Are you ready to stand out in your next interview? Understanding and preparing for Clam Sorting Techniques interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Clam Sorting Techniques Interview

Q 1. Describe the different methods used for clam sorting.

Clam sorting employs a variety of methods, ranging from manual hand-sorting to automated systems. Manual sorting is common for smaller operations and involves skilled sorters examining each clam for size, shape, shell condition, and presence of contaminants. This method allows for close inspection and precise grading. However, it’s labor-intensive and can be slow. Automated sorting, on the other hand, utilizes machines with sensors and conveyors to classify clams based on pre-programmed criteria such as size and weight. These systems are significantly faster and can handle large volumes, but they may not be as adept at detecting subtle quality issues that a human eye can catch. Some operations also use a combination of both methods, leveraging the strengths of each. For example, automated systems might pre-sort clams by size, and then human sorters would perform a final quality check to ensure only the highest-quality clams make it to market.

- Manual Sorting: This relies on human observation and manual separation of clams into different categories.

- Automated Sorting: This involves machinery with sensors that measure size, weight, and sometimes even shell integrity, automatically directing clams to different bins.

- Hybrid Systems: A combination of manual and automated methods, often used for efficient and high-quality sorting.

Q 2. What are the key quality characteristics assessed during clam sorting?

Key quality characteristics assessed during clam sorting include:

- Size and Weight: Clams are typically graded according to size, often categorized into small, medium, and large sizes, or by weight, crucial for pricing and market demands.

- Shell Condition: The shells must be intact and free from cracks, chips, or significant damage. Damaged shells indicate potential compromise of the clam’s meat quality and shelf life.

- Meat Condition: The clam meat should be plump, firm, and free of discoloration or unusual odors, indicating freshness and quality.

- Presence of Contaminants: Thorough inspection is necessary to eliminate clams containing sand, mud, parasites, or other unwanted substances that pose a health risk.

- Species Identification: Correctly identifying the clam species is crucial to ensure compliance with regulations and to avoid mixing different species.

Think of it like selecting produce at a grocery store – you want the freshest, firmest items without any blemishes. The same principles apply to clam sorting, only with a focus on specific characteristics important for clam quality.

Q 3. Explain the importance of sanitation and hygiene in clam sorting processes.

Sanitation and hygiene are paramount in clam sorting to prevent contamination and ensure food safety. Clams are susceptible to bacterial growth, especially in warm conditions. Improper hygiene can lead to foodborne illnesses. Maintaining cleanliness throughout the process is vital.

- Clean Equipment: All sorting equipment, including tables, containers, and machinery, must be thoroughly cleaned and sanitized regularly, ideally between batches.

- Hand Hygiene: Sorters must maintain impeccable hand hygiene, washing their hands frequently and wearing appropriate gloves to prevent cross-contamination.

- Water Quality: If water is used during sorting, it must be clean and of appropriate quality to prevent contamination. Chlorinated water might be used in some facilities.

- Facility Cleanliness: The entire sorting facility needs to be kept clean and free of debris to minimize sources of contamination.

Imagine a kitchen – if you wouldn’t prepare food in a dirty kitchen, you wouldn’t sort clams in an unsanitary environment. The principles are the same: cleanliness is crucial for preventing contamination and ensuring food safety.

Q 4. How do you identify and handle clams with potential contaminants?

Identifying and handling clams with potential contaminants requires a keen eye and adherence to strict protocols. Clams exhibiting any of the following should be immediately rejected:

- Visible contaminants: Sand, mud, or other visible debris in the shell or meat.

- Unusual odors: Offensive or putrid odors indicate spoilage.

- Discoloration: Unnatural discoloration of the meat or shell may signify bacterial growth or other issues.

- Parasites or diseased tissue: The presence of parasites or diseased tissue is a clear indication of unsuitability for consumption.

Rejected clams should be disposed of properly, often through separate waste streams to avoid contaminating other products. Training sorters to identify these signs and consistently follow rejection protocols is essential to maintain quality control and food safety. A simple example would be discarding a clam with a visibly broken shell or one that exhibits an unusual, foul odor.

Q 5. What are the different sizes and grades of clams?

Clam sizes and grades vary depending on the species and market demands. However, some common grading systems exist. Sizes are often categorized using measurements like shell length or weight, and these may be further categorized into specific grades based on meat quality. For example, ‘Little Neck’ clams are a specific size classification for certain clam species. Other species might be graded using weight categories, like ‘select’ or ‘jumbo’. These classifications are often standardized by industry associations or regulations, ensuring consistency across suppliers and markets.

