual tool brainstorms potential causes categorized by factors like Man, Machine, Material, Method, Measurement, and Environment (or variations thereof). It’s excellent for group discussions and identifying many potential causes.

- 5 Whys: A simple yet effective method that repeatedly asks “Why?” to drill down to the root cause. By repeatedly questioning the reason behind a problem, you progressively uncover deeper issues until the fundamental cause is identified.

- Pareto Chart: This chart identifies the vital few causes from the trivial many. It ranks causes by their frequency or impact, highlighting the most significant contributors to the problem.

- Fault Tree Analysis (FTA): A top-down, deductive approach used to analyze potential failures in a system. It starts with an undesired event (top event) and works backward to identify the underlying causes that could lead to it. Often used for complex systems.

- Cause and Effect Matrix: This technique helps to identify relationships between potential causes and effects, providing a structured view of cause-and-effect scenarios.

Example: Imagine a manufacturing process where products are frequently defective. A Fishbone diagram might reveal that poor material quality (Material), operator error (Man), and machine malfunction (Machine) are all contributing factors. Further investigation using the 5 Whys could pin down the root cause to a specific supplier providing substandard material.

Q 9. How do you calculate process capability indices (Cp, Cpk)?

Process capability indices (Cp and Cpk) measure how well a process is performing relative to its specifications. They quantify the consistency and centering of a process.

Cp (Process Capability): This index measures the potential capability of a process, ignoring the process’s centering. It shows how much variation the process has relative to the specification width. A higher Cp indicates better potential capability.

Cp = (USL - LSL) / (6 * σ)

Where:

- USL = Upper Specification Limit

- LSL = Lower Specification Limit

- σ = Standard Deviation of the process

Cpk (Process Capability Index): This index considers both the variation and the centering of a process. It’s a more realistic measure of process capability since it accounts for whether the process mean is centered within the specification limits. A higher Cpk indicates better actual capability.

Cpk = min[(USL - μ) / (3 * σ), (μ - LSL) / (3 * σ)]

Where:

- μ = Process Mean

Example: A process has a USL of 10, an LSL of 0, a mean of 5, and a standard deviation of 1. Then:

Cp = (10 - 0) / (6 * 1) = 1.67

Cpk = min[(10 - 5) / (3 * 1), (5 - 0) / (3 * 1)] = min[1.67, 1.67] = 1.67

In this case, the process is well-centered, so Cp and Cpk are equal. A Cpk of 1.67 indicates a capable process.

Q 10. Explain the concept of process sigma and its significance.

Process sigma (σ) represents the number of standard deviations between the process mean and the nearest specification limit. It’s a measure of process performance, reflecting the number of defects per million opportunities (DPMO).

Significance: Process sigma provides a standardized way to compare process performance across different industries and organizations. A higher sigma level indicates fewer defects and improved process quality. It’s a key metric in Six Sigma projects to track improvements and measure the effectiveness of implemented solutions.

Example: A 3-sigma process has roughly 66,800 DPMO, indicating a relatively high defect rate. A 6-sigma process, on the other hand, aims for only 3.4 DPMO, representing significantly improved quality.

Process sigma directly links to customer satisfaction. Higher sigma levels translate to more reliable products or services, leading to increased customer loyalty and reduced costs associated with rework, warranty claims, and customer complaints.

Q 11. What is the difference between common cause and special cause variation?

Understanding the difference between common cause and special cause variation is fundamental to process improvement.

Common Cause Variation: This is the inherent, natural variation within a process. It’s due to many small, unpredictable factors constantly affecting the process. It’s inherent to the system and usually remains relatively constant over time. Think of it as the ‘noise’ in the system.

Special Cause Variation: This variation stems from identifiable sources outside the usual process. It’s not inherent to the system and is usually temporary. Special cause variations disrupt the normal pattern and indicate that something unusual is affecting the process. These are the ‘signals’ we need to investigate and address.

