Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Construction Specifications Institute (CSI) Standards interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Construction Specifications Institute (CSI) Standards Interview

Q 1. Explain the purpose and structure of the CSI MasterFormat.

The CSI MasterFormat is a standardized organizational system for construction specifications. Think of it as a meticulously organized filing cabinet for all the elements of a building project. Its purpose is to provide a consistent numbering system for organizing project requirements, ensuring everyone – from architects and engineers to contractors and subcontractors – is on the same page. This eliminates confusion caused by different naming conventions and ensures efficient communication.

Its structure is hierarchical. It’s divided into 50 numbered divisions, each representing a major area of construction work. For example, Division 02 is for Existing Conditions, Division 03 is for Concrete, and Division 16 is for Electrical. Within each division are sections and subsections, further detailing specific aspects. This detailed breakdown allows for incredibly precise specification of every aspect of the project.

For example, Division 03 (Concrete) might contain sections on concrete formwork, reinforcing steel, cast-in-place concrete, and precast concrete. Each section would then be broken down further into subsections outlining specific aspects like materials, installation, quality control, and testing.

Q 2. Describe the difference between a specification section and a division.

A division in the CSI MasterFormat is a broad category encompassing a major area of work, such as concrete (Division 03) or plumbing (Division 22). It’s the highest level of organization. A specification section, on the other hand, falls *within* a division and details specific requirements for a particular aspect of that work.

Think of it like this: a division is the chapter, and a specification section is a detailed paragraph within that chapter. For example, within Division 03 (Concrete), Section 03300 might be ‘Cast-in-Place Concrete’. This section will specify the type of concrete mix, placement methods, finishing requirements, and other critical details. Each division contains multiple sections, each addressing specific aspects of that major construction area.

Q 3. How would you handle conflicting information between drawings and specifications?

Conflicting information between drawings and specifications is a common challenge. The general rule is that the more specific document governs. If drawings show a detail not explicitly covered in the specifications, the drawings take precedence. However, if the specifications have a more detailed requirement that contradicts the drawings, the specification usually wins out, especially if it’s a critical safety or performance issue.

My approach involves a methodical process: first, I carefully review both the drawings and the specifications to identify the conflict. Then, I analyze the information to determine which document contains the more specific or critical detail. I document the conflict and my resolution, clearly explaining the rationale. Finally, I request clarification from the architect or engineer to confirm the intended outcome and avoid any misunderstandings that might lead to errors or disputes on the project.

Ideally, these conflicts should be identified and resolved *before* construction begins to prevent costly delays and rework. Clear communication and coordination between the design team and the construction team are crucial to prevent these issues.

Q 4. What are the key components of a well-written specification section?

A well-written specification section comprises several key components designed to ensure clarity, completeness, and enforceability. These include:

- General: This section sets the overall scope, references relevant standards (like ASTM or ANSI), and establishes quality control procedures.

- Products: This section details the specific materials and equipment required, including manufacturer names, model numbers, and performance characteristics. It’s essential to allow for acceptable alternatives to avoid locking into a single vendor, while maintaining minimum performance standards.

- Execution: This spells out the installation methods, construction techniques, and sequencing of work, including quality control measures, testing requirements, and acceptable tolerances.

- Submittals: This section defines the required documentation and samples to be submitted for approval by the architect or engineer before installation. This ensures the chosen products meet the specified standards and that any potential issues are addressed in advance.

- Drawings: Any relevant drawings are referenced here, establishing visual support for the written specifications.

- Quality Assurance/Quality Control: Details on inspection and testing procedures throughout the process are included here to ensure work meets specifications.

Imagine baking a cake – the specifications are your recipe. A good recipe provides clear instructions (execution), lists all the ingredients (products), and defines the desired outcome (general). Missing even one crucial detail can result in a poorly baked cake or a construction project with issues.

Q 5. Explain the importance of using appropriate language in construction specifications.

Using precise and unambiguous language is paramount in construction specifications. Vague language can lead to misinterpretations, costly errors, and disputes. Avoid terms like ‘approximately’ or ‘suitable’ where possible. Instead, use specific quantities, measurements, and performance criteria.

For example, instead of ‘Use suitable concrete’, specify ‘Use a minimum compressive strength of 4,000 psi, ready-mixed concrete conforming to ASTM C94’. The clarity reduces the room for error and ensures everyone understands the expectations. Ambiguous language can be interpreted differently, leading to disagreements and rework, potentially even compromising the safety and integrity of the structure. Precision and clarity minimize miscommunication and maintain consistency.

