Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Converter operation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Converter operation Interview

Q 1. Explain the principle of operation of a DC-DC converter.

A DC-DC converter changes a DC voltage level to another DC voltage level. Imagine you have a 12V battery, but your device needs 5V. A DC-DC converter steps that 12V down to the required 5V. This is achieved using a switching element (like a transistor) that rapidly switches on and off, creating a chopped DC signal. This chopped signal is then filtered to produce a smoother, regulated DC output voltage. The switching frequency is typically much higher than the frequencies of interest in the output, allowing for smaller filter components.

The core principle involves controlling the duty cycle – the percentage of time the switch is on during each switching cycle. A higher duty cycle results in a higher output voltage, and vice versa. The output voltage is regulated using feedback control, comparing the actual output voltage to the desired voltage and adjusting the duty cycle accordingly.

Q 2. Describe different types of DC-DC converters (e.g., buck, boost, buck-boost).

Several DC-DC converter topologies exist, each with its own advantages and disadvantages. The most common are:

- Buck Converter: This steps down the input voltage. Think of it like a dimmer switch for DC power. It’s simple and efficient for step-down applications.

- Boost Converter: This steps up the input voltage. Imagine needing a higher voltage than your battery provides; this converter boosts it to the required level. It’s crucial in applications needing higher voltages than the input source.

- Buck-Boost Converter: This can step both up and down the input voltage, offering flexibility. It’s more complex but useful where voltage inversion is required, such as in negative voltage generation.

- Cuk Converter: This is another type that can invert the polarity of the output voltage while offering continuous input current.

- SEPIC (Single-Ended Primary Inductor Converter): Similar to the Cuk converter, but with a different topology, providing both voltage inversion and step-up or step-down capabilities.

Q 3. What are the advantages and disadvantages of different DC-DC converter topologies?

The choice of DC-DC converter topology depends heavily on the specific application requirements:

- Buck Converter: Advantages: Simple, efficient for step-down, low component count. Disadvantages: Output voltage is always less than the input voltage.

- Boost Converter: Advantages: Can generate output voltage higher than input. Disadvantages: Higher component count, can be less efficient than buck converter, discontinuous input current.

- Buck-Boost Converter: Advantages: Can step up or step down, voltage inversion. Disadvantages: More complex, can have lower efficiency than buck or boost converters.

- Cuk and SEPIC Converters: Advantages: Continuous input current, voltage inversion. Disadvantages: More complex than basic topologies, potentially lower efficiency.

For example, a mobile phone charger might use a buck converter to efficiently step down the mains voltage to the phone’s battery voltage. A high-voltage DC-DC converter in a computer’s power supply might utilize a boost converter to generate the necessary high voltage for certain components. Choosing the right topology is a critical part of power supply design.

Q 4. Explain the operation of an AC-DC converter (rectifier).

An AC-DC converter, also known as a rectifier, converts alternating current (AC) to direct current (DC). Think about how your phone charger works – it takes the AC power from your wall socket and transforms it into the DC power your phone needs. This is primarily done using diodes, which allow current to flow only in one direction. The simplest form is a half-wave rectifier, which uses a single diode to allow only one half-cycle of the AC waveform to pass through. A full-wave rectifier, using four diodes or a bridge rectifier, utilizes both halves of the AC waveform, resulting in a more efficient conversion and smoother DC output.

The output of a rectifier is usually pulsating DC, meaning it’s not a smooth, constant voltage. This is because the rectified AC waveform still has variations. To get a smoother DC output, filters are usually added.

Q 5. What are the different types of AC-DC converters?

Several types of AC-DC converters exist, classified primarily by their topology and control methods:

- Half-wave rectifier: Simplest form, uses a single diode, inefficient.

- Full-wave rectifier: Uses multiple diodes (bridge rectifier common), more efficient than half-wave.

- Controlled rectifiers: Use thyristors (like SCRs) or transistors to control the amount of AC passed to the output, allowing for adjustable DC output voltage. These are commonly used in variable power supplies.

