Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Computer-Aided Design (CAD) and Simulation Software Knowledge interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Computer-Aided Design (CAD) and Simulation Software Knowledge Interview

Q 1. Explain the difference between wireframe, surface, and solid modeling.

The three modeling techniques – wireframe, surface, and solid modeling – represent different levels of geometric representation in CAD. Think of it like building a house: wireframe is the blueprint showing only lines and points; surface modeling adds the walls and roof but ignores the interior structure; and solid modeling creates a complete, three-dimensional representation, including the interior.

- Wireframe Modeling: This is the simplest form, defining the object using only lines and points to represent its edges. It’s like a skeletal structure. It’s quick and efficient for basic shapes but lacks information about surfaces and volume. Useful for early design concepts and 2D drawings. Example: A simple sketch of a chair showing only the outline of the legs and seat.

- Surface Modeling: This technique defines the object using curves and surfaces. It accurately represents the exterior shape but doesn’t define the interior volume. Think of a car body – you can see the curves and shapes, but it’s not a solid, it’s a shell. Great for creating aesthetically pleasing shapes, particularly in automotive and product design. Example: Designing a sleek, curved bottle.

- Solid Modeling: This is the most advanced and comprehensive technique, representing the object as a solid with defined volume and mass properties. It’s like a digital replica of the physical object. This method is essential for engineering applications, such as finite element analysis (FEA), because it provides complete geometric information. Example: Designing a complex engine part where internal features and mass distribution are critical.

Q 2. Describe your experience with different CAD software packages (e.g., AutoCAD, SolidWorks, Creo).

My CAD software experience spans several leading packages. I’ve extensively used AutoCAD for 2D drafting and detailing, particularly for architectural and construction drawings. I’m highly proficient in SolidWorks, a powerhouse for 3D solid modeling, where I’ve worked extensively on mechanical design projects, from concept to manufacturing-ready designs. My experience with Creo (formerly Pro/ENGINEER) includes complex assembly modeling and simulation, often for large-scale industrial projects requiring robust design validation. In each case, my expertise extends beyond basic modeling to encompass advanced features like FEA and design optimization.

For example, in a recent project using SolidWorks, I designed a complex robotic arm, leveraging its advanced assembly tools to manage hundreds of individual components. The project required detailed simulations using SolidWorks Simulation to ensure structural integrity and optimize movement. My experience with Creo came into play when I was involved in designing a major component for a wind turbine; the focus here was on the advanced features for managing large assemblies and integrating design changes efficiently.

Q 3. What are the common file formats used in CAD and how do they differ?

Several file formats are commonly used in CAD, each with its strengths and limitations. Understanding their differences is crucial for seamless data exchange.

- STEP (Standard for the Exchange of Product data): A neutral format widely used for exchanging CAD data between different software packages. It’s a robust format supporting complex 3D models and maintains geometric integrity well. It’s like a universal language for CAD.

- IGES (Initial Graphics Exchange Specification): Another neutral format, though slightly less versatile than STEP, particularly for very complex models. It’s older than STEP and some data can be lost during translation.

- DWG (Drawing): AutoCAD’s native format, essential for its vast user base. It’s widely understood but proprietary, sometimes presenting challenges in interoperability with other software.

- DXF (Drawing Exchange Format): A text-based version of DWG, enabling better interoperability than DWG but potentially losing some data during conversion.

- STL (Stereolithography): Primarily used for 3D printing and rapid prototyping. It represents the surface geometry as a mesh of triangles, making it suitable for manufacturing but not ideal for detailed design modifications.

Choosing the right format depends on the application. For instance, STEP or IGES would be ideal when exchanging models between different CAD systems, whereas STL is preferred when preparing a model for 3D printing.

Q 4. Explain the concept of constraints in CAD modeling.

Constraints in CAD modeling are geometric relationships that define how different components or features interact. They are essential for creating robust and flexible designs. Think of them as the rules that govern how parts fit together and behave.

Imagine building with LEGOs. Constraints are like the connections between bricks – they determine how the structure is assembled and how it will react to forces. In CAD, constraints can specify distances, angles, parallelism, perpendicularity, tangency, and more. They ensure that the design maintains its intended geometry and behaves predictably. For example, if you want two surfaces to always remain parallel as you modify other aspects of the design, you’d use a parallel constraint. Constraints greatly improve design efficiency, reduce errors, and provide more design flexibility because if you change one part, the others will adjust according to the constraints.

Q 5. How do you handle large and complex assemblies in CAD?

Managing large and complex assemblies effectively requires a strategic approach. Simply opening a massive assembly and trying to work with it directly is often inefficient and can cause software instability.