Analogy: Imagine a dartboard. Common cause variation is like consistently hitting the board within a certain area, showing natural variation in your throw. Special cause variation would be suddenly hitting the dartboard way outside your normal range, indicating something like a sudden gust of wind or a change in your stance.

Q 12. How do you identify and address special cause variation?

Identifying and addressing special cause variation involves several steps:

- Control Charts: These visual tools plot data over time, helping identify points outside the control limits which suggest special cause variation. Control charts like X-bar and R charts for variables data and p-charts and c-charts for attributes data are commonly used.

- Statistical Process Control (SPC): SPC uses control charts and other statistical techniques to monitor and control process variation. It helps to quickly identify and react to unusual events.

- Root Cause Analysis (RCA): Once a special cause variation is identified, RCA tools (discussed in Question 1) are used to pinpoint the underlying reasons.

- Corrective Actions: Once the root cause is identified, corrective actions are implemented to eliminate the special cause variation and prevent recurrence. This may involve changes to equipment, processes, training, or materials.

- Verification: After implementing corrective actions, the process is monitored to ensure that the special cause variation has been eliminated and the process is back under control.

Example: A control chart shows a point outside the control limits. RCA reveals that a new machine operator was improperly trained, leading to inconsistent product quality. Corrective action involves providing additional training and verification includes monitoring the chart to see if the process returns within control limits.

Q 13. Explain the concept of hypothesis testing.

Hypothesis testing is a statistical method used to make inferences about a population based on sample data. It involves formulating a hypothesis about the population and then testing whether the sample data provides enough evidence to reject or fail to reject that hypothesis.

The process generally involves:

- Formulating Hypotheses: Defining a null hypothesis (H0), which represents the status quo or no effect, and an alternative hypothesis (H1 or Ha), which represents the effect we are trying to detect.

- Setting Significance Level (α): This is the probability of rejecting the null hypothesis when it’s actually true (Type I error). A common significance level is 0.05.

- Collecting Data: Gathering a representative sample from the population.

- Performing Test: Choosing an appropriate statistical test based on the type of data and hypotheses, and calculating a test statistic.

- Making Decision: Comparing the test statistic to a critical value or calculating a p-value. If the p-value is less than the significance level, we reject the null hypothesis; otherwise, we fail to reject it.

Example: A company wants to test if a new marketing campaign increased sales. H0: The campaign had no effect on sales. H1: The campaign increased sales. They collect sales data before and after the campaign and perform a t-test. If the p-value is less than 0.05, they reject H0 and conclude the campaign was effective.

Q 14. What are the different types of hypothesis tests?

The choice of hypothesis test depends on the type of data (categorical or numerical) and the nature of the hypotheses.

- t-test: Used to compare the means of two groups. Independent samples t-test is used when comparing two different groups, while a paired t-test is used when comparing the same group at two different times.

- ANOVA (Analysis of Variance): Used to compare the means of three or more groups.

- Chi-square test: Used to analyze categorical data and determine if there’s a significant association between two categorical variables.

- Z-test: Used to test hypotheses about a population mean when the population standard deviation is known.

- One-sample Z-test: Compares the mean of a single sample to a known population mean.

- Two-sample Z-test: Compares the means of two independent samples when population standard deviations are known.

- Proportion Z-test: Compares a sample proportion to a known population proportion.

Example: To compare the average defect rates of two different manufacturing lines, a two-sample t-test would be appropriate. To determine if there’s an association between gender and customer preference for a product, a chi-square test would be used.

Q 15. Describe your experience with design of experiments (DOE).

