Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Container Loading and Handling interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Container Loading and Handling Interview

Q 1. Explain the importance of proper weight distribution in container loading.

Proper weight distribution in container loading is paramount for safety and stability throughout the shipping process. An improperly loaded container can lead to instability during transport, increasing the risk of accidents, damage to cargo, and potential injury to personnel. Think of it like balancing a seesaw; if the weight isn’t distributed evenly, one side will tilt, creating an imbalance.

Optimal weight distribution aims to achieve a low center of gravity, minimizing the risk of shifting or toppling during transit. This involves strategically placing heavier items lower and closer to the container’s center, and lighter items higher and towards the edges. We use sophisticated software and techniques to calculate the optimal placement for each item, considering its weight, dimensions, and fragility. For example, heavy machinery would be loaded towards the bottom and center, while lighter boxes of clothing might be stacked higher and against the sides, filling the gaps and ensuring the weight is distributed evenly.

Ignoring proper weight distribution can result in fines, delays, and damaged goods. In extreme cases, it can lead to serious accidents during handling and transport. Therefore, meticulous planning and execution are crucial for safe and efficient container loading.

Q 2. Describe different methods for securing cargo within a container.

Securing cargo within a container is crucial to prevent shifting and damage during transit. Several methods are employed, depending on the nature and fragility of the goods.

- lashing: This involves using straps, chains, or ropes to secure items to the container walls or floor. We use strong, high-tensile straps rated for specific weights, ensuring they are correctly tensioned and fastened to prevent slippage. Proper lashing is vital for preventing damage and ensuring cargo integrity. For example, a pallet of heavy machinery needs several strategically placed lashing points to ensure it stays in place under various conditions.

- Blocking and bracing: Wooden blocks or other suitable materials are used to create a stable barrier preventing cargo from moving. Bracing utilizes wooden or metal supports to prevent shifting or collapsing of stacks. This is especially important for irregular or oddly shaped items. For instance, we would brace a large piece of equipment against the container walls, ensuring it doesn’t shift during transit.

- Dunnage: This refers to materials used to fill voids and prevent shifting. It could be anything from air bags to cardboard inserts to prevent the items from moving within the container. It’s especially crucial for fragile items or items with irregular shapes. Think of it like packaging a delicate glass vase—you need to fill all the empty spaces to prevent it from shifting and breaking.

- Containerized load securing devices (CLSD): These are specialized tools for securing cargo, often employing a system of tensioning devices to guarantee cargo remains fixed.

The choice of securing method depends on the specific type of cargo and the length of the journey. A longer journey will require more robust securing measures than a short one.

Q 3. What are the key considerations for loading hazardous materials?

Loading hazardous materials requires meticulous attention to detail and strict adherence to regulations. The safety of personnel, the environment, and the integrity of other cargo are all at stake.

- Proper Identification and Documentation: Hazardous materials must be clearly identified and documented with the appropriate UN numbers, class labels, and safety data sheets (SDS). This information is vital for emergency responders and handling personnel.

- Segregation and Containment: Incompatible hazardous materials must be kept separate to prevent dangerous reactions. Specialized containers and packaging are often required to ensure containment and prevent leakage. We ensure that incompatible materials are never placed in the same container, or even near each other in separate containers.

- Emergency Response Planning: A comprehensive emergency response plan must be in place, including contact information for emergency services and procedures for dealing with spills or accidents.

- Packaging and Labeling: The materials must be properly packaged to withstand the rigors of transportation and clearly labeled according to international regulations.

- Compliance with Regulations: All loading procedures must comply with international and national regulations for the transport of hazardous materials, such as the International Maritime Dangerous Goods (IMDG) Code or similar regulations.

Failure to comply with these regulations can lead to severe penalties, environmental damage, and potential loss of life. A comprehensive understanding of hazardous materials classification and handling is essential for safe and compliant operations.

Q 4. How do you ensure compliance with international shipping regulations?

Compliance with international shipping regulations is achieved through diligent attention to detail and a proactive approach. This begins with understanding the specific regulations governing the cargo and the destination country.

- Documentation: Accurate and complete documentation is critical. This includes bills of lading, packing lists, commercial invoices, certificates of origin, and any required permits or licenses. Any discrepancies can lead to delays or even rejection of the shipment.

- Cargo Inspection: Regular inspections of the loaded containers ensure everything is compliant with regulations and secured properly. This minimizes the risk of non-compliance issues.

- Training: Personnel involved in container loading and handling must receive comprehensive training on relevant regulations and best practices. This includes understanding the appropriate handling, documentation, and safety procedures.

- Staying Updated: Shipping regulations frequently change. Staying informed about these changes through industry publications, training, and professional development is crucial to maintain compliance.

- Relationship with Authorities: Maintaining a good relationship with port authorities, customs officials, and other regulatory bodies is important to resolve potential issues quickly and efficiently.

Non-compliance can result in significant fines, delays, and reputational damage. A commitment to continuous improvement and adherence to regulations is essential for smooth and compliant operations.

Q 5. What are the different types of containers and their applications?

Various container types cater to different cargo needs:

- Dry Freight Containers (Standard Containers): The most common type, used for general cargo. They are durable, weatherproof, and stackable.

- Refrigerated Containers (Reefer Containers): These containers are equipped with refrigeration units to maintain a specific temperature range, ideal for perishable goods like food and pharmaceuticals.

- Open-Top Containers: These containers have a removable roof, allowing for easy loading and unloading of oversized or heavy equipment.

- Flatrack Containers: These containers have a low profile and no side walls, making them suitable for exceptionally large or heavy cargo.

- Tank Containers: Specialized containers designed to transport liquids or gases in bulk.

- Half-Height Containers: Containers half the height of standard containers, offering flexibility in mixed loads.

The choice of container type depends on the specific characteristics of the cargo. Selecting the appropriate container type is vital to ensure the cargo’s safety and integrity during transit.

Q 6. Describe your experience with container stacking techniques.

My experience with container stacking techniques emphasizes safety and efficiency. I’ve worked extensively with various stacking plans, considering weight distribution, cargo type, and stability. Proper stacking is vital for optimizing space utilization and preventing damage during transport.

