Preparation is the key to success in any interview. In this post, we’ll explore crucial Concrete Flatwork Installation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Concrete Flatwork Installation Interview

Q 1. Describe your experience with different concrete mixes and their applications.

My experience encompasses a wide range of concrete mixes, each tailored to specific applications. The choice of mix depends heavily on the project’s requirements, including strength, durability, finish, and the environmental conditions. For instance, a high-strength mix (e.g., 5000 psi) might be needed for heavily loaded industrial floors, while a lower-strength mix (e.g., 3000 psi) would suffice for residential patios. I’ve worked extensively with mixes incorporating various admixtures like air-entraining agents (improving freeze-thaw resistance), water reducers (increasing workability), and accelerators (reducing setting time). For example, on a recent project involving a large commercial parking lot, we used a mix designed for high abrasion resistance and rapid strength gain to minimize project downtime. In another instance, for a decorative concrete overlay, we chose a specialized mix with a fine aggregate gradation for a smoother, more easily workable consistency. Selecting the appropriate mix is crucial for ensuring both quality and longevity.

Q 2. Explain the process of preparing a subgrade for concrete flatwork.

Preparing the subgrade is paramount; it’s the foundation upon which the concrete’s durability rests. Think of it like building a house – you wouldn’t build on unstable ground! The process begins with excavating to the required depth, ensuring proper compaction to prevent settling. I typically use a plate compactor to achieve optimal density, checking compaction levels with a density gauge to meet specifications. Next, I lay a layer of well-graded, compacted base material (e.g., crushed stone or gravel) for drainage and further stability. The thickness of this base layer depends on the project’s load requirements and soil conditions. Finally, we ensure a level surface using a screed, often employing laser leveling technology for large projects to guarantee an accurate, consistent base for the concrete pour. Any irregularities can lead to problems such as cracking and uneven wear, so this stage is vital.

Q 3. What are the different types of concrete finishes and their uses?

Concrete finishes are as diverse as the projects themselves.

- Broomed finish: Creates a textured, slip-resistant surface, ideal for driveways and walkways. The broom creates channels that help with water drainage.

- Troweled finish: Provides a smooth, polished surface, frequently used in interiors or high-traffic areas where aesthetics are important. Various levels of troweling create different levels of smoothness.

- Stamped finish: Mimics the appearance of natural stone, brick, or tile. This is done by pressing stamps into the concrete before it sets.

- Exposed aggregate finish: Exposes the aggregate (stones and gravel) by washing away the cement paste, creating a unique, textured look commonly used for decorative pavements.

- Colored concrete: Achieved by adding pigments to the concrete mix, offering a wide range of aesthetic choices.

Q 4. How do you ensure proper concrete consolidation?

Proper concrete consolidation is crucial for eliminating air pockets and ensuring a dense, strong, and durable slab. This is primarily achieved through vibration. I use either internal vibrators (needle vibrators) for smaller pours or external vibrators (plate vibrators) for larger areas. These tools create vibrations that help the concrete settle and release trapped air, leading to a more homogeneous and robust structure. The key is to vibrate the concrete just enough to eliminate voids without over-vibrating, which can lead to segregation (separation of cement paste from aggregate). Visual cues, like the release of air bubbles, and proper vibration time are crucial indicators of successful consolidation. Over-vibration can lead to segregation and weakening of the concrete. Under-vibration leads to voids and weakened sections which compromises the final product.

Q 5. What are the common causes of cracking in concrete flatwork and how do you prevent them?

Cracking in concrete flatwork is a common problem, often stemming from a combination of factors.

- Shrinkage: As concrete dries, it shrinks, causing stress that can lead to cracking. This is minimized through proper curing practices and control joints.

- Thermal stress: Temperature changes cause the concrete to expand and contract, resulting in stress. Expansion joints mitigate this issue.

- Poor subgrade preparation: Uneven or unstable subgrades can cause differential settlement, leading to cracks.

