Preparation is the key to success in any interview. In this post, we’ll explore crucial Construction Best Practices and Industry Standards interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Construction Best Practices and Industry Standards Interview

Q 1. Describe your experience with Lean Construction principles.

Lean Construction focuses on eliminating waste and maximizing value in the construction process. Think of it like streamlining a factory assembly line, but for buildings. My experience involves implementing Lean principles across various projects, from large-scale commercial developments to smaller residential builds. This includes utilizing tools like Last Planner® System, which focuses on collaborative weekly planning to improve predictability and reduce rework. I’ve also implemented 5S methodologies (Sort, Set in Order, Shine, Standardize, Sustain) to create more organized and efficient job sites, reducing material handling time and improving safety. For example, on a recent high-rise project, implementing a pull system for material delivery, based on the Last Planner system, reduced material waste by 15% and significantly improved the flow of work.

Beyond these specific tools, my approach involves fostering a culture of continuous improvement. This means regularly engaging the entire project team – from architects and engineers to subcontractors and laborers – in identifying and eliminating waste. This collaborative approach ensures buy-in and fosters a proactive problem-solving environment.

Q 2. Explain your understanding of OSHA regulations.

My understanding of OSHA regulations is comprehensive, covering everything from hazard communication and fall protection to personal protective equipment (PPE) and emergency action plans. OSHA regulations are paramount to ensuring a safe and healthy work environment. I’m familiar with all relevant standards and regularly update my knowledge to stay compliant with any changes. On every project, I meticulously develop and enforce a comprehensive safety plan. This includes regular safety meetings, job hazard analyses (JHAs) for each task, and proactive inspections to identify and mitigate potential hazards. For instance, if working near a trench, I would ensure the appropriate shoring and slope protection are in place, and that workers have received the proper training and are using the necessary PPE, like hard hats and safety harnesses. Non-compliance can lead to severe penalties, but more importantly, it can lead to injuries and even fatalities, which is something I take very seriously.

Q 3. How do you manage project risks and mitigation strategies?

Project risk management is a proactive process, not a reactive one. I utilize a structured approach, starting with risk identification through brainstorming sessions, checklists, and reviewing historical project data. Once risks are identified, I assess their likelihood and potential impact. This allows me to prioritize mitigation strategies. My preferred method involves using a risk register, a document that tracks identified risks, their likelihood, potential impact, assigned owner, mitigation strategies, and contingency plans. For example, if a risk is inclement weather delaying the project, the mitigation strategy could be securing a covered storage area for materials and adjusting the schedule to account for potential delays. A contingency plan might involve accelerated work once the weather improves. Regular monitoring and reporting are crucial to ensure that risks remain under control. This is achieved via regular project meetings, progress reporting, and the use of specialized project management software to track both schedule and budget.

Q 4. What are your methods for conflict resolution on a construction site?

Conflict resolution on a construction site requires a diplomatic yet firm approach. My strategy is based on open communication and collaboration. I encourage all parties involved to express their concerns and perspectives openly, creating a safe space for discussion. I facilitate these discussions by actively listening, asking clarifying questions, and identifying the root cause of the conflict. I don’t aim to impose solutions but instead guide the parties towards finding mutually agreeable resolutions. Sometimes, this involves compromise, and other times it necessitates mediating between conflicting interests. If direct dialogue fails, then I’m prepared to escalate the issue to higher management and involve other dispute resolution methods, like mediation or arbitration if necessary. The ultimate goal is to maintain a productive work environment, minimizing disruption and ensuring project completion.

Q 5. Describe your experience with various project delivery methods (e.g., Design-Bid-Build, Design-Build).

I have extensive experience with various project delivery methods, including Design-Bid-Build, Design-Build, and Construction Management at Risk (CMAR). Design-Bid-Build involves separate design and construction contracts, which can lead to potential conflicts between the architect and the contractor. Design-Build integrates design and construction under a single contract, allowing for better collaboration and often leading to faster project delivery and cost savings. CMAR combines elements of both, where the construction manager assists the owner in managing the project, while also assuming risk for the construction cost. My experience with these methods allows me to select the most appropriate delivery method based on project complexity, budget constraints, and project timeline. For example, I successfully completed a large hospital expansion using the Design-Build method, leveraging the collaborative aspects of this approach to expedite the project and minimize cost overruns.

Q 6. How do you ensure project quality control and assurance?

Quality control (QC) and quality assurance (QA) are integral parts of my project management approach. QA focuses on preventing defects before they occur, through planning and process monitoring, while QC involves inspecting and testing work to ensure it meets requirements. I implement a robust QA/QC program that involves comprehensive inspections at various stages of the project. This includes regular site visits, material testing, and review of submittals. Clear quality standards and acceptance criteria are established upfront, ensuring everyone is working towards the same goals. Documentation is key; thorough records are maintained for all inspections and testing, along with any corrective actions taken to address identified defects. I also use check sheets, quality control plans, and statistical process control methods where appropriate to systematically monitor the work and identify trends.