We utilize specialized software to create optimal stacking plans, taking into account factors such as weight, center of gravity, and the stability of the different types of containers being stacked. For instance, heavier containers are placed lower in the stack, while lighter ones are placed higher. We also consider the structural integrity of the containers and the overall stability of the stack to avoid collapse or shifting during transit.

Safety is paramount. We adhere to strict guidelines to ensure that the stack is stable and secure, preventing accidents or damage to the containers or their contents. Regular inspections during the stacking process are crucial to identify and resolve any potential stability issues. In my experience, effective communication between the stacking crew and the supervisors is key to ensure a safe and efficient stacking process.

Q 7. How do you manage space optimization within a container?

Space optimization is crucial to maximize container capacity and reduce transportation costs. It’s an art as much as a science.

- 3D Planning Software: Using specialized software allows us to create a detailed 3D model of the container and the cargo, enabling efficient placement and minimizing wasted space.

- Careful Item Selection and Placement: Strategically placing smaller items in gaps and utilizing every available cubic inch is vital. This can involve nesting boxes or using custom-designed inserts for fragile items.

- Understanding Cargo Dimensions: Accurate measurements of all items are crucial to ensure that they fit within the container’s dimensions without exceeding weight limits or compromising stability.

- Weight Distribution: Distributing weight evenly helps prevent shifting and maximize stability, further enabling efficient space utilization.

- Load Consolidation: Combining several smaller shipments into one container when possible.

Effective space optimization not only reduces shipping costs but also minimizes the environmental impact by reducing the number of containers needed. It’s a constant effort to find the best balance between space utilization and cargo security.

Q 8. What are the safety procedures you follow while loading and unloading containers?

Safety is paramount in container loading and unloading. My procedures begin with a thorough pre-operation inspection of the area, equipment, and containers themselves. This includes checking for any damage, ensuring the ground is level and stable, and verifying that all equipment is functioning correctly. I always wear appropriate personal protective equipment (PPE), including safety boots, high-visibility clothing, and hard hats.

Before any loading or unloading commences, a detailed risk assessment is performed, identifying potential hazards and outlining mitigation strategies. We implement strict traffic management protocols to control the movement of vehicles and personnel around the loading area. Clear communication is vital; we utilize hand signals, radios, and pre-planned communication strategies to coordinate activities among the team. Furthermore, I consistently enforce strict adherence to weight limits for equipment and containers to prevent overloading and potential accidents. Regular safety briefings are given to the team to address specific concerns and reinforce safety practices.

For example, during a recent operation involving a particularly heavy container, we utilized two forklifts instead of one to distribute the load and maintain stability. This proactive measure prevented a potential tipping incident and ensured worker safety.

Q 9. How do you handle damaged or defective containers?

Damaged or defective containers are handled with extreme caution and according to established protocols. Initial steps involve a thorough inspection to identify the nature and extent of the damage. This assessment determines whether the container is safe for further use or if it requires repair or replacement.

Minor damage, such as dents or scratches, might be documented and the container still used if deemed structurally sound. However, significant damage, such as structural cracks or compromised door seals, mandates the container’s immediate removal from service. I’d coordinate with the appropriate personnel to either repair the container (if feasible and cost-effective) or arrange for its replacement. This process always involves detailed documentation, including photographic evidence, to support any claims and track the resolution.

In one instance, a container arrived with a damaged corner. We carefully inspected it for structural integrity. After confirming it was safe, we proceeded with unloading, but prioritized that specific container and its contents to minimize further risk.

Q 10. Explain the process of verifying cargo weight and dimensions.

Verifying cargo weight and dimensions is crucial for safe and efficient loading. Weight verification typically involves using certified scales to weigh the cargo before loading. This information is compared with the shipper’s documentation to ensure accuracy. Discrepancies are investigated and resolved before proceeding. Dimensions are verified using measuring tapes and/or laser measuring tools. These measurements are crucial for optimal space utilization and to ensure the cargo fits within the container without exceeding weight capacity.

Accurate weight verification helps prevent overloading, which can lead to structural damage, fines, and safety hazards. Precise dimensional verification optimizes space utilization within the container, minimizing wasted space and improving efficiency. I always cross-reference these figures with the shipping documents to prevent inconsistencies and potential issues.

For instance, a recent shipment of oddly shaped machinery required careful measurement to ensure we loaded it in a way that maximized space and maintained structural integrity. Precise measurements prevented shifting during transit and enabled us to load additional items.

Q 11. What is your experience with using loading and unloading equipment (forklifts, cranes, etc.)?

I possess extensive experience operating various loading and unloading equipment, including forklifts, reach stackers, and container cranes. My certifications include [List relevant certifications here, e.g., forklift operator certification, crane operator certification]. I am proficient in the safe operation, maintenance, and pre-operational checks required for these machines. My experience includes operating both standard and specialized equipment, adapting to diverse cargo types and challenging loading environments.

Operating forklifts safely requires a meticulous approach to loading, unloading, and maneuvering. I ensure that loads are properly secured, that weight limits are not exceeded, and that the surrounding area is clear before operating. Similar stringent safety protocols are followed when operating cranes and other heavy machinery.

One example involves loading oversized cargo using a reach stacker. Precise maneuvering and careful load securing were essential for preventing damage to both the cargo and the equipment. My experience enabled the successful and efficient completion of this complex task.

Q 12. How do you prevent cargo shifting during transit?

Preventing cargo shifting during transit is critical for ensuring safety and preventing damage. This involves proper cargo securing techniques. The method depends on the cargo type and weight. Common techniques include the use of lashing straps, dunnage (protective material), blocking (material to prevent shifting), and bracing to immobilize cargo. Proper weight distribution is also vital; heavier items should be loaded at the bottom and near the center of gravity to prevent imbalance.

We follow stringent guidelines for securing different types of cargo. For example, fragile items require extra padding and bracing, while heavier items necessitate stronger lashing and blocking. We consider the route and expected weather conditions when determining the level of securing required.

In one instance, a shipment of glassware required very specific bracing and dunnage to prevent breakage. Proper securing prevented any damage during transport, demonstrating the importance of adapting techniques to specific cargo needs.

Q 13. How do you address container damage or loss during transit?

Addressing container damage or loss during transit involves a multi-step process. Firstly, a thorough investigation is carried out upon arrival to determine the extent of the damage or loss and its cause. This includes inspection of the container, examination of the cargo, and review of handling and transportation records. Photographic evidence is crucial for documenting the condition.

