Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Cotton Picker Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Cotton Picker Operation Interview

Q 1. Describe your experience operating different types of cotton pickers.

My experience encompasses operating various cotton picker models, from traditional spindle pickers to more advanced roller-type machines and even some strip pickers. Spindle pickers, for example, are known for their gentle handling of the cotton bolls, minimizing fiber damage, but they are generally slower. Roller-type pickers are significantly faster and more efficient, processing larger volumes in a shorter time. However, they can be more prone to damaging the cotton if not properly maintained and operated. I’ve worked with John Deere, Claas, and Case IH models, each with its unique features and operational nuances that I’ve mastered through extensive hands-on experience and continuous training. For instance, learning to adjust the spindle speed on a spindle picker based on boll maturity is crucial for optimal yield and minimal fiber breakage. Similarly, understanding the optimal roller pressure in a roller picker is essential for maintaining efficiency and preventing damage.

Q 2. Explain the process of pre-harvest preparation for optimal cotton picking.

Pre-harvest preparation is critical for a smooth and efficient cotton picking operation. It starts with scouting the field to assess the maturity of the cotton bolls. Ideally, you want the majority of bolls to be open and ready for harvest. Next comes field preparation; this involves clearing any obstacles like rocks, debris, and other impediments that could damage the picker. This may involve pre-harvest weed control and any necessary adjustments to irrigation scheduling. Furthermore, I carefully check the cotton picker itself. This includes inspections of the picking mechanism, cleaning systems, and seed cotton transport systems. This often involves lubricating moving parts, tightening bolts, and replacing worn-out components. Ensuring the machine’s readiness before entering the field is key to preventing breakdowns and maintaining efficiency. This pre-emptive step saves significant time and effort during harvesting.

Q 3. How do you identify and address common mechanical issues in a cotton picker?

Identifying and addressing mechanical issues swiftly is vital for maximizing uptime. I’ve developed a systematic approach to troubleshooting. It starts with listening – unusual noises, like a grinding sound or a change in engine pitch, often signal a problem. Then I visually inspect components, checking for leaks, broken parts, or anything out of the ordinary. Common issues I’ve encountered include clogged cleaning systems (requiring thorough cleaning and potentially part replacement), issues with the picking mechanism (like worn spindles or rollers), and problems with the seed cotton transport system (such as belt slippage or blockages). I regularly check fluid levels (engine oil, hydraulic fluid) and air filters to prevent larger issues. My experience allows me to diagnose and fix most problems on-site, minimizing downtime. In more complex situations, I can effectively communicate the problem to a mechanic, providing the necessary details for prompt resolution. This proactive approach minimizes machine downtime and keeps the harvest on track.

Q 4. What safety procedures do you follow while operating a cotton picker?

Safety is paramount. Before starting any operation, I perform a thorough pre-operation inspection of the machine, ensuring all guards are in place and all safety features are functional. I always wear appropriate Personal Protective Equipment (PPE), including safety glasses, hearing protection, and sturdy work boots. I’m mindful of potential hazards, like moving parts, high-voltage equipment, and the risk of entrapment. I follow all company safety guidelines and regulations and carefully observe my surroundings to avoid collisions with other equipment or personnel. I also understand the importance of proper shut-down procedures and communicate effectively with anyone working near the picker. Furthermore, I consistently monitor my physical and mental state to avoid operating under fatigue or stress, which can greatly increase the risk of accidents.

Q 5. How do you maintain the optimal speed and efficiency of the cotton picker?

Maintaining optimal speed and efficiency depends on several factors. Firstly, adjusting the picker’s speed to match the field conditions and cotton maturity is crucial. Too fast, and the quality suffers; too slow, and productivity is compromised. Regular calibration of the picking mechanism ensures optimal performance. Cleanliness is paramount; consistent cleaning of the cleaning systems prevents blockages and maintains optimal airflow for efficient seed cotton separation. Proper maintenance, as previously discussed, also contributes to efficiency. I continuously monitor the picker’s performance, paying attention to indicators like seed cotton moisture content and machine capacity. This involves making timely adjustments based on data collected to optimize both speed and output. Regularly reviewing the machine’s performance data enables proactive adjustments, preventing potential issues and keeping the harvesting process efficient.