Q 7. What software and technology are you proficient in for construction management?

I’m proficient in a range of software and technology used in construction management. This includes project management software like Microsoft Project and Primavera P6 for scheduling and resource allocation. I’m also experienced with BIM (Building Information Modeling) software such as Revit and AutoCAD for design and coordination. For cost management, I utilize software like Procore and other cloud-based construction management platforms. These platforms enhance communication and collaboration amongst team members and stakeholders, providing real-time data and progress updates. Furthermore, I’m comfortable utilizing drone technology for site surveying and progress monitoring, and am adept at using various field measurement tools for precise data capture and analysis. My technological proficiency ensures efficient project management and enhanced collaboration among project teams.

Q 8. How do you handle schedule delays and cost overruns?

Schedule delays and cost overruns are unfortunately common in construction. My approach is proactive and multifaceted, focusing on prevention and mitigation. Prevention starts with meticulous planning. This includes realistic scheduling using proven techniques like Critical Path Method (CPM), thorough risk assessment identifying potential delays (e.g., material shortages, weather, subcontractor issues), and detailed cost estimation incorporating contingency buffers.

When delays occur, I immediately initiate a formal process. This involves:

- Identifying the root cause: We meticulously analyze the delay, holding meetings with relevant stakeholders – including subcontractors, suppliers, and the client – to determine the precise cause. Is it a material delay? A design change? Subcontractor performance issues?

- Developing a recovery plan: Once the cause is identified, we develop a detailed recovery plan outlining revised timelines, resource allocation adjustments, and potential cost implications. This plan is presented to the client for approval.

- Implementing the plan and monitoring progress: We rigorously track the implementation of the recovery plan, using project management software to monitor progress against the revised schedule and budget. Regular progress meetings are held to address any emerging issues.

- Documenting everything: Maintaining clear documentation of all delays, their causes, mitigation efforts, and cost impacts is crucial for transparency and potential claims management.

For example, on a recent high-rise project, an unexpected delay occurred due to a supplier failing to deliver structural steel on time. Our response involved identifying an alternative supplier, negotiating expedited delivery, and implementing a revised construction sequence to minimize the impact on the overall project timeline. While there was an added cost, it was significantly less than the potential costs of a longer delay.

Q 9. Explain your experience with value engineering.

Value engineering is a crucial part of my approach to project management. It’s a collaborative process focusing on enhancing value by improving function, while simultaneously reducing costs without sacrificing quality or performance. My experience involves identifying areas for improvement in design, materials, or construction methods early in the project lifecycle.

For instance, on a recent school renovation project, we used value engineering to replace the initially specified high-end marble flooring with a more cost-effective but equally durable porcelain tile. This substitution saved a significant amount without compromising the building’s aesthetic appeal or functionality.

The process I typically follow includes:

- Understanding project goals and constraints: Clear communication with the client to understand their priorities and budget limitations is key.

- Team brainstorming: Bringing together architects, engineers, contractors, and subcontractors to collaboratively identify potential cost-saving opportunities without compromising performance.

- Evaluating alternatives: Thoroughly assessing the cost-benefit analysis of different options.

- Presenting recommendations: Clearly outlining the proposed changes, their cost implications, and their impact on project quality and schedule.

- Implementation and monitoring: Implementing the agreed-upon changes and tracking their impact on cost and performance.

Value engineering is not about cutting corners; it’s about smart decision-making that maximizes value for the client. It requires creative problem-solving and a deep understanding of construction materials and techniques.

Q 10. What is your approach to safety training and implementation?

Safety is paramount. My approach to safety training and implementation is proactive, comprehensive, and firmly based on industry best practices and relevant regulations (e.g., OSHA). It’s not merely a checklist but an ingrained culture.

My safety program includes:

- Pre-construction safety planning: A detailed safety plan is developed at the outset, addressing specific hazards associated with the project.

- Comprehensive safety training: All workers, including subcontractors, receive mandatory safety training tailored to their specific tasks. This includes hazard identification, fall protection, and emergency response procedures. We utilize a combination of classroom training, hands-on demonstrations, and online modules.

- Regular safety inspections: Regular inspections are conducted to identify and rectify any safety hazards. These inspections are documented and addressed promptly.

- Toolbox talks: Short, regular safety talks are conducted at the start of each workday to discuss specific safety concerns and reinforce safe work practices.

- Incident reporting and investigation: A clear and transparent process for reporting and investigating safety incidents to identify root causes and prevent future occurrences.

- Incentive programs: We utilize incentive programs to encourage safe work practices and reward employees and subcontractors for demonstrating exemplary safety performance.

I believe a strong safety culture is built through leadership commitment, employee empowerment, and continuous improvement. A safe work environment is not just a requirement; it’s a cornerstone of efficient and successful project delivery.

Q 11. How do you manage subcontractors and maintain effective communication?

Managing subcontractors effectively requires a combination of clear communication, robust contracts, and consistent monitoring. I establish clear expectations from the start, outlining responsibilities, deadlines, and communication protocols.

My approach includes:

- Pre-qualification: Subcontractors are rigorously pre-qualified based on their experience, financial stability, safety record, and insurance coverage.

- Detailed contracts: Comprehensive contracts clearly outline scope of work, payment terms, insurance requirements, and dispute resolution mechanisms.

- Regular meetings: Regular meetings are held with subcontractors to review progress, address any issues, and ensure coordination between different trades.

- Progress monitoring: Subcontractor performance is closely monitored to ensure they are meeting their commitments on time and within budget. We utilize project management software to track progress and manage communication.

- Open communication: Maintaining open and transparent communication with subcontractors is critical for addressing challenges promptly and fostering collaboration.

For example, on a recent project, a subcontractor experienced a delay due to unforeseen site conditions. By promptly addressing the issue through open communication, collaborating on a revised schedule, and securing additional resources, we successfully mitigated the delay and kept the project on track.

Q 12. Describe your experience with building information modeling (BIM).

Building Information Modeling (BIM) is an integral part of my workflow. I’m proficient in using BIM software to create and manage 3D models of buildings and infrastructure projects. BIM enhances collaboration, improves project coordination, and minimizes errors.

My experience with BIM includes:

- Model creation and management: Creating and managing detailed 3D models incorporating architectural, structural, and MEP (Mechanical, Electrical, and Plumbing) information.

- Clash detection and resolution: Using BIM software to identify and resolve potential clashes between different building systems before construction begins, preventing costly rework on site.

- 4D and 5D BIM: Utilizing 4D (time) and 5D (cost) BIM to simulate construction sequencing and cost estimation, improving scheduling and budgeting accuracy.

- Collaboration and coordination: Facilitating effective collaboration among project stakeholders by providing a centralized platform for sharing and reviewing model data.

- Construction documentation: Generating accurate and comprehensive construction documents directly from the BIM model, reducing errors and improving communication.

BIM drastically improves efficiency and reduces risks by allowing for proactive problem-solving and better coordination among all stakeholders. A recent project saw a 15% reduction in construction time through the effective use of 4D BIM for sequencing and scheduling.

Q 13. What are your methods for tracking project progress and reporting?

Tracking project progress and reporting involves a combination of quantitative and qualitative methods. I utilize project management software to track key performance indicators (KPIs), such as schedule adherence, budget performance, and safety metrics.

My methods include:

- Project management software: Using software like Primavera P6 or Microsoft Project to track progress against the baseline schedule and budget.

- Regular progress meetings: Conducting regular meetings with the project team to review progress, address any issues, and ensure alignment with project goals.

- Progress reports: Preparing regular progress reports for the client, summarizing key performance indicators, highlighting any issues or challenges, and outlining mitigation strategies.

- Photographs and videos: Documenting project progress visually through photographs and videos, providing a clear record of progress and any changes made during the construction process.

- Data analysis: Analyzing project data to identify trends and potential issues, allowing for proactive adjustments to ensure project success.

These reports not only track progress but also provide valuable insights into project performance and potential risk areas allowing for timely intervention. Clear, concise, and visual reporting is essential for effective communication with the client and maintaining transparency.

Q 14. How do you handle change orders and contract modifications?

Change orders and contract modifications are a common aspect of construction projects. My approach is to manage them systematically and transparently to minimize disputes and maintain project integrity.

My process involves:

- Formal request: All change requests must be submitted formally in writing, clearly describing the nature of the change, its impact on the schedule and budget, and any necessary supporting documentation.

- Review and evaluation: The change request is carefully reviewed by the project team, including the client, to assess its feasibility, impact, and cost implications.

- Negotiation: Discussions are held with the client to negotiate the terms of the change order, including price adjustments, schedule revisions, and any necessary contractual modifications.

- Formal documentation: Once agreement is reached, a formal change order is issued, clearly outlining all agreed-upon terms and conditions. This includes updated drawings, specifications, and cost estimates.

- Tracking and monitoring: The implementation of the change order is tracked and monitored carefully to ensure it’s executed according to the agreed-upon terms.

Transparency is key. By maintaining detailed documentation and involving all stakeholders in the process, we can prevent disputes and ensure that everyone is aware of and agrees to the changes. A well-managed change order process is critical for maintaining the integrity of the project and avoiding costly disputes.

Q 15. What is your experience with sustainable building practices?

Sustainable building practices are crucial for minimizing the environmental impact of construction projects throughout their lifecycle. My experience encompasses implementing strategies across various project phases, from design to demolition. This includes specifying and sourcing sustainable materials like recycled content steel, reclaimed wood, and low-VOC paints. I’ve also been involved in projects incorporating renewable energy sources such as solar panels and geothermal systems. Furthermore, I’m experienced in designing for energy efficiency, focusing on building envelope performance, high-performance windows, and optimized HVAC systems. For instance, on a recent school renovation, we reduced energy consumption by 40% by implementing a combination of these strategies. Water conservation measures, such as low-flow fixtures and rainwater harvesting, are also integral to my approach. I believe that by meticulously selecting materials and methods, we can significantly reduce a building’s carbon footprint and create healthier, more environmentally responsible structures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of different contract types (e.g., Lump Sum, Cost Plus).