Depending on the findings of the investigation, claims are filed with the relevant parties (shipping lines, insurers, etc.). The claim process involves providing comprehensive documentation to support the claim, including photographs, damage reports, and relevant transportation records. Close collaboration with insurance adjusters and shipping companies is crucial for a timely and fair resolution.

In a past instance, a container arrived with significant damage, resulting in cargo loss. A thorough investigation, detailed documentation, and diligent communication with the involved parties led to a successful claim resolution, compensating for the loss and preventing similar issues in the future.

Q 14. Describe your experience with inventory management related to container loading.

Inventory management in container loading is integral to efficiency and accuracy. This starts with a precise inventory of goods received, using methods like barcode scanning or RFID tagging. This ensures we have a detailed record of each item before loading begins. The next step involves optimizing space utilization within the container based on the items’ dimensions and weight, minimizing wasted space and maximizing efficiency.

Throughout the loading process, a rigorous inventory tracking system is maintained. This allows us to verify that all items loaded match the inventory list, ensuring nothing is missing or misplaced. Real-time tracking enables immediate identification and resolution of discrepancies, preventing errors that could delay shipments or cause conflicts.

I’ve utilized various inventory management systems, from simple spreadsheets to sophisticated software solutions. In one case, using barcoding improved inventory accuracy significantly, reducing errors and improving overall efficiency.

Q 15. How do you manage discrepancies between shipping documents and actual cargo?

Discrepancies between shipping documents and actual cargo are a common challenge in container handling. They can range from minor inaccuracies in quantity to significant differences in cargo type or even missing items. My approach involves a systematic process beginning with a thorough pre-loading check against the packing list, commercial invoice, and other relevant documentation. This involves physically verifying each item against the documentation, noting any discrepancies immediately.

For minor discrepancies, like a slight variation in weight (within acceptable tolerance), I’d document the difference, noting the cause if possible, and proceed with appropriate adjustments to the documentation. For significant discrepancies, such as missing items or incorrect cargo, a thorough investigation is launched. This may involve contacting the shipper and consignee, reviewing warehouse records, and possibly conducting a full inventory recount. Photography and detailed notes are crucial during this process. Ultimately, a reconciliation report is generated, detailing all discrepancies and their resolution. This report ensures transparency and accountability throughout the supply chain.

For example, I once discovered a discrepancy where a shipment of electronics had fewer units than indicated on the packing list. Through careful investigation, we found that a pallet had been accidentally left behind at the warehouse. By quickly addressing this, we minimized delays and ensured the shipment reached its destination promptly. The incident highlighted the importance of thorough pre-loading checks and strong communication throughout the process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the potential risks associated with improper container loading?

Improper container loading poses several significant risks, impacting safety, efficiency, and legal compliance. These risks can be categorized into:

- Safety Hazards: Incorrect weight distribution can lead to instability during transport, causing accidents, injuries, and damage to cargo. Improper securing of cargo can result in shifting during transit, potentially causing damage or even container collapse.

- Cargo Damage: Improper stacking and inadequate protection can lead to crushing, abrasion, and damage to goods. Sensitive items might be damaged by exposure to moisture, temperature fluctuations, or vibration if not properly protected.

- Delays and Increased Costs: Damaged or improperly loaded containers can lead to delays in transit, requiring repairs, inspections, and potential cargo replacement. This results in increased transportation costs and potential penalties for missed delivery deadlines.

- Legal and Insurance Issues: Failure to adhere to safety regulations and proper loading procedures can lead to legal liability, insurance claims, and fines. Insurance companies may refuse claims if improper loading practices are identified as the cause of damage.

For instance, overloading a container can exceed the weight limits, causing structural damage to the container and posing a safety hazard to drivers and other road users. Similarly, failing to properly secure hazardous materials can lead to catastrophic consequences.

Q 17. How do you ensure the timely loading and unloading of containers?

Ensuring timely loading and unloading requires meticulous planning and coordination. This involves several key steps:

- Advanced Planning: This includes securing appropriate container types, scheduling cranes and other equipment, and coordinating with trucking companies and warehouse staff. Precise arrival times for containers and cargo need to be established and communicated to all relevant parties.

- Efficient Processes: Streamlining the workflow, optimizing loading sequences, and utilizing efficient technologies like barcode scanning and automated systems improves speed and accuracy.

- Clear Communication: Maintaining open communication between all stakeholders (shippers, consignees, trucking companies, port authorities) through the use of regular updates, reporting tools, and issue-tracking systems is critical.

- Contingency Planning: Having backup plans to deal with potential delays, equipment malfunctions, or unforeseen circumstances minimizes disruption. This includes having alternative transport options, backup equipment, and skilled personnel available to handle unexpected challenges.

For example, by using a pre-defined loading plan and coordinating effectively with the truck drivers and warehouse staff, I have consistently been able to load containers well within the allocated timeframe, avoiding delays and associated costs.

Q 18. Describe your experience with different types of cargo and their handling requirements.

My experience encompasses a wide variety of cargo types, each with unique handling requirements. These include:

- General Cargo: This includes packaged goods, ranging from clothing and electronics to furniture and machinery. Proper stacking, securing, and protection from environmental factors are essential.

- Refrigerated Cargo (Reefer): These shipments require temperature control throughout the journey. Maintaining the correct temperature setting, checking the reefer unit’s functionality, and ensuring proper ventilation are critical.

- Hazardous Materials: These require specialized handling procedures, including specific documentation, packaging, and labeling in compliance with regulations like IMDG Code. Strict safety protocols are essential to prevent accidents and environmental damage. This includes careful attention to segregation and adequate hazard warning labeling.

- Liquid Bulk Cargo: This often involves tankers and specialized handling equipment. Ensuring proper filling levels, tank integrity, and compliance with regulations on the handling of hazardous liquids is crucial.

- Oversized and Heavy Cargo: This often necessitates specialized equipment, securement techniques, and permits to ensure safe transportation.

I’ve successfully handled shipments of various complexities, including fragile ceramics requiring custom crating, oversized machinery needing precise placement and securement, and sensitive pharmaceuticals requiring strict temperature monitoring. My experience in each case has involved understanding the specific cargo characteristics, referring to the appropriate guidelines and regulations, and implementing suitable handling practices.

