Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Color Separation and Spot Color Printing interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Color Separation and Spot Color Printing Interview

Q 1. Explain the difference between process color (CMYK) and spot color printing.

The core difference between process color (CMYK) and spot color printing lies in how colors are created. Process color uses a combination of four inks – Cyan, Magenta, Yellow, and Key (black) – to create a wide range of colors by overlapping them. Think of it like mixing paints to get a specific shade. Spot color, on the other hand, uses pre-mixed, single inks, each with its unique formula and color. This is like using a specific color of paint straight from the can.

For instance, a vibrant Pantone blue would be a spot color, while a similar blue achieved by mixing CMYK inks would be a process color. The latter might not perfectly match the vibrancy or specific hue of the Pantone blue.

Q 2. Describe the process of color separation for a four-color print job.

Color separation for a four-color print job is the process of breaking down a full-color image into four separate plates, one for each CMYK ink. This is traditionally done using specialized software. The software analyzes the image’s color information, determining the precise percentage of each CMYK ink needed to reproduce each color in the image on each plate. For example, a bright red might be comprised of 0% Cyan, 100% Magenta, 100% Yellow, and 0% Black. These percentages are then used to create the halftone dots which form the image on each plate.

Think of it like a color filter separating the light: each plate only prints its designated color’s value, and together they recreate the image. Modern digital workflows automate much of this process, but understanding the fundamentals is crucial for quality control and troubleshooting.

Q 3. What are the common spot color systems used in printing (e.g., Pantone)?

The most widely recognized and used spot color system is Pantone Matching System (PMS). Pantone provides a standardized library of spot color formulas, each assigned a unique number (e.g., Pantone 18-1664 TPX – a classic red). This ensures that a specific color can be consistently reproduced across different printers and locations. Other spot color systems exist but lack the widespread adoption and standardization of Pantone. Designers specify the Pantone number directly within their artwork, ensuring accurate color reproduction by the printer.

Imagine it like a universal language for color: everyone using Pantone understands the same ‘code’ for a given shade.

Q 4. How do you handle color matching in spot color printing?

Color matching in spot color printing involves a meticulous process. It begins with selecting the appropriate spot color from a system like Pantone. A color proof, often a physical sample created by the printer using the chosen spot color ink, is then compared to the design file. Small adjustments might be needed to account for variations in paper stock, ink density, and the printing process. Experienced printers utilize color measuring instruments – spectrophotometers – to objectively quantify the color values and ensure precision matching.

This iterative process, involving visual checks and instrument measurements, is crucial for guaranteeing the final printed product matches the client’s expectations, often involving several rounds of adjustments and proofing.

Q 5. What are the advantages and disadvantages of using spot colors versus process colors?

Spot and process colors each have their own strengths and weaknesses:

- Spot Colors: Advantages: Vibrant, consistent colors, particularly for specific brand colors or metallic effects (gold, silver). Ideal for logos and branding where consistency is crucial.

- Spot Colors: Disadvantages: More expensive (requires additional ink plates), limited color gamut compared to process, difficult to create smooth color gradients.

- Process Colors: Advantages: Cost-effective (fewer plates), wider color gamut allowing for a broader range of colors, smoother gradients.

- Process Colors: Disadvantages: Can be less vibrant than spot colors, color consistency can vary slightly between print runs due to variations in ink and press settings.

The best choice depends on the specific project requirements and budget. For example, a corporate logo would likely benefit from spot color for its brand consistency, while a full-color photograph would usually be better suited to process colors.

Q 6. Explain the concept of color gamut and its relevance to spot color printing.

The color gamut represents the range of colors that can be reproduced using a particular printing method or device. Spot color printing has a limited gamut because it’s restricted to the specific inks available. Process color printing has a broader gamut since mixing CMYK inks allows for a greater variety of colors but may still not capture the full spectrum of visible light. This is critical because a color outside a printing system’s gamut cannot be perfectly reproduced, leading to color shifts or limitations in achieving the desired shades.

Imagine a painter’s palette: spot color is using only the colors pre-mixed on the palette, while process color is mixing those pre-mixed paints to create additional shades but still within the limits of the paints available.

Q 7. How do you ensure color consistency across different printing methods?

Ensuring color consistency across different printing methods requires careful planning and execution. Using standardized color systems such as Pantone is essential. Calibrating equipment, particularly printers and spectrophotometers, is crucial. Color profiles, which provide a numerical description of a printer’s capabilities, should be used and regularly checked. The printer’s experience and expertise play a critical role, as they can fine-tune press settings and ink densities to maintain consistency. Accurate pre-press proofing procedures are also key to verifying color accuracy before proceeding to production printing.

This is similar to a chef following a precise recipe, using calibrated equipment to ensure consistent results. Even slight variations in ingredients or cooking temperature could lead to inconsistencies in the final dish.

