Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Color Mixing and Formulation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Color Mixing and Formulation Interview

Q 1. Explain the difference between additive and subtractive color mixing.

Additive and subtractive color mixing are two fundamentally different approaches to creating colors. Imagine shining a flashlight on a wall – that’s additive. Imagine painting on a canvas – that’s subtractive.

Additive color mixing is the process of combining different colored lights. The primary colors in additive mixing are red, green, and blue (RGB). When you combine these colors, you create other colors. Combining all three at full intensity produces white light. Think of your computer or television screen; each pixel is made up of tiny red, green, and blue subpixels whose combined intensities create the image.

Subtractive color mixing is the process of combining different colored pigments or dyes. The primary colors in subtractive mixing are cyan, magenta, and yellow (CMY), along with black (K), often called CMYK. These pigments absorb certain wavelengths of light, and the remaining wavelengths are reflected to our eyes, creating the perceived color. The more pigments you add, the darker the resulting color. Think of mixing paints; each pigment absorbs some of the light, resulting in a darker color than the individual components. For example, mixing cyan and magenta pigments results in blue.

The key difference lies in the way colors are created: additive mixing combines light, creating brighter colors as you add more light sources; subtractive mixing combines pigments that absorb light, creating darker colors as you add more pigments.

Q 2. Describe the CIE color space and its importance in color formulation.

The CIE (Commission Internationale de l’Éclairage) color space is an internationally standardized system for defining and representing colors. It’s crucial in color formulation because it provides a quantitative and objective method to describe any color, irrespective of the viewing conditions or the device used to produce it.

The CIE 1931 XYZ color space is a cornerstone. It defines colors using three coordinates, X, Y, and Z, representing the stimulation of three hypothetical color receptors in the human eye. The Y value represents luminance (brightness), while X and Z represent the chromaticity (color hue and saturation). The CIE color space doesn’t directly correspond to what we perceive, but serves as a mathematical framework. It’s important to note that other CIE color spaces exist, such as CIE L*a*b* (CIELAB) which is more perceptually uniform – meaning that equal numerical differences in the L*a*b* values correspond to similar perceived color differences.

In color formulation, the CIE color space allows for precise communication between manufacturers, designers, and consumers. It facilitates color matching, quality control, and the development of color standards. For instance, a paint manufacturer can specify a target color using CIE L*a*b* coordinates, allowing the production team to accurately reproduce it consistently across different batches and manufacturing locations. Without a standardized system like CIE, color matching would be highly subjective and unreliable.

Q 3. How do you perform a color match using a spectrophotometer?

Color matching with a spectrophotometer involves measuring the spectral reflectance or transmittance of a sample and comparing it to a standard or target color. Here’s a step-by-step process:

- Prepare the sample: Ensure the sample is clean, dry, and evenly illuminated.

- Calibrate the spectrophotometer: This step is crucial for accurate measurements. Follow the manufacturer’s instructions for calibration using a white and black standard.

- Measure the sample: Place the sample in the spectrophotometer and initiate the measurement. The instrument measures the spectral reflectance or transmittance at various wavelengths.

- Obtain color data: The spectrophotometer will output the color data in a specific color space, such as CIE L*a*b*, XYZ, or others. This data represents the color of your sample numerically.

- Compare to the target: Compare the sample’s color data to the target color data. This might involve using color difference formulas (like Delta E) to quantify the difference.

- Adjust formulation: If the sample doesn’t match the target, you’ll need to adjust the formulation of your colorant mixture (e.g., adding more pigment or changing the base). Re-measure after each adjustment.

- Iterate: Repeat steps 3-6 until the color difference between the sample and target is within the acceptable tolerance.

The process utilizes sophisticated software that aids in the formulation adjustment. It often involves sophisticated algorithms that suggest necessary pigment adjustments to minimize the color difference.

Q 4. What are metamerism and how does it affect color matching?

Metamerism is a phenomenon where two colors appear identical under one set of lighting conditions but different under another. This occurs because the spectral power distributions of the two colors are different, but their perceived color is the same due to the limitations of human color vision.

For example, two fabrics might appear the same blue under fluorescent lighting but look distinctly different under incandescent lighting. This is because the reflectance curves of the two fabrics differ, resulting in different combinations of light wavelengths being reflected under different light sources. This significantly impacts color matching because a match achieved under one light source may not hold true under another.

