Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Composite Material Selection and Testing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Composite Material Selection and Testing Interview

Q 1. Explain the difference between thermoset and thermoplastic composite materials.

The key difference between thermoset and thermoplastic composite materials lies in their molecular structure and how they respond to heat. Think of it like this: thermosets are like eggs – once they’re cooked (cured), they can’t be melted and reshaped. Thermoplastics, on the other hand, are like wax – they can be repeatedly melted and remolded.

Thermosets undergo an irreversible chemical change during curing, forming a rigid, cross-linked network. This makes them strong and heat-resistant but also brittle and difficult to recycle. Examples include epoxy and polyester resins commonly used in aerospace and automotive parts.

Thermoplastics, conversely, have a linear or branched molecular structure that allows them to soften when heated and solidify upon cooling. This allows for easier processing and recycling, but they generally have lower strength and heat resistance compared to thermosets. Polypropylene and nylon are thermoplastic polymers that can be used in composite materials, often for less demanding applications.

Q 2. Describe three common methods for testing the tensile strength of a composite material.

Testing the tensile strength of a composite material involves determining its resistance to stretching forces until failure. Three common methods are:

- Universal Testing Machine (UTM): This is the most common method. A specimen is gripped at both ends and subjected to a controlled tensile load until failure. The force at failure, along with the initial dimensions of the specimen, is used to calculate tensile strength. Think of it like stretching a rubber band until it breaks.

- Instron Testing Machine: A specific type of UTM, offering advanced features like precise load control and high-resolution data acquisition for detailed analysis of the material’s behavior under stress.

- Tensile Testing with Digital Image Correlation (DIC): This technique uses digital cameras to track the deformation of the specimen during the test. DIC provides a more comprehensive picture of strain distribution, allowing for the identification of localized weaknesses and failure initiation points. This gives a much more detailed understanding than just the ultimate tensile strength.

Q 3. What are the advantages and disadvantages of using carbon fiber reinforced polymers (CFRP)?

Carbon fiber reinforced polymers (CFRP) are highly sought after for their exceptional properties but also come with limitations.

Advantages:

- High Strength-to-Weight Ratio: CFRP offers unmatched strength and stiffness relative to its weight, making it ideal for aerospace, automotive, and sporting goods applications where weight reduction is critical. Imagine a bicycle frame that’s both incredibly strong and lightweight.

- High Stiffness: CFRP exhibits excellent rigidity, resisting deformation under load, essential in applications requiring precise dimensional stability.

- Fatigue Resistance: CFRP can withstand repeated loading cycles without significant degradation, crucial for components subject to continuous stress.

Disadvantages:

- High Cost: Carbon fiber production is expensive, leading to high material costs.

- Difficult to Manufacture: Requires specialized manufacturing techniques and equipment, increasing production costs.

- Susceptibility to Damage: CFRP can be susceptible to impact damage, which can be difficult to detect and repair.

- Low Impact Resistance: Compared to some metals, CFRP’s impact strength can be comparatively low. A sharp impact might cause catastrophic failure.

Q 4. How do you select an appropriate composite material for a specific application?

Selecting the right composite material for a specific application requires a systematic approach. It’s not a guess-and-check process! You need to understand the needs of your design and the capabilities of various materials.

The process typically involves:

- Defining Requirements: What are the critical performance parameters? Strength, stiffness, weight, temperature resistance, cost, etc.?

- Material Screening: Based on requirements, initially screen potential materials based on databases and literature. Many commercially available tools can help you make this initial screening.

- Material Testing: Conduct mechanical, thermal, and other relevant tests to verify the material’s suitability under the intended service conditions. This is where the tensile testing discussed earlier comes into play.

- Prototyping and Validation: Create prototypes to test the material’s performance in a realistic setting and validate your design.

- Cost-Benefit Analysis: Analyze the total cost of ownership, considering material costs, manufacturing, assembly, and lifecycle management.

For example, if you’re designing a wind turbine blade, you’d prioritize high strength, stiffness, fatigue resistance, and cost-effectiveness. This might lead to a fiberglass-reinforced polymer composite as a cost-effective alternative to CFRP.

Q 5. Explain the concept of fiber volume fraction and its significance in composite properties.

Fiber volume fraction (Vf) represents the proportion of reinforcing fibers in a composite material by volume. It’s a crucial parameter that significantly influences the overall properties of the composite.

It’s calculated as:

Vf = (Volume of fibers) / (Total volume of composite)

A higher fiber volume fraction generally results in:

- Increased Strength and Stiffness: More fibers mean more load-bearing capacity.

- Increased Modulus: Higher stiffness means less deformation under load.

However, excessively high fiber volume fractions can lead to:

- Poor Wettability: Difficulty in achieving uniform resin distribution around the fibers, leading to weaknesses.

- Increased Brittleness: Reducing the ductility and impact resistance of the composite.

