Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Crane Boom Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Crane Boom Operation Interview

Q 1. Explain the different types of crane booms and their applications.

Crane booms come in various types, each designed for specific lifting tasks. The choice depends on factors like the load’s weight, reach needed, and the job site’s constraints.

- Lattice Boom Cranes: These booms are constructed from a series of interconnected triangular sections. They offer a high strength-to-weight ratio, making them ideal for lifting heavy loads at significant distances. Think of them as incredibly strong and versatile scaffolding for lifting. I’ve used them extensively on large construction projects, like building skyscrapers.

- Telescopic Boom Cranes: These booms consist of multiple sections that can be extended or retracted hydraulically. This offers flexibility in adjusting the reach and lifting capacity. They’re commonly seen in smaller construction projects, where maneuverability is key. I remember using one to carefully place pre-fabricated building components on a tight city site.

- Fixed Boom Cranes: These cranes have a boom of a fixed length and are often used in situations requiring a stable and consistent reach. Think of the cranes you often see in ports or shipyards unloading containers – many are fixed boom type.

- Knuckle Boom Cranes: These are characterized by their articulated boom, enabling them to reach awkward positions and maneuver in tight spaces. They are frequently used in specialized applications, such as setting up equipment in narrow alleys or working on uneven terrain. I’ve found them indispensable for working in confined industrial settings.

Understanding these types and their capabilities is essential for selecting the right crane for a specific application and ensuring safe operation.

Q 2. Describe the process of calculating the load capacity of a crane boom.

Calculating a crane boom’s load capacity isn’t a simple formula but rather a complex process that considers multiple factors. It’s not something done on-the-fly; it requires careful reference to the crane’s specifications and load charts.

The process generally involves:

- Consulting the Crane’s Load Chart: This chart, provided by the manufacturer, is crucial. It shows the maximum safe load capacity for different boom lengths and angles.

- Determining the Boom Length and Angle: Accurate measurements are paramount. The length of the extended boom and the angle of the boom relative to the horizontal directly affect the load capacity.

- Accounting for Radius and Wind Speed: The distance of the load from the crane’s pivot point (radius) significantly impacts capacity. High wind speeds reduce the safe carrying capacity considerably – it’s not uncommon to need to stop work in high winds.

- Considering the Load’s Weight and Center of Gravity: Unevenly distributed loads or loads with high centers of gravity affect stability. This needs to be taken into account to prevent tipping.

- Applying Safety Factors: A safety factor, usually a percentage reduction of the theoretical capacity, is always applied to account for unforeseen circumstances and prevent accidents. This factor might be defined by local regulations as well.

Software applications are frequently used today to assist in these calculations, but understanding the underlying principles is critical for safe operation, and I always verify the software calculations against the manufacturer’s load charts.

Q 3. What are the safety regulations and procedures you must follow when operating a crane boom?

Safety is paramount in crane boom operations. Compliance with regulations and adherence to strict procedures are non-negotiable. These vary by location but generally include:

- Pre-operation Inspections: A thorough inspection of the crane, boom, rigging equipment, and surrounding area must be conducted before every lift. This includes checking for any damage, wear, or loose components.

- Proper Licensing and Certification: Operators must possess the necessary licenses and certifications demonstrating their competence and understanding of safety procedures. This is not only essential for the operators’ safety but for the overall safety of the construction site and public.

- Load Capacity Limits: Never exceed the crane’s rated load capacity. This applies to any crane configuration, including different boom lengths and angles.

- Safe Working Loads: Understanding and strictly adhering to safe working load (SWL) limits for all lifting components is critical. SWL markings must be clearly visible and adhered to.

- Emergency Shutdown Procedures: All personnel must be familiar with emergency stop procedures and understand how to shut down the crane safely in case of an emergency. Regular training drills are crucial for effective responses.

- Communication Protocols: Clear and effective communication between the crane operator, signal person, and ground crew is essential. Pre-defined hand signals or radio communication should be used.

- Fall Protection and Personal Protective Equipment (PPE): Appropriate PPE must be worn at all times, including hard hats, safety glasses, and high-visibility clothing.

Ignoring safety regulations can lead to catastrophic accidents, making adherence to them not just a matter of policy, but a moral imperative.

Q 4. How do you identify and assess potential hazards during crane boom operations?

Identifying and assessing hazards is a crucial part of pre-operation planning and ongoing crane operation. This involves a systematic approach, employing both visual inspections and situational awareness.

- Site Survey: Before commencing operations, a thorough site survey is essential. This includes identifying potential obstacles, such as overhead power lines, underground utilities, uneven ground, and any nearby structures.