- Insufficient consolidation: Air pockets within the concrete can create weak points, predisposing it to cracking.

- Overloading: Exceeding the concrete slab’s design load capacity leads to structural failure and potential cracking.

Q 6. Describe your experience with different types of concrete curing methods.

I utilize various curing methods, each suited to specific project needs and environmental conditions.

- Water curing: Keeping the concrete surface continuously moist for a set period helps maintain hydration and minimizes shrinkage cracking. This can involve ponding (covering the concrete with water) or using wet burlap.

- Membrane curing: Applying a curing compound (a liquid membrane) seals in moisture, reducing evaporation and preventing premature drying. This method works well in hot, dry climates.

- Curing blankets: These insulated blankets maintain a consistent temperature and moisture level, promoting even hydration. They are particularly useful in cold or windy conditions.

Q 7. How do you control the thickness and levelness of concrete pours?

Controlling thickness and levelness is vital for a functional and aesthetically pleasing concrete flatwork. For thickness, we use accurately calibrated screeds, set to the desired thickness based on project specifications and engineering calculations. For levelness, we employ a combination of techniques. On smaller projects, a hand screed and level are used. Larger projects often leverage laser screeds for precise leveling across extensive areas. Continuous monitoring with a level and straight edge during the pouring process is crucial to promptly address any deviations. After the initial screeding, any minor imperfections are addressed by floating and troweling. This process refines the surface to the desired level of smoothness and ensures consistency in the finished product. Careful attention to detail in these steps is essential for achieving the specified levelness and thickness.

Q 8. Explain your experience with using power tools and equipment related to concrete flatwork.

My experience with power tools and equipment in concrete flatwork is extensive. I’m proficient in operating and maintaining a wide range of machinery, from smaller tools like power trowels and grinders to larger equipment such as concrete saws, ride-on power floats, and even small concrete pumps for larger pours. I understand the nuances of each piece of equipment, including their optimal settings for different concrete mixes and project requirements. For example, I know how the blade speed on a power trowel affects the final surface finish – a slower speed for a smoother finish, and a faster speed for a more textured surface. I also understand the importance of regular maintenance to ensure optimal performance and prevent costly downtime. This includes things like blade sharpening, regular oil changes, and checking for any signs of wear and tear before each use. Safety is always paramount, and I’m meticulous about ensuring all equipment is functioning correctly and that appropriate safety measures are in place before operation.

Q 9. What safety precautions do you take while working with concrete?

Safety is my top priority on every job site. When working with concrete, there are numerous hazards, so I meticulously follow all relevant safety protocols. This includes wearing appropriate Personal Protective Equipment (PPE) at all times, such as safety glasses, hard hats, gloves, steel-toed boots, and hearing protection. I also ensure the work area is properly secured and marked to prevent unauthorized access. Before pouring concrete, I thoroughly inspect the site for any potential hazards, such as uneven ground or obstacles that could cause tripping. I’m also vigilant about managing the potential for chemical burns from concrete and using proper cleaning procedures. We always have readily available first-aid supplies and emergency contacts at hand. Furthermore, I am trained in fall protection techniques and utilize harnesses and appropriate fall protection equipment when working at heights. Proper ventilation is crucial when working with concrete admixtures, and I ensure that adequate ventilation is maintained, especially in enclosed spaces.

Q 10. How do you manage concrete placement in different weather conditions?

Managing concrete placement in different weather conditions requires adaptability and planning. In hot weather, we use methods to prevent premature drying, such as applying curing compounds immediately after finishing and using shade structures to shield the concrete from direct sunlight. We also adjust the water content of the mix and might use admixtures to control setting time. Conversely, in cold weather, we take measures to protect the concrete from freezing, including insulating the formwork, using blankets, and employing anti-freeze admixtures in the mix. We often monitor temperatures throughout the pouring and curing process, ensuring the concrete doesn’t freeze before it gains sufficient strength. I have experience working in a range of climates and temperatures, adapting my techniques accordingly to ensure the integrity of the concrete.