Design of Experiments (DOE) is a powerful statistical methodology used to efficiently investigate the relationship between multiple input factors (independent variables) and one or more output responses (dependent variables). Instead of changing one factor at a time, DOE allows us to systematically vary multiple factors simultaneously, revealing interactions between factors that would be missed with a one-factor-at-a-time approach. This leads to a more complete understanding of the process and helps optimize it for improved performance. In my experience, I’ve utilized DOE extensively in various projects, from optimizing manufacturing processes to improving product design. For example, I helped a client optimize their chemical reaction process by using a full factorial DOE to identify the optimal temperature and pressure settings, resulting in a 15% increase in yield and a 10% reduction in waste.

My experience includes designing and analyzing various DOE types, including full factorial, fractional factorial, Taguchi designs, and response surface methodologies (RSM), selecting the appropriate design based on the project’s objectives and constraints. I’m proficient in interpreting the results, generating predictive models, and making data-driven recommendations for process improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of DOE?

There are several types of DOE, each suited for different situations. The choice depends on the number of factors, the desired level of detail, and the resources available. Some common types include:

- Full Factorial Designs: These designs explore all possible combinations of factor levels. They provide a complete picture of the factor effects and interactions, but can become very large and resource-intensive with many factors.

- Fractional Factorial Designs: These are more efficient versions of full factorial designs, especially when many factors are involved. They carefully select a subset of all possible combinations, still allowing estimation of main effects and some interactions.

- Taguchi Designs: These orthogonal arrays are designed to minimize the number of experimental runs required while still providing valuable information about factor effects. They are particularly useful when resources are limited.

- Response Surface Methodologies (RSM): These designs are used to optimize a process by fitting a response surface model to the data, allowing for finding the optimal settings for the factors.

The choice among these methods depends on the specific project requirements and constraints.

Q 17. How do you select the appropriate DOE for a given situation?

Selecting the appropriate DOE involves carefully considering several factors:

- Number of factors and levels: How many factors need to be investigated, and how many levels (settings) does each factor have?

- Resources available: How many experimental runs can be conducted given time and budget constraints?

- Objectives of the experiment: What is the goal? Is it to identify the most significant factors, optimize a response, or understand interactions between factors?

- Expected interactions: Are interactions between factors anticipated? Full and fractional factorial designs are better suited for exploring interactions.

- Prior knowledge: Is there any prior knowledge about the process that can inform the design?

A structured approach, often involving a Design Selection Matrix or flowchart, can aid in the decision-making process. For instance, if a high level of accuracy is needed and resources allow, a full factorial design might be selected. However, if resources are limited and many factors are involved, a fractional factorial or Taguchi design would be more appropriate.

Q 18. What is the difference between a regression model and an ANOVA model?

Both ANOVA (Analysis of Variance) and regression models are used to analyze data and understand the relationship between variables, but they differ in their approach and assumptions:

- ANOVA primarily focuses on comparing means of different groups or treatments. It tests whether there are statistically significant differences in the means of the response variable across different levels of the independent variable(s). It often uses categorical independent variables.

- Regression models explore the relationship between a dependent variable and one or more independent variables. It aims to find a mathematical equation that best predicts the dependent variable based on the independent variables. Independent variables can be continuous or categorical.

In DOE, both are often used. ANOVA is commonly used in the initial analysis of variance to assess the significance of the main effects and interactions. Regression models, like polynomial regression, are often used to create a predictive model based on the significant factors identified using ANOVA.

Q 19. Explain the concept of correlation and regression analysis.

Correlation measures the strength and direction of the linear relationship between two variables. A correlation coefficient, typically denoted by ‘r’, ranges from -1 to +1. A value of +1 indicates a perfect positive linear relationship (as one variable increases, the other increases), -1 indicates a perfect negative linear relationship (as one variable increases, the other decreases), and 0 indicates no linear relationship.

Regression analysis goes beyond correlation by building a model to predict the value of a dependent variable based on the value of one or more independent variables. It determines the best-fitting line (or surface in multiple regression) that minimizes the difference between observed and predicted values. Regression provides an equation that can be used for prediction and understanding the effect of independent variables on the dependent variable.