Finding the optimal fiber volume fraction is crucial for balancing desired properties and manufacturability. This involves careful consideration of the resin system and fiber type.

Q 6. Describe different types of fiber reinforcements used in composites.

Various fiber reinforcements are used in composites, each with unique characteristics:

- Carbon Fiber: Known for its high strength-to-weight ratio, stiffness, and chemical resistance, making it ideal for high-performance applications.

- Glass Fiber: A cost-effective option offering good strength, stiffness, and chemical resistance. Widely used in various industries.

- Aramid Fiber (Kevlar): Exceptional tensile strength and impact resistance, often used in ballistic protection and high-strength applications.

- Basalt Fiber: A relatively new entrant, basalt fiber offers good strength, high temperature resistance and is a sustainable alternative to glass fiber.

- Natural Fibers: Increasingly popular due to their sustainability. Examples include flax, hemp, and jute fibers. They often have lower strength and stiffness but offer environmentally friendly advantages.

The choice of fiber depends on the application’s specific requirements. For instance, a racing bicycle might use carbon fiber for its lightweight and high-strength properties, while a boat hull might utilize fiberglass for its cost-effectiveness and durability.

Q 7. What are the common failure modes of composite materials?

Composite materials can fail in several ways, often in complex and unpredictable manners:

- Fiber Fracture: Breaking of individual fibers due to excessive tensile stress. This is a common failure mode, especially under high tensile loading.

- Matrix Cracking: Formation of cracks in the resin matrix. This can be caused by stress concentrations, impact damage, or thermal stresses.

- Fiber-Matrix Debonding: Separation between fibers and the matrix, reducing load transfer and weakening the composite.

- Delamination: Separation of layers in laminated composites, often caused by impact damage or interlaminar shear stresses. Think of layers in a cake separating.

- Buckling: Instability of fibers or layers under compressive stresses, leading to sudden failure.

- Shear Failure: Failure due to shear stresses, often occurring at interfaces or in the matrix.

Understanding these failure modes is critical for designing reliable composite structures. Proper design and material selection are crucial in mitigating these risks. Proper testing and analysis helps designers predict these modes and account for them during the design process.

Q 8. Explain the importance of non-destructive testing (NDT) in composite manufacturing.

Non-destructive testing (NDT) is crucial in composite manufacturing because it allows us to evaluate the integrity of the material without causing damage. Think of it like getting an X-ray for a bone fracture – you can see the problem without breaking the bone further. In composites, defects like delamination (separation of layers), voids (air pockets), or fiber misalignment can significantly compromise the structural performance. NDT helps us identify these flaws early on, preventing costly failures later in the product lifecycle.

For example, imagine a wind turbine blade, a critical component made from composite materials. A small internal flaw undetected during manufacturing could lead to catastrophic failure, potentially causing significant damage and even injury. NDT is the safety net that prevents such scenarios.

Q 9. What are the different types of NDT techniques used for composite materials?

Several NDT techniques are employed for composite materials, each with its strengths and weaknesses. Common methods include:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws. Think of it like sonar – the sound waves reflect off discontinuities, revealing their location and size.

- Radiographic Testing (RT): Uses X-rays or gamma rays to penetrate the material and create an image revealing internal defects. Similar to medical X-rays, this method allows visualization of internal structures.

- Thermographic Testing (TT): Detects variations in temperature to identify flaws. Heat dissipation patterns can highlight defects like delaminations.

- Acoustic Emission Testing (AET): Monitors the acoustic signals generated by a stressed material. This is useful for detecting growing cracks or damage during load testing.

- Visual Inspection (VI): While seemingly simple, visual inspection is often the first and sometimes the only NDT technique needed, detecting surface defects such as cracks or resin bleed.

The choice of NDT technique depends on factors like the type of composite, the expected defect types, and the required sensitivity. Often, a combination of techniques is used for comprehensive evaluation.

Q 10. How do you interpret a stress-strain curve for a composite material?

A stress-strain curve for a composite material provides crucial information about its mechanical behavior. The curve plots stress (force per unit area) against strain (deformation per unit length). Key features to interpret include:

- Young’s Modulus (Elastic Modulus): The slope of the linear portion of the curve represents the stiffness of the material. A steeper slope indicates higher stiffness.

- Proportional Limit: The point beyond which the material no longer behaves linearly, showing deviation from Hooke’s Law.

- Yield Strength: The stress at which the material begins to deform permanently.

- Ultimate Tensile Strength: The maximum stress the material can withstand before failure.

- Fracture Strength: The stress at which the material fractures.

By comparing the stress-strain curves of different composite materials, we can make informed decisions about which material is most suitable for a given application. For instance, a material with high ultimate tensile strength and high stiffness might be chosen for an aircraft wing, while a material with good impact resistance might be preferred for a sports equipment.

