Cracking a skill-specific interview, like one for Corn Harvesting Techniques, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Corn Harvesting Techniques Interview

Q 1. Describe the optimal moisture content for corn harvesting.

Optimal corn moisture content for harvest is crucial for grain quality and storage. Ideally, you want to harvest when the grain moisture is between 15% and 20%. Going below 15% risks excessive grain breakage during harvesting, while exceeding 20% increases the chance of mold growth and spoilage during storage. Think of it like baking a cake – you need the right amount of moisture for the best texture and longevity. Factors like weather and hybrid variety will influence the exact ideal moisture content for a specific field. Regular field checks using a moisture meter are essential to determine the optimal harvest timing.

Q 2. Explain the different types of corn headers and their applications.

Corn headers are the crucial attachment on the combine responsible for cutting and feeding the corn stalks into the machine. Several types cater to different needs and field conditions:

- Row-Crop Headers: These are the most common type, designed for harvesting corn grown in rows. They have a series of rollers and knives that cut the stalks and convey the ears into the combine. Different widths are available to match the planter spacing.

- Draper Headers: These are more gentle on the crop, using a flexible cutting system to effectively harvest corn in uneven or lodged (fallen over) conditions. They tend to be more expensive but minimize kernel loss.

- Strip Till Headers: Specifically designed for corn planted using strip till methods, where fertilizer and tillage are limited to strips. These headers only harvest the corn from the planted strips, minimizing damage to the surrounding un-tilled areas.

Choosing the right header depends on factors such as planting method, field conditions, and budget. A farmer with consistently flat fields and planted in rows could use a conventional row-crop header, while someone dealing with lodged corn might opt for a draper header for better yield.

Q 3. What are the key factors influencing corn yield?

Corn yield is a complex interplay of factors, and maximizing it requires attention to detail across the entire growing season. Key factors include:

- Planting Density and Stand Establishment: Achieving the optimal number of healthy plants per acre is fundamental. Too few plants mean lost potential, while too many leads to competition for resources.

- Soil Fertility and Nutrition: Corn is a heavy feeder, requiring adequate nutrients like nitrogen, phosphorus, and potassium. Soil testing and balanced fertilization are crucial.

- Weed Control: Weeds compete with corn for sunlight, water, and nutrients, significantly impacting yield. Effective weed management strategies are vital.

- Pest and Disease Management: Insects and diseases can devastate a corn crop. Monitoring and timely application of appropriate controls are essential.

- Water Availability: Consistent access to water during critical growth stages is vital for optimal yield. Drought stress can drastically reduce yields.

- Weather Conditions: Favorable growing season temperatures and adequate rainfall are important for high yields. Unfavorable conditions like severe storms can damage plants.

- Hybrid Selection: Choosing a hybrid suited to the specific environment and management practices is crucial for maximizing yield potential.

In essence, maximizing corn yield is a holistic approach, requiring diligent management at each step.

Q 4. How do you calibrate a combine for optimal harvesting efficiency?

Calibrating a combine is essential for optimal harvesting efficiency, minimizing grain loss and maximizing throughput. The process typically involves several steps:

- Check and adjust the header: Ensure the header is properly aligned and cutting at the correct height.

- Set the cylinder speed: This determines the aggressiveness of the threshing process. Too fast can lead to excessive grain breakage, while too slow can result in unthreshed ears. Start with the manufacturer’s recommendation and adjust based on observation.

- Adjust concave clearance: The concave works in conjunction with the cylinder to separate kernels from the cob. Correct clearance prevents grain loss or excessive damage.

- Check sieve settings: The sieves separate grain from chaff and other debris. Proper settings prevent grain loss and ensure clean grain.

- Monitor grain loss: Regularly check for grain loss at various points along the combine, such as the header, cylinder, and sieves. Adjust settings as needed.

- Use a grain loss monitor: Modern combines have grain loss monitors that quantify the loss. This provides quantitative data to guide adjustments.

- Test regularly: Conditions can change throughout the day or across fields. Frequent calibration checks are needed.

Think of calibration as fine-tuning a musical instrument: you need the right balance to produce the best sound (yield) with minimal waste (grain loss). Regular checks and adjustments are necessary to maintain this balance.

Q 5. Describe the process of pre-harvest scouting for corn.

Pre-harvest scouting for corn involves systematically assessing the field before starting the harvest to identify areas with varying maturity and potential problems. This involves:

- Visual inspection: Walk through representative sections of the field, noting maturity differences, stalk lodging, disease or pest pressure, and weed interference.