Q 6. Explain your understanding of different cotton varieties and their impact on harvesting.

Different cotton varieties significantly impact harvesting. Some varieties have stronger bolls that may require more robust picking mechanisms to avoid damage, while others have a higher tendency to shed, affecting the efficiency of the harvest. Fiber length also matters. Longer fibers are more likely to be damaged by certain picking methods. Understanding the characteristics of each variety I’m harvesting, such as boll size, boll retention, and fiber strength, allows me to adjust the picker settings accordingly – optimizing speed, spindle or roller pressure and even the cleaning system – to minimize loss and maximize yield. For example, a variety known for weak bolls would require a slower speed and gentler picking action compared to a variety with strong, tightly-held bolls.

Q 7. Describe your experience with different types of cotton harvesting systems.

My experience includes working with different cotton harvesting systems, including the conventional cotton pickers already mentioned, along with strip pickers and even some hand-harvesting methods in smaller, specialized situations. Strip pickers remove the entire plant, including the cotton bolls, which are later processed separately. This method is efficient in certain conditions but can impact soil health and requires more extensive post-harvest processing. Hand-harvesting, while labor-intensive, offers greater control and precision, which is beneficial for specialty cotton varieties or research plots. Understanding the strengths and limitations of each system helps me select the most appropriate method based on factors like the field size, cotton variety, and available resources. The choice ultimately aims to maximize both efficiency and cotton quality.

Q 8. How do you ensure the quality of the harvested cotton?

Ensuring high-quality harvested cotton involves a multi-faceted approach, starting long before the picker even touches the field. It begins with proper crop management—choosing the right cotton variety for the soil and climate, implementing effective pest and disease control, and employing sound irrigation techniques. All these factors directly influence fiber length, strength, and overall quality.

During harvesting, the focus shifts to the cotton picker’s settings. We carefully monitor the machine’s speed, the drum’s rotation, and the cleaning system’s efficiency. Too fast, and we risk damaging the fibers; too slow, and we lose productivity. Regular cleaning of the machine prevents contamination from previous harvests or debris. We also pay close attention to the moisture content of the harvested cotton, aiming for an optimal level to prevent deterioration and maintain fiber quality. Finally, prompt and careful handling of the harvested cotton, avoiding prolonged exposure to sunlight and rain, is crucial to preserving its quality before ginning.

For example, I once noticed a slight increase in leaf contamination during a particular harvest. By adjusting the picker’s cleaning system and slowing the harvesting speed slightly, we significantly reduced the leaf content, improving the final product’s grade and fetching a better price for the farmer.

Q 9. How do you manage cotton module building and handling?

Cotton module building and handling is a critical stage that directly impacts the quality and marketability of the harvested cotton. Modules are large, compressed bales of cotton, typically weighing several tons, providing efficient storage and transportation. Efficient module building requires a well-maintained and calibrated module builder attached to the cotton picker. This ensures consistent density and size of the modules, preventing damage and streamlining logistics.

Proper handling involves careful placement of modules in designated areas, avoiding damage from exposure to weather elements or equipment. We use specialized equipment like module trailers and trucks designed for safe transport. Accurate record-keeping of module location, weight, and quality parameters is essential for efficient inventory management and traceability. I’ve personally overseen the implementation of a new module handling system that reduced transportation costs by 15% by optimizing truck loading patterns.

Q 10. What is your experience with preventative maintenance on a cotton picker?

Preventative maintenance is the cornerstone of efficient and reliable cotton picker operation. It significantly reduces downtime and extends the lifespan of the machine. My preventative maintenance routine includes regular inspections of all critical components such as the picking drums, cleaning systems, conveyors, and the module builder. This involves checking for wear and tear, lubrication levels, and potential issues before they escalate into major problems.

- Daily Checks: Inspecting belts, hoses, and fluid levels before each day’s operation.

- Weekly Checks: More thorough inspections of major components and cleaning of critical areas.

- Monthly Checks: More detailed inspections, potentially including disassembly and cleaning of specific components.

- Seasonal Checks: Before and after the harvesting season, complete overhauls and servicing are conducted.