Q 11. Explain the influence of matrix material on composite properties.

The matrix material plays a vital role in determining the overall properties of a composite. It acts as the binder, holding the reinforcement fibers together and transferring loads between them. The matrix significantly influences:

- Strength and Stiffness: A strong matrix enhances the overall strength and stiffness of the composite. For example, epoxy resins are widely used for their high strength and stiffness.

- Toughness and Fracture Resistance: A tough matrix helps absorb energy during impact, improving the composite’s resistance to damage. Some thermoplastic matrices offer superior toughness compared to thermosets.

- Durability and Chemical Resistance: The matrix’s resistance to environmental factors like moisture, temperature, and chemicals directly affects the composite’s durability and lifespan. For instance, some specialized matrices offer excellent resistance to chemicals used in harsh environments.

- Processing Characteristics: The matrix material’s viscosity, cure time, and other processing characteristics affect the manufacturability of the composite. For example, a low-viscosity matrix is easier to infiltrate into complex fiber architectures.

Choosing the right matrix is crucial in tailoring the composite’s properties to specific application requirements. This involves considering the trade-offs between various properties based on the specific needs.

Q 12. Describe the concept of fatigue in composite materials.

Fatigue in composite materials refers to the progressive and localized structural damage that occurs when a material is subjected to repeated cyclic loading. Imagine bending a paper clip back and forth repeatedly; eventually, it will break, even if the force applied in each cycle is less than its ultimate tensile strength. This is fatigue failure.

In composites, fatigue can lead to matrix cracking, fiber breakage, delamination, and eventually complete failure. The fatigue life (number of cycles to failure) is affected by factors like the magnitude of the cyclic load, the frequency of loading, and the environmental conditions. Understanding fatigue behavior is essential in designing composite structures that can withstand long-term cyclic loading in applications such as aircraft wings or wind turbine blades.

Fatigue testing is crucial to determine the fatigue life of a composite material under specific loading conditions and to establish design criteria to prevent premature failure.

Q 13. How do environmental factors affect the performance of composite materials?

Environmental factors can significantly impact the performance and longevity of composite materials. Exposure to:

- Moisture: Can cause absorption into the matrix, leading to swelling, reduced stiffness, and strength degradation. This is especially critical for some matrix types.

- Temperature: Extreme temperatures (both high and low) can affect the mechanical properties, potentially leading to thermal expansion mismatch between the matrix and the reinforcement, causing stress and failure.

- Ultraviolet (UV) radiation: Can degrade the matrix, especially in polymeric composites, leading to embrittlement and reduced strength. This effect is often mitigated using UV-resistant additives.

- Chemicals: Certain chemicals can attack and degrade the matrix, leading to corrosion and strength reduction. Selecting matrix materials with appropriate chemical resistance is important for these situations.

Understanding the influence of environmental factors is crucial for designing durable composite structures. Protective coatings, specialized matrix materials, and design modifications are employed to mitigate environmental effects and enhance long-term performance.

Q 14. Explain the process of curing composite materials.

Curing is the process of converting a liquid resin into a solid polymer network in composite materials. It’s essential to form the strong, stable composite structure. The specific curing process depends on the type of resin system (thermoset or thermoplastic).

Thermoset resins undergo irreversible chemical changes during curing, forming a cross-linked network that cannot be melted and reshaped. This process often involves applying heat and pressure in an autoclave or oven. The curing schedule (temperature and time) is critical for achieving optimal properties. Inadequate curing can lead to weak bonding, porosity, and reduced mechanical performance. Think of it like baking a cake – the oven temperature and baking time dictate the final result.

Thermoplastic resins soften when heated and solidify upon cooling, allowing for repeat processing. They generally don’t undergo the same cross-linking as thermosets. This process can involve techniques like injection molding, compression molding, or extrusion, depending on the final shape and the required level of precision.

Proper curing is critical to ensure the desired mechanical, physical, and chemical properties of the final composite part. Careful control of the curing parameters is essential for producing high-quality, reliable components.

Q 15. What are the common defects found in composite materials and how are they detected?

Common defects in composite materials significantly impact their performance and lifespan. These defects can be broadly categorized into processing-induced flaws and material-inherent issues. Processing flaws often arise during manufacturing and include things like:

- Voids: Empty spaces within the material, reducing strength and stiffness. Think of it like Swiss cheese – the more holes, the weaker the structure.

- Porosity: Similar to voids, but referring to a higher concentration of small interconnected pores. This can weaken the material and reduce its resistance to moisture ingress.

- Delamination: Separation of layers within the laminate, severely compromising structural integrity. Imagine peeling layers off a cake – the cake is no longer structurally sound.

- Fiber misalignment: Fibers not oriented optimally to carry load, leading to reduced strength in a specific direction. Think of laying bricks – if they’re not straight, the wall is weak.