To mitigate metamerism, color matching should be conducted under multiple light sources, simulating different lighting conditions that the final product might encounter. Spectrophotometers and color-matching software allow for analyzing spectral curves, identifying potential metameric matches, and ensuring consistency under different lighting scenarios.

Q 5. Explain the concept of color tolerance and its practical implications.

Color tolerance defines the acceptable range of variation for a specific color. It’s expressed as a numerical value, often using Delta E (ΔE), which quantifies the perceived difference between two colors. A smaller ΔE value indicates a closer match, while a larger value signifies a greater difference. Color tolerance is crucial because it sets the limits of acceptable variation in color during manufacturing and production.

For example, a paint manufacturer might specify a ΔE tolerance of 1.0 for a particular shade of blue. This means that any paint produced must have a color difference of no more than 1.0 ΔE from the target color. If the paint falls outside this tolerance, it’s considered unacceptable and requires correction. Color tolerance helps ensure product consistency, meets customer expectations, and prevents costly rework or product rejection.

The practical implications are significant. Defining appropriate color tolerances prevents unnecessary waste, allows for minor manufacturing variations, saves time and resources, and ensures product quality.

Q 6. How do you handle color inconsistencies in a production environment?

Color inconsistencies in production stem from various factors: raw material variations, instrument calibration issues, changes in environmental conditions (temperature, humidity), and operator errors. Addressing these issues requires a multi-pronged approach:

- Establish strict quality control: Implement rigorous testing procedures throughout the manufacturing process using calibrated instruments.

- Use standardized color measurement techniques: Employ a consistent color measurement protocol, including specified color spaces, illumination sources, and viewing geometries.

- Monitor raw materials: Regularly inspect and analyze the quality of raw materials to ensure consistency.

- Calibrate instruments regularly: Frequent calibration of spectrophotometers and other color measurement instruments guarantees accuracy.

- Control environmental factors: Maintain a stable production environment by controlling temperature and humidity.

- Train personnel: Provide comprehensive training to operators on proper color measurement and handling procedures.

- Utilize color management software: Leverage color management software to predict and simulate color changes due to different factors.

Implementing these steps minimizes color inconsistencies and ensures consistent, high-quality product output.

Q 7. Describe different color measurement instruments and their applications.

Several instruments measure color, each with specific applications:

- Spectrophotometers: These are the most common and precise instruments. They measure the spectral reflectance or transmittance of a sample, providing detailed spectral data that allows for accurate color characterization and matching. They’re used in quality control, color formulation, and research.

- Colorimeters: These instruments measure the color coordinates of a sample directly, often in CIE L*a*b* or other color spaces. They’re simpler and less expensive than spectrophotometers but less precise. They are suitable for quick, on-site quality checks.

- Densitometers: Primarily used in the printing industry, densitometers measure the optical density of printed inks, providing a measure of the ink’s concentration and color. They are used to control ink density during printing operations.

- Visual Color Comparators: Simple tools that offer visual color comparison. These are less precise but useful for quick, subjective assessments, such as matching a dye to a fabric sample. They are not as reliable for precise color matching as spectrophotometers or colorimeters.

The choice of instrument depends on the specific application, required level of accuracy, cost constraints, and ease of use.

Q 8. What are the key challenges in formulating colors for different substrates?

Formulating colors for different substrates presents unique challenges because the substrate’s properties significantly influence how the colorant interacts and ultimately appears. Think of it like painting a mural – you wouldn’t use the same paint on wood as you would on canvas. The texture, porosity, and chemical composition of the substrate all play a role.

- Light Absorption and Scattering: A glossy surface reflects more light, altering the perceived color compared to a matte surface, which absorbs more. This necessitates adjustments in pigment concentration and selection.

- Substrate Transparency/Opacity: Transparent substrates like glass require different colorants than opaque ones like paper. For glass, you might need specialty inks that adhere well and remain vibrant without obscuring the transparency.

- Chemical Interactions: Certain pigments might react with the substrate, leading to discoloration or fading. For instance, acidic pigments on alkaline substrates can cause a chemical reaction affecting the final color.

- Adhesion: Ensuring the colorant adheres properly to the substrate is crucial. Poor adhesion can lead to peeling, flaking, or uneven color distribution. This often requires specialized binders or surface treatments.

For example, formulating a vibrant blue for a car’s metallic paint requires a different approach than formulating the same blue for a cotton t-shirt. The metallic flakes in the car paint interact with light differently, demanding specialized pigments and binders to achieve the desired effect.

