Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Compliance with Safety and Environmental Regulations interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Compliance with Safety and Environmental Regulations Interview

Q 1. Explain your understanding of OSHA regulations.

OSHA, or the Occupational Safety and Health Administration, sets and enforces standards designed to protect workers from hazards in the workplace. My understanding encompasses a wide range of regulations, including those covering hazard communication (SDS and labeling), personal protective equipment (PPE), machine guarding, lockout/tagout procedures, confined space entry, fall protection, and emergency action plans. I’m familiar with the OSHA General Duty Clause, which mandates employers provide a workplace free from recognized hazards, even if not explicitly covered by a specific standard. I also understand the importance of OSHA recordkeeping, inspections, and the potential penalties for non-compliance, including fines and citations. For example, in a previous role, I assisted in implementing a comprehensive lockout/tagout program to prevent accidental machine starts, resulting in a significant reduction in near-miss incidents.

Beyond the specific standards, I understand the process of conducting OSHA inspections, including the opening conference, walkthrough, closing conference, and the issuance of citations. This understanding allows me to proactively identify potential hazards and implement corrective actions before an inspection.

Q 2. Describe your experience with ISO 14001 environmental management systems.

My experience with ISO 14001 Environmental Management Systems involves implementing, maintaining, and auditing these systems in various industrial settings. ISO 14001 provides a framework for organizations to systematically manage their environmental impacts. This includes identifying environmental aspects (activities that can impact the environment), assessing their associated risks and opportunities, setting environmental objectives and targets, implementing and monitoring controls, and continually improving the EMS. I’ve been involved in every stage of the process, from the initial gap analysis to document control and internal audits. I’ve also participated in external audits to ensure compliance with the standard. For example, in a previous role, we implemented an ISO 14001 compliant system resulting in a 20% reduction in waste generation and a 15% decrease in energy consumption.

I understand the Plan-Do-Check-Act (PDCA) cycle central to ISO 14001, which is essential for continuous improvement. This cyclical approach helps identify areas for improvement and refine environmental performance consistently. A strong understanding of legal and regulatory requirements is critical, ensuring compliance with all relevant environmental regulations, which varies significantly depending on location and industry.

Q 3. How do you conduct a risk assessment?

Conducting a risk assessment involves systematically identifying hazards, analyzing their potential consequences, and evaluating the likelihood of those consequences occurring. It’s a crucial step in any safety and environmental management program. My approach typically follows a structured methodology, often using a matrix or scoring system. I begin by identifying potential hazards through a variety of methods, including site surveys, hazard checklists, job safety analyses (JSAs), and input from employees. Then, I analyze the severity of potential consequences, ranging from minor injuries to environmental damage or fatalities. Finally, I assess the likelihood of each hazard occurring. The combination of severity and likelihood determines the overall risk level, allowing prioritization of risk mitigation efforts.

For instance, in a manufacturing facility, I might identify the hazard of chemical spills. I’d then assess the severity (potential for injury, environmental contamination, equipment damage) and likelihood (frequency of handling chemicals, effectiveness of current safeguards). This assessment would inform the implementation of controls, such as improved spill containment, enhanced employee training, and regular equipment inspections.

Q 4. What are the key components of a successful environmental compliance program?

A successful environmental compliance program requires several key components working together. First, strong leadership commitment is crucial. Management must demonstrate a genuine commitment to environmental stewardship and allocate the necessary resources. Second, a thorough understanding of all applicable environmental regulations is vital. This involves staying updated on changes in legislation and interpreting regulations in the context of the specific operations. Third, effective training programs for employees at all levels are essential to instill environmental responsibility and ensure compliance. Fourth, robust monitoring and record-keeping systems are necessary to track environmental performance and demonstrate compliance to regulatory agencies.

Furthermore, a proactive approach to identifying and mitigating potential environmental risks is key. This includes conducting regular environmental audits and implementing robust procedures for handling waste, emissions, and other environmental aspects. Finally, a culture of environmental responsibility needs to be fostered throughout the organization. This includes encouraging employee participation in environmental initiatives and rewarding environmentally responsible behaviors. In essence, it’s a holistic approach integrating policies, procedures, training, and a commitment to continuous improvement.

Q 5. Explain your experience with environmental audits.

My experience with environmental audits includes both internal and external audits. Internal audits are crucial for identifying gaps in compliance and areas for improvement within an organization’s environmental management system. I’ve conducted numerous internal audits, using checklists and procedures to ensure all aspects of the EMS are reviewed. I’ve focused on verifying the effectiveness of implemented controls, reviewing compliance with regulations, and identifying opportunities for improvement. This typically involves reviewing records, observing operations, and interviewing employees. Findings are documented in a comprehensive report, detailing non-conformances and recommending corrective actions.