- Switch-mode rectifiers: Employ switching elements for higher efficiency, especially at higher power levels. These are often found in modern power supplies due to their efficiency.

Q 6. Describe the role of filters in AC-DC and DC-DC converters.

Filters in AC-DC and DC-DC converters are essential for smoothing the output voltage and removing unwanted ripple and noise. In AC-DC converters, filters typically consist of capacitors and sometimes inductors. Capacitors store energy during the peaks of the rectified waveform and release it during the troughs, smoothing the output voltage. Inductors, in addition to capacitors, can further reduce ripple by opposing changes in current. In DC-DC converters, filters are similarly used, commonly consisting of an LC (inductor-capacitor) filter to smooth the pulsed output of the switching element. The choice of filter components depends on factors like the desired ripple voltage, switching frequency, and the load characteristics. A larger capacitor generally leads to a smoother output but increases the size and cost of the converter. The filter’s design is crucial for the quality and stability of the DC output.

Q 7. How do you troubleshoot a faulty converter?

Troubleshooting a faulty converter involves a systematic approach:

- Visual Inspection: Check for any obvious physical damage (burnt components, loose connections).

- Input Voltage Check: Verify that the input voltage is within the converter’s specifications.

- Output Voltage Check: Measure the output voltage and compare it to the expected value. Use a multimeter.

- Ripple Voltage Measurement: Check the ripple voltage on the output. Excessive ripple indicates a problem with the filter.

- Component Testing: Individually test key components like diodes, transistors, inductors, and capacitors using a multimeter or other suitable test equipment.

- Load Testing: Test the converter under different load conditions to identify potential issues related to the load.

- Switching Frequency Check: Observe the switching waveform using an oscilloscope to ensure it’s functioning correctly. This often requires more advanced test equipment.

- Thermal Analysis: Excessive heat generation may indicate a faulty component.

A systematic approach combined with the right test equipment and knowledge of the specific converter topology are key to successful troubleshooting. Remember safety precautions when working with electrical circuits!

Q 8. What are the common failure modes of converters?

Converter failure modes are diverse and depend heavily on the converter’s topology, components, and operating conditions. Common issues include:

- Component failures: Semiconductor switches (IGBTs, MOSFETs) can fail due to overcurrent, overvoltage, or thermal stress. Capacitors can suffer from aging, dielectric breakdown, or excessive ripple current. Inductors can saturate, overheat, or experience winding failures.

- Control circuit malfunctions: Faults in the control circuitry, such as a faulty microcontroller or sensor, can lead to incorrect switching patterns, instability, and ultimately converter failure. This could manifest as erratic output voltage or current.

- Overheating: Excessive heat generation, due to conduction losses, switching losses, or inadequate cooling, can damage components and degrade performance. This often leads to accelerated aging and eventual failure.

- Overcurrent: Exceeding the rated current capacity of components can cause immediate damage or lead to progressive degradation. This can be triggered by short circuits, overloads, or control circuit malfunctions.

- Overvoltage: Exceeding the rated voltage of components can lead to insulation breakdown and component failure. This could result from spikes in the input voltage or internal voltage transients.

- Magnetic saturation: In inductive components, saturation can lead to increased losses and potentially damage.

For instance, imagine a solar power inverter. A sudden surge in solar panel output could overload the converter, leading to an overcurrent failure of its IGBTs. Regular maintenance and preventive measures, like thermal monitoring and protection circuits, are crucial to mitigate these risks.

Q 9. Explain the concept of switching frequency in converters.

Switching frequency refers to the rate at which the semiconductor switches in a converter turn on and off. It’s typically expressed in Hertz (Hz) or kilohertz (kHz). Think of it like a light switch flickering on and off; the faster it flickers, the higher the switching frequency. In converters, this ‘flickering’ controls the flow of power to the output.

For example, a DC-DC converter might operate at a switching frequency of 100kHz. This means the switches turn on and off 100,000 times per second. The choice of switching frequency is crucial as it influences many aspects of converter design and performance.