Q 6. How do you ensure consistency and clarity in your specifications?

Consistency and clarity are maintained through careful planning and execution. I use a combination of strategies to achieve this:

- MasterFormat adherence: Consistent use of the CSI MasterFormat ensures logical organization and minimizes the risk of inconsistencies and omissions.

- Template Usage: Employing standardized specification section templates helps maintain consistent formatting, language, and content across the project. This allows for improved readability and makes it easier to spot any inconsistencies.

- Cross-referencing: Within the specification, I use clear and consistent cross-referencing to link related sections, avoiding redundancy and ensuring a logical flow of information.

- Review and Feedback: Multiple reviews of specifications from different viewpoints, including peers and project team members, are critical to identify and correct inconsistencies or ambiguities before project commencement. This process also aids in clarifying any potential issues.

- Version Control: Tracking changes using version control software is important, allowing for easy identification of updates and reducing the chance of working with outdated information.

Think of it like writing a well-structured essay. A clear outline, consistent grammar, and thorough proofreading all contribute to a polished, easily understood final product. The same principles apply to writing construction specifications.

Q 7. Describe your experience with different specification writing software.

I’ve worked extensively with several specification writing software packages throughout my career. These tools significantly improve efficiency and consistency in the specification writing process. I have experience with both dedicated specification writing software like SpecLink and also with more general document management and drafting software, such as Microsoft Word with customized templates and plugins, which can be adapted for specification writing with a bit more effort and attention to detail. Each has its own strengths and weaknesses. Dedicated specification writing software often offers features like MasterFormat integration, built-in libraries of standard clauses, and version control. General purpose software needs to be meticulously configured for effective specification writing. My choice depends on the project size and complexity and the client’s preferences.

The key to success isn’t just the software itself but the ability to leverage its features to streamline the writing process, ensuring quality and efficiency in creating comprehensive and error-free construction documents.

Q 8. How do you manage revisions and updates to construction specifications?

Managing revisions and updates to construction specifications requires a robust system. Think of it like managing a living document that evolves throughout the project lifecycle. We use a version control system, often a digital platform, to track all changes. Each revision is clearly identified with a revision number and date, and a detailed log outlines all modifications. This is crucial for transparency and accountability. For example, if a material change is made, the reason for the change, along with the impact assessment (cost, schedule, etc.), is documented. This ensures all stakeholders are informed and understand the implications of each update. We typically employ a formal change order process, requiring approval from relevant parties before integrating a revision into the official specification document.

- Version Control Software: Tools like Procore, BIM 360, or even simple numbered revisions in a shared document can help track changes.

- Change Order Process: A formal process outlining steps for requesting, reviewing, approving, and documenting changes.

- Revision Logs: Detailed records of every change, including the date, author, reason for change, and impact assessment.

Q 9. Explain the process of creating a specification section from scratch.

Creating a specification section from scratch involves a methodical process. It’s like building a recipe – you start with the desired outcome and break down the process step-by-step. First, we determine the appropriate CSI MasterFormat division and section for the work. For example, Division 03 is Concrete, and Section 03300 is Cast-in-Place Concrete. Then, we define the scope of work – what exactly needs to be specified? Next, we outline the requirements, including material specifications, performance criteria, testing procedures, and installation methods. We’ll then incorporate relevant industry standards, building codes, and best practices. Finally, we carefully review and edit the section to ensure clarity, consistency, and completeness. For example, specifying flooring might include details on the type of flooring, thickness, installation method, expected durability and performance requirements, and required quality assurance tests.

- Define Scope: Clearly outline the work to be specified.

- MasterFormat Division & Section: Identify the correct CSI MasterFormat classification.

- Requirements: Include material properties, performance standards, installation procedures, and quality control measures.

- Codes & Standards: Incorporate relevant codes (e.g., IBC, NFPA) and standards (e.g., ASTM).

- Review & Edit: Ensure clarity, consistency, and completeness.

Q 10. How do you ensure specifications comply with relevant building codes and regulations?