- Resin-rich or fiber-rich areas: Uneven distribution of resin and fibers, creating localized weak spots.

Detection methods vary depending on the defect type and severity. Non-destructive techniques like ultrasonic inspection (detecting voids and delaminations), X-ray radiography (revealing internal structures and flaws), and visual inspection (identifying surface imperfections) are commonly used. Destructive testing, including cross-sectioning and microscopy, can provide detailed information about the internal structure and defect characteristics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different manufacturing processes for composite materials (e.g., hand layup, autoclave molding).

Composite manufacturing encompasses a wide range of techniques, each offering unique advantages and limitations. Here are a few examples:

- Hand Layup: A simple and versatile method where layers of reinforcement are manually placed in a mold, impregnated with resin, and cured. It’s cost-effective for small-scale production and complex shapes but lacks precision and consistency.

- Autoclave Molding: A high-pressure, high-temperature process used for high-performance composites. Prepreg (pre-impregnated) materials are placed in a mold, then subjected to controlled heat and pressure within an autoclave to ensure complete resin flow and void removal. This results in superior mechanical properties and excellent dimensional stability, but is more expensive and complex.

- Pultrusion: A continuous process where resin-impregnated fibers are pulled through a heated die to form a profile with a constant cross-section. It’s ideal for producing long, uniform parts like rods or beams but is limited in shape complexity.

- Resin Transfer Molding (RTM): Liquid resin is injected into a mold containing the reinforcement material. This provides good control over fiber orientation and resin content, is cost-effective for medium-volume production, and lends itself to complex shapes. However, it requires careful control of resin flow.

- Filament Winding: Fibers are wound around a mandrel according to a specific pattern, then impregnated with resin and cured. It’s excellent for producing cylindrical structures like pressure vessels and pipes, offering high strength-to-weight ratios but limited to specific geometries.

Q 17. How would you design a test to determine the impact resistance of a composite material?

Designing an impact resistance test for a composite material requires careful consideration of the specific application and the type of impact expected. A common method involves using an Izod or Charpy impact test. For Izod, a notched specimen is clamped vertically, and a pendulum is released to strike the specimen. The energy absorbed during fracture is measured. Charpy uses a horizontally supported specimen.

However, these standard tests may not fully capture real-world impact scenarios. For more realistic simulations, you might utilize:

- Drop-weight impact testing: This involves dropping a weight onto a composite specimen from a specified height, measuring the energy absorbed or the extent of damage. This allows for varied impact energies and configurations.

- Instrumented impact testing: Sensors measure force, displacement, and velocity during the impact event, providing detailed information about the material’s response. This allows for more advanced analysis and understanding of failure mechanisms.

Test parameters like impact energy, impact velocity, and specimen geometry (size, thickness, notch type) should be carefully selected to reflect the anticipated service conditions. The choice of test method and parameters will directly influence the interpretation of the results. For instance, the energy absorbed during the impact, the type of fracture (brittle, ductile), and the extent of damage (delamination, fiber breakage) are all crucial aspects to consider when assessing the material’s impact resistance.

Q 18. Explain the significance of void content in composite materials.

Void content in composite materials is a critical factor affecting their mechanical properties. Voids are essentially microscopic holes or pores within the material that disrupt the continuous fiber-matrix interface. Think of it as weakening links in a chain – each void reduces the overall strength and stiffness of the composite.

High void content leads to:

- Reduced strength and stiffness: Voids act as stress concentrators, weakening the material and making it more susceptible to failure under load.

- Decreased fatigue life: The presence of voids accelerates fatigue crack initiation and propagation, leading to premature failure.

- Increased susceptibility to moisture absorption: Voids provide pathways for moisture to penetrate the material, causing degradation and swelling.

- Reduced impact resistance: Voids can weaken the material’s ability to absorb impact energy.

Therefore, controlling void content during manufacturing is crucial to ensure the desired mechanical properties and performance of the composite. Techniques like vacuum bagging, autoclave molding, and proper resin impregnation are employed to minimize void formation.

Q 19. What are the different types of resin systems used in composite materials?

Resin systems are the binding agents in composite materials, transferring loads from fiber to fiber and protecting the reinforcement from environmental degradation. Several types exist, each with unique properties:

- Polyester resins: Relatively inexpensive and easy to process, but offer lower mechanical properties compared to other systems. Commonly used in less demanding applications.

- Vinyl ester resins: Improved chemical resistance and mechanical properties compared to polyesters, making them suitable for more demanding environments.

- Epoxy resins: High strength, stiffness, and chemical resistance, making them ideal for high-performance applications like aerospace and automotive industries. However, they can be more expensive and require specialized curing techniques.

- Phenolic resins: Excellent thermal stability and high strength at elevated temperatures. Used in applications requiring fire resistance and heat tolerance.