Q 10. How does switching frequency affect converter efficiency?

Switching frequency significantly impacts converter efficiency. Higher switching frequencies generally lead to smaller passive components (inductors and capacitors), reducing their size and cost. However, they also increase switching losses.

Lower switching frequencies: Minimize switching losses but require larger, heavier inductors and capacitors, increasing conduction losses and potentially affecting efficiency negatively due to larger component sizes.

Higher switching frequencies: Reduce component size and weight, lowering conduction losses, but introduce more switching losses due to the increased number of transitions. Efficiently managing this trade-off is key to optimizing efficiency.

The optimal switching frequency is a balance between these competing factors and often depends on other design considerations like the control scheme and the application requirements. For instance, in high-power applications, the optimal switching frequency might be lower to manage higher switching losses, whereas in portable devices, a higher frequency might be preferable despite higher switching losses to minimize size and weight.

Q 11. What is the importance of thermal management in converter operation?

Thermal management is crucial for reliable and efficient converter operation. Converters generate heat due to conduction losses in components (resistance in wires and components) and switching losses (energy dissipated during the switching transitions). Excessive heat can damage components, reduce efficiency, and eventually lead to failure. Therefore, maintaining appropriate operating temperatures is critical for longevity and performance.

Imagine a server farm with thousands of power supplies; effective thermal management is vital to prevent overheating and ensure the continued operation of the entire system. Poor thermal management can result in premature component failure, downtime, and increased maintenance costs.

Q 12. Describe different cooling methods for converters.

Several cooling methods are employed for converters, depending on the power level and application requirements:

- Natural convection: Relies on the natural movement of air to dissipate heat. Suitable for low-power converters. A simple example is a small adapter for a laptop.

- Forced convection: Uses fans to force air over the heat-generating components, improving heat dissipation. Common in many electronics.

- Conduction: Uses a heat sink to transfer heat away from the components to a larger surface area for better heat dissipation. Heat sinks are often used with fans.

- Liquid cooling: Employs a liquid coolant (water or specialized fluids) to absorb heat from the components. This method is used in high-power applications.

The choice of cooling method depends on the power level, ambient temperature, and cost constraints. High-power converters often require more sophisticated cooling solutions like liquid cooling to prevent thermal runaway.

Q 13. Explain the concept of Pulse Width Modulation (PWM) in converters.

Pulse Width Modulation (PWM) is a control technique used to regulate the average power delivered to a load by varying the width of regularly spaced pulses. Think of it as controlling the brightness of a light bulb by rapidly switching it on and off. The longer the light is on in each cycle, the brighter it appears. Similarly, in converters, varying the pulse width alters the average output voltage or current.

In a PWM converter, a high-frequency switching signal is used to control the average output. The duty cycle, which is the ratio of the on-time to the total period of the pulse, determines the average output value. A higher duty cycle results in a higher average output. For instance, a 50% duty cycle means the switch is on for half the period and off for the other half.

PWM is widely used in DC-DC converters and inverters because it allows for efficient control and regulation of the output voltage and current.

Q 14. How do you measure the efficiency of a converter?

Converter efficiency is measured as the ratio of output power to input power, typically expressed as a percentage.

Efficiency (%) = (Output Power / Input Power) * 100

To measure efficiency, you need to measure both the input and output power. Input power is typically measured using a wattmeter connected to the input terminals of the converter. Output power is measured using a wattmeter connected to the output terminals. It’s crucial to perform measurements under the desired operating conditions, including the load current and input voltage. A common approach involves measuring the voltage and current at both the input and output, and calculating the power accordingly (Power = Voltage x Current).

For example, if a converter has an input power of 100W and an output power of 90W, its efficiency is (90W / 100W) * 100 = 90%. High efficiency is desirable to minimize energy waste and improve overall system performance.

Q 15. What are the safety precautions when working with high-voltage converters?

