Preparation is the key to success in any interview. In this post, we’ll explore crucial Corrosion Modeling and Simulation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Corrosion Modeling and Simulation Interview

Q 1. Explain the difference between uniform and localized corrosion.

Corrosion, the deterioration of a material due to its interaction with its environment, can manifest in different forms. Uniform corrosion, also known as general corrosion, is a relatively predictable type where the material deteriorates at a relatively even rate across its surface. Imagine a rusty nail; if the rust is evenly distributed, it’s an example of uniform corrosion. This makes it easier to predict the material’s lifespan and to apply protective measures. Localized corrosion, on the other hand, attacks specific areas of the material, leaving other regions largely unaffected. This is far more dangerous because it can lead to unexpected failures with potentially catastrophic consequences, as it’s harder to detect and mitigate. Think of pitting corrosion, where small holes form on the surface, or crevice corrosion, which occurs in narrow gaps or crevices where the environment is stagnant and oxygen-deficient. The difference lies primarily in the rate and distribution of the corrosion process: uniform corrosion is widespread and gradual, while localized corrosion is concentrated and often rapid.

Q 2. Describe the Nernst equation and its application in corrosion modeling.

The Nernst equation is a cornerstone of electrochemical thermodynamics, describing the potential of an electrode (half-cell) relative to a standard electrode (usually the standard hydrogen electrode). It’s crucial in corrosion modeling because it helps us understand the driving force behind electrochemical reactions. The equation is: E = E° - (RT/nF)lnQ, where E is the electrode potential, E° is the standard electrode potential, R is the ideal gas constant, T is the temperature in Kelvin, n is the number of electrons transferred in the reaction, F is the Faraday constant, and Q is the reaction quotient. In corrosion, this allows us to predict the potential difference between the anodic (oxidation) and cathodic (reduction) reactions. For example, we can use the Nernst equation to predict the potential of an iron electrode in a solution of varying pH, determining how this affects its corrosion rate. Different environments create different values of Q, which directly impact the electrode potential and consequently the corrosion rate. Essentially, the Nernst equation provides a quantitative link between the solution chemistry and the electrochemical reactions causing corrosion.

Q 3. What are the common electrochemical techniques used to study corrosion?

Electrochemical techniques are vital tools for understanding and quantifying corrosion. Some of the most common techniques include:

- Potentiodynamic Polarization: This involves measuring the current response of a material as its potential is systematically varied. It helps determine the corrosion potential and corrosion current density, from which the corrosion rate can be calculated.

- Potentiostatic Polarization: In this technique, the potential of the electrode is held constant, and the current is monitored. This is useful for studying passivation behavior (the formation of a protective oxide layer).

- Linear Polarization Resistance (LPR): A less time-consuming method, where a small potential perturbation is applied around the corrosion potential, and the slope of the current-potential curve is used to estimate the corrosion rate. This method is highly sensitive to the corrosion rate.

- Electrochemical Impedance Spectroscopy (EIS): A powerful technique that uses small alternating current signals to probe the corrosion process and extract information about the various processes involved (e.g., charge transfer, diffusion). It provides a detailed picture of the corrosion mechanism.

- Cyclic Voltammetry: This technique examines the potential and current during a potential sweep, which helps identify different electrochemical processes and helps to understand electrochemical mechanisms in corrosion

The choice of technique depends on the specific information needed and the complexity of the corrosion system.

Q 4. How does polarization resistance relate to corrosion rate?

Polarization resistance (Rp) is a measure of the resistance to current flow in a corrosion cell at the corrosion potential. It’s directly related to the corrosion rate through Stern-Geary equation: icorr = βaβc / (2.303 Rp(βa + βc)) where icorr is the corrosion current density, βa and βc are the Tafel slopes (representing the slopes of the anodic and cathodic polarization curves). Essentially, a lower polarization resistance indicates a higher corrosion rate and vice versa. Imagine trying to push water through a pipe: a small Rp is like a wide pipe with low resistance, allowing a high flow rate (high corrosion rate). A large Rp is a narrow pipe with high resistance, restricting flow (low corrosion rate). LPR is a popular method to quickly estimate corrosion rates, but it’s important to note that it assumes linear behavior, which may not always hold true for highly complex systems.

Q 5. Explain the principles of cathodic protection.

Cathodic protection is a widely used corrosion prevention technique where a sacrificial anode (a more readily corrodible metal) is connected to the structure to be protected. This forces the structure to become the cathode, preventing oxidation and corrosion. Imagine a metal pipe buried underground. Connecting a sacrificial zinc anode to the pipe makes the pipe cathodic, forcing the zinc to corrode instead. This ensures that the pipe remains protected. The sacrificial anode continuously supplies electrons to the structure, maintaining it at a potential where corrosion is suppressed. The effectiveness depends on factors such as the potential difference between the anode and the cathode, the conductivity of the electrolyte, and the size and spacing of the anodes. Different types of cathodic protection systems are implemented depending on the type and condition of the material to be protected.