Different contract types offer varying levels of risk and responsibility for both the client and the contractor. A Lump Sum contract, also known as a fixed-price contract, specifies a fixed total price for the project. The contractor assumes the risk of cost overruns, while the client has a clear understanding of the total cost upfront. This is best suited for projects with well-defined scopes and minimal design changes. In contrast, a Cost Plus contract involves reimbursing the contractor for all actual costs incurred plus a predetermined fee or percentage markup. This type of contract offers flexibility for projects with evolving designs or uncertain scopes, shifting the cost risk to the client. Other contract types include Unit Price contracts, where the price is based on a defined quantity of work, and Target Cost contracts, which aim to incentivize cost control by sharing potential savings between the client and contractor. Selecting the appropriate contract type depends heavily on the project’s complexity, risk tolerance, and the client-contractor relationship. In my experience, successfully navigating these different contract types requires clear communication, detailed specifications, and a thorough understanding of potential risks.

Q 17. How do you ensure compliance with building codes and regulations?

Compliance with building codes and regulations is paramount for safety and legal reasons. My approach involves a multi-faceted strategy starting with thorough due diligence at the outset of every project. This includes researching and identifying all applicable codes and regulations at the local, state, and national levels. I work closely with architects, engineers, and inspectors throughout the project lifecycle to ensure all plans, specifications, and construction processes align with these requirements. We utilize building information modeling (BIM) software to check compliance against codes and generate comprehensive documentation. Regular inspections and quality control measures are implemented to identify and rectify any non-compliance early on. This proactive approach minimizes delays, avoids costly rework, and helps to maintain project safety. Maintaining detailed records of inspections, approvals, and any variations from original plans is crucial for demonstrating compliance and mitigating potential legal issues.

Q 18. What are your skills in cost estimation and budgeting?

Accurate cost estimation and budgeting are fundamental to successful project delivery. My skills encompass various methods, including parametric estimating, bottom-up estimating, and analogous estimating. I use specialized software and tools to create detailed cost breakdowns, factoring in material costs, labor rates, equipment rentals, and contingency allowances. I’ve developed expertise in analyzing historical data to refine my estimations and improve accuracy over time. For instance, on a recent high-rise project, my detailed budget allowed for proactive adjustments when material prices unexpectedly fluctuated, preventing potential cost overruns. Regular monitoring and reporting against the approved budget is critical, and I utilize various techniques to track progress, identify potential risks, and implement corrective measures to maintain the project’s financial viability. Transparent communication with clients on budget performance is essential to build trust and manage expectations effectively.

Q 19. Describe your experience with project closeout procedures.

Project closeout procedures are crucial for ensuring a smooth transition and minimizing potential liabilities. My experience encompasses all aspects of this phase, starting with completing all outstanding work and ensuring that the project meets all contractual obligations. This includes obtaining final inspections and approvals from relevant authorities and documenting all changes and as-built conditions. Then, I manage the process of final payment to contractors and subcontractors, ensuring that all invoices and claims have been properly reviewed and approved. We meticulously compile and organize all project documents into a comprehensive archive for future reference. This includes contracts, drawings, specifications, test results, and maintenance manuals. Finally, a post-project review is conducted to identify lessons learned and improve future project performance. By thoroughly following these steps, we minimize potential disputes, preserve historical data for future reference and complete the project efficiently and professionally.

Q 20. How do you manage stakeholder expectations?

Managing stakeholder expectations is crucial for successful project delivery. My approach involves establishing clear communication channels from the outset of the project. I proactively engage all stakeholders—clients, architects, engineers, contractors, and community members—to understand their expectations and concerns. Regular meetings and progress reports, delivered through various media (e.g., presentations, email, project management software), ensure that everyone is informed and aligned. I prioritize transparency and address any issues or concerns promptly and effectively. For example, on a recent community project, I hosted regular public forums to address local residents’ concerns and incorporate their feedback into the project plans, fostering a collaborative and mutually respectful working relationship. This proactive communication strategy leads to increased buy-in and reduces the potential for conflicts or misunderstandings throughout the project lifecycle.

Q 21. Explain your experience with procurement and material management.

Efficient procurement and material management are essential for on-time and within-budget project delivery. My experience involves developing detailed material specifications, sourcing competitive bids from qualified suppliers, and negotiating favorable contracts. I utilize software solutions to track material orders, deliveries, and inventory levels. Strategies such as just-in-time delivery minimize storage costs and reduce waste. I also implement quality control procedures to ensure that all materials meet the required specifications. On a recent large-scale project, I developed a centralized procurement system that improved material ordering efficiency by 20% and reduced material costs by 15%. This system also provided real-time visibility into inventory levels and anticipated delivery schedules. Proactive risk management, including anticipating potential material shortages, ensures project continuity and avoids costly delays.

Q 22. What is your approach to resolving disputes with clients?

My approach to resolving disputes with clients prioritizes open communication and collaboration. I believe that proactive communication is key to preventing disputes altogether. This means regularly updating clients on project progress, addressing concerns immediately, and maintaining transparent documentation. If a dispute does arise, I follow a structured process. First, I listen carefully to the client’s concerns, ensuring I fully understand their perspective. Then, I clearly explain the relevant contractual obligations and project specifications. If a mutually agreeable solution isn’t immediately found, I suggest mediation as a neutral and efficient way to resolve the issue. Only as a last resort would I consider litigation. For example, on a recent project where there was a disagreement about the timing of a payment, we were able to successfully resolve the issue through open dialogue, reviewing the contract’s payment schedule together, and ultimately reaching a mutually satisfactory agreement. This preserved our professional relationship and avoided costly and time-consuming legal battles.

Q 23. How familiar are you with LEED certification?

I am very familiar with LEED (Leadership in Energy and Environmental Design) certification. I have extensive experience in designing and constructing projects that meet LEED standards, across various rating systems including LEED v4 and LEED v4.1. My understanding encompasses all aspects, from the initial planning stages, which involves material selection (choosing sustainable options), energy modeling, and waste management strategies to the implementation, documentation, and eventual certification process. For example, I successfully led a team to achieve LEED Gold certification for a multi-family residential building by incorporating features such as high-performance windows, efficient HVAC systems, and recycled building materials, demonstrating my commitment to sustainable building practices.

Q 24. Describe your experience with site logistics and planning.

Site logistics and planning are crucial for efficient project execution. My experience includes developing comprehensive site plans that optimize material delivery, equipment staging areas, and worker access, minimizing disruptions and ensuring a safe work environment. This involves detailed coordination with subcontractors, suppliers, and the client. For example, on a recent large-scale commercial construction project, I implemented a Just-in-Time (JIT) delivery system for materials, significantly reducing storage costs and site congestion. This improved workflow and safety by minimizing unnecessary traffic and potential hazards. My plans always include contingency plans to handle unforeseen events such as material delays or equipment malfunctions, ensuring minimal impact on the overall schedule.

Q 25. How do you manage project documentation and record keeping?

I maintain meticulous project documentation and record-keeping using a combination of digital and physical methods. All project documents, including contracts, drawings, specifications, change orders, and inspection reports, are stored in a centralized, easily accessible digital system. This allows for efficient retrieval of information by all stakeholders. Furthermore, I utilize cloud-based collaboration tools to facilitate real-time document sharing and version control. Critical documents also have physical copies kept in a secure location. This approach ensures that all information is readily available, complies with regulatory requirements, and provides a clear audit trail for the entire project lifecycle. A robust system helps prevent disputes, avoids delays, and facilitates efficient project closeout.

Q 26. What are your experience with different types of construction materials?

My experience encompasses a wide range of construction materials, including steel, concrete, timber, masonry, and various specialized materials like composite materials and high-performance insulation. I am familiar with their properties, applications, limitations, and best practices for installation and maintenance. I understand the importance of material selection based on factors like structural integrity, durability, cost, and environmental impact. For instance, on a recent project, I opted for cross-laminated timber (CLT) instead of traditional steel for structural elements. This decision was based on its sustainability, aesthetic appeal, and faster construction time, demonstrating my ability to balance performance and eco-conscious decision-making.

Q 27. What is your experience with construction estimating software?

I am proficient in several construction estimating software packages including, but not limited to, PlanSwift, Timberline, and On-Screen Takeoff. I can accurately estimate material quantities, labor costs, and equipment rental fees, producing comprehensive and reliable cost estimates. I understand the importance of incorporating contingencies to account for unforeseen circumstances. My expertise enables me to prepare detailed cost breakdowns, facilitating informed decision-making during the bidding and budgeting phases of a project. For example, using PlanSwift, I recently created an estimate that was within 1% of the final project cost, showcasing my ability to generate accurate and reliable cost estimates.

Q 28. How do you handle unforeseen site conditions?

Handling unforeseen site conditions requires a proactive and methodical approach. My strategy starts with thorough site investigation and due diligence during the pre-construction phase to identify potential risks. However, despite thorough planning, unexpected conditions do occur. When they do, my process involves a systematic approach: 1. Immediate documentation: Photographing and documenting the condition, 2. Notification: Informing the client and relevant stakeholders, 3. Assessment: Evaluating the impact on the project schedule and budget, 4. Mitigation: Developing and implementing a solution to address the issue, and 5. Documentation of all changes: Updating plans and cost estimates. For example, on a project where we unexpectedly encountered bedrock during excavation, we adapted by adjusting the foundation design, engaging specialized contractors, and modifying the schedule and budget accordingly. This transparent process ensured the project’s completion while maintaining open communication with the client.

