Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Cotton Harvester Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Cotton Harvester Operation Interview

Q 1. Describe the different types of cotton harvesters and their applications.

Cotton harvesters are broadly categorized into two main types: stripper harvesters and spindle pickers. The choice depends largely on the cotton variety and field conditions.

- Stripper Harvesters: These machines are faster and more efficient for harvesting short-staple cotton grown in drier conditions. They literally strip the cotton bolls from the plant, collecting both open and unopened bolls. This results in higher trash content in the harvested cotton, requiring more cleaning. Think of them as a ‘rough and ready’ approach.

- Spindle Pickers: These are more selective harvesters. They use spindles that gently remove the open cotton bolls from the plant, leaving behind unopened bolls and reducing trash content. This leads to higher quality cotton but at a slightly slower harvest rate. They are better suited for long-staple cotton varieties and wetter conditions, offering a more ‘delicate’ harvest.

In practice, the choice often comes down to balancing speed and quality. For a large farm with short-staple cotton, a stripper harvester might be the best choice for sheer volume. A farm specializing in high-quality, long-staple cotton might opt for a spindle picker to preserve fiber integrity.

Q 2. Explain the process of setting up a cotton harvester for optimal performance.

Setting up a cotton harvester for optimal performance is a crucial step that involves several key adjustments, all impacting efficiency and quality. It’s akin to tuning a finely crafted instrument.

- Proper Height Adjustment: The harvester’s height must be adjusted to match the height of the cotton plants. Too high, and you’ll miss bolls; too low, and you risk damaging the plants or the machine itself. This is often adjusted with hydraulic controls, and careful observation of the machine’s performance helps fine-tune the height.

- Conveyer System Check: The conveyors that transport the cotton to the modules must be checked for blockages or wear. A smooth flow is essential for preventing jams and ensuring consistent output. Regular lubrication is crucial here.

- Sensor Calibration: Modern harvesters have sensors that monitor factors like boll density and moisture content. These sensors need to be regularly calibrated to ensure accurate data input and optimal harvesting strategy. Improper calibration could result in wasted time and reduced yields.

- Module Management: The size and condition of the modules (containers for the harvested cotton) should be checked. Full modules need to be replaced timely, and any damage could lead to leaks or spills. Efficient module management is crucial for timely harvesting.

Imagine a symphony orchestra; each instrument needs to be properly tuned and coordinated. Similarly, every aspect of the harvester needs to be aligned for peak performance.

Q 3. How do you ensure the safety of yourself and others while operating a cotton harvester?

Safety is paramount in cotton harvesting. A cotton harvester is a large, powerful machine that can be dangerous if not operated carefully. Safety procedures should be followed meticulously.

- Pre-operation Checks: Thorough pre-operation checks are essential, verifying the machine’s functionality and identifying potential hazards.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, hearing protection, and sturdy work boots. This protects you from potential injuries due to moving parts, dust, and debris.

- Awareness of Surroundings: Constantly be aware of your surroundings, especially regarding other workers, machinery, and obstacles in the field. Clear communication and designated safety zones are critical.

- Regular Breaks: Take regular breaks to avoid fatigue, as fatigue greatly increases the risk of accidents.

- Emergency Procedures: Familiarize yourself with emergency shut-off procedures and know what to do in case of a malfunction or accident.

Remember, safety is not just a guideline; it’s a non-negotiable commitment. A minor oversight could have major consequences.

Q 4. What are the common maintenance checks you perform on a cotton harvester before operation?

Before operating a cotton harvester, I conduct a comprehensive series of maintenance checks, akin to a pre-flight checklist for an airplane.

- Fluid Levels: Checking engine oil, transmission fluid, hydraulic fluid, and coolant levels is crucial. Low levels can lead to catastrophic failure.

- Tire Pressure: Proper tire inflation ensures optimal traction and reduces wear and tear.

- Belt Tension: Checking the tension of all belts and replacing worn belts prevents slippage and breakdowns.

- Electrical System: A quick check of the battery, lights, and other electrical components is necessary to ensure safe and efficient operation.

- Picking Components: Inspecting the picking components (spindles or strippers) for wear, tear, or damage is essential for proper harvesting. Worn parts can reduce efficiency and damage the cotton.