- Component simplification: Replacing detailed components with simplified representations for initial design exploration and early-stage simulations. Think using placeholders for smaller, less critical parts during the initial design phases.

- Sub-assemblies: Breaking down the large assembly into smaller, manageable sub-assemblies. This is analogous to assembling modules of a building before putting them all together.

- Lightweight components: Employing lightweight components, which reduce file size without sacrificing essential geometric information. This speeds up performance significantly.

- Efficient assembly techniques: Using top-down or bottom-up assembly methods, depending on project complexity. Top-down starts with the largest components, and bottom-up starts with the smaller ones.

- Component suppression and visibility: Hiding or suppressing parts that are not actively being worked on improves performance.

- Design review optimization: Limiting the number of components that are visible during design reviews by selectively turning them off. This is useful for focusing on specific sub-assemblies during team reviews.

Efficiently handling large assemblies in CAD necessitates meticulous planning and the strategic application of these techniques.

Q 6. Describe your experience with parametric modeling.

Parametric modeling is a powerful CAD technique where the model’s geometry is defined by parameters or variables. Instead of manually creating each feature, parameters control the shape and dimensions. Changing a parameter automatically updates the entire model, providing immense flexibility and efficiency. Think of it as a recipe: parameters are ingredients, and the model is the result.

For example, imagine designing a box. In parametric modeling, you’d define parameters for length, width, and height. Changing any of these parameters automatically adjusts the box’s dimensions. This is crucial for iterative design and design optimization. If you need to modify the size of the box, you simply change the parameters, and the model updates accordingly. This eliminates the need for manual adjustments and reduces the risk of errors. This is especially powerful when dealing with complex parts with many interdependencies.

Q 7. Explain the process of creating detailed drawings from a 3D model.

Creating detailed drawings from a 3D model is a crucial step in manufacturing and design communication. It involves extracting 2D views, sections, and annotations to clearly define the object’s dimensions, tolerances, and manufacturing specifications.

- View generation: The CAD software automatically generates standard orthographic views (front, top, side) from the 3D model. These views are essential for visualizing the object from different perspectives.

- Section views: Creating section views to reveal internal features and geometry not visible in the external views.

- Dimensioning and tolerancing: Adding dimensions and tolerances to ensure precision in manufacturing. This usually involves specifying the required accuracy and acceptable variations in the final product’s measurements.

- Annotations: Adding annotations like notes, surface finishes, and material specifications to provide comprehensive information about the part.

- Bill of Materials (BOM): Generating a BOM that lists all the components used in an assembly.

- Drawing standards adherence: Ensuring the drawings comply with relevant industry standards (e.g., ASME Y14.5 for mechanical drawings).

The process typically involves selecting the appropriate views, adding dimensions and tolerances based on manufacturing requirements, and then annotating the drawings to clarify any ambiguous aspects.

Q 8. What are your preferred methods for dimensioning and tolerancing?

My preferred methods for dimensioning and tolerancing are based on the principles of ASME Y14.5, the standard for geometric dimensioning and tolerancing (GD&T). This isn’t just about stating sizes; it’s about defining the acceptable variations in those sizes and the shapes of features. I prioritize clarity and avoid ambiguity. For instance, instead of simply stating a diameter, I’ll use GD&T symbols to specify tolerances for roundness, cylindricity, and position. This ensures that the part produced will function correctly even with minor variations in manufacturing.

- Basic Dimensioning: I use clear, concise dimensions with appropriate units (usually millimeters or inches depending on the project). I avoid redundant dimensions and ensure dimensions are placed logically for easy interpretation.

- Tolerancing: I use bilateral tolerances (e.g., ±0.1mm) when possible, but also utilize unilateral tolerances (e.g., 0.0+0.1mm) where tighter control is needed on one side of the nominal dimension. I also utilize geometric tolerances, such as position, perpendicularity, and flatness, to control the form and orientation of features crucial for proper assembly and function.

- Feature Control Frames (FCFs): These are my go-to for specifying geometric tolerances. They clearly communicate the tolerance zone, the feature of size being controlled, and the datum references used. For example, a feature control frame might specify the position tolerance of a hole relative to a datum plane and datum axis, ensuring it is correctly located for mating with another part.

Choosing the right method depends entirely on the application. A simple part might only require basic dimensioning and tolerances, while a complex assembly will require a more detailed approach using GD&T to ensure proper functionality and interchangeability.

Q 9. How do you ensure the accuracy and precision of your CAD models?

Ensuring accuracy and precision in CAD models is a multi-faceted process that starts with meticulous planning. It involves a combination of careful modeling techniques, rigorous quality checks, and leveraging the capabilities of the CAD software.