Q 8. Describe your experience with color proofing and its importance in spot color jobs.

Color proofing is a crucial step in the pre-press process, especially for spot color jobs, where specific ink colors are used rather than process colors (CMYK). It involves creating a physical or digital representation of the final printed piece to ensure the colors match the client’s expectations and the design intent. This is far more important in spot color because slight variations in color can be significantly more noticeable than with process colors, which are more forgiving.

In my experience, I’ve used various proofing methods, including soft proofs (digital proofs on calibrated monitors) and hard proofs (printed proofs on the same stock and using the same printing process as the final job). For spot color jobs, a hard proof is generally essential, as it allows for a visual verification of the exact spot color shades against the client’s pantone reference or color swatch. Any discrepancies are identified and corrected *before* the actual print run, thus preventing costly reprints and delays. For example, a client’s corporate logo, printed using a specific Pantone color, would require meticulous color proofing to ensure consistent brand identity across all materials.

Q 9. What software and tools are you familiar with for color separation and management?

My expertise encompasses a wide range of software and tools for color separation and management. I’m proficient in Adobe Creative Suite (Photoshop, Illustrator, InDesign), which are industry standards for color manipulation and prepress preparation. These tools allow me to accurately create spot color separations, manage color profiles, and generate accurate color proofs. I also have experience with dedicated color management software like X-Rite Color i1Profiler and GMG ColorProof, which allow for fine-tuning of color profiles and detailed color analysis. In terms of hardware, I’m familiar with spectrophotometers (like X-Rite i1 iSis) and densitometers, which are crucial for measuring and quantifying colors accurately. These are essential for ensuring the consistency and accuracy of the color in both the proofing stage and the final output.

Q 10. How do you handle color variations between different print runs?

Color variations between print runs can stem from many factors: variations in the printing press, ink consistency, paper stock, environmental conditions, etc. To minimize these variations, rigorous quality control measures are implemented. This includes using calibrated equipment for consistent color measurement throughout the process, employing a standardized color management system (with consistent ICC profiles), and maintaining meticulous control over the printing environment (temperature, humidity).

Furthermore, I always recommend producing a color control strip on each print run. This strip contains known color patches, allowing for immediate comparison with previous print runs and helping identify any unexpected shifts. If discrepancies arise, analysis is conducted to pinpoint the source of the variation. It might involve recalibrating the printing press, examining the ink batches, or even testing a new paper stock. Careful documentation of each print run, including all relevant settings and conditions, is crucial for effective troubleshooting and future consistency.

Q 11. Explain the significance of color profiles (ICC profiles) in color management.

ICC profiles (International Color Consortium profiles) are digital files that characterize the color properties of a device, such as a monitor, printer, or scanner. They act as translators, enabling devices to communicate and reproduce colors consistently across various platforms. For example, an ICC profile for a specific printer defines how that printer interprets and renders colors. Without them, the same color could appear drastically different on different devices.

In spot color printing, accurate ICC profiles are vital to ensure the intended spot color is accurately reproduced. The profile for the specific printer and the spot color ink being used must be correctly assigned and embedded within the print file. This ensures that the color is interpreted and rendered consistently across different printers that might utilize the same ink but have slightly different physical characteristics.

Q 12. What is dot gain, and how does it affect spot color printing?

Dot gain refers to the increase in the size of ink dots during the printing process. Think of it like this: you intend to print a small dot of color, but during the printing process, the dot spreads slightly, resulting in a larger dot on the paper. This is caused by the interaction between the ink and the substrate (paper). Dot gain affects spot color printing by altering the perceived color and tone of the print. A higher dot gain can lead to darker, less saturated colors than intended.

Managing dot gain is crucial for accurate spot color reproduction. This is often addressed through careful calibration of the printing press and the use of compensation techniques during the pre-press process. Software tools allow for adjustments to account for the expected dot gain, ensuring the final printed color matches the design intent.

Q 13. How do you troubleshoot color inconsistencies in a print job?

Troubleshooting color inconsistencies involves a systematic approach. First, I’d visually inspect the print job, identifying the specific areas with color deviations. Then I’d check the color control strip (if present) to assess the overall consistency across the sheet. This helps determine if the inconsistency is localized or widespread. Next, I’d examine the pre-press files, verifying the accuracy of color separations, the correct application of spot color definitions, and the accuracy of the ICC profiles used.

If the problem isn’t in the digital files, I’d investigate the printing process. This involves assessing the press settings, ink consistency, paper moisture content, and the overall printing environment. Using a spectrophotometer, I would measure the colors in the problematic areas and compare them to the target values. Based on these measurements, adjustments would be made to the press settings, ink, or other variables to correct the color inconsistencies. This iterative process of analysis, adjustment, and verification is essential to obtain the desired color accuracy.

Q 14. Describe your experience working with different substrates and their impact on color reproduction.

