The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Covering interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Covering Interview

Q 1. Describe your experience with different types of covering materials.

My experience encompasses a wide range of covering materials, from common options like vinyl and fabric to more specialized materials such as automotive wrap vinyl, high-performance laminates, and even specialized textiles for upholstery. Each material presents unique challenges and requires a tailored approach.

- Vinyl: I’ve extensively worked with various grades of vinyl, from budget-friendly options for smaller projects to high-end, cast vinyl films used for vehicle wraps and long-term signage. The difference in flexibility and durability significantly impacts installation techniques.

- Fabric: Experience with fabrics extends to upholstery projects, where precise cutting and careful application are crucial for a professional finish. Different fabrics – from delicate silks to durable canvas – require different handling and adhesive methods.

- Laminates: I’ve worked with both pressure-sensitive and heat-activated laminates, understanding the importance of proper pressure application and temperature control for optimal adhesion and bubble-free results. These are critical for protecting printed surfaces or adding a layer of durability.

Understanding the properties of each material – its flexibility, stretch, thickness, and adhesive compatibility – is fundamental to achieving a successful installation.

Q 2. What safety precautions do you take when installing coverings?

Safety is paramount. My approach follows strict safety protocols, starting with proper personal protective equipment (PPE). This includes safety glasses to protect my eyes from flying debris, gloves to prevent skin irritation from adhesives, and a respirator in environments with strong solvent fumes.

- Work Area Preparation: I always ensure the work area is well-ventilated and free of obstacles to prevent tripping or accidents. Proper lighting is also critical for precise work.

- Tool Safety: Sharp tools like utility knives and scissors are handled with extreme care, and blades are always properly stored when not in use. I regularly inspect tools for damage.

- Adhesive Handling: Adhesives should be handled according to manufacturer’s instructions, ensuring proper ventilation and avoiding skin contact. Flammable adhesives are used with utmost caution, away from any ignition sources.

Beyond the immediate physical hazards, I’m also mindful of ergonomic factors, taking regular breaks to prevent fatigue and strain. A safe working environment leads to better quality work and reduces the risk of workplace injuries.

Q 3. Explain your process for measuring and cutting covering materials.

Accurate measuring and cutting are vital for a seamless finish. My process involves a series of steps:

- Accurate Measurement: I use a measuring tape and a ruler to take precise measurements of the surface to be covered, accounting for any curves or irregularities. I always double-check my measurements to avoid errors.

- Pattern Creation: For complex shapes, I create a paper pattern to ensure an accurate cut on the covering material. This is particularly important for projects involving curves or multiple pieces.

- Material Cutting: I use sharp utility knives or shears, depending on the material, to cut the covering material along the marked lines. A straight, clean cut is essential to avoid fraying or imperfections.

- Test Fitting (if necessary): Before final application, I often perform a test fit to check the accuracy of the cut and ensure a proper fit on the surface. This allows for adjustments before committing to the final installation.

The use of a self-healing cutting mat protects the work surface and prevents the blade from becoming dull. Precision is key, as mistakes in cutting can be difficult to correct.

Q 4. How do you handle difficult installations or unexpected challenges?

Difficult installations or unexpected challenges are a part of the job. My approach involves problem-solving and adaptability:

- Assessment: I carefully assess the nature of the challenge. Is it a material defect? A measurement error? An unforeseen obstacle?

- Research and Planning: I consult relevant resources, including manufacturer’s instructions, online tutorials, and even colleagues for insights into potential solutions. A well-planned approach is key.

- Creative Solutions: I’m not afraid to think outside the box. This might involve using different tools or techniques, adapting the installation method, or incorporating additional materials to address the problem.

- Documentation: If the problem is complex or recurring, I thoroughly document the issue, the solution employed, and any lessons learned to improve future projects.

For example, I once encountered a surface with significant unevenness during a vinyl wrap installation. Instead of abandoning the project, I used a heat gun and careful stretching techniques to conform the vinyl to the surface, creating a smooth finish.

Q 5. What types of adhesives are you familiar with and when would you use each?

My experience spans various adhesives, each suited to different materials and applications:

- Pressure-Sensitive Adhesives (PSA): These are common for vinyl and some fabrics. They activate upon contact and require little to no additional activation. They’re ideal for relatively straightforward applications and easily repositionable.

- Contact Cement: This is a strong adhesive used for bonding heavier materials and requires both surfaces to be coated and allowed to dry before applying. It provides a robust bond but is less forgiving of mistakes. Suitable for materials like laminates.

- li>Heat-Activated Adhesives: Often found in laminates and some specialized films, these adhesives require heat to activate. A heat gun or laminator is used to melt the adhesive and create a secure bond. They are best for creating a consistent, smooth finish on delicate materials.