For example, a correlation analysis might show a strong positive correlation between advertising expenditure and sales, while a regression analysis could provide an equation predicting sales based on the amount spent on advertising.

Q 20. How do you interpret regression coefficients?

Regression coefficients represent the change in the dependent variable associated with a one-unit change in the corresponding independent variable, holding other independent variables constant. They indicate the slope of the regression line (or surface) for each independent variable.

For example, in a linear regression model predicting house price (dependent variable) based on square footage and number of bedrooms (independent variables), the coefficient for square footage might be 100, suggesting that for every additional square foot, the house price is predicted to increase by $100, holding the number of bedrooms constant. The sign of the coefficient indicates the direction of the relationship (positive or negative). The statistical significance of the coefficient, usually determined by a p-value, indicates whether the effect of that independent variable is likely to be real or due to chance.

Q 21. Describe your experience with statistical software packages (e.g., Minitab, JMP).

I have extensive experience using Minitab and JMP for statistical analysis, including DOE. Minitab’s user-friendly interface and comprehensive DOE capabilities have been invaluable in designing, analyzing, and interpreting experiments. I’ve used it for various tasks, from creating experimental designs to performing ANOVA and regression analysis, generating response surface plots, and producing comprehensive reports for stakeholders.

JMP, with its powerful visualization tools and interactive capabilities, is also a strong tool in my arsenal. Its dynamic capabilities allow for quick exploration of data and easy adjustment of models. I’ve used JMP extensively for analyzing complex datasets and developing robust predictive models.

My proficiency extends beyond basic data analysis; I’m skilled in utilizing advanced features within both software packages to tackle complex statistical problems and effectively communicate results to both technical and non-technical audiences.

Q 22. How do you handle outliers in your data?

Outliers are data points significantly different from other observations. Handling them is crucial because they can skew results and mislead analysis. My approach involves a multi-step process:

- Identification: I use visual tools like box plots and scatter plots to identify potential outliers. Statistical methods, such as the Z-score or Interquartile Range (IQR) method, are also employed to quantify their deviation from the norm. For instance, a Z-score above 3 or below -3 often indicates an outlier.

- Investigation: Once identified, I don’t automatically discard them. I investigate the root cause. Is it a data entry error? A genuine anomaly? Perhaps a special cause variation affecting a small subset of data? Understanding the ‘why’ is key.

- Treatment: The treatment depends on the investigation’s findings. If it’s a data entry error, I correct it. If it’s a genuine but infrequent anomaly, I might keep it and note its impact on the analysis. If it represents a special cause variation, I would explore that separately and potentially treat it as a new project. Sometimes, transformation techniques like logarithmic transformations can mitigate the influence of outliers without removing them.

- Documentation: Regardless of my chosen approach, I meticulously document every step—how outliers were identified, investigated, and handled—ensuring transparency and reproducibility.

For example, in a project analyzing customer service call times, an outlier of an extremely long call might indicate a system malfunction or a particularly complex issue requiring separate investigation, rather than just being an error to be removed.

Q 23. What is your experience with presenting findings to senior management?

Presenting findings to senior management requires clear, concise communication tailored to their needs and understanding. I’ve consistently prioritized a structured approach:

- Executive Summary: I begin with a compelling executive summary highlighting key findings, recommendations, and the overall impact on the business. This allows them to grasp the essence quickly.

- Visualizations: I rely heavily on clear, impactful visuals like charts and graphs, minimizing jargon and complex statistical terms. A picture truly is worth a thousand words in this context.

- Storytelling: I frame the data within a narrative, showcasing the problem, the solutions implemented, and the achieved results. This helps engage them emotionally and intellectually.

- Data-Driven Recommendations: My recommendations are always grounded in data, highlighting the potential ROI or cost savings and the quantified impact on key performance indicators (KPIs).

- Q&A: I always allocate time for questions and actively engage in a discussion to address any concerns or ambiguities.