Q 11. Describe your experience with reading and interpreting blueprints and plans for concrete flatwork.

I have extensive experience reading and interpreting blueprints and plans for concrete flatwork. I’m comfortable understanding and translating various symbols, dimensions, and specifications to accurately lay out the project. This includes identifying critical details such as elevations, grades, reinforcement requirements, joint locations, and tolerances. For example, I can decipher symbols indicating the type and placement of rebar, which is crucial for structural integrity. I also understand the importance of checking the plans for any revisions or changes before starting the work. On a recent project, the blueprints indicated a subtle change in grade that needed careful consideration to prevent ponding. My ability to thoroughly understand and interpret the plans ensured a perfect outcome.

Q 12. Explain the importance of proper joint placement and sealing in concrete.

Proper joint placement and sealing are essential for the longevity and structural integrity of concrete flatwork. Control joints are strategically placed to relieve stresses in the concrete caused by shrinkage and thermal expansion and contraction. These joints are typically saw-cut after the concrete has partially cured to create clean, controlled cracks. Without them, random cracking would likely occur. Expansion joints, on the other hand, separate different concrete slabs to allow for movement. These are often constructed using flexible materials. Sealing these joints is crucial to prevent water penetration and damage from freeze-thaw cycles. We use high-quality sealants designed for concrete, ensuring proper adhesion and durability. Neglecting proper joint placement and sealing can lead to premature cracking, spalling, and significant repairs down the line.

Q 13. How do you troubleshoot problems such as honeycombing or surface defects?

Troubleshooting problems like honeycombing (voids within the concrete) or surface defects is a critical part of the job. Honeycombing often results from improper consolidation during placement or insufficient vibration. To resolve this, we adjust our vibration techniques and ensure thorough consolidation of the concrete in the future. Surface defects, like laitance (a weak layer on the surface), can be caused by excessive water or improper finishing. We address this by ensuring proper mixing ratios and executing the finishing process according to specifications. For surface cracks, we need to determine the cause—shrinkage, improper curing, or underlying structural issues—to provide an appropriate solution. For example, if it’s due to shrinkage, we may need to add more control joints. Every situation is different, and identifying the root cause is vital for creating the best solution.

Q 14. What experience do you have with different types of concrete formwork?

I have experience with various types of concrete formwork, including wood forms, steel forms, and even some experience with aluminum forms. Wood forms are common for smaller projects, requiring careful construction and bracing to maintain alignment and prevent bowing. Steel forms are often preferred for larger projects or when higher precision is needed, offering greater strength and durability. Aluminum forms are lighter and easier to handle, often used for curved or intricate designs. I understand the importance of properly preparing the forms—oiling to prevent sticking, ensuring proper alignment, and adequate bracing—before concrete placement. My experience includes building forms from scratch, ensuring they are structurally sound and meet the required dimensions according to the plans. Proper formwork is crucial for achieving the desired shape and finish of the concrete flatwork.

Q 15. Describe your experience with using control joints and expansion joints.

Control joints and expansion joints are crucial for preventing cracking in concrete flatwork. Control joints are intentionally created weaknesses that guide cracking in predictable locations, minimizing damage. Expansion joints, on the other hand, accommodate movement caused by temperature changes or foundation settlement. They are completely separated sections, allowing for expansion and contraction without stressing the concrete.

My experience encompasses designing and installing both types in various projects. For instance, on a large warehouse floor, I specified saw-cut control joints at regular intervals (typically 10-15 feet apart depending on slab thickness and anticipated stresses) to manage shrinkage cracking. In a driveway adjacent to a house, I used a pre-formed expansion joint material at the interface between the driveway and the house foundation to account for differential settlement and temperature variations. The selection of joint type and spacing depends critically on factors like slab thickness, expected load, and climate.