- Precise Input Data: Accuracy begins with accurate input data. This includes using precise measurements, relying on reliable sources for imported data, and carefully checking all dimensions and specifications.

- Constraint-Based Modeling: I heavily rely on constraints to define relationships between model features. This avoids the accumulation of small errors that can propagate through the model and provides a stable geometry less prone to unexpected changes.

- Model Validation: Regular checks are crucial. This includes visually inspecting the model for inconsistencies, using the software’s inbuilt analysis tools to check for errors (e.g., gaps, overlaps, or interference), and validating against design specifications.

- Version Control: Employing a robust version control system (e.g., Git for CAD data) enables tracking changes and easy reversion if necessary. This is particularly important in collaborative projects.

- Finite Element Analysis (FEA) Validation (when applicable): When dealing with complex geometries or critical structural components, FEA serves as an excellent way to validate model behavior under expected loads and conditions.

Imagine designing a precise gear. Without meticulous attention to dimensions and tolerances, the teeth wouldn’t mesh correctly. My approach ensures the gear meets the stringent requirements for proper functionality.

Q 10. Explain your understanding of Finite Element Analysis (FEA).

Finite Element Analysis (FEA) is a powerful computational technique used to predict how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. It works by breaking down a complex geometry into a large number of smaller, simpler elements (hence ‘finite elements’). Each element is assigned material properties, and equations governing physical behavior are applied to these elements. The software then solves these equations simultaneously to provide a detailed analysis of stresses, strains, displacements, and other relevant parameters within the model.

Think of it like building a model out of LEGO bricks. Each brick is an element, and the way they are connected and interact represents the structure’s behavior under load. FEA allows us to predict how the entire structure will react to forces without needing to physically test it, saving time and resources.

- Meshing: This critical step divides the model into elements. The mesh density influences the accuracy of the results; finer meshes offer higher accuracy but increase computational cost.

- Boundary Conditions: These define how the model interacts with its surroundings. Examples include fixed supports, applied forces, and temperature gradients.

- Material Properties: Accurate material properties (e.g., Young’s modulus, Poisson’s ratio) are vital for realistic simulations.

FEA is indispensable in designing everything from aircraft wings to medical implants, ensuring structural integrity and optimal performance.

Q 11. Describe your experience using FEA software (e.g., ANSYS, Abaqus).

I have extensive experience with ANSYS and Abaqus, two leading FEA software packages. My proficiency extends to both static and dynamic analyses, as well as various specialized analyses such as thermal, modal, and nonlinear analyses.

- ANSYS: I’m comfortable using ANSYS Workbench for pre-processing, solving, and post-processing. I’ve utilized its various modules, including Mechanical APDL (for advanced scripting and customization), and have experience with various element types and material models to suit the problem at hand.

- Abaqus: Abaqus is particularly strong in nonlinear analysis, and I have experience modeling complex material behaviors (e.g., plasticity, viscoelasticity), contact interactions, and large deformations. I’m also skilled in using Abaqus CAE for model creation and visualization.

For example, I used ANSYS to analyze the stress distribution in a complex automotive component under various loading conditions, optimizing the design to minimize weight while maintaining structural integrity. In another project, I leveraged Abaqus’s nonlinear capabilities to simulate the crashworthiness of a vehicle chassis.

Q 12. How do you interpret and analyze FEA results?

Interpreting and analyzing FEA results involves a systematic approach to identify critical areas and extract meaningful insights from the vast amount of data generated.

- Visual Inspection: I begin by visually inspecting contour plots and deformed shapes to identify regions of high stress, strain, or displacement. This provides a general understanding of the model’s response.

- Data Extraction: I then extract quantitative data from specific points or regions of interest. This includes extracting values of stress, strain, displacement, and other relevant parameters.

- Validation: I compare the results with theoretical predictions or experimental data whenever possible to ensure accuracy and reliability. Discrepancies often require reviewing the model setup, mesh quality, and material properties.

- Failure Criteria: I apply appropriate failure criteria (e.g., Von Mises stress, maximum shear stress) to assess the likelihood of failure under the given loading conditions.

- Report Generation: Finally, I generate comprehensive reports that summarize the key findings, including visualizations and data tables. These reports communicate the analysis results to stakeholders clearly and concisely.

Let’s say we’re analyzing a bridge. By examining the stress contours and displacement plots, we can identify areas of high stress concentration and potential failure points, allowing for design modifications to enhance structural integrity.

Q 13. Explain the concept of Computational Fluid Dynamics (CFD).

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical methods and algorithms to solve and analyze problems that involve fluid flows. It’s a powerful tool for simulating the behavior of liquids and gases under various conditions.