- Moisture testing: Use a moisture meter to measure grain moisture in multiple locations across the field to pinpoint areas that may need different harvest approaches.

- Yield estimation: Conduct yield estimation in several areas to get a sense of the overall yield potential.

- Identify problem areas: Note areas with significant lodging, disease, or other issues that may require special harvesting techniques or adjustments.

- Plan harvest strategy: Based on the scouting data, develop a harvesting plan that addresses different maturity levels and potential problems across the field.

Pre-harvest scouting allows for planning and reduces losses during the actual harvest. It’s like planning a complex construction project; a detailed assessment before starting is critical for successful completion.

Q 6. Explain different methods for corn grain storage and preservation.

Proper corn grain storage and preservation are vital to maintaining quality and preventing losses. Methods include:

- On-farm storage: This involves using bins, silos, or bags to store grain on the farm. Proper aeration is crucial to prevent mold and spoilage. Consider the bin’s size and capacity relative to your yield. Proper cleaning of the storage space before storing is essential.

- Commercial storage: Farmers can use commercial grain storage facilities for larger quantities or when on-farm storage is insufficient. This option often involves higher storage fees but offers professional management.

- Drying: Drying corn to the ideal moisture content (13-15%) before storage is essential for preventing mold and pest infestation. This can be done using various drying techniques including on-farm dryers or commercial drying facilities.

- Treatment with insecticides or fungicides: In some cases, using approved insecticides or fungicides to protect the grain from pests and diseases may be necessary, particularly if moisture content is not optimal.

Proper storage ensures grain quality and prevents significant post-harvest losses. It’s like preserving food at home – you use the right techniques to prevent spoilage.

Q 7. What are the common problems encountered during corn harvesting and their solutions?

Common problems encountered during corn harvesting include:

- High moisture content: This leads to spoilage and reduced grain quality. Solution: Delay harvesting until moisture content is appropriate or use drying methods.

- Lodging: Fallen corn stalks make harvesting difficult and increase losses. Solution: Use a draper header or adjust combine settings for better pickup.

- Excessive grain breakage: Aggressive threshing settings can lead to broken kernels. Solution: Adjust cylinder speed and concave clearance.

- Clogging: Wet or damp conditions can cause material to clog in the combine. Solution: Adjust sieve settings, clean regularly, and maintain proper machine operation.

- Uneven maturity: Parts of the field may mature at different rates. Solution: Harvest in multiple passes, adjusting settings based on maturity.

- Mechanical breakdowns: Equipment failures during harvest are always a possibility. Solution: Proper pre-harvest maintenance and having a backup plan are crucial.

Troubleshooting these issues requires a combination of knowledge, experience, and attention to detail. Regular maintenance, pre-harvest scouting, and prompt adjustments during harvest are key to minimizing issues.

Q 8. How do you maintain and troubleshoot corn harvesting equipment?

Maintaining and troubleshooting corn harvesting equipment requires a proactive and systematic approach. Think of it like regular car maintenance – preventative care minimizes downtime and costly repairs.

- Preventative Maintenance: This includes regular lubrication of moving parts, checking and tightening bolts, inspecting belts and chains for wear, and cleaning out debris from the header, feeder house, and combine components. We should also check filters regularly and replace them as needed. A well-maintained machine runs smoother and more efficiently.

- Troubleshooting: When problems arise, a systematic approach is key. Start by identifying the symptom (e.g., reduced throughput, uneven chopping, excessive grain loss). Then, consult the operator’s manual and systematically check the potential causes. For example, reduced throughput could be due to a clogged header, a malfunctioning feeder house, or a problem with the threshing mechanism.

- Diagnostic Tools: Modern combines often have onboard computers that provide diagnostic codes and performance data. These tools are invaluable for identifying and resolving complex problems. Knowing how to interpret these codes and data is a critical skill for any corn harvester.

- Regular Inspections: Before every harvesting day, a thorough visual inspection of the equipment is mandatory. This helps catch potential problems early and prevents major breakdowns in the field.

For example, last season, we had a combine experiencing uneven chopping. Through careful inspection, we found a worn knife section on the chopper. Replacing this part solved the issue immediately, saving significant time and yield losses.

Q 9. What safety procedures are essential during corn harvesting operations?

Safety during corn harvesting is paramount. It’s not just about protecting the operators; it’s also about protecting the equipment and the environment. Think of it like this: a safe harvest is a productive harvest.