In a recent project, I presented findings to the CEO and CFO, showcasing a 15% reduction in operational costs by streamlining a manufacturing process. The visual representation of the cost reduction, alongside a clear explanation of the implemented changes, resonated strongly with them and resulted in immediate buy-in.

Q 24. Describe a situation where you had to overcome a significant challenge in a Six Sigma project.

In a Six Sigma project focused on reducing customer wait times at a call center, we encountered a significant challenge: a legacy system that hampered our ability to accurately track call handling times. The system was prone to errors and lacked the necessary data granularity.

To overcome this, I implemented a multi-pronged approach:

- Data Validation: First, I meticulously validated the existing data, identifying patterns of errors and inconsistencies. This allowed me to estimate the extent of data inaccuracy.

- Parallel Data Collection: We implemented a parallel data collection system using a more reliable method—a separate logging system alongside the legacy one—to obtain more accurate data for a specific period.

- Root Cause Analysis: We conducted a root cause analysis to understand the source of the errors in the legacy system and to prevent future issues. This involved interviews with IT staff and call center agents.

- Data Reconciliation: The data from both the legacy and parallel systems was carefully reconciled, allowing us to adjust our findings and account for the system errors.

- System Upgrade Proposal: Finally, I presented a proposal to upgrade the legacy system, justifying the investment based on the improved data quality and the expected reduction in operational costs resulting from efficient wait time management.

This situation highlighted the importance of adaptability and problem-solving in Six Sigma. Successfully navigating this challenge improved the quality of our data significantly, eventually leading to a 20% reduction in customer wait times.

Q 25. How do you measure the success of a Six Sigma project?

Measuring the success of a Six Sigma project goes beyond simply completing the DMAIC (Define, Measure, Analyze, Improve, Control) cycle. It’s about quantifying the impact on key business metrics. Success is measured through:

- Meeting Project Goals: Did the project achieve its pre-defined goals in terms of defect reduction, cycle time improvement, cost savings, or customer satisfaction enhancement? This is usually tracked against a baseline established during the ‘Measure’ phase.

- Return on Investment (ROI): Quantify the financial benefits achieved through the project, comparing the costs of implementation to the savings or revenue generated. For instance, a reduced defect rate translates into lower rework costs.

- Sustainable Improvements: Are the implemented improvements sustainable in the long term? A successful project ensures that the gains are not temporary but ingrained in the process through effective control plans.

- Stakeholder Satisfaction: Assess the satisfaction levels of all relevant stakeholders—management, employees, and customers—ensuring buy-in and acceptance of the changes.

In essence, success means delivering demonstrable, measurable, and lasting improvements to the business while adhering to the defined project scope and budget.

Q 26. What are some key metrics you would use to track project progress?

Tracking project progress requires a combination of quantitative and qualitative metrics. Key metrics I use include:

- Defect Rate: Tracks the frequency of defects or errors in a process (e.g., defects per million opportunities (DPMO)).

- Cycle Time: Measures the time taken to complete a process step. Reduction in cycle time indicates increased efficiency.

- Cost Savings: Monitors the financial benefits resulting from process improvements (e.g., reduction in material waste or labor costs).

- Customer Satisfaction: Measures customer perception of the process (e.g., using surveys, feedback forms).

- Project Timeline Adherence: Tracks the project’s progress against the planned schedule.

- Budget Adherence: Monitors the project’s expenses against the allocated budget.

- Risk Register Updates: Tracks identified risks, their likelihood, and the implemented mitigation strategies.

These metrics are regularly monitored and reported to stakeholders, ensuring transparency and proactive management of the project.

Q 27. Explain your understanding of Lean principles and how they integrate with Six Sigma.

Lean principles focus on eliminating waste and maximizing value from a customer’s perspective. Six Sigma, on the other hand, emphasizes reducing variation and improving process capability. They are highly complementary and work best when integrated.