Working with high-voltage converters demands rigorous safety protocols. The most crucial aspect is preventing accidental contact with energized components. This necessitates the use of proper personal protective equipment (PPE), including insulated gloves, safety glasses, and arc-flash suits depending on the voltage level. Before any work begins, the converter must be completely de-energized and locked out/tagged out to prevent accidental re-energization. This lockout/tagout procedure is critical and should follow strict company procedures.

Furthermore, regular inspection of equipment for any signs of damage or wear is crucial. Faulty insulation, loose connections, and damaged components can lead to electrical hazards. Finally, a thorough understanding of the converter’s operational characteristics and emergency shutdown procedures is essential for all personnel. This includes knowing the location of emergency shut-off switches and the steps to take in the event of an electrical arc flash or other incident. Think of it like handling a powerful wild animal – respect, caution, and meticulous preparation are key to safe interaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the significance of control loops in converter operation?

Control loops are the backbone of efficient and stable converter operation. They act as a feedback mechanism, constantly monitoring the output of the converter and making adjustments to maintain the desired parameters. Imagine trying to fill a glass of water: you wouldn’t just pour the water in without looking – you’d adjust the flow rate to avoid overfilling or underfilling. Similarly, control loops maintain precise voltage, current, or frequency levels by comparing the actual output to the desired setpoint. This comparison generates an error signal that is then used to adjust the control signals to the converter itself. Without them, the converter’s output would be unstable and prone to fluctuations, leading to inefficient operation and potentially damage to connected equipment.

Q 17. Explain the role of feedback mechanisms in converter control.

Feedback mechanisms are integral to converter control, providing the essential information needed for the control loops to function effectively. They continuously measure the actual output of the converter – such as voltage, current, or frequency – and compare it to the desired setpoint. This comparison generates an error signal that the control loop uses to adjust the converter’s input signals, thereby reducing the error and maintaining the desired output. For example, if a converter is designed to deliver a constant 100V and the actual output drops to 98V, the feedback mechanism detects this error and relays it to the control loop. The loop then adjusts the gate signals to the power switches in the converter to increase the output voltage until the 100V setpoint is reached again. This constant feedback ensures stability and accuracy.

Q 18. Describe the different types of control strategies used in converters (e.g., PI, PID).

Several control strategies are employed in converters, each with its strengths and weaknesses. Proportional (P) control directly adjusts the output based on the error signal. It’s simple, but often leads to steady-state error. Integral (I) control eliminates steady-state error by accumulating the error over time. However, it can lead to overshoot and oscillations. Proportional-Integral (PI) control combines the best of both, providing fast response with zero steady-state error. Proportional-Integral-Derivative (PID) control adds a derivative term that anticipates future error based on the rate of change. This improves response time and reduces overshoot. The choice of control strategy depends on the specific application and the desired performance characteristics. For example, a high-precision application might warrant a PID controller for optimal accuracy, while a less critical application might use a simpler PI controller.

Q 19. How do you diagnose problems using converter monitoring systems?

Converter monitoring systems provide a wealth of data that can be used to diagnose problems. The first step is reviewing the system’s historical data and identifying any unusual trends or deviations from normal operation. This might involve checking voltage, current, frequency, temperature, and other relevant parameters. If anomalies are detected, further investigation is needed. This could include checking for faults in the converter’s hardware, examining the control loop performance, and analyzing the feedback signals. Modern monitoring systems often provide sophisticated alarm systems, highlighting potential problems. For instance, a sudden increase in temperature could indicate a faulty component, while a recurring error signal in the control loop might point to a control algorithm issue. Thorough analysis using diagnostic tools and a deep understanding of the converter’s operation are critical to pinpoint the root cause.

Q 20. What are the key performance indicators (KPIs) for converter operation?

Key Performance Indicators (KPIs) for converter operation vary depending on the specific application. However, some common KPIs include: Efficiency (ratio of output power to input power), indicating energy loss; Power factor, measuring the effectiveness of power utilization; Output voltage/current regulation, quantifying stability and precision; Switching frequency, related to efficiency and component stress; Temperature of components, crucial for reliability and longevity; Harmonics, reflecting the quality of the output waveform; and Overall system uptime, indicating reliability and availability. Monitoring these KPIs helps ensure optimal performance, predict potential failures, and improve overall system efficiency. For instance, consistently low efficiency might signal the need for component replacement or improved control strategies.

Q 21. Explain the concept of power factor correction in converters.

Power factor correction (PFC) improves the efficiency of converters by reducing the reactive power drawn from the mains. In simple terms, it ensures that the current drawn by the converter is in phase with the voltage, maximizing the real power delivered. Without PFC, converters can draw a significant amount of reactive power, resulting in higher current demand and increased energy losses. PFC is typically implemented using passive components like capacitors and inductors or active components like switched-mode power supplies (SMPS). For example, a PFC circuit might use a boost converter to shape the input current waveform and draw it more in phase with the mains voltage. This reduces the harmonic distortion and improves the overall efficiency of the system. The benefits of good PFC include reduced electricity bills for users and less strain on the power grid.

Q 22. How do you handle emergency situations involving converter malfunctions?

Handling converter malfunctions requires a calm and systematic approach. My first step is always safety – ensuring the immediate area is secured and personnel are clear of any potential hazards. This might involve isolating the converter from the power source or initiating emergency shutdown procedures, depending on the specific converter type and the nature of the malfunction.

Next, I diagnose the problem. This involves carefully reviewing alarm messages, monitoring system logs, and visually inspecting the converter for any obvious issues like overheating or damaged components. Specialized diagnostic tools are often employed at this stage.

Once the problem is identified, I implement the appropriate corrective action. This could range from simple troubleshooting steps (like checking connections or resetting circuit breakers) to more complex repairs requiring specialized tools and expertise. If the problem is beyond my immediate capabilities, I escalate it to the appropriate maintenance team or manufacturer support.

Throughout the entire process, comprehensive documentation is crucial. Detailed records are kept, including the time of the malfunction, the symptoms observed, the steps taken to diagnose and resolve the issue, and any subsequent preventative measures implemented. This ensures future incidents can be handled efficiently and helps to identify patterns that might indicate underlying problems.

Q 23. Describe your experience with different converter brands and models.

My experience encompasses a wide range of converter brands and models, including ABB, Siemens, and Eaton. I’ve worked extensively with both high-power industrial converters used in heavy machinery and smaller, more specialized converters for niche applications. For example, I’ve had considerable experience with ABB’s ACS880 series for motor control in industrial automation, and with Eaton’s Power Xpert systems for power quality management. Each brand and model has its own unique characteristics, strengths, and weaknesses, and I’ve learned to adapt my troubleshooting and maintenance techniques accordingly. This includes familiarity with their respective software interfaces and diagnostic capabilities.

Experience with different models has taught me the value of understanding the specific design features and operational parameters of each device to ensure optimal performance and longevity.

Q 24. What software or tools do you use to monitor and control converters?

Monitoring and controlling converters typically involves a combination of hardware and software. On the hardware side, this often includes programmable logic controllers (PLCs), remote terminal units (RTUs), and data acquisition systems (DAS). These devices collect real-time data from the converter, such as voltage, current, temperature, and operating status.

On the software side, I utilize specialized supervisory control and data acquisition (SCADA) systems, such as those offered by Schneider Electric or Rockwell Automation. These systems provide a centralized interface for monitoring multiple converters simultaneously, visualizing operational data, and generating reports. I also leverage the manufacturer-specific software provided with each converter, enabling detailed diagnostics and parameter adjustments. For example, ABB’s DriveSPC software allows for in-depth monitoring and configuration of their drives. The specific tools used depend on the application and the complexity of the converter system.

Q 25. How do you ensure the safety and reliability of converter operation?