- Weather Conditions: Wind speed, precipitation, and visibility significantly impact safe operation. Operations should be suspended in adverse weather conditions, as specified in the safety guidelines.

- Ground Conditions: The ground’s stability is crucial. Soft or unstable ground may compromise the crane’s stability, necessitating the use of ground mats or other supporting structures.

- Load Condition: Checking the weight and how the load is secured is vital. A load that shifts could cause an accident.

- Personnel Safety: Ensure that the work area is clearly marked and that personnel are kept at a safe distance from the crane’s operating radius. This includes establishing exclusion zones.

- Equipment Condition: Regularly check the crane’s condition, paying special attention to the boom, hoisting mechanism, and brakes. Any signs of wear or damage should be immediately addressed and rectified.

A comprehensive hazard identification and risk assessment process, documented meticulously, forms the bedrock of safe crane operations. Failing to do so can have deadly consequences.

Q 5. Explain the importance of proper rigging techniques in crane boom operation.

Proper rigging techniques are absolutely crucial for safe and efficient crane boom operation. Improper rigging can lead to load instability, equipment damage, and serious injuries or fatalities.

Key aspects of proper rigging include:

- Selecting the Right Rigging Hardware: Using appropriately sized and rated slings, shackles, hooks, and other rigging components is vital. The SWL of each component should be checked and should never be exceeded.

- Proper Sling Angles: Using slings at too narrow an angle can dramatically reduce their capacity. A general rule of thumb is to keep the sling angles as close to 60 degrees as possible to distribute the load efficiently across the sling legs.

- Secure Load Attachment: The load must be securely fastened to the rigging equipment, using appropriate securing methods to prevent shifting or slippage during lifting. The correct attachment point on the load needs to be determined as well.

- Load Balance: Ensuring the load is balanced to avoid any unnecessary stresses on the crane or rigging equipment is paramount. This requires careful consideration of the load’s center of gravity.

- Inspection Before and After Use: Rigging equipment should be inspected before each use and again after use to ensure it is in good condition and free of damage. Damaged equipment should be immediately replaced.

Rigging isn’t just about attaching the load; it’s about understanding the physics of load distribution, stress points, and equipment limitations. Improper rigging is a common cause of crane accidents, so rigorous attention to detail is critical.

Q 6. Describe your experience with different types of crane boom controls.

Throughout my career, I’ve had extensive experience with various crane boom control systems. Modern cranes utilize a range of control methods, each offering different levels of precision and automation.

- Conventional Lever Controls: These are the more traditional mechanical controls, which are very reliable but can require significant operator skill to execute precision movements.

- Joystick Controls: These provide more precise and proportional control of the crane’s movements, making them easier to operate and ideal for complex lifting tasks. I find them significantly better for fine adjustments when positioning sensitive loads.

- Computerized Control Systems: Many modern cranes incorporate computerized control systems that provide increased safety features, data logging, and remote operation capabilities. These are usually integrated with sensors to provide real-time feedback on load capacity and safety limits.

- Radio Remote Controls: These allow the operator to control the crane from a distance, providing enhanced safety in hazardous environments or when visibility is limited. The use of these is critical for working on larger construction sites where operators need to be at a safe distance from the crane.

Understanding the nuances of each control system is critical to safe and efficient operation. Knowing how to react in different control scenarios and situations has prevented multiple accidents in my experience.

Q 7. How do you handle unexpected situations or emergencies during crane operations?

Handling unexpected situations and emergencies demands quick thinking, calm decision-making, and adherence to established procedures. My approach involves:

- Immediate Assessment: Quickly assess the nature and severity of the situation. Is it a mechanical failure, a load instability, or an environmental hazard?

- Emergency Shutdown: If necessary, immediately initiate the emergency shutdown procedures to secure the crane and prevent further incidents. This involves a sequential process: stop lift, lower boom, secure the load.

- Communication: Communicate the situation to the ground crew, supervisors, and emergency services as appropriate. Clear and concise communication is crucial to coordinate rescue efforts.

- Evacuation and Safety: Ensure the safety of all personnel in the vicinity by clearing the danger zone and following evacuation procedures.

- Post-Incident Procedures: After the situation is under control, implement post-incident procedures, including damage assessment, investigation, reporting, and documenting the incident thoroughly.

Regular training and emergency drills prepare us for such events, enabling us to react effectively and minimize potential harm. The ability to think on your feet and calmly assess a potentially dangerous situation is something you learn through experience, but the foundation must be built on rigorous training and safety protocols.

Q 8. What are the signs of a malfunctioning crane boom and how would you respond?

A malfunctioning crane boom can manifest in several ways, all posing significant safety risks. Signs can be subtle or obvious. For example, you might notice unusual noises like creaking, groaning, or metallic grinding during operation, indicating potential wear and tear or structural damage. A boom that bends or deflects excessively under load, beyond its normal flex, is a serious warning sign. Oil leaks from hydraulic cylinders or joints are another red flag, suggesting compromised seals and potential hydraulic failure. Difficulty in extending or retracting the boom, including sluggish movement or complete failure to respond to controls, points to problems in the hydraulic system or mechanical linkages. Finally, any visible damage, such as cracks, dents, or corrosion on the boom structure, requires immediate attention.

My response to any of these signs would follow a strict protocol: First, I would immediately cease all lifting operations and secure the load. Second, I would conduct a thorough visual inspection of the entire boom structure, paying close attention to the areas exhibiting problems. Third, I would report the malfunction to my supervisor and the relevant safety personnel. Depending on the severity of the issue, I may need to call for a qualified crane inspector for a full assessment. Under no circumstances would I attempt to operate the crane until it has been deemed safe by a competent authority.

Q 9. Explain your understanding of load charts and how you use them.

Load charts are crucial safety documents that provide the maximum allowable load capacity of a crane for different boom lengths and angles. They are essentially a graphical representation of the safe working load limits, preventing overloading and potential catastrophic failures. Think of it like a recipe for safe lifting; follow the instructions, and the result is a successful lift.

I use load charts extensively before, during, and after every lifting operation. Before a lift, I identify the weight of the load, the boom length required, and the boom angle. I then locate this information on the load chart to ensure that the combination is within the safe operating limits. During the lift, I constantly monitor the load and the boom configuration, referring back to the chart if conditions change. After the lift, I ensure all data is properly recorded to maintain a detailed history of the operation.

For example, if the chart shows a maximum capacity of 10 tons at a 30-meter boom extension and a 45-degree angle, I will refuse any load exceeding 10 tons under these conditions. Non-compliance would risk compromising the structural integrity of the crane and could lead to an accident. Always prioritizing safety is paramount.

Q 10. How do you ensure the stability of the crane during lifting operations?

Ensuring crane stability is paramount for safe operation. This involves several key factors. First, proper outrigger placement is vital. Outriggers provide a wider base, significantly improving the crane’s stability. The ground conditions must also be suitable; soft or uneven ground can compromise stability. Before deploying outriggers, I always inspect the ground for any potential hazards.

Secondly, the load’s center of gravity plays a critical role. I always consider the load’s weight distribution and its potential to shift during lifting. If the center of gravity is off, it can cause instability. Careful planning and smooth operation are critical here. Additionally, wind conditions significantly affect stability. High winds can cause the boom to sway, increasing the risk of tipping. Lifting operations are often halted in high-wind conditions. Finally, proper counterweight distribution helps to counterbalance the lifted load, ensuring stable operation. All these factors work in concert to maintain stability. I might visualize it as a three-legged stool—if any leg is weak, the whole structure is at risk.

Q 11. What are the limitations of a crane boom, and how do you work within those limits?

Crane booms have inherent limitations, primarily in their lifting capacity, reach, and angle. The load chart clearly defines these limits. Exceeding these limits can lead to structural failure. The boom’s maximum lifting capacity decreases with increasing reach and angle. For example, lifting a heavy load at maximum reach requires the boom to be at its minimum angle and the crane to be in optimal stability conditions.

I work within these limits by meticulously consulting and adhering to the load chart for each operation. Before any lift, I carefully assess the weight of the load, desired placement, and required boom configuration. If the required conditions exceed the limits, I will develop an alternate plan, potentially involving multiple lifts, using a larger crane, or adjusting the placement of the load. Safety is the absolute priority, and working within the limitations of the equipment ensures this.

Q 12. Describe your experience with different types of crane boom attachments.

My experience encompasses a wide range of crane boom attachments, including hooks, magnets, buckets, and specialized lifting beams. Hooks are the most common attachment, suitable for general lifting tasks. Magnets are ideal for handling ferrous materials efficiently, while buckets are perfect for bulk material handling. Specialized lifting beams are designed for particular loads, providing secure and controlled lifting. Each attachment requires a specific understanding of its capabilities and limitations. For instance, a magnet’s holding power is affected by the material’s magnetic properties and its surface condition.

For example, I have used a clamshell bucket for moving bulk material in construction projects, a specialized lifting beam to handle delicate machinery components, and a magnet to transport steel plate. Before attaching any load to a crane boom, I perform a thorough inspection of both the load and the attachment to make sure everything is properly secured and suited for the task at hand.

Q 13. How do weather conditions affect crane boom operation, and what precautions do you take?

Weather conditions significantly impact crane boom operation. High winds can cause the boom to sway violently, increasing the risk of tipping and load swing. Rain and snow can reduce visibility and create slippery conditions, affecting the stability of the crane and the safety of personnel. Extreme temperatures can also affect the performance of the crane’s hydraulic systems and the load-bearing capacity of the boom.

To mitigate these risks, I adhere to strict weather-related safety protocols. High winds necessitate suspending operations altogether. In light rain, I might proceed cautiously, but with enhanced vigilance. Snow or ice conditions typically require a full cessation of operations. I always consult weather forecasts prior to starting any lifting operation and remain updated throughout the day. I always prioritize safety above all else, understanding that operating under adverse weather conditions can compromise safety significantly.

Q 14. Explain the process of pre-operational checks for a crane boom.

Pre-operational checks are non-negotiable for safe crane boom operation. My process starts with a thorough visual inspection of the entire crane, including the boom, cables, hydraulics, and other components, checking for any signs of damage, leaks, or wear. I then verify the functionality of all controls, ensuring smooth and responsive operation. Next, I check the load charts to confirm that the crane is appropriately configured for the intended lift. This is followed by a check of the outrigger deployment mechanism and the surrounding area to ensure it’s suitable for stable operation.

The specific checks often include examining the boom for cracks, dents, or corrosion; inspecting the hydraulic hoses and cylinders for leaks; testing the emergency stop mechanisms; and confirming the functionality of the load indicators. Finally, I conduct a test lift with a small load to ensure the crane is operating smoothly and safely before attempting the main lift. This structured approach minimizes the risk of failure and significantly enhances safety.

Q 15. How do you communicate effectively with the signal person and other crew members?

Effective communication with the signal person and crew is paramount for safe crane operation. It’s not just about giving and receiving instructions; it’s about building trust and ensuring everyone understands the plan. I utilize a clear, concise, and standardized system. Before any lift, we conduct a thorough job briefing, confirming the load weight, center of gravity, and intended placement. During the lift, I use hand signals that are universally recognized and reinforced verbally, especially in noisy environments. For example, if there’s a slight misalignment, I’ll verbally confirm the adjustment with the signal person before proceeding. After the lift, we conduct a post-lift debrief, discussing any challenges and identifying areas for improvement in future operations. Open communication channels are key—if someone has a concern, they should feel empowered to voice it immediately. This collaborative approach minimizes misunderstandings and prevents accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of crane accidents, and how can they be prevented?

Crane accidents stem from a variety of factors, but many are preventable with diligent safety practices. Common causes include operator error (improper rigging, exceeding load capacity, neglecting pre-lift checks), equipment failure (inadequate maintenance, structural defects), environmental factors (wind, unstable ground conditions), and inadequate communication. Prevention involves a multi-pronged approach. First, rigorous pre-operational checks of the crane and all lifting equipment are essential. This includes visual inspections for damage, verifying load capacity, and testing all mechanisms. Operator training is crucial, ensuring proficiency in safe operating procedures and emergency response. Regular maintenance schedules and thorough inspections help prevent equipment failure. Understanding and mitigating environmental risks, such as wind speed limitations, are critical. And finally, clear communication protocols, as discussed previously, are non-negotiable for a safe working environment.

Q 17. Describe your experience with different types of lifting slings and their applications.

My experience encompasses a wide range of lifting slings, each with its specific strengths and applications. I’m proficient with wire rope slings, which are exceptionally strong and durable, ideal for heavy lifting and harsh environments. However, they require careful inspection for fraying or kinking. I also have extensive experience with synthetic web slings, known for their flexibility and ease of handling. They’re less prone to damage from abrasion than wire rope, making them suitable for delicate loads. Chain slings provide high strength and resistance to abrasion and impact, but require careful attention to wear and stretch. Selecting the appropriate sling hinges on the load’s characteristics (weight, shape, fragility), the lifting environment, and the crane’s capabilities. For instance, I would choose synthetic web slings for a fragile piece of equipment, whereas wire rope slings would be preferred for a heavy steel beam. Proper sling angle is also critical; exceeding the manufacturer’s recommendations can significantly reduce the sling’s working load limit.

Q 18. How do you inspect a crane boom for damage or wear and tear?

Inspecting a crane boom for damage is a systematic process that starts with a visual examination. I check for obvious signs of damage, such as cracks, dents, bends, or corrosion. I pay close attention to welds and connections, looking for signs of stress or fatigue. I examine the boom’s surface for any pitting or rust that could compromise its structural integrity. The boom’s hoisting mechanism is carefully checked for proper functioning and wear. Any signs of lubricant leaks or unusual noises are noted. I also look for evidence of previous repairs, ensuring they were performed correctly and haven’t weakened the boom. Beyond the visual inspection, a more thorough inspection might involve non-destructive testing (NDT) methods such as ultrasonic testing or magnetic particle inspection, depending on the severity of concerns or regulatory requirements. Comprehensive documentation of every inspection is crucial to maintain a history of the boom’s condition.

Q 19. Explain your understanding of the different types of crane boom configurations.

Crane booms come in various configurations, each designed for specific applications. The most common are lattice booms, which are constructed from interconnected members, offering a high strength-to-weight ratio and are commonly used for heavier lifts. They are also more easily extended or shortened to achieve various reach. Then there are telescopic booms, which consist of nested sections that can be extended hydraulically, offering increased versatility in terms of reach and lifting capacity. They are ideal for jobs requiring variable reach. Finally, we have the jib booms, which are shorter booms mounted on the main boom and are mainly used to extend the reach or to position the load in tight spaces or areas with obstructions. The choice of boom type depends heavily on the specific lifting requirements and the characteristics of the worksite. For example, a lattice boom would be suitable for constructing a high-rise building, whereas a telescopic boom might be better suited for a smaller construction site where maneuverability is paramount.

Q 20. How do you maintain a crane boom to ensure its safe operation?

Maintaining a crane boom is vital for safety and longevity. This involves regular lubrication of moving parts, keeping the boom clean and free of debris, and promptly addressing any signs of damage. Regular inspections, as described earlier, are critical. I also ensure proper storage procedures, protecting the boom from weather elements when not in use. Paints and coatings help prevent corrosion, thus extending the lifespan and improving safety. Any repairs or replacements should be conducted by qualified personnel using approved materials, adhering strictly to the manufacturer’s specifications. Maintaining detailed maintenance logs, tracking inspections, repairs, and parts replacements is crucial for compliance and traceability. A well-maintained boom, subjected to a rigorous maintenance program, minimizes risk and maximizes operational efficiency.

Q 21. Describe your experience with working at height and the associated safety measures.

Working at height is an inherent part of crane operation, and safety is always my top priority. I adhere strictly to all safety regulations and utilize appropriate fall protection equipment, such as harnesses and lanyards, ensuring they are correctly fitted and inspected before use. I am well-versed in the use of scaffolding, platforms, and other elevated work areas. Regular training on safety procedures and emergency response is crucial. Before commencing any work at height, I conduct a thorough risk assessment, identifying potential hazards and implementing appropriate control measures. This includes evaluating weather conditions, structural integrity of the work area, and ensuring secure access and egress. Communication is key, using clear verbal signals and visual confirmation to maintain situational awareness. Ultimately, I treat every lift and work at height with the seriousness and attention to detail it deserves, ensuring not only my safety but also the safety of the entire crew.

Q 22. How do you plan a crane lift to ensure its safety and efficiency?

Planning a safe and efficient crane lift involves a meticulous process that begins long before the crane even arrives on site. It’s like planning a complex military operation – every detail matters.

- Site Survey: Thorough assessment of the area, including ground conditions, obstructions, access routes, and proximity to power lines or other hazards. We need to know exactly what we’re working with.

- Load Analysis: Precisely determining the weight, center of gravity, and dimensions of the load. This isn’t just a guess; we use detailed calculations and engineering drawings. An incorrect weight estimation can have catastrophic consequences.

- Crane Selection: Choosing the right crane with sufficient lifting capacity, reach, and stability for the specific task. This isn’t about picking the biggest crane; it’s about finding the right tool for the job.

- Lift Plan Development: Creating a detailed plan outlining the lifting sequence, including crane positioning, rigging methods, signaling procedures, and emergency protocols. This plan is like a roadmap for the entire operation.

- Risk Assessment: Identifying and mitigating potential hazards, such as wind conditions, ground instability, and operator fatigue. We need to think about all the ‘what-ifs’ and how to handle them.

- Communication and Coordination: Establishing clear communication channels among the crane operator, riggers, signal person, and other personnel involved. Miscommunication is a recipe for disaster.

For example, during a recent bridge construction project, we meticulously surveyed the area to identify potential ground instability due to nearby riverbanks. This led us to choose a crawler crane, which provides superior stability on uneven terrain, over a mobile crane. The lift plan detailed specific procedures to stabilize the load and account for potential wind gusts.

Q 23. What are the legal requirements related to crane operation in your region?

Legal requirements for crane operation vary by region, but generally involve strict adherence to national and local safety regulations. These often include licensing and certification for operators, regular crane inspections and maintenance, and detailed record-keeping. Think of it as a driver’s license, but for operating heavy machinery.

- Operator Certification: Operators must possess valid licenses demonstrating proficiency and knowledge of safe operating procedures. In my region, this includes a thorough written and practical exam.

- Regular Inspections: Cranes undergo routine inspections to ensure their structural integrity and operational safety. These inspections are conducted by qualified personnel and documented meticulously.

- Safety Regulations Compliance: We strictly adhere to regulations regarding load limits, wind speeds, and safe working practices. There are specific regulations regarding load charts, rigging techniques, and proximity to overhead power lines.

- Thorough Documentation: Detailed records of all crane operations, including pre-lift inspections, load charts, and any incidents, must be maintained. This helps in tracing issues and improving safety procedures.

Ignoring these regulations can result in hefty fines, operational shutdowns, and, more importantly, serious injuries or fatalities. Safety is not just a priority; it’s the law.

Q 24. Describe your experience with using different types of crane boom monitoring systems.

Throughout my career, I’ve worked with various crane boom monitoring systems, each with unique strengths and weaknesses. These systems are vital for enhancing safety and efficiency.

- Load Moment Indicators (LMIs): These are standard equipment, providing real-time data on the crane’s load, radius, and stability. They prevent overloading and tipping by constantly monitoring these factors. It’s like having a co-pilot in the cab that constantly checks if the crane is operating within its limits.

- Wireless Remote Monitoring Systems: These systems allow for remote monitoring of critical parameters such as boom angle, hook height, and load weight. This is beneficial for lifts in hazardous environments where an on-site operator might be at risk.

- Advanced Sensor Systems: Newer systems incorporate advanced sensors to detect wind speed, ground conditions, and even potential structural issues with the crane itself. These provide early warnings to avert potential accidents. This is like having a sophisticated weather forecasting system specifically for the crane operation.

I’ve found that integrating these different systems enhances situational awareness and proactive safety measures, resulting in smoother and safer operations. For instance, during a high-rise construction project, the wireless remote monitoring system allowed us to oversee the lifting operations from a safe distance, providing a better overall view of the complex process.

Q 25. How do you handle difficult or challenging lifting tasks?

Challenging lifts require a methodical approach that combines experience, ingenuity, and a healthy dose of caution. It’s like solving a complex puzzle.

- Detailed Analysis: We start by thoroughly analyzing the specific challenges, such as limited access, confined spaces, or unusual load configurations. We need to break down the challenge into manageable parts.

- Alternative Strategies: We explore different lifting strategies, including using specialized rigging techniques, temporary supports, or multiple cranes if necessary. It might require thinking outside the box.

- Collaboration and Expertise: We consult with engineers, structural experts, and other professionals to find the safest and most effective solution. This ensures that we have all the information and skills needed.

- Rigorous Safety Precautions: We implement additional safety measures, such as spotters, extra safety lines, and meticulous planning to account for the increased risks. Safety must always be the top priority.

For example, we once had to lift a massive transformer into a tight, confined space with limited overhead clearance. We used a combination of specialized rigging, a smaller, more maneuverable crane, and a carefully choreographed lift sequence to complete the task safely and efficiently.

Q 26. Explain your understanding of load moment indicator (LMI) systems.

A Load Moment Indicator (LMI) system is a critical safety device that continuously monitors and displays the crane’s load moment, preventing overloading and potential tipping. It’s like a sophisticated warning system for the crane.

The LMI calculates the load moment – a measure of the potential for the crane to tip over – by considering factors such as the load weight, the boom’s radius, and the crane’s configuration. It uses sensors to measure these factors and displays the load moment against a safe working load. If the calculated load moment exceeds the safe limit, the LMI system will typically sound an alarm and prevent further lifting or hoisting, thus averting a potentially dangerous situation.

Modern LMIs often incorporate additional features like load weight displays, boom angle indicators, and even real-time graphical representations of the crane’s stability. These systems are essential for safe and efficient operation, minimizing the risk of accidents.

Q 27. Describe a time you had to troubleshoot a problem with a crane boom.

During a large-scale demolition project, the main hoist of our crane unexpectedly experienced intermittent power failures. It was like a sudden cardiac arrest in a vital organ of our operation.

Our initial troubleshooting focused on the power supply to the crane, checking for faulty connections and voltage drops. However, the problem persisted. We then systematically checked the internal wiring of the hoist mechanism itself, discovering a loose connection within the motor controller. Once this was tightened, the power failures stopped and the crane resumed normal operations.