Q 6. What are the different types of anodic protection?

Anodic protection, unlike cathodic protection, involves maintaining the structure at a highly anodic potential to form a passive layer. This passive layer, typically a metal oxide, prevents further corrosion. It’s achieved by applying a controlled anodic potential to the structure using an external power source. There are different types of anodic protection:

- Passive Anodic Protection: This involves polarizing the metal to a potential within the passive region of its polarization curve, where a protective oxide film forms.

- Transpassive Anodic Protection: This is used in some special cases where the metal forms a relatively stable passive oxide film in the transpassive region, above the passivation potential.

Anodic protection is often applied to materials with a well-defined passive region, such as stainless steel. The process requires precise control of the applied potential to ensure that the passive layer is maintained without causing excessive oxidation or other undesirable effects. It’s a powerful method, but it demands careful monitoring and control and is often used in specific and limited applications.

Q 7. Describe the factors influencing crevice corrosion.

Crevice corrosion, a highly localized form of corrosion, occurs in confined spaces or crevices where the environment is stagnant and often depleted in oxygen. Several factors influence its occurrence:

- Geometry: The narrowness and depth of the crevice are crucial; tighter crevices promote more severe corrosion.

- Solution Chemistry: The chemical composition of the solution within the crevice is different from the bulk solution, typically more acidic and depleted in oxygen. This creates an electrochemical cell, driving corrosion.

- Material Properties: Some materials are more susceptible to crevice corrosion than others. Stainless steels, known for their passive behavior in bulk solutions, can experience severe crevice corrosion.

- Temperature: Higher temperatures generally accelerate the rate of crevice corrosion.

- Chloride Concentration: Chloride ions are particularly aggressive and play a significant role in initiating crevice corrosion.

Imagine a bolt and nut connection; the narrow space between them creates a crevice susceptible to corrosion. Understanding these factors is critical in designing and selecting materials and systems that are resistant to this type of localized corrosion.

Q 8. Explain the mechanism of pitting corrosion.

Pitting corrosion is a localized form of corrosion that results in the formation of small, deep pits or holes on a metal surface. Imagine a tiny hole forming and growing deeper like a small crater on the surface of a coin. This is unlike uniform corrosion where the metal degrades evenly. The mechanism involves the breakdown of the passive film, a protective oxide layer that usually shields the metal from the corrosive environment. This breakdown occurs at specific points due to factors like surface imperfections, inclusions, or chloride ions in the solution. Once the passive film is breached, a localized galvanic cell is created. The pit itself becomes anodic (where oxidation occurs, releasing metal ions into the solution), while the surrounding metal acts as the cathode (where reduction occurs). This leads to an accelerated attack at the pit’s base, deepening the pit and consuming metal rapidly, while the rest of the surface remains seemingly unaffected.

For instance, stainless steel, known for its corrosion resistance due to its passive chromium oxide layer, is susceptible to pitting corrosion in chloride-containing environments. The chlorides can penetrate the passive film, initiate localized corrosion, and dramatically reduce the material’s lifespan.

Q 9. What is stress corrosion cracking and how is it modeled?

Stress corrosion cracking (SCC) is a failure process that occurs when a metal is subjected to a combination of tensile stress and a corrosive environment. It’s not just about the corrosion itself, but rather the synergistic effect of stress and corrosion working together to cause cracking. Imagine a stretched rubber band that’s also slowly dissolving; it will crack much faster than if only stretched or only dissolving. The process typically leads to brittle cracking, even at stresses lower than the material’s yield strength.

Modeling SCC is complex and usually involves integrating mechanical and electrochemical models. This often involves Finite Element Analysis (FEA), where the material’s stress distribution under load is calculated alongside electrochemical conditions. Models often incorporate empirical relationships that describe crack growth kinetics, taking into account factors like the applied stress, the corrosive environment (pH, temperature, presence of specific ions), and the material’s properties. For example, the slow strain rate test (SSRT) is an experimental method coupled with fracture mechanics to study and model SCC.

Q 10. How do you use Finite Element Analysis (FEA) in corrosion simulation?

Finite Element Analysis (FEA) is a powerful tool for simulating corrosion processes, especially when dealing with complex geometries or non-uniform corrosion conditions. In corrosion simulation, FEA is used to solve electrochemical equations in three dimensions, allowing the prediction of corrosion rates, potential distributions, and current densities across the surface of a component. It divides the component into many small elements (meshing) and applies electrochemical principles to each element.

For example, consider a pipeline with a weld defect. FEA can model the stress concentration around the weld, alongside the electrochemical properties of the pipe material and the surrounding environment. The simulation will predict the potential and current density distribution, revealing the areas most susceptible to corrosion. This allows engineers to design more robust components or develop effective corrosion mitigation strategies, such as cathodic protection.