I always meticulously document all maintenance activities, including parts replaced and any adjustments made. This detailed record helps us identify trends, predict potential failures, and optimize our maintenance schedule. For instance, by consistently monitoring the wear on our picking drums, we were able to anticipate their replacement, scheduling the maintenance during a less busy period, preventing significant downtime.

Q 11. How do you handle unexpected equipment malfunctions during harvesting?

Unexpected equipment malfunctions are an inherent risk in cotton harvesting. My approach focuses on quick diagnosis and efficient problem-solving. We carry a comprehensive toolkit containing spare parts for frequently failing components. The first step is to safely stop the machine and assess the situation. We use troubleshooting guides and contact technical support when necessary. If the problem is minor, we might be able to fix it on-site. If it’s a more significant issue, we have a system in place for quickly calling in a repair crew or switching to a backup machine.

Communication is key. We keep the farm manager and other relevant stakeholders updated on the situation and the estimated downtime. I also emphasize the importance of regular training for the team, empowering them to identify and address minor issues independently. In one instance, a sudden hydraulic leak caused significant downtime. Our quick response, utilizing our backup machine while a repair crew fixed the issue, minimized the impact on the overall harvest.

Q 12. Describe your experience with GPS-guided cotton harvesting systems.

My experience with GPS-guided cotton harvesting systems is extensive. These systems significantly improve harvesting efficiency and reduce overlaps and missed areas, leading to cost savings and maximizing yield. GPS guides the cotton picker using satellite signals to precisely follow pre-programmed routes, ensuring that every row is harvested effectively and once. The system provides real-time data on the area covered, the speed of harvesting and other critical parameters.

The precision offered by GPS allows for optimized harvesting strategies, such as targeting specific areas with higher yields or managing variations in field conditions. This level of control translates into a substantial reduction in time and resources needed for harvesting, maximizing profitability. I’ve worked with several GPS systems and have found that proper calibration and integration with other farm management systems are key to achieving optimal performance.

Q 13. How do you calculate harvesting yield and efficiency?

Calculating harvesting yield and efficiency involves several steps. First, we measure the harvested area using GPS data or field maps. We then weigh the harvested cotton modules to determine the total weight. The yield is typically expressed in pounds or kilograms per acre (or hectare). To calculate efficiency, we divide the harvested area by the time taken for the harvest. This gives us a rate in acres (or hectares) per hour.

We also consider factors like machine downtime and the number of operators involved. For example, Yield (lbs/acre) = Total weight of cotton (lbs) / Harvested area (acres) and Efficiency (acres/hour) = Harvested area (acres) / Harvesting time (hours). Comparing these figures to previous years and industry benchmarks allows us to identify areas for improvement and optimize our harvesting strategies. I routinely analyze these metrics to identify bottlenecks and improve overall productivity.

Q 14. How do you monitor and adjust the picker’s settings for optimal performance?

Monitoring and adjusting the picker’s settings for optimal performance is a continuous process. We monitor various parameters throughout the harvest, including the machine’s speed, the picking drum’s rotation speed, the cleaning system’s efficiency, and the moisture content of the harvested cotton. These settings must be adjusted based on factors such as the cotton’s maturity, the density of the crop, and weather conditions.

For instance, if the cotton is drier than usual, we might need to reduce the picking drum’s speed to prevent fiber damage. If the crop is dense, we might slow the forward speed of the machine to ensure complete harvesting. Regularly checking the machine’s sensors and using on-board computer systems aids in making data-driven decisions for adjustments. We also collect samples of harvested cotton to assess the quality and make necessary adjustments to the picker settings accordingly. Experience plays a significant role in fine-tuning these settings for the best results, optimizing both yield and quality.

Q 15. What is your experience with various cotton picker attachments and accessories?

My experience encompasses a wide range of cotton picker attachments and accessories. I’m proficient with various types of spindles, including those designed for different boll sizes and cotton varieties. I’ve worked extensively with different types of cleaning systems, from simple trash removal systems to more advanced ones that utilize air streams and screens to separate cotton from debris. I’m also familiar with various types of conveyors and unloading mechanisms, adapting my approach based on the specific needs of the field and the picker’s capacity. For example, I’ve used both side-delivery and rear-delivery systems, choosing the optimal setup based on factors like field size and terrain. Furthermore, I’m experienced with GPS-guided steering systems, which significantly increase harvesting efficiency and reduce overlap. Finally, I’m familiar with different types of sensors and monitoring equipment that help track performance and identify potential issues early.