Compliance with building codes and regulations is paramount. We ensure compliance by actively referencing the applicable codes within the specifications themselves. For example, we explicitly state that all work shall conform to the International Building Code (IBC) or local equivalent. We also incorporate specific code requirements directly into the sections, such as fire-resistance ratings for assemblies or accessibility guidelines for fixtures. Regular updates are crucial; we track code changes through professional organizations like ICC (International Code Council) to stay current. We also utilize code checking software and engage specialists where necessary, particularly when dealing with complex or specialized systems. This proactive approach minimizes the risk of non-compliance and potential project delays or legal issues.

- Code References: Explicitly cite relevant codes within the specifications.

- Incorporate Requirements: Directly integrate code-specific requirements into the sections.

- Stay Updated: Regularly monitor code changes and updates.

- Software & Specialists: Utilize code-checking tools and consult specialists when needed.

Q 11. What are the benefits of using standardized specification formats like CSI MasterFormat?

Standardized formats like CSI MasterFormat offer significant advantages. Imagine trying to find a specific detail in a disorganized document – a nightmare! MasterFormat provides a logical and consistent organization, making it far easier to navigate and locate information. This standardized structure streamlines communication among all project stakeholders – architects, engineers, contractors, and subcontractors. It also facilitates more efficient bidding and cost estimation because everyone understands where to find information. Furthermore, it fosters greater accuracy in project management, leading to fewer errors and omissions. Think of it as a universal language for construction specifications, enhancing collaboration and efficiency across the entire project team.

- Organization: Consistent structure for easy navigation.

- Communication: Improves communication between stakeholders.

- Bidding & Costing: Simplifies the bidding and cost estimation processes.

- Accuracy: Reduces errors and omissions.

Q 12. How do you handle submittals and shop drawings in relation to specifications?

Submittals and shop drawings are integral to verifying that the work meets the specified requirements. We establish a clear submittal process within the specifications, detailing what needs to be submitted, when, and to whom. Each submittal is reviewed for compliance with the specifications and relevant codes. We’ll check if materials meet specified performance criteria, dimensions are accurate, and installation methods are appropriate. Any discrepancies or non-conformances are noted, and a formal response is provided to the contractor. This rigorous review helps ensure that the final product matches the design intent. For example, we might require submittals for structural steel detailing, ensuring the fabrication meets specified tolerances and strength requirements.

- Submittal Process: A detailed process defined in the specifications.

- Review & Compliance: Thorough review for adherence to specifications and codes.

- Formal Response: Documentation of approvals, revisions, or rejections.

Q 13. Describe your experience working with different types of construction projects.

My experience spans a wide range of construction project types. I’ve worked on residential, commercial, and industrial projects, including high-rise buildings, hospitals, schools, and manufacturing facilities. This diverse experience has exposed me to different material selections, construction methods, and regulatory requirements. For example, specifying materials for a high-rise building differs significantly from specifying materials for a residential project. The demands for fire safety, structural integrity, and sustainability are all much higher in a high-rise. This variety has enhanced my understanding of various project contexts and allowed me to adapt my specification approach to meet the unique challenges and opportunities of each type of project.

Q 14. How do you incorporate sustainable design principles into specifications?

Incorporating sustainable design principles is critical. We integrate these principles by specifying sustainable materials with recycled content, low embodied carbon, and locally sourced options. We also consider the building’s lifecycle, specifying energy-efficient systems like high-performance glazing and LED lighting. Water conservation is addressed through the specification of low-flow fixtures and water-efficient landscaping. Additionally, we factor in the building’s impact on indoor environmental quality, specifying low-VOC (volatile organic compound) materials to improve occupant health and well-being. This is reflected in the selection of paints, adhesives, and other interior finishes. For instance, we might specify FSC-certified wood for cabinetry to promote responsible forest management.

- Sustainable Materials: Prioritize recycled content, low embodied carbon, and local sourcing.

- Energy Efficiency: Specify high-performance systems and appliances.

- Water Conservation: Use low-flow fixtures and efficient landscaping.

- Indoor Air Quality: Specify low-VOC materials to improve occupant health.

Q 15. How do you manage multiple projects with differing specification requirements?

Managing multiple projects with diverse specification requirements necessitates a robust organizational system. I utilize a project management software that allows for clear separation of project files and specifications. For each project, I create a dedicated folder containing all relevant specifications, drawings, and submittals. This prevents accidental cross-contamination. Furthermore, I maintain a master spreadsheet tracking key aspects of each project, including deadlines, client requirements, and specific specification deviations. This overview provides a bird’s-eye view of all active projects, highlighting potential conflicts or resource allocation challenges early on. Think of it like a conductor managing an orchestra – each instrument (project) has its unique part, but the conductor ensures harmony and timely execution. I also implement regular check-ins to ensure consistency and address any emerging issues promptly.