- Spray Adhesives: These are used for smaller projects or when working with fabrics that require a more even distribution of the adhesive. They’re convenient but require careful application to avoid overspray.

The choice of adhesive depends on the materials being bonded, the expected durability, and the desired level of repositionability.

Q 6. Describe your experience with different application techniques (e.g., heat activation, adhesive application).

I’m proficient in various application techniques:

- Dry Application (PSA): This involves applying pressure-sensitive adhesives directly to the surface. It’s common for vinyl wraps, where precision and careful smoothing are key to avoid air bubbles and wrinkles.

- Wet Application (PSA): Used primarily with vinyl films, this technique involves applying a soapy water solution to the surface and the adhesive backing. The water acts as a lubricant, allowing for repositioning and easier smoothing.

- Heat Activation: For heat-activated laminates and certain films, I use a heat gun or laminator to activate the adhesive. Precise temperature control and even heat distribution are essential to avoid scorching or uneven bonding.

- Adhesive Application (Contact Cement): I apply contact cement to both surfaces, following the manufacturer’s instructions regarding open and closed times. Careful alignment and firm pressure are required for a strong and lasting bond.

The chosen technique impacts the final result and the ease of installation. Understanding the nuances of each technique is crucial for a quality outcome.

Q 7. How do you ensure proper adhesion and prevent bubbling or wrinkling?

Preventing bubbling and wrinkling is crucial for a professional finish. My strategies include:

- Surface Preparation: A clean, smooth, and dry surface is fundamental. Any dust, debris, or imperfections can interfere with adhesion.

- Proper Adhesive Application: Consistent, even application of adhesive is key. Avoid excessive adhesive, which can lead to oozing and wrinkling.

- Squeegee Technique: Using a squeegee or similar tool to smoothly apply pressure and remove air bubbles is vital. Work from the center outward, ensuring all air is expelled.

- Heat Gun (if needed): A heat gun can be used to gently heat and stretch the material, especially in areas with curves or corners, to ensure conformity.

- Proper Material Selection: Choosing the appropriate material for the job is essential. Some materials are more prone to bubbling than others.

For example, when working with vinyl, I use a felt-edged squeegee to avoid scratching the material while effectively removing air bubbles. Patience and attention to detail are crucial in this stage.

Q 8. How do you clean and prepare surfaces before applying coverings?

Proper surface preparation is paramount for a successful covering installation. It ensures the covering adheres properly and lasts for years. The cleaning process depends heavily on the surface material and the existing condition.

- For walls: Begin by removing any loose paint, wallpaper, or debris using a scraper and putty knife. Then, thoroughly clean the surface with a degreaser and a scrub brush, rinsing and drying completely. Any imperfections, such as holes or cracks, should be filled with appropriate filler and sanded smooth.

- For floors: Sweep or vacuum the floor to remove all dust and debris. Depending on the floor type, you may need to use a specialized cleaner. For example, hardwood floors require a cleaner designed specifically for wood, while concrete floors may require a degreaser. Ensure the floor is completely dry before applying any covering.

- For furniture: Dust and wipe down the surfaces with a damp cloth. Remove any existing finishes or imperfections as needed, taking care to protect the surrounding area. For delicate surfaces, a mild cleaner should be used.

Remember, the goal is a clean, dry, and smooth surface, free from dust, grease, or other contaminants that could prevent proper adhesion.

Q 9. What tools and equipment are essential for your work?

The tools and equipment necessary vary depending on the type of covering and the surface being covered, but some essentials include:

- Measuring tools: Tape measure, ruler, square

- Cutting tools: Utility knife, carpet knife (for flooring), scissors (for fabric)

- Surface preparation tools: Scraper, putty knife, sanding block, brushes, cleaning solutions, vacuum cleaner

- Application tools: Roller, squeegee (for vinyl), trowel (for tile adhesive)

- Other tools: Safety glasses, work gloves, knee pads (for flooring), seam roller (for vinyl flooring)

For larger-scale projects, power tools like a floor sander or a pneumatic stapler may be beneficial. Always prioritize safety by using appropriate personal protective equipment (PPE).

Q 10. Explain your experience with different types of surface preparation.

My experience encompasses diverse surface preparation techniques, including:

- Preparing drywall: This involves patching holes, sanding surfaces smooth, and priming the wall to ensure proper paint adhesion if needed under the covering.

- Preparing wood surfaces: This may involve sanding to remove imperfections, filling gaps with wood filler, and applying a primer or sealer to prevent the wood from absorbing moisture from the covering. For example, I once worked on a project where we had to meticulously sand old wooden paneling before applying a new fabric wall covering; the result was a truly stunning transformation.