- Brake System: Functionality of the braking system is paramount for safe operation.

These checks are not just routine procedures; they are vital for preventing costly downtime and ensuring operator safety. I treat this pre-operation check as a crucial safety measure.

Q 5. Describe your experience troubleshooting mechanical issues on a cotton harvester.

Troubleshooting mechanical issues on a cotton harvester requires a systematic approach and good diagnostic skills. My experience involves a range of problems, from simple fixes to complex repairs.

For instance, I once encountered a situation where the harvester’s picking unit was malfunctioning, resulting in reduced harvesting efficiency. By systematically checking each component of the picking system, including the spindles and associated gears, I pinpointed the issue to a worn-out gear. This required replacing the gear, which restored the harvester’s functionality.

Another time, the harvester experienced frequent stoppages due to a clogged conveyor system. After careful inspection, I found that a build-up of cotton debris was the culprit. I cleared the blockage and adjusted the system to prevent future build-up, adding extra lubrication to reduce friction.

My troubleshooting methodology involves a combination of observation, diagnostic tools (like multimeters and pressure gauges), and a strong understanding of the harvester’s mechanical systems. It’s like being a detective, carefully examining clues to solve the mystery behind the malfunction.

Q 6. How do you adjust the harvester settings based on varying field conditions (e.g., soil type, crop density)?

Adjusting harvester settings based on varying field conditions is key to optimizing performance and minimizing losses. It’s a balancing act that requires experience and keen observation.

- Soil Type: Heavy clay soils might require slower speeds and adjustments to the ground-following mechanisms to avoid damage. Sandy soils may allow for higher speeds.

- Crop Density: In densely packed fields, you might adjust the harvester’s speed to a slower setting, preventing overloading and ensuring complete harvest.

- Boll Maturity: If the bolls are not fully mature, adjustments might be needed to minimize the collection of immature bolls.

- Moisture Content: High moisture content might require slower speeds to prevent damage to the delicate cotton fibers.

These adjustments often involve modifications to the harvester’s hydraulic systems and control settings, requiring a detailed understanding of how these systems interact. Each field presents a unique set of challenges, demanding adaptability and precision.

Q 7. What are the signs of a malfunctioning cotton harvester, and how do you diagnose them?

Identifying malfunctioning components of a cotton harvester requires careful observation and diagnostic skills. Several signs can indicate trouble.

- Reduced Harvesting Rate: A significantly lower harvesting rate than expected could indicate problems with the picking mechanism, conveyors, or other key components.

- Excessive Trash Content: Higher than usual levels of trash (leaves, stems, etc.) suggest issues with the cleaning system or the picking mechanism itself.

- Unusually High Engine Temperature: Elevated engine temperature could signal issues with the cooling system or even engine problems.

- Strange Noises: Unusual noises, such as grinding or squealing, often point to problems with bearings, belts, or gears.

- Leaks: Leaks of fluids (oil, hydraulic fluid, coolant) could indicate damage to hoses, seals, or other components. This requires immediate attention.

Diagnosing these issues requires a systematic approach. Start with a visual inspection, checking for obvious problems. Then, use diagnostic tools to pinpoint the root cause. Experience and a deep understanding of the harvester’s workings are essential for efficient diagnosis and repair.

Q 8. Explain the process of harvesting cotton modules.

Harvesting cotton modules involves several key steps. First, the cotton is picked from the plant using a cotton harvester, which either strips the cotton from the bolls (stripper harvester) or uses spindles to gently remove the cotton fibers (spindle picker). The harvested cotton is then compacted into large modules – essentially, giant rectangular bales – within the harvester itself. These modules are typically around 4 to 6 tons and are designed for easy transport and storage. Once a module is full, the harvester automatically discharges the module onto the ground. The modules then are picked up by specially equipped trailers for transport to the gin. Imagine it like a giant, automated cotton-packing machine, maximizing efficiency in the field.

- Picking: Removing cotton fibers from the plants.

- Compaction: Pressing the cotton fibers into a dense module.

- Discharge: Releasing the compacted module from the harvester.