Q 11. What software packages are you familiar with for corrosion modeling?

I am familiar with several software packages used for corrosion modeling, each with its strengths and weaknesses. These include COMSOL Multiphysics, which is a powerful, versatile platform capable of handling complex coupled phenomena like electrochemical reactions and fluid flow; ANSYS, known for its robust FEA capabilities, particularly in structural analysis; and specialized corrosion simulation software such as CORROSION. My experience also extends to using MATLAB for data analysis and custom code development for specific corrosion models. The choice of software depends on the specific problem, the complexity of the geometry, and the available computational resources.

Q 12. Explain the concept of Pourbaix diagrams and their use in corrosion prediction.

A Pourbaix diagram, also known as a potential-pH diagram, is a graphical representation of the thermodynamic stability of different phases of a chemical species, typically a metal and its various oxides and hydroxides, as a function of pH and electrode potential (voltage). Imagine a map showing the preferred states of a metal under different conditions—will it be dissolved in solution, form a passive layer, or exist as a solid metal? The diagram is constructed using thermodynamic data (Gibbs free energy), helping predict whether corrosion will occur under a given set of conditions.

In corrosion prediction, a Pourbaix diagram indicates the regions of immunity (where the metal is stable), corrosion (where the metal dissolves), and passivation (where a protective oxide layer forms). By knowing the pH and potential of the environment, one can determine the thermodynamically favored state of the metal and thus estimate its susceptibility to corrosion. For example, the Pourbaix diagram of iron shows that it is relatively stable at high pH (alkaline) and at low potential (less oxidizing conditions) whereas it is unstable (prone to corrosion) under acidic conditions and high potentials.

Q 13. Describe different types of corrosion inhibitors and their mechanisms.

Corrosion inhibitors are substances added to a corrosive environment to decrease the rate of corrosion. There are several types, each acting via a different mechanism.

- Anodic inhibitors: These interfere with anodic reactions, reducing the metal’s dissolution rate. They often form a protective layer on the metal surface.

- Cathodic inhibitors: These inhibit the cathodic reactions, thus reducing the overall corrosion rate. Examples include oxidizing agents such as chromates and nitrates.

- Mixed inhibitors: These affect both anodic and cathodic reactions. They often form a film over the entire surface, hindering both oxidation and reduction processes.

- Volatile corrosion inhibitors (VCIs): These are typically organic compounds that evaporate and form a protective layer on the metal surface, providing protection in enclosed spaces.

For example, zinc chromate was once widely used as an anodic inhibitor in paints but due to toxicity concerns, it has been largely replaced with less harmful alternatives like zinc phosphate.

Q 14. How do you determine the corrosion rate from experimental data?

Determining the corrosion rate from experimental data often involves measuring the weight loss of a specimen over time (weight loss method), measuring the volume of hydrogen gas evolved (for hydrogen evolution reactions), or employing electrochemical techniques such as Tafel extrapolation or linear polarization resistance. The weight loss method is a simple and widely used approach.

Weight loss method:

1. Weigh the specimen accurately before exposure to the corrosive environment.

2. After a defined exposure period, clean the specimen thoroughly to remove corrosion products.

3. Weigh the specimen again.

4. The difference in weight is the weight loss due to corrosion.

5. Calculate the corrosion rate using the formula: Corrosion Rate (mm/year) = (Wloss / A * t) * K, where Wloss is the weight loss (g), A is the surface area of the specimen (cm2), t is the exposure time (h), and K is a constant that depends on the metal’s density and unit conversions (typically 87.6 for iron).

Electrochemical techniques are more sophisticated and provide more detailed information about the corrosion process, but they require specialized equipment and expertise.

Q 15. What are the limitations of corrosion models?

Corrosion models, while powerful tools for predicting material degradation, have inherent limitations. These limitations stem from the complexity of corrosion processes, which are influenced by numerous interacting factors that are often difficult to fully characterize.

- Simplified Chemistry: Models often simplify complex electrochemical reactions, neglecting minor species or intricate reaction pathways. For example, a model might assume a single corrosion reaction when, in reality, several competing reactions occur simultaneously.

- Idealized Geometries and Microstructures: Models often use simplified geometries and homogenous material properties, whereas real-world components have complex shapes and microstructures that significantly affect localized corrosion rates. Think of a pitted surface versus a perfectly smooth one.

- Environmental Variability: Predicting corrosion accurately requires precise knowledge of the environment (temperature, humidity, pH, presence of aggressive ions, etc.). Real-world environments are dynamic and often unpredictable, making accurate input parameters difficult to obtain.