- Spindle Types: I’ve used both single-row and multi-row spindles, adjusting the settings based on the maturity and density of the cotton.

- Cleaning Systems: My experience includes working with both air-based and mechanical cleaning systems, optimizing their performance according to the type of debris present in the field.

- Unloading Systems: I understand the nuances of side- and rear-delivery systems and can adjust the setup for optimal unloading efficiency and to minimize damage to the cotton.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of cotton fiber properties and their impact on harvesting.

Understanding cotton fiber properties is crucial for efficient harvesting. Fiber length, strength, maturity, and micronaire (a measure of fiber fineness) directly impact the harvesting process. Longer, stronger fibers are less likely to be damaged during picking, resulting in higher quality and yield. Conversely, shorter, weaker fibers or immature bolls are more prone to breakage and loss. High micronaire fibers can sometimes be more difficult to pick cleanly, potentially leading to more trash contamination. For instance, a variety known for short, weak fibers requires a gentler picking process and potentially different spindle settings to minimize damage and loss. Similarly, harvesting fields with immature bolls demands careful adjustment of the picker’s settings to avoid damaging the developing cotton.

I consistently monitor fiber properties through reports and on-site assessments. This allows me to adapt harvesting techniques—speed, spindle adjustments, and cleaning system settings—to optimize yields while preserving fiber quality. Think of it like carefully handling delicate fruit; you need a different approach for picking strawberries compared to picking oranges.

Q 17. How do you ensure the safety of yourself and others during the harvesting process?

Safety is paramount during cotton harvesting. Before each harvest, I conduct a thorough pre-operational inspection of the cotton picker, ensuring all safety features are functioning correctly. This includes checking the emergency stops, guarding mechanisms around moving parts, and the condition of the lighting and warning systems. While operating the machine, I always adhere to safe operating procedures, maintaining awareness of my surroundings and observing all traffic rules. I wear appropriate personal protective equipment (PPE), including hearing protection, safety glasses, and sturdy work boots. Communication is key; I communicate frequently with other personnel working in the field, using radios or hand signals to ensure everyone’s safety. For example, before any maintenance or repair, I ensure the machine is completely shut down and locked out to prevent accidental activation.

Regular training and refresher courses keep me up-to-date on the latest safety protocols and procedures. I believe that a proactive approach to safety is not just a requirement but a personal commitment to my well-being and that of my colleagues.

Q 18. Describe your experience working in a team environment during harvesting.

Harvesting cotton is a team effort. I’ve worked extensively in team environments, coordinating with other operators, field supervisors, and maintenance personnel. Effective communication is essential. We use radios and regular meetings to share information about field conditions, equipment issues, and any safety concerns. For instance, I’ve often collaborated with other operators to strategically divide the workload, optimizing our overall efficiency and minimizing downtime. In the event of equipment malfunctions, we work collaboratively to troubleshoot problems or call for support. A strong team dynamic ensures smooth operations, enhances productivity, and promotes a safe working environment. We help each other, share knowledge, and consistently strive for improvement.

In essence, it’s about teamwork, shared responsibility, and consistent communication, allowing us to overcome challenges efficiently and successfully complete our harvests.

Q 19. How do you handle challenging weather conditions during cotton harvesting?

Weather conditions significantly impact cotton harvesting. Heavy rain can make fields muddy and inaccessible, causing damage to the soil and hindering the picker’s operation. Strong winds can damage plants, making it difficult to harvest undamaged cotton, and potentially causing damage to the machine itself. Excessive heat can impact the productivity of both the machine and the crew. I adjust my harvesting strategy according to the weather conditions. For example, in wet conditions, I might reduce my harvesting speed to prevent damaging the soil and clogging the machine. If strong winds are forecast, I might postpone harvesting or alter my schedule to optimize working conditions.

Knowing the expected weather forecast is crucial for planning our daily harvesting schedule. Having a contingency plan, such as alternative harvesting strategies or the ability to shelter the machine if needed, is equally important. It’s about being adaptable and making informed decisions based on the ever-changing weather conditions.