- Transportation: Moving the modules to storage or processing facilities.

Q 9. What are the optimal harvesting conditions for maximizing cotton yield and quality?

Optimal harvesting conditions are crucial for maximizing both yield and quality. The ideal scenario involves dry weather. High humidity and rain can lead to discoloration and staining of the cotton fibers, reducing the quality and making it more difficult to process. The cotton should be at its peak maturity, meaning the bolls have fully opened, and the fibers are fully developed. This usually happens in late summer or early fall, depending on the variety and climate. We aim to harvest when the cotton moisture content is between 6-8%, which balances easy picking with minimal risk of fiber damage. Harvesting too early results in lower yields and shorter fibers; harvesting too late can lead to increased trash contamination and lower quality. It’s a balancing act.

Q 10. How do you manage the harvesting process in challenging weather conditions?

Challenging weather conditions present significant obstacles during cotton harvesting. Heavy rain necessitates stopping the operation entirely to avoid damaging the cotton and machinery. Strong winds can negatively impact the harvester’s stability and cause uneven picking. In such conditions, we prioritize the safety of equipment and personnel. Preemptive measures, such as checking weather forecasts rigorously and having a flexible harvest schedule, are key. During periods of light rain or wind, we might adjust the harvesting speed to compensate for the conditions, but safety always comes first. We carefully monitor equipment to make sure that mud or debris doesn’t affect machine performance. A thorough post-harvest cleaning and maintenance procedure is crucial.

Q 11. Describe your experience with GPS-guided cotton harvesting.

My experience with GPS-guided cotton harvesting has been extremely positive. It allows for precise navigation within the field, ensuring that we cover the entire area without overlaps or missed rows, which optimizes yield. This system uses satellite signals to pinpoint the harvester’s location and guide it along pre-planned routes. The software integrates with yield maps allowing for data analysis to improve future harvests. For example, we can identify areas with lower yield and investigate factors like soil quality or irrigation to address those issues in the next planting season. The precision and efficiency gains are substantial, leading to cost savings and a more sustainable harvesting operation. It’s essentially like having an autopilot system for the harvester.

Q 12. How do you ensure the efficient transportation of harvested cotton modules?

Efficient transportation of harvested cotton modules is critical for maintaining the quality of the cotton and minimizing delays. We use heavy-duty trailers designed specifically for carrying cotton modules, ensuring they are securely fastened and protected from damage during transit. The number of trailers needed depends on the size of the harvest and the distance to the gin. We schedule transport routes carefully to minimize downtime and traffic congestion. Effective communication between the harvesting crew and the transportation team is vital to maintain a smooth, continuous flow of cotton modules from the field to the gin. We often use specialized software to track trailer location and availability in real time. Think of it as a carefully choreographed logistics operation, where every step is synchronized for optimal efficiency.

Q 13. What is your experience with different types of cotton harvesting systems (e.g., spindle, stripper)?

I have extensive experience with both spindle and stripper cotton harvesting systems. Spindle pickers are gentler on the cotton fibers, resulting in higher quality and less trash contamination, but their harvesting speed is often slower than strippers. Stripper harvesters are more aggressive, harvesting faster but potentially leading to more damaged fibers and increased trash in the harvested cotton. The choice between the two depends largely on the specific cotton variety being harvested, the desired fiber quality, and the economic considerations of speed versus quality. In some cases, we may even use a combination of both systems depending on the field conditions and the type of cotton. The choice is based on a cost-benefit analysis of speed, fiber quality, and the volume of cotton to be harvested.

Q 14. Explain the importance of maintaining proper harvesting speed and its impact on yield.

Maintaining the proper harvesting speed is paramount for maximizing yield and minimizing losses. Too slow a speed can lead to increased harvesting time, labor costs, and potential damage to the cotton plants from repeated passes. Too fast a speed, on the other hand, can result in incomplete picking and leaving behind significant amounts of harvestable cotton, reducing overall yield. The optimal speed depends on factors like the density of the cotton crop, the type of harvesting system used, and the condition of the equipment. Experienced operators learn to adjust the harvesting speed based on real-time field conditions. Think of it like driving – you adjust your speed depending on the traffic and road conditions. In cotton harvesting, we constantly monitor the picking efficiency and adjust speed to find that ideal balance between speed and thoroughness.