Q 9. Explain the importance of color standardization in various industries.

Color standardization is paramount in numerous industries to ensure consistency and quality. Imagine a clothing company producing a range of shirts in different batches; without standardization, you’d end up with noticeable color variations between batches, leading to customer dissatisfaction and brand damage.

- Quality Control: Standardized color allows for precise quality control throughout the manufacturing process. Comparing a sample’s color to a standardized reference ensures that every item meets the expected color specifications.

- Global Communication: Standardized color systems like Pantone enable global communication and collaboration. Designers, manufacturers, and clients can all refer to a common color language, eliminating confusion and misinterpretations.

- Brand Identity: Maintaining consistent brand colors across different products and marketing materials is essential for building brand recognition and consumer trust. This requires adherence to precise color standards.

- Legal Compliance: In some industries, like food and pharmaceuticals, specific color standards and regulations must be followed to ensure safety and product integrity.

For instance, the automotive industry heavily relies on standardized color systems to ensure consistent color matching across vehicle parts and model years. Similarly, the printing industry uses standardized color profiles to guarantee accurate reproduction of colors across different printing devices and substrates.

Q 10. How do you calculate color differences using Delta E values?

Delta E (ΔE) values quantify the perceived difference between two colors. It’s essentially a numerical representation of how much two colors differ visually to the human eye. A lower ΔE value indicates a smaller color difference, while a higher value implies a greater difference.

Calculating ΔE involves using color difference formulas, most commonly the CIE76, CIE94, or CMC(l:c) formulas. These formulas take into account the differences in L* (lightness), a* (red-green), and b* (yellow-blue) coordinates of the two colors in the CIELAB color space. The specific formula used depends on the application and the desired level of accuracy.

ΔE = √[(ΔL*)² + (Δa*)² + (Δb*)²] // Simplified CIE76 formula

Where:

- ΔL* represents the difference in lightness

- Δa* represents the difference in red-green

- Δb* represents the difference in yellow-blue

The interpretation of ΔE values is crucial: a ΔE of less than 1 is generally imperceptible to the human eye, while a ΔE of 3 or more is easily noticeable. The exact thresholds depend on the context, substrate and color itself.

For example, in quality control of printed materials, a ΔE of less than 1 between the target color and the printed color is often considered acceptable, while a higher ΔE value might necessitate adjustments to the printing process.

Q 11. What are the different types of colorants used in various applications?

A wide array of colorants exist, each with its unique properties, making them suitable for different applications.

- Pigments: Insoluble colorants that provide opacity and color intensity. Examples include titanium dioxide (white), carbon black (black), and various organic pigments for vibrant hues. They’re used in paints, inks, plastics, and cosmetics.

- Dyes: Soluble colorants that offer bright, transparent colors. Used extensively in textiles, food, and some inks. They tend to be less lightfast than pigments.

- Organic Colorants: Naturally derived or synthetically produced colorants based on organic molecules. They often offer a broader range of vibrant colors but can be less durable than inorganic colorants.

- Inorganic Colorants: Derived from minerals or other inorganic sources. Often known for their lightfastness and durability but might offer a more limited color range. Examples include iron oxides (reds, yellows, browns) and ultramarine blue.

- Pearlescent and Fluorescent Colorants: These add special effects, like pearlescence or fluorescence, to coatings and products.

The choice of colorant depends on factors like desired color, opacity, lightfastness, cost, application method, and regulatory requirements. For instance, food coloring utilizes specific dyes that are safe for consumption, whereas automotive paints require pigments that withstand harsh weather conditions.

Q 12. Explain the principles of colorant dispersion and its effect on color quality.

Colorant dispersion is the process of evenly distributing colorant particles within a binding medium (e.g., resin, solvent). It’s an essential step in color formulation because proper dispersion directly impacts the color quality, appearance, and overall performance of the final product.

Poorly dispersed colorants lead to several issues:

- Uneven Color: Clumps of pigment create mottled or streaky appearances.

- Reduced Color Intensity: Agglomerated particles scatter light less effectively, leading to duller, less vibrant colors.

- Reduced Durability: Poor dispersion weakens the film’s integrity, impacting the color’s resistance to fading, cracking, or other damage.

- Poor Gloss: Un-dispersed particles can roughen the surface, leading to a less glossy finish.