- Preparing concrete surfaces: This often requires cleaning and degreasing the concrete, repairing any cracks or damage, and applying a primer to enhance adhesion. The correct primer is crucial; incorrect primer on a concrete floor can cause paint blistering.

- Preparing existing tile: This often involves ensuring that the existing tiles are firmly attached and free of cracks or debris. If the tiles are damaged or loose, removal and replacement may be required.

The chosen method is heavily dependent on the covering material and the substrate condition. Thorough inspection and appropriate preparation are always key to a long-lasting and professional finish.

Q 11. Describe your process for removing existing coverings.

Removing existing coverings is a crucial and sometimes challenging step. The method varies widely depending on the type of covering.

- Wallpaper removal: Often involves scoring the wallpaper with a scoring tool, then applying a wallpaper remover solution to soften the adhesive. After sufficient soaking time, use a scraper or steamer to carefully remove the wallpaper. Be mindful of not damaging the underlying wall.

- Carpet removal: Involves carefully cutting the carpet into manageable sections, removing the tack strips along the walls, and then lifting and rolling the carpet sections.

- Tile removal: This usually involves using a hammer and chisel or a demolition hammer to remove individual tiles. Be extremely careful to avoid damage to the underlying substrate. Safety glasses and protective gear are essential.

I always prioritize minimizing damage to the underlying surface. A careful approach and appropriate tools are vital in this stage.

Q 12. How do you manage waste materials during and after installation?

Waste management is a crucial aspect of responsible covering installation. I follow a systematic approach:

- Segregation: I separate different types of waste, such as cardboard packaging, plastic film, and leftover covering material. This makes recycling and disposal much easier.

- Recycling: Wherever possible, I recycle materials like cardboard and plastic.

- Disposal: Waste materials that cannot be recycled are disposed of according to local regulations and in designated disposal containers.

- Clean-up: After completing the job, I thoroughly clean the work area, removing all debris and ensuring proper disposal of cleaning materials.

Environmental responsibility is paramount; I always strive to minimize waste and adhere to environmentally friendly practices.

Q 13. How do you determine the appropriate amount of material needed for a job?

Accurately determining material quantity is essential for avoiding waste and ensuring a project’s success. My process includes:

- Precise measurements: I carefully measure the area to be covered, taking into account any windows, doors, or other obstructions. I always add extra for waste and potential mistakes.

- Material calculations: I utilize the manufacturer’s guidelines to determine the exact amount of material required per square foot or square meter. This varies for different covering types.

- Considering waste: I add a percentage (usually 5-10%) to account for waste due to cutting, trimming, and potential mistakes.

- Supplier consultation: I consult with the supplier for advice and to ensure I have enough material on hand.

Accurate calculations save money and time by avoiding material shortages or excess.

Q 14. What are the common problems encountered during covering installation, and how do you resolve them?

Several common problems can arise during covering installation:

- Uneven surfaces: This can lead to wrinkles or bubbles in the covering. The solution is to properly prepare the surface to ensure it’s smooth and even before installation.

- Poor adhesion: This is often caused by inadequate surface preparation or improper application. The solution involves proper cleaning and degreasing, using appropriate adhesive, and applying the covering correctly.

- Seaming issues: Mismatched seams or visible seams can detract from the appearance. The solution lies in careful measurement, precise cutting, and proper application of seam adhesive. Experience helps in getting these perfect.

- Air bubbles: These can be caused by improper smoothing techniques or trapped air. The solution is to use a squeegee or roller to smooth out the covering and release trapped air during application.

Careful planning, thorough preparation, and skillful execution minimize these issues, resulting in a high-quality finish. If problems do occur, I assess the situation systematically and implement the appropriate corrective measures. Attention to detail is crucial in problem-solving, allowing for successful completion of the project.

Q 15. What is your experience with different types of seams and joining techniques?

My experience with seams and joining techniques is extensive, encompassing a wide range of methods depending on the material and application. Think of seams as the ‘stitches’ that hold a covering together. The choice of seam depends heavily on the material’s properties and the desired strength and aesthetics.

- Seams for flexible materials (fabrics, films): I’m proficient in various sewing techniques like straight seams, zigzag seams, overlocking (serging), and French seams for durability and neatness. For example, a French seam is ideal for high-end applications where the raw edges are completely enclosed for a professional finish.

- Seams for rigid materials (metal sheets, panels): Here, we employ welding, riveting, bolting, or adhesive bonding, depending on the material and the structural requirements. For instance, welding is essential for creating strong, leak-proof seams in metal ductwork, while adhesives might be preferred for joining less robust materials like plastic panels.