Q 15. How do you prevent damage to the cotton crop during harvesting?

Preventing crop damage during cotton harvesting is crucial for maximizing yield and profitability. It involves a multi-pronged approach focusing on machine operation, field conditions, and pre-harvest preparation.

Proper Machine Adjustment: The stripper or spindle picker needs to be correctly adjusted for the specific cotton variety and its maturity. Incorrect settings can lead to excessive boll breakage or leaf inclusion. For example, the cylinder speed and concave clearance must be optimized to gently remove the cotton from the bolls without damaging the plant. Too aggressive a setting can tear bolls, while too gentle might leave significant amounts of cotton unharvested.

Careful Field Navigation: Operators must avoid driving over wet or uneven terrain, which can compact the soil, damage plant roots, and increase the likelihood of machine breakdowns. We use GPS guidance systems to ensure consistent rows and minimize overlap, further protecting the crop.

Pre-Harvest Assessment: Before commencing harvesting, a thorough inspection of the field identifies any areas with unusually high moisture content, weak plants, or potential obstacles like rocks or debris. These problem areas should be harvested last or with adjusted settings to minimize damage.

Harvesting at Optimal Maturity: Harvesting too early results in lower yields and fiber quality. Harvesting too late increases the chances of boll rot and other damage. We rely on regular field scouting and moisture testing to determine the ideal harvest window.

Career Expert Tips:

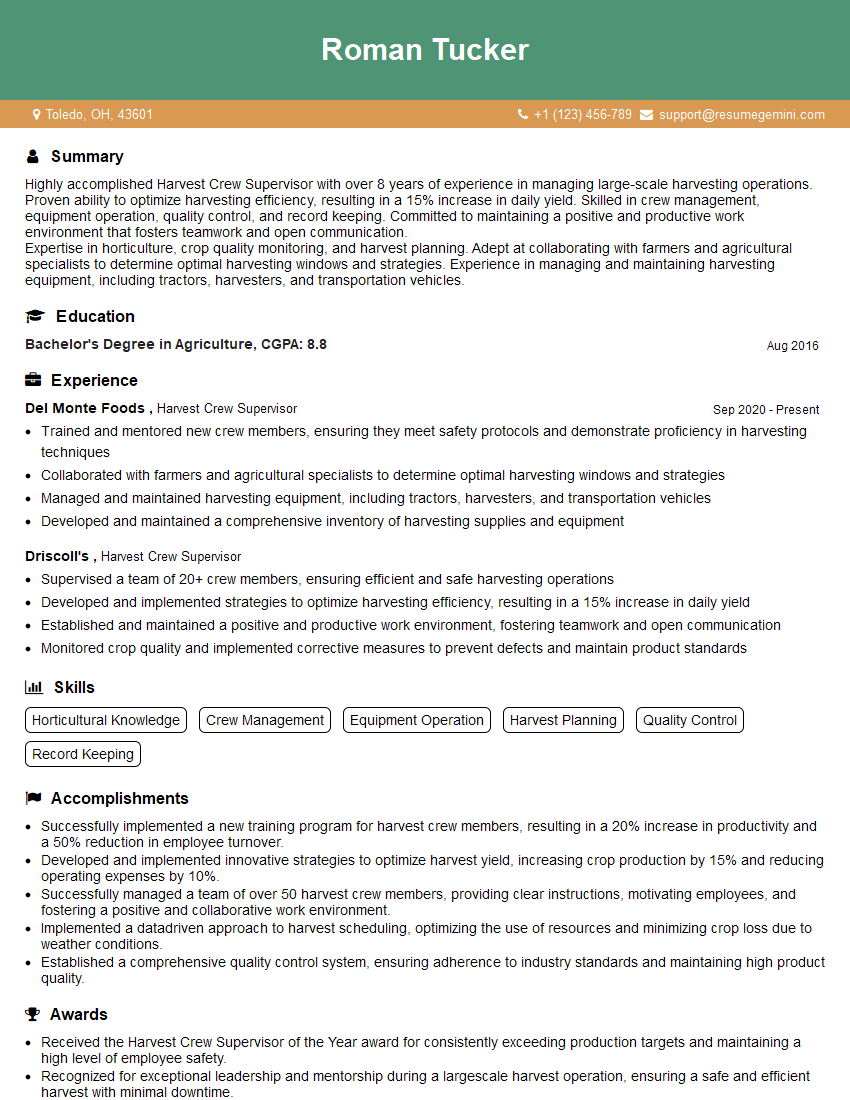

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with preventative maintenance on cotton harvesting equipment.