Think of it like creating a virtual wind tunnel. Instead of physically building and testing a model, CFD lets us simulate how air flows around an object, allowing us to predict drag, lift, and other aerodynamic characteristics.

- Governing Equations: CFD solves the Navier-Stokes equations, which describe the motion of fluids. These equations are complex and often require sophisticated numerical techniques to solve.

- Mesh Generation: Similar to FEA, CFD requires meshing the computational domain. The mesh quality significantly impacts the accuracy and stability of the solution.

- Boundary Conditions: Appropriate boundary conditions define the fluid flow at the boundaries of the computational domain (e.g., inlet velocity, outlet pressure).

- Turbulence Modeling: Many fluid flows are turbulent, requiring turbulence models to account for the chaotic nature of the flow.

CFD is crucial in designing everything from aircraft and cars to pipelines and medical devices, helping engineers optimize designs for efficiency and performance.

Q 14. Describe your experience using CFD software (e.g., ANSYS Fluent, OpenFOAM).

My experience encompasses both ANSYS Fluent and OpenFOAM, two prominent CFD software packages, each with its strengths and weaknesses.

- ANSYS Fluent: A widely used commercial software, Fluent offers a user-friendly interface and a wide range of turbulence models and physical models (e.g., heat transfer, multiphase flow). I’ve used it extensively for simulating various flow phenomena, including external aerodynamics, internal flows, and heat transfer.

- OpenFOAM: An open-source CFD toolbox, OpenFOAM provides great flexibility and customization options. It’s powerful for tackling complex fluid dynamics problems, but it requires a deeper understanding of the underlying numerical methods. I’ve used it for advanced simulations where I needed more control over the solver parameters and meshing techniques.

For instance, I used ANSYS Fluent to optimize the design of a ventilation system in a building, ensuring adequate air circulation and minimizing energy consumption. For a more complex simulation of multiphase flow in a chemical reactor, I chose OpenFOAM for its greater control over the solver parameters and its ability to handle complex boundary conditions.

Q 15. How do you validate the results of your simulations?

Validating simulation results is crucial to ensure the accuracy and reliability of the model. It’s like checking your recipe before baking a cake – you want to be confident the final product will be as expected. This involves a multi-pronged approach:

- Comparison with Analytical Solutions: If possible, compare your simulation results with known analytical solutions or established formulas. This provides a benchmark for accuracy. For example, for simple beam bending, compare your Finite Element Analysis (FEA) results to the classic beam theory calculations.

- Experimental Validation: The gold standard. Conduct physical experiments on a prototype or a real-world system to compare the simulation’s predictions with real-world measurements. This is essential for complex systems where analytical solutions are unavailable.

- Mesh Convergence Studies: For numerical methods like FEA, refining the mesh (increasing the number of elements) and observing the effect on results is critical. If the results change significantly with mesh refinement, the simulation isn’t converged and further refinement is needed to ensure accuracy.

- Benchmarking against Established Software or Results: If you’re using a new software or method, running a well-documented benchmark problem and comparing your results to published data is a valuable validation step.

- Sensitivity Analysis: Determine how sensitive the results are to changes in input parameters. If small changes in input lead to large variations in output, this indicates potential problems with the model or simulation setup.

By combining these methods, you build confidence in your simulation’s accuracy and reliability. Remember that perfect agreement is rarely achievable, but a reasonable level of correlation should be expected.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common challenges in CAD modeling and simulation?

CAD modeling and simulation present several challenges. Think of it like building a complex LEGO castle: you need the right pieces, the right instructions, and patience!

- Geometric Complexity: Modeling intricate geometries accurately can be time-consuming and resource-intensive. High-fidelity models require significant computational power, especially for complex simulations. For instance, modeling the intricate internal structure of a human heart for blood flow analysis demands advanced CAD capabilities and considerable computing resources.

- Meshing Issues: Generating appropriate meshes for FEA is crucial, but can be challenging for complex geometries. Improper meshing leads to inaccurate or unconverged solutions. Imagine trying to build a LEGO castle with unevenly sized bricks – the structure might be unstable.

- Material Modeling: Accurately representing material behavior in simulations is crucial. Simple material models might not capture real-world complexities, leading to inaccurate predictions. Choosing the right material model is akin to selecting the right type of LEGO brick for its intended purpose: a small brick won’t work for a large castle wall.

- Simulation Time: Running simulations, particularly large-scale ones, can take considerable time. This can limit the number of design iterations possible. Think about having to wait for the LEGO castle to dry before you can add more bricks.

- Data Management: Organizing and managing large datasets generated during CAD modeling and simulation is critical. Poor data management can lead to errors and inconsistencies.