External audits, conducted by third-party certification bodies, assess an organization’s compliance with standards such as ISO 14001. I have assisted organizations in preparing for these audits, ensuring all necessary documentation is available and procedures are adequately implemented. My experience involves understanding the audit process, responding to auditor questions, and addressing any identified non-conformances. Successful external audits demonstrate a high level of environmental compliance and commitment to best practices.

Q 6. Describe your experience with incident reporting and investigation.

Incident reporting and investigation are critical components of any safety and environmental management system. My experience involves developing and implementing robust systems for reporting and investigating incidents, ranging from minor spills to major accidents. The process begins with prompt reporting—often through a designated reporting system—that includes detailed information about the incident, including date, time, location, and involved personnel. Then, a thorough investigation is undertaken to determine the root cause of the incident, identify contributing factors, and recommend preventative measures. This might involve interviewing witnesses, reviewing records, analyzing data, and potentially using specialized investigation techniques.

For example, if a chemical spill occurred, the investigation would analyze factors like the cause of the spill (equipment failure, human error), the effectiveness of existing spill containment measures, and the adequacy of employee training. The findings would then inform corrective actions, such as improved equipment maintenance, enhanced training procedures, and revision of safety protocols. The goal is not only to address the immediate incident but also to prevent similar incidents from happening in the future. Proper documentation of the incident, investigation, and corrective actions is crucial for continuous improvement and demonstrating compliance.

Q 7. How do you ensure compliance with air emission regulations?

Ensuring compliance with air emission regulations requires a multi-faceted approach. First, a thorough understanding of all applicable regulations is crucial, which varies significantly depending on the location, industry, and specific emission sources. This might include federal, state, and local regulations. Next, regular monitoring and testing are necessary to ensure emissions remain within permitted limits. This often involves using specialized equipment to measure emissions and collecting samples for analysis. Then, effective emission control technologies must be implemented and maintained. These might include scrubbers, filters, or other technologies designed to reduce emissions. Regular maintenance and calibration of this equipment are crucial for optimal performance.

Beyond technology, strong record-keeping practices are essential to demonstrate compliance. This includes meticulously documenting emission monitoring data, maintenance records for emission control equipment, and any corrective actions taken to address exceedances. Furthermore, employee training is critical to ensure personnel understand their roles in emissions control and are proficient in operating and maintaining the necessary equipment. Finally, a proactive approach to identifying and mitigating potential emission issues is crucial, incorporating regular assessments and continuous improvement efforts to ensure long-term compliance.

Q 8. How do you manage hazardous waste?

Hazardous waste management is a multifaceted process requiring strict adherence to regulations. It begins with proper waste characterization – identifying the type and quantity of hazardous materials generated. This involves understanding their physical, chemical, and toxicological properties, consulting relevant safety data sheets (SDS), and classifying them according to local, national, and international regulations (e.g., EPA hazardous waste codes in the US).

Next is segregation and containment. Hazardous wastes are separated according to their characteristics and stored in designated containers, ensuring they are properly labeled and secured to prevent spills, leaks, or unauthorized access. This might involve using specialized drums, bins, or tanks depending on the waste type. For example, reactive materials are kept separate from incompatible substances to prevent dangerous reactions.

Then comes treatment, disposal, or recycling. Depending on the waste type and regulatory requirements, it may be treated on-site (e.g., neutralization, incineration) or transported to a licensed facility for appropriate disposal or recycling. This always involves meticulous record-keeping, tracking waste from cradle to grave, with detailed manifests documenting transportation and disposal. Regular audits ensure ongoing compliance.

Finally, emergency preparedness is crucial. Plans must be in place to handle spills, leaks, or other incidents, including appropriate personal protective equipment (PPE), emergency response procedures, and training for personnel. Think of a chemical spill – immediate containment, cleanup, and notification to the relevant authorities are paramount. Proper emergency response can minimize the environmental and health impacts.

Q 9. What is your experience with wastewater treatment regulations?

My experience with wastewater treatment regulations spans over a decade, working with various industries including manufacturing and food processing. I’m proficient in navigating the complexities of the Clean Water Act (CWA) in the US, specifically the National Pollutant Discharge Elimination System (NPDES) permit process. This involves understanding effluent limitations, monitoring requirements, and reporting procedures.

I have extensive experience in developing and implementing wastewater treatment plans, optimizing processes to meet permit limits, and managing the associated compliance documentation. This includes conducting regular sampling and analysis, interpreting results, and making necessary adjustments to treatment processes. For instance, I once helped a food processing plant reduce its BOD (Biochemical Oxygen Demand) levels by over 30% through process optimization and the implementation of a new anaerobic digestion system.

I’m also familiar with various wastewater treatment technologies, including activated sludge, membrane bioreactors, and advanced oxidation processes. Selecting the appropriate technology is critical based on the characteristics of the wastewater and the regulatory requirements. Successful implementation necessitates careful consideration of cost, efficiency, and long-term sustainability.