Q 19. How do you handle unexpected delays or challenges during the loading process?

Unexpected delays or challenges during the loading process require a proactive and adaptable approach. My strategy involves:

- Identifying the Cause: Quickly determining the root cause of the delay – whether it’s equipment malfunction, logistical issues, or unforeseen circumstances – is the first step.

- Assessing the Impact: Evaluating the impact of the delay on the overall schedule, potential costs, and compliance with deadlines is crucial.

- Developing Solutions: Identifying and implementing appropriate solutions, which might involve re-scheduling, utilizing alternative resources, or negotiating with stakeholders, to mitigate the impact of the delay.

- Communication and Documentation: Maintaining clear communication with all relevant parties and documenting the delay, the actions taken, and the resulting outcome is vital for accountability and continuous improvement.

For instance, during a recent storm that caused port delays, I proactively coordinated with shipping lines and warehouse staff to re-schedule the arrival and departure times of containers and trucks, preventing major disruptions to the entire operation. Effective communication and contingency plans minimized the impact of the unexpected event.

Q 20. What is your familiarity with container tracking systems?

I am highly familiar with various container tracking systems, including both software-based and hardware-based solutions. My experience includes using systems that provide real-time location tracking, container status updates, and historical data analysis. This includes systems that integrate with various shipping lines, ports, and logistics providers. I understand the importance of using reliable and accurate tracking information to monitor the movement of containers, ensure timely delivery, and manage potential risks.

Examples of systems I’m familiar with include [System Name 1], [System Name 2], and others that allow for tracking containers from origin to destination. My proficiency extends to using these systems to identify potential delays, resolve discrepancies, and generate reports for stakeholders.

Q 21. How do you maintain accurate records of loaded containers?

Maintaining accurate records of loaded containers is critical for efficient operations and compliance. My approach involves a multi-layered system:

- Digital Documentation: Using digital systems like dedicated loading management software and electronic data interchange (EDI) to record container details, cargo manifests, and other relevant information.

- Physical Documentation: Maintaining physical copies of important documents, including packing lists, bills of lading, and loading manifests, as a backup to digital records.

- Barcode and RFID Technology: Utilizing barcode and RFID technology for precise tracking and identification of containers and their contents, reducing manual errors and improving accuracy.

- Regular Audits and Reconciliations: Conducting regular audits and reconciliation checks to ensure data accuracy and identify any discrepancies between physical inventory and recorded data. This involves comparing physical inventories with digital records.

- Secure Data Storage: Storing all container records in a secure and accessible system, ensuring data integrity and protecting information from unauthorized access.

This multi-layered approach ensures data integrity and allows for easy access to information, enhancing efficiency and transparency throughout the entire process. The use of digital tools reduces the risk of human error and ensures accurate, auditable records for compliance and improved operations.

Q 22. What are the environmental considerations related to container handling?

Environmental considerations in container handling are crucial for minimizing the industry’s carbon footprint and protecting ecosystems. This involves several key areas:

- Air Pollution: Diesel fumes from handling equipment (forklifts, cranes, trucks) contribute significantly to air pollution. Mitigation strategies include using low-emission equipment, optimizing routes to reduce idling time, and exploring alternative fuel sources like electricity or biofuels.

- Noise Pollution: The constant movement and operation of machinery generate considerable noise, impacting nearby communities. Solutions include implementing noise barriers, using quieter equipment, and scheduling operations during less sensitive times.

- Water Pollution: Spills of hazardous materials from containers can contaminate waterways. Strict adherence to safety protocols, proper waste management, and containment systems are essential for preventing such incidents. Regular inspections and maintenance of equipment are crucial to avoid leaks.

- Waste Management: The disposal of packaging materials and other waste generated during the handling process needs careful planning. Recycling programs, waste segregation, and partnerships with responsible waste management companies are vital.

- Carbon Footprint: The transportation of containers contributes to greenhouse gas emissions. Optimizing routes, using fuel-efficient vessels and trucks, and exploring green shipping initiatives are crucial steps to reduce the environmental impact.

For example, in a recent project, we implemented a system to monitor fuel consumption of our handling equipment, leading to a 15% reduction in diesel usage within six months. This demonstrates the tangible impact of focusing on these environmental considerations.

Q 23. How do you communicate effectively with different stakeholders during the loading process?

Effective communication during container loading is paramount. I use a multi-pronged approach involving:

- Clear and Concise Instructions: I provide detailed loading plans with diagrams, specifications of cargo, and weight limits to all involved parties – including stevedores, drivers, and warehouse personnel. Using precise language avoids misunderstandings.

- Regular Updates: I maintain open communication channels, providing real-time updates on the progress of loading, any potential delays, or changes in plans. This is achieved through daily briefings, email updates, and even the use of collaborative project management software.

- Active Listening: I actively listen to concerns or suggestions from stakeholders, fostering a collaborative environment where everyone feels comfortable voicing their input. This allows for proactive problem-solving and prevents issues from escalating.

- Documentation: I meticulously document every step of the process, including the loading sequence, weight distribution, and any special handling requirements. This ensures accountability and serves as a reference point if any discrepancies arise.

- Technology: Using communication platforms like instant messaging and video conferencing enables real-time collaboration and efficient information dissemination, especially across geographically dispersed teams.

For instance, during a particularly complex project involving oversized cargo, I used daily video conferences to keep all stakeholders informed, allowing for quick resolution of any arising challenges.

Q 24. Describe your experience with the use of container loading software or systems.

I have extensive experience using various container loading software systems, including CargoWise One and BluJay Solutions. These systems offer significant advantages over manual methods:

- Optimized Loading Plans: The software utilizes algorithms to generate optimal loading plans, maximizing space utilization and minimizing weight imbalances. This reduces transportation costs and improves stability.

- Real-Time Tracking: These systems often provide real-time tracking of container locations and status, enabling better inventory management and improved efficiency.

- Improved Communication: Many systems integrate with communication platforms, facilitating seamless information sharing between stakeholders.

- Reduced Errors: Automated processes minimize human error in documentation and planning, leading to fewer loading errors and improved safety.

- Reporting and Analytics: Software provides detailed reports on loading efficiency, helping identify areas for improvement and optimization.

In one project, using CargoWise One allowed us to reduce the number of containers needed by 5%, significantly impacting transport costs. The system’s automated reporting feature also helped us identify and rectify recurrent issues with container weight distribution.

Q 25. Explain your approach to problem-solving in the event of a loading error.

My approach to problem-solving during loading errors involves a methodical, step-by-step process:

- Immediate Stoppage: The first step is to immediately stop the loading process to prevent further errors or potential damage.

- Assessment and Identification: Carefully assess the situation to identify the exact nature and extent of the error. This includes reviewing the loading plan, verifying cargo information, and checking the condition of the container.

- Root Cause Analysis: Determine the underlying cause of the error. Was it a mistake in the loading plan, a communication breakdown, or a technical malfunction? This step is crucial for preventing future occurrences.

- Corrective Action: Develop and implement a corrective action plan to rectify the error. This may involve rearranging cargo, replacing damaged materials, or adjusting the loading plan.

- Documentation: Thoroughly document the error, the corrective actions taken, and any lessons learned. This documentation serves as a record and aids in future improvements.

- Communication: Communicate the issue and the corrective actions to all stakeholders involved. Transparency is crucial to maintain trust and confidence.

For example, if a container is overloaded, I would first halt the process, then reassess the weight distribution and redistribute the cargo to ensure compliance with safety regulations. This would be followed by updating all relevant parties and documenting the entire incident.

Q 26. How do you prioritize tasks when multiple containers need loading simultaneously?

Prioritizing tasks when multiple containers need simultaneous loading involves a strategic approach that prioritizes several key factors:

- Urgency and Deadlines: Containers with tight deadlines or urgent delivery requirements are prioritized. This may involve assigning more resources to these containers.

- Cargo Type and Handling Requirements: Containers with hazardous materials or specialized handling needs often require priority to ensure safety and compliance.

- Container Size and Weight: Larger and heavier containers might be prioritized to optimize the loading sequence and equipment utilization.

- Destination and Route: Containers destined for the same location or using the same transportation route might be grouped together to streamline logistics.

- Resource Availability: The availability of handling equipment, personnel, and storage space influences the prioritization of tasks.

I often use a Kanban board or a similar visual management system to track the progress of each container and adjust priorities as needed. This ensures a smooth and efficient loading process even under pressure.

Q 27. What is your experience with various types of container seals and their applications?

My experience encompasses various container seals, each with specific applications:

- Bolt Seals: These are commonly used and offer a good level of security. They are relatively inexpensive and easy to apply, making them suitable for most general cargo.

- High-Security Seals: These provide enhanced tamper-evident features, often incorporating unique serial numbers for tracking and verification. They are preferred for high-value or sensitive goods.

- Cable Seals: These are used for securing containers with openings or access points that require a more flexible sealing mechanism.

- Plastic Seals: While offering less security than metal seals, they are suitable for less valuable goods and offer a cost-effective solution.

- Electronic Seals: These utilize electronic sensors to monitor seal integrity and provide real-time data on tampering attempts. They offer the highest level of security and are particularly beneficial for high-value or sensitive shipments.

The choice of seal depends on the value and nature of the cargo, the level of security required, and budget constraints. I always ensure compliance with relevant regulations and industry best practices regarding seal usage and documentation.

Q 28. Describe your understanding of the International Maritime Dangerous Goods (IMDG) Code.

The International Maritime Dangerous Goods (IMDG) Code is a comprehensive set of regulations governing the safe transportation of dangerous goods by sea. My understanding encompasses:

- Classification of Dangerous Goods: The IMDG Code classifies dangerous goods into nine classes based on their hazards (e.g., explosives, flammable liquids, toxic substances). Accurate classification is critical for safe handling and transportation.

- Packaging Requirements: The Code specifies packaging requirements for different types of dangerous goods, ensuring proper containment and preventing leaks or spills. This includes testing requirements and approval standards.

- Labeling and Marking: Containers carrying dangerous goods must be clearly labeled and marked according to the IMDG Code, indicating the class and nature of the hazardous material.

- Documentation: Comprehensive documentation is required for shipping dangerous goods, including declarations and certificates. This paperwork ensures compliance and facilitates proper handling throughout the transportation chain.

- Emergency Response: The IMDG Code outlines procedures for handling emergencies involving dangerous goods during transportation, including spill response and safety protocols.

Non-compliance with the IMDG Code can result in serious consequences, including accidents, environmental damage, and legal penalties. I ensure strict adherence to all relevant IMDG Code provisions during the handling and loading of dangerous goods.

Key Topics to Learn for Container Loading and Handling Interview

- Container Types and Specifications: Understanding different container sizes (TEU, FEU), types (dry van, reefer, open top, etc.), and their weight limitations is crucial for efficient loading and space optimization.

- Weight Distribution and Stability: Learn how to calculate and distribute weight evenly within a container to prevent instability and damage during transit. Practical application includes understanding the impact of center of gravity on load security.

- Cargo Securing Techniques: Master various cargo securing methods, including lashing, bracing, and dunnage, to prevent shifting and damage during transportation. This includes understanding relevant safety regulations and best practices.

- Hazardous Materials Handling: Gain a thorough understanding of regulations and procedures for handling hazardous materials, including proper labeling, documentation, and securing methods. This is crucial for safety and compliance.

- Container Loading Plans and Documentation: Learn how to create efficient loading plans, utilizing software and understanding the importance of accurate documentation for tracking and customs purposes. Practical application includes using stowage plans and bills of lading.

- Inventory Management and Tracking: Understand how to manage inventory within a containerized environment, ensuring accuracy and efficiency in loading, unloading, and tracking processes. This includes familiarity with inventory management systems.

- Equipment and Technology: Familiarity with various handling equipment (cranes, forklifts, etc.) and container tracking technologies (GPS, RFID) will demonstrate a comprehensive understanding of the field.

- Safety Regulations and Compliance: Thorough knowledge of relevant safety regulations and best practices is paramount. This includes understanding potential hazards and mitigation strategies.

- Problem-Solving and Decision-Making: Be prepared to discuss scenarios requiring quick thinking and problem-solving, such as unexpected delays, damage to cargo, or equipment malfunctions.