Ensuring safety and reliability in converter operation is paramount. My approach is multi-faceted, and begins with meticulous adherence to safety protocols. This includes regular safety inspections, ensuring proper grounding, using appropriate personal protective equipment (PPE), and following lockout/tagout procedures during maintenance.

Reliability is enhanced through proactive maintenance. This involves scheduled inspections, preventative maintenance tasks (like cleaning and lubrication), and thorough testing to identify potential issues before they escalate into failures. I regularly review operational logs for signs of unusual behavior, and implement corrective actions promptly. Real-time monitoring helps to immediately detect and respond to anomalies. Redundancy measures, where applicable, are also crucial for enhancing system reliability. Having backup systems or components can prevent downtime in case of a primary system failure. Proper training for personnel is a crucial part, ensuring everyone understands the risks and safety procedures.

Q 26. Explain your experience with maintaining and repairing converters.

My experience in maintaining and repairing converters spans various levels of complexity. Routine maintenance includes tasks like cleaning, tightening connections, inspecting for wear and tear, and verifying correct operational parameters. More complex repairs involve component replacement, circuit board troubleshooting, and firmware updates. This requires a thorough understanding of electronics, power systems, and the specific architecture of the converter.

I always follow manufacturer-recommended procedures and use specialized tools. When troubleshooting, a systematic approach is vital – starting with basic checks and progressing to more in-depth diagnostics. Documentation is crucial, recording all maintenance activities, repairs made, and any parts replaced. This helps track the history of the converter and facilitates future maintenance planning. Keeping spare parts on hand for common failures minimizes downtime.

Q 27. Describe a challenging converter-related problem you solved.

One challenging problem involved a high-power converter in a critical industrial process experiencing intermittent failures. The problem was initially difficult to diagnose because the failures were sporadic, with no consistent pattern. Standard diagnostic tools didn’t reveal any obvious issues. My approach involved a systematic process of elimination.

First, I meticulously reviewed the operational logs, looking for any correlations between the failures and environmental factors or operational parameters. I then performed a thorough inspection of all connections, wiring, and components, paying close attention to any signs of overheating or wear. Through careful investigation, we eventually discovered a subtle issue with a specific power module that was failing intermittently under certain load conditions. This was not immediately apparent with standard testing methods. This involved replacing the faulty module. Following the repair, the converter has operated reliably. The problem highlighted the value of careful observation, data analysis and methodical troubleshooting when faced with intermittent failures.

Q 28. How do you stay updated on the latest advancements in converter technology?

Staying current in converter technology is vital. I actively participate in industry conferences and workshops, attending seminars and presentations to learn about the latest advancements in converter design, control strategies, and power electronics. I regularly read technical publications and journals focused on power electronics and related fields. Professional networking plays a key role – discussions with colleagues and attending conferences helps to exchange ideas and best practices.

Manufacturer websites and online resources are valuable sources of information about new products and updates. I also pursue relevant professional development courses and training programs to enhance my skills and knowledge base, focusing on areas like power electronics and embedded systems. Keeping abreast of emerging standards and regulatory compliance requirements is also critical for maintaining safe and compliant operations. This commitment to continuous learning ensures I remain at the forefront of this dynamic field.

Key Topics to Learn for Converter Operation Interview

- Converter Types and Principles: Understand the different types of converters (AC-DC, DC-DC, DC-AC) and their underlying operating principles, including voltage regulation and power conversion efficiency.

- Circuit Analysis and Design: Be prepared to discuss the key components within converter circuits (e.g., transistors, diodes, inductors, capacitors) and their roles in the conversion process. Practice analyzing simple converter circuits and understanding their behavior under different load conditions.

- Control Strategies: Familiarize yourself with common control techniques used in converters, such as pulse-width modulation (PWM) and their impact on efficiency and performance. Be ready to explain how these strategies maintain desired output voltage and current.

- Power Losses and Efficiency: Understand the various sources of power loss in converters (conduction, switching, etc.) and how to calculate overall efficiency. Be able to discuss techniques for minimizing these losses.