Q 10. Explain your understanding of spill prevention, control, and countermeasures (SPCC).

Spill Prevention, Control, and Countermeasures (SPCC) plans are crucial for facilities that store or handle significant quantities of oil and other hazardous substances. The primary goal is to prevent spills from happening in the first place, and then to minimize their impact if they do occur. These plans are legally mandated, with specific requirements determined by factors such as storage capacity and proximity to waterways.

A comprehensive SPCC plan includes several key elements: a facility description detailing storage areas and potential spill pathways; spill prevention measures such as secondary containment, leak detection systems, and proper equipment maintenance; spill response procedures, specifying steps to take in case of a spill, including containment, cleanup, and notification; and a training program ensuring personnel know their roles and responsibilities. It’s not simply a document; it’s a living document requiring regular updates and revisions to reflect changes in facility operations or new regulations.

For instance, I’ve developed SPCC plans for a variety of facilities, including a large manufacturing plant and a fuel storage depot. The plans detailed everything from the type of containment systems used to the emergency response team’s procedures, including contact lists for local agencies and emergency services. Regular drills and inspections ensured everyone was prepared and that the plan remained effective.

Q 11. How do you ensure compliance with water quality regulations?

Ensuring compliance with water quality regulations necessitates a multi-pronged approach. It starts with understanding the specific requirements relevant to the facility’s location and operations, usually defined by federal, state, and local laws. These often address parameters such as pH, temperature, dissolved oxygen, and various pollutants (heavy metals, organic chemicals).

This understanding translates into a robust monitoring program. This involves regular sampling of wastewater discharges or surface water according to a pre-defined schedule and methodology. The samples are then analyzed by a certified laboratory, and the results are carefully documented and compared against regulatory limits. Any exceedances require prompt investigation, corrective actions, and reporting to the authorities.

Beyond monitoring, proactive measures are key. This could involve implementing best management practices (BMPs) to prevent pollution at its source, upgrading wastewater treatment systems, or employing technologies to reduce pollutant discharges. Regular training of personnel on water quality issues and compliance procedures is also vital. Think of it like regular car maintenance – proactive measures prevent bigger problems later. Finally, keeping meticulous records of all monitoring data, compliance actions, and corrective measures is critical for demonstrating compliance and transparency.

Q 12. Describe your experience with developing and implementing safety training programs.

I have extensive experience in developing and implementing safety training programs for diverse workforces. My approach emphasizes a needs-based assessment to tailor training to the specific hazards and risks faced by employees. This might involve conducting job hazard analyses (JHAs) to identify potential hazards and the necessary safety precautions.

Training programs incorporate a mix of methods – classroom instruction, hands-on demonstrations, simulations, and online modules – to cater to different learning styles. For example, for a chemical handling safety training, I would combine classroom instruction on chemical properties and hazards with a hands-on demonstration of proper chemical handling techniques and protective equipment usage. I’d also incorporate interactive scenarios to test their knowledge of emergency procedures.

A critical component is ensuring the training is engaging and effective. Utilizing real-world case studies, interactive exercises, and regular assessments can enhance engagement and knowledge retention. Post-training evaluations and feedback help assess effectiveness and make improvements. Ultimately, a robust safety training program fosters a safety-conscious culture, reducing accidents and improving overall safety performance.

Q 13. How do you handle non-compliance situations?

Handling non-compliance situations requires a prompt, thorough, and transparent response. The first step is to identify the nature and extent of the non-compliance. This often involves reviewing monitoring data, inspection reports, or other relevant documentation. It’s crucial to accurately assess the root cause of the non-compliance – is it a systemic issue, a procedural failure, or a one-time event?

Once the root cause is identified, a corrective action plan (CAP) is developed. This plan outlines the steps needed to address the non-compliance, prevent its recurrence, and restore compliance. This could include upgrading equipment, modifying operational procedures, or providing additional employee training. The CAP should include specific timelines, responsible parties, and performance indicators to measure its effectiveness.

Depending on the severity of the non-compliance, it may be necessary to report the issue to the relevant regulatory authorities. This should be done promptly and transparently, providing all relevant information. It’s also important to document all actions taken, including the CAP, its implementation, and the results. This thorough documentation is crucial for demonstrating a commitment to compliance and mitigating potential penalties.

Q 14. What are your strategies for improving safety performance?

Improving safety performance is an ongoing process, not a one-time event. My strategies focus on proactive measures, employee engagement, and continuous improvement. This begins with a strong safety culture, fostered through leadership commitment, clear communication, and employee empowerment.

Data-driven decision-making is key. Tracking key safety indicators, such as accident rates, near misses, and safety violations, helps identify trends and areas needing attention. This data informs the development and implementation of targeted interventions. For instance, a high incidence of slips, trips, and falls might lead to improved housekeeping procedures and additional employee training.