Preventative maintenance is paramount to avoiding costly downtime during the crucial harvesting season. My experience involves a rigorous schedule incorporating daily, weekly, and seasonal checks.

Daily Checks: This includes inspecting belts, hoses, lubricating moving parts, and checking fluid levels. A simple example is checking the oil level in the engine and transmission before each day’s operation. A low oil level can cause serious engine damage.

Weekly Checks: This involves a more thorough inspection of critical components, such as the picking mechanism, cleaning system, and gathering parts. We might use this time to tighten bolts, clean filters, and adjust components for optimal performance.

Seasonal Checks: Before the harvest begins and after it concludes, a comprehensive inspection and servicing are performed. This may include replacing worn parts, overhauling the engine, or repairing any damages identified during the season. For example, we might replace worn pickers or overhaul the seed cotton cleaning system.

These checks are meticulously documented, ensuring traceability and facilitating proactive maintenance to minimize breakdowns.

Q 17. How do you handle unexpected equipment failures during the harvesting season?

Unexpected equipment failures are inevitable during a long harvest season. Our response involves a combination of preparation, efficient troubleshooting, and resourcefulness.

On-board diagnostics: Modern harvesters have advanced diagnostic systems that help pinpoint the source of the problem. Understanding these systems is vital for quickly identifying and addressing issues.

Spare Parts Inventory: We maintain a comprehensive inventory of common replacement parts, such as belts, hoses, and filters, to minimize downtime. Knowing where parts are and accessing them quickly is crucial.

Communication Network: We have established a robust communication network with a reliable mechanic and parts supplier. This enables prompt assistance and quick access to replacement parts.

Troubleshooting Skills: My experience allows me to diagnose many problems on-site, often getting the harvester operational again in a short period. I can diagnose issues based on error codes or symptoms and rectify them quickly. I also know when to call in a professional mechanic for specialized repair.

The ultimate goal is to minimize disruption to the harvest schedule and ensure maximum yield retrieval.

Q 18. What are the key performance indicators (KPIs) you monitor during cotton harvesting?

Key Performance Indicators (KPIs) are essential for tracking harvesting efficiency and overall productivity. We monitor several KPIs, including:

Yield per acre: This tracks the total amount of cotton harvested per unit of land, providing a direct measure of productivity.

Harvesting speed: This indicates the efficiency of the harvester’s operation and helps identify potential areas for improvement. A slower speed might indicate issues with the picking mechanism.

Moisture content: This is crucial for determining fiber quality and managing post-harvest processes. High moisture content can lead to problems during storage.

Machine operating time vs. downtime: Tracking this ratio provides insight into the reliability of the equipment and identifies areas for preventative maintenance improvements. A high downtime indicates inefficiencies needing attention.

Foreign material content: This measures the amount of unwanted material (leaves, trash, etc.) mixed with the cotton, reflecting the effectiveness of the cleaning system.

Regularly analyzing these KPIs provides valuable insights for optimizing harvesting operations, maximizing efficiency and profitability.

Q 19. How do you communicate effectively with other members of the harvesting crew?

Effective communication is essential for a successful cotton harvest. This involves clear, concise communication, proactive information sharing, and fostering a collaborative team environment.

Pre-harvest briefings: Before commencing the harvest, we hold briefings to discuss the field conditions, planned routes, potential challenges, and safety procedures.

Two-way radios: Two-way radios provide instant communication between the harvester operator, the truck driver, and the field supervisor, enabling quick responses to any unforeseen issues.

Regular check-ins: Throughout the day, we conduct regular check-ins to address concerns, coordinate activities, and ensure the smooth flow of operations.