Achieving good dispersion often involves using specialized equipment like high-shear mixers, three-roll mills, or attritors, combined with careful selection of dispersing agents (wetting agents and dispersants) to break down agglomerates and maintain a stable dispersion.

Imagine trying to mix powdered paint into water without properly dispersing it – you would end up with clumps of paint that don’t mix evenly, resulting in an uneven color. Effective dispersion ensures the paint particles are thoroughly mixed, leading to a smooth, even, and vibrant color.

Q 13. Describe your experience with different color mixing software and tools.

Throughout my career, I’ve extensively used a variety of color mixing software and tools, both proprietary and open-source. This experience has allowed me to compare and contrast different approaches to color formulation.

- Pantone Connect: A widely used software for color management and communication, particularly in the graphic design and fashion industries. Its library of Pantone colors simplifies color selection and matching.

- Colorimetric Software Packages: I’ve worked extensively with software that allows for precise color calculations based on spectrophotometer data. These allow me to adjust formulations based on measured data for optimal color accuracy.

- Spectrophotometers and Colorimeters: Essential tools for measuring and quantifying color. I have experience operating various types of these instruments, ranging from portable hand-held devices to high precision laboratory models. This experience allows me to get accurate measurements of color and control quality.

- Custom Software/Spreadsheets: For specific applications, I’ve developed custom software and spreadsheets for automating color formulation calculations and managing large datasets of color recipes.

My experience spans different software interfaces and functionalities, making me comfortable adapting to new tools and technologies as needed. I regularly compare measured data from spectrophotometers with software predictions to ensure consistent and accurate results.

Q 14. How do you troubleshoot color formulation issues?

Troubleshooting color formulation issues requires a systematic and analytical approach. It’s often a process of elimination and careful experimentation.

- Identify the Problem: Begin by clearly defining the discrepancy between the desired color and the actual color. Quantify the difference using Delta E values and describe the nature of the problem (e.g., too dark, too dull, off-shade).

- Analyze the Formulation: Examine the colorant recipe, paying close attention to the type and quantity of each colorant, the dispersion technique used, and the substrate itself.

- Check the Raw Materials: Verify the quality and consistency of the raw materials. It is important to regularly calibrate instruments and standardize materials.

- Review the Process: Evaluate all steps of the process, from mixing and dispersion to application and drying. Look for inconsistencies in mixing time, temperature, or application techniques.

- Systematic Adjustments: Make small, incremental adjustments to the formulation based on your analysis. Document every change and its effect on the final color.

- Spectrophotometric Analysis: Utilize spectrophotometry to measure and quantify the color differences, guiding further adjustments to achieve target specifications.

For example, if the final color is duller than expected, you might investigate the dispersion process, the type of binder, or the presence of any interfering substances. If the color is off-shade, you might need to adjust the ratios of individual colorants in the recipe. Thorough record-keeping during this troubleshooting process is essential for future reference.

Q 15. What are the safety precautions you take when working with colorants and chemicals?

Safety is paramount in color formulation. Working with colorants and chemicals requires a meticulous approach. My standard operating procedure always begins with a thorough review of the Safety Data Sheets (SDS) for each material. This provides crucial information on hazards, handling precautions, and emergency response procedures. I always work in a well-ventilated area, preferably a dedicated lab with proper exhaust systems.

Personal Protective Equipment (PPE) is non-negotiable. This includes safety glasses, gloves (nitrile or other appropriate material based on chemical compatibility), lab coats, and sometimes respirators depending on the volatility of the materials. I follow strict procedures for waste disposal, segregating materials according to their hazard classification and adhering to local regulations. Spills are handled immediately with appropriate absorbents and cleanup procedures, documented thoroughly. Regular safety training keeps me updated on best practices and emergency procedures. For example, recently, I had to handle a new pigment with high skin sensitization potential. I immediately consulted the SDS and implemented extra precautions, including double gloving and more frequent hand washing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate color records and formulations?

Maintaining accurate color records is crucial for consistency and reproducibility. I utilize a digital database system, ideally a dedicated software for color management, to store all formulations. Each entry includes a unique identification number, detailed ingredient list with percentages (by weight or volume), batch numbers, date of creation, and, critically, spectrophotometer readings (in a standardized color space like CIELAB). This provides objective color data that goes beyond subjective visual assessments. I also include notes on any observations or adjustments made during the formulation process. Physical samples, labeled meticulously, are stored in a controlled environment to minimize degradation. For example, I recently used this system to perfectly reproduce a color from a project completed six months prior, saving both time and resources. The digital system allows easy searching, filtering and color comparison between different batches and projects.