Lean’s principles, such as 5S (Sort, Set in Order, Shine, Standardize, Sustain), Kaizen (continuous improvement), and Value Stream Mapping, provide a framework for identifying and eliminating waste within a process. This waste reduction makes the process more efficient and provides a solid foundation for Six Sigma’s focus on variation reduction. Once waste is removed, Six Sigma’s tools then help to standardize and control the remaining steps, minimizing variation.

Six Sigma’s statistical tools like DMAIC and Design of Experiments (DOE) can then be used to fine-tune the processes identified and streamlined by Lean. For example, Lean helps identify bottlenecks in a production line, and Six Sigma helps optimize the remaining process steps to minimize defects and increase process capability.

The synergy between Lean and Six Sigma delivers superior results. Lean’s focus on waste elimination ensures that the process is optimized before applying Six Sigma’s tools for precise process control and variation reduction.

Q 28. Describe a time you had to deal with conflicting priorities or stakeholder demands.

In a project aimed at improving order fulfillment speed, I encountered conflicting priorities between the sales team, who prioritized fast order processing to meet aggressive sales targets, and the warehouse team, who emphasized accuracy to minimize errors and returns. The sales team desired faster fulfillment, even if it meant a higher error rate, while the warehouse team prioritized accuracy, even if it meant slower fulfillment times.

To resolve this conflict, I employed the following strategies:

- Facilitate Communication: I organized a facilitated workshop involving representatives from both teams. This created a safe space for each team to express their concerns and understand the other’s perspective.

- Define Common Goals: We collaboratively redefined our goals to encompass both speed and accuracy. The focus shifted from prioritizing one over the other to finding a balance that optimized both metrics.

- Data-Driven Decisions: I used data to demonstrate the trade-offs between speed and accuracy, illustrating the financial implications of both errors and delays. This provided a common ground for decision-making.

- Develop a Compromise Solution: Through collaborative brainstorming, we devised a solution that involved streamlining the order processing system while implementing stronger quality checks in the warehouse. This addressed both teams’ concerns.

- Regular Monitoring and Adjustments: We implemented a system for regularly monitoring the key metrics (speed and accuracy) and making necessary adjustments to the process to maintain the desired balance.

By fostering collaboration, using data to inform decisions, and finding a compromise that met both teams’ core objectives, we successfully resolved the conflict and achieved significant improvements in both order fulfillment speed and accuracy.

Key Topics to Learn for Certified Six Sigma Black Belt (CSSBB) Interview

- DMAIC Methodology: Understand each phase (Define, Measure, Analyze, Improve, Control) thoroughly, including practical application in various scenarios and potential challenges in each stage.

- Statistical Process Control (SPC): Master control charts (X-bar and R, p-chart, c-chart, etc.), process capability analysis (Cp, Cpk), and their interpretation to drive process improvement.

- Design of Experiments (DOE): Grasp the fundamentals of DOE, including factorial designs, fractional factorial designs, and the use of statistical software for analysis and interpretation.

- Hypothesis Testing: Demonstrate a clear understanding of hypothesis testing principles, including t-tests, ANOVA, and Chi-square tests, and their application in Six Sigma projects.

- Measurement Systems Analysis (MSA): Explain the importance of MSA, different types of MSA studies (Gauge R&R, Attribute Agreement Analysis), and how to interpret the results to ensure data reliability.

- Root Cause Analysis (RCA): Familiarize yourself with various RCA techniques (5 Whys, Fishbone Diagram, Fault Tree Analysis) and their application in identifying and resolving the root causes of problems.

- Project Management and Leadership: Showcase your understanding of project planning, execution, and closure, including team leadership, stakeholder management, and risk management within a Six Sigma framework.

- Lean Principles: Demonstrate knowledge of Lean principles (Value Stream Mapping, Kaizen, 5S) and their integration with Six Sigma methodologies for achieving operational excellence.