Q 17. How do you troubleshoot and resolve errors in CAD models or simulations?

Troubleshooting errors in CAD models and simulations requires a systematic approach, much like solving a detective mystery.

- Examine Error Messages: Carefully read error messages from the software. They often provide valuable clues about the nature and location of the problem.

- Check Geometry for Errors: Verify that your CAD model is free from errors such as gaps, intersections, and non-manifold geometry. CAD software often has tools for geometry checks.

- Inspect Mesh Quality: For simulations involving meshing, visually inspect the mesh for issues like poor element quality, excessive element distortion, or overly coarse/fine regions. Re-meshing might be required.

- Review Material Properties and Boundary Conditions: Double-check that material properties and boundary conditions are accurately defined. Small errors here can lead to significant discrepancies in simulation results.

- Simplify the Model: If dealing with a complex model, consider simplifying it to isolate the source of the error. This is similar to building a smaller LEGO model to test a particular technique before applying it to a larger construction.

- Consult Documentation and Online Resources: Software documentation and online forums can provide valuable insights and solutions to common problems.

- Contact Technical Support: For persistent errors, contacting the software vendor’s technical support team can be invaluable.

Remember, patience and persistence are key to effectively troubleshooting CAD models and simulations.

Q 18. Describe your experience with CAD data management and version control.

Effective CAD data management and version control are essential for collaborative projects. Think of it as keeping a meticulously organized and versioned history for your design, making sure everyone is using the correct and most up-to-date design.

My experience includes using various systems such as:

- PDM (Product Data Management) systems: I’ve worked extensively with systems like Teamcenter and Windchill, using them to manage CAD files, revisions, and associated documentation. These systems allow for secure storage, version control, and collaborative workflows.

- Git-based Version Control for CAD: I’ve used Git alongside CAD software, utilizing tools like Git LFS (Large File Storage) to handle the large file sizes typical of CAD models. This allows for branching, merging, and tracking changes effectively.

- Cloud-based CAD Data Management: I’m familiar with cloud-based storage and collaboration platforms like Autodesk A360 and Onshape, using their integrated version control and data management functionalities.

I understand the importance of implementing robust naming conventions, proper metadata, and thorough documentation to ensure data traceability and collaboration efficiency.

Q 19. Explain your understanding of design for manufacturing (DFM).

Design for Manufacturing (DFM) is a crucial aspect of product development that aims to optimize the design for efficient and cost-effective manufacturing. It’s like planning a construction project meticulously – you want to minimize waste, optimize material use, and choose the right tools and techniques from the beginning.

Key aspects of DFM include:

- Manufacturability: Ensuring that the design is feasible to produce using the selected manufacturing processes. This involves considering factors like material selection, tolerances, and assembly methods.

- Cost Optimization: Minimizing material costs, labor costs, and overall production costs by making the design as efficient as possible.

- Assembly considerations: Designing for ease of assembly reduces production time and labor costs. Simplified designs often lead to fewer errors during the assembly process.

- Testability: Designing products with built-in mechanisms for easy testing and quality control. This minimizes the need for expensive and time-consuming post-production testing procedures.

- Sustainability: Using environmentally friendly materials and processes, minimizing waste, and designing for recyclability. This reduces the environmental impact of the product throughout its lifecycle.

Q 20. How do you incorporate DFM principles into your CAD models?

I incorporate DFM principles into CAD models using several strategies, like considering manufacturing constraints during the design phase and using DFM analysis tools:

- Using Manufacturing Process Simulation: Simulating manufacturing processes like injection molding, casting, or machining, to predict potential issues and optimize the design for the selected process. This allows for early identification of potential problems, saving time and resources.

- Employing DFM Analysis Software: Utilizing specialized software tools that automate the DFM analysis, providing feedback on manufacturability, cost, and other aspects. This can highlight areas of the design that might be problematic during production.

- Following Design Guidelines: Adhering to established design guidelines and best practices relevant to the chosen manufacturing processes, such as minimizing sharp corners or avoiding thin walls in castings.

- Collaboration with Manufacturing Engineers: Close collaboration with manufacturing engineers throughout the design process. Their expertise ensures manufacturability and cost-effectiveness.

- Material Selection: Choosing materials suitable for the chosen manufacturing method and end-use application. Consider factors like material cost, properties, and availability.

By proactively integrating DFM considerations, I help to avoid costly design changes later in the development cycle.

Q 21. Describe your experience with tolerance analysis.

Tolerance analysis is crucial for ensuring that parts manufactured within specified tolerances will assemble and function correctly. It’s like ensuring all LEGO bricks fit together perfectly to build the intended structure.