- Control Joints: Saw cuts, formed joints using pre-formed material.

- Expansion Joints: Pre-formed expansion joint fillers, isolation joint material, construction joints allowing separation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper drainage in concrete flatwork installations?

Proper drainage is essential to prevent water damage and ensure the longevity of concrete flatwork. This involves designing the slab with a consistent slope towards designated drainage points, often utilizing a combination of techniques.

I always ensure a minimum slope of 1/4 inch per foot towards drains or natural grades. This is achieved by careful grading of the sub-base prior to concrete placement. We use laser screeds for large projects to ensure accurate grading across extensive areas, achieving a consistent slope. Additional measures such as drainage channels and catch basins are incorporated where necessary, especially in areas with high rainfall or poor soil drainage. For instance, in a patio project, I incorporated a slight slope towards a nearby landscaped area, preventing water accumulation. Proper drainage also involves ensuring that any joints are sealed to prevent water infiltration beneath the surface of the concrete.

Q 17. What is your experience with concrete sawing and cutting techniques?

Concrete sawing and cutting is a common practice in concrete flatwork, primarily for creating control joints, but also for cutting openings for utilities or repairs. I’m proficient with both hand-held saws (for smaller projects) and larger, ride-on saws (for large-scale projects). I choose the appropriate technique and equipment based on the size, depth, and location of the cut.

For example, on a large parking lot, I used a ride-on saw with diamond blades to create control joints accurately and efficiently. The saw’s depth control ensures consistent joint depth across the entire surface. The correct choice of blade is critical to ensure clean cuts and avoid chipping or cracking the concrete. For smaller projects, like cutting around a pipe, a hand-held saw with a specific blade type would be appropriate.

Safety is paramount; I always use appropriate safety gear including eye protection, hearing protection, and dust masks when operating saws.

Q 18. How do you calculate the amount of concrete needed for a given project?

Calculating the amount of concrete needed is a fundamental aspect of flatwork. This involves accurately determining the volume of the concrete slab, accounting for both surface area and thickness. There are numerous online calculators, but the core principle is simple.

The formula is: Volume = Length x Width x Thickness. All measurements must be in the same units (feet, inches, meters, etc.). Remember to account for any waste (typically around 5-10% depending on the complexity of the pour). I always add an extra amount to compensate for unexpected events or irregularities. For example, for a 10ft x 15ft patio with a 4-inch thick slab, the calculation would be:

Volume = 10ft x 15ft x (4in/12in/ft) = 50 cubic feet

Converting cubic feet to cubic yards (1 cubic yard = 27 cubic feet) would be approximately 1.85 cubic yards. Adding 10% waste gives approximately 2.04 cubic yards. It’s critical to communicate this calculation clearly with the concrete supplier to ensure sufficient material is delivered.

Q 19. Describe your experience with different types of concrete additives and their functions.

Concrete additives modify the properties of concrete, impacting its workability, strength, durability, and setting time. I’ve used various additives throughout my career, including:

- Accelerators: Speed up the setting time, useful in cold weather.

- Retarders: Slow down the setting time, beneficial in hot weather or large pours.

- Air-entraining agents: Improve freeze-thaw resistance.

- Water reducers: Increase workability with less water, improving strength.

- Superplasticizers: Significantly increase workability and strength.

For instance, in a summer project, I used a retarder to extend the working time of the concrete during a large commercial slab pour. Selecting the right additive requires understanding the specific job requirements and environmental conditions.

Q 20. How do you ensure the quality of concrete flatwork meets the specified standards?

Ensuring quality concrete flatwork involves meticulous attention to detail throughout the entire process. This starts with proper sub-base preparation, ensuring a stable and well-compacted foundation. Accurate grading and formwork are essential for achieving the desired surface level and slope. Consistent concrete mixing and placement are crucial, followed by proper finishing techniques. Finally, curing is critical to allow for proper hydration and strength development.

I always follow established industry standards and project specifications. Regular quality checks throughout the process, including visual inspections and slump tests, ensure adherence to standards. Documentation of materials, procedures, and inspections is also vital.

Q 21. What is your experience with different concrete testing methods?

Various methods are used to test concrete, depending on the specific property being assessed. I’m familiar with several common testing methods:

- Slump Test: Measures the consistency or workability of the fresh concrete.

- Air Content Test: Determines the amount of air entrained in the concrete, influencing its durability.

- Compressive Strength Test: Measures the strength of the hardened concrete using compression testing machines.

- Flexural Strength Test (Beam Test): Measures the tensile strength of the hardened concrete.

For instance, on a recent bridge deck project, compressive strength testing was crucial to ensure the concrete met the required specifications for structural integrity. These tests were performed at various ages to monitor the strength development over time. These tests ensure compliance with project requirements and the overall quality and safety of the construction project.

Q 22. How do you handle unexpected situations or problems during concrete installation?

Unexpected situations are commonplace in concrete flatwork. My approach is methodical and prioritizes problem-solving. For instance, if I encounter unexpected subsurface conditions like unstable soil, I wouldn’t simply proceed. Instead, I’d immediately stop work and assess the situation. This might involve contacting a geotechnical engineer for further investigation to determine the best course of action – perhaps adding compacted gravel for a stable base, or adjusting the concrete mix design to compensate for the soil’s instability. If significant delays are likely, I’d immediately communicate with the client and project manager to develop a revised plan and agree on any necessary adjustments to the schedule and budget. Another example might be encountering unexpectedly high temperatures during pouring. Here, I’d implement strategies to mitigate heat-related cracking, such as using a cooler mix, adding admixtures to slow setting time, and using proper curing techniques including covering the concrete to prevent rapid moisture loss.

- Immediate Assessment: Stop work, identify the problem, assess its impact.

- Expert Consultation: Seek advice from engineers or specialists if needed.

- Revised Plan: Develop a new strategy to address the problem.

- Client Communication: Transparency is key; keep the client informed of any changes.

Q 23. Describe your experience with working as part of a team on concrete projects.

Teamwork is crucial in concrete flatwork. I’ve consistently worked in collaborative environments, where my role has spanned from leading a crew to being a contributing member. On a recent large-scale project for a commercial plaza, we had a team of five: a foreman, two skilled laborers, one apprentice, and myself as the lead. My responsibilities included planning the pour sequence, managing material delivery, and ensuring the team adhered to safety protocols. Effective communication, clear task delegation, and mutual respect were paramount. For example, to ensure efficiency and prevent errors, we utilized a daily checklist to verify equipment, materials, and safety gear before starting each day. We also held brief daily meetings to coordinate tasks, address any issues from the previous day, and plan the day’s work. This collaborative spirit led to a successful and timely completion of the project within the allocated budget.

Q 24. What is your approach to quality control and assurance during concrete flatwork installations?

Quality control and assurance are paramount in concrete flatwork. My approach begins with meticulous planning – selecting the correct concrete mix design for the application and anticipated conditions, as well as ensuring proper compaction of the subgrade. During the pour, I consistently monitor the concrete’s consistency, ensuring proper placement and consolidation to eliminate voids. After pouring, curing is crucial. I utilize appropriate curing methods, such as membrane curing or water curing, to prevent early cracking and ensure the concrete achieves its design strength. Finally, I conduct thorough inspections, checking for things like surface imperfections, cracks, and ensuring the final surface meets the project specifications and meets the specified levelness tolerance. For instance, we use a laser level to regularly check for surface flatness throughout the pour. Any issues are documented, and corrective actions are implemented immediately. We maintain detailed records of all aspects of the project, from material usage to quality control checks, providing a comprehensive audit trail for verification.

Q 25. Describe your experience with different types of concrete repair techniques.