- Personal Protective Equipment (PPE): This includes wearing hearing protection, safety glasses or face shields, and sturdy work boots. Gloves are also essential to prevent cuts and blisters.

- Machine Operation: Never operate machinery while fatigued or under the influence of drugs or alcohol. Understand the controls and safety features of the equipment thoroughly before operating it. Always be aware of your surroundings, especially when operating near roads or other people.

- Emergency Procedures: Know where emergency exits are located and how to use the machine’s safety shut-off mechanisms. Have a clear communication plan in case of an emergency.

- Field Awareness: Be aware of potential hazards in the field, such as ditches, uneven terrain, and overhead power lines. Before starting the combine, walk the field to look for any obstructions.

- Fire Prevention: Corn harvesting equipment is prone to fires due to excessive heat and friction. Maintain the machine in good working condition to minimize this risk. Have a fire extinguisher on hand and know how to use it.

A specific example: We implemented a daily pre-harvest safety checklist last year, which included machine inspections, PPE checks, and a quick briefing about potential field hazards. This simple step significantly reduced the number of minor accidents and near misses.

Q 10. Describe the impact of weather conditions on corn harvesting decisions.

Weather significantly impacts harvesting decisions. It’s a delicate balance between maximizing yield and minimizing losses due to weather-related damage. Imagine it like baking a cake – you need the right conditions to get the perfect outcome.

- Moisture Content: High moisture content in the corn grain can lead to spoilage and reduced storage life. This necessitates harvesting at the optimal moisture level, which is typically below 15%.

- Temperature: Extreme heat can stress the equipment, increasing the risk of mechanical failures. Extremely cold temperatures can lead to freezing and damage of the crop.

- Rain: Rain reduces field visibility and makes the ground muddy. Harvesting in wet conditions can lead to soil compaction, damage to the plants, and increased grain loss.

- Wind: Strong winds can make operating equipment difficult and may cause crop lodging, making harvesting more challenging and increasing losses.

For instance, last year, we experienced a period of unseasonably wet weather. We had to postpone harvesting for several days to allow the fields to dry, even though it meant slightly higher grain moisture content. It was a calculated risk, but preserving field integrity was paramount to long term soil health and ultimately yield.

Q 11. Explain the importance of proper header adjustments.

Proper header adjustments are crucial for maximizing efficiency and minimizing grain loss. Think of the header as the first point of contact – a precise adjustment ensures a clean, efficient harvest.

- Cutting Height: Adjusting the cutting height to match the crop’s height ensures that the ears are cleanly cut and avoids cutting too low, causing ground damage, or too high, resulting in losses.

- Snout Adjustment: Proper snout adjustment ensures that the crop is fed evenly into the combine, minimizing losses and preventing blockages.

- Reel Speed and Angle: The reel speed and angle need to be adjusted to gently feed the crop into the header, preventing crop damage and loss. Too fast or too aggressive of a reel can strip the corn from the stalk.

- Concave Setting: Adjusting the concave setting for the combine properly, dependent on maturity, prevents crop breakage and maximizes throughput.

For example, improper reel speed can lead to significant losses by shattering the ears before they reach the combine. Fine-tuning the reel speed to match crop conditions can significantly reduce this type of loss. This is a task that requires constant monitoring and adjustment throughout the harvest season.

Q 12. How do you manage crop losses during harvesting?

Managing crop losses during harvesting requires a multi-faceted approach. It’s about minimizing losses at every stage of the process, from cutting to storage. It’s like a chain – one weak link compromises the entire process.

- Pre-Harvest Assessment: Evaluate the crop’s maturity and uniformity to plan harvesting strategy accordingly.

- Header Adjustments: Proper header adjustments as described previously are crucial to minimizing losses in the field.

- Combine Settings: Optimal combine settings (cylinder speed, concave clearance, and fan speed) influence the amount of grain lost through shattering, spillage, and inefficient separation.

- Regular Monitoring: Constantly monitor loss indicators (both visual and through sensors) and adjust equipment settings or harvesting procedures as needed.

- Post-Harvest Inspections: Inspect the harvested material to identify areas for improvement in future operations.

We once experienced significant losses due to an improperly adjusted concave. By closely monitoring losses and adjusting the concave, we were able to drastically reduce losses in the following fields.

Q 13. What are the advantages and disadvantages of different harvesting methods?