My experience with tolerance analysis includes:

- Statistical Tolerance Analysis: Using statistical methods to determine the overall variation in assembly dimensions based on the individual tolerances of the components. This typically involves using Monte Carlo simulations or other statistical techniques.

- Worst-Case Tolerance Analysis: Determining the maximum possible variation in assembly dimensions based on the extreme values of individual component tolerances. This provides a more conservative estimate of assembly variation.

- Geometric Dimensioning and Tolerancing (GD&T): I’m proficient in using GD&T symbols and notations to define tolerances and geometric controls on CAD models. This ensures that the design intent is clear and unambiguous for manufacturers.

- Tolerance Stack-up Analysis: Analyzing how individual component tolerances accumulate to affect the overall dimensions and functionality of the assembly. This helps identify critical tolerances that require tighter control.

- Software Tools: I’ve used various software tools for tolerance analysis, including those integrated within CAD packages and dedicated tolerance analysis software.

Through tolerance analysis, I strive to design robust assemblies that are less sensitive to manufacturing variations, thereby improving the quality and reliability of the final product.

Q 22. Explain your understanding of different meshing techniques in FEA.

Meshing is a crucial preprocessing step in Finite Element Analysis (FEA) where a complex geometry is divided into smaller, simpler elements (like triangles or tetrahedra). The accuracy and efficiency of the simulation heavily depend on the mesh quality. Different techniques exist, each with its strengths and weaknesses:

- Structured Meshing: This approach generates a highly organized mesh with elements of regular shape and size. It’s computationally efficient but can be challenging to apply to complex geometries. Think of it like tiling a perfectly rectangular room – easy and straightforward.

- Unstructured Meshing: This offers greater flexibility in handling complex shapes, adapting to curves and intricate details. However, it often results in more elements and increased computational cost. Imagine fitting irregular puzzle pieces together to cover an oddly shaped area.

- Adaptive Meshing: This technique dynamically refines the mesh during the simulation process. It automatically adds elements in regions with high stress concentrations or gradients, improving accuracy where it’s most needed while saving computational resources. This is like having a painter focus on the details where they matter most, leaving the background simpler.

- Hybrid Meshing: This combines structured and unstructured approaches, leveraging the advantages of both. For instance, a structured mesh might be used in simple regions, transitioning to an unstructured mesh near complex features. It’s a pragmatic approach to balance efficiency and accuracy.

The choice of meshing technique depends on factors like the geometry’s complexity, the desired accuracy, and the available computational resources. Software like ANSYS, Abaqus, and COMSOL offer various meshing options and controls.

Q 23. How do you choose appropriate boundary conditions for simulations?

Selecting appropriate boundary conditions is paramount for a realistic and accurate simulation. Boundary conditions define how the model interacts with its environment. Incorrect choices can lead to inaccurate or meaningless results. The key is understanding the physics of the problem.

- Fixed Supports/Constraints: These restrict the movement of specific nodes or surfaces, mimicking real-world supports like clamps or welds. For example, in a stress analysis of a cantilever beam, one end might be fixed, preventing translation and rotation.

- Loads: These represent forces or pressures acting on the model, such as gravity, pressure loads (e.g., internal pressure in a pipe), or surface tractions.

- Symmetry Conditions: These can simplify the model by exploiting symmetry. For instance, if a component is symmetric, you can model only half and apply symmetry boundary conditions along the plane of symmetry, reducing computational effort.

- Thermal Conditions: These are essential for thermal simulations and specify temperatures or heat fluxes at boundaries. This might involve specifying a constant temperature at a surface or defining a convective heat transfer coefficient.

Proper boundary conditions require a deep understanding of the physical system being simulated and careful consideration of how these idealized conditions reflect the real-world setup. An incorrect boundary condition can render an otherwise well-executed simulation meaningless.

Q 24. Describe your experience with optimization techniques in CAD or simulation.

I have extensive experience using optimization techniques in both CAD and simulation. Optimization aims to find the best design within specific constraints, such as minimizing weight while maintaining strength or maximizing efficiency. I’ve utilized both gradient-based and gradient-free methods:

- Gradient-Based Methods (e.g., Nelder-Mead, conjugate gradient): These require calculating the gradient of the objective function (what you’re trying to optimize). They’re efficient for smooth, continuous functions but can get stuck in local optima.

- Gradient-Free Methods (e.g., Genetic Algorithms, Simulated Annealing): These don’t require gradient calculations and are robust for complex, discontinuous functions but can be computationally more expensive.

In practice, I’ve used these methods for:

- Topology Optimization: Finding the optimal material distribution within a given design space to minimize weight under stress constraints.