- Seams for composite materials: This requires a more nuanced approach, often involving a combination of techniques. For example, when working with fiberglass-reinforced plastic, I might utilize adhesive bonding in conjunction with mechanical fasteners for enhanced strength and reliability.

Choosing the right technique requires a deep understanding of material science and engineering principles. For example, a poorly chosen seam in a high-pressure environment could lead to catastrophic failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of material compatibility and limitations.

Material compatibility is crucial; it’s all about choosing materials that play nicely together. Incompatible materials can lead to issues like chemical reactions (corrosion, degradation), adhesion failure, or dimensional instability. For example, using certain types of glues on incompatible plastics can lead to the glue dissolving the plastic.

Limitations are inherent to every material. Some materials are inherently weak, brittle, or prone to degradation under specific conditions. For example, certain fabrics might shrink when exposed to heat or moisture. Knowing these limitations is paramount to ensuring a successful covering application. I always consult material datasheets to understand these constraints and choose appropriate materials and joining methods.

In practice, I always factor in environmental conditions—temperature, humidity, UV exposure, and chemical interactions—when selecting materials. A covering for outdoor use requires significantly different materials and techniques than an indoor application.

Q 17. How do you ensure the final installation meets quality standards?

Quality control is an integral part of my process. I follow a multi-step approach to ensure that every installation meets the highest standards.

- Pre-installation checks: This involves carefully inspecting the substrate (the surface being covered) for imperfections and addressing any issues before starting the installation. This ensures a smooth, properly-fitting application from the get-go.

- Adherence to specifications: I meticulously follow blueprints, drawings, and specifications, using precise measuring tools to ensure accurate cutting and placement. I maintain detailed records of materials used and installation procedures.

- In-process inspections: Regular checks during the installation process help identify and correct any errors promptly. This proactive approach prevents small problems from escalating into major issues.

- Final inspection: Once the installation is complete, a thorough final inspection involves verifying seam integrity, material consistency, adherence to design specifications, and overall aesthetic appeal. This inspection often includes functional testing to confirm proper performance.

My goal is not just to complete the job but to deliver a product that is durable, reliable, and aesthetically pleasing, meeting or exceeding client expectations. I’ve found that meticulous attention to detail pays off in the long run, minimizing the risk of rework and ensuring customer satisfaction.

Q 18. Describe your experience with working from blueprints or specifications.

I have extensive experience interpreting and working from blueprints and detailed specifications. My approach involves a careful review of the documents to fully understand the design intent, including dimensions, material specifications, and assembly details.

I use measuring tools, templates, and marking techniques to accurately transfer the design to the substrate. I also ensure all materials are properly identified and accounted for before beginning the installation. If ambiguities arise in the drawings, I proactively seek clarification from the design team or client to avoid potential errors. Precision is key here; working from inaccurate blueprints can lead to a flawed outcome.

For example, I recall a project where the blueprint specified a specific type of sealant for a certain joint. By meticulously following the specifications, I avoided a potential leakage problem.

Q 19. How do you handle customer inquiries or complaints?

Handling customer inquiries and complaints is a crucial aspect of my job. I believe in addressing them promptly and professionally. My approach involves active listening to understand the issue from the customer’s perspective.

I ask clarifying questions to get the complete picture and then provide a clear, concise explanation of the situation. If the issue is valid, I propose solutions that are practical, cost-effective, and resolve the problem quickly. Even if the complaint is unfounded, I strive to maintain a calm and respectful demeanor while explaining the situation clearly. Documentation is key; I meticulously record all communications and resolutions.

Building a strong rapport with customers is important. Addressing their concerns promptly fosters trust and confidence in my work. I aim to leave every customer feeling satisfied and understood, even if the situation doesn’t perfectly meet their initial expectations.

Q 20. What is your experience with different types of substrates (e.g., wood, metal, plastic)?

My experience encompasses a variety of substrates, including wood, metal, and plastic. Each substrate requires a different approach to covering.

- Wood: Wood surfaces require preparation such as sanding and priming to ensure proper adhesion. The choice of covering material and adhesive depends on the type of wood, its finish, and the intended application.

- Metal: Metal surfaces often need cleaning and preparation to remove rust or other contaminants. The covering process might involve welding, riveting, or adhesive bonding, depending on the material and the desired outcome.

- Plastic: Plastic surfaces can be challenging due to their varying properties. I choose adhesives carefully to ensure compatibility and avoid reactions that might damage the plastic. The surface may also require cleaning or preparation before application.

Understanding the specific properties of each substrate is essential to select the appropriate covering materials and techniques. For example, applying a water-based adhesive to a plastic surface that is not compatible could result in the adhesive destroying the plastic.

Q 21. How do you deal with uneven or damaged surfaces?

Dealing with uneven or damaged surfaces requires a systematic approach. It’s not just about applying the covering; it’s about creating a stable and aesthetically pleasing finish.

- Assessment: I first assess the extent and nature of the damage. This might involve identifying cracks, holes, or significant variations in surface level. A detailed assessment is crucial for choosing the right repair strategy.

- Surface preparation: This is often the most critical step. I might use fillers, patching compounds, or other methods to level out the surface and prepare it for covering. This step ensures a smooth, even finish and prevents the covering from highlighting imperfections.

- Material selection: The choice of covering material and adhesive needs to account for the repaired surface. I might opt for more flexible materials or adhesives to accommodate any remaining imperfections.

- Application: Careful application of the covering material is essential to ensure proper coverage and a visually appealing outcome. I always use techniques that minimize the visibility of any repairs.

My goal is to make the repair as seamless as possible, maintaining the aesthetic integrity of the final product. Sometimes, however, substantial damage might necessitate more extensive repairs or even replacement of the underlying substrate.

Q 22. Describe your experience with different finishing techniques.

My experience encompasses a wide range of finishing techniques for covering installations, tailored to the specific material and project requirements. This includes everything from precise hand-finishing for intricate details to using specialized power tools for larger-scale applications.

- Seaming and Joining: I’m proficient in various seaming techniques, including heat-sealing, ultrasonic welding, and adhesive bonding, ensuring seamless and durable joins, depending on the material (e.g., vinyl, fabric, or membrane).

- Trimming and Cutting: I utilize precision cutting tools – from sharp utility knives to specialized shears – to achieve clean, accurate cuts and avoid damaging the underlying substrate. For curved surfaces, I employ specialized techniques to ensure a perfect fit.

- Edge Finishing: This involves techniques like binding, hemming, and welting to protect the edges of the covering and enhance its aesthetic appeal. The method chosen is always dependent on the material and the desired finish.

- Surface Treatments: Depending on the material, I might incorporate surface treatments such as priming, sealing, or applying protective coatings to increase durability and longevity. This often includes understanding the chemical compatibility of different materials.

For instance, on a recent project involving a large-scale vinyl wrap, I employed a combination of heat-sealing and precision trimming to achieve a flawless, bubble-free finish. The project demanded attention to detail and a thorough understanding of the vinyl’s properties to prevent shrinkage and warping.

Q 23. How do you maintain your tools and equipment?

Maintaining my tools and equipment is crucial for both safety and efficiency. I follow a rigorous cleaning and maintenance schedule, adapting it to the specific tool and its usage. This ensures optimal performance and extends their lifespan.

- Regular Cleaning: After each use, I thoroughly clean all tools and equipment, removing debris, dust, and adhesive residue. This prevents build-up and ensures precise operation.

- Sharpening and Lubrication: Cutting tools, such as blades and shears, are regularly sharpened to maintain accuracy and efficiency. Moving parts of power tools are lubricated as per the manufacturer’s instructions to ensure smooth operation and prevent damage.

- Storage and Protection: Tools are stored in a designated area, organized and protected from damage or environmental factors. Blades and sharp tools are always kept covered or sheathed.

- Regular Inspection and Repair: I regularly inspect tools for any signs of wear and tear, damage, or malfunction. Minor repairs are carried out promptly, while significant issues are addressed by qualified professionals.

Think of it like caring for a finely tuned instrument; proper maintenance ensures it consistently performs at its best, minimizing downtime and producing high-quality work.

Q 24. What are your time management skills like in a high-pressure environment?

In high-pressure situations, effective time management is paramount. My approach is based on a combination of planning, prioritization, and adaptability.

- Prioritization: I assess tasks based on urgency and importance using methods like the Eisenhower Matrix (urgent/important). Critical tasks are tackled first to avoid delays.

- Detailed Planning: I break down large projects into smaller, manageable tasks with clear timelines. This allows for better tracking of progress and identification of potential bottlenecks early on.

- Adaptability: Unexpected issues are bound to arise. I’m able to quickly adapt my schedule and prioritize tasks to address unexpected delays without compromising overall project completion.

- Effective Communication: I maintain open communication with stakeholders, keeping them updated on progress and potential challenges. This prevents misunderstandings and allows for collaborative problem-solving.

For example, during a recent rush job, I successfully managed to complete the installation ahead of the deadline by effectively prioritizing tasks and communicating potential delays proactively.

Q 25. How do you prioritize tasks to ensure project completion within deadlines?

Prioritizing tasks effectively is key to meeting deadlines. I typically use a combination of techniques to ensure projects are completed on time.

- Project Breakdown: I start by breaking down the project into smaller, manageable tasks, each with a defined timeframe.

- Dependency Mapping: I identify dependencies between tasks to determine the optimal sequence for completion. This helps avoid unnecessary delays.

- Resource Allocation: I consider the resources required for each task (materials, tools, personnel) to ensure efficient allocation.

- Regular Monitoring and Adjustment: I regularly monitor progress against the schedule. If necessary, I make adjustments to the plan to address any unforeseen issues or delays.

A Gantt chart is a helpful visual tool I often use for tracking progress and dependencies, helping me visualize the entire project’s timeline and potential conflicts.

Q 26. Describe your experience working independently and as part of a team.

I’m comfortable working both independently and collaboratively. My experience has shown me the value of both approaches, and I adapt my style to suit the project and team dynamics.

- Independent Work: I’m self-motivated and disciplined, able to manage my time and resources effectively to complete assigned tasks with minimal supervision. This is particularly useful for smaller, self-contained projects.

- Teamwork: I value collaboration and communication, actively participating in team discussions and sharing my knowledge and expertise with colleagues. This is crucial for larger, complex projects requiring coordination and specialized skills.

I believe in a collaborative approach and actively contribute to a positive and productive team environment. For example, on a recent large-scale project, I worked closely with the design team to ensure the covering installation perfectly complemented the overall design aesthetic.

Q 27. What is your understanding of relevant health and safety regulations?

Safety is my top priority. I have a thorough understanding of relevant health and safety regulations, including OSHA standards (or equivalent in your region) pertaining to working at heights, handling of materials, and use of power tools.

- Personal Protective Equipment (PPE): I always use appropriate PPE, such as safety glasses, gloves, respirators, and safety harnesses when working at heights or with hazardous materials.

- Safe Tool Handling: I follow safety procedures for using power tools and machinery, ensuring proper maintenance and safe operation.

- Material Handling: I’m trained in safe lifting and carrying techniques to prevent injuries. I ensure materials are stored and handled correctly to avoid accidents.

- Hazard Identification and Mitigation: I’m proficient in identifying and mitigating potential hazards on the worksite, taking proactive measures to ensure a safe working environment.

My commitment to safety isn’t just about following rules, it’s about creating a culture of safety and preventing accidents. Regular safety training keeps my knowledge up-to-date and ensures that I remain aware of best practices.

Q 28. How do you stay updated on the latest trends and technologies in covering installation?

Staying current with the latest trends and technologies in covering installation is crucial for maintaining a competitive edge and delivering high-quality results. I achieve this through a multi-faceted approach.

- Industry Publications and Journals: I regularly read trade magazines and journals focused on covering installation and related fields. This keeps me informed about new materials, techniques, and best practices.

- Professional Organizations: Membership in professional organizations provides access to networking opportunities, conferences, and continuing education courses, allowing me to stay updated on industry advancements.

- Online Resources and Webinars: I utilize online resources, such as manufacturer websites and industry-specific webinars, to access the latest product information and technical updates.

- Manufacturer Training: I actively participate in manufacturer-sponsored training programs to deepen my understanding of new materials and their application techniques.

For example, I recently completed a training course on the installation of a new, self-adhesive covering material that significantly reduces installation time and enhances durability. Continual learning is an integral part of my professional development.

Key Topics to Learn for Covering Interview

- Fundamentals of Covering: Understanding the core principles and definitions related to the field. This includes theoretical frameworks and their practical implications.

- Practical Applications of Covering Techniques: Explore real-world scenarios and case studies demonstrating how Covering principles are applied in various contexts. Consider different industry applications and their unique challenges.

- Problem-Solving in Covering: Develop your ability to identify, analyze, and propose solutions to common problems encountered while working with Covering. Practice different problem-solving methodologies.

- Advanced Covering Concepts: Research and understand more complex topics within Covering, depending on the specific role you are applying for. Focus on areas that align with the job description.

- Data Analysis and Interpretation within Covering: Practice interpreting data relevant to Covering and drawing meaningful conclusions. Demonstrate your ability to use data to inform decision-making.

- Collaboration and Communication in Covering: Understand the importance of teamwork and effective communication in Covering projects. Prepare examples showcasing your collaboration skills.

Next Steps

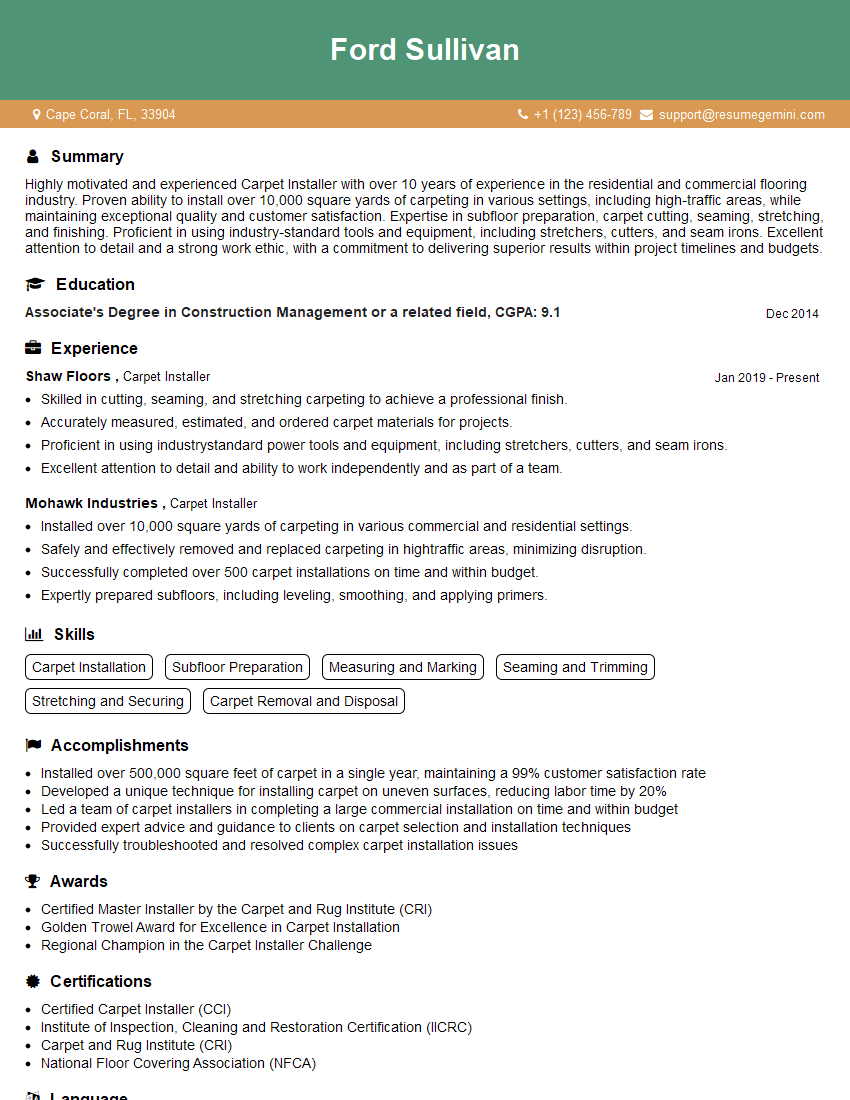

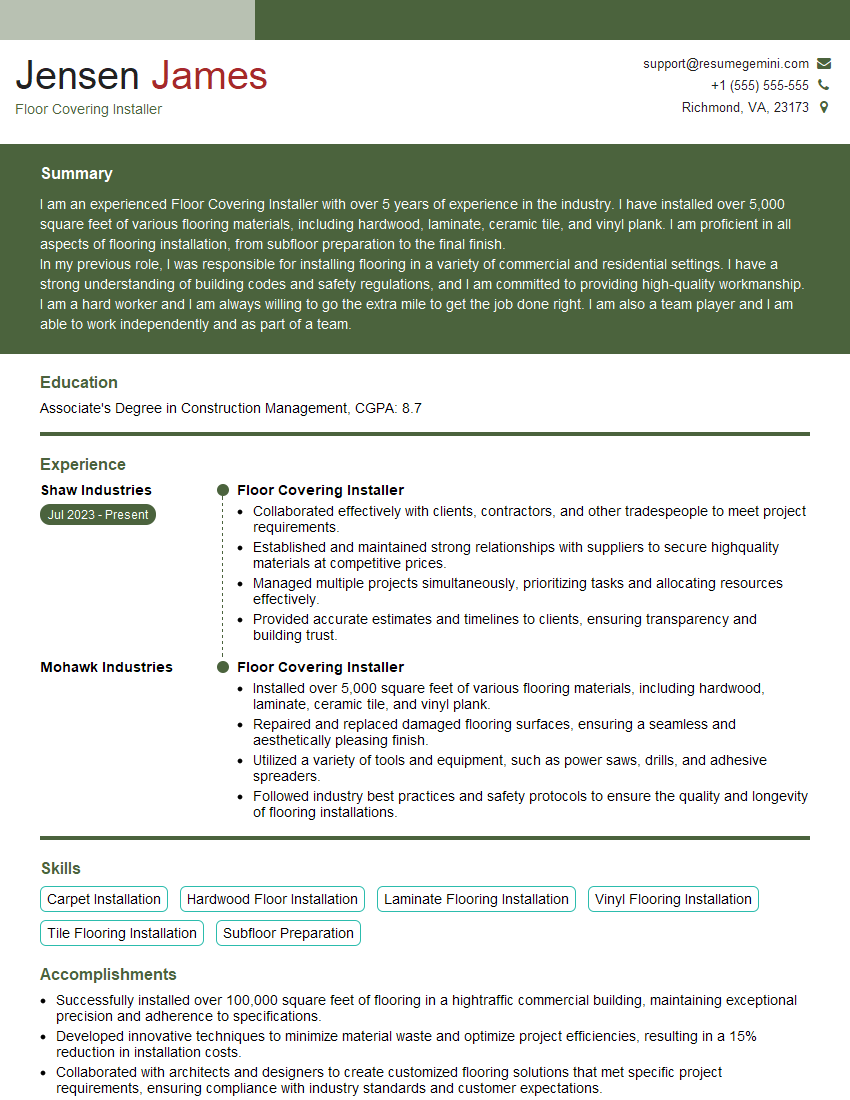

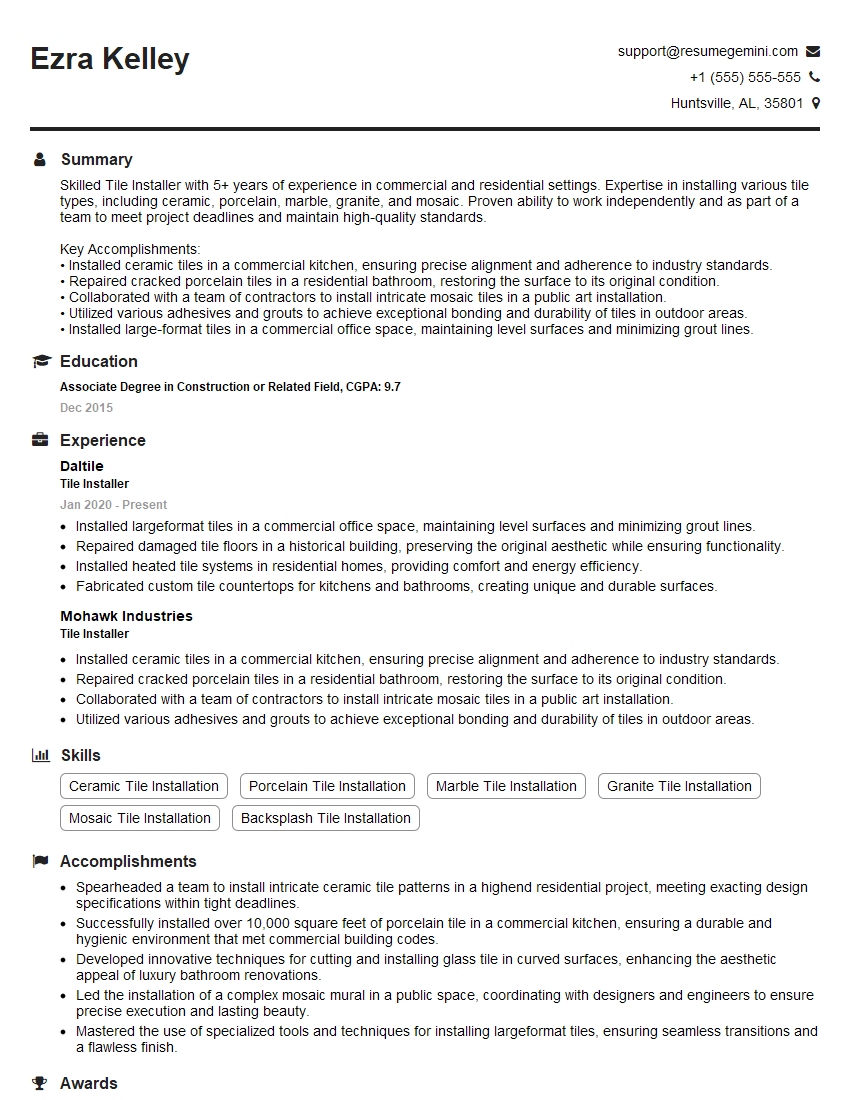

Mastering Covering opens doors to exciting career opportunities and significant professional growth. Demonstrating a strong understanding of these concepts is crucial for interview success and securing your desired role. To maximize your chances, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specifics of Covering roles. Examples of resumes optimized for Covering positions are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good