Career Expert Tips:

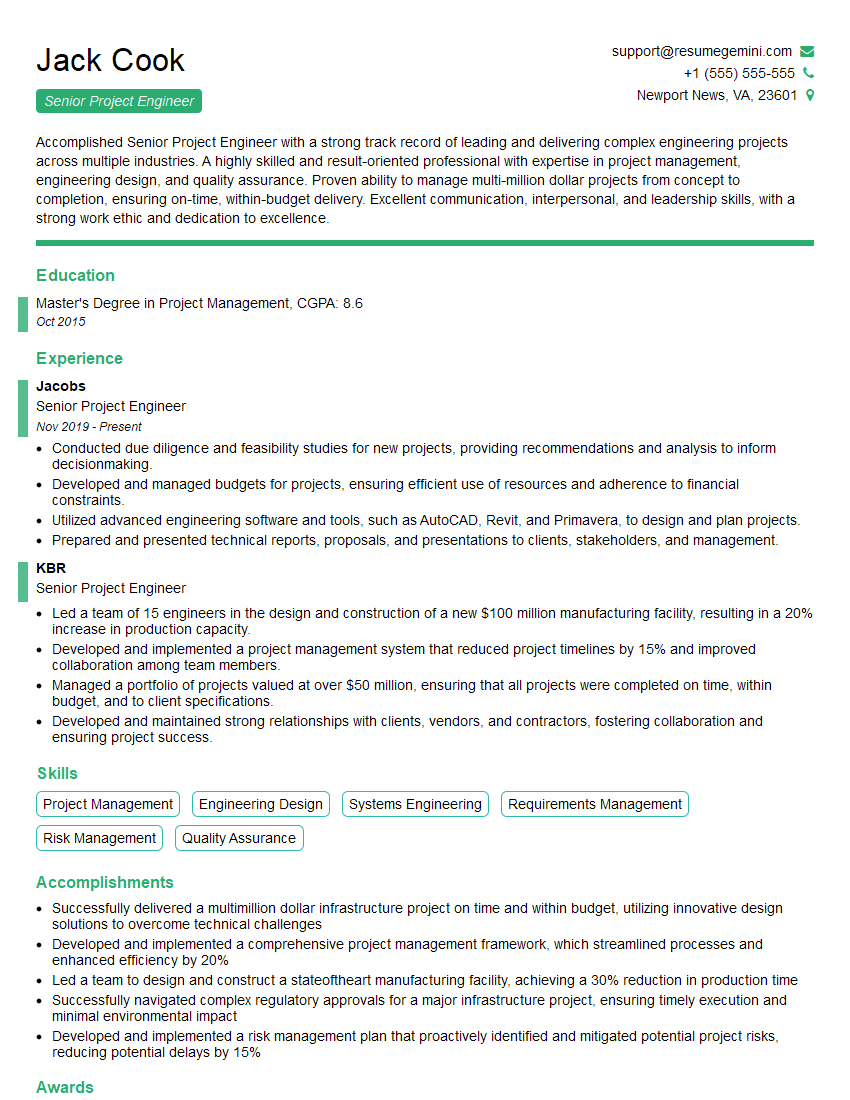

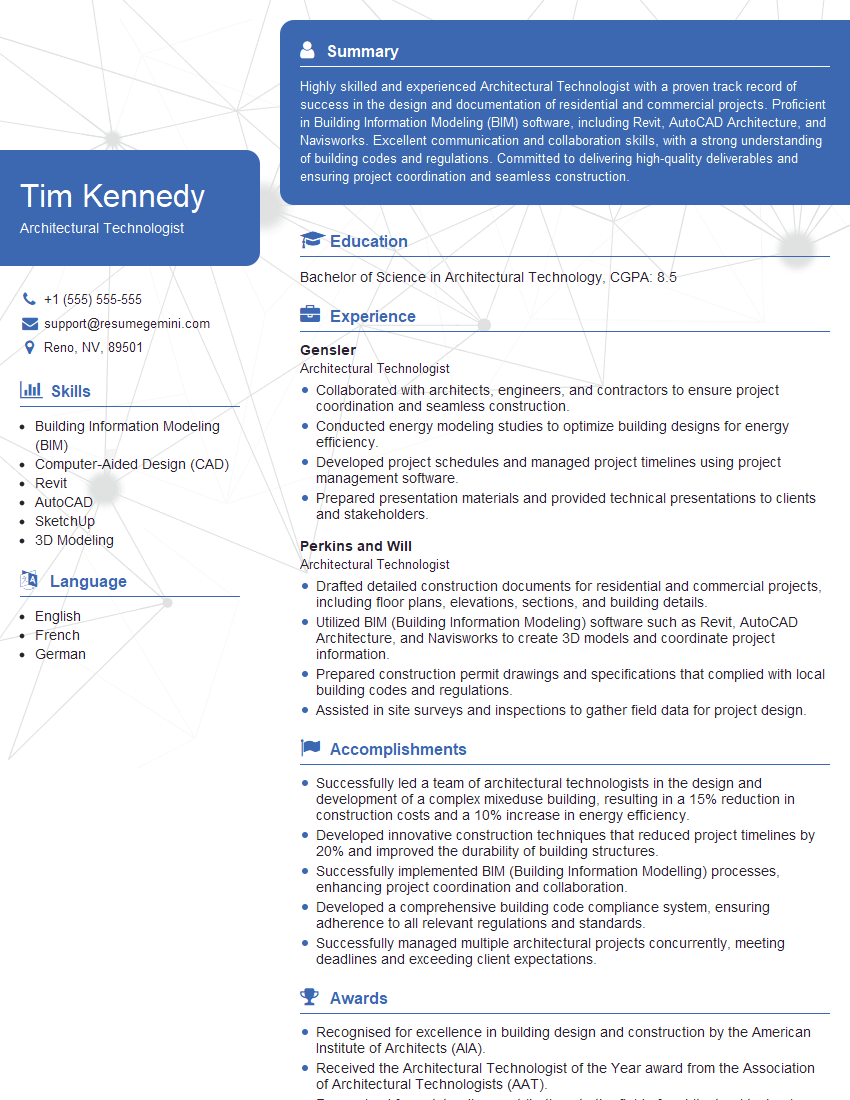

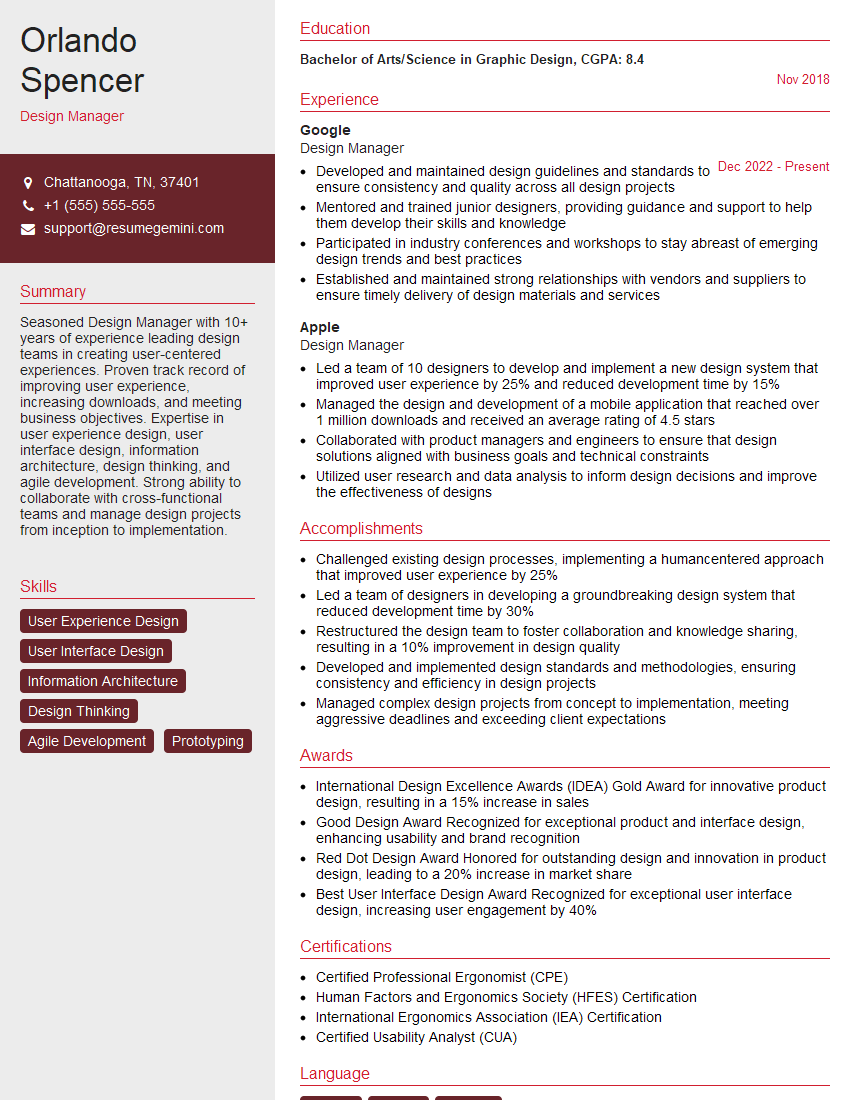

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with value engineering in relation to specifications?

Value engineering, in relation to specifications, is the systematic process of identifying and implementing cost-effective alternatives without sacrificing quality or performance. My experience involves working closely with design teams and contractors to explore options for substituting materials or construction methods. For example, I might suggest using a prefabricated structural system instead of traditional on-site construction, potentially reducing labor costs and project duration. This requires a detailed understanding of both the specifications and the market availability of suitable alternatives. It’s crucial to thoroughly document all proposed changes, ensuring compliance with building codes and the owner’s overall vision. Success in value engineering requires collaboration and a deep understanding of the specifications, identifying areas where adjustments can be made without compromising safety or functionality. A recent project involved substituting a high-cost hardwood flooring with a durable, equally aesthetically pleasing engineered wood, resulting in significant savings without impacting the project’s overall appeal.

Q 17. Explain how specifications impact the bidding process.