This experience underscored the importance of thorough electrical checks and preventative maintenance. A simple loose connection could have resulted in a serious accident. We also implemented a more robust inspection routine post-incident.

Q 28. How do you stay updated on the latest safety regulations and best practices for crane operation?

Staying updated on safety regulations and best practices is paramount in this field. It’s like keeping your medical license current – continuous learning is a necessity.

- Industry Publications and Journals: I regularly read trade magazines and journals to stay abreast of the latest safety standards and technological advancements. It’s about understanding both theoretical advancements and practical implications.

- Professional Organizations: Membership in professional organizations like the Association of Crane and Rigging Professionals provides access to training materials, conferences, and networking opportunities. Sharing knowledge is crucial for the industry.

- Manufacturer Training: Attending training courses offered by crane manufacturers keeps me updated on the specific features and safety protocols of different crane models. The manufacturer often knows their product best.

- Regulatory Agency Updates: Staying informed on changes to national and local safety regulations is essential to maintain compliance and ensure safe operating practices. Regulations evolve, and staying current prevents any accidental violation.

Continuous learning isn’t just about compliance; it’s about enhancing operational safety and improving efficiency. The crane industry is constantly evolving, and I need to evolve with it.

Key Topics to Learn for Crane Boom Operation Interview

- Crane Boom Mechanics: Understanding the physics of boom operation, including load capacity, center of gravity, and stability calculations. Practical application: Calculating safe working loads for various boom configurations and load types.

- Safe Operating Procedures (SOPs): Thorough knowledge of industry-standard safety protocols, pre-operation checks, and emergency procedures. Practical application: Describing your approach to a scenario involving a potential safety hazard during operation.

- Load Chart Interpretation & Application: Accurately interpreting load charts to determine safe lifting capacities under different conditions (wind speed, boom angle, etc.). Practical application: Explaining how you would select the appropriate crane and boom configuration for a specific lifting task.

- Rigging Techniques: Understanding proper slinging, attaching, and releasing loads, including various rigging hardware and their limitations. Practical application: Detailing your experience with different types of slings and their application in specific lifting scenarios.

- Troubleshooting & Maintenance: Identifying and addressing common mechanical issues, performing basic maintenance checks, and understanding preventative maintenance schedules. Practical application: Describing your problem-solving process when encountering a malfunction during operation.

- Communication & Teamwork: Effective communication with ground crew, signal persons, and supervisors to ensure safe and efficient operation. Practical application: Describing your experience working collaboratively in a team environment on complex lifting projects.

- Regulations & Compliance: Familiarity with relevant safety regulations and compliance requirements for crane boom operation. Practical application: Explaining your understanding of relevant OSHA or other regional safety standards.