Post-harvest debriefings: At the end of each day or week, we conduct debriefings to discuss performance, identify areas for improvement, and address any issues that need attention.

Open communication ensures everybody is aware of what’s happening, preventing potential misunderstandings and enabling efficient problem-solving.

Q 20. Explain your understanding of cotton harvesting regulations and safety standards.

Understanding and adhering to cotton harvesting regulations and safety standards is paramount. This includes both federal and state regulations regarding:

Environmental protection: Regulations concerning soil conservation, water quality, and the responsible disposal of waste materials.

Worker safety: Following safety guidelines related to operating machinery, proper personal protective equipment (PPE) usage, and emergency procedures.

Machine compliance: Ensuring the harvester complies with all relevant safety and emissions standards.

Transportation regulations: Adhering to regulations related to the transport of harvested cotton, including weight limits and safe driving practices.

I am up-to-date on all relevant regulations in my area and ensure that all aspects of our operations are conducted safely and in compliance with all applicable laws and best practices. We regularly attend safety training and refresh our knowledge of current regulations.

Q 21. Describe your experience with yield monitoring and data analysis in cotton harvesting.

Yield monitoring and data analysis are critical for improving harvesting efficiency and decision-making. Modern cotton harvesters are equipped with yield monitoring systems that collect data on various parameters.

Data Collection: The system collects data such as yield per acre, moisture content, harvesting speed, and machine operating time. This data is often collected and stored digitally for future analysis.

Data Analysis: We use this data to identify areas in the field with high or low yields and understand factors influencing these differences. This information might reveal insights into soil nutrient levels, irrigation effectiveness, or the impact of pest control strategies.

Decision-Making: By analyzing yield data, we can adjust harvesting strategies and optimize future planting plans. For instance, if we identify an area consistently underperforming, we may analyze soil samples, review planting methods and consider adjustments for the following year.

Precision Agriculture: Yield monitoring supports precision agriculture techniques by informing targeted input management, ensuring resources are utilized efficiently.

Data analysis assists in improving overall farm productivity and profitability over time.

Q 22. How do you adapt your harvesting strategy based on real-time data and feedback?

Adapting harvesting strategies based on real-time data is crucial for maximizing yield and efficiency. We use various sensors and telematics integrated into modern cotton harvesters. These provide data points like moisture content, boll maturity, and machine performance metrics (e.g., picking rate, cleaning efficiency). For instance, if the moisture sensor indicates high moisture content in a specific field section, we might adjust the harvesting speed to prevent clogging or damage to the cotton. Similarly, if a sensor shows low boll maturity in one area, we may choose to postpone harvesting in that section to allow for optimal maturation. This dynamic approach, relying on real-time feedback, avoids unnecessary waste and improves the quality of the harvested cotton. Think of it like a chef adjusting their cooking based on the food’s temperature – constant monitoring and adjustments ensure the best outcome.

Q 23. What is your experience with using technology to improve cotton harvesting efficiency?

Technology has revolutionized cotton harvesting. GPS-guided harvesters ensure precise row following, minimizing overlaps and reducing fuel consumption. Yield monitoring systems provide real-time data on harvesting rates, allowing for immediate adjustments to optimize the process. We also utilize machine learning algorithms to predict potential mechanical issues before they arise. For example, analyzing vibration data from the harvester’s components can signal impending bearing failure, enabling preemptive maintenance. This proactive approach prevents costly downtime during peak harvesting season. Imagine having a ‘check-engine’ light for your cotton harvester, predicting problems before they occur – a massive boost to efficiency and cost-effectiveness.

Q 24. How do you address issues related to cotton harvesting waste and environmental impact?

Minimizing waste and environmental impact is paramount. We employ best practices like careful machine setup to reduce leaf and trash inclusion in the harvested cotton. Regular maintenance of the cleaning systems within the harvester ensures efficient separation of cotton from debris. We also focus on minimizing soil compaction by utilizing appropriate tire pressures and avoiding harvesting in excessively wet conditions. Furthermore, we adhere to strict regulations regarding pesticide application, proper disposal of waste materials, and fuel-efficient operation of the equipment. It’s about sustainable practices – maximizing yield while protecting the environment for future harvests. We treat the land as a long-term asset, not just a short-term resource.