- Computational Limitations: Complex models require significant computational resources, limiting the scope and scale of simulations. High-fidelity simulations of large structures or long timescales can be computationally prohibitive.

- Uncertainty in Input Parameters: The accuracy of a corrosion model is heavily dependent on the accuracy of input parameters like material properties, environmental conditions, and electrochemical data. Uncertainty in these inputs propagates to the model’s predictions.

Addressing these limitations often involves combining multiple modeling techniques, using advanced experimental characterization to refine model input, and employing sensitivity analysis to identify critical parameters affecting prediction accuracy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you validate a corrosion model?

Validating a corrosion model is crucial to ensure its reliability and predictive capabilities. It involves comparing the model’s predictions with experimental observations obtained under controlled conditions.

- Experimental Data Collection: Conduct well-designed experiments that mimic the conditions relevant to the model. This might involve electrochemical techniques (e.g., potentiodynamic polarization, electrochemical impedance spectroscopy), weight loss measurements, or visual inspection of corroded samples.

- Model Calibration: Adjust model parameters to minimize the discrepancy between experimental data and model predictions. This often involves iterative adjustments, comparing the model’s output to the experimental data.

- Statistical Analysis: Use statistical methods (e.g., regression analysis, goodness-of-fit tests) to quantify the agreement between model predictions and experimental data. This determines the model’s accuracy and reliability.

- Sensitivity Analysis: Assess how sensitive the model’s predictions are to changes in input parameters. This identifies critical parameters that need accurate measurement and helps to estimate prediction uncertainty.

- Predictive Validation: Test the model’s ability to predict corrosion behavior under conditions not used during model calibration. This provides a more robust assessment of the model’s generalizability.

For example, if modeling the corrosion of a steel pipeline in a specific soil environment, we’d compare the model’s predicted corrosion rate to corrosion rates measured from field samples or laboratory experiments using soil from the same location. Discrepancies would highlight areas where the model needs refinement or further experimental investigation.

Q 17. Explain the role of environmental factors in corrosion.

Environmental factors play a dominant role in corrosion, acting as the driving force for electrochemical reactions. They significantly influence the rate and type of corrosion that occurs.

- Temperature: Higher temperatures generally accelerate corrosion reactions by increasing the rate of electrochemical processes and enhancing the solubility of corrosive species.

- pH: The acidity or alkalinity of the environment profoundly impacts corrosion. Acidic environments (low pH) are generally more corrosive to most metals, while alkaline environments can be either protective or corrosive, depending on the specific metal and the environment.

- Oxygen Availability: Oxygen often acts as a cathodic depolarizer, accelerating corrosion reactions, particularly in the presence of moisture. Removing oxygen from the environment can significantly reduce corrosion rates.

- Presence of Aggressive Ions: Ions such as chlorides, sulfates, and nitrates can accelerate corrosion by breaking down passive films or facilitating aggressive electrochemical reactions. For instance, chloride ions are notorious for causing pitting corrosion in stainless steels.

- Humidity and Moisture: Moisture is essential for most corrosion processes, as it provides an electrolyte for the electrochemical reactions to occur. High humidity levels can increase the rate of corrosion.

Imagine a rusty nail – the oxygen in the air, along with moisture, combines with iron to create iron oxide (rust). This illustrates how readily available environmental factors drive corrosion.

Q 18. Describe different types of corrosion testing methods.

Various methods exist for testing corrosion, each with its strengths and weaknesses, chosen based on the specific application and the type of corrosion being investigated.

- Weight Loss Measurement: A simple, widely used method that involves measuring the weight change of a specimen exposed to a corrosive environment over a period. It provides a measure of overall corrosion rate but lacks information on localized corrosion.

- Electrochemical Techniques: These sophisticated methods provide detailed information on the corrosion process. Examples include:

- Potentiodynamic Polarization: Measures the corrosion potential and corrosion current density to determine corrosion rate.

- Electrochemical Impedance Spectroscopy (EIS): Provides insights into the properties of the corrosion layer and its protective capability.

- Linear Polarization Resistance (LPR): A simpler electrochemical technique to measure corrosion rate.

- Immersion Tests: Specimens are immersed in a corrosive solution under controlled conditions to assess corrosion behavior. These provide overall corrosion rates but may not capture localized forms of attack.

- Salt Spray Testing: Exposes specimens to a salt spray environment to simulate marine atmospheric corrosion. Commonly used for assessing corrosion resistance of coatings.

- Crevice Corrosion Testing: Specifically designed to evaluate susceptibility to crevice corrosion, where corrosion is accelerated in confined spaces between materials.

The choice of method depends heavily on the specific research question. For example, if assessing a coating’s long-term performance in a marine environment, salt spray testing might be appropriate; while EIS might be better for understanding the protective behavior of a passivating layer.

Q 19. How do you select an appropriate corrosion model for a given application?