Regular safety audits and inspections, conducted by both internal and external personnel, provide objective evaluations of safety performance and identify potential hazards. Implementing a robust hazard reporting system encourages employees to identify and report safety concerns without fear of retribution. Finally, participating in industry best practice sharing and benchmarking helps to adopt leading safety practices and continuously enhance our safety programs.

Q 15. How familiar are you with emergency response planning?

Emergency response planning is crucial for minimizing the impact of unforeseen events like chemical spills, fires, or natural disasters. It involves developing a comprehensive plan that outlines procedures for handling emergencies, ensuring the safety of personnel and the environment. This includes identifying potential hazards, establishing communication protocols, defining roles and responsibilities, and detailing evacuation procedures.

My experience encompasses developing and implementing emergency response plans for various industrial settings. For example, while working with a chemical manufacturing plant, I led the development of a plan that addressed the specific hazards associated with their operations. This included creating detailed response protocols for different scenarios, conducting regular drills to ensure preparedness, and managing the inventory of emergency equipment. We also integrated the plan with local emergency services to ensure seamless collaboration during a real incident.

A well-defined plan incorporates elements like site-specific hazard assessments, emergency contact lists, detailed response procedures for specific scenarios (e.g., chemical spills, fires), and post-incident analysis procedures for continuous improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with permit applications and renewals.

Permitting is a critical aspect of environmental compliance. It involves applying for and obtaining necessary permits to operate facilities that could potentially impact the environment. This process requires thorough documentation and adherence to regulatory requirements. Renewals necessitate demonstrating continued compliance with the conditions specified in the original permit.

In my career, I have successfully managed numerous permit applications and renewals, from simple air emissions permits to complex water discharge permits. For instance, I guided a client through the application process for a National Pollutant Discharge Elimination System (NPDES) permit. This involved preparing comprehensive reports detailing their wastewater treatment processes, conducting thorough monitoring, and submitting all required documentation to the regulatory agency. The successful renewal required demonstrating ongoing compliance and addressing any potential issues identified during the review period.

The process typically involves detailed preparation of forms, supporting documentation including environmental assessments, technical calculations (e.g., emission estimations, pollutant loading calculations), and consistent communication with regulatory authorities throughout the process.

Q 17. How do you stay up-to-date on changes in environmental regulations?

Staying current on environmental regulations is essential to maintaining compliance. The regulatory landscape is dynamic, with frequent updates and amendments. This requires a proactive approach involving a variety of resources.

My strategy includes subscribing to relevant newsletters and journals (such as those published by the EPA and relevant state agencies), attending industry conferences and workshops, actively participating in professional organizations like the Society of Environmental Toxicology and Chemistry (SETAC), and utilizing online resources such as government websites and legal databases. I also regularly review relevant legal updates and consult with legal counsel when necessary to ensure I understand the implications of any changes.

Think of it like learning a living language – continuous effort is essential to fluency. You cannot passively wait for information; active engagement is key to staying abreast of evolving requirements. For example, regularly checking the EPA’s website for updates on relevant regulations and guidance is a crucial part of my routine.

Q 18. Explain your experience with environmental monitoring and reporting.

Environmental monitoring and reporting are critical components of compliance. Monitoring involves systematically collecting data on environmental parameters (e.g., air and water quality, waste generation), while reporting involves summarizing the data and submitting it to regulatory authorities. This process demonstrates compliance with permits and regulations.

My experience includes designing and implementing comprehensive environmental monitoring programs for various industries. For example, I developed a program for a manufacturing facility to monitor air emissions, wastewater discharge, and solid waste generation. This involved selecting appropriate sampling methods, conducting regular monitoring activities, analyzing the collected data, and preparing comprehensive reports for submission to the relevant agencies. The reporting included detailed summaries of the data, statistical analysis where applicable, and any corrective actions taken to address any non-compliance issues.

Effective monitoring and reporting requires a meticulous approach. Data must be accurately collected, analyzed, and documented to demonstrate compliance. For instance, regular calibration and maintenance of monitoring equipment, as well as robust quality control procedures, are crucial to the accuracy and validity of the data.

Q 19. How do you manage environmental data and reporting?

Managing environmental data and reporting requires a structured and systematic approach. This involves using appropriate tools and techniques to organize, analyze, and interpret the data for accurate and timely reporting. This ensures compliance with regulatory requirements and facilitates data-driven decision-making.

I utilize a combination of software and databases to manage environmental data. This could include Environmental Management Systems (EMS) software, spreadsheets (Excel), and specialized databases. For example, I have used EMS software to track environmental performance indicators, manage permits, and prepare reports. The chosen system depends on the needs of the specific project or facility. Using such systems helps maintain consistent data organization, promotes accessibility, streamlines reporting processes, and reduces errors. Data validation and quality control measures are crucial throughout the process to ensure accuracy and integrity.

