Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Crane Management interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Crane Management Interview

Q 1. What are the different types of cranes and their applications?

Cranes are classified into various types based on their design, mobility, and operational characteristics. Here are some key examples:

- Tower Cranes: These are tall, freestanding cranes typically used in large-scale construction projects, offering high lifting capacity and reach. Think of the massive cranes you see on skyscrapers under construction.

- Mobile Cranes: These cranes are mounted on wheeled or tracked vehicles, offering excellent mobility on construction sites. They are versatile and are used for a wide range of lifting tasks, from moving heavy equipment to placing prefabricated building components.

- Overhead Cranes: These cranes run along tracks fixed to the ceiling or walls of a building, often found in factories and warehouses. They are ideal for moving materials within a confined space.

- Crawler Cranes: Known for their stability and high lifting capacity, these cranes are mounted on tracks and are used for heavy lifting applications, such as bridge construction and large-scale industrial projects. Their heavy base provides excellent stability even on uneven terrain.

- Floating Cranes: As the name suggests, these cranes are mounted on barges or ships and are used for lifting and moving heavy objects in water, such as installing offshore platforms or raising sunken vessels.

- Truck-Mounted Cranes: Often seen on smaller construction sites or for utility work, these are cranes mounted on the bed of a truck, providing mobility and ease of transport.

The application of each type depends heavily on the specific project requirements, the weight and size of the load, the site conditions, and accessibility.

Q 2. Explain the process of pre-operational crane inspections.

Pre-operational crane inspections are crucial for ensuring the safe operation of the crane and preventing accidents. A thorough inspection should cover all critical components and involve a multi-step process:

- Visual Inspection: This involves carefully examining all parts of the crane, including the boom, hoist, slew mechanism, structural components, cables, hooks, and safety devices for any signs of damage, wear, corrosion, or misalignment. Pay close attention to cracks, deformations, loose bolts, or frayed wires.

- Functional Testing: This involves physically testing the crane’s systems, including lifting and lowering the load, slewing (rotating), and moving the boom. It checks for smooth operation, proper functionality of brakes and safety mechanisms, and the absence of any unusual noises or vibrations.

- Documentation: A detailed checklist should be used to document the inspection process. Any defects or issues found during the inspection should be recorded accurately, and corrective actions should be taken immediately before further operation.

- Operator’s Check: The crane operator should also conduct their own pre-operational checks, ensuring familiarity with the crane and its condition.

Imagine a scenario where a loose bolt was overlooked. During operation, that could lead to catastrophic failure, endangering personnel and property. A systematic and thorough pre-operational inspection serves as the first line of defense against such accidents.

Q 3. Describe your experience with load charts and weight calculations.

Load charts are essential documents that specify the safe working load limits (SWL) of a crane under different configurations (boom length, radius, and angle). Accurate weight calculation is paramount to avoid exceeding the crane’s capacity, which can lead to structural failure.

My experience involves using load charts provided by manufacturers and independently calculating weights based on the material’s density, dimensions, and other properties (e.g., using weight estimates for components if no accurate individual weights are known).

For instance, when lifting a steel beam, I would first ascertain its dimensions and density to calculate the weight and then refer to the crane’s load chart to verify that the lifting capacity at the required radius and boom length is not exceeded. Safety factors are also considered, often exceeding the calculated weight by a significant margin to account for unforeseen variables.

I’ve also utilized specialized software to calculate these weights and check against the load charts, improving accuracy and efficiency. In essence, accurate weight calculation and meticulous compliance with load charts are non-negotiable aspects of ensuring crane safety.

Q 4. How do you ensure the safety of personnel and equipment during crane operations?

Ensuring personnel and equipment safety during crane operations requires a multi-faceted approach:

- Proper Training and Certification: All crane operators should be properly trained and certified to operate the specific type of crane. This includes comprehensive instruction on safe operating procedures, emergency response, and hazard recognition.

- Risk Assessment: A thorough risk assessment should be conducted before each lift, taking into consideration the weight of the load, environmental factors, nearby obstacles, and the competency of the operating crew. This assessment identifies potential hazards and defines mitigation strategies.

- Safe Operating Procedures: Clear and concise safe operating procedures should be developed and followed religiously. This includes procedures for lifting, lowering, maneuvering the load, and emergency stops.

- Signal Persons: Qualified signal persons are essential, particularly in complex lifting operations, to guide the operator and ensure clear communication. Hand signals should be standardized and understood by everyone involved.

- Exclusion Zones: Clearly defined exclusion zones should be established around the crane’s operating area to prevent unauthorized personnel from entering the danger zone.

- Regular Maintenance: Regular maintenance and inspections of the crane are essential to identify potential problems before they can cause accidents.

Imagine a scenario without exclusion zones – a worker carelessly walking into the swing radius could result in a severe accident. A proactive approach that incorporates all these elements is essential for preventing such incidents.

Q 5. What are the common causes of crane accidents and how can they be prevented?

Crane accidents are often attributed to several common causes:

- Operator Error: Inadequate training, fatigue, and lack of awareness of safe operating procedures are common causes of operator errors leading to accidents. This includes exceeding the crane’s capacity, improper lifting techniques, and failure to follow safety protocols.

- Mechanical Failure: Defective components, inadequate maintenance, and improper repair can lead to mechanical failures, causing the crane to malfunction during operation. This could involve structural failure, cable breakage, or brake failure.

- Environmental Factors: Adverse weather conditions such as high winds or heavy rain can compromise the stability of the crane and lead to accidents. Ground conditions also play a role; uneven or unstable ground can impact the crane’s stability.

- Inadequate Planning: Poor planning and risk assessment can lead to unforeseen hazards during crane operation. This includes neglecting to consider the weight of the load, the height of the lift, or the presence of obstacles.

Prevention involves meticulous planning, regular inspections, comprehensive operator training, and a robust safety culture. Implementing preventative measures like thorough pre-operational checks, establishing clear communication protocols, and consistently enforcing safety regulations significantly reduces the risk of crane accidents.

Q 6. Explain your understanding of crane load stability and swing radius.

Crane load stability and swing radius are crucial considerations for safe crane operation.

Load Stability: refers to the crane’s ability to maintain balance while supporting a load. Factors affecting stability include the weight of the load, the crane’s configuration (boom length and angle), and ground conditions. An unstable load risks tipping the crane, causing catastrophic failure.

Swing Radius: represents the area encompassed by the crane’s rotating boom. This area constitutes a significant hazard zone as the swinging load can cause serious damage or injuries if other people or equipment are within this radius. Understanding and respecting the swing radius is crucial for establishing safe exclusion zones and preventing accidents.

For example, imagine a scenario where a crane is lifting a heavy load close to a building. If the load were to swing unexpectedly, it could collide with the building, causing damage. A proper understanding of both load stability and swing radius would involve selecting an appropriate crane configuration, assessing ground stability, and creating a robust exclusion zone around the swing radius.

Q 7. Describe your experience with different types of crane rigging.

Crane rigging involves the selection and proper attachment of lifting equipment to the load. Different types of rigging are used depending on the load’s shape, weight, and characteristics.

- Wire Rope Slings: These are strong, versatile slings commonly used for lifting various loads. Different configurations are available, including single-leg, two-leg, three-leg, and four-leg slings, offering varied load distribution capabilities.

- Chain Slings: These slings offer superior resistance to abrasion compared to wire rope, but they can be heavier and have a lower breaking strength for the same size compared to wire ropes. Similar configurations exist as wire rope slings.

- Synthetic Webbing Slings: These slings are lightweight, easy to handle, and provide good grip, but they are generally not suited for sharp edges or high temperatures.

- Other Lifting Accessories: This includes shackles, hooks, clamps, spreader beams, and other specialized attachments used to securely connect the sling to the load and the crane hook. The choice of accessory significantly impacts load distribution and safe lifting.

Selecting the right type of rigging is critical. Using an unsuitable sling for a load could lead to equipment damage or injury. For instance, using a webbing sling to lift a heavy object with sharp edges can easily cut the webbing and lead to load failure. Proper inspection and maintenance of rigging equipment are crucial to ensure their continued safe operation.

Q 8. How do you handle unexpected situations or emergencies during crane operations?

Handling unexpected situations during crane operations requires a calm, decisive approach and adherence to established emergency protocols. My first priority is always the safety of personnel and property. This involves immediately stopping the operation, assessing the situation, and taking appropriate action based on the nature of the emergency.

- Equipment Malfunction: If a crane component malfunctions, I would immediately shut down the crane, secure the load, and report the incident to the supervisor. Depending on the severity, this might involve contacting qualified maintenance personnel for repairs or initiating a complete inspection of the crane before further use.

- Environmental Factors: Unexpected weather changes like strong winds or heavy rain necessitate immediate action. I would lower the load safely, secure the crane, and evacuate the area until conditions improve. This might involve implementing a weather monitoring system to anticipate such changes.

- Human Error: Mistakes in signaling or communication can lead to dangerous situations. My response would involve clear and concise communication with the crane operator and ground crew to rectify the error and prevent recurrence. This emphasizes the importance of rigorous training and regular communication drills.

In all cases, a thorough post-incident investigation is crucial to identify the root cause and implement corrective actions to prevent future occurrences. Documentation of the incident, including witness statements and photographic evidence, is vital for this process.

Q 9. What are the relevant safety regulations and standards for crane operation?

Crane operation is governed by a complex framework of safety regulations and standards, varying slightly depending on location. However, some overarching principles apply globally. Key regulations often involve:

- OSHA (Occupational Safety and Health Administration) Regulations (US): These regulations cover crane inspection, operator certification, load limits, and safe operating practices. They mandate regular inspections, operator training, and strict adherence to safety procedures.

- ASME (American Society of Mechanical Engineers) Standards: These provide detailed technical standards for crane design, construction, and maintenance, ensuring structural integrity and operational safety.

- ANSI (American National Standards Institute) Standards: These set forth guidelines for crane safety, including signaling procedures, load securing techniques, and emergency response plans.

- Local and National Regulations: Specific regulations vary by country and region. These might address specific environmental considerations, permit requirements, or site-specific safety protocols.

Understanding and adhering to these regulations is paramount. I regularly attend refresher courses and stay updated on any changes to maintain my competency.

Q 10. Explain your experience with crane maintenance and troubleshooting.

My experience with crane maintenance and troubleshooting is extensive. I’ve been involved in all aspects, from routine inspections to complex repairs. I am proficient in identifying and addressing various issues, including:

- Preventative Maintenance: This includes regular inspections of all crane components (hoist mechanisms, brakes, structural members, electrical systems) according to established schedules. This helps prevent major failures and extends the lifespan of the equipment. I meticulously document all inspections and any remedial actions taken.

- Troubleshooting: I have experience diagnosing and rectifying mechanical, electrical, and hydraulic faults. This involves systematically examining components, identifying the root cause of malfunction, and implementing appropriate repairs. This often entails working with specialized technicians when needed.

- Record Keeping: Comprehensive record keeping is critical. I maintain detailed logs of maintenance activities, repairs, and inspections, ensuring compliance with safety regulations and providing a history of the crane’s operational health.

For example, I once identified a failing bearing in a crane’s hoist mechanism during a routine inspection, preventing a potential catastrophic failure that could have resulted in significant downtime and safety risks.

Q 11. Describe your experience with crane communication and signaling procedures.

Effective communication and signaling are essential for safe crane operations. My experience encompasses various communication methods, including:

- Hand Signals: I am highly proficient in using standardized hand signals to communicate with crane operators, ensuring clear instructions regarding lifting, lowering, swinging, and other movements. Regular training and practice are vital to maintain proficiency in hand signals.

- Radio Communication: I use two-way radios for clear communication, especially in noisy environments or when visual contact is limited. Clear, concise language and confirmation of instructions are critical to ensure everyone is on the same page.

- Written Communication: Lift plans and other written documentation provide critical instructions and ensure everyone understands the lift procedures. This documentation might include details like load weight, center of gravity, and potential hazards.

I always ensure that all involved parties understand the signals and communication methods before initiating any lift. A shared understanding minimizes the risk of miscommunication and accidents.

Q 12. How do you ensure compliance with safety regulations and company policies?

Ensuring compliance with safety regulations and company policies is a core element of my work. This involves a multi-faceted approach:

- Regular Training: I participate in regular safety training to stay updated on best practices and regulatory changes. This keeps my knowledge current and ensures I am using the safest and most efficient methods.

- Documentation: I meticulously maintain all necessary documentation, including inspection reports, maintenance logs, and training records. This demonstrates adherence to regulations and allows for easy auditing.

- Proactive Reporting: I report any potential safety hazards or non-compliance issues immediately. This proactive approach prevents problems from escalating and ensures a safe working environment for everyone. This might include reporting faulty equipment or unsafe work practices.

- Compliance Audits: I actively participate in and support compliance audits, both internal and external. This ensures that our operations consistently meet all standards and regulations.

By adhering to these measures, I contribute to maintaining a workplace culture that prioritizes safety and prevents accidents.

Q 13. What is your experience with different types of lifting accessories?

My experience with different types of lifting accessories is broad and covers a wide range of equipment used for safe and efficient lifting operations. This includes:

- Slings: I’m familiar with various sling types, including wire rope slings, chain slings, and synthetic web slings, and understand their respective strengths, limitations, and proper inspection techniques. I know how to select the appropriate sling based on the load characteristics and working conditions. Incorrect sling selection can lead to catastrophic failures.

- Hooks: I understand the different types of hooks and their load capacities, ensuring that the correct hook is used for the specific lifting task. Regular inspections for damage or wear are crucial to prevent hook failures.

- Shackles: I am experienced in using shackles for connecting slings and other lifting attachments. I understand the importance of properly securing shackles and inspecting them for damage or wear.

- Other Attachments: This includes specialized attachments like spreader beams, clamps, and vacuum lifters, which are used for specific lifting requirements. The selection of these attachments must be done carefully to match the load and ensure safe lifting operations.

I always ensure that all lifting accessories are properly inspected before each use to ensure they are in good condition and suitable for the intended load. This preventative approach contributes significantly to safety.

Q 14. How do you manage risk assessments related to crane operations?

Risk assessment is a crucial aspect of crane operations. My approach involves a systematic process:

- Identification of Hazards: This involves identifying all potential hazards associated with the crane operation, including equipment malfunctions, environmental factors, and human error. This stage often involves a thorough site survey, reviewing past incident reports, and considering all possible scenarios.

- Risk Analysis: Once hazards are identified, I assess the likelihood of each hazard occurring and the potential severity of its consequences. This typically involves a qualitative or quantitative analysis, considering factors such as load weight, working height, and environmental conditions.

- Risk Control Measures: Based on the risk assessment, I develop and implement control measures to mitigate the identified risks. These measures could include using appropriate lifting equipment, implementing safety procedures, providing personal protective equipment (PPE), and using engineering controls like barriers and warning systems.

- Documentation and Review: All aspects of the risk assessment, including identified hazards, risk levels, and control measures, are documented. Regular review and updating of the risk assessment are essential to ensure its continued relevance and effectiveness.

The goal is to reduce the probability and severity of incidents to an acceptable level, minimizing the risks associated with crane operations.

Q 15. Explain your understanding of crane capacity and limitations.

Crane capacity refers to the maximum weight a crane can safely lift under specific conditions, while limitations encompass factors restricting its operational capabilities. Understanding both is crucial for safe and efficient operation.

Capacity: This is usually expressed in tons or kilograms and varies based on factors like the crane’s model, boom length, radius, and the configuration of the load (e.g., its shape, center of gravity).

Limitations: These include:

- Radius: The distance between the crane’s center of rotation and the load. Capacity decreases as radius increases.

- Boom Angle: The angle of the crane’s boom affects its lifting capacity; lifting capacity is usually lower at steeper angles.

- Wind Speed: High wind speeds significantly reduce safe lifting capacity and may completely halt operations.

- Ground Conditions: The stability of the crane’s foundation influences its capacity. Soft ground or uneven terrain reduces the safe lifting capacity.

- Load Sway: The pendulum-like motion of the load during lifting can become dangerous at higher weights and wind speeds, introducing a crucial limitation.

Practical Application: Before any lift, a lift plan must be prepared. This plan considers the load weight, dimensions, and center of gravity. It also incorporates all relevant capacity limitations based on the crane’s specifications and site conditions, using load charts provided by the manufacturer to determine if the lift is within safe parameters.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you plan and coordinate crane lifts in a construction site?

Planning and coordinating crane lifts requires meticulous attention to detail and thorough risk assessment. It involves a multi-step process:

Pre-lift Planning: This includes studying the site layout, identifying potential hazards, determining the lift path, selecting the appropriate crane and rigging equipment, calculating the weight and center of gravity of the load, and preparing a detailed lift plan, including emergency procedures.

Communication: Establishing clear communication channels between the crane operator, riggers, signal persons, spotters, and other site personnel is crucial. This often involves designated hand signals and two-way radios.

Risk Assessment: A thorough risk assessment identifies potential hazards, such as overhead obstructions, nearby personnel, power lines, and unstable ground conditions. This dictates control measures needed to mitigate risks.

Site Preparation: This involves preparing the crane’s foundation, ensuring the area around the crane is clear, and establishing designated safe zones for personnel.

Lift Execution: The lift is executed according to the lift plan, with constant communication and monitoring. The crane operator follows signals from the signal person, who ensures the safe execution of the lift.

Post-lift Inspection: After the lift, a thorough inspection of the crane and rigging equipment is conducted to ensure there is no damage.

Example: Imagine lifting a large prefabricated section for a building. The plan would detail the crane’s position, the lifting points on the section, the path it will take, wind speed limits, and emergency stop procedures. Communication protocols would be established, and spotters would be positioned to monitor the lift’s progress and ensure the safