Preparation is the key to success in any interview. In this post, we’ll explore crucial Crane and Rigging Equipment Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Crane and Rigging Equipment Operation Interview

Q 1. Describe your experience with different types of cranes (e.g., tower, mobile, overhead).

My experience encompasses a wide range of crane types, each demanding a unique skill set. I’ve extensively operated tower cranes on high-rise construction projects, understanding their intricate counterweight systems and precise movements crucial for placing large, heavy components with pinpoint accuracy. Working with mobile cranes, I’m proficient in navigating various terrains and adapting lifting techniques to overcome site limitations – for instance, adjusting the boom angle and outriggers for stability on uneven ground. Finally, my familiarity with overhead cranes in industrial settings emphasizes safe and efficient material handling within confined spaces, requiring meticulous attention to swing radius and load clearance. Each crane type presents distinct operational challenges and safety considerations which I’ve consistently addressed through careful planning and adherence to best practices.

Q 2. Explain the process of pre-lift planning and risk assessment.

Pre-lift planning is paramount. It’s like meticulously mapping out a complex journey before embarking. We start with a thorough site survey, identifying potential hazards like overhead power lines, obstructions, and unstable ground conditions. Next, we analyze the load characteristics – weight, dimensions, center of gravity – and select the appropriate crane, rigging, and lifting technique. This includes detailed calculations to ensure the crane’s capacity is sufficient and that the load is balanced correctly to prevent tipping or swinging. Risk assessment involves identifying potential hazards – like equipment malfunction, human error, or environmental factors – and implementing control measures to mitigate them. This might involve using additional personnel for guiding, establishing exclusion zones, or selecting alternative lifting strategies. A comprehensive lift plan, including diagrams, weight calculations, and safety procedures, is then created and reviewed by all involved parties. Think of it as a comprehensive roadmap ensuring a safe and successful lift.

Q 3. What are the critical safety regulations you follow when operating a crane?

Safety is non-negotiable. I strictly adhere to OSHA regulations (or equivalent local standards) which cover all aspects of crane operation. These include daily inspections of the crane’s structural integrity, mechanical components, and safety devices like brakes and limit switches. Proper licensing and certification are crucial, demonstrating my competency and commitment to safety. I always ensure load charts are consulted and respected, never exceeding the crane’s Safe Working Load (SWL). Communication is key: maintaining clear communication with the crane operator, riggers, and ground crew is essential to prevent accidents. Weather conditions are also carefully monitored; lifting operations are suspended during high winds, thunderstorms, or other unsafe weather. Furthermore, I rigorously follow lockout/tagout procedures when performing maintenance or repairs, guaranteeing complete isolation of the equipment. All these measures are not merely rules, but essential practices that safeguard everyone on the site.

Q 4. How do you identify and mitigate potential hazards during rigging operations?

Identifying hazards during rigging is a proactive process. I start by visually inspecting the rigging hardware for damage, wear, or defects before each lift. This includes checking slings, shackles, hooks, and wire ropes for any signs of fraying, corrosion, or distortion. Proper tagging and documentation of inspection results are also crucial. I also consider environmental factors such as ground conditions, overhead obstructions, and weather conditions. This might involve using different types of slings to account for load characteristics or implementing additional safety measures such as ground mats or extra personnel for load stabilization. Any potential hazards are mitigated through appropriate control measures like using additional support, modifying rigging techniques, or implementing stricter safety protocols. For example, if the ground is unstable, we might use a larger base for the crane or utilize wooden mats to distribute the load. It’s a continuous risk assessment and mitigation process to ensure the safety of the operation.

Q 5. Describe your experience with various rigging hardware (e.g., shackles, slings, hooks).

My experience with rigging hardware is extensive and covers a range of materials and configurations. I’m proficient in using various types of shackles, understanding the difference between bow shackles and D-shackles and their appropriate applications based on load angles and stress points. I can select and inspect wire rope slings, chain slings, and synthetic web slings, knowing their respective strengths, limitations, and appropriate applications for different load types and shapes. Hook selection is equally important, ensuring the hook’s SWL is compatible with the load and the hook’s condition is verified. Regular inspections and maintenance are key to preventing failures. Recognizing the signs of wear, like deformation or corrosion, is paramount to preventing accidents. I’m also familiar with using other essential components like spreader beams, load shackles, and other rigging devices, always ensuring their compatibility and suitability for the specific lift.

Q 6. Explain the different types of slings and their appropriate applications.

Different slings serve different purposes. Wire rope slings offer high strength and durability, ideal for heavy loads and harsh conditions. However, they can be prone to kinking and damage if not handled carefully. Chain slings provide good strength and are relatively resistant to abrasion, making them suitable for heavier loads and rougher applications, but the links can wear out over time. Synthetic web slings are lightweight, easy to handle, and less prone to damage from shock loads, but they are not as strong as wire rope or chain slings. Their flexibility makes them excellent for lifting awkwardly shaped loads. Selecting the appropriate sling depends on the load’s weight, shape, and the environment. For instance, a delicate piece of equipment might need a synthetic web sling to prevent damage, whereas heavy steel beams might necessitate a wire rope or chain sling. The angle of the lift also influences sling selection; using multiple slings to reduce the angle on each sling distributes the load more evenly and enhances safety.

Q 7. How do you calculate the safe working load (SWL) for a lift?

Calculating the Safe Working Load (SWL) isn’t a guess; it’s a precise calculation essential for safety. The SWL is the maximum load a piece of equipment or rigging can handle safely. For a crane, the SWL is determined by the crane’s manufacturer and is usually displayed on the crane’s load chart. This chart indicates the SWL for various boom lengths and radii. For slings, the SWL is often indicated on the sling itself or in manufacturer’s documentation. However, the SWL can be affected by factors like the sling angle – a sling at a greater angle than 30 degrees from vertical will decrease its load capacity. The formula for calculating reduced load capacity due to sling angle is typically provided by sling manufacturers. I always consult manufacturer’s specifications and consider any reducing factors, like angle, before making a lift plan. It’s a crucial calculation to ensure the safety of the equipment, personnel, and the load itself.

Q 8. What are the limitations of using different types of slings?

Different sling types have unique strengths and weaknesses, limiting their applications. For instance, wire rope slings are incredibly strong and durable but can suffer from internal damage that’s difficult to detect, leading to catastrophic failure. They’re also susceptible to kinking and crushing, significantly reducing their load capacity. Nylon slings are flexible and easy to handle but are vulnerable to abrasion, UV degradation, and heat damage. Their strength is also affected by moisture and exposure to chemicals. Chain slings offer high tensile strength and resistance to abrasion but can be prone to stretching and wear at the links, especially near the hooks. Regular inspection is crucial for all sling types, and using the wrong sling for a given load or environment can lead to accidents.

- Example: A sharp edge on a load would quickly cut a nylon sling, requiring the use of a chain sling or a sling protector.

- Example: Lifting a hot load would require a sling specifically designed for high temperatures, potentially eliminating nylon as an option.

Q 9. Explain the importance of proper load securing techniques.

Proper load securing is paramount for safety and preventing damage. Improperly secured loads can shift during lifting, causing equipment damage, injury, or even fatalities. Techniques like using the correct type and number of slings, ensuring even load distribution, and employing proper hitching methods are essential. For example, choker hitches should be used cautiously and only when absolutely necessary because they concentrate stress on a small portion of the sling. Using soft shackles or proper padding can protect slings from damage caused by sharp edges or uneven surfaces of the load.

- Example: A heavy steel beam needs to be lifted using multiple slings distributed evenly along its length to prevent bending or twisting.

- Example: Securing a bulky, irregularly shaped object might require additional straps or chains to prevent shifting and ensure stability during the lift.

Remember, proper documentation of the securing method is equally important for traceability and future reference.

Q 10. What are the emergency procedures in case of a crane malfunction?

Emergency procedures for crane malfunctions prioritize safety. The first step is to immediately stop all crane operations and lower the load gently if possible. Then, depending on the nature of the malfunction, you’d activate emergency brakes, if equipped, and if safe to do so. Clear the area around the crane to prevent injury to anyone who may be in the vicinity. Contact emergency services and report the incident to the supervisor or relevant authority. Finally, begin the investigation into the cause of the malfunction to prevent future incidents. Depending on the circumstance, this may include shutting off power to the crane.

Example: If the crane’s boom starts to lower unexpectedly, the operator should immediately activate the emergency brakes, then carefully lower the load using the emergency controls while keeping a safe distance.

Training and regular drills on emergency procedures are crucial for swift and effective responses in such situations.

Q 11. How do you communicate effectively with the signal person?

Effective communication with a signal person is non-negotiable for safe crane operation. It should be based on a standardized set of hand signals agreed upon by the operator and signal person. Any ambiguities must be clarified beforehand. The operator should maintain visual contact with the signal person at all times. Clear, concise, and unambiguous communication are vital. Verbal confirmation of each step is advisable. If visibility is compromised, a radio communication system must be used as a backup.

Example: Before starting any lift, the operator should verify the signal person’s understanding of the lift plan, including the path of travel, and any potential obstacles. Any deviation from the plan should be immediately discussed and confirmed.

Regular training on hand signals and communication protocols is crucial for both the operator and the signal person.

Q 12. Describe your experience with load charts and crane capacity.

Load charts and crane capacity are fundamental to safe operation. A load chart specifies the maximum weight a crane can lift at various boom lengths and radii. It accounts for factors influencing stability, like ground conditions and crane configuration. Before any lift, I always consult the load chart to ensure the crane’s capacity exceeds the weight of the load, considering additional factors like wind speed. Exceeding the crane’s capacity risks structural damage or catastrophic failure. The condition of the crane itself (age, maintenance records) will also inform the safe working load.

Example: If a load chart indicates a maximum capacity of 10 tons at a 20-meter boom radius, lifting an 11-ton load at that radius would be unsafe.

Experience has taught me the importance of careful analysis and conservative estimations when working with load charts. Safety is always paramount.

Q 13. Explain your understanding of crane stability and its influencing factors.

Crane stability is crucial for safe operation, and numerous factors influence it. These include the crane’s own weight distribution, the load weight and its position relative to the crane, ground conditions (bearing capacity of the soil, slope, etc.), wind speed and direction, and the crane’s configuration (boom angle, radius). An unstable crane risks tipping over, resulting in a very dangerous situation. Proper counterweighting and suitable outrigger settings (if applicable) are essential for enhancing stability. Operating within the crane’s rated capacity, as determined by the load charts, is critical to maintaining stability.

Example: Lifting a heavy load with a long boom extension significantly reduces the crane’s stability; therefore, reducing the boom length or using a crane with higher capacity is necessary.

Understanding these factors allows me to make informed decisions to ensure the stability of the crane throughout the operation.

Q 14. How do you inspect a crane before and after operation?

Pre- and post-operation inspections are non-negotiable for safe crane operation. Before operation, I thoroughly inspect the crane’s structure for any signs of damage or wear, including checking cables, hooks, sheaves, and other critical components. I verify the functionality of the brakes, emergency stops, and other safety mechanisms. I also check the ground conditions to make sure it is firm and level for proper stability. After operation, I repeat this process, paying particular attention to any parts that may have experienced additional stress during the lift. Any issues discovered are reported immediately, and the crane is taken out of service until repairs or replacements are completed.

Example: A cracked boom section discovered during a pre-operation check would require immediate attention before any lifting is attempted.

A detailed checklist and thorough documentation of every inspection are crucial to ensure a safe working environment.

Q 15. What are the common causes of crane accidents and how to prevent them?

Crane accidents, unfortunately, are not uncommon. They stem from a variety of factors, often involving a combination of human error and equipment malfunction. Common causes include:

- Operator error: This is the leading cause, encompassing issues like inadequate training, fatigue, exceeding crane capacity, improper rigging, or failing to conduct pre-lift checks. For instance, an operator might underestimate the weight of a load, leading to an overload and subsequent collapse.

- Equipment failure: Mechanical breakdowns, such as brake failure, structural defects, or hydraulic leaks, can lead to catastrophic events. Regular maintenance, detailed inspections, and adherence to manufacturer’s guidelines are crucial to mitigating this risk. Think of a worn-out cable snapping under stress.

- Improper rigging: Using inappropriate slings, improper hitching, or neglecting to properly secure the load can cause it to shift, swing, or drop. For example, using a damaged sling or not properly distributing the load on the sling points is dangerous.

- Environmental factors: High winds, adverse weather conditions, or unstable ground can compromise crane stability and operation. Working in high winds beyond the crane’s operational limits is a common issue.

- Lack of communication: Poor communication between the crane operator, rigger, and ground crew can result in mishaps. For example, misinterpreting hand signals can cause a load to be positioned incorrectly.

Prevention strategies revolve around rigorous training programs for operators, implementing strict safety protocols, regular maintenance schedules, thorough pre-lift inspections, and robust communication channels. A safety-first culture, coupled with strong risk assessment procedures, is paramount.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of lifting techniques.

My experience encompasses a wide range of lifting techniques, tailored to specific load characteristics and job site conditions. This includes:

- Conventional lifting: This involves using standard crane hooks, slings, and shackles to lift and place loads. I’m proficient in calculating safe working loads, selecting appropriate rigging equipment, and executing lifts safely and efficiently. For example, I regularly lift pre-fabricated building sections using multiple slings ensuring even load distribution.

- Critical lifts: These involve loads with unique characteristics or challenges. This requires detailed planning, including risk assessments, specialized rigging, and close coordination with engineers and site supervisors. One example involves lifting very heavy equipment with precision placement requirements.

- Tandem lifting: Employing multiple cranes to lift exceptionally heavy or unwieldy objects requires precise synchronization and advanced planning to prevent imbalance and potential accidents. This is often the case with large industrial components.

- Derrick lifting: The use of derricks allows access to hard to reach areas, requiring expertise in their unique setup and operation considerations. I’ve used this technique for construction projects.

- Specialized lifting techniques: Depending on the load (e.g., fragile, oversized, or oddly shaped objects), additional techniques and equipment such as vacuum lifters, spreader beams, and magnetic lifters are necessary. I’ve worked with these methods for both construction and industrial applications.

My approach to any lifting technique prioritizes safety, efficiency, and a thorough understanding of the load and its surroundings.

Q 17. How do you handle unexpected situations during a lift?

Handling unexpected situations during a lift demands immediate action based on training and experience. My approach is guided by the following steps:

- Assess the situation: Immediately stop the lift and identify the problem. Is there a load shift? Equipment malfunction? Adverse weather conditions?

- Communicate: Inform the ground crew, rigger, and supervisor about the situation. Clear and concise communication is crucial.

- Implement corrective actions: Based on the nature of the problem, take appropriate actions. This could involve securing the load, adjusting rigging, calling for assistance, or contacting maintenance personnel.

- Document the event: Detailed documentation helps prevent future occurrences and aids in incident investigations.

- Resume operations (when safe): Only resume the lift once the problem has been resolved and safety is ensured.

For example, if I notice a load swinging unexpectedly due to a gust of wind, I would immediately stop the lift, assess the wind speed, and determine if the lift can safely continue or if it needs to be postponed. Safety is always the top priority.

Q 18. What are your experience with different types of load configurations?

My experience includes working with various load configurations, each requiring a different approach to rigging and lifting:

- Single-point lifts: Simple and straightforward, using a single hook to lift a centrally balanced load.

- Multi-point lifts: More complex, using multiple slings or attachments to distribute the load weight and maintain stability for irregularly shaped or heavy loads. Proper sling angles and load distribution are critical to prevent damage or instability.

- Oversized loads: Requires specialized rigging techniques, including spreader beams or other equipment designed to distribute the load effectively and prevent damage. Accurate load calculations are paramount.

- Fragile loads: Demands careful handling, specialized lifting equipment (e.g., vacuum lifters), and protection against damage. This might also involve additional padding or custom rigging solutions.

In each case, selecting appropriate rigging hardware, calculating load limits, and ensuring the proper distribution of weight are essential to prevent accidents and ensure safe handling.

Q 19. Explain the importance of regular crane maintenance.

Regular crane maintenance is paramount for safety and efficiency. Neglecting maintenance can lead to catastrophic failures, resulting in serious injuries or fatalities and significant financial losses.

Regular maintenance involves:

- Daily inspections: Checking for visible defects, loose bolts, hydraulic leaks, and proper functioning of safety devices.

- Periodic inspections: More thorough inspections conducted by qualified technicians, often following manufacturer’s recommended schedules. These may include non-destructive testing (NDT) methods to detect hidden defects.

- Preventative maintenance: Regular lubrication, replacement of worn parts, and other proactive measures to prevent equipment failure. This can involve replacing worn ropes or inspecting braking systems.

- Repair and overhaul: Addressing any identified issues during inspections or after incidents.

A well-maintained crane is a safe crane, and this should be the top priority.

Q 20. How do you ensure the proper functioning of safety devices on a crane?

Ensuring the proper functioning of safety devices is non-negotiable. My approach involves:

- Pre-operational checks: Thoroughly inspect all safety devices before each use, verifying that limit switches, overload protection systems, and emergency stops are functioning correctly. This is a critical part of my pre-lift checklist.

- Regular testing: Safety devices should be regularly tested, often through load testing and functional checks, to guarantee they operate as intended. Records of these tests should be diligently maintained.

- Calibration: Some safety devices, such as load cells, need regular calibration to maintain accuracy. Ensuring calibration is up to date and certified is crucial.

- Maintenance and repair: Any faulty safety devices should be immediately repaired or replaced by qualified technicians.

Treating safety devices with the same level of diligence as the primary lifting mechanisms is crucial. They are the last line of defense against accidents.

Q 21. What are the legal requirements for crane operation in your area?

Crane operation is heavily regulated, and the specifics vary depending on location. In my area, legal requirements encompass:

- Licensing and certification: Operators must possess valid licenses and certifications demonstrating competency and adherence to safety standards.

- Regular inspections: Cranes must undergo regular inspections, usually by accredited inspectors, to ensure they meet safety standards and are in good working order. The frequency of inspections depends on crane type and usage.

- Operator training: Operators must receive thorough training and ongoing professional development to stay updated on best practices and regulations.

- Pre-lift plans: A comprehensive lift plan, including risk assessment, should be prepared for every lift operation exceeding certain parameters (weight, height etc.).

- Compliance with relevant standards: Operations must adhere to national and local safety standards and regulations for crane operations, rigging, and load securing. This usually includes compliance with OSHA (or equivalent) standards.

- Accident reporting: All accidents or near-miss incidents must be reported to relevant authorities and thoroughly investigated.

Staying informed about and adhering to all relevant legislation is non-negotiable for safe and legal crane operations.

Q 22. Explain your experience working with different types of ground conditions.

Ground conditions significantly impact crane stability and lifting capacity. My experience encompasses working on various surfaces, from firm, level ground to soft soil, uneven terrain, and even sloped areas.

- Firm, level ground: This is the ideal scenario, offering maximum stability. We use standard outriggers and ensure the crane’s footprint is appropriately sized for the load.

- Soft soil: On soft soil, we take precautions to prevent ground subsidence. This includes using larger, wider outrigger pads, or in extreme cases, utilizing ground mats or cribbing to distribute the weight. I’ve personally overseen projects where we constructed a temporary reinforced platform for heavier lifts on particularly soft ground.

- Uneven terrain: Uneven ground necessitates careful leveling and shimming to ensure the crane’s stability. Precise measurements are crucial, and we often use laser levels for accuracy. I once had to use multiple layers of cribbing to achieve a stable base on a steeply sloped construction site.

- Sloped areas: Working on slopes requires careful consideration of the crane’s center of gravity and potential for tipping. We use advanced calculations and may opt for smaller, more maneuverable cranes or employ specialized techniques like anchoring or counterweights. A project involving the installation of a large HVAC unit on a hillside required a thorough risk assessment and the use of multiple safety lines.

In all cases, a thorough site assessment is the first step, followed by selecting appropriate equipment and implementing safety measures to mitigate the risks associated with the specific ground conditions.

Q 23. How do you ensure the safety of personnel in a crane work area?

Ensuring personnel safety is paramount in crane operations. My approach is multi-faceted and involves a combination of pre-planning, communication, and enforcement of safety protocols.

- Pre-task planning: This includes conducting thorough risk assessments, identifying potential hazards (e.g., overhead power lines, nearby structures), developing safe operating procedures, and communicating them to the entire team.

- Designated work areas and exclusion zones: Clearly defined work areas and exclusion zones, marked with signage and barriers, help prevent unauthorized personnel from entering hazardous areas. We always maintain a safe distance from swinging loads.

- Pre-lift inspections and communication: Before every lift, we conduct thorough inspections of the crane, rigging equipment, and load. Clear and concise communication between the crane operator, riggers, and ground personnel is crucial to ensure everyone understands their roles and responsibilities. I use hand signals and radio communication extensively to avoid misunderstandings.

- Personal Protective Equipment (PPE): Strict adherence to PPE requirements, including hard hats, safety glasses, high-visibility clothing, and appropriate footwear, is mandatory for everyone in the work area.

- Emergency response planning: We have well-defined emergency procedures and conduct regular safety training to equip personnel with the knowledge and skills to respond effectively in case of an accident.

Safety isn’t just a checklist; it’s a culture we actively foster on every project. Proactive measures, clear communication, and a commitment to safety best practices are key to preventing accidents.

Q 24. Describe your experience with different types of weather conditions affecting crane operation.

Weather conditions significantly impact crane operations. Experience has taught me to adapt to various situations, prioritizing safety and efficiency.

- High winds: Strong winds can affect crane stability and make lifting operations hazardous. We often have to postpone or cancel operations above a certain wind speed, which is typically determined by the crane’s specifications and the load being lifted. I’ve had to delay projects multiple times due to unexpected high-wind conditions.

- Rain and snow: These conditions can reduce visibility, make surfaces slippery, and potentially damage equipment. We employ appropriate safety measures, including using weatherproof equipment, additional lighting, and extra caution during lifting operations. Working in snowy conditions often necessitates using de-icing agents and careful monitoring of ground conditions.

- Extreme temperatures: Extreme heat can lead to equipment malfunction, and cold temperatures can affect material strength. We adjust operating procedures according to the temperature, taking necessary precautions and ensuring the well-being of the crew by providing adequate hydration or warm clothing.

- Fog and low visibility: Limited visibility necessitates extra care and caution, often requiring additional lighting and potentially halting operations until visibility improves.

In all these weather-related situations, the priority is always safety. We consult weather forecasts, monitor conditions closely throughout the day, and never hesitate to halt operations if conditions become unsafe.

Q 25. What is your experience with load testing and certification?

Load testing and certification are critical for ensuring the safe and efficient operation of cranes and rigging equipment. My experience includes both witnessing and conducting load tests.

- Witnessing load tests: I have regularly witnessed load tests conducted by certified professionals, meticulously documenting the process, verifying the results, and ensuring compliance with relevant standards and regulations.

- Conducting load tests (under supervision): Under the supervision of experienced professionals, I’ve assisted in the execution of load tests, ensuring the correct equipment and procedures are utilized, and accurately recording all data. This involves careful calibration of load cells and precise measurements.

- Certification processes: I understand the importance of keeping all relevant certificates up-to-date, including those for cranes, rigging equipment, and personnel. I’m familiar with different certification bodies and standards, such as ASME and OSHA regulations.

- Documentation: Meticulous documentation is essential. This includes maintaining detailed records of load test results, equipment inspections, and certification details. I ensure all documentation complies with industry standards and company procedures.

Load testing isn’t just a formality; it’s a vital step in guaranteeing the safety and reliability of our lifting operations. Thorough testing and accurate record-keeping provide the assurance that our equipment is capable of handling the intended loads safely.

Q 26. How familiar are you with the latest crane technology and safety advancements?

I’m highly familiar with the latest crane technology and safety advancements. My knowledge encompasses several key areas:

- Advanced crane control systems: I am proficient in using cranes equipped with modern control systems, including those with features like load moment indicators (LMIs), anti-collision systems, and advanced monitoring capabilities. These technologies significantly enhance safety and operational efficiency.

- Wireless remote control systems: I have experience operating cranes using wireless remote controls, allowing for safer operation in confined or hazardous spaces.

- Sensor-based safety systems: I’m familiar with systems that use sensors to monitor crane operations, detect potential hazards, and provide real-time alerts to the operator. This includes systems that warn of proximity to obstacles or overloaded conditions.

- Digital load monitoring and data logging: I’m experienced with systems that digitally record load data, allowing for precise tracking of lifting operations and facilitating thorough post-operation analysis.

- Automated crane systems: While I haven’t operated fully automated systems, I am aware of their growing role in the industry and understand the safety considerations involved in their deployment.

Continuous professional development is crucial in this field. I regularly attend industry seminars, workshops, and training courses to stay up-to-date on the latest technological advancements and safety procedures.

Q 27. Describe a challenging rigging situation you faced and how you overcame it.

One challenging rigging situation involved lifting a large, unusually shaped transformer into a tightly confined substation. The transformer had several delicate components and limited access hampered the use of standard rigging techniques.

The challenge: The transformer’s shape and weight distribution made it unstable, and the proximity of high-voltage equipment and other structures limited the available rigging angles and lifting points. Traditional methods risked damaging the transformer or the surrounding infrastructure.

My solution: I collaborated with the engineering team and developed a custom rigging plan using specialized slings and spreader beams. We calculated the precise angles and load distribution to ensure safe handling. We also employed additional safety measures such as load monitoring devices and multiple safety lines. The entire process was meticulously planned and executed, requiring precise communication and coordination among the rigging crew and the crane operator.

The outcome: Through careful planning, effective communication, and use of specialized rigging techniques, we successfully lifted and positioned the transformer without incident. This experience reinforced the importance of adaptability, creative problem-solving, and the critical role of collaboration in overcoming complex rigging challenges.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of [Insert Salary Range], commensurate with my experience, skills, and the responsibilities associated with this position. I am open to discussing this further and believe my contributions to your team will justify this range.

Key Topics to Learn for Crane and Rigging Equipment Operation Interview

- Crane Types and Capabilities: Understanding the different types of cranes (tower, mobile, overhead, etc.) and their specific applications, lifting capacities, and limitations.

- Rigging Techniques and Safety Procedures: Mastering proper rigging techniques, including selecting appropriate slings, hitches, and load securing methods. Thorough knowledge of relevant safety regulations and best practices is crucial.

- Load Calculations and Stability: Understanding the principles of load calculations, center of gravity, and ensuring crane stability during lifting operations. This includes identifying potential hazards and mitigating risks.

- Pre-Operational Inspections and Maintenance: Knowing how to perform thorough pre-operation checks of cranes and rigging equipment, identifying potential malfunctions and ensuring proper maintenance procedures are followed.

- Emergency Procedures and Response: Familiarity with emergency protocols in case of equipment malfunction, load instability, or accidents. This includes knowing how to safely shut down equipment and initiate emergency response procedures.

- Communication and Teamwork: Effective communication with crane operators, riggers, and other team members is paramount. Understanding hand signals, radio communication, and collaborative problem-solving is key.

- Applicable Regulations and Standards: Demonstrating knowledge of relevant safety regulations, industry standards (e.g., OSHA), and best practices for crane and rigging operations.

- Troubleshooting and Problem Solving: Being able to identify and troubleshoot common problems with cranes and rigging equipment, and develop effective solutions to ensure safe and efficient operations.

Next Steps

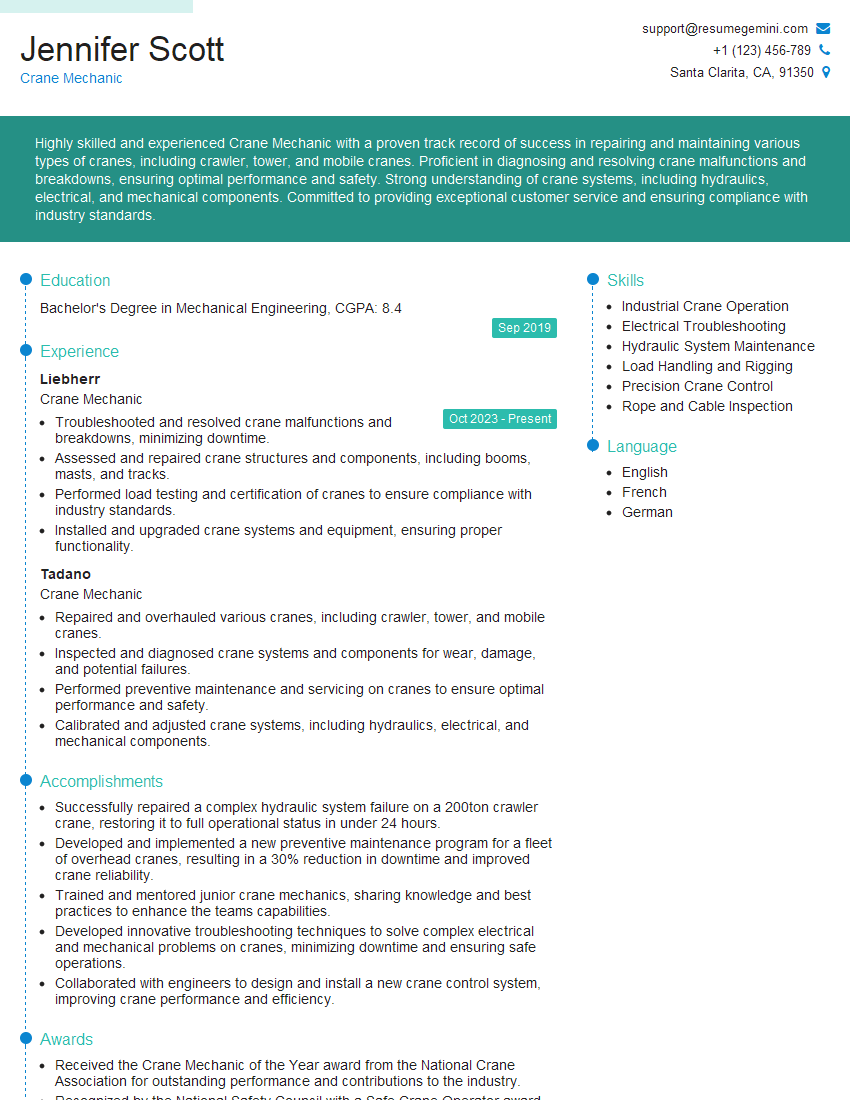

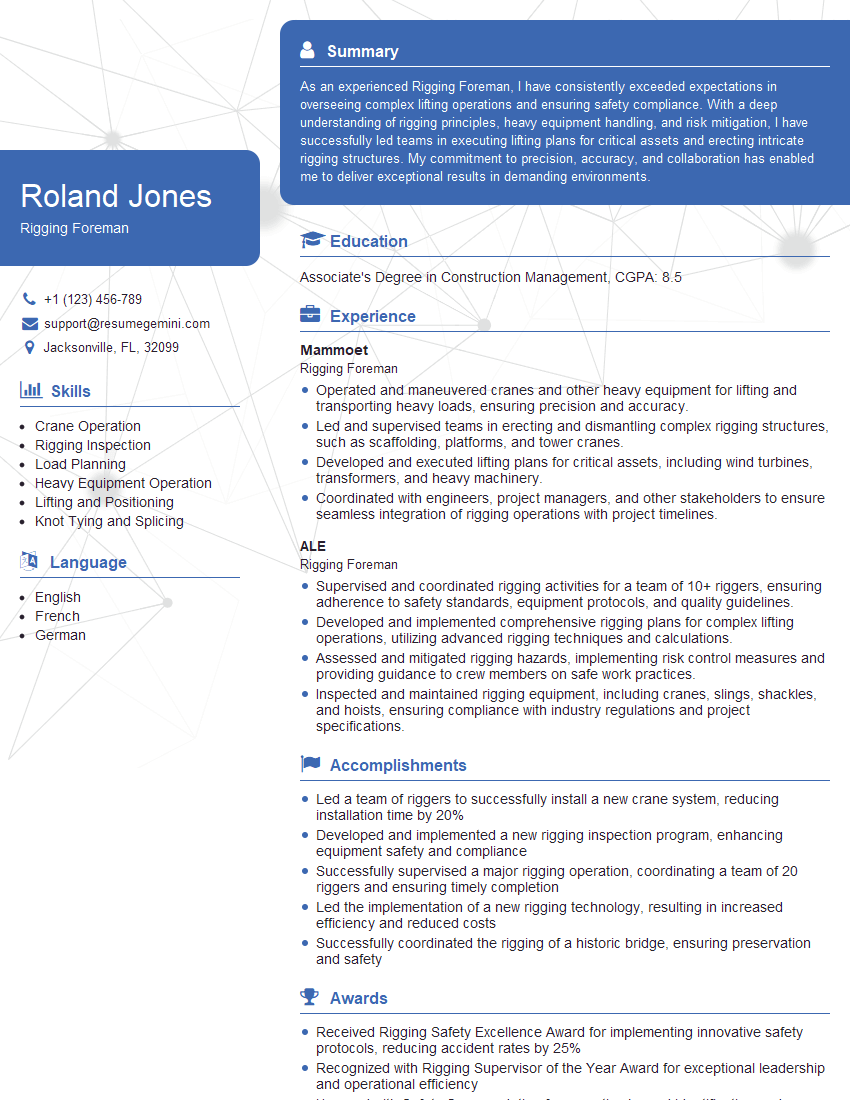

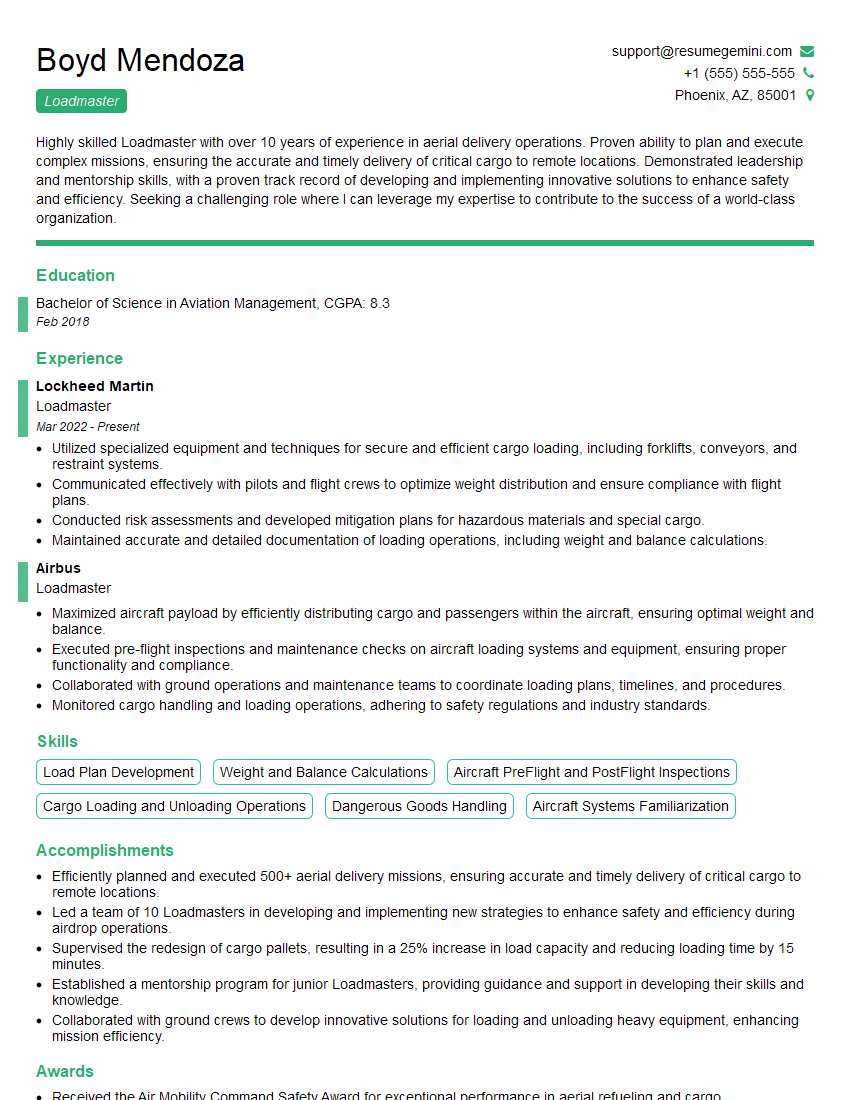

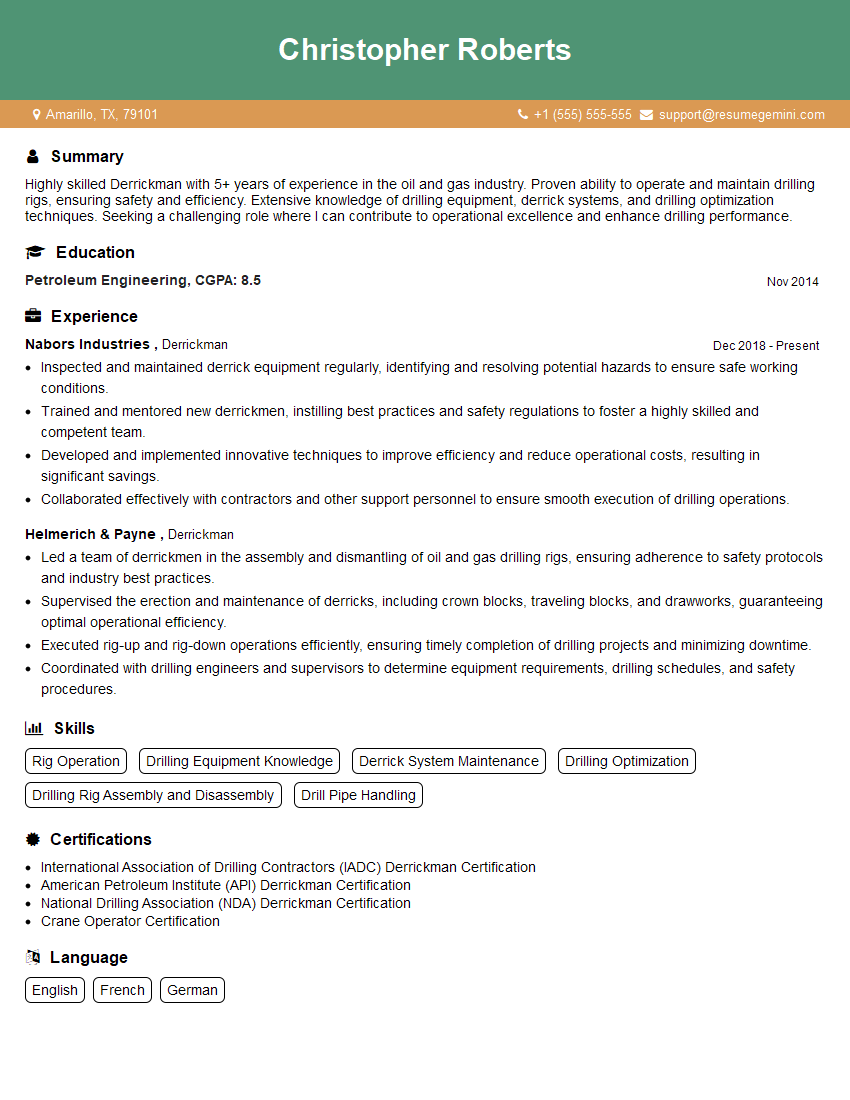

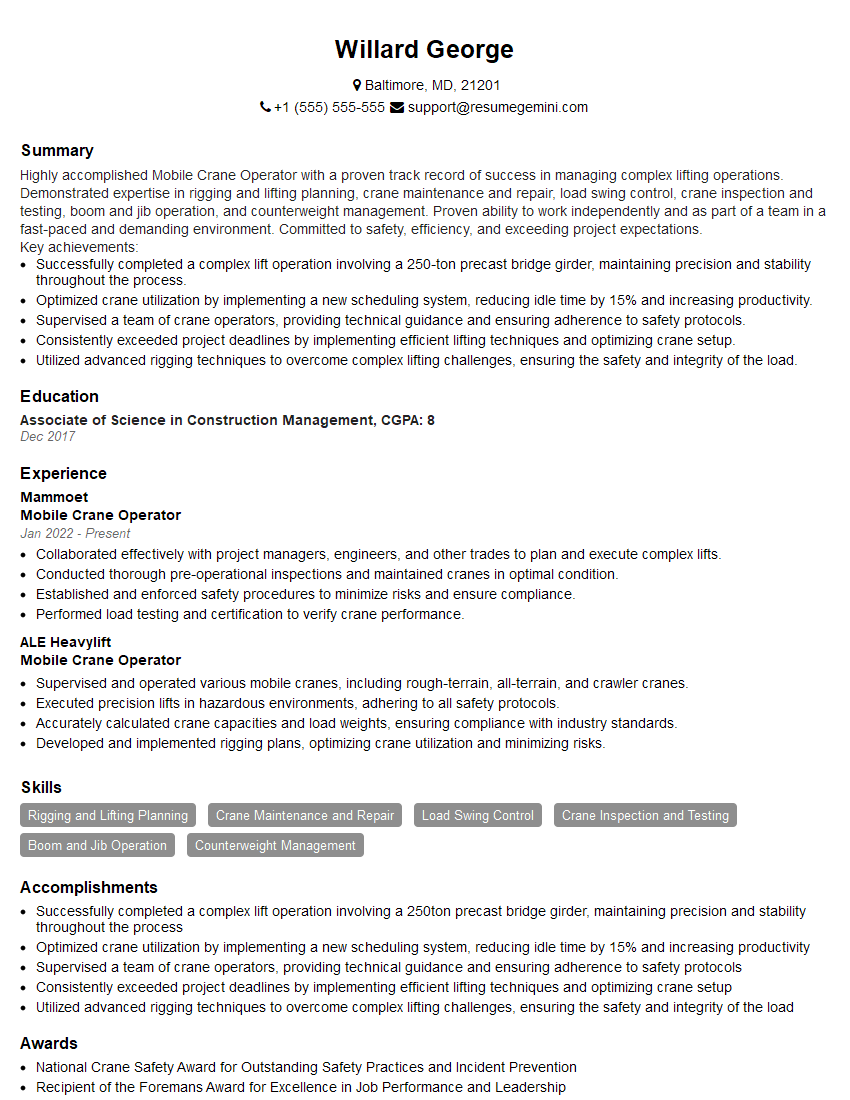

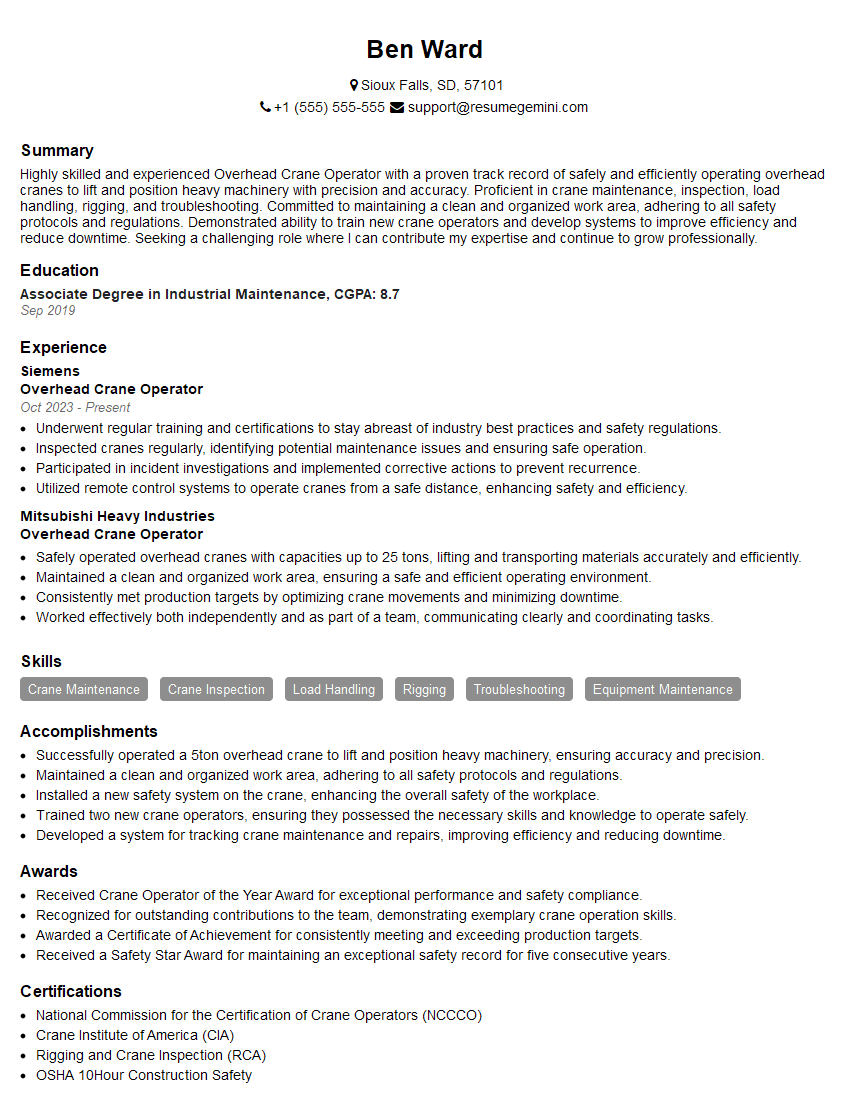

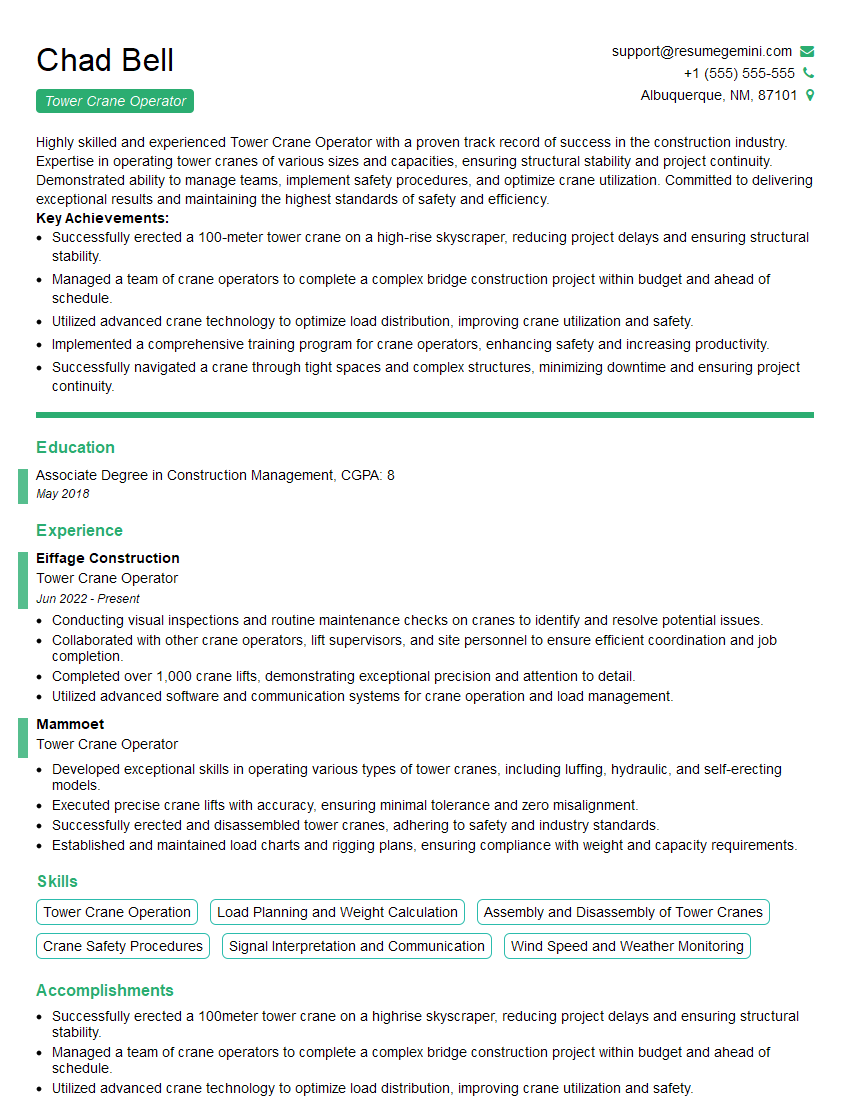

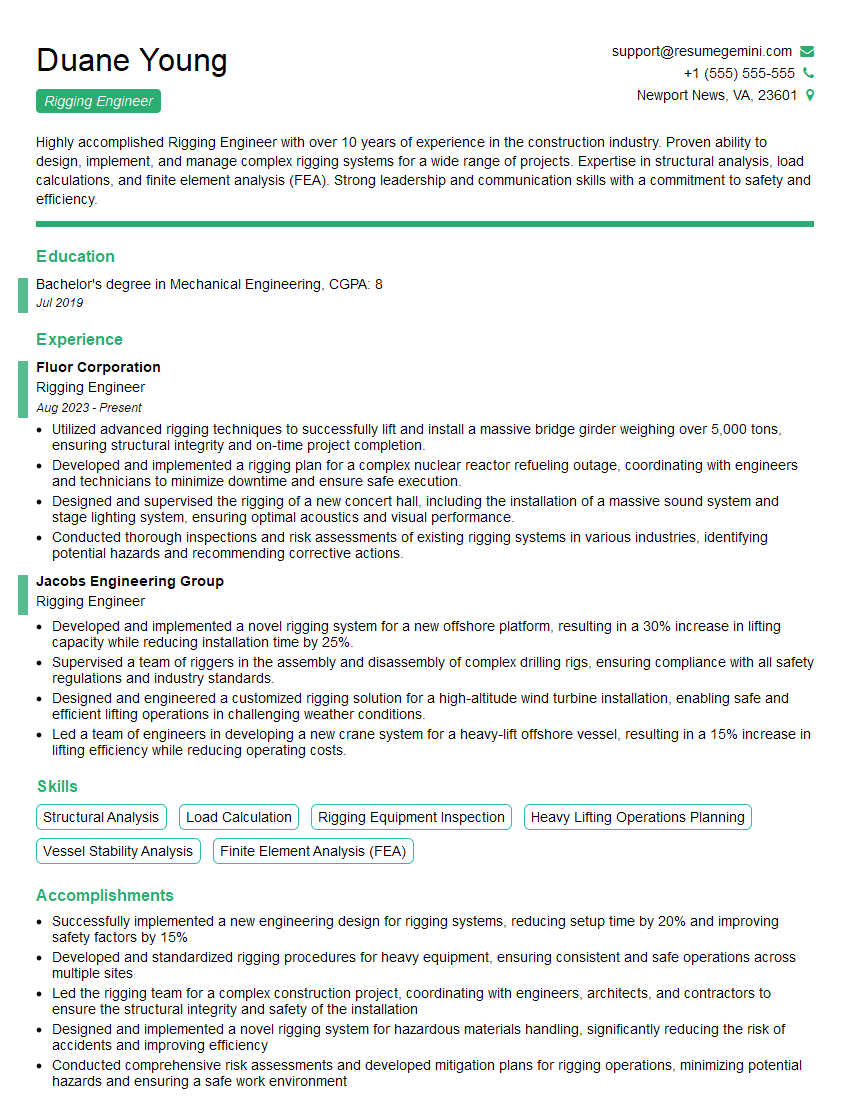

Mastering Crane and Rigging Equipment Operation opens doors to exciting career opportunities with excellent growth potential in construction, manufacturing, and logistics. A strong resume is your key to unlocking these opportunities. To maximize your chances, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that grabs the attention of recruiters. They offer examples of resumes tailored to Crane and Rigging Equipment Operation to help you get started. Invest the time to craft a compelling resume – it’s your first impression and sets the stage for interview success!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good