Different substrates (printing materials like paper, cardstock, or other specialty materials) significantly impact color reproduction. The type of paper (coated vs. uncoated, its brightness, and its absorbency) affects how ink is absorbed and reflected, altering the final color appearance. Coated papers typically result in more vibrant colors with less dot gain, while uncoated papers tend to exhibit higher dot gain and softer, less saturated colors. For example, a Pantone 185 C might appear significantly different when printed on a glossy coated stock versus a matte uncoated stock.

My experience includes working with a wide range of substrates, and I always consider the substrate’s properties during the color management process. This involves selecting the appropriate ICC profiles for the specific substrate, adjusting the color separations to compensate for its characteristics, and potentially creating custom profiles for unique substrates if high color accuracy is crucial. Thorough testing and proofing on the intended substrate are crucial to ensure the desired color results are achieved.

Q 15. What are some common issues encountered during spot color printing, and how do you address them?

Spot color printing, while offering vibrant and consistent colors, presents unique challenges. Common issues include:

- Trapping issues: Where two spot colors meet, one might bleed over the other, creating an uneven edge. This is particularly noticeable with light colors against dark ones. Addressing this involves careful trapping adjustments in the design software, specifying the type of trap (e.g., inside, outside) and the amount of overlap.

- Ink consistency: Variations in ink viscosity across different batches can lead to color inconsistencies throughout a print run. Regular color checks throughout the print job and using standardized ink mixing techniques are crucial to mitigate this.

- Color matching challenges: Achieving precise color matching between the proof and the final printed piece can be difficult, especially with complex spot colors. Utilizing color management systems and working closely with the printer to establish a color profile for the specific inks and press are vital steps.

- Drying issues: Some spot colors, particularly those with high pigment concentrations, can take longer to dry, potentially causing smudging or offsetting. Selecting the right paper and using appropriate drying methods are important solutions.

- Press limitations: Not all printing presses are equally equipped to handle spot colors accurately. The press condition, the skill of the press operator, and the type of printing method (e.g., offset, screen) all have an impact.

Successfully addressing these issues requires a proactive approach, encompassing pre-press planning, precise color management, careful press setup, and rigorous quality control throughout the printing process. I find it extremely beneficial to work closely with the printer to establish clear communication and expectations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the correct ink density for a spot color?

Determining the correct ink density for a spot color is a crucial step in achieving the desired color. It’s not simply a matter of intuition; rather, it’s a precise process that involves a combination of techniques.

- Pantone specifications: For Pantone colors, the Pantone Formula Guide provides exact ink recipes. These recipes specify the percentages of each base color (cyan, magenta, yellow, and black – CMYK in process color) needed to match the spot color.

- Color proofs: I always rely on accurate color proofs created using a calibrated proofing system that closely matches the intended press conditions. These proofs serve as a benchmark, providing visual confirmation of the target color.

- Spectrophotometer readings: A spectrophotometer is a crucial tool. I use it to measure the color values of the print samples. By comparing these readings to the target values, any necessary adjustments can be made to the ink density to ensure accurate color reproduction.

- Density measurements: Density readings using a densitometer also help assess the accuracy of the color reproduction. Density is a critical factor in determining the overall visual richness and vibrancy of the spot color.

- Printer collaboration: Close collaboration with the printer is essential. Experienced press operators can offer valuable input, sharing their knowledge of the press and ink behavior to fine-tune the density for optimal results.

Remember, the ink density is often interconnected with other factors such as substrate type and printing conditions, which must be considered. I always document all the parameters and measurements involved during this process to ensure consistency and traceability.

Q 17. What is the difference between a colorimetric and spectral measurement?

Colorimetric and spectral measurements both quantify color, but they approach it differently.

- Colorimetric measurement simplifies color to three or four values (often L*a*b* or XYZ), representing the color’s perceived lightness, redness/greenness, and yellowness/blueness. It’s like describing a color with a simplified shorthand. Think of it as a summary of color.

- Spectral measurement captures the color’s reflectance or transmittance at many different wavelengths across the visible spectrum. This produces a detailed profile showing how much light is reflected or transmitted at each wavelength. It’s like creating a detailed fingerprint of the color, providing much more information.

The key difference is resolution: Colorimetric measurement is a summary; spectral measurement is much more detailed, capturing the full spectral distribution. I typically utilize spectral measurement in critical applications because of its high precision and the capacity to make very fine adjustments for color matching.

Q 18. Explain your experience with colorimetric calculations.

My experience with colorimetric calculations is extensive. I’m proficient in using color management software (like X-Rite i1Profiler or similar) to perform transformations between different color spaces (e.g., RGB, CMYK, Lab).

For instance, I’ve used colorimetric calculations to:

- Convert RGB designs to CMYK: Ensuring accurate color representation during the transition from digital design to print. This requires careful profiling to minimize color shifts.