Data visualization techniques (e.g., charts, graphs) are critical for effective communication of the data, enabling decision makers to easily grasp trends and understand environmental performance.

Q 20. What is your experience with environmental impact assessments?

Environmental Impact Assessments (EIAs) are systematic studies conducted to predict the likely environmental consequences of a proposed project or development. The goal is to identify potential impacts, evaluate their significance, and propose mitigation measures to reduce negative effects. EIAs are essential for informing decision-making and ensuring environmentally sound practices.

I have significant experience in conducting and reviewing EIAs for a wide range of projects, including infrastructure developments, industrial facilities, and resource extraction projects. For example, I participated in the EIA for a new highway project. This involved assessing potential impacts on air and water quality, noise levels, habitat disruption, and other relevant factors. The process included detailed field studies, modeling, and stakeholder engagement to ensure comprehensive assessment and incorporation of mitigation measures into the project design. The resulting EIA report guided decision-makers in balancing development needs with environmental protection.

A well-structured EIA includes a comprehensive description of the project, an assessment of potential environmental impacts, mitigation measures, and a plan for monitoring and managing those impacts. Public participation and consultation are vital components of a robust EIA.

Q 21. How do you ensure compliance with transportation regulations for hazardous materials?

Ensuring compliance with transportation regulations for hazardous materials is critical to prevent accidents and protect public health and the environment. These regulations dictate how hazardous materials are packaged, labeled, transported, and handled during shipment. Non-compliance can lead to significant penalties and environmental damage.

My experience involves developing and implementing hazardous materials transportation plans that comply with regulations such as those set forth by the Department of Transportation (DOT). This includes ensuring proper documentation (e.g., shipping papers, emergency response information), selecting appropriate containers, and training personnel on safe handling procedures. I have worked with companies to ensure their transportation practices meet these regulations, frequently addressing issues such as proper placarding, route planning, and emergency response procedures for incidents involving hazardous materials spills during transit.

For instance, I helped a company revise their transportation plan for the movement of corrosive chemicals, ensuring compliance with the DOT’s hazardous materials regulations and implementation of a rigorous training program for drivers and handlers. Regular audits and training are essential for maintaining compliance.

Q 22. Explain your experience with conducting safety inspections.

Conducting safety inspections involves a systematic process of evaluating workplaces to identify hazards and ensure compliance with safety regulations. It’s like a thorough health check for your workplace. My experience encompasses a wide range of industries, from manufacturing to construction. I utilize checklists tailored to specific work areas and regulations, ensuring comprehensive coverage. For instance, in a manufacturing setting, I’d meticulously check machinery guarding, emergency stop mechanisms, proper use of PPE (Personal Protective Equipment), and adherence to lockout/tagout procedures. In construction, this would involve assessing fall protection systems, scaffolding stability, trenching safety, and the use of appropriate equipment. Beyond checklists, I also conduct walkthroughs, observing employee work practices and identifying potential hazards they might overlook. Any deficiencies are documented with photos and detailed reports, outlining corrective actions and deadlines for implementation. Follow-up inspections ensure that these actions are completed effectively.

Q 23. Describe your experience with developing and implementing safety procedures.

Developing and implementing safety procedures is crucial for a proactive safety culture. It’s like creating a safety roadmap for your workplace. My approach starts with a thorough hazard analysis, identifying potential risks within each work process. This involves brainstorming sessions with employees, reviewing incident reports, and analyzing industry best practices. Once hazards are identified, I develop detailed procedures to mitigate those risks. These procedures are clear, concise, and use simple language, easily understood by all employees. For example, a procedure for operating a forklift might cover pre-operation checks, safe operating practices, and emergency procedures. Each step is documented with clear visuals where necessary. Implementation involves training sessions using various methods – hands-on demonstrations, interactive workshops, and online modules – to ensure employees fully understand and can confidently apply the procedures. Regular updates and revisions of these procedures, based on feedback and incident investigations, are vital for keeping them current and effective.

Q 24. How do you communicate safety and environmental compliance requirements to employees?

Communicating safety and environmental compliance requirements effectively is paramount. It’s not enough to just have rules; employees must understand and embrace them. My strategy employs a multi-faceted approach. Firstly, I utilize various communication channels, tailoring the message to the audience. This includes toolbox talks, safety posters, email updates, and online training modules. Secondly, I prioritize interactive methods like workshops and Q&A sessions to foster understanding and encourage employee participation. For instance, when introducing a new safety procedure, I would first explain the rationale behind it, making the connection clear between the procedure and its impact on employee safety. Thirdly, I use visual aids like videos and infographics to simplify complex information, enhancing engagement. Finally, consistent reinforcement through regular communication and reminders keeps safety at the forefront of everyone’s minds. Making safety personal, highlighting real-life examples and near-miss incidents, creates a stronger impact than simply reciting regulations.