Q 20. What is your experience with data collection and reporting related to cotton harvesting?

Data collection and reporting are integral to modern cotton harvesting. I’m experienced in using various technologies to gather data on harvesting parameters, such as yield, harvesting speed, machine performance, and location data using GPS. This information is typically collected via onboard computer systems integrated into the cotton picker. I am comfortable using this data to generate reports that detail daily progress, overall harvest yields, and potential areas for improvement. These reports are crucial for tracking harvest efficiency and identifying potential issues in a timely manner. For example, analyzing data on harvesting speed and yield can help to optimize machine settings and route planning for future harvests. This data-driven approach to harvesting allows for continuous improvement and increased efficiency.

I’m proficient in interpreting these data reports and using that information to refine harvesting strategies for future harvests, essentially utilizing the data to learn and optimize the overall process.

Q 21. How do you troubleshoot issues related to cotton picker sensors and electronics?

Troubleshooting cotton picker sensors and electronics requires a systematic approach. I begin by carefully reviewing the error codes and diagnostic messages displayed on the machine’s onboard computer. I then systematically check connections, wiring, and sensor readings using the appropriate diagnostic tools. This often includes using multimeters to check for voltage and continuity. For example, if a sensor indicating a blockage in the cleaning system is malfunctioning, I would first check the sensor’s wiring for any damage or loose connections before replacing the sensor itself.

If the issue is more complex, I would consult the machine’s service manual or contact the manufacturer’s support team for assistance. However, through experience, I’ve gained a comprehensive understanding of the common issues and troubleshooting procedures for various cotton picker models and can effectively resolve a majority of problems independently. My systematic approach is key to ensuring a quick and efficient resolution to any electronic or sensor-related issues.

Q 22. Explain your experience with different types of cotton picker cleaning systems.

Cotton picker cleaning systems are crucial for maintaining harvest efficiency and fiber quality. My experience encompasses several types, each with its strengths and weaknesses. The most common are the saw-tooth cleaning systems, which utilize a series of rotating saws to remove trash and debris from the harvested cotton. These are effective but can sometimes damage the fibers if not properly adjusted. I’ve also worked extensively with air-flow cleaning systems which use a combination of air pressure and screens to separate cotton from foreign matter. This method is gentler on the fibers and generally produces cleaner cotton but can be less effective in extremely trashy conditions. Finally, some newer machines incorporate hybrid systems combining elements of both saw-tooth and air-flow methods, aiming for optimal cleaning efficiency and fiber protection. For instance, I once worked with a machine that used a saw-tooth system for initial cleaning, followed by an air-flow system for final purification; this resulted in a significant reduction in trash content and improved overall lint quality compared to using just one method. The choice of cleaning system often depends on factors like the type of cotton being harvested, the field conditions, and the desired level of cleanliness.

Q 23. How do you handle and dispose of waste materials generated during harvesting?

Waste management during cotton harvesting is critical for environmental compliance and responsible farming practices. The primary waste materials are typically cotton trash (leaves, stems, bolls), and occasionally, some soil and other foreign materials. My approach involves a multi-step process. Firstly, I ensure that the cotton picker’s cleaning system is operating at peak efficiency to minimize the amount of trash mixed with the cotton. Secondly, we carefully collect and manage the waste materials that are separated by the picker. This typically involves utilizing the picker’s built-in waste collection systems or, in some cases, employing specialized trailers to haul the waste away. Lastly, we typically dispose of the waste through responsible methods. This could involve composting the organic material to enrich the soil or carefully disposing of it in designated areas to avoid environmental contamination. In my experience, adhering to strict local and regional regulations concerning waste management is crucial, and I meticulously document all waste disposal procedures to ensure complete compliance.

Q 24. Describe your experience with the different types of cotton modules and their handling.

Cotton modules are large, tightly compressed units of cotton, typically weighing several thousand pounds. They are crucial for efficient transport and storage of the harvested crop. I have experience handling several types, including round modules (which are cylindrical), and square modules (which are rectangular). Round modules are generally better suited for handling and transportation on larger farms where efficient movement is paramount. Square modules, on the other hand, offer better space utilization in storage, especially when storage space is limited. The handling of these modules is crucial. It involves using specialized equipment like module builders and transporters to efficiently and safely move these large units. For instance, I’ve used forklifts, module handlers, and even large trucks equipped with cranes. Safety precautions, such as wearing appropriate safety gear and ensuring proper machine maintenance, are absolutely essential when handling modules, given their substantial weight and the potential for accidents.