- Polyimide resins: Exceptional thermal stability and chemical resistance, suitable for extreme environments. Used in high-temperature applications.

The selection of a resin system depends on the specific requirements of the application, considering factors such as cost, mechanical properties, chemical resistance, thermal stability, and processability.

Q 20. How do you ensure the quality control of composite materials during manufacturing?

Quality control in composite manufacturing is essential to ensure consistent performance and reliability. It involves implementing a robust system throughout the manufacturing process, starting from raw material inspection to final product testing. Key aspects include:

- Raw material inspection: Verifying the quality of fibers, resins, and other materials using techniques such as tensile testing, chemical analysis, and visual inspection.

- Process monitoring: Tracking parameters such as temperature, pressure, and cure time during manufacturing to maintain consistency and prevent defects.

- Non-destructive testing (NDT): Employing techniques like ultrasonic inspection, X-ray radiography, and thermography to detect internal flaws without damaging the part.

- Destructive testing: Performing tests such as tensile, flexural, and impact tests on representative samples to verify mechanical properties.

- Dimensional inspection: Verifying that the manufactured parts meet the required dimensional tolerances using techniques such as coordinate measuring machines (CMMs).

- Documentation and traceability: Maintaining thorough records of all materials, processes, and test results to ensure accountability and traceability.

A well-defined quality control plan, incorporating statistical process control (SPC) techniques and regular audits, is crucial for maintaining consistent product quality and meeting customer requirements.

Q 21. Describe the concept of laminate theory in composites.

Laminate theory provides a framework for predicting the macroscopic mechanical behavior of a composite laminate based on the properties of its individual layers (laminae). It considers the orientation, thickness, and material properties of each lamina to determine the overall stiffness and strength of the laminate.

Key concepts include:

- Stress and strain transformation: Relating stresses and strains in the lamina coordinate system to the global laminate coordinate system.

- Classical Laminate Theory (CLT): A simplified theory assuming thin laminae and small deflections. It uses stiffness matrices to predict laminate behavior under various loading conditions. This is a widely used approach for initial design and analysis.

- First-order shear deformation theory (FSDT): This accounts for shear deformation, which is important for thicker laminates and higher shear loads.

- Higher-order shear deformation theories (HSDT): These offer greater accuracy but involve more complex calculations. They are used for very thick laminates.

Laminate theory is crucial for designing composite structures by predicting their stiffness, strength, and failure modes under various loading conditions. Software tools frequently use laminate theory to perform finite element analysis (FEA), helping engineers optimize composite designs for specific applications.

Q 22. How do you choose the appropriate layup sequence for a composite structure?

Choosing the optimal layup sequence for a composite structure is crucial for achieving the desired mechanical properties and performance. It involves strategically arranging layers of reinforcement fibers (e.g., carbon, glass, aramid) within a matrix material (e.g., epoxy, polyester). The sequence determines the overall stiffness, strength, and failure behavior of the composite. Consider this analogy: think of building a wall – stacking bricks (fibers) in different orientations (layup) affects the wall’s resistance to different forces (loads).

The process typically involves considering factors such as:

- Loading conditions: Understanding the primary load directions (tension, compression, shear) is paramount. For example, a wing spar experiences primarily tensile loads along its length, so the strongest fibers should be aligned along this direction.

- Required properties: Do you prioritize high strength, stiffness, or impact resistance? A layup with fibers predominantly aligned in the load direction would maximize strength and stiffness. If impact resistance is key, a cross-ply or quasi-isotropic layup might be more suitable.

- Manufacturing constraints: The layup must be compatible with the chosen manufacturing process (e.g., hand layup, autoclave curing, resin transfer molding). Complex layups can increase manufacturing cost and complexity.

- Cost considerations: The cost of materials and manufacturing processes varies significantly. Selecting the most economical layup that satisfies performance requirements is vital.

For example, a simple layup for a tensile member might be [0]4, indicating four layers with fibers oriented at 0 degrees to the load direction. A more complex layup for a component experiencing multi-directional loads could be [0/45/-45/90]s, which represents a symmetric layup with fibers oriented at 0, 45, -45, and 90 degrees. Software like ANSYS or ABAQUS can help optimize the layup by simulating various scenarios.

Q 23. Explain how to design a composite structure for specific load requirements.

Designing a composite structure for specific load requirements involves a multi-step process integrating material selection, layup optimization, and structural analysis. This is similar to designing any structure; however, composite structures offer the advantage of tailoring their properties through the selection of materials and fiber orientation.

- Define load requirements: Thoroughly document all expected loads, including magnitude, direction, and frequency (static, dynamic, fatigue). This could involve finite element analysis (FEA) to predict load distributions.

- Select materials: Choose the reinforcement fibers and matrix based on the load requirements and desired properties. High-strength carbon fibers might be suitable for high-stress applications, whereas glass fibers may be more cost-effective for lower-stress components. The matrix material selection influences the durability, temperature resistance, and chemical resistance of the composite.