Next Steps

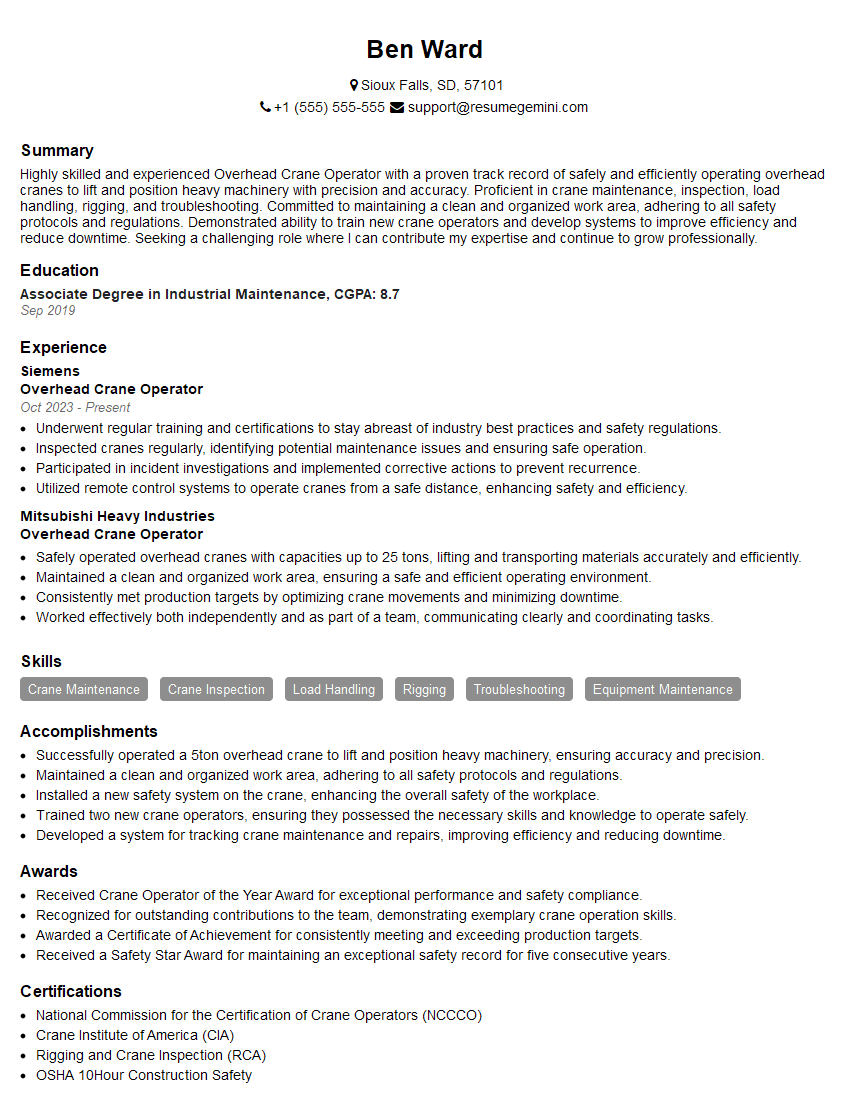

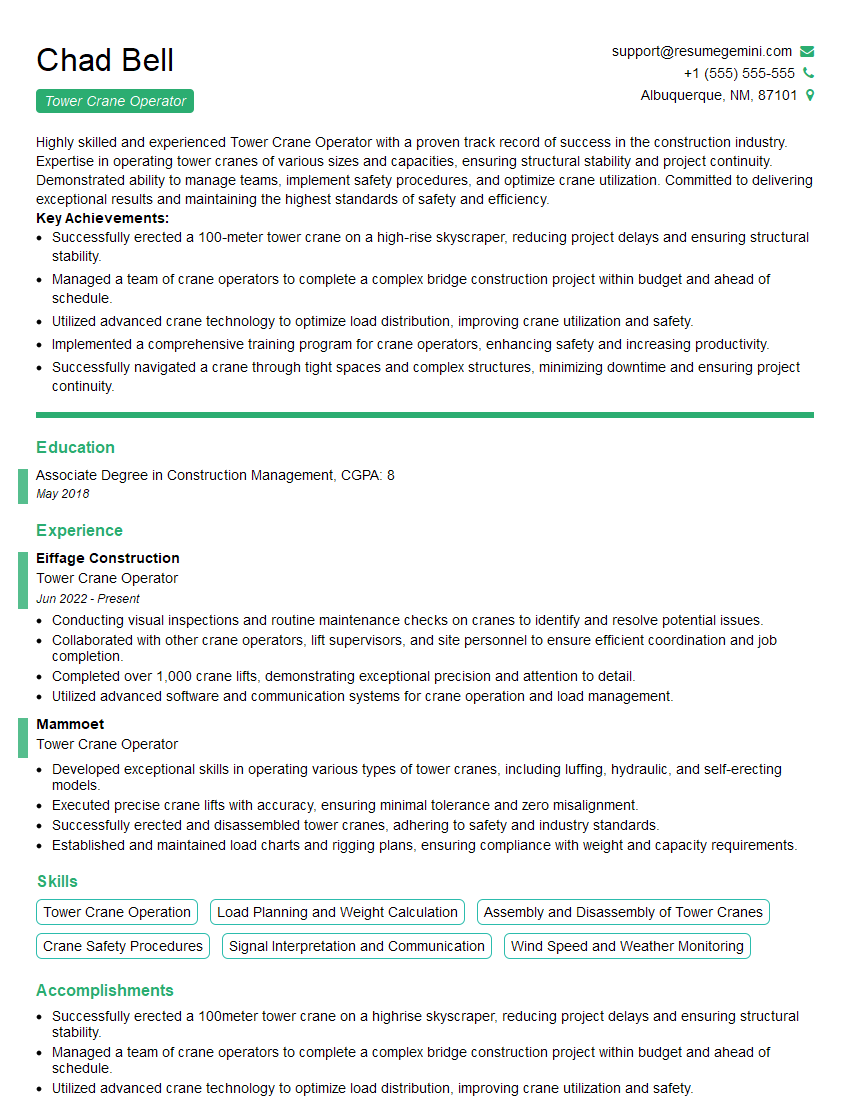

Mastering Crane Boom Operation opens doors to rewarding and high-demand careers within construction, logistics, and industrial settings. To stand out to potential employers, a well-crafted resume is crucial. Building an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you create a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Crane Boom Operation are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good