It’s important to note that the specific size and grade designations can vary significantly based on the species and the market’s needs. For instance, a ‘large’ clam for one species may have significantly different dimensions than a ‘large’ clam of another species. Consult industry standards or market specifications to gain a complete understanding for a given clam species.

Q 6. How do you ensure efficient and accurate clam sorting?

Ensuring efficient and accurate clam sorting involves several key strategies:

- Proper Training: Thoroughly train sorters to identify quality characteristics and adhere to established grading standards. Regular refresher training reinforces consistency.

- Standardized Procedures: Implement clear and consistent sorting protocols to minimize variability and ensure quality. This includes defining criteria for each grade and establishing rejection criteria.

- Regular Quality Control: Implement a robust quality control system, including regular checks by supervisors, to identify and address any inconsistencies or errors.

- Efficient Workflow: Optimize the sorting layout and workflow to maximize efficiency and minimize handling time. This might involve conveyor systems, specialized sorting tables, or ergonomic designs.

- Technology Integration: Consider using automated sorting equipment where feasible to increase throughput and reduce labor costs while maintaining quality.

A well-designed system with well-trained personnel and clear guidelines is the key to accurate and efficient clam sorting. Think of it as an assembly line – each step needs to be efficient and effective to achieve the desired output.

Q 7. Describe your experience with different clam sorting equipment.

My experience encompasses a range of clam sorting equipment, from simple hand-sorting tables to sophisticated automated systems. I’ve worked with:

- Conveyor belt systems: These transport clams along a conveyor, often incorporating size-grading mechanisms to automatically separate clams based on dimensions.

- Optical sorting machines: These machines use cameras and sensors to assess clam characteristics such as size, shape, and shell condition, automatically rejecting clams that do not meet predefined quality standards.

- Weight sorters: These machines use scales to weigh clams and sort them based on weight, ensuring uniformity within each grade.

- Manual sorting tables with specialized tools: Even in manual settings, specialized tools, like clam-sized measuring guides or trays with size-specific compartments, can help maintain sorting consistency and efficiency.

Each system has its strengths and weaknesses. Automated systems offer higher throughput and consistent grading, while manual systems provide better flexibility and the ability to identify subtle quality issues. The choice depends on factors like production volume, budget, and desired quality levels.

Q 8. What safety measures are crucial during clam sorting?

Safety is paramount in clam sorting. We prioritize preventing injuries and contamination. This begins with personal protective equipment (PPE), including cut-resistant gloves to protect against sharp shells, waterproof aprons to prevent clam juice splashes, and non-slip footwear to maintain balance on potentially wet surfaces.

Furthermore, we maintain a clean and organized workspace to minimize tripping hazards. Regular cleaning and disinfection of sorting tables and equipment are essential to prevent cross-contamination and the spread of bacteria. We also follow strict hygiene protocols, including handwashing before and after handling clams and avoiding any contact between the clams and unclean surfaces. Proper waste disposal procedures for broken shells and other refuse is critical to avoid further accidents. Regular safety training for all personnel is a non-negotiable component of our operations.

Q 9. How do you handle damaged or broken clams during the sorting process?

Damaged or broken clams are handled with care to ensure they don’t contaminate the rest of the batch. First, we visually inspect each clam; any showing signs of damage (broken shells, discolored meat, or unusual odors) are immediately segregated. These clams are then disposed of according to established food safety protocols, typically via separate waste streams to avoid mixing with good clams. This prevents compromising the quality and safety of the acceptable product. Documentation of the quantity of rejected clams and reasons for rejection are maintained for traceability and quality control purposes. This meticulous approach is critical for maintaining a high standard of product quality and food safety.

Q 10. Explain your understanding of food safety regulations related to clam sorting.

My understanding of food safety regulations regarding clam sorting is extensive. We adhere strictly to guidelines set by organizations like the FDA (Food and Drug Administration) and relevant local health authorities. These regulations cover various aspects, including water quality (for clams harvested from the wild), temperature control during handling and storage, prevention of cross-contamination, and proper sanitation procedures. We maintain detailed records of clam origin, handling procedures, and temperature logs. This ensures traceability and facilitates prompt investigation in case of any quality or safety issues. Regular audits and inspections are welcomed as a way of confirming our compliance and further improving our procedures.

Q 11. What are the common challenges faced during clam sorting, and how do you address them?