Q 25. How do you measure the effectiveness of your safety and environmental programs?

Measuring the effectiveness of safety and environmental programs is essential for continuous improvement. It’s like tracking the progress of a fitness plan – you need to monitor your results to see what’s working and what isn’t. Key performance indicators (KPIs) are crucial here. We track leading indicators like the number of safety training hours completed, the frequency of safety inspections, and the number of near-miss reports submitted. These indicators help us assess our proactive efforts. Lagging indicators, like the number of accidents, injuries, and environmental incidents, show the effectiveness of our programs in preventing harm. Data analysis plays a critical role, identifying trends and highlighting areas needing attention. For example, a spike in near-miss reports related to a specific machine might indicate a need for enhanced training or equipment modification. Regular reporting to management, coupled with data visualization, ensures transparency and keeps everyone informed about progress and challenges.

Q 26. Describe your experience with regulatory agency interactions.

Interacting with regulatory agencies is a critical aspect of compliance. It’s like maintaining a positive relationship with important stakeholders. My experience involves regular communication with agencies like OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency). This involves proactively submitting required reports, promptly responding to inquiries, and actively participating in inspections. I maintain detailed records of all interactions, including correspondence, inspection reports, and any corrective actions implemented. A strong understanding of relevant regulations is essential. When addressing agency concerns, I present clear, concise, and well-documented evidence of our compliance efforts. Building a collaborative relationship with regulatory agencies ensures smoother compliance processes and minimizes potential conflicts. Proactive communication avoids surprises and facilitates timely resolution of any issues.

Q 27. How do you use data analytics to support compliance efforts?

Data analytics significantly enhances compliance efforts. It’s like having a powerful lens to focus on key aspects of your safety and environmental performance. We utilize data from various sources, including safety incident reports, environmental monitoring data, and inspection findings. This data is analyzed to identify trends, patterns, and areas needing improvement. For instance, using statistical analysis, we can pinpoint high-risk activities or equipment that contribute disproportionately to incidents. This allows us to allocate resources effectively and prioritize risk mitigation efforts. Data visualization tools, such as dashboards and charts, help communicate findings to stakeholders. We use data to track KPI performance, demonstrating the effectiveness of implemented safety and environmental programs. In essence, data analytics enables data-driven decision making, promoting a more proactive and effective approach to compliance.

Q 28. Explain your experience with developing and implementing a sustainability program.

Developing and implementing a sustainability program is a crucial step towards responsible environmental stewardship. It’s like building a greener future for your organization. My experience starts with identifying key environmental aspects of our operations. This involves conducting a material flow analysis to assess resource consumption, waste generation, and energy usage. Based on this analysis, we develop a comprehensive sustainability strategy incorporating goals, targets, and action plans. This strategy might include initiatives to reduce energy consumption through energy efficiency upgrades, implement waste reduction and recycling programs, source sustainable materials, and decrease carbon emissions. Implementation involves employee engagement and training programs to foster a culture of environmental responsibility. Progress is tracked through KPI monitoring and regular reporting, ensuring transparency and accountability. The program’s success is measured not just by its environmental impact but also by its contribution to the organization’s overall goals, highlighting its business value.

Key Topics to Learn for Compliance with Safety and Environmental Regulations Interview

- Regulatory Frameworks: Understanding key legislation (e.g., OSHA, EPA regulations) and their practical implications for different industries.

- Risk Assessment and Management: Identifying, analyzing, and mitigating safety and environmental risks through practical methods like HAZOP studies and environmental impact assessments.

- Environmental Monitoring and Reporting: Understanding procedures for collecting, analyzing, and reporting environmental data; familiarity with relevant reporting software and databases.

- Emergency Response Planning: Developing and implementing effective emergency response plans for various scenarios, including spill response and evacuation procedures.

- Compliance Auditing and Inspections: Conducting internal audits to ensure regulatory compliance and preparing for external inspections; understanding corrective action processes.

- Sustainable Practices and Green Initiatives: Demonstrating knowledge of environmentally friendly practices, waste reduction strategies, and sustainable business models.

- Incident Investigation and Reporting: Conducting thorough investigations into safety and environmental incidents, accurately documenting findings, and implementing corrective actions to prevent recurrence.

- Stakeholder Communication: Effectively communicating compliance-related information to employees, management, regulatory agencies, and the public.

- Continuous Improvement: Applying principles of continuous improvement to enhance safety and environmental performance through data analysis and process optimization.