Q 25. What are your strategies for maximizing the efficiency of the cotton harvesting process?

Maximizing efficiency involves several strategies. Careful field planning, including optimizing harvest routes and field layouts, is critical. Ensuring proper machine maintenance and pre-harvest inspections prevent costly downtime. Skilled operators play a vital role; well-trained personnel maximize harvester performance. Using GPS guidance systems, we reduce overlaps and improve fuel efficiency. Efficient communication and coordination among the harvesting team are crucial for smooth operation and quick response to any issues. It’s about synergy – a well-coordinated effort from planning to execution, making the most of every minute of harvest time. It’s not just about the machine; it’s the entire operation.

Q 26. How do you train new operators on the safe and effective operation of cotton harvesters?

Training new operators is a multi-stage process. We start with classroom instruction covering harvester mechanics, safety procedures, and operational best practices. This includes hands-on training with simulations and virtual reality to familiarize operators with the equipment before actual field operation. Following classroom training, operators undergo supervised field training, starting with simple tasks and gradually progressing to more complex operations. Regular performance monitoring and feedback sessions are crucial for continuous improvement and refining skills. Safety is paramount, so we emphasize safe operation procedures throughout the training, ensuring operators understand and apply safety protocols effectively. We essentially build a strong foundation, then provide the hands-on experience needed for proficiency.

Q 27. Describe your experience with different types of cotton (e.g., upland, Pima).

My experience encompasses various cotton types. Upland cotton, the most widely grown variety, requires a different harvesting approach compared to Pima cotton, known for its extra-long staple fibers. Upland cotton often requires faster harvesting speeds, while Pima’s delicate fibers necessitate gentler handling and adjustments to the harvester’s settings. For example, we might use different spindle speeds and cleaning intensities depending on the cotton type. The key is adaptability. We adjust our strategies based on the specific characteristics of each variety to ensure optimal yield and fiber quality. Think of it like tailoring your cooking approach to different ingredients – each requires a unique method to achieve the best results.

Q 28. How do you manage and mitigate the risk of equipment downtime during peak harvesting season?

Managing equipment downtime during peak season is critical. We employ a preventative maintenance program with regular inspections and scheduled servicing. This includes proactive checks of crucial components and timely replacement of worn parts. A well-stocked parts inventory minimizes delays caused by part shortages. Our team undergoes specialized training in troubleshooting and quick repairs. Furthermore, we use predictive maintenance technologies, leveraging data analytics to anticipate potential failures. It’s about proactive planning and well-trained personnel – preventing issues before they lead to downtime. It’s like having a skilled mechanic who can anticipate and address potential problems before they disrupt a race car’s performance.

Key Topics to Learn for Cotton Harvester Operation Interview

- Machine Operation & Maintenance: Understanding the mechanical components, hydraulic systems, and electronic controls of a cotton harvester. This includes preventative maintenance procedures and troubleshooting common malfunctions.

- Harvesting Techniques: Mastering optimal harvesting speeds, techniques for efficient picking, and adjustments needed for varying field conditions (e.g., terrain, crop density).

- Safety Procedures: Knowledge of all relevant safety regulations, emergency protocols, and personal protective equipment (PPE) requirements for operating a cotton harvester.

- Yield Monitoring & Data Analysis: Understanding how to monitor harvesting yields, interpret data from onboard computers, and make adjustments to optimize efficiency and quality.

- Module Handling & Transportation: Safe and efficient handling of harvested cotton modules, including loading, unloading, and transportation to storage facilities.

- Environmental Awareness: Understanding the environmental impact of cotton harvesting and best practices for minimizing negative effects, such as soil compaction and water usage.

- Problem-Solving & Troubleshooting: Demonstrating the ability to diagnose and resolve mechanical issues, make quick decisions in challenging situations, and prioritize tasks effectively.

Next Steps

Mastering Cotton Harvester Operation opens doors to a rewarding career with excellent growth potential within the agricultural industry. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Take advantage of the examples of resumes tailored to Cotton Harvester Operation provided to further strengthen your application and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good