Corn harvesting methods vary significantly, each with its own advantages and disadvantages. The best method depends on factors like field size, crop conditions, and budget.

| Harvesting Method | Advantages | Disadvantages |

|---|---|---|

| Conventional Harvesting (Combine): | Efficient for large fields, high throughput, relatively low labor cost. | Higher initial investment, susceptible to weather delays, potential for higher losses if not properly maintained. |

| Hand Harvesting: | Suitable for small-scale operations, minimizes losses in uneven fields, adaptable to various crop conditions. | Labor intensive, low throughput, higher labor costs. |

| Mechanical Picking: | Suitable for high-moisture corn, less susceptible to losses from lodged crops. | Higher initial investment, may not be suitable for all field conditions. |

Choosing the right method depends on your specific circumstances. A large commercial operation will likely choose a conventional combine, whereas a smaller farm might opt for hand harvesting for parts of its crop.

Q 14. How do you monitor and optimize combine performance?

Monitoring and optimizing combine performance is essential for maximizing yield and efficiency. Think of it as fine-tuning a high-performance engine – small adjustments can have a big impact.

- Loss Monitors: Use loss monitors to measure grain loss at different stages of the harvesting process and adjust combine settings to minimize losses.

- Moisture Sensors: Monitor grain moisture content to ensure that the grain is harvested at the optimal moisture level.

- Throughput Monitoring: Track combine throughput to identify any bottlenecks or inefficiencies. Adjust settings and speeds as needed to maintain optimal throughput.

- Fuel Consumption Tracking: Monitor fuel consumption to identify areas for improvement in combine efficiency.

- Data Analysis: Use data from onboard computers and sensors to identify patterns and trends in combine performance. Use these insights to make adjustments for future operations.

By tracking and analyzing data from our combines, we discovered that slightly adjusting the cylinder speed reduced losses by 5% while maintaining a similar throughput. This seemingly small change led to significant gains in overall yield.

Q 15. Describe the process of grain unloading and transportation.

Grain unloading and transportation after corn harvesting is a crucial logistical operation impacting efficiency and profitability. It typically involves several steps.

- Unloading from the combine: Harvested corn is initially stored in the combine’s grain tank. Once full, it’s unloaded either directly into a waiting grain cart or a grain truck using an auger system. The speed of this process depends on the combine’s unloading capacity and the efficiency of the receiving vehicle.

- Transport to storage: Grain carts move the corn to a central location, such as a grain truck or a nearby storage silo. Grain trucks, with larger capacities, then transport the corn over longer distances to the grain elevator, a farm silo, or other storage facilities. The choice of transport vehicle depends on the distance, terrain, and volume of corn harvested.

- Storage and handling: At the storage facility, corn is typically dried (to prevent spoilage) and then stored in large bins or silos. Efficient storage minimizes losses and maintains grain quality. The process requires proper aeration and monitoring to avoid mold or insect infestation.

For example, a large farm might employ a fleet of grain carts and trucks, working in coordination with the combine, to minimize downtime and maximize harvesting efficiency. Careful planning of routes and storage capacity is vital for seamless operation. Logistics software can optimize the entire process, scheduling transport and minimizing delays.

Career Expert Tips:

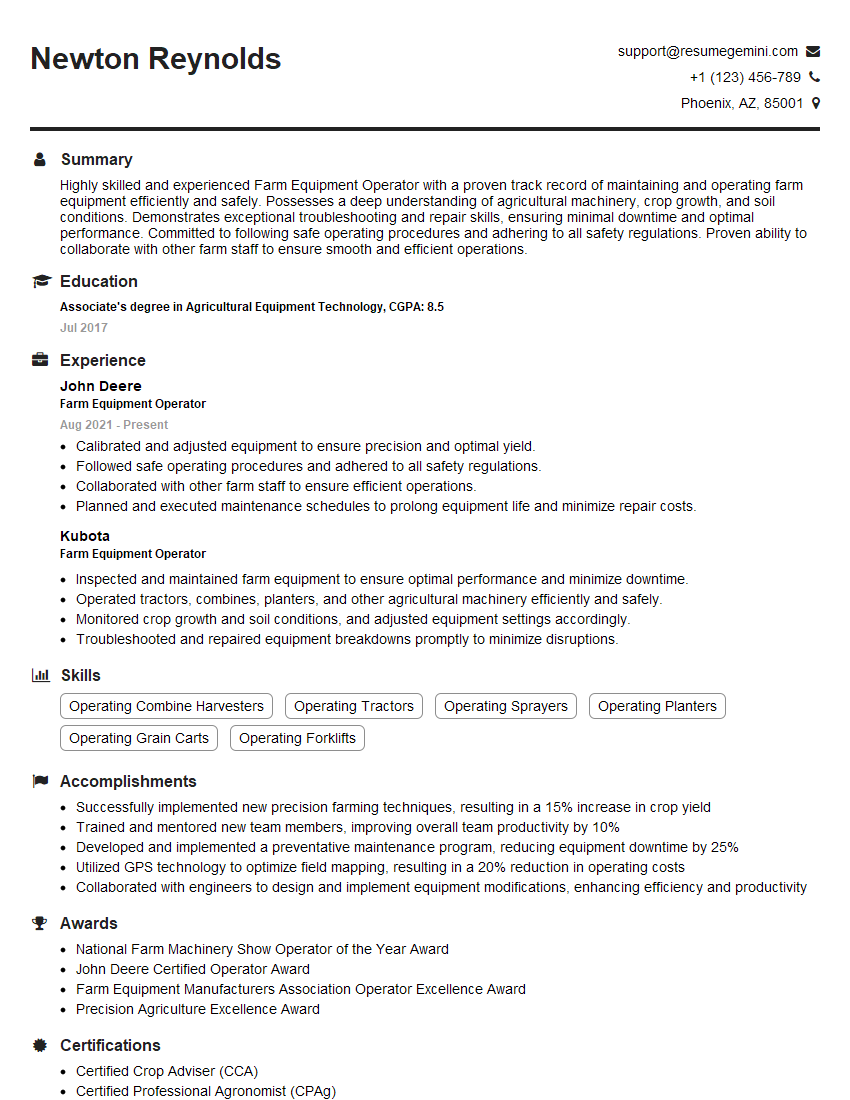

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does GPS technology improve corn harvesting efficiency?

GPS technology significantly enhances corn harvesting efficiency by providing precise location data, enabling various improvements.

- Automated steering: GPS-guided steering systems allow combines to follow pre-programmed paths, reducing overlap and minimizing skipped areas. This leads to uniform harvesting and increased yield.

- Variable rate technology (VRT): GPS data, integrated with yield maps from previous harvests, allows for VRT applications of inputs such as fertilizers and pesticides. This optimizes resource usage, reduces costs, and improves crop yields in subsequent seasons.

- Improved mapping and monitoring: GPS enables the creation of detailed harvest maps, showing yield variations across the field. This information is invaluable for identifying areas needing improvement in soil management or planting practices.

- Data analysis and decision making: GPS-generated data provides valuable insights that can be used to optimize harvesting strategies, including speed, header width, and unloading points.

Imagine a farmer using GPS-guided steering: Instead of manually maneuvering the combine, the GPS system automatically guides the machine along straight lines, minimizing errors and maximizing coverage. The data collected can later be used to improve field management for future harvests.

Q 17. Explain the principles of precision agriculture in corn harvesting.

Precision agriculture in corn harvesting utilizes technology and data analysis to optimize every aspect of the process, from planting to harvest.

- Site-specific management: Understanding variations within the field (soil type, topography, previous yields) allows farmers to tailor harvesting strategies to each specific area. This ensures consistent quality and avoids loss of yield in challenging areas.

- Yield monitoring: Real-time yield monitoring helps to identify areas with low yields or other issues. This enables immediate adjustments to harvesting parameters or future field management practices.

- Data integration and analysis: Precision agriculture integrates various data sources (GPS, yield monitors, soil sensors) to provide a comprehensive view of the field. This data is used to refine decision-making, predict potential problems, and optimize overall efficiency.

- Variable rate harvesting: Advanced systems can adjust harvesting parameters (e.g., header height, ground speed) in real-time based on the conditions in each section of the field. This helps to maintain consistent quality and minimize losses.

For example, a farmer might use sensors to measure soil moisture and adjust the combine’s header height accordingly. In dry areas, the header height can be lowered to minimize crop losses, while in wetter areas, it might be raised to avoid soil compaction.

Q 18. What are the economic factors affecting corn harvesting decisions?

Several economic factors significantly influence corn harvesting decisions.

- Grain prices: High grain prices incentivize efficient harvesting to maximize yield and revenue. Lower prices might lead to a more cautious approach.

- Harvesting costs: Fuel prices, labor costs, machine maintenance, and repair expenses directly impact the overall profitability of the harvest. Farmers strive to minimize these costs while maximizing yield.