- Predict color changes based on substrate: Different paper types absorb inks differently, impacting the final color. I employ colorimetric calculations to anticipate these shifts and make adjustments in advance.

- Calculate spot color equivalents: Approximating a spot color using process colors (CMYK) when the spot color is unavailable, providing a close alternative. This involves optimizing the CMYK values to best match the target spot color’s L*a*b* coordinates.

- Monitor color consistency: Throughout the printing process, colorimetric data gathered from spectrophotometer readings are analyzed to ensure consistency and adjust the press parameters as needed. This allows me to detect and correct subtle color variations early on.

My expertise in these calculations has been instrumental in providing clients with predictable and accurate color reproduction, exceeding expectations on a number of challenging projects.

Q 19. How would you handle a client’s request for a specific pantone color not readily available?

When a client requests a Pantone color that’s not readily available, several options exist:

- Pantone Color Matching System (PMS): First, I verify that the specific Pantone color truly isn’t available. Sometimes, there are similar alternatives within the Pantone library. If it’s a very close relative, I might suggest this alternative and create a color proof to ensure acceptance.

- Custom color matching: If no suitable alternative exists, I would work with the printer to create a custom spot color. This involves using a spectrophotometer to measure the color from a sample provided by the client (a fabric swatch, for example) and using that data to develop an ink recipe that closely matches the target color.

- Process color approximation: As a last resort, a close approximation of the color using process colors (CMYK) may be necessary. This method however, will likely result in a slightly different shade than the originally requested Pantone color, and the stability of this reproduction may be less reliable.

- Client communication: Throughout this process, clear communication with the client is paramount. I will explain the alternatives, their limitations, and their potential impact on cost and delivery timelines.

The approach taken will depend on the client’s budget, color criticality, and the overall project requirements. My experience has taught me to handle these situations with careful analysis and transparent communication.

Q 20. Explain the process of creating a custom spot color.

Creating a custom spot color is a meticulous process that requires specialized equipment and expertise.

- Obtain a color sample: The client will provide a color sample – be it a fabric swatch, a paint chip, or a digital image. The sample defines the target color.

- Spectrophotometric measurement: Using a spectrophotometer, I measure the spectral reflectance or transmittance of the color sample. This captures the color’s exact spectral profile.

- Ink formulation: This spectral data is used by a color matching software or by an experienced color technician to formulate an ink recipe. This involves determining the proportions of each base pigment needed to achieve the desired color. Several iterations of this process are often needed.

- Test prints: Test prints are made using the formulated ink to validate the color match. A spectrophotometer measures the test print’s color, and the recipe is refined to minimize any discrepancies.

- Color approval: The client approves the final color match before it’s used in large-scale printing.

The whole process demands precision and a skilled understanding of color science and ink behavior. It is vital to record all parameters during each step so that the color can be reproduced consistently for future orders.

Q 21. What is your experience with different printing presses and their capabilities regarding spot color?

My experience spans various printing presses, including offset, screen printing, and digital printing presses. Each has its own capabilities and limitations regarding spot color:

- Offset Printing: Offset presses are highly versatile and generally produce excellent results with spot colors. However, setup and ink changes can be time-consuming and potentially costly.

- Screen Printing: Screen printing is an ideal method for high-impact spot colors, especially with vibrant and opaque inks. It’s excellent for producing very large quantities as well.

- Digital Printing: Digital printing offers the advantage of on-demand printing, reducing waste and eliminating setup costs. However, the number of spot colors that can be used is sometimes more restricted. The color gamut may also be limited.

My knowledge extends to different press configurations and ink types, allowing me to select the most appropriate method for each project, ensuring optimum color accuracy and efficiency. I also understand the limitations of each press and adapt my color management strategies accordingly. For example, I know that achieving specific metallic or fluorescent colors may require different approaches across these platforms.

Q 22. How do you ensure accurate color reproduction across different printing devices?

Accurate color reproduction across different printing devices is paramount. Think of it like baking a cake – you need the same ingredients and precise measurements to get consistent results. In print, this consistency relies on a combination of color management techniques and device profiling.

Firstly, we use a standardized color space, typically CMYK (Cyan, Magenta, Yellow, and Black) or sometimes Pantone Matching System (PMS) for spot colors. This provides a common language for all devices. Secondly, we create ICC profiles for each device (printer, monitor, scanner). These profiles act as translators, mapping the color values in the digital file to the specific color capabilities of each device. Without them, colors can appear drastically different. For example, a vibrant green on your screen might print as a dull olive green without a proper profile.

To ensure accuracy, we utilize color proofing. This involves creating a physical proof – a sample print – using the target printing method. This allows us to compare the screen colors to the final printed output and make adjustments to the file before the final print run. Proofing is crucial to catch unexpected color shifts and avoid costly reprints.

Furthermore, we always establish clear communication with the print vendor, specifying the required color standards and providing them with the relevant ICC profiles. Regular color calibration of all devices is also essential to maintain consistent results over time.

Q 23. Describe your workflow for managing and handling color separation files.

My workflow for managing and handling color separation files begins with meticulous organization. I always use a consistent file naming convention and keep files neatly organized in dedicated folders. Think of it like a well-stocked library – easy to find what you need when you need it.

I typically receive files in a digital format like PDF or TIFF, and I always verify they meet the necessary resolution and color specifications. I use dedicated software such as Adobe Acrobat Pro and Adobe Photoshop to assess and prepare the files. This includes checking for color inconsistencies, low resolution areas, and embedded profiles. This is where attention to detail is critical to avoid problems downstream.

For color separation, I leverage software to separate the CMYK or spot colors into individual plates. This process ensures each color is printed correctly on its respective plate. I’ll double-check all separations carefully, making sure each plate has the proper information and no elements are unintentionally omitted or duplicated.

Finally, after separation, I conduct a pre-flight check before exporting the separated files in the appropriate format for the printing press. This step is crucial and saves a lot of time and potential problems in printing.

Q 24. What are your methods for quality control in spot color printing?

Quality control in spot color printing requires a multifaceted approach. It’s not just about getting the right color on the page; it’s about consistency and ensuring it matches the client’s expectations. We start with a detailed review of the provided Pantone color specifications – it’s critical to be exact.

My methods include:

- Color Proofing: Just as with CMYK, creating a spot color proof is fundamental. This lets us compare the printed color to the PMS standard, verifying accuracy.

- Ink Consistency Checks: We rigorously monitor the ink mixing process, particularly during set up, ensuring the exact amount of each ingredient is used. This is a must for consistent color across runs. This is where experience and understanding of ink behaviour is essential

- Visual Inspection: I always perform a thorough visual inspection of printed sheets, checking for color variations, banding, or other defects. I often use a light box for close analysis.

- Spectrophotometer Measurements: We employ a spectrophotometer to measure the color values objectively and numerically. This provides quantifiable data for comparison to the target PMS values. Discrepancies here are often highlighted and require adjustments.

I always maintain detailed records of color specifications, proof approvals, and quality control measurements. This documentation is essential for addressing potential issues later on and shows a meticulous approach to the job.

Q 25. How familiar are you with various print finishing techniques that impact color appearance?

Print finishing techniques significantly affect color appearance. Think of it as applying makeup after putting on your clothes – it enhances and modifies the overall look. My familiarity with these techniques is extensive, and I consider their impact during the design phase.

For instance, lamination can alter color saturation; matte lamination can dull colors while gloss lamination intensifies them. Similarly, coating types, such as UV coatings, affect the final color and its perceived brightness. Even the type of paper impacts color; uncoated papers generally appear more muted than coated ones. Other finishing processes like embossing and foil stamping also affect color by adding texture and shine, potentially altering the perception of the printed colors.

Understanding these effects is vital in predicting the final outcome and selecting the appropriate techniques to best showcase the design’s colors. I often discuss the finishing techniques with the client to determine the desired look and effect and advise them about the impact on the colors.

Q 26. How do you maintain and calibrate color measuring devices?

Maintaining and calibrating color measuring devices is critical for accurate color reproduction. Neglecting this can lead to significant color inaccuracies that ripple through the entire print production process.

My routine involves regular cleaning of the device’s measuring head to prevent dust and debris from affecting readings. I then use calibration plates or tiles provided by the device manufacturer. These plates are specifically designed to provide known color values that the spectrophotometer uses for calibration.

The calibration process usually involves placing the calibration plate under the device’s measuring head and following the manufacturer’s instructions, often guided by the device’s software. This process ensures that the device is reading colors accurately relative to a set standard. Frequency of calibration depends on the device and usage frequency; however, I generally calibrate at least monthly, or more often if the device is used heavily.

Maintaining detailed calibration logs is essential to trace any potential discrepancies. This creates a valuable history of the device performance and helps troubleshoot issues quickly should they arise.

Q 27. Describe your experience in working with print vendors and managing color expectations.

Working with print vendors and managing color expectations requires clear communication and a collaborative approach. It’s about building trust and ensuring everyone is on the same page. I begin by providing detailed instructions regarding color specifications, including the color space (CMYK or PMS), ICC profiles, and color proofing information. Open communication is key to success.

I always schedule a pre-press meeting with the vendor to discuss the project requirements and review the files. This allows us to address any potential problems or concerns early on, avoiding costly delays or reprints. During this meeting, I confirm ink types and paper stock to ensure we have the appropriate materials to achieve the desired color results.

After receiving the first press proof, I conduct a thorough comparison against the provided reference and the proof, using both visual inspection and spectrophotometer measurements. Any discrepancies are addressed immediately. This iterative process ensures the final product accurately reflects the design intent and client’s expectations.

Building strong relationships with print vendors is crucial. Over time, I’ve established working relationships with vendors I trust because they know my work standards and provide consistently accurate results.

Key Topics to Learn for Color Separation and Spot Color Printing Interviews

- Color Models: Understanding CMYK, RGB, Pantone Matching System (PMS), and their respective applications in print production. Focus on the differences and when each is appropriate.

- Color Separation Techniques: Explore the process of separating a full-color image into its CMYK components. Understand the role of halftones and the impact of screen angles.

- Spot Color Printing: Master the principles of using spot colors, including PMS color selection, ink mixing, and considerations for achieving accurate color reproduction.

- File Preparation for Print: Learn about preparing files for different printing methods, including proper resolution, color profiles, and bleed settings. Understand the importance of preflighting.

- Color Management: Grasp the concepts of color profiles, color spaces, and their importance in maintaining color consistency throughout the printing process. Practice using color management tools.

- Troubleshooting Color Issues: Develop skills in identifying and resolving common color problems in print, such as banding, moiré patterns, and inaccurate color reproduction. Practice problem-solving approaches.

- Press Considerations: Familiarize yourself with different printing presses and their impact on color reproduction. Understand the role of press calibration and color proofing.

- Practical Applications: Consider real-world examples like packaging design, corporate branding, and fine art printing. How do color choices impact the final product?