Specifications are the cornerstone of the bidding process. Clear, concise, and unambiguous specifications enable contractors to accurately estimate project costs and schedules. Vague or incomplete specifications lead to discrepancies in bids, potential disputes, and ultimately project delays and cost overruns. Think of it as a recipe – a precise recipe ensures everyone bakes the same cake, whereas a vague one leads to various interpretations and ultimately, very different cakes! The level of detail directly impacts the number of bidders. Precise specifications attract more qualified bidders, while ambiguous ones may deter them, leading to less competition. I always prioritize complete and accurate specifications, using the CSI MasterFormat system for organization and clarity to ensure a fair and competitive bidding process.

Q 18. How do you address potential ambiguities in specifications?

Addressing ambiguities in specifications requires proactive communication and meticulous review. First, I carefully review all specifications for any potential inconsistencies or unclear language before they’re released. I use checklists and cross-referencing techniques to identify possible conflicts. If ambiguities are identified after releasing the specifications, I issue addenda, formal written changes that clarify the original document. These addenda are distributed to all involved parties to ensure everyone works from the same updated information. Open communication with contractors is crucial; I encourage questions and clarification requests. Delaying clarification can lead to costly revisions later in the project. Remember, proactive communication is always cheaper than reactive problem-solving!

Q 19. What are the common challenges in writing construction specifications?

Common challenges in writing construction specifications include balancing completeness with conciseness, ensuring clarity and avoiding ambiguity, and staying current with evolving building codes and material technologies. Another challenge is managing conflicts between different specification sections. For instance, achieving consistency between architectural, structural, and mechanical specifications can be complex. Finally, ensuring that the specifications align with the project budget and schedule is crucial. Using a standard like CSI MasterFormat helps mitigate some of these issues by providing a structured framework for organizing information and ensuring a consistent approach to specification writing across projects.

Q 20. How do you prioritize different aspects of a specification section?

Prioritizing aspects within a specification section involves a hierarchical approach. First, I prioritize items related to safety and life safety. This includes aspects like fire protection, emergency egress, and structural integrity. Next, I prioritize items critical to the functionality of the building, followed by items impacting aesthetic aspects or user experience. This prioritization helps guide the contractor’s work, emphasizing critical aspects early in the process and ensuring their proper execution. I clearly define each item’s priority level in the specifications, using clear language or numerical rankings where appropriate. This ensures everyone is on the same page regarding the importance of different aspects of the work.

Q 21. Describe your knowledge of different construction materials and their specifications.