Selecting the right corrosion model involves carefully considering the specific application and the type of corrosion expected. There’s no one-size-fits-all answer; the choice depends on factors like material, environment, and the level of detail required.

- Type of Corrosion: Different models are suited for different corrosion mechanisms. For example, a pitting corrosion model is not suitable for uniform corrosion, and vice versa. Identifying the dominant corrosion mechanism is crucial.

- Material Properties: The model must accurately reflect the material’s electrochemical properties, including its potential, passive film behavior, and susceptibility to specific corrosion types.

- Environmental Conditions: The model must account for relevant environmental factors, such as temperature, pH, oxygen concentration, and the presence of aggressive ions. The complexity of the environment influences model selection.

- Required Accuracy: The level of accuracy needed will influence the complexity of the model. A simple empirical model might suffice for initial estimations, while a complex, physics-based model may be necessary for precise predictions.

- Computational Resources: Complex models often require significant computational resources. This needs to be considered in light of available computing power and time constraints.

For instance, modeling uniform corrosion in a simple environment may only require a simple empirical model, while predicting pitting corrosion in a complex chloride-containing solution might necessitate a sophisticated electrochemical model incorporating pit initiation and growth kinetics.

Q 20. Explain the concept of passivation and its role in corrosion resistance.

Passivation is the formation of a thin, protective oxide layer on the surface of a metal that significantly reduces its corrosion rate. This layer acts as a barrier, preventing further interaction between the metal and the corrosive environment.

The formation of this passive layer is a spontaneous process governed by electrochemical reactions. The oxide film is typically very thin (nanometers) but extremely effective at preventing further corrosion. Its stability depends on environmental factors like pH and the presence of aggressive ions.

Metals that exhibit passivation, such as stainless steels, aluminum, and titanium, demonstrate superior corrosion resistance in specific environments. The breakdown of this protective layer (e.g., by chloride ions in stainless steels) can lead to localized corrosion like pitting or crevice corrosion.

Imagine a metal coated with an invisible, protective shield – that’s essentially the passive film. It’s the key to the remarkable corrosion resistance of many commonly used metals in various applications.

Q 21. How do you account for the effects of temperature on corrosion?

Temperature significantly impacts corrosion rates. Generally, an increase in temperature accelerates the rate of electrochemical reactions involved in corrosion.

Several ways exist to account for temperature effects in corrosion modeling:

- Arrhenius Equation: This equation is widely used to describe the temperature dependence of reaction rates. The corrosion rate constant (k) can be expressed as:

k = A * exp(-Ea / (R * T))- Where:

Ais the pre-exponential factorEais the activation energyRis the gas constantTis the absolute temperature- Empirical Correlations: Empirical correlations based on experimental data can be used to quantify the temperature dependence of corrosion rates for specific materials and environments.

- Thermodynamic Considerations: Temperature impacts the solubility of corrosion products and the stability of passive films. Thermodynamic calculations can help predict the impact of temperature changes on these processes.

- Electrochemical Models: Incorporating the temperature dependence of electrochemical parameters (like exchange current densities and Tafel slopes) into electrochemical corrosion models provides a more accurate representation of the temperature effect.

For example, in high-temperature applications like power plants, accurate temperature modeling is crucial for predicting the lifespan of components exposed to corrosive environments. Neglecting temperature effects can lead to significant underestimation of the corrosion rate, potentially causing premature failure.

Q 22. Describe the role of microstructure in corrosion susceptibility.

Microstructure plays a crucial role in determining a material’s susceptibility to corrosion. Think of it like this: a material’s surface isn’t a uniform, featureless plane; it’s a complex landscape of grains, grain boundaries, inclusions, and precipitates. These microstructural features significantly influence the electrochemical reactions that drive corrosion.

Grain boundaries: These are regions where crystal lattices meet, often possessing a higher energy state than the grain interiors. This higher energy makes grain boundaries more reactive and prone to attack, creating preferential corrosion paths. Imagine a brick wall – the mortar between bricks (grain boundaries) is weaker than the bricks themselves (grains).

Inclusions and precipitates: These are small, foreign particles embedded within the material. They can act as either cathodic or anodic sites, depending on their composition and the surrounding matrix. This creates localized corrosion cells, accelerating the overall corrosion process. Think of a rusty nail – the impurities in the iron create areas that corrode more easily.

Phase composition: Different phases within a material have different electrochemical potentials. This difference can lead to galvanic corrosion, where one phase acts as an anode and corrodes while another acts as a cathode. Stainless steel, for instance, relies on a passive chromium-rich oxide layer for corrosion resistance. If this layer is compromised by improper processing leading to uneven phase distribution, localized corrosion can occur.

Understanding the microstructure is, therefore, paramount in selecting materials for specific corrosive environments and predicting their lifetime.

Q 23. What are the different types of coatings used for corrosion protection?