Common challenges in clam sorting include variations in clam size and shape, which can slow down the process. We mitigate this through the use of specialized sorting equipment, such as automated size graders and manual sorting aids. Another challenge is ensuring consistent quality throughout the batch. We address this by implementing rigorous quality control checks at multiple stages of the process and using well-trained sorters. Maintaining a consistent workflow despite variations in clam availability can be difficult. We plan for seasonal fluctuations, implementing flexible scheduling and prioritizing efficiency techniques. We also address any equipment malfunctions promptly to minimize downtime. Finally, maintaining appropriate temperature throughout the process to ensure freshness requires consistent monitoring and proactive intervention.

Q 12. How do you maintain the quality and freshness of clams during sorting?

Maintaining clam quality and freshness during sorting is critical. We employ several strategies. First, we minimize handling time by using efficient sorting techniques and employing enough personnel to process clams quickly. Secondly, we keep clams chilled at their optimal temperature throughout the sorting process, usually between 33°F and 40°F (0°C and 4°C). This is achieved through the use of refrigerated surfaces, chilled water baths (if appropriate), and efficient cold storage facilities. Third, we work in a clean environment, minimizing exposure to contaminants. These practices are essential for preserving the taste, texture, and overall quality of the clams, ensuring that consumers receive a superior product.

Q 13. How do you manage the workflow and ensure timely processing?

Workflow management is crucial for timely processing. We utilize a combination of strategies. First, a well-defined sorting line is established, with clear roles and responsibilities assigned to each team member. This streamlines the process and enhances efficiency. Second, we use a First-In, First-Out (FIFO) system for managing clam batches, ensuring that older clams are processed first to avoid spoilage. Third, we employ real-time monitoring of our progress, allowing for adjustments and quick solutions to any bottlenecks. Finally, we regularly review and optimize our processes, introducing improvements based on performance data and any identified inefficiencies. This iterative approach ensures we meet our production goals while maintaining high quality.

Q 14. Describe your experience working under pressure in a fast-paced clam sorting environment.

I’ve worked in several high-pressure clam sorting environments, particularly during peak seasons. One memorable instance involved a large unexpected delivery that required us to process several thousand pounds of clams within a very tight timeframe. We immediately adjusted our workflow, bringing in additional staff and optimizing our sorting line configuration. This involved quick decision-making, clear communication, and close team coordination. The pressure was intense, but by working together and efficiently, we met the deadline without compromising quality or safety. It highlighted the importance of teamwork, adaptability, and proactive problem-solving under pressure – skills that are essential for success in this demanding industry.

Q 15. How do you ensure the accurate recording and tracking of sorted clams?

Accurate clam tracking is crucial for maintaining quality control and meeting market demands. We employ a multi-layered system. First, each harvesting batch receives a unique identifier, usually a lot number tied to the harvesting location and date. Then, during the sorting process, each grade of clam (e.g., extra large, large, medium) is weighed and counted separately using calibrated scales and digital counters. This data is meticulously recorded on standardized forms, both manually and digitally inputted into our inventory management system. This system allows for real-time tracking of clam quantities, enabling us to identify any discrepancies early on. Finally, traceability is ensured through detailed record keeping, which connects each lot number to its subsequent processing steps, all the way to the final sale, allowing for easy retrieval of information about specific clam batches if required.

For instance, if we discover a problem with a specific lot, we can immediately trace its origin, helping us to pinpoint the source of the problem and prevent its recurrence. This system is not only vital for accurate reporting but also aids in preventing potential issues like product recalls.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the different types of defects found in clams and how to identify them.

Clams, unfortunately, aren’t always perfect. Defects can significantly impact their market value. We encounter several types, including:

- Shell damage: This includes cracks, chips, or broken shells, often caused by rough handling or natural predators. We visually inspect each clam for these damages.

- Disease: Some clams can suffer from diseases causing discoloration, lesions, or abnormal shell growth. We often use a combination of visual inspection and sometimes even a simple touch test; unhealthy clams often feel softer or have a different texture.

- Contamination: Sand, mud, or other foreign materials inside the clam are unacceptable. This is mostly checked after shucking and is easily identifiable.

- Undersize/Oversize: Clams outside the specified size range for each grade are categorized separately. This usually involves using calibrated size gauges during sorting.

Identifying these defects requires careful examination and experience. We train our sorters to recognize the subtle indicators of each defect. For example, a slight discoloration might indicate early signs of disease, and a consistently smaller-than-average clam might suggest an environmental issue during growth. It’s a combination of keen observation and knowledge of clam biology.