Next Steps

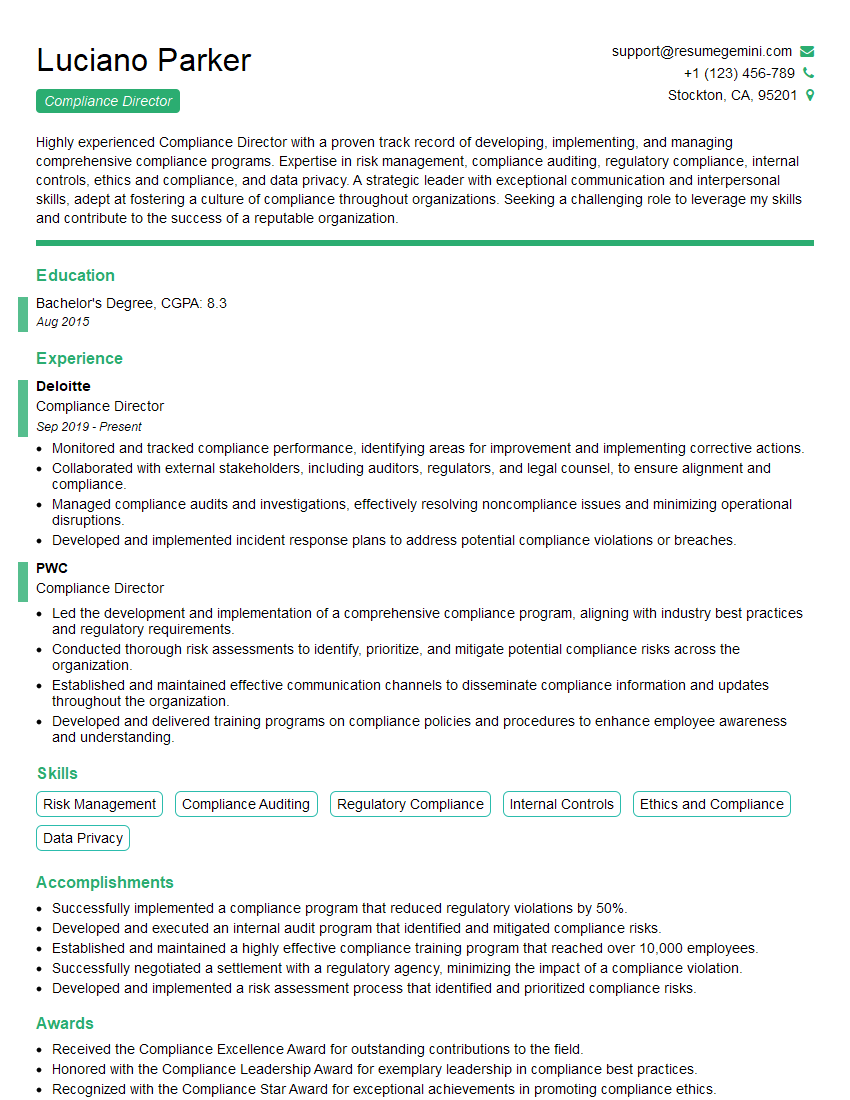

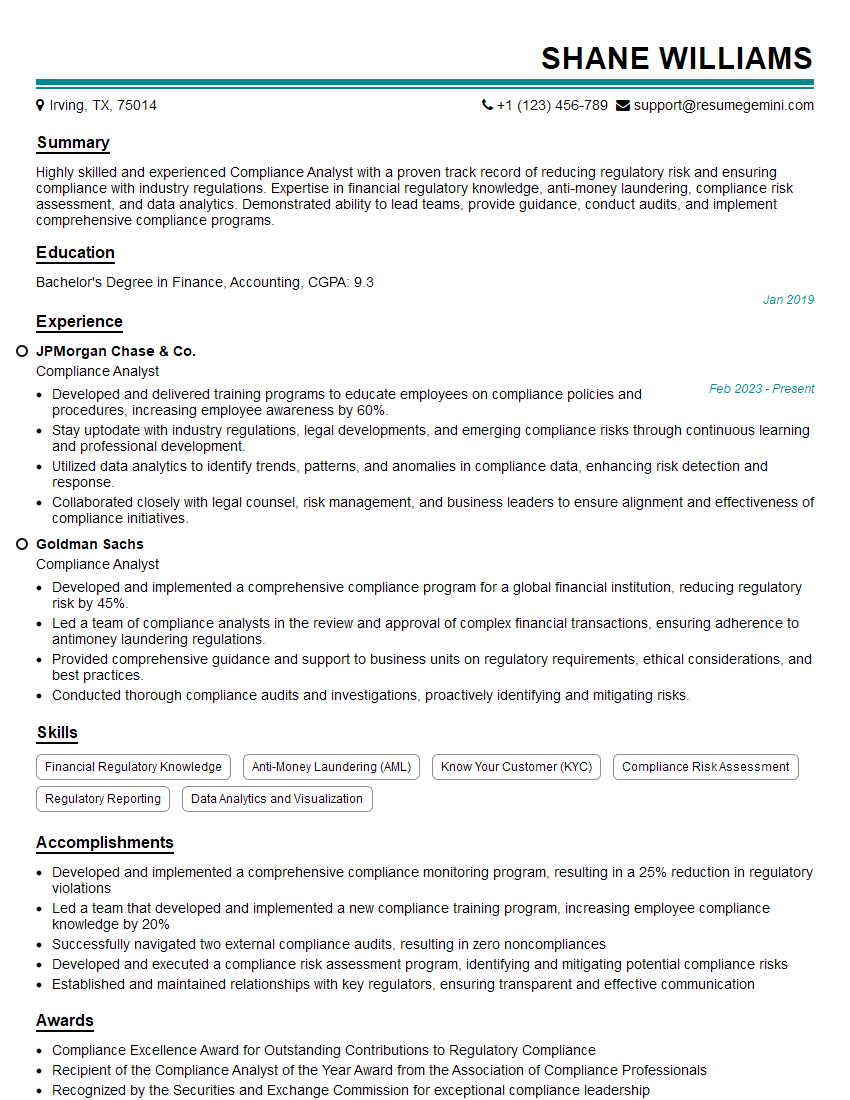

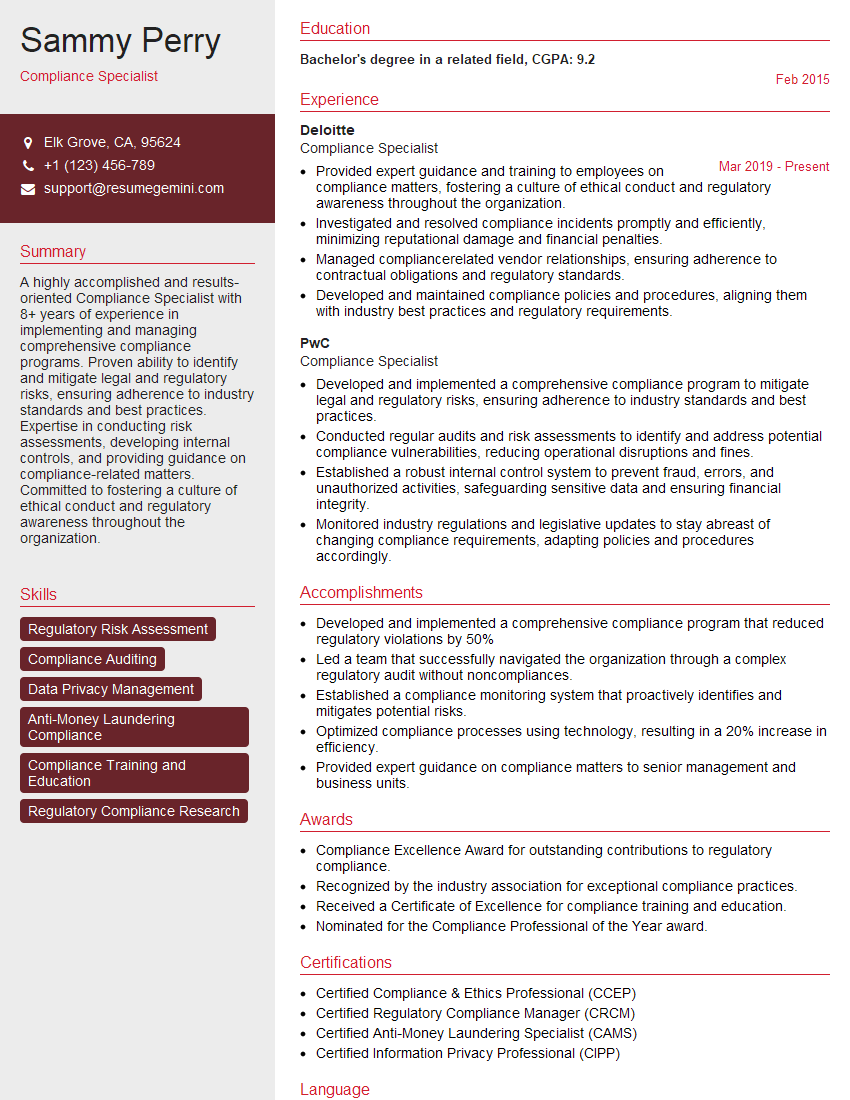

Mastering Compliance with Safety and Environmental Regulations is crucial for career advancement in various sectors. A strong understanding of these principles demonstrates responsibility, competence, and a commitment to ethical business practices, making you a highly valuable asset to any organization. To significantly boost your job prospects, it’s essential to create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Compliance with Safety and Environmental Regulations are available, showcasing best practices to help you present your qualifications effectively. Take the next step towards your dream job – craft a compelling resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good