- Drying costs: If the grain needs to be dried before storage, the associated energy costs become a significant factor, especially during wet harvests.

- Storage costs: The costs of storing harvested corn, including bin rental or construction, influence the timing of the harvest. Farmers might choose to harvest earlier to free up storage capacity if needed.

- Market conditions: The overall market demand for corn and the anticipated future prices influence the timing and strategies employed during the harvest.

For instance, if fuel prices rise sharply, a farmer might optimize the harvesting route to minimize travel distance, or opt for slightly lower harvesting speeds to conserve fuel, even if it slightly extends the harvest period.

Q 19. How do you determine the optimal harvesting speed?

Determining the optimal harvesting speed is a balancing act between maximizing throughput and minimizing losses. Several factors influence this decision.

- Crop maturity: The corn’s moisture content is critical. Harvesting too early can lead to significant losses due to immature kernels, while harvesting too late increases the risk of losses from lodging (plants falling over) and damage from weather or pests.

- Combine capacity: The combine’s engine power, threshing capacity, and grain tank size influence the maximum sustainable speed without compromising quality or causing blockages.

- Field conditions: Uneven terrain, wet soil, or heavy crop residue can necessitate a slower speed to prevent damage to the combine and ensure consistent harvesting.

- Loss monitoring: Continuous monitoring of grain losses (via the combine’s loss monitors) helps farmers adjust speed to minimize losses and optimize efficiency.

A farmer might start with a moderate speed, continuously monitoring losses. If losses increase, the speed should be reduced. Conversely, if losses remain consistently low, the speed can be slightly increased, within the combine’s safe operating limits and considering field conditions. Experience and field-specific conditions play a crucial role in finding this optimal balance.

Q 20. Describe the impact of soil conditions on corn harvesting.

Soil conditions significantly impact corn harvesting efficiency and potential losses.

- Soil moisture: Excessive soil moisture can lead to compaction, making it difficult to harvest efficiently and causing damage to the combine and the soil structure. Very dry soil can also cause problems by increasing the amount of dust and potentially increasing the risk of header damage.

- Soil type: Heavy clay soils are more prone to compaction and can cause wheel slippage, reducing harvesting speed and efficiency. Sandy soils are generally easier to work with.

- Soil structure: Good soil structure allows for better root penetration and more stable plants, facilitating smoother harvesting. Poor soil structure can contribute to lodging, making harvesting more difficult and leading to increased losses.

- Surface residue: High levels of crop residue can interfere with harvesting operations, clogging the combine or affecting the evenness of harvest. Proper residue management practices are important.

Imagine harvesting corn in a field with very wet, heavy clay soil. The combine might struggle to move through the field efficiently, potentially damaging the soil structure and resulting in delays and losses. Conversely, harvesting in a well-drained field with a suitable soil structure allows for a smooth and efficient operation.

Q 21. Explain the role of yield monitoring in corn production.

Yield monitoring is an essential aspect of corn production, providing real-time and post-harvest data to optimize farming practices.

- Real-time yield assessment: During harvesting, yield monitors measure the amount of grain harvested per unit area. This data allows farmers to assess the yield variability across the field and make immediate adjustments to harvesting parameters (e.g., speed, header height) if needed.

- Precise yield maps: Yield data is often stored digitally, creating detailed yield maps for the entire field. These maps highlight areas of high and low yield, enabling farmers to investigate the causes of variations.

- Improved decision making: Yield data is critical in planning future planting strategies. By identifying areas of consistently low yield, farmers can focus their efforts on addressing soil fertility issues, pest control, or other factors limiting productivity.

- Economic analysis: Accurate yield data is crucial for economic analysis, allowing farmers to calculate their total production costs, returns, and overall profitability.

For instance, a yield map might reveal a consistently lower yield in one part of the field. This could lead a farmer to conduct a soil test in that area to determine if nutrient deficiencies are affecting corn growth. The data could also help inform decisions regarding future fertilizer application rates or planting strategies.

Q 22. How do you address issues related to lodging during harvest?

Lodging, or the bending over of corn stalks, is a significant challenge during harvest, leading to harvesting difficulties and yield losses. Addressing this requires a multi-pronged approach starting even before planting.

Proper Planting Density: Overcrowding leads to weak stalks prone to lodging. Maintaining the recommended plant population per acre is crucial.

Variety Selection: Choosing corn hybrids with strong stalks and good standability is essential. Look for hybrids known for their resistance to lodging in your specific region and soil conditions.

Nutrient Management: Balanced fertilization, particularly potassium, strengthens stalks. Deficiencies weaken the plant, making it susceptible to lodging.

Pest and Disease Management: Timely pest and disease control prevents weakening of plants. Early detection and intervention are crucial.

Harvesting Techniques: Using appropriate combine header settings, such as reducing ground speed and header height, minimizes damage to lodged crops. A careful approach is essential to prevent further stalk breakage.

For example, a farmer who consistently experiences lodging might consider rotating to a different hybrid known for better standability, or adjusting their fertilization program to include more potassium.

Q 23. What are the common causes of combine breakdowns and how to prevent them?

Combine breakdowns are costly and disruptive. Common causes include:

Blocked Conveyors and Separators: Wet grain, excessive crop volume, or foreign materials can clog the combine’s machinery. Regular cleaning and preventative maintenance are key.

Engine Issues: Lack of proper lubrication, air filters needing replacement, or fuel system problems frequently cause engine failure. Adhering to a strict maintenance schedule is vital.

Electrical Problems: Wiring issues, damaged sensors, or faulty components can disrupt the combine’s various systems. Regular electrical checks are beneficial.

Hydraulic System Failure: Leaking hoses, worn seals, or contaminated fluid can compromise the hydraulic systems that operate many combine functions. Timely fluid changes and inspections are needed.

Wear and Tear on Cutting Components: Knives, reel, and auger wear down with continuous use, ultimately affecting cutting efficiency and causing damage. Regular sharpening and replacement of worn components are critical.

Prevention involves: A thorough pre-harvest inspection; regular maintenance following the manufacturer’s recommendations; keeping the combine clean; and using high-quality lubricants and filters.

Q 24. Explain the process of cleaning and maintaining a grain bin.

Proper grain bin cleaning and maintenance are crucial to prevent spoilage, insect infestation, and maintain grain quality.

Emptying the Bin Completely: Ensure the bin is entirely emptied before cleaning. Any residual grain can harbor pests and mold.

Cleaning the Interior Walls and Floor: Use a broom, brush, or appropriate cleaning equipment to remove any grain dust, debris, or spilled grain. A high-pressure air blower can be beneficial, but exercise caution.

Inspecting for Damage: Check for any cracks or holes in the bin walls or floor. Repair any damage promptly to prevent future issues.

Disinfection: Applying a suitable grain bin disinfectant will eliminate bacteria and fungi. Always follow the manufacturer’s instructions.

Aerate the Bin: Allow the bin to air out completely after cleaning to prevent moisture buildup.

Pest Control: Implement preventative pest control measures such as using insecticides or fumigants (when appropriate and following regulations).

Imagine leaving leftover food in your refrigerator—it would spoil. The same principle applies to grain bins; thorough cleaning prevents spoilage and ensures grain quality is maintained.

Q 25. What are the different types of corn dryers and their applications?

Corn dryers are essential for reducing grain moisture content to safe storage levels. Different types exist, each with specific applications:

Batch Dryers: These dryers process a set amount of grain at a time. They’re suitable for smaller operations or when high-moisture grain needs to be dried rapidly. Think of them as a large oven for grains.

Continuous-Flow Dryers: These dryers continuously process grain, offering high drying capacity. They are preferred for larger operations with high volumes of grain needing drying. They work like a conveyor belt system for drying.

High-Temperature Dryers: These dryers utilize high temperatures for faster drying, suitable for high-moisture grain. They require careful monitoring to avoid damaging the grain.

Low-Temperature Dryers: These dryers use lower temperatures and longer drying times, minimizing the risk of grain damage. They are ideal for preserving grain quality.

Combination Dryers: Some systems combine both high and low-temperature drying stages for optimal efficiency and grain quality.

The choice of dryer depends on factors like the volume of grain, desired drying time, available energy sources, and budget.

Q 26. Describe the impact of weed control on corn harvest yield.

Effective weed control significantly impacts corn harvest yield. Weeds compete with corn for essential resources like water, nutrients, and sunlight.

Reduced Yield: Uncontrolled weeds can drastically reduce corn yields by hindering plant growth and development. A dense weed population literally steals resources from the corn plants.

Increased Harvesting Challenges: Weeds can make harvesting more difficult and time-consuming, potentially leading to more grain losses or damage to the combine.

Lower Grain Quality: Weeds can contaminate the harvested grain, reducing its quality and market value. The presence of unwanted materials in the grain can be costly.