Q 17. How do you determine the market value of different grades of clams?

Market value for clams is primarily determined by size, quality, and species. Larger clams generally command higher prices. For example, ‘extra large’ littleneck clams will always fetch a higher price than ‘medium’ ones. Quality, as determined by the absence of defects, directly impacts value, with pristine clams earning a premium. Species also play a role. Certain types of clams, like littlenecks or manila clams, are more highly sought after and therefore command higher prices than less popular varieties.

We use real-time market data and historical sales records to establish a price range for each clam grade. We also factor in fluctuations in demand – for example, prices can increase during peak seasons or special events. Think of it like the stock market, only with clams!

Q 18. Describe your knowledge of different clam species and their characteristics.

My experience encompasses a wide range of clam species, each with unique characteristics influencing sorting and handling. For instance:

- Littleneck Clams (Protothaca staminea): Highly valued for their small size and sweet taste. Sorting focuses on size uniformity and shell condition.

- Manila Clams (Venerupis philippinarum): Known for their delicate flavor. Their relatively uniform shape simplifies the sorting process.

- Hard-shell Clams (Mercenaria mercenaria): Larger and more robust than littlenecks. Sorting is more concerned with size and shell integrity due to their larger size and more prominent potential for damage.

Understanding these differences is crucial. For example, the delicate nature of Manila clams demands extra care during sorting to prevent shell damage. Conversely, the sturdier hard-shell clams can withstand more rigorous handling, though size grading still remains vital.

Q 19. How do you maintain a clean and organized work environment during clam sorting?

Maintaining a sanitary and organized workspace is paramount in clam sorting. Our facility employs strict hygiene protocols. We use sanitized work surfaces, regularly disinfect equipment, and ensure proper handwashing among our personnel. Clams are handled with care to avoid cross-contamination, and waste is disposed of properly and promptly.

Organization is equally important. We use clearly labeled bins and containers for each clam grade and sort them by size and quality, keeping different species separated to prevent mixing. A well-organized workspace not only ensures quality control but also boosts productivity and team morale. A clean and efficient setup makes sorting less error-prone and promotes a more positive work environment.

Q 20. What is your experience with automated clam sorting systems?

I have extensive experience working with automated clam sorting systems. These systems typically utilize optical sensors and image recognition software to analyze clams based on size, shape, and other visual characteristics. The systems significantly increase efficiency and accuracy compared to manual sorting, and can often identify defects undetectable by the human eye. However, they are not without limitations. For example, systems may struggle to accurately identify subtle defects like early signs of disease that are still easily identified by a well-trained human sorter.

My experience includes both the operation and maintenance of these systems. I understand their capabilities and limitations and recognize that a blend of human expertise and automated technology delivers the optimal result. Often the best approach combines automated pre-sorting with a human expert’s final quality check.

Q 21. How do you handle discrepancies in clam counts or weights?

Discrepancies in clam counts or weights are addressed systematically. We first verify the accuracy of the weighing and counting equipment using calibration checks. If equipment is functioning correctly, we then retrace the sorting and handling process, looking for possible sources of error such as accidental miscounts, spillage, or damage during transport. Internal audits, comparing recorded weights and counts to physical inventory, are regularly performed to identify and correct any inconsistencies. Thorough documentation is crucial in pinpointing the cause of discrepancies and preventing future issues.

For example, if a discrepancy arises, we might review the video recordings from the sorting area (if available) or re-examine the specific batches involved. A thorough investigation helps us understand the root cause and implement corrective measures, ensuring accurate reporting and accountability.

Q 22. Describe your troubleshooting skills related to clam sorting equipment.

Troubleshooting clam sorting equipment requires a systematic approach. I start by identifying the problem – is it a mechanical issue, a sensor malfunction, or a software glitch? For example, if clams aren’t being properly sized, I’d first check the calibration of the sizing mechanism. If that’s correct, I’d move on to examine the conveyor belt for obstructions or damage. If the problem is related to a sensor (like one detecting shell damage), I would check its power supply and connections, potentially replacing it if necessary. I always maintain a detailed log of troubleshooting steps, including the issue, actions taken, and the final resolution. This log is invaluable for future reference and preventative maintenance.

A particularly challenging case involved a recurring jam in the shucking mechanism. After systematically checking each component, from the blades themselves to the automated clam-feeding system, I discovered a subtle misalignment in the conveyor tracks leading to the shucking unit, causing clams to bunch up. A simple adjustment resolved the issue, saving significant downtime and preventing product loss.

Q 23. How do you handle customer complaints regarding clam quality?

Handling customer complaints regarding clam quality is crucial for maintaining positive relationships. I begin by actively listening to the customer’s concerns, asking clarifying questions to understand the specifics of the issue. Is it related to size, freshness, or shell damage? I then investigate internally, reviewing our quality control logs and production records from that specific batch. This might involve examining samples from the batch to verify the customer’s claims.

If the complaint is justified, I immediately apologize for the inconvenience and work collaboratively with the customer to find a solution – this might include offering a replacement shipment or a partial refund. If the complaint is unfounded (for example, improper handling after delivery), I explain our quality control procedures clearly and calmly, aiming for a mutually understanding solution. Documentation is key – every complaint is logged with details of the issue, actions taken, and the resolution, improving our processes and preventing future occurrences.

Q 24. What are your strategies for improving the efficiency of the clam sorting process?

Improving clam sorting efficiency involves a multi-pronged approach. Firstly, optimizing the equipment is key – regular maintenance, calibration, and timely repairs minimize downtime and maximize throughput. This includes preventative maintenance schedules to avoid costly breakdowns.

Secondly, optimizing workflow is crucial. This involves analyzing the sorting process to identify bottlenecks. For example, if manual inspection is slowing down the process, we could consider investing in automated quality control systems with image recognition software to identify defects quickly and efficiently. Improving employee training and establishing clear operational procedures also dramatically improves efficiency.

Thirdly, data-driven analysis helps us pinpoint areas for improvement. By tracking key performance indicators (KPIs) like sorting speed, reject rates, and downtime, we can identify patterns and make data-backed improvements to our processes.

Q 25. Describe your experience working as part of a team in a clam sorting environment.

Teamwork is essential in a clam sorting environment. My experience involves actively participating in team meetings, sharing information, and contributing my expertise to solve problems collectively. I’ve worked in teams where clear communication and mutual respect were paramount, enabling us to achieve shared goals efficiently. I believe in fostering a collaborative environment where every team member feels valued and respected.

For instance, during a period of high demand, our team worked collaboratively, adjusting our workflow to manage the increased volume effectively. By actively communicating potential challenges and sharing workload strategically, we successfully met the demand without compromising quality. I value open communication, active listening, and a willingness to support my colleagues – this creates a strong, productive team environment.

Q 26. How do you adapt your clam sorting techniques to different clam sizes and types?

Adapting clam sorting techniques to different sizes and types involves understanding the unique characteristics of each species. Different clams have different shell shapes, sizes, and fragility. For example, smaller clams might require gentler handling to avoid damage, while larger clams might necessitate adjustments to the sizing mechanisms. The sorting equipment needs to be versatile and adaptable to handle this variability.

This often involves adjusting the settings on the sorting machines, such as changing the size calibrators or conveyor belt speeds. In some cases, multiple sorting lines might be required, each optimized for a specific size or type of clam. Manual sorting might be necessary for particularly delicate or irregularly-shaped clams, requiring trained personnel to handle them carefully.

Q 27. Explain your understanding of the importance of traceability in clam processing.

Traceability in clam processing is paramount for food safety and regulatory compliance. It allows us to track clams from their origin (harvest location) through every stage of processing – sorting, packing, and distribution – ensuring we can quickly identify and address any potential issues. This involves detailed record-keeping, including batch numbers, harvest dates, processing dates, and location information.

Effective traceability protects consumers by allowing swift identification and removal of contaminated or substandard products. This is critical in preventing outbreaks of foodborne illnesses and maintaining consumer confidence. In addition, accurate traceability aids in meeting regulatory requirements and reduces the risk of recalls or fines.

Q 28. How do you ensure the proper labeling and packaging of sorted clams?

Proper labeling and packaging of sorted clams is crucial for maintaining quality and complying with regulations. Labels must clearly display the species, size, weight, harvest date, packing date, and any relevant allergen information. They must also adhere to all relevant regulations concerning labeling standards. The packaging itself must protect the clams from damage and maintain freshness during transport and storage. This usually involves using appropriate containers and refrigeration to maintain product quality.

I ensure that labels are accurate, legible, and securely attached to each package. We utilize automated labeling systems where possible to ensure consistency and speed. We regularly review our labeling and packaging procedures to ensure they comply with updated regulations and maintain high standards of quality and safety.