- Shape Optimization: Modifying the geometry of a component to improve its performance, such as reducing drag on an airfoil.

- Parametric Studies: Exploring the effect of different design parameters on the overall performance through automated simulations.

For instance, I once optimized the design of a bracket to minimize its weight while satisfying stress limits. By using a genetic algorithm coupled with FEA, we identified a lighter design with improved strength compared to the initial design. Software packages like OptiStruct and modeFRONTIER are often used for these purposes.

Q 25. Explain your understanding of different types of simulations (e.g., static, dynamic, thermal).

Different simulation types cater to various engineering problems. Here are some common ones:

- Static Analysis: Simulates the response of a structure under constant loads. It determines displacements, stresses, and strains in a structure under steady-state conditions, suitable for analyzing structures under constant loads like buildings under gravity.

- Dynamic Analysis: Analyzes how a structure responds to time-varying loads. It accounts for inertia effects and can predict vibrations, impacts, or transient phenomena. Examples include analyzing a building’s response to an earthquake or the impact of a car crash.

- Thermal Analysis: Simulates heat transfer within a system. It predicts temperature distributions, heat fluxes, and thermal stresses. Applications include designing efficient heat sinks, analyzing electronic component temperature, or determining the temperature profile in a building.

- Fluid Dynamics (CFD): Simulates fluid flow and heat transfer. It predicts velocities, pressures, and temperatures in fluids. Applications include analyzing airflow around an aircraft wing, designing efficient piping systems, or modeling blood flow in arteries.

- Nonlinear Analysis: This type of analysis considers effects like large deformations, material nonlinearities (plasticity), and contact interactions, which are often crucial for more realistic simulations.

The selection of the appropriate simulation type depends entirely on the problem being addressed. A static analysis is sufficient for a bridge under constant loading, whereas a dynamic analysis would be necessary for a structure experiencing vibrations or shocks.

Q 26. How do you ensure the quality of your CAD models and simulations?

Ensuring quality in CAD models and simulations is critical for reliable results. My approach involves a multi-faceted strategy:

- CAD Model Quality Check: I meticulously check the CAD model for errors like gaps, overlaps, inconsistencies, and missing faces before importing it into the simulation software. Tools within CAD software, and external plugins, can assist with this process.

- Mesh Quality Assessment: After meshing, I thoroughly assess the mesh quality. Metrics such as element aspect ratio, skewness, and Jacobian are evaluated. Poor mesh quality can lead to inaccurate results, requiring re-meshing.

- Convergence Studies: I perform convergence studies by refining the mesh and verifying that the results converge to a stable solution. This helps ensure the solution’s independence from the mesh density.

- Independent Verification: Whenever possible, I compare simulation results with experimental data, analytical solutions, or results from other simulation tools. This provides a crucial validation of the results.

- Documentation and Reporting: Detailed documentation of the process, including mesh parameters, boundary conditions, and material properties, is maintained. Clear and comprehensive reports are generated, explaining assumptions, limitations, and potential sources of error.

A thorough quality assurance process instills confidence in the simulation results, ensuring that they accurately represent the real-world behavior of the design.

Q 27. Describe a time you had to solve a complex CAD or simulation problem. What was your approach?

I once faced a challenging project involving the simulation of a complex assembly subjected to dynamic loading. The assembly consisted of multiple interacting components with intricate geometries and different material properties. Initial simulations yielded inconsistent results and convergence issues.

My approach involved a systematic troubleshooting process:

- Detailed Geometry Review: I first meticulously reviewed the CAD models of all components, identifying and resolving any geometrical imperfections or inconsistencies.

- Mesh Refinement Strategy: I employed an adaptive meshing technique, focusing on regions experiencing high stress concentrations. This strategy allowed for accurate representation of stress gradients while maintaining computational efficiency.

- Boundary Condition Validation: I rigorously reviewed and validated the boundary conditions, ensuring they accurately reflected the physical constraints and loads.

- Material Property Verification: I verified the material properties used in the simulation, consulting technical documentation and conducting material tests where necessary.

- Iterative Simulation and Analysis: I performed iterative simulations, carefully analyzing the results at each step. This iterative process allowed for the identification and correction of errors or assumptions.

Through this systematic approach, I was able to obtain reliable and consistent simulation results, providing valuable insights for design improvements and validation. The key was breaking down the complex problem into smaller, manageable steps, systematically addressing each potential source of error.

Key Topics to Learn for Computer-Aided Design (CAD) and Simulation Software Knowledge Interview

- Fundamental CAD Concepts: Understanding 2D and 3D modeling principles, geometric constraints, and parametric modeling techniques. Be prepared to discuss different CAD software functionalities and their applications.