- Optimize layup: Employ software (ANSYS, ABAQUS, etc.) to analyze and optimize the layup sequence. The goal is to achieve the required strength and stiffness while minimizing weight. This stage often involves iterative simulations and design adjustments.

- Structural analysis: Perform finite element analysis (FEA) to validate the design and predict failure modes. This step is critical to ensure the structure meets safety standards and performance requirements.

- Prototype and testing: Fabricate prototypes to verify the design and conduct experimental tests to validate the analysis. Compare experimental results with FEA predictions to refine the design.

For example, in designing a wind turbine blade, understanding the aerodynamic loads and centrifugal forces is critical. The layup would be optimized to handle these loads while minimizing weight for efficient energy production. Similarly, designing a high-performance aircraft component requires careful consideration of aerodynamic loads, impact forces, and thermal stresses. The material selection and layup would reflect these considerations.

Q 24. What software packages are you familiar with for composite material analysis (e.g., ABAQUS, ANSYS)?

I’m proficient in several software packages for composite material analysis, including ANSYS and ABAQUS. These tools enable the creation of complex finite element models to simulate the behavior of composite structures under various loading conditions. My experience spans using these programs for tasks ranging from linear static analysis to nonlinear dynamic simulations, including fatigue and fracture analysis. I’ve utilized ANSYS’s composite prepPost for layup definition and visualization, and ABAQUS’s user subroutine capabilities for implementing advanced material models.

Beyond ANSYS and ABAQUS, I have also worked with LS-DYNA for impact simulation and HyperMesh for pre-processing model creation, which are valuable for modeling complex failure scenarios in composite components.

Q 25. Describe your experience with material characterization techniques.

My experience with material characterization encompasses a wide range of techniques used to determine the mechanical, physical, and chemical properties of composite materials. This knowledge allows me to assess material suitability and predict structural performance.

- Tensile testing: Determining the ultimate tensile strength, modulus of elasticity, and Poisson’s ratio.

- Flexural testing: Measuring the flexural strength and modulus.

- Shear testing: Assessing the shear strength and modulus.

- Impact testing: Evaluating the impact resistance and energy absorption capabilities, often using Izod or Charpy tests.

- Fatigue testing: Determining the fatigue life under cyclic loading.

- Micromechanical testing: Assessing the properties of individual fibers and the matrix material.

- Thermo-mechanical testing: Determining the behavior of the material under varying temperature conditions.

- Non-destructive testing (NDT): Techniques like ultrasound, X-ray, and thermography to detect internal flaws without damaging the sample.

I’m experienced in using standard testing equipment and adhering to relevant ASTM and ISO standards. I also have experience in interpreting the obtained data and relating it back to the material’s microstructure.

Q 26. Explain your experience with failure analysis of composite materials.

My experience in composite failure analysis involves identifying the root cause of failures and implementing corrective actions. This is an iterative process that often involves multiple analysis techniques and requires attention to detail.

The process generally involves:

- Visual inspection: Carefully examining the failed part to identify the location and nature of the failure.

- Microscopic analysis: Using optical microscopy or scanning electron microscopy (SEM) to examine the microstructure of the failed region and determine the failure mechanism (e.g., fiber breakage, delamination, matrix cracking).

- Mechanical testing: Conducting mechanical tests on undamaged samples to determine the material properties and compare them to design specifications.

- Finite element analysis (FEA): Simulating the loading conditions to identify potential stress concentrations and areas of high strain.

- Non-destructive testing (NDT): Employing techniques like ultrasound or X-ray to detect internal flaws in other parts of the same batch.

A real-world example involved a failed carbon fiber composite pressure vessel. Through failure analysis, we identified delamination originating from a manufacturing defect, leading to improved quality control protocols.

Q 27. How would you address a situation where a composite part fails unexpectedly during testing?

Addressing an unexpected composite part failure during testing requires a systematic approach focused on thorough investigation and corrective actions.

- Document everything: Meticulously document the testing setup, conditions, and observations leading up to the failure. This includes photographs, videos, and detailed notes.

- Initial Assessment: Conduct a thorough visual inspection of the failed component to identify the location and type of failure (e.g., fiber breakage, delamination, matrix cracking).

- Advanced Analysis: Depending on the findings of the visual inspection, implement appropriate advanced techniques: microscopic analysis (optical or SEM), NDT (ultrasonic or X-ray inspection), and chemical analysis.

- Root Cause Determination: Analyze the data from all the investigation techniques to identify the root cause of the failure. Potential causes include material defects, design flaws, manufacturing errors, or unforeseen loading conditions.

- Corrective Actions: Based on the root cause analysis, implement the necessary corrective actions, including redesigning the component, improving manufacturing processes, or modifying the testing procedure.