Key Topics to Learn for Clam Sorting Techniques Interview

- Clam Identification and Classification: Understanding different clam species, their sizes, and identifying key characteristics for accurate sorting.

- Sorting Methods and Equipment: Familiarization with various manual and automated sorting techniques, including sieving, grading, and specialized machinery. Understanding the advantages and limitations of each method.

- Quality Control and Standards: Knowledge of industry standards for clam size, shape, and quality. Understanding procedures for identifying and removing damaged or unsuitable clams.

- Hygiene and Safety Procedures: Familiarity with proper sanitation protocols and safety regulations within a clam processing environment.

- Efficiency and Productivity: Understanding techniques for maximizing sorting speed and minimizing waste while maintaining quality standards. This includes optimizing workflow and equipment usage.

- Problem-Solving and Troubleshooting: Ability to identify and resolve issues related to equipment malfunctions, inconsistent clam quality, and variations in sorting efficiency.

- Regulatory Compliance: Understanding and adhering to relevant food safety regulations and industry best practices regarding clam handling and processing.

Next Steps

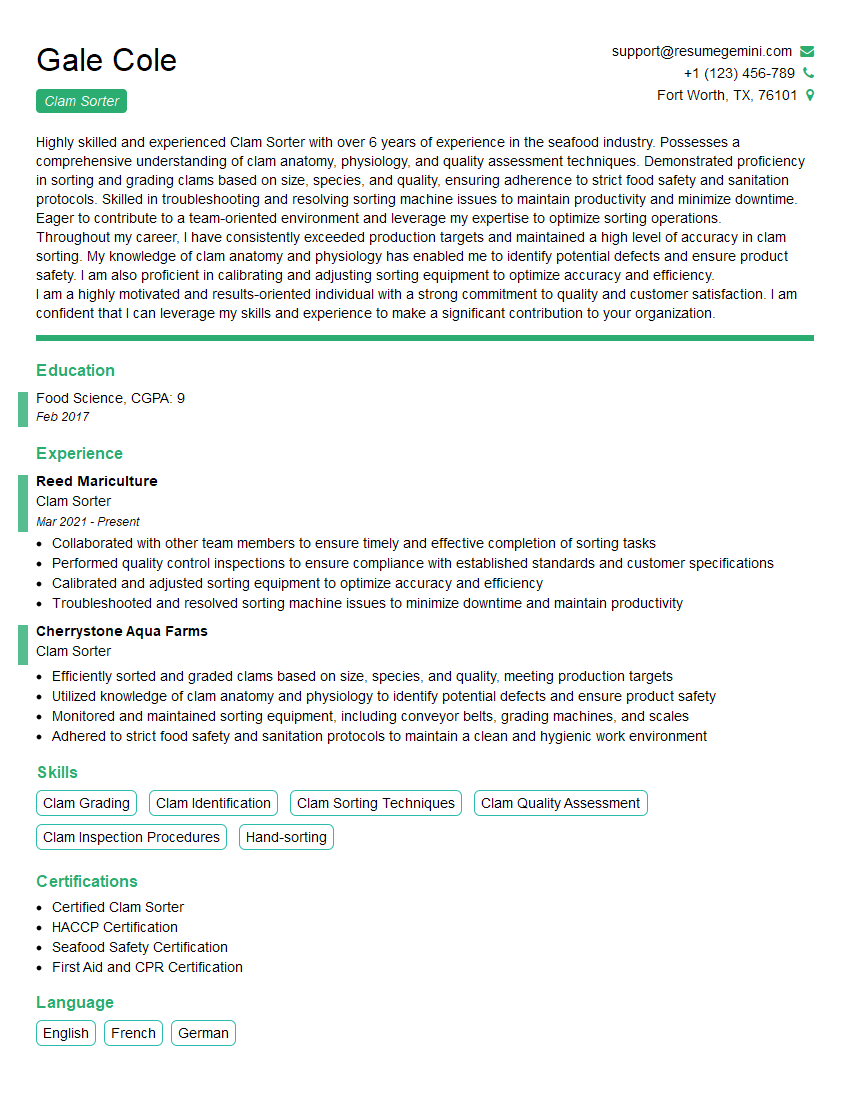

Mastering clam sorting techniques opens doors to rewarding careers in the seafood industry, offering opportunities for advancement and specialization. A strong resume is crucial for showcasing your skills and experience to potential employers. Building an ATS-friendly resume is essential for getting your application noticed. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume tailored to the specific requirements of clam sorting positions. Examples of resumes tailored to Clam Sorting Techniques are available to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good