Next Steps

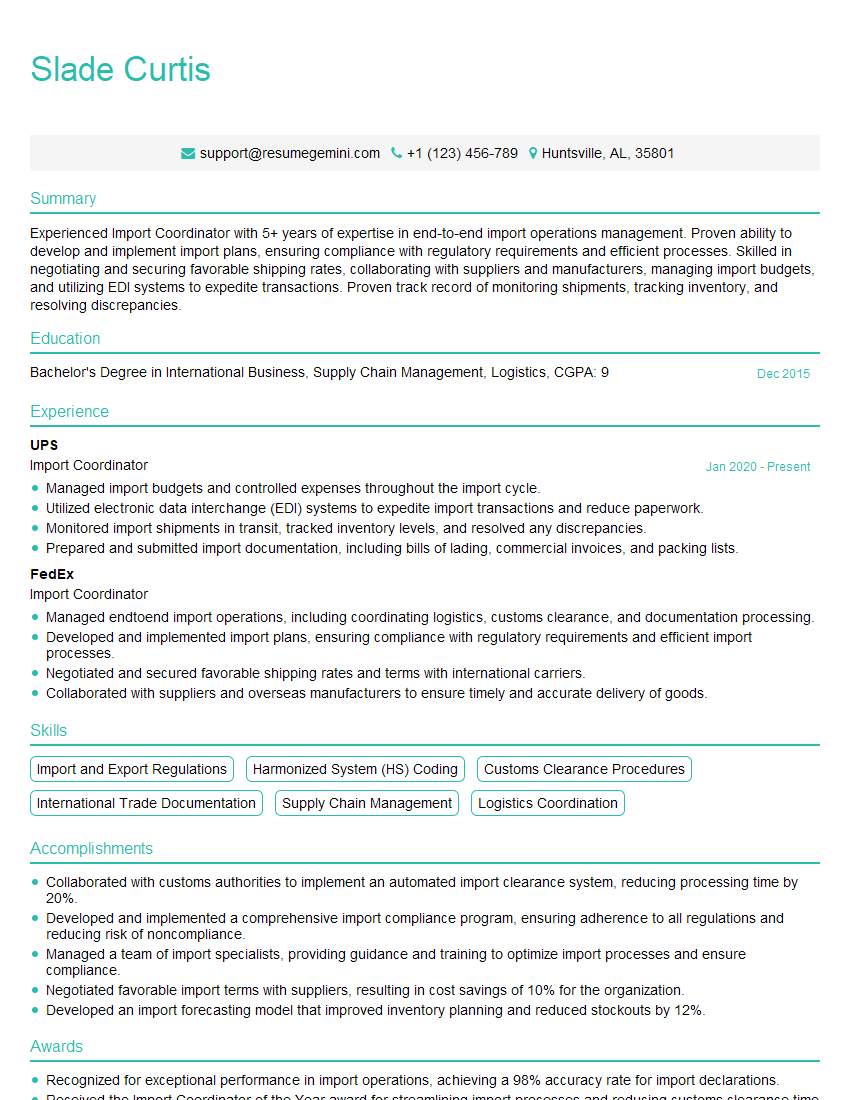

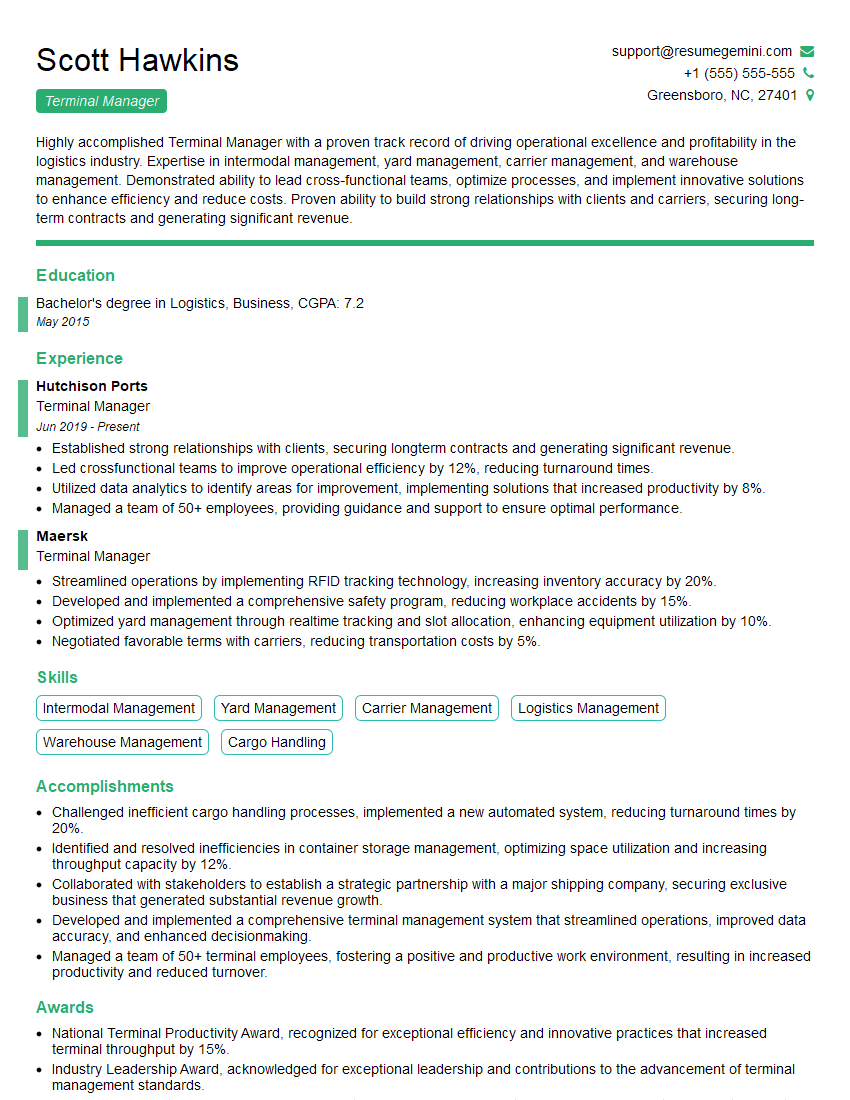

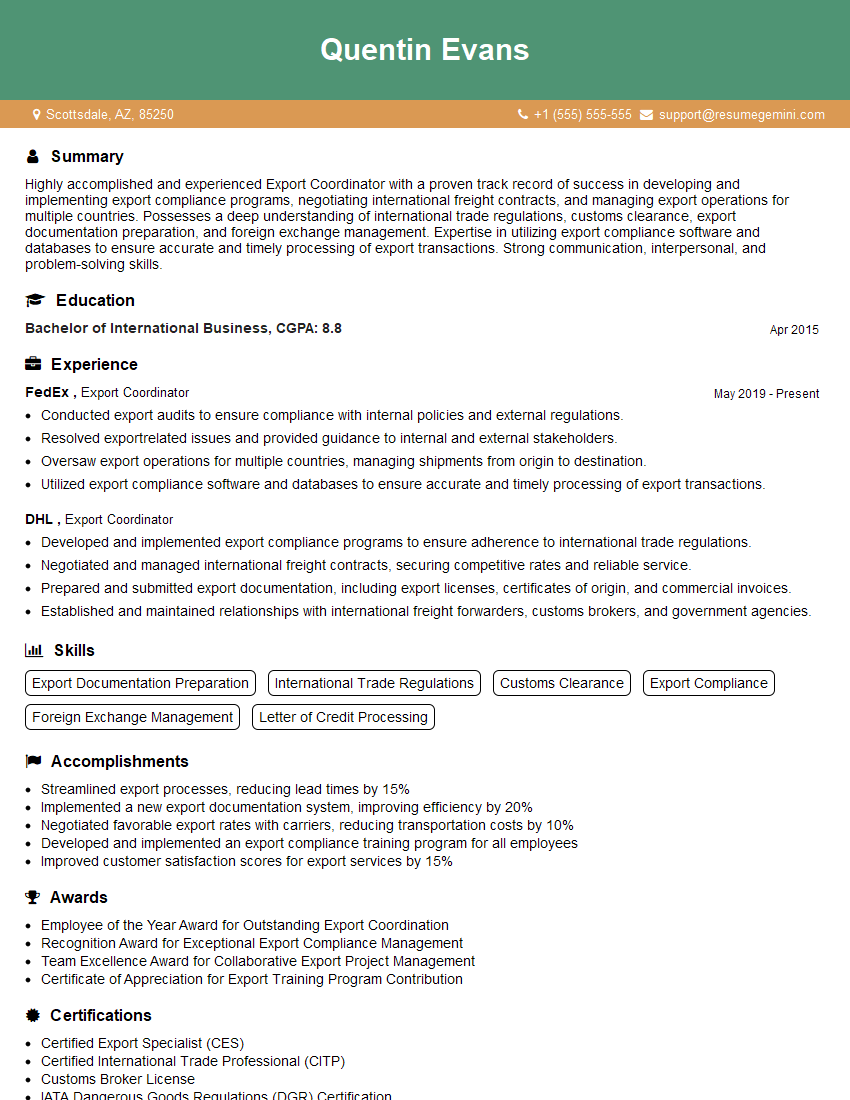

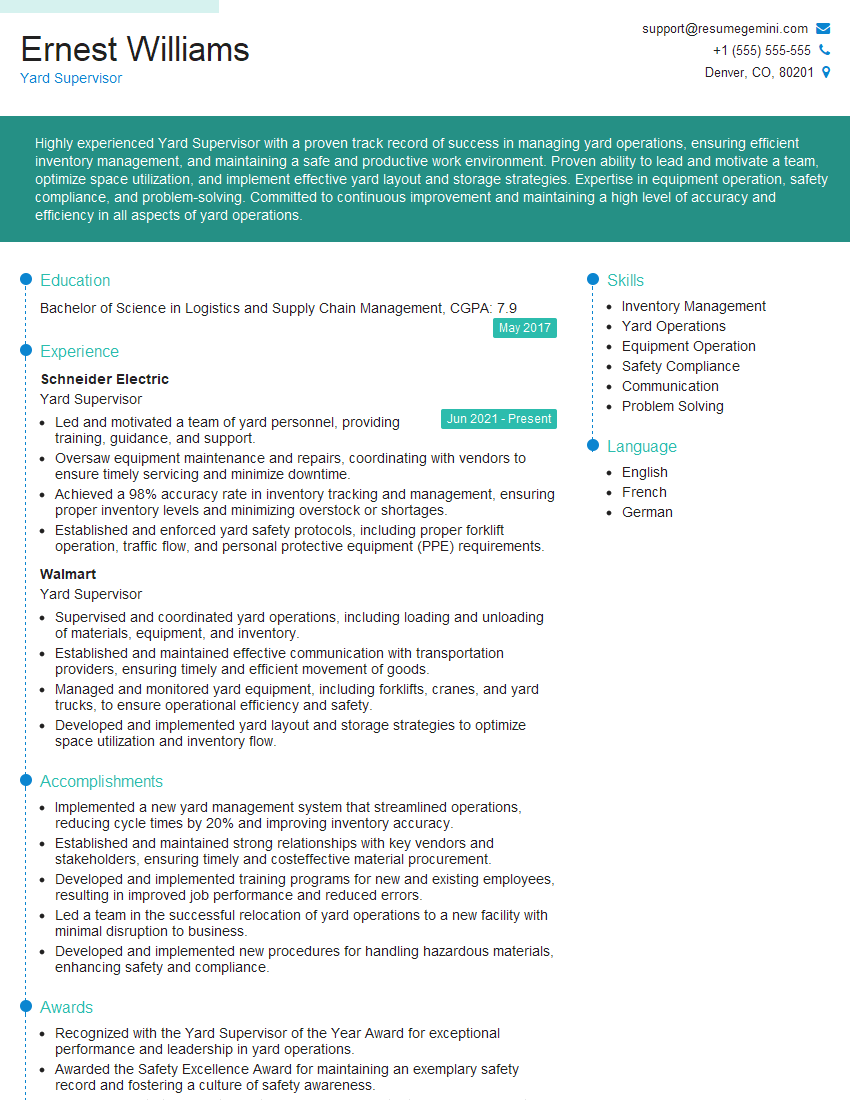

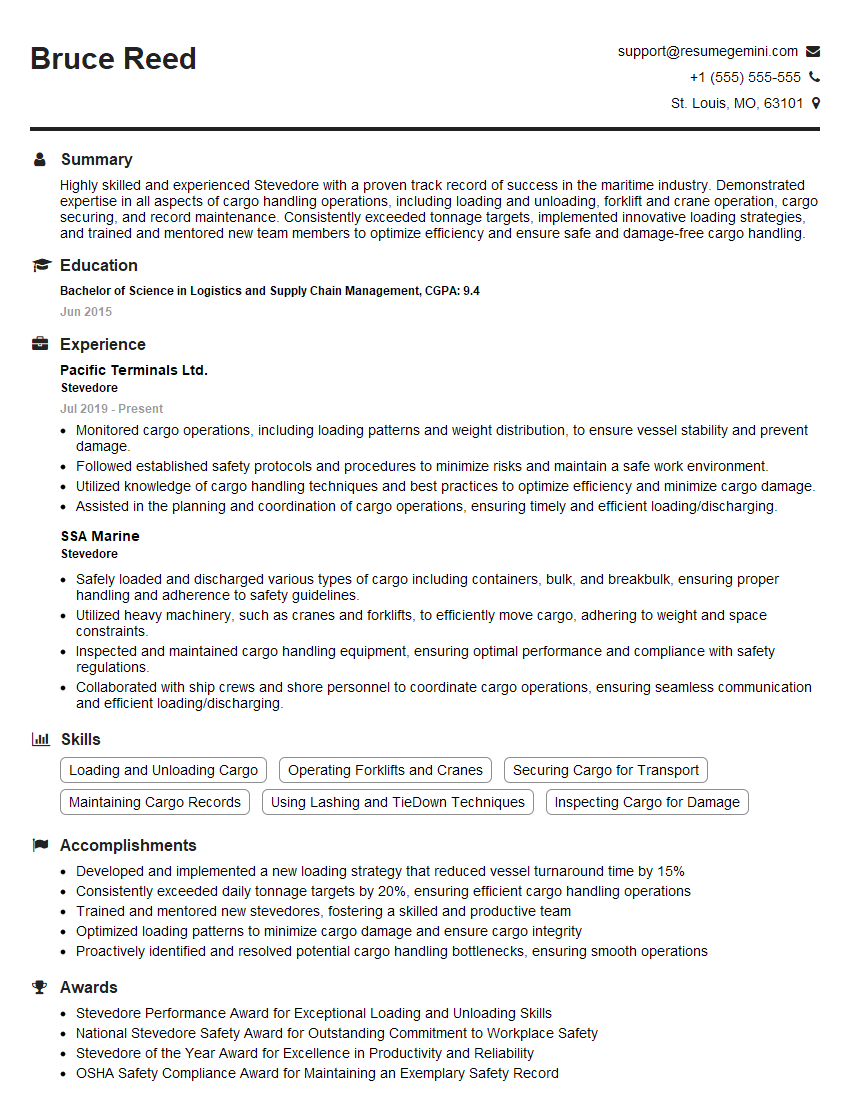

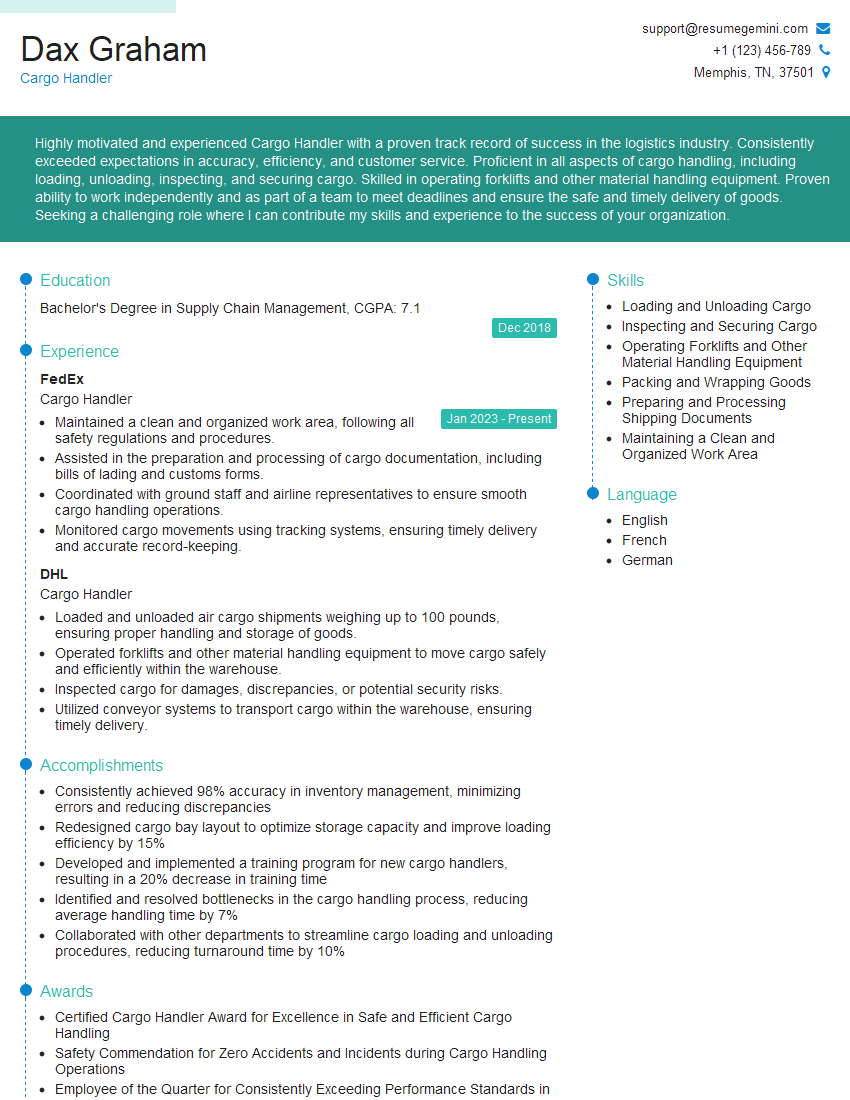

Mastering Container Loading and Handling opens doors to diverse and rewarding careers in logistics, shipping, and international trade. A strong understanding of these principles is highly valued by employers. To maximize your job prospects, creating a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Container Loading and Handling positions are available to guide your process. Invest time in crafting a standout resume – it’s your first impression to potential employers!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good