Key Topics to Learn for Construction Best Practices and Industry Standards Interview

- Safety Regulations and Procedures: Understanding OSHA standards, site safety plans, personal protective equipment (PPE) requirements, and hazard identification/risk assessment methodologies. Practical application includes demonstrating knowledge of incident reporting and prevention strategies.

- Quality Control and Assurance: Familiarize yourself with quality management systems (QMS), inspection and testing procedures, and the use of quality control documentation. Practical application involves explaining how to address non-conformances and implement corrective actions.

- Project Management Methodologies: Mastering project scheduling techniques (e.g., Critical Path Method), budget management, resource allocation, and risk management strategies. Practical application includes explaining how to handle project delays and cost overruns effectively.

- Building Codes and Regulations: Deep understanding of local, state, and national building codes, zoning ordinances, and permitting processes. Practical application involves demonstrating knowledge of code compliance procedures and potential consequences of non-compliance.

- Sustainable Construction Practices: Knowledge of LEED certification, green building materials, energy efficiency strategies, and waste reduction techniques. Practical application includes explaining the benefits of sustainable construction and its impact on the environment.

- Contract Administration and Legal Aspects: Understanding different contract types (e.g., lump sum, cost-plus), change orders, dispute resolution methods, and legal liabilities. Practical application includes explaining the process of managing contracts and resolving disagreements.

- Technology in Construction: Familiarity with Building Information Modeling (BIM), construction software, and digital tools used for project planning, execution, and management. Practical application includes describing how technology improves efficiency and collaboration.