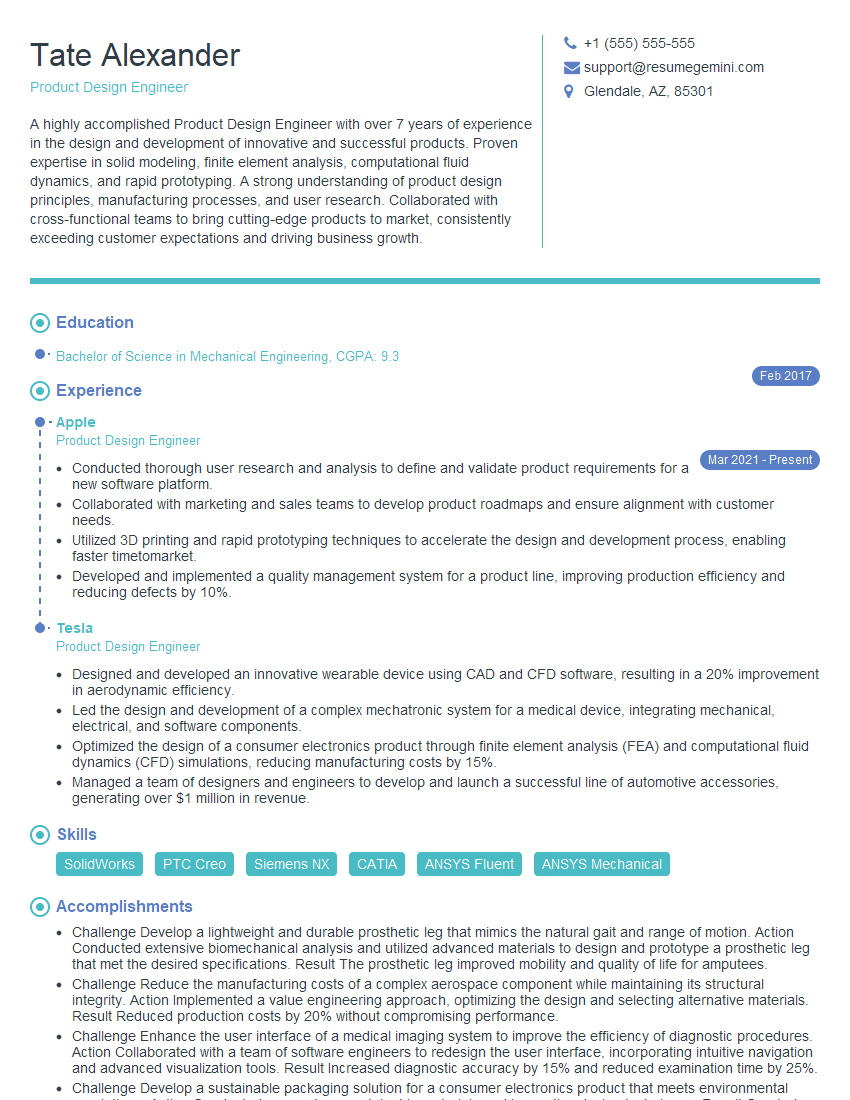

- Specific Software Proficiency: Demonstrate expertise in at least one major CAD software (e.g., AutoCAD, SolidWorks, Creo, CATIA). Highlight your skills in modeling, drafting, and design modifications. Be ready to discuss projects where you utilized these skills.

- Simulation Techniques: Explain your understanding of finite element analysis (FEA), computational fluid dynamics (CFD), or other relevant simulation methods. Discuss how simulation results inform design decisions and problem-solving.

- Design for Manufacturing (DFM): Show your awareness of manufacturing processes and how design choices impact manufacturability, cost, and assembly. Be able to discuss tolerance analysis and design optimization.

- Data Management & Collaboration: Describe your experience with CAD data management systems, version control, and collaborative design workflows. Highlight your ability to work effectively in a team environment.

- Problem-Solving & Design Thinking: Be prepared to discuss your approach to solving complex design challenges. Showcase your ability to analyze problems, develop solutions, and iterate on designs based on feedback and simulation results.

- Industry Standards & Best Practices: Demonstrate familiarity with relevant industry standards and best practices for CAD modeling and simulation. This shows attention to detail and professionalism.

Next Steps

Mastering Computer-Aided Design (CAD) and Simulation Software Knowledge is crucial for career advancement in engineering and related fields. A strong understanding of these tools opens doors to exciting opportunities and higher earning potential. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Computer-Aided Design (CAD) and Simulation Software Knowledge to help you get started. Invest time in crafting a strong resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good