Next Steps

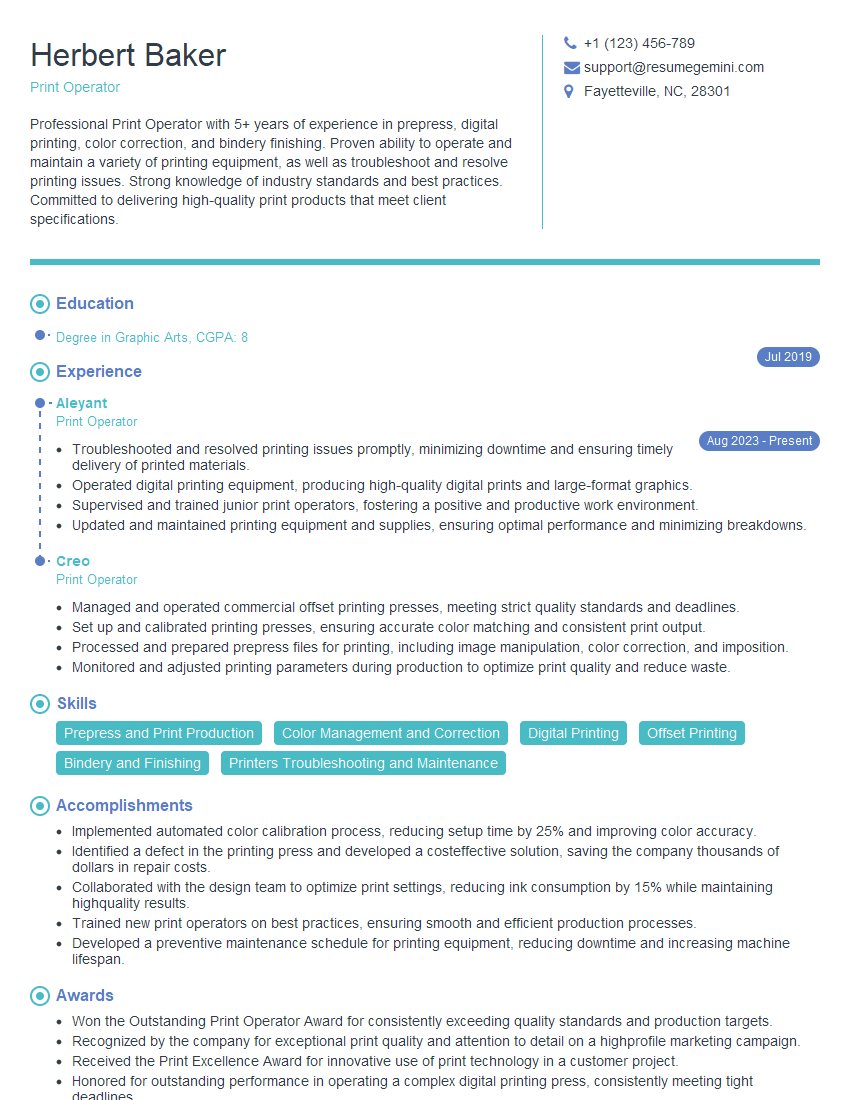

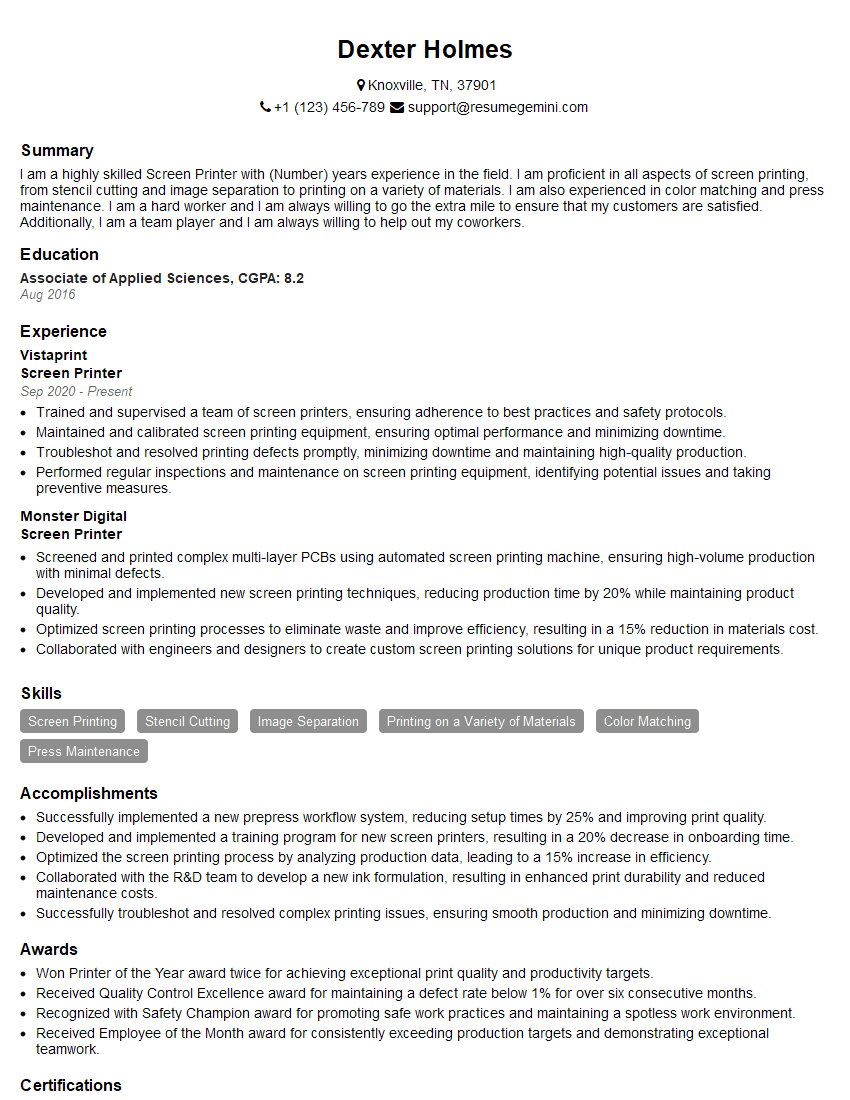

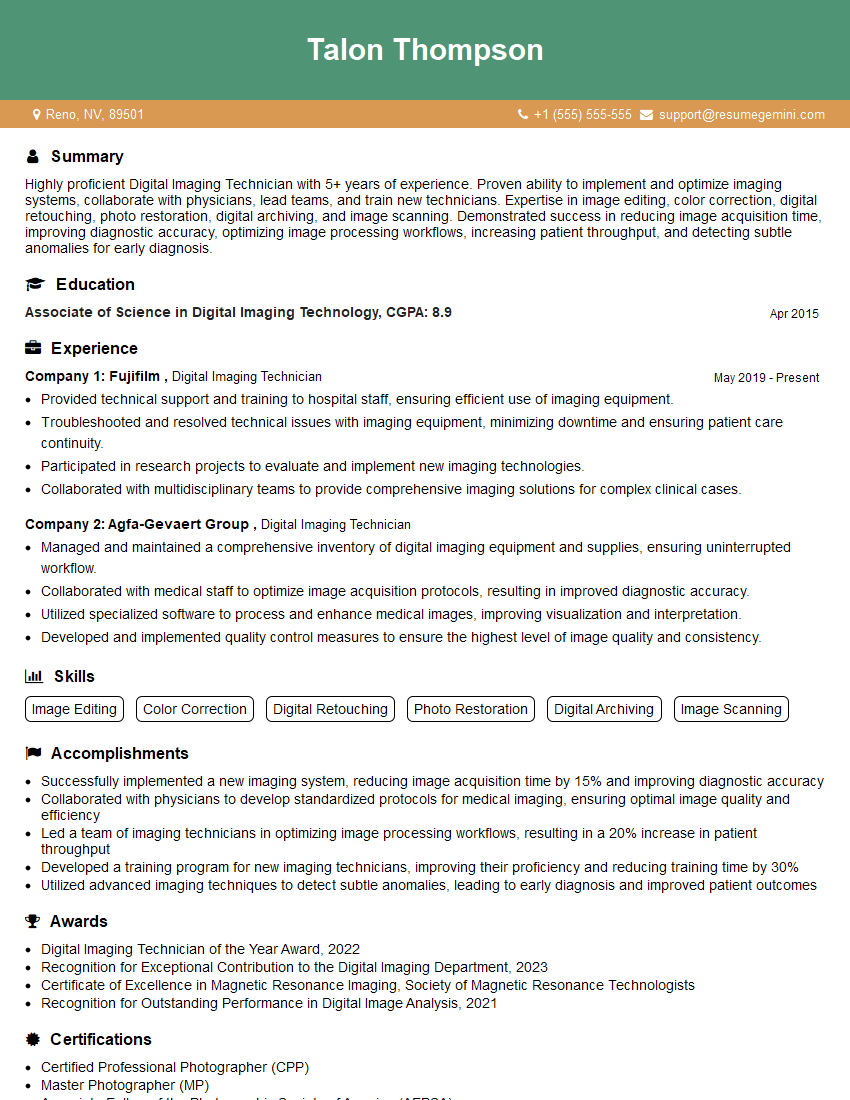

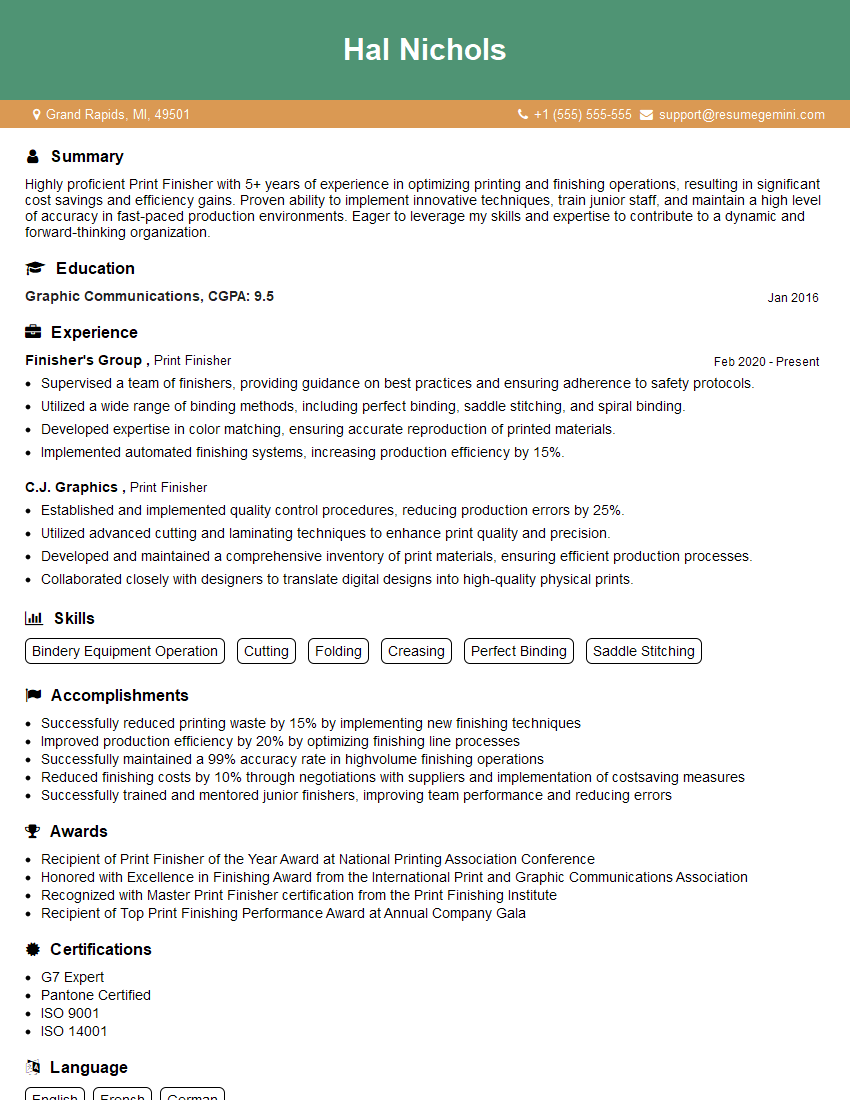

Mastering Color Separation and Spot Color Printing is crucial for career advancement in the graphic arts and printing industries. A strong understanding of these concepts demonstrates valuable technical skills and opens doors to exciting opportunities. To maximize your job prospects, create an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource for building professional and effective resumes. They offer examples of resumes tailored to Color Separation and Spot Color Printing to help you showcase your skills effectively. Take the next step in your career journey – craft a compelling resume that captures your expertise and sets you apart from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good