Q 17. Explain your understanding of different color spaces (e.g., RGB, CMYK, LAB).

Understanding color spaces is essential for accurate color communication and reproduction. RGB (Red, Green, Blue) is an additive color model, used primarily in digital displays like monitors and screens. It describes how light is mixed to create color. CMYK (Cyan, Magenta, Yellow, Key/Black) is a subtractive color model, used for printing. It describes how inks absorb light to create color. Finally, LAB (L*a*b*) is a device-independent color space designed to approximate human color perception. L* represents lightness, a* represents the red-green axis, and b* represents the yellow-blue axis. This makes it ideal for color matching and formulation across different devices and media.

The key difference lies in their application. If I’m designing a website, RGB is critical. If I’m formulating ink for printing, CMYK is the relevant space. However, for accurate color matching across these different media, I often rely on the LAB space, converting between color spaces as needed, using dedicated software tools. For example, a client might provide a color in RGB, but the final product is printed, requiring accurate conversion to CMYK while ensuring visual consistency through the use of the LAB color space.

Q 18. Describe your experience with different types of pigments (e.g., organic, inorganic).

My experience encompasses a wide range of pigments, both organic and inorganic. Organic pigments are carbon-based and often offer vibrant, intense colors but can be less lightfast and weather-resistant than their inorganic counterparts. Examples include azo pigments and phthalocyanines. Inorganic pigments are derived from mineral sources and tend to be more durable and heat-resistant, but might offer a narrower range of colors. Examples include titanium dioxide (white), iron oxides (reds, yellows, browns), and ultramarine (blue).

The choice depends on the application. For instance, for exterior paints, I would prioritize inorganic pigments for their superior weatherability. For a high-quality artistic print where vibrant color is key, an organic pigment might be chosen, alongside appropriate protective coatings. The understanding of pigment properties, like particle size distribution, tinting strength, and transparency, is crucial for formulating effective color systems. A recent project involved matching a very specific shade of green, requiring a blend of both organic and inorganic pigments to achieve the desired hue and stability.

Q 19. How do you handle customer requests for specific color matches?

Handling customer color match requests involves a structured approach. First, I obtain a color sample from the customer – whether it’s a physical object or a digital image. I then use a spectrophotometer to measure the color’s coordinates in the LAB color space. This provides objective data to work from. I then use my knowledge of pigment properties and color mixing principles to create a formulation that closely matches the target color. This often involves iterative adjustments and fine-tuning, using software to simulate color mixes and predict the final result.

Depending on the substrate and application, I adjust the formulation to account for differences in light scattering and absorption. The entire process is carefully documented, including spectrophotometer readings at each stage, to ensure consistent results. The color is then tested under various lighting conditions to assess its metamerism (whether the color appears different under different lights) and ensure a successful match.

Q 20. Explain the role of rheology in color formulation.

Rheology, the study of the flow and deformation of matter, plays a crucial role in color formulation. The viscosity, or thickness, of a colorant system significantly impacts its application properties. Too thick, and the application might be difficult; too thin, and it might run or sag. Rheological modifiers are used to achieve the desired flow and consistency for specific applications. For example, in paints, appropriate rheological additives are crucial for brush flow, sprayability, and leveling. In inks for screen printing, careful control of viscosity is vital for proper transfer and definition.

Understanding rheology helps me create formulations that are not only visually appealing but also easy to apply and process. A recent project involved formulating a highly pigmented ink for a specific type of textile printing that demanded a precise rheology profile to prevent clogging and bleeding of the colors during the printing process.

Q 21. Describe your experience with color stability testing.

Color stability testing is critical to ensure the long-term performance of a colorant system. This involves exposing the formulated color to various environmental stressors such as light, heat, humidity, and chemicals. Accelerated weathering tests, using Xenon arc lamps, are commonly used to simulate years of exposure in a short time. I also test for color changes and degradation caused by chemicals, such as cleaning agents or UV stabilizers.

The results of these tests are crucial for determining the lightfastness, weatherability, and overall durability of the formulated color. For instance, a recent project required extensive color stability testing of an automotive paint formulation to ensure it retained its color and gloss over many years of exposure to sunlight, rain, and other environmental factors. The data obtained allowed us to make necessary adjustments to the formulation and guarantee the paint’s long-term performance and client satisfaction.