- Data Analysis and Interpretation: Highlight your proficiency in using statistical software (Minitab, JMP, etc.) for data analysis and interpreting results to support decision-making.

- Communication and Presentation Skills: Prepare to articulate complex statistical concepts clearly and concisely, both verbally and visually, to various audiences.

Next Steps

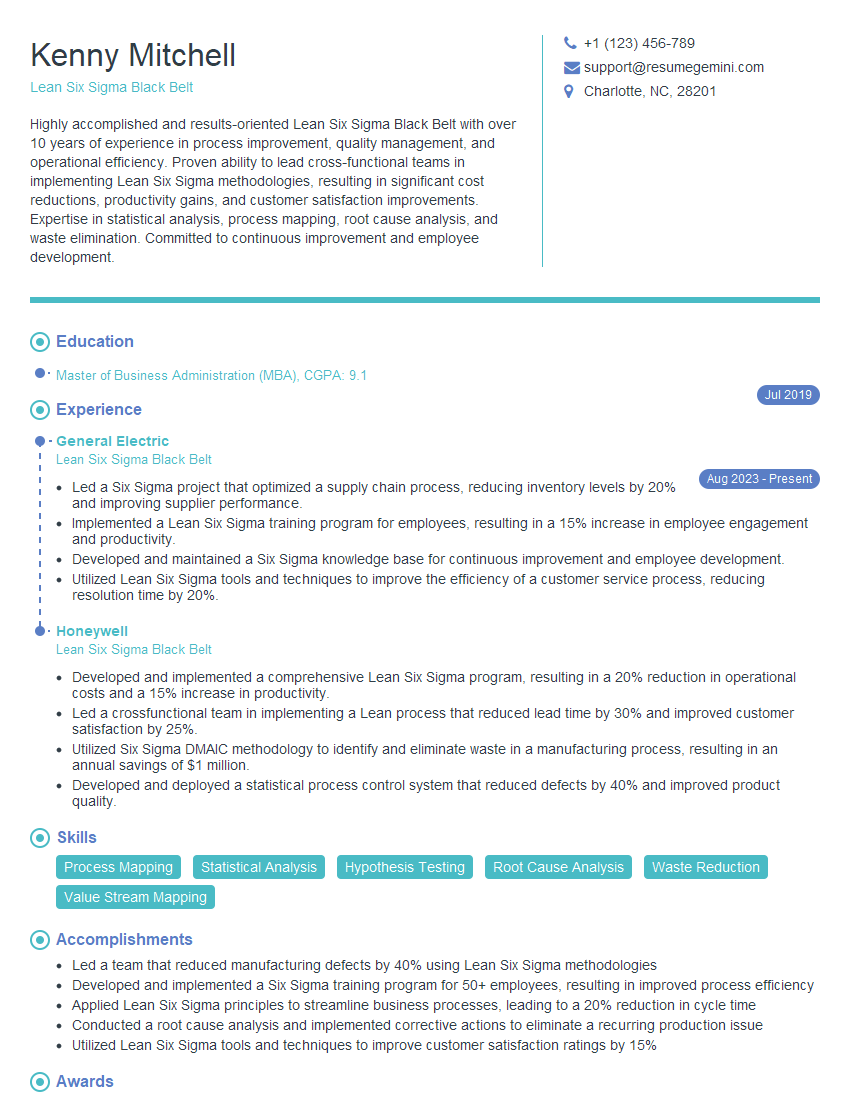

Mastering the Certified Six Sigma Black Belt (CSSBB) body of knowledge significantly enhances your career prospects, opening doors to leadership roles and higher earning potential. To maximize your job search success, create a compelling and ATS-friendly resume that showcases your skills and accomplishments. ResumeGemini is a trusted resource to help you build a professional and effective resume. Examples of resumes tailored to the Certified Six Sigma Black Belt (CSSBB) are available to provide you with a strong starting point.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good