Q 25. How do you comply with all relevant safety and environmental regulations?

Compliance with safety and environmental regulations is paramount in cotton harvesting. I rigorously follow all relevant OSHA (Occupational Safety and Health Administration) guidelines regarding machine operation, personal protective equipment (PPE), and safe work practices. This includes regular safety inspections of the equipment, proper training for all personnel involved in the operation, and the strict enforcement of safety rules on the job site. Regarding environmental regulations, I ensure that all waste materials are disposed of in compliance with EPA (Environmental Protection Agency) standards and any other state or local laws. This includes proper handling of pesticides and herbicides, minimizing soil erosion during harvesting, and preventing water pollution from runoff. I maintain detailed records of all safety and environmental practices, ensuring transparency and accountability in all aspects of the operation. Proactive measures, such as regular maintenance of machinery to prevent breakdowns and prompt responses to any safety incidents, are pivotal in maintaining a safe and compliant work environment.

Q 26. What is your knowledge of different types of soil conditions and their effects on harvesting?

Soil conditions significantly impact cotton harvesting. Different soil types present unique challenges. For instance, clay soils can be very sticky, making it difficult for the picker to navigate the field and potentially causing damage to the plants. Conversely, sandy soils might be too loose, making the cotton plants less stable and susceptible to being pulled out of the ground by the picker. Rocky soils pose a high risk of damage to the machinery. My knowledge of soil types allows me to adjust harvesting techniques accordingly. For example, I might slow down the picker’s speed when operating in heavy clay soils to prevent compaction and damage to the plants. In sandy soils, I might adjust the picker’s settings to minimize the risk of pulling up plants. Regular soil testing allows for preemptive measures to adjust harvesting parameters for optimal performance and minimal soil degradation.

Q 27. How do you adapt your harvesting techniques based on varying field conditions?

Adapting harvesting techniques based on field conditions is vital for maximizing efficiency and yield. My approach involves a combination of pre-harvest planning and on-the-go adjustments. Before harvesting, I carefully assess the field’s conditions, including soil type, crop density, and the presence of obstacles. This informs my decisions on the type of equipment to use and the optimal harvesting speed. During harvesting, I constantly monitor the machine’s performance and make adjustments as needed. For example, if I encounter areas with dense vegetation, I might slow the picker down or adjust the picking height to prevent damage. If I notice excessive soil compaction in certain areas, I might modify the route to avoid those areas or utilize different machinery altogether. Real-time assessment and responsive adjustments are key to successful and efficient harvesting under diverse conditions. For instance, I’ve had to modify the route several times during harvesting due to unexpected wet patches or unusually dense growth, which requires making tactical decisions to prevent damages to the plants and equipment.

Q 28. Explain your experience with post-harvest procedures such as cleaning and maintenance.

Post-harvest procedures are crucial for maintaining equipment longevity and ensuring the quality of the harvested cotton. My experience includes thorough cleaning of the cotton picker after each day’s work. This involves removing accumulated trash, cleaning the cleaning systems, and lubricating moving parts. Regular maintenance is equally important, encompassing tasks like checking and replacing worn parts, inspecting hydraulic systems, and verifying the functionality of all components. I adhere to a strict maintenance schedule to prevent major breakdowns and ensure operational efficiency. This includes regular oil changes, filter replacements, and inspections of critical components like belts, chains, and bearings. Additionally, I oversee the storage of the cotton modules, ensuring proper ventilation to prevent deterioration and maintaining cleanliness to minimize the risk of pest infestation. Careful attention to post-harvest procedures is key to maximizing the lifespan of the equipment and ensuring the quality and integrity of the harvested cotton.

Key Topics to Learn for Your Cotton Picker Operation Interview

- Machine Operation & Maintenance: Understanding the mechanical components of a cotton picker, including the picking mechanism, cleaning system, and transportation system. Be prepared to discuss preventative maintenance procedures and troubleshooting common mechanical issues.