Various coatings are employed for corrosion protection, each offering unique advantages and disadvantages. The choice depends heavily on the specific application, the corrosive environment, and the cost considerations.

Metallic Coatings: These include zinc (galvanizing), aluminum, chromium, and nickel coatings, often applied through processes like electroplating, hot-dipping, or physical vapor deposition. They work primarily by sacrificial protection (e.g., zinc) or by forming a barrier layer (e.g., chromium).

Organic Coatings: These are paints, varnishes, and polymers. They provide a physical barrier that prevents the corrosive environment from contacting the substrate. Their effectiveness depends on factors like film thickness, adhesion, and permeability.

Inorganic Coatings: Examples include conversion coatings (phosphate, chromate) and ceramic coatings. Conversion coatings form a thin, adherent layer on the substrate, providing chemical or physical protection. Ceramic coatings offer excellent chemical resistance but can be brittle.

Composite Coatings: These combine different coating types to leverage their individual benefits. For example, a metallic coating underneath an organic coating offers both sacrificial and barrier protection.

The selection of the appropriate coating needs careful consideration of the specific corrosion mechanism involved and the overall performance requirements.

Q 24. Explain the principles of electrochemical impedance spectroscopy (EIS).

Electrochemical Impedance Spectroscopy (EIS) is a powerful non-destructive technique used to characterize the corrosion behavior of materials. It involves applying a small amplitude sinusoidal AC voltage to the electrode and measuring the resulting current response. This response provides information about the different processes occurring at the electrode-electrolyte interface, such as charge transfer, diffusion, and film formation.

The key principle lies in the impedance, which is a complex number representing the opposition to the flow of alternating current. It’s expressed as Z = Z’ + jZ”, where Z’ is the real part (resistance) and Z” is the imaginary part (reactance). The impedance spectrum (plot of Z’ vs. Z”) reveals information about the different layers and processes at the interface, allowing for the identification of corrosion mechanisms and the evaluation of coating integrity.

Imagine trying to push water through a pipe with various constrictions. EIS measures the overall resistance to water flow (corrosion resistance) as well as the characteristics of each constriction (individual corrosion processes).

Q 25. How do you interpret EIS data?

Interpreting EIS data involves fitting an equivalent circuit model to the experimental impedance spectrum. This model represents the electrochemical system as a network of resistors (R), capacitors (C), and inductors (L), each representing a specific process. The values of the components in the equivalent circuit are extracted through fitting algorithms, providing quantitative information about the system’s properties.

For example, a simple equivalent circuit for a coated metal might include:

Rs: Solution resistance

Rc: Coating resistance

Cc: Coating capacitance

Rct: Charge transfer resistance

Cdl: Double layer capacitance

A high Rc value indicates a highly protective coating, while a low Rct value suggests a high corrosion rate. The values of the capacitances provide information about the thickness and dielectric properties of the different layers.

Software packages are commonly used for data fitting and analysis. Expertise is critical, as the choice of an appropriate equivalent circuit is crucial for a meaningful interpretation of results. Incorrect circuit selection can lead to inaccurate conclusions about corrosion mechanisms.

Q 26. Describe your experience with corrosion failure analysis.

My experience with corrosion failure analysis includes a wide range of approaches, from visual inspection and macroscopic examination to advanced microscopic techniques and electrochemical measurements. I’ve worked on numerous projects involving the failure analysis of various metallic and non-metallic components. For example, I was once involved in investigating the failure of a pipeline transporting highly corrosive chemicals. The analysis involved a meticulous investigation of the failed section, including visual inspection, chemical analysis, and microscopic examination to identify the corrosion mechanism.

The process typically involves:

Visual inspection: Identifying the type, location, and extent of the corrosion damage.

Microscopic analysis: Using techniques such as optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) to characterize the microstructure and corrosion products.

Chemical analysis: Determining the composition of the material and corrosion products using techniques like X-ray diffraction (XRD), X-ray fluorescence (XRF), and energy-dispersive X-ray spectroscopy (EDS).

Electrochemical measurements: Employing techniques such as EIS and potentiodynamic polarization to determine the corrosion rate and mechanisms.

Based on this comprehensive investigation, I can develop a root cause analysis and recommend corrective measures to prevent future failures.

Q 27. How do you manage and interpret large datasets in corrosion modeling?

Managing and interpreting large datasets in corrosion modeling requires efficient data management strategies and powerful computational tools. I am proficient in utilizing various programming languages such as Python and MATLAB, alongside specialized software packages, to handle and analyze extensive corrosion datasets effectively.

My approach generally includes:

Data cleaning and preprocessing: Identifying and handling missing or erroneous data points.

Data visualization: Employing various plotting techniques to identify trends and patterns in the data.