My experience encompasses various concrete repair techniques. These include methods for repairing cracks (such as epoxy injection or surface patching), addressing surface deterioration (through resurfacing or grinding), and fixing spalling (using specialized mortars and patching techniques). For instance, I’ve successfully repaired cracks in a warehouse floor using epoxy injection. This involved drilling small holes along the crack, injecting epoxy resin under pressure to fill the void, and then carefully finishing the surface for a seamless repair. Another example involves addressing scaling on an exterior patio. Here, we utilized a combination of surface cleaning, grinding to remove the deteriorated concrete, and then applying a high-quality concrete overlay for a lasting repair. Each repair technique requires a thorough understanding of the underlying cause of the damage to prevent recurrence. We always investigate the root cause before performing the repair, to ensure that the repair is long-lasting.

Q 26. How do you manage project timelines and deadlines for concrete flatwork projects?

Managing project timelines effectively involves meticulous planning and proactive problem-solving. Before commencing any project, I develop a detailed schedule that incorporates all phases, from site preparation and material ordering to pouring, finishing, and curing. This schedule includes buffer time to account for unforeseen delays. I regularly monitor progress against this schedule, identifying potential bottlenecks early. For example, on a recent sidewalk project, we anticipated potential rain delays. We adjusted the schedule to prioritize certain tasks to be completed before the predicted rain and reserved contingency time for potential weather disruptions. Regular communication with the client and the project team keeps everyone informed of progress and any necessary adjustments to the timeline. This ensures that everyone is aligned and expectations are managed effectively throughout the process. In addition, using technology, like project management software, allows for tracking of materials, personnel, and progress.

Q 27. What is your familiarity with relevant building codes and regulations?

I’m well-versed in relevant building codes and regulations, including those pertaining to concrete flatwork. My knowledge extends to local, state, and national standards, such as those set by the American Concrete Institute (ACI) and the International Building Code (IBC). I understand requirements for concrete mix design, placement, finishing, and curing, as well as accessibility guidelines for pedestrian areas and slopes. Before every project, I review the relevant codes and ensure the project plan complies. This includes verifying specifications for compressive strength, air entrainment, and surface tolerances. Further, I make sure all safety requirements on site and around the work are adhered to. Regularly updating my knowledge through industry publications and continuing education keeps me abreast of any changes or revisions to the codes. This ensures we deliver compliant and safe projects.

Q 28. Explain your understanding of the importance of sustainability in concrete construction.

Sustainability is paramount in concrete construction. It involves minimizing the environmental impact throughout the project lifecycle. My approach includes specifying low-carbon cement and recycled aggregates, reducing the embodied carbon of the concrete. Furthermore, I prioritize efficient water usage during curing and strive to minimize waste generation through careful planning and material ordering. On a recent project, we incorporated fly ash as a supplementary cementitious material, reducing the amount of Portland cement needed and thus the carbon footprint of the concrete. We also focused on responsible waste management, separating and recycling materials whenever possible. By making conscious choices at every stage, we can significantly reduce the environmental impact of our projects, while maintaining the high-quality finishes expected.

Key Topics to Learn for Concrete Flatwork Installation Interview

- Site Preparation and Layout: Understanding grading, compaction, and formwork construction for optimal surface preparation. This includes knowledge of different soil types and their impact on the project.

- Concrete Mix Design and Properties: Knowing the factors influencing concrete strength, workability, and durability. Practical application involves understanding how to adjust mix designs based on project requirements and weather conditions.

- Finishing Techniques: Mastering various finishing methods like screeding, floating, troweling, and brooming to achieve desired surface textures and finishes. This includes understanding the tools and techniques for each method.

- Curing and Protection: Understanding the importance of proper curing methods to ensure concrete strength and durability. This includes knowledge of different curing techniques and their application in various weather conditions.

- Troubleshooting and Problem Solving: Identifying and resolving common issues such as cracking, surface defects, and improper curing. Practical application involves knowing how to diagnose problems and implement corrective actions.