- Validation Testing: After implementing corrective actions, conduct further testing to validate the effectiveness of the implemented solutions and ensure the reliability of the improved design or process.

This structured process aims to not only address the immediate problem but also prevent future occurrences and enhance understanding of the material and its limitations.

Q 28. What are your strategies for staying updated on advancements in composite materials and testing?

Staying current in the rapidly evolving field of composite materials and testing requires a multi-faceted approach.

- Professional Societies and Conferences: Active participation in organizations like the American Society for Composites (ASC) and attending relevant conferences and workshops provides access to cutting-edge research and interactions with leading experts.

- Publications and Journals: Regularly reading peer-reviewed journals (e.g., Composites Science and Technology, Composites Part A) and industry publications keeps me informed about the latest advancements in materials, manufacturing techniques, and testing methodologies.

- Online Resources and Databases: Utilizing online resources like scientific databases (e.g., Web of Science, Scopus) and industry websites provides access to a wide range of information.

- Industry Collaboration: Collaborating with other engineers and researchers within the industry facilitates knowledge exchange and allows exposure to new techniques and applications.

- Continuing Education: Participating in short courses, workshops, and training programs ensures my skills remain up-to-date with emerging technologies and best practices.

This continuous learning approach ensures my expertise remains relevant and I can effectively tackle the challenges in the ever-changing landscape of composite materials and testing.

Key Topics to Learn for Composite Material Selection and Testing Interview

- Material Properties & Selection Criteria: Understanding the mechanical, physical, and chemical properties of various composite materials (e.g., fiber types, matrix resins) and how to select the optimal material based on application requirements (strength, stiffness, weight, cost, environmental resistance).

- Manufacturing Processes & Their Impact: Exploring how different manufacturing techniques (e.g., hand lay-up, autoclave molding, pultrusion) influence the final properties of the composite and how to choose the most suitable process for a given design.

- Mechanical Testing Methods: Mastering standard testing methods for composites, including tensile, flexural, compressive, shear, and impact testing. Understanding the interpretation of test results and their relevance to material performance.

- Non-Destructive Testing (NDT): Familiarizing yourself with various NDT techniques like ultrasonic testing (UT), radiographic testing (RT), and thermographic testing for detecting flaws and assessing the quality of composite structures.

- Failure Analysis & Design Considerations: Understanding common failure mechanisms in composites (e.g., delamination, fiber breakage) and how to incorporate this knowledge into the design process to prevent failures. This includes exploring the use of Finite Element Analysis (FEA) for predictive modeling.

- Environmental Effects & Durability: Learning about the impact of environmental factors (e.g., temperature, humidity, UV radiation) on the long-term performance of composites and methods to improve their durability.

- Cost-Effectiveness & Life Cycle Analysis: Considering the total cost of ownership, including material costs, manufacturing costs, and maintenance costs, when selecting and designing with composites.