Statistical analysis: Utilizing regression analysis, machine learning algorithms, or other statistical methods to uncover relationships between different variables and build predictive models.

High-performance computing: Employing parallel computing techniques or cloud-based computing resources to accelerate the computational processes involved in complex simulations.

For example, I recently used machine learning to predict corrosion rates in a complex, multi-component system. This involved training a model on a large dataset of experimental corrosion data, resulting in a robust predictive tool to guide material selection and optimize design.

Q 28. What are your strategies for problem-solving complex corrosion issues?

My strategies for problem-solving complex corrosion issues involve a systematic approach that combines theoretical understanding with practical experimentation and advanced analytical techniques.

I typically follow these steps:

Problem definition and characterization: Thoroughly understanding the nature of the corrosion problem, including the environment, materials involved, and the consequences of the corrosion.

Literature review and knowledge gathering: Researching relevant literature and existing data to identify potential corrosion mechanisms and solutions.

Experimental investigation: Designing and conducting experiments to validate hypotheses and gather quantitative data. This might include electrochemical measurements, material characterization, or environmental monitoring.

Modeling and simulation: Employing advanced computational tools and corrosion models to predict corrosion behavior and test potential solutions.

Solution implementation and monitoring: Implementing the proposed solution, monitoring its effectiveness, and making adjustments as needed.

A collaborative approach is often crucial. I would involve material scientists, engineers, and other domain experts in addressing complex corrosion issues. The use of advanced techniques, such as in-situ observation, and coupled multi-physics simulation helps reach more accurate solutions, thereby reducing the cost of material failures.

Key Topics to Learn for Corrosion Modeling and Simulation Interview

- Electrochemical Principles: Understand fundamental concepts like electrode potentials, polarization curves, and electrochemical kinetics. Be prepared to discuss their application in corrosion prediction.

- Corrosion Mechanisms: Develop a strong understanding of various corrosion mechanisms, including uniform corrosion, pitting corrosion, crevice corrosion, stress corrosion cracking, and hydrogen embrittlement. Know how environmental factors influence these processes.

- Material Selection and Degradation: Discuss the impact of material properties (e.g., composition, microstructure) on corrosion resistance. Be able to explain how modeling helps predict material lifetime and optimize selection.

- Numerical Methods and Software: Familiarize yourself with common numerical techniques used in corrosion modeling (e.g., finite element analysis, finite difference methods). Showcase experience with relevant software packages (mention specific ones if you have experience).

- Experimental Techniques and Validation: Understand how experimental data (e.g., electrochemical measurements, weight loss measurements) is used to validate and refine corrosion models. Discuss the importance of model calibration and validation.

- Practical Applications: Be ready to discuss practical applications of corrosion modeling in diverse industries, such as oil & gas, aerospace, automotive, and infrastructure. Prepare examples of how simulation has improved design, reduced costs, or enhanced safety.

- Advanced Topics (depending on the role): Explore advanced topics such as coupled phenomena (e.g., corrosion and stress), multi-physics simulations, and probabilistic modeling. Tailor your preparation to the specific job description.