- Safety Procedures & Regulations: Demonstrate knowledge of all relevant safety protocols, including operating procedures, emergency shutdowns, and personal protective equipment (PPE) requirements. Be ready to discuss your experience adhering to safety guidelines.

- Harvesting Techniques & Optimization: Explain how to efficiently harvest cotton while minimizing crop damage and maximizing yield. Discuss strategies for adapting to varying field conditions and weather patterns.

- Data Collection & Analysis: Many modern cotton pickers utilize technology to track yield, moisture content, and other relevant data. Be prepared to discuss your experience with data collection and how this information is used to improve efficiency.

- Quality Control & Assessment: Describe the process of assessing the quality of the harvested cotton, including identifying and addressing issues such as contamination or damage. Explain how you ensure the harvested cotton meets industry standards.

- Problem-Solving & Troubleshooting: Be ready to discuss instances where you encountered problems during operation and how you effectively solved them. Highlight your analytical and critical thinking skills in this context.

- Teamwork & Communication: Cotton picking often involves teamwork. Discuss your experience collaborating with others, communicating effectively, and contributing to a positive work environment.

Next Steps

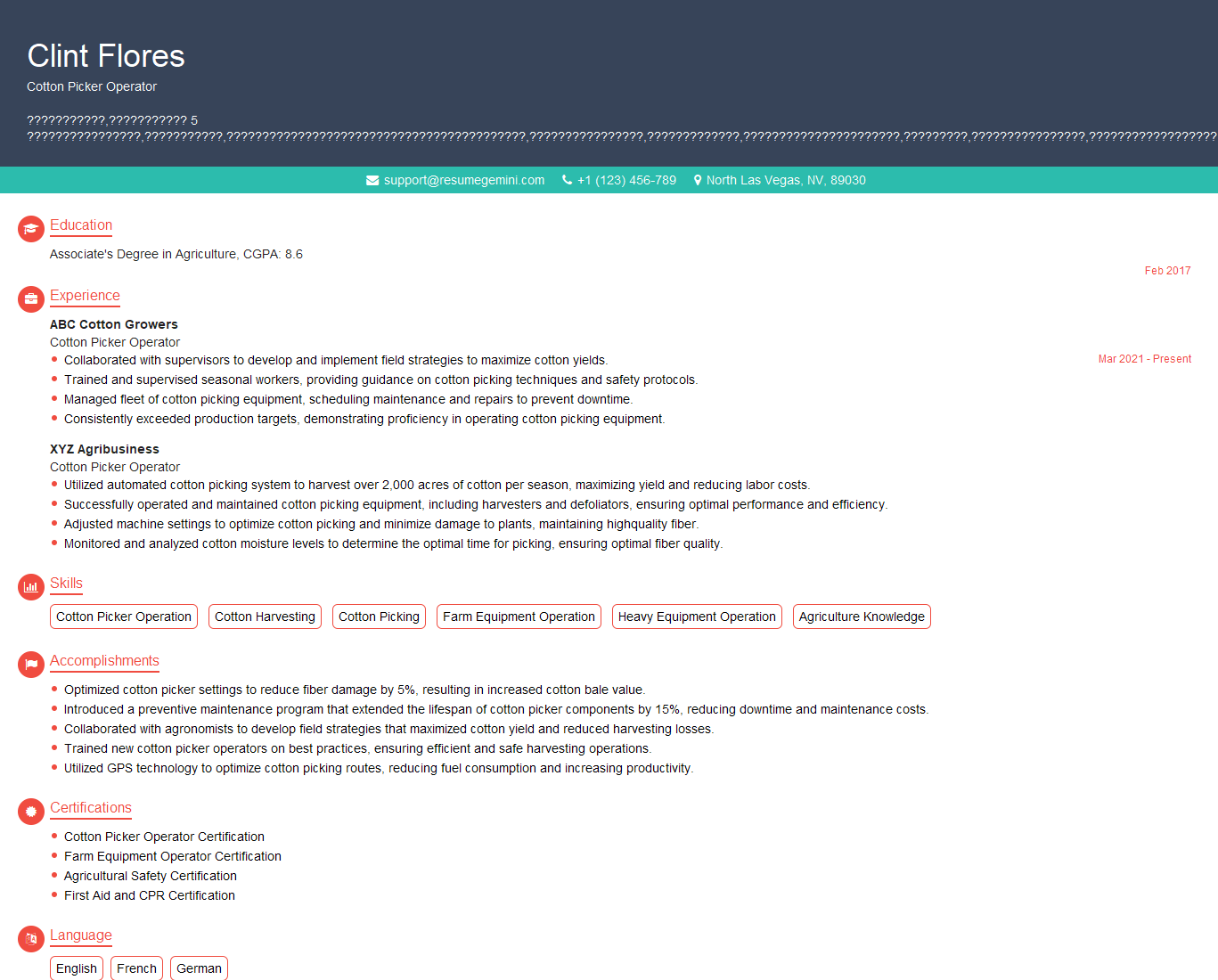

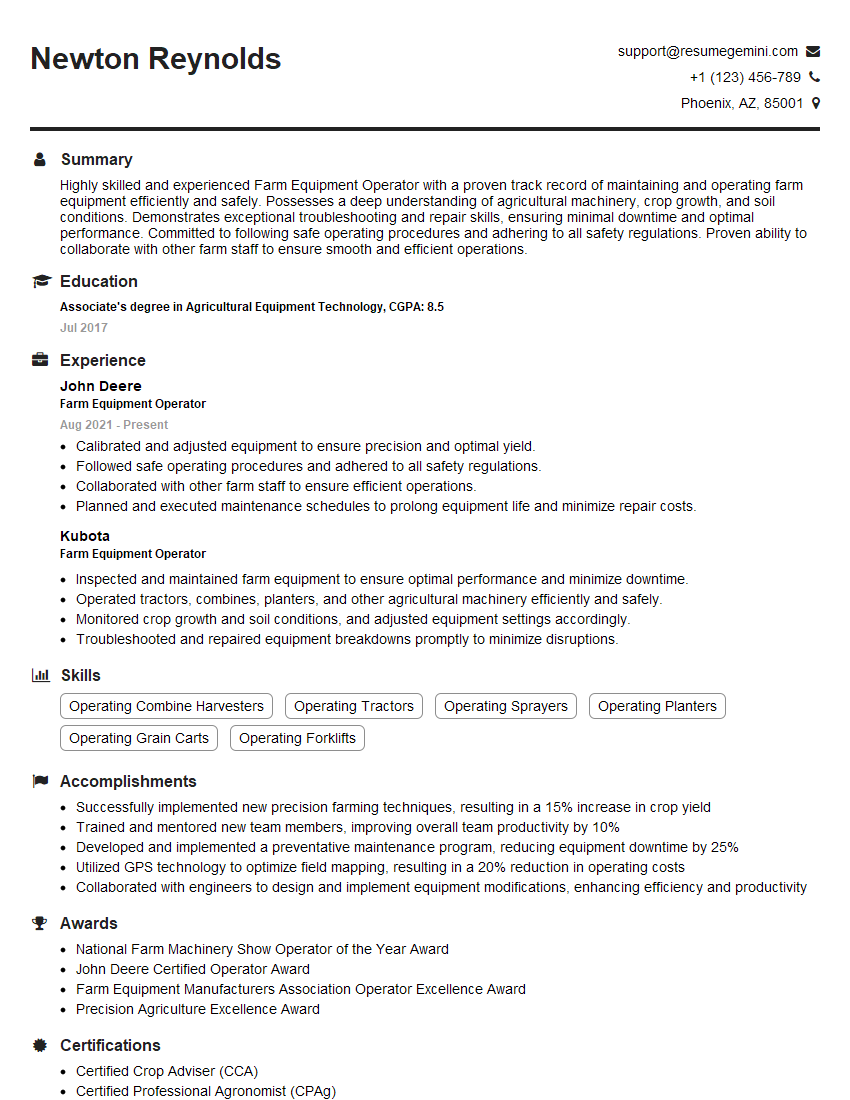

Mastering Cotton Picker Operation can significantly enhance your career prospects within the agricultural industry, opening doors to higher-paying positions and greater responsibilities. To stand out from the competition, a well-crafted, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. We provide examples of resumes tailored to the Cotton Picker Operation field to guide you in crafting the perfect application. Take the next step toward your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good