For example, a field with heavy weed pressure might yield significantly less than a weed-free field, even if the corn plants were otherwise healthy. Implementing a comprehensive weed management strategy, involving herbicides, tillage, and cover crops, is crucial for maximizing corn yields and maintaining grain quality.

Q 27. Explain the role of data analysis in optimizing corn harvesting strategies.

Data analysis plays a vital role in optimizing corn harvesting strategies. Utilizing data from various sources improves efficiency and profitability.

Yield Monitoring: Yield monitors provide real-time data on harvest yield, allowing farmers to identify areas with low yields for future improvements.

Moisture Content Monitoring: Real-time moisture data guides harvesting decisions and helps determine when to dry the grain, minimizing losses.

GPS Mapping: GPS data allows precise mapping of fields, optimizing harvesting routes and minimizing overlaps or missed areas.

Combine Data: Combine data loggers record various parameters like engine performance, fuel consumption, and harvesting speed, facilitating maintenance and optimizing operating parameters.

Weather Data: Integrating weather data helps in planning harvesting schedules, avoiding delays due to adverse conditions.

By analyzing this data, farmers can create more efficient harvesting plans, improve resource allocation, and minimize losses. For instance, data showing consistently low yields in a specific field section might indicate a nutrient deficiency, prompting soil testing and corrective measures.

Q 28. What are the environmental considerations related to corn harvesting?

Corn harvesting has environmental implications that need careful consideration.

Soil Erosion: Harvesting activities, particularly on sloped fields, can contribute to soil erosion if not managed properly. Conservation tillage and no-till farming techniques are used to address this.

Greenhouse Gas Emissions: Fuel consumption by machinery contributes to greenhouse gas emissions. Choosing fuel-efficient machinery and optimizing harvesting practices help reduce this impact.

Water Pollution: Runoff from fields during harvest can carry fertilizers and pesticides into waterways. Implementing best management practices (BMPs) to minimize this is critical.

Biodiversity Loss: Intensive corn production can negatively affect biodiversity. Practices like integrating cover crops or creating habitat strips mitigate some of the biodiversity impact.

Energy Consumption: Drying corn requires substantial energy. Optimizing drying techniques and utilizing renewable energy sources can reduce energy consumption.

Sustainable corn production requires a holistic approach, incorporating environmental considerations at each stage, from planting to harvest. Farmers are increasingly adopting environmentally friendly practices to minimize their environmental footprint.

Key Topics to Learn for Corn Harvesting Techniques Interview

- Corn Maturity Assessment: Understanding the optimal harvest window based on moisture content, kernel development, and plant health. Practical application includes using moisture meters and visual inspection techniques.

- Harvesting Equipment Operation: Familiarity with various combine harvesters, their components (headers, augers, threshing mechanisms), and safe operating procedures. Practical application involves troubleshooting common mechanical issues and optimizing machine settings for different field conditions.

- Yield Monitoring and Optimization: Understanding yield mapping, GPS technology integration, and data analysis for optimizing harvest efficiency and maximizing yield. Practical application includes interpreting yield data to inform future planting strategies and resource allocation.

- Grain Handling and Storage: Proper techniques for grain drying, cleaning, and storage to maintain quality and prevent spoilage. Practical application involves understanding different drying methods and selecting appropriate storage facilities based on capacity and climate.

- Post-Harvest Management: Practices related to stalk management, soil conservation, and residue management for sustainable agriculture. Practical application includes understanding the environmental impact of different post-harvest techniques and implementing best practices.

- Safety Procedures and Regulations: Adherence to safety protocols during harvesting operations, including machine operation, personal protective equipment (PPE), and emergency procedures. Practical application involves recognizing and mitigating potential hazards in the field.

- Precision Agriculture Techniques: Understanding the role of technology in optimizing corn harvesting, including variable rate harvesting and sensor-based monitoring. Practical application involves integrating data from various sources to make informed decisions.

Next Steps

Mastering corn harvesting techniques is crucial for advancing your career in agriculture, opening doors to specialized roles and higher earning potential. A well-crafted resume is key to showcasing your skills and experience to potential employers. Building an ATS-friendly resume increases your chances of getting noticed by applicant tracking systems. ResumeGemini is a trusted resource to help you create a professional and impactful resume. Examples of resumes tailored to corn harvesting techniques are available, allowing you to tailor your application to specific job opportunities. Invest the time to build a strong resume – it’s an investment in your future.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good