Q 22. What is your experience with different types of color measurement standards?

Color measurement standards are crucial for ensuring consistent color communication and reproduction across different stages of the color formulation process. My experience encompasses several key standards, including:

- CIE L*a*b*: This is the most widely used color space in the industry, representing color in terms of lightness (L*), red-green opponent (a*), and yellow-blue opponent (b*). I use this extensively for precise colorimetric calculations and comparisons.

- CIE XYZ: This forms the basis for many other color spaces, representing color mathematically. It’s vital for understanding the theoretical underpinnings of colorimetry and for performing color transformations.

- ΔE (Delta E): This represents the difference between two colors in a given color space. Lower ΔE values indicate closer color matches. I regularly use ΔE formulas, such as ΔE*ab and ΔE*00, to assess the acceptability of color matches within specified tolerances.

- Munsell Color System: This system uses a three-dimensional color notation – hue, value (lightness), and chroma (saturation) – that’s visually intuitive and useful for initial color assessment and communication. I use it alongside other more precise methods.

Understanding these standards and their nuances allows me to effectively communicate color requirements, analyze measurement data from spectrophotometers, and ensure color consistency across various applications and production processes.

Q 23. How do you determine the appropriate concentration of colorants in a formulation?

Determining the appropriate concentration of colorants is a critical step in color formulation and requires a blend of science and artistry. It’s rarely a simple calculation, but rather an iterative process. I typically employ these methods:

- Color Matching Software: I utilize sophisticated software packages that allow me to predict colorant concentrations based on target color values and the colorant properties. These programs often incorporate algorithms that consider the specific substrate, solvent, and other formulation components.

- Laboratory Batching: Through iterative experimentation, I create small batches of color formulations with varying colorant concentrations, measuring and adjusting until the desired color is achieved. This is crucial to account for unforeseen interactions between colorants and other materials.

- Beer-Lambert Law (Absorbance): For transparent formulations, this law offers a mathematical relationship between absorbance, concentration, and path length. I use this to create initial estimates for colorant concentrations.

- Experience and Intuition: Years of experience provide an intuitive understanding of colorant behaviour and interactions. This allows me to make informed decisions and optimize the formulation efficiently.

Often, I employ a combination of these methods, refining my estimates through experimentation and applying colorimetric calculations to ensure the final formulation meets the required specifications.

Q 24. Describe your experience in using quality control methods for color accuracy.

Quality control for color accuracy is paramount. My experience includes using a range of methods to maintain consistency and meet customer requirements. These include:

- Spectrophotometry: This is my primary method for objectively measuring color. I use spectrophotometers to capture the spectral reflectance or transmittance of samples, providing precise color data in various color spaces (e.g., CIE L*a*b*). This ensures consistency and provides numerical data for tracking and reporting.

- Visual Evaluation: Although objective measurements are crucial, human visual perception also plays a critical role. I use trained personnel who assess the color under controlled lighting conditions to account for metamerism, the phenomenon where colors appear different under varying light sources.

- Statistical Process Control (SPC): For large-scale production, SPC techniques help to monitor color variability throughout the manufacturing process. I use control charts to track color measurements and identify any trends that could indicate quality issues.

- Standard Operating Procedures (SOPs): Detailed SOPs outlining the color measurement process, instrument calibration, and acceptance criteria are crucial for maintaining consistency and traceability.

The combination of these methods ensures that color accuracy is maintained throughout the entire process, from initial formulation to final product.

Q 25. Explain the impact of different solvents on color formulation.

Solvents play a vital role in color formulation, impacting not only the solubility and dispersion of colorants but also the final color appearance. Different solvents can affect:

- Solubility of Colorants: A solvent must effectively dissolve the colorant for proper dispersion and to prevent settling or aggregation, leading to uneven color. Water-based, organic, and solvent blends require different colorant selections.

- Color Strength and Shade: The solvent’s refractive index can influence the perceived color. A change in solvent can subtly alter the hue, chroma, or even lightness.

- Film Formation: In coatings and paints, the solvent’s evaporation rate significantly impacts film formation and the final appearance. Too-fast evaporation can cause cracking, while too-slow evaporation can result in long drying times and undesirable textures.

- Color Stability: The solvent’s chemical properties can influence color stability over time. Some solvents might react with colorants, leading to fading or color shift.