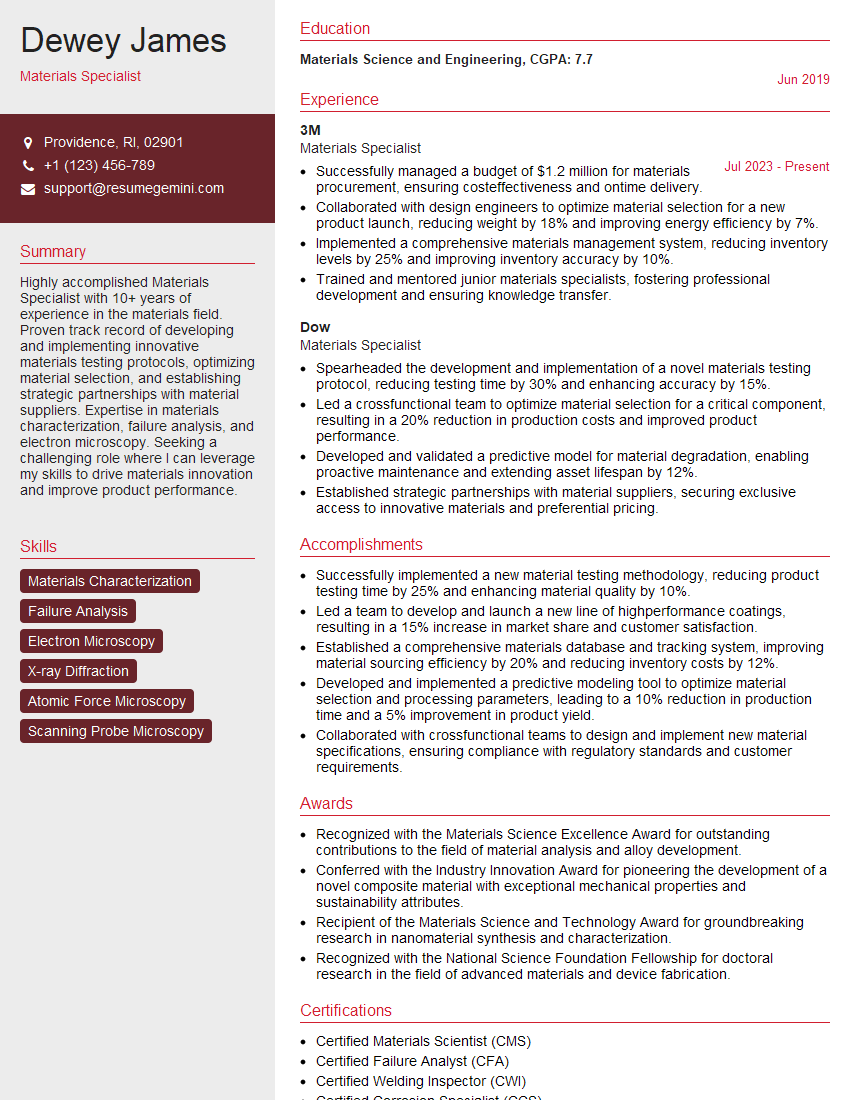

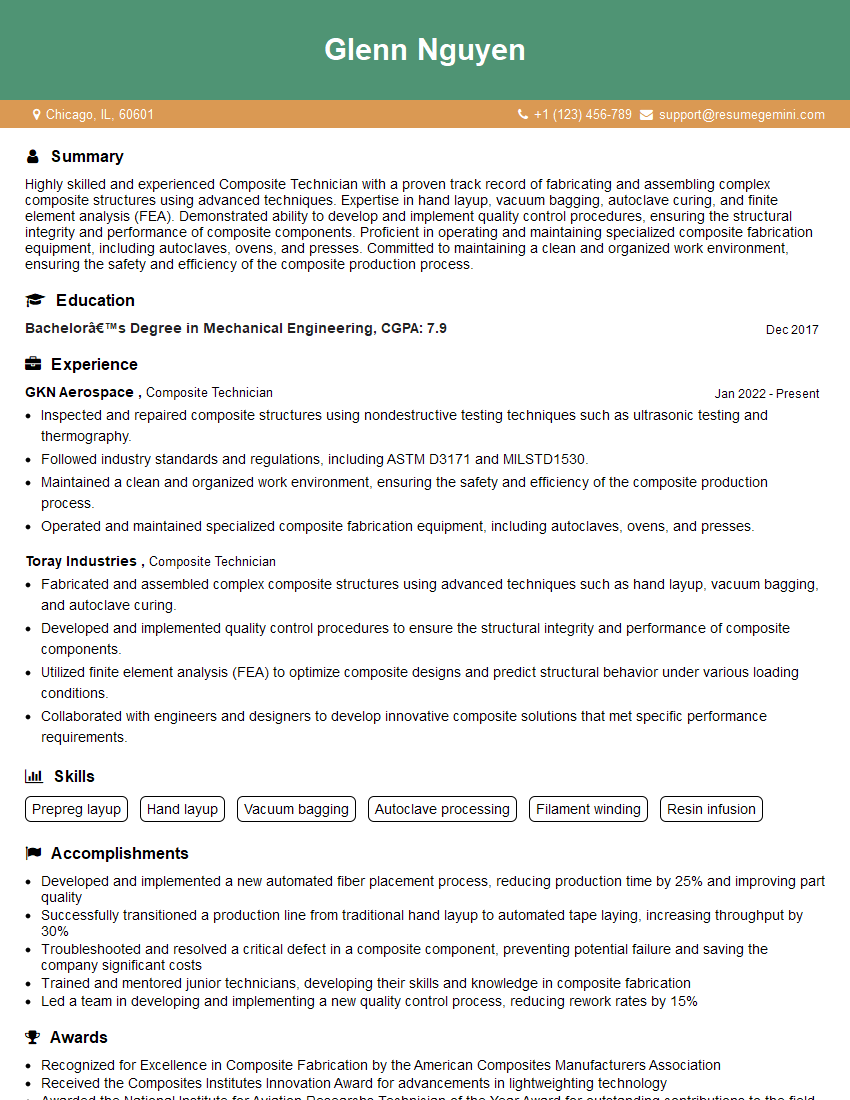

Next Steps

Mastering Composite Material Selection and Testing is crucial for career advancement in various industries, opening doors to exciting roles in aerospace, automotive, marine, and renewable energy sectors. A strong understanding of these concepts will significantly enhance your interview performance and overall professional credibility. To maximize your job prospects, it’s essential to create an ATS-friendly resume that effectively highlights your skills and experience. We strongly recommend using ResumeGemini to build a professional and impactful resume tailored to your specific experience. ResumeGemini provides examples of resumes specifically designed for candidates in Composite Material Selection and Testing to guide your creation process. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good