- Protection and Safety Mechanisms: Know the common protection circuits and safety measures employed in converter designs to prevent damage from overcurrent, overvoltage, and other faults. Discuss the importance of safety standards and regulations in converter operation.

- Troubleshooting and Diagnostics: Develop your ability to troubleshoot common problems in converter systems. This includes identifying faulty components and using diagnostic tools to pinpoint malfunctions.

- Practical Applications: Be prepared to discuss real-world applications of converters in various industries, such as renewable energy systems, power supplies, electric vehicles, and industrial automation.

Next Steps

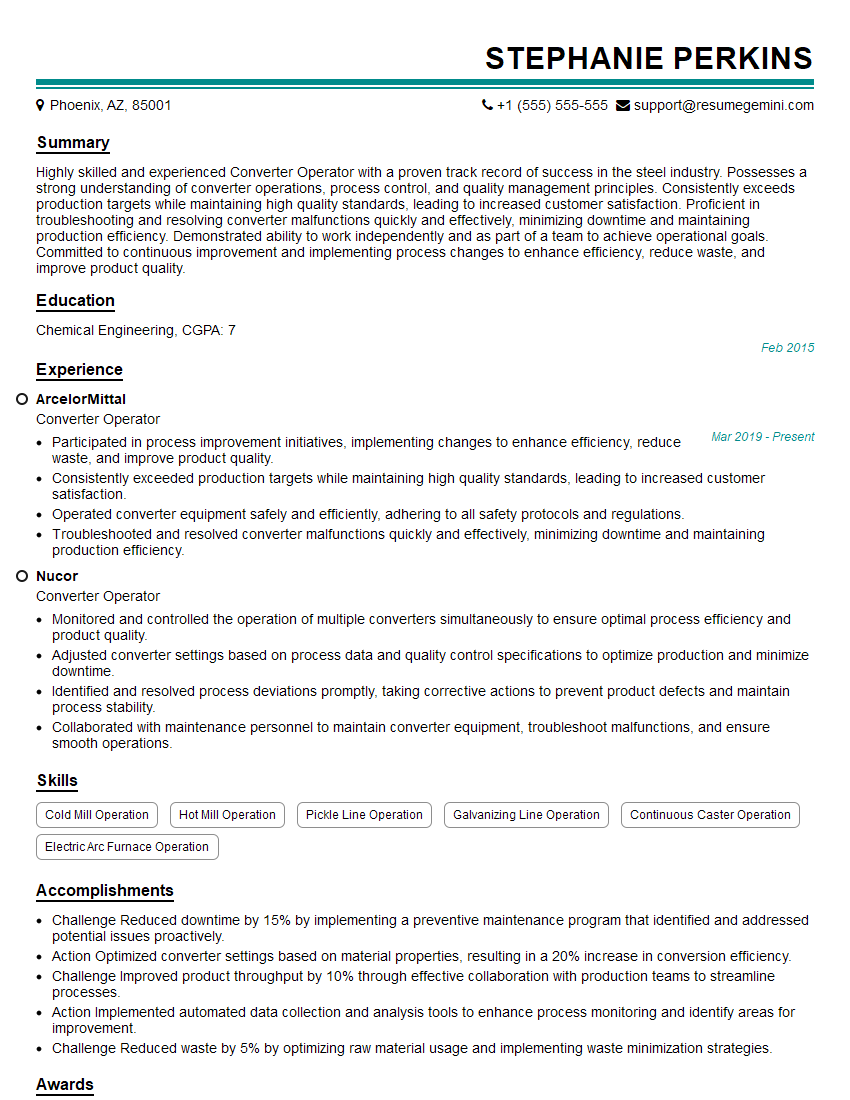

Mastering converter operation opens doors to exciting and rewarding career opportunities in a rapidly growing technological field. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of converter operation roles. Examples of resumes tailored to this field are available to guide you through the process, ensuring your application stands out from the competition. Invest time in crafting a strong resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good