Therefore, solvent selection is not simply a matter of solubility but a critical consideration that affects color, stability, and the overall quality of the final product. I need to carefully consider the specific requirements of each application and the behavior of different colorants in different solvent systems.

Q 26. How do you handle unexpected color shifts during the manufacturing process?

Unexpected color shifts during manufacturing can be frustrating but are often solvable with a systematic approach. My strategy involves:

- Immediate Investigation: The first step is to pinpoint the source of the shift. This involves analyzing raw materials, examining the manufacturing process, and comparing the affected batch to previous successful batches.

- Spectrophotometric Analysis: Precise color measurements help quantify the shift and identify the extent of the problem. This allows for objective evaluation and aids in identifying the root cause.

- Raw Material Analysis: Verifying the quality and consistency of raw materials, including colorants, solvents, and binders, is crucial. Variations in raw material quality are often the culprit.

- Process Adjustments: Once the cause is identified, adjustments to the manufacturing process might be necessary. This could involve changes in mixing time, temperature, or the addition of specific additives to compensate for the shift.

- Re-Formulation: In some instances, a slight re-formulation of the colorant mixture is required to compensate for the unexpected shift. This may necessitate adjustments to colorant concentrations or the introduction of new colorants.

Through careful analysis and systematic adjustments, most unexpected color shifts can be corrected, ensuring the final product maintains the desired color.

Q 27. What are your strategies for optimizing color formulation costs?

Optimizing color formulation costs requires a multifaceted approach balancing quality and cost-effectiveness. My strategies include:

- Colorant Selection: Choosing less expensive but equally effective colorants can significantly reduce costs. I prioritize cost-effective colorants without compromising quality or performance.

- Efficient Use of Colorants: Precise calculations and optimized colorant ratios minimize waste and maximize color strength. This reduces the amount of colorants needed per unit of product.

- Solvent Selection: Choosing less expensive, readily available solvents that still provide adequate performance can lead to savings. I carefully evaluate the trade-offs between solvent cost and performance.

- Waste Reduction: Implementing strategies to minimize waste throughout the formulation and production process is vital. This includes optimized batch sizes, proper storage, and waste recycling programs.

- Supplier Negotiations: Maintaining strong relationships with suppliers and negotiating favorable pricing agreements can significantly impact the overall cost of raw materials.

By carefully considering all aspects of the formulation and production process, a balanced approach to cost optimization can be achieved without sacrificing the quality of the final product.

Q 28. Describe a challenging color matching problem you solved and your approach.

One particularly challenging color matching problem involved matching a highly specific, pearlescent automotive paint. The target color exhibited a complex interplay of base color, metallic flake orientation, and a unique iridescent effect. The challenge lay in accurately replicating this effect, given the inherent variability of pearlescent pigments and the sensitivity of the visual perception of metallic finishes.

My approach involved several steps:

- Detailed Spectrophotometric Analysis: I first performed rigorous spectrophotometric measurements of the target color under various lighting conditions, capturing both the spectral reflectance and the angular variation of the pearlescent effect. This gave me a comprehensive dataset to work with.

- Pigment Selection and Characterization: I carefully selected and characterized a range of pearlescent pigments, evaluating their individual spectral properties and particle size distribution. I tested various combinations to find pigments that matched the spectral characteristics of the target color.

- Iterative Formulation and Adjustment: Using color matching software and laboratory batching techniques, I iteratively refined the formulation, carefully controlling pigment concentrations and flake orientation. I closely monitored the angular distribution of light using goniospectrophotometry.

- Visual Evaluation under Controlled Lighting: Throughout the process, I conducted visual evaluations under different light sources to ensure the final formulation accurately reproduced the target color’s visual appeal, accounting for metamerism.

Through this methodical approach, involving sophisticated instrumentation, thorough pigment selection, and iterative adjustments, we successfully achieved an extremely close match, satisfying the exacting requirements of the automotive manufacturer. The solution underscored the importance of combining sophisticated instrumental analysis with a deep understanding of the properties and interactions of the materials involved.

Key Topics to Learn for Your Color Mixing and Formulation Interview

- Color Theory Fundamentals: Understanding color models (RGB, CMYK, LAB), color spaces, and their practical implications in different applications.

- Color Measurement and Instrumentation: Familiarity with spectrophotometers, colorimeters, and their use in quality control and formulation.

- Pigment and Dye Properties: Knowledge of pigment characteristics (particle size, opacity, tinting strength), dye solubility, and their impact on color formulation.