My knowledge of construction materials and their specifications encompasses a wide range, including concrete, steel, wood, masonry, and various finishes. For each material, I understand its properties, applications, performance characteristics, and common industry standards. This includes familiarity with relevant ASTM (American Society for Testing and Materials) and other industry-specific standards. For example, I know the different concrete mix designs and their corresponding compressive strength requirements, and I understand the various grades and types of steel used in construction, along with their respective yield strengths. My knowledge extends to specifying appropriate testing procedures and quality control measures for each material to ensure compliance with project requirements and applicable building codes. This is not just about knowing the materials but also understanding how to specify them correctly to achieve the desired outcome – effectively translating design intent into achievable realities for the construction team.

Q 22. How do you integrate BIM data with construction specifications?

Integrating BIM (Building Information Modeling) data with construction specifications is crucial for a streamlined and efficient project. It allows for a dynamic, interconnected approach, moving beyond static documents. We achieve this by linking specific elements within the BIM model to corresponding sections and details within the specifications.

For example, a specific window type in the BIM model can be linked to a particular specification section detailing its manufacturer, performance requirements, and installation methods. This linkage ensures that the design intent, as reflected in the BIM model, directly aligns with the written requirements in the specifications. Changes in one automatically trigger updates in the other, preventing discrepancies and promoting consistency. Tools like dedicated software plugins and APIs facilitate this integration, automating the process and minimizing errors. This process fosters better communication between design teams, contractors, and other stakeholders, ensuring everyone is working from a single source of truth.

In practice, this might involve using a common data environment (CDE) where both the BIM model and the specifications reside. This ensures a traceable, auditable, and accurate data flow. The benefits extend to cost estimation, material ordering, and clash detection, making the entire process smoother and potentially less costly.

Q 23. What is your familiarity with different specification writing methods (e.g., prescriptive vs. performance-based)?

I’m proficient in both prescriptive and performance-based specification writing methods. Prescriptive specifications explicitly detail the exact products and materials to be used (e.g., ‘Use Acme Brand Window, Model X’). This approach offers clarity and simplicity but can limit innovation and potentially increase costs if a superior alternative is unavailable. Performance-based specifications, on the other hand, focus on defining the required outcomes or performance characteristics (e.g., ‘Windows shall achieve a minimum R-value of 6 and meet ASTM E283 requirements’). This allows for greater flexibility in product selection, encouraging innovation and potentially leading to cost savings.

Choosing the right method depends on the project’s complexity and objectives. Often, a hybrid approach is most effective, combining prescriptive details for critical aspects with performance-based requirements for other components. For example, a project may use performance-based specs for insulation and prescriptive specs for structural steel. This allows flexibility while maintaining control over critical items.

Q 24. How do you ensure that specifications are legally sound and protect the interests of the owner?

Legally sound specifications are paramount to protecting the owner’s interests. This involves several key strategies:

- Clear and unambiguous language: Avoid vague terms and use precise wording to eliminate potential for misinterpretation. Define all terms and use industry-standard terminology.

- Reference relevant codes and standards: Incorporating references to building codes, industry standards (like ASTM and ANSI), and other regulatory documents ensures compliance and provides a legal framework.

- Detailed scope of work: The specifications must clearly outline the extent of work, responsibilities, and deliverables to prevent disputes over omissions or additional costs.

- Appropriate warranties and guarantees: Ensure the specifications require appropriate warranties and guarantees from the contractors and suppliers to protect the owner from defects or failures.

- Dispute resolution mechanisms: Include clear provisions for handling disputes, such as mediation or arbitration clauses.

Regular review and updates are also crucial, keeping pace with changes in regulations and best practices. A poorly written specification can lead to costly litigation and project delays, underscoring the importance of clear, legally compliant documentation.

Q 25. Explain your experience with the different parts of a specification section (e.g. General, Products, Execution).

My experience encompasses all parts of a CSI MasterFormat specification section. Each section typically includes:

- General: This section sets the overall tone and scope of the work described in the following parts. It may include quality standards, submittal requirements, testing procedures, and project-specific requirements.

- Products: This section details the specific materials and equipment needed. It should include manufacturer names and model numbers if using prescriptive methods, or performance criteria if using performance specifications. It may contain allowances for substitutions with equivalent materials, always subject to the approval of the architect or owner.

- Execution: This crucial section describes how the work should be performed. It covers installation methods, sequencing, quality control, and other procedural details. This is where detailed workmanship standards are defined.

I’m experienced in working with all three parts, ensuring consistency and clarity throughout the specification. I understand the importance of clearly defining responsibilities and expectations at each stage. For example, if a specification requires a specific type of caulking, both the product and its proper execution (application method, joint preparation) are equally vital to ensure a successful outcome.