Next Steps

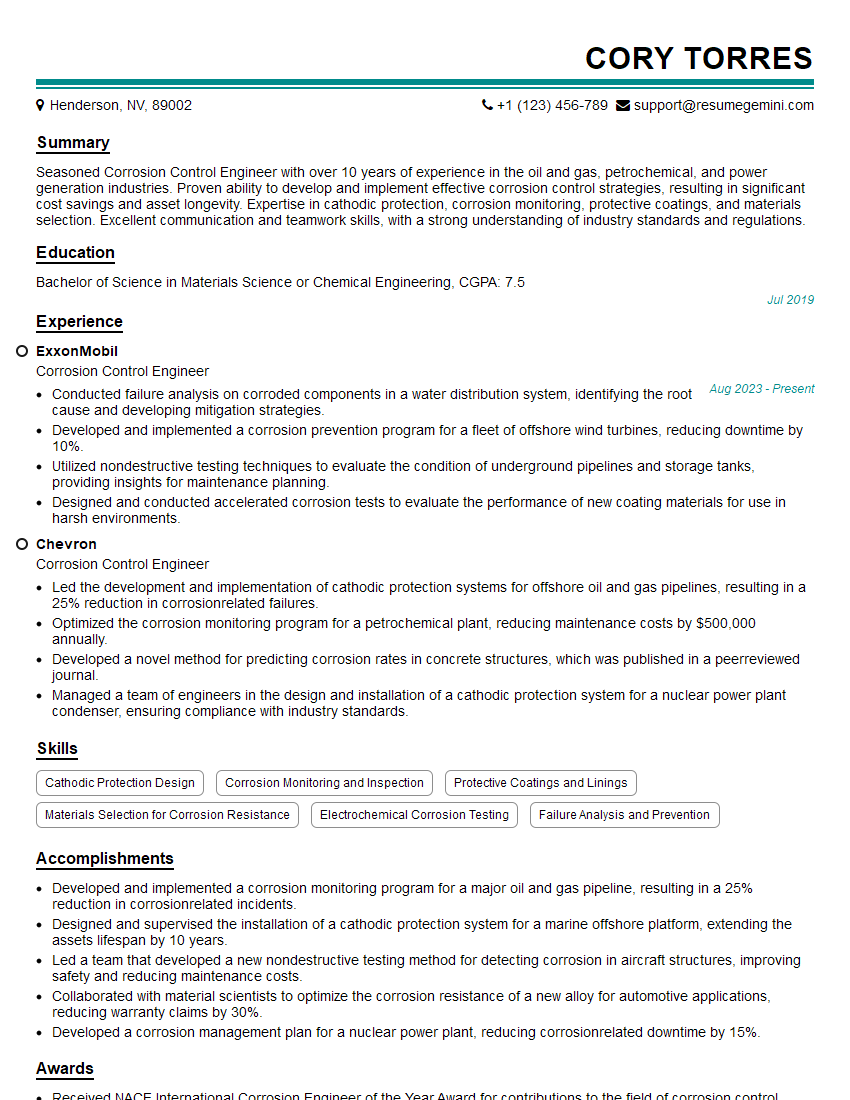

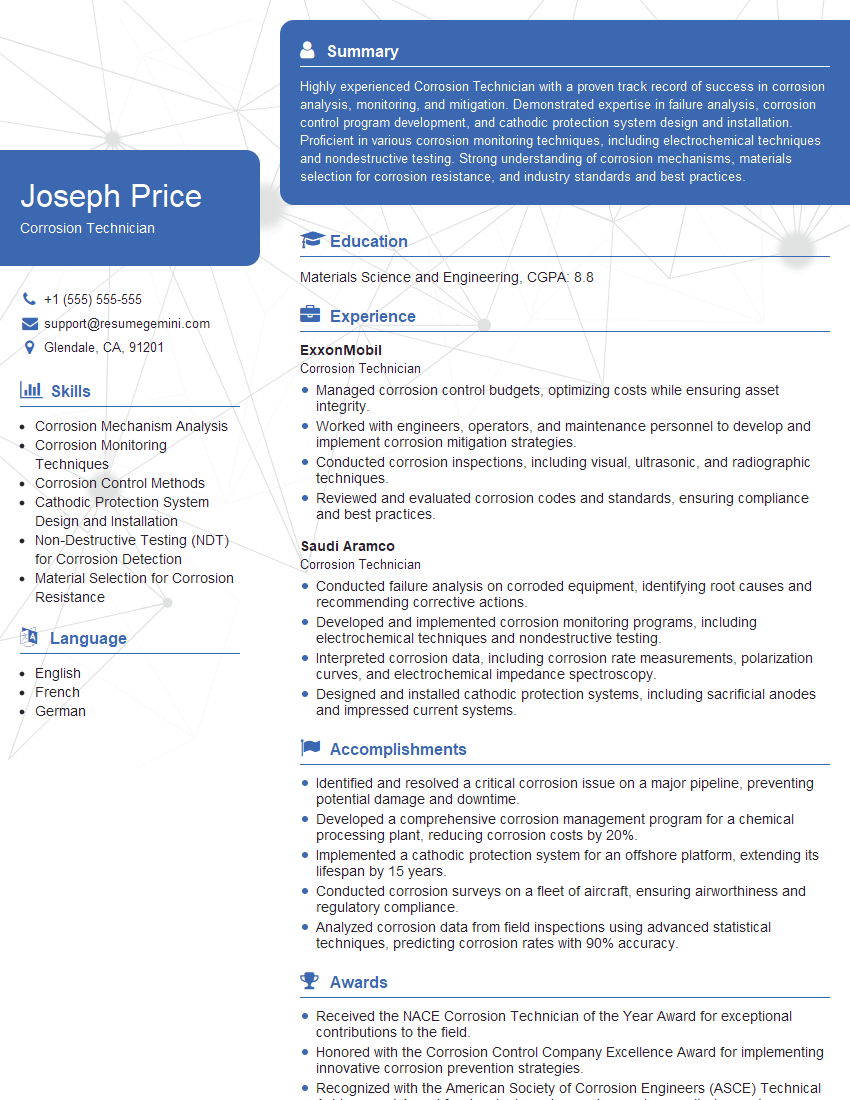

Mastering corrosion modeling and simulation significantly enhances your career prospects in various engineering and scientific fields. It demonstrates a high level of technical expertise and problem-solving skills, opening doors to challenging and rewarding opportunities. To maximize your chances of landing your dream role, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your skills and experience in Corrosion Modeling and Simulation. Examples of resumes tailored to this field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good