- Formulation Techniques: Mastering techniques for creating accurate color matches, understanding different mixing methods (e.g., subtractive, additive), and handling various substrates.

- Practical Applications: Experience in specific industries like paints, coatings, plastics, textiles, or cosmetics, highlighting your understanding of application-specific challenges and solutions.

- Color Matching Algorithms and Software: Familiarity with color matching software and algorithms, and their role in efficient and precise color formulation.

- Troubleshooting and Problem-Solving: Demonstrate your ability to identify and solve common color formulation issues, such as metamerism and color drift.

- Quality Control and Standards: Understanding color quality standards and control processes, and how to ensure consistent color reproduction.

- Health and Safety Regulations: Awareness of relevant safety regulations and handling procedures for pigments, dyes, and other materials.

- Sustainable Practices: Understanding environmentally friendly colorants and formulation techniques.

Next Steps

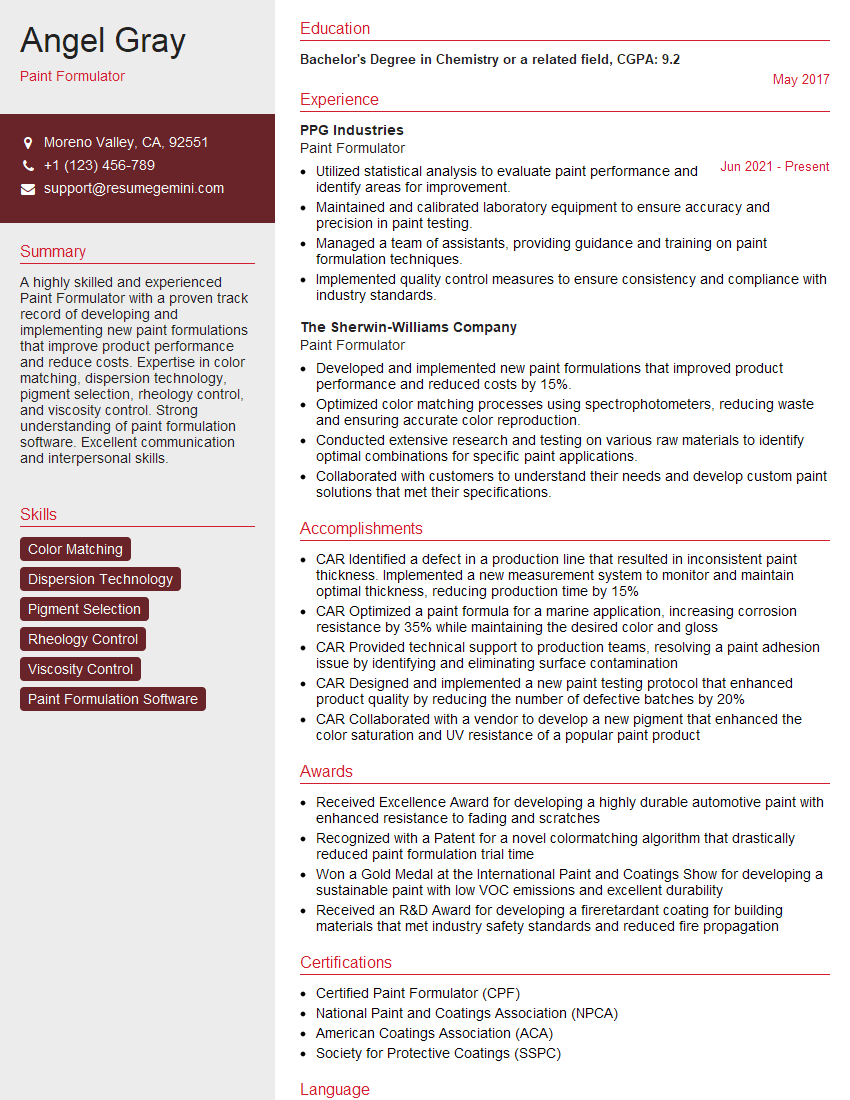

Mastering color mixing and formulation opens doors to exciting career opportunities in diverse industries. A strong understanding of these principles is highly valued by employers and directly impacts your ability to contribute effectively. To maximize your job prospects, create a compelling, ATS-friendly resume that showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. They provide examples of resumes tailored to Color Mixing and Formulation to guide you through the process. Invest the time to craft a strong resume; it’s your first impression and a key step in securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good