- Safety Regulations and Procedures: Familiarity with OSHA safety standards and best practices for concrete work, including personal protective equipment (PPE) and fall protection.

- Tools and Equipment: Understanding the operation and maintenance of common concrete flatwork tools and equipment, from power trowels to concrete saws.

- Estimating and Project Management: Basic understanding of project costing, scheduling, and resource allocation for concrete flatwork installations.

Next Steps

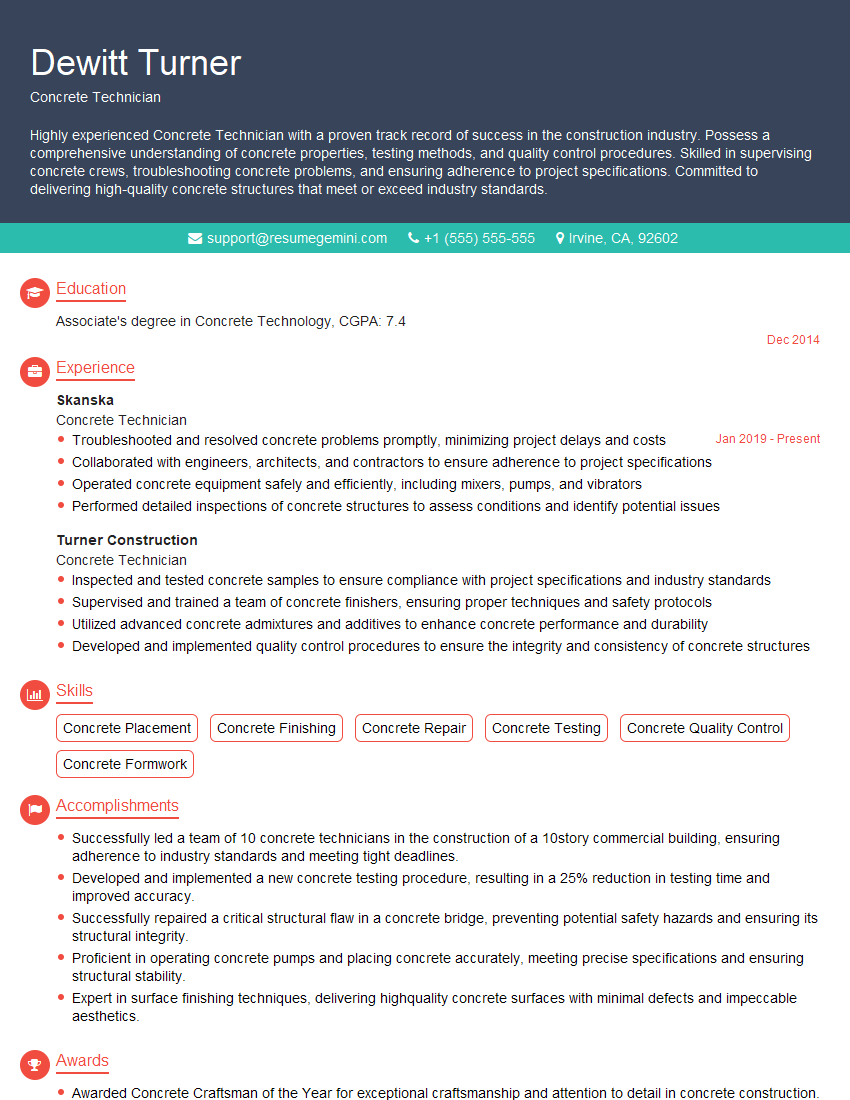

Mastering Concrete Flatwork Installation opens doors to a rewarding career with excellent earning potential and opportunities for advancement. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting your application noticed. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your expertise in Concrete Flatwork Installation. ResumeGemini provides examples of resumes tailored to this specific field, helping you craft a document that stands out from the competition. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good