Next Steps

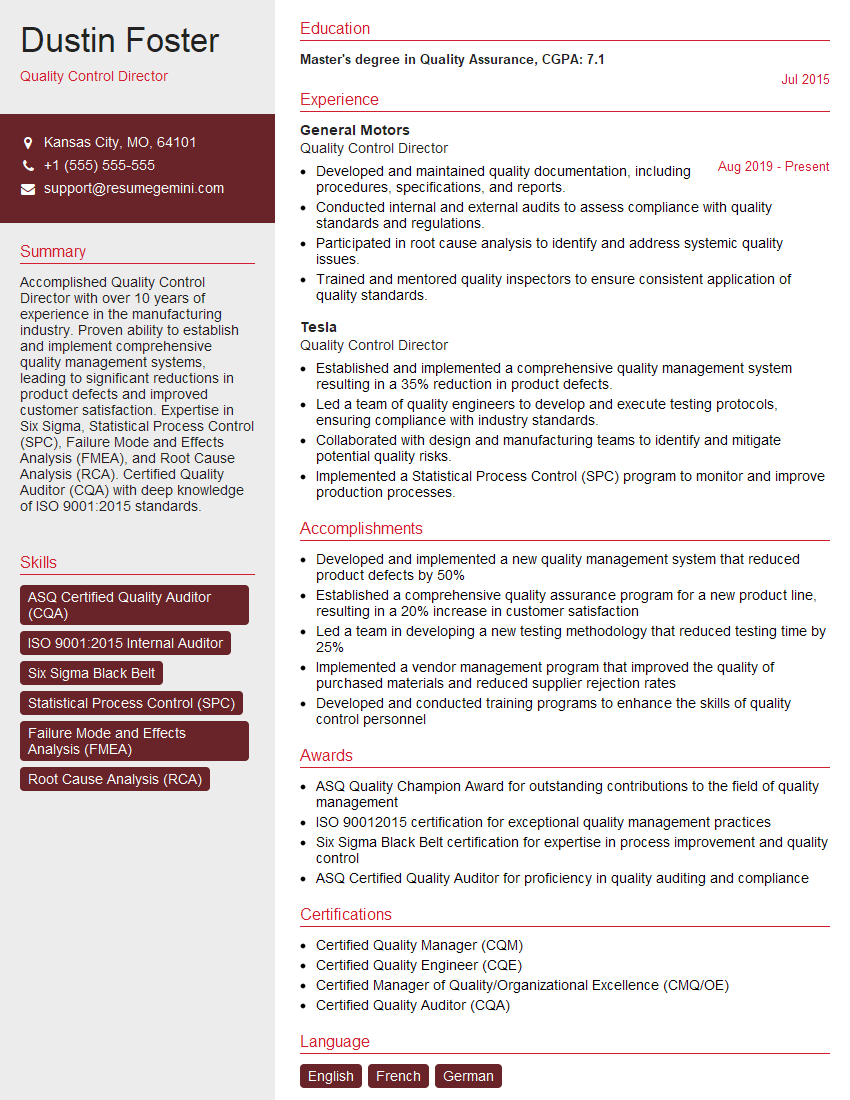

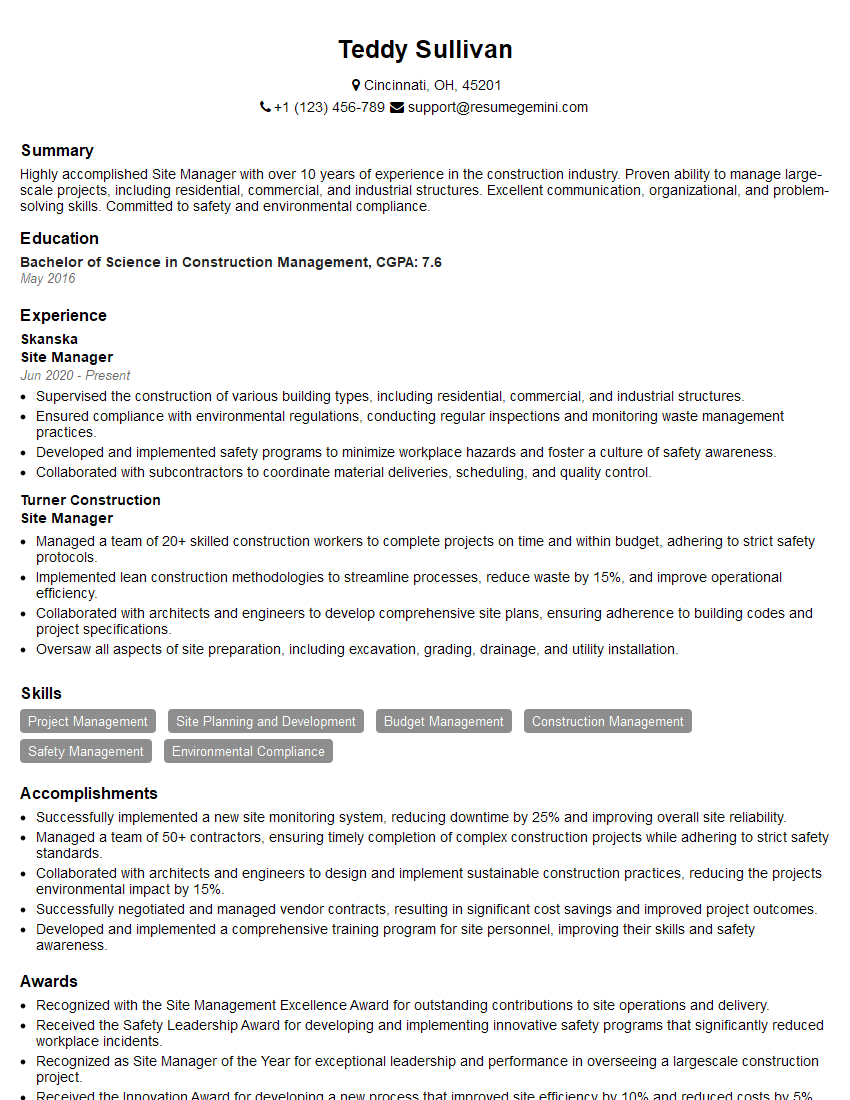

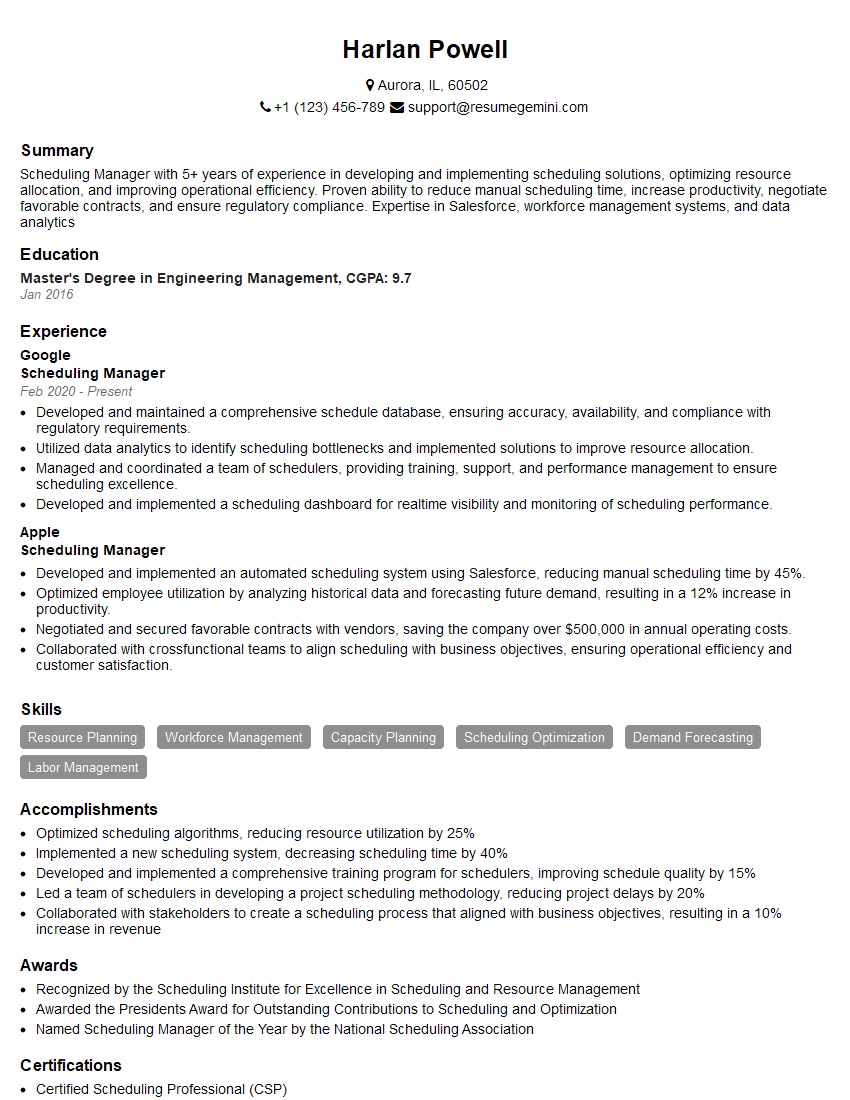

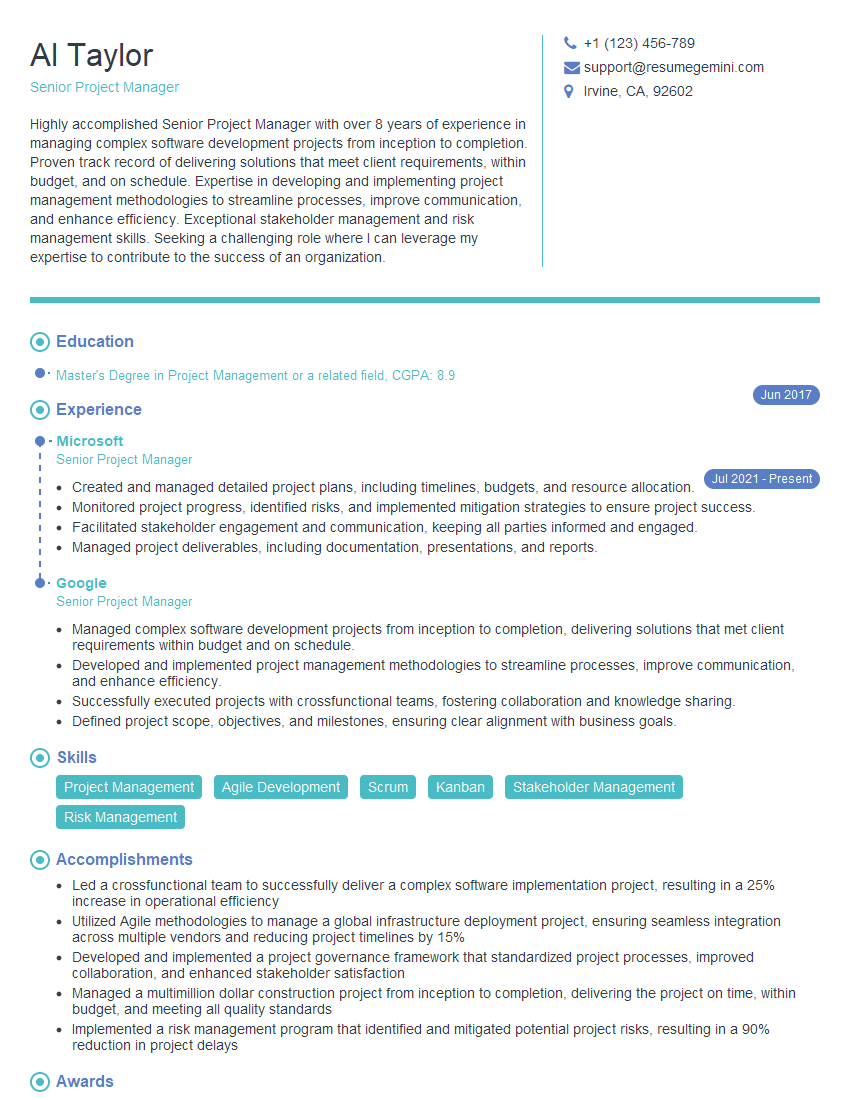

Mastering Construction Best Practices and Industry Standards is crucial for career advancement in this dynamic field. A strong understanding of these principles demonstrates professionalism, competence, and a commitment to safety and quality, leading to increased opportunities and higher earning potential. Creating an ATS-friendly resume is vital for getting your application noticed. We strongly encourage you to use ResumeGemini to build a professional and impactful resume that highlights your expertise in these areas. ResumeGemini provides examples of resumes tailored to Construction Best Practices and Industry Standards, ensuring your application stands out from the competition. Take the next step toward your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good