Q 26. Describe your experience coordinating specifications with other project team members (architects, engineers, etc.).

Effective coordination with architects, engineers, and other project team members is essential for creating successful construction specifications. My approach involves regular meetings, collaborative software, and proactive communication. I believe in using a collaborative approach where everyone has a voice and can contribute their expertise. This often involves utilizing tools such as BIM software or cloud-based document sharing platforms that allow for real-time collaboration. I proactively seek feedback on draft specifications, ensuring that all team members are informed and involved in the process.

A recent project involved close coordination with the structural engineer to ensure that the specifications for the foundation system aligned perfectly with their design calculations and structural drawings. This required several collaborative sessions to address potential conflicts and to ensure the seamless integration of all specifications.

Q 27. How do you stay current with the latest updates and revisions to CSI MasterFormat and other relevant standards?

Staying current with CSI MasterFormat and other relevant standards is a continuous process. I actively participate in industry associations like the CSI, attend relevant conferences and workshops, and subscribe to industry publications. I regularly check for updates and revisions to the MasterFormat, ensuring my knowledge remains up-to-date. Understanding the latest changes in codes and standards is critical to producing compliant and effective specifications. I also regularly review relevant publications and online resources for best practices.

Online training courses are invaluable for staying current on the latest trends and updates. The CSI website and other professional organizations provide excellent resources that facilitate continuous learning and adaptation to new methodologies and technologies.

Q 28. Describe a time you had to resolve a conflict related to construction specifications.

On a recent high-rise project, a conflict arose concerning the specification of fire-rated glazing. The architect specified a particular brand, while the structural engineer raised concerns about its load-bearing capacity. My role was to mediate and find a solution that met both the aesthetic requirements and the structural integrity of the building.

My approach involved: 1) Gathering all relevant data from both parties, including technical specifications and load calculations; 2) Researching alternative fire-rated glazing systems that met both criteria; 3) Facilitating discussions between the architect and engineer to find common ground; 4) Presenting the alternatives and their respective pros and cons to the owner; 5) Ultimately, we selected a different product, which met the fire-rating requirements and the structural engineer’s load capacity concerns without compromising the architect’s design vision. This demonstrated my ability to navigate technical disagreements and deliver a solution that satisfied all stakeholders.

Key Topics to Learn for Construction Specifications Institute (CSI) Standards Interview

- MasterFormat and its Organization: Understanding the hierarchical structure of MasterFormat, including divisions, sections, and their purpose in organizing project specifications. Practical application: Quickly locating relevant information within a specification document.

- Specification Writing Principles: Grasping the fundamentals of clear, concise, and unambiguous specification writing, including the use of proper terminology and avoiding conflicts. Practical application: Analyzing existing specifications for clarity and completeness, and identifying potential issues.

- CSI’s UniFormat: Familiarizing yourself with UniFormat’s role in organizing construction information for cost estimating and project management. Practical application: Using UniFormat to create a detailed cost breakdown for a project.

- Standard Specifications and their Usage: Understanding the application and adaptation of standard specifications to unique project requirements. Practical application: Modifying standard specifications to meet specific client needs or site conditions.

- Contract Documents and their Interrelationship: Knowing how specifications relate to other contract documents like drawings, general conditions, and agreements. Practical application: Identifying potential conflicts between different contract documents and proposing solutions.

- Technology and CSI Standards: Exploring how digital tools and technologies are integrated with CSI standards in modern construction projects (BIM, digital specifications). Practical application: Understanding the benefits and challenges of utilizing digital specifications in a project workflow.

- Problem-solving with CSI Standards: Developing skills to interpret ambiguous sections and resolve conflicts between different parts of the specifications. Practical application: Analyzing a problematic specification section and proposing a clear and unambiguous solution.

Next Steps

Mastering Construction Specifications Institute (CSI) Standards is crucial for career advancement in the construction industry. A strong understanding of these standards demonstrates professionalism, efficiency, and a commitment to quality. To significantly boost your job prospects, creating an ATS-friendly resume is essential. This ensures your application gets noticed by recruiters and hiring managers. We recommend using ResumeGemini to build a professional and impactful resume that highlights your CSI knowledge. ResumeGemini provides examples of resumes tailored to Construction Specifications Institute (CSI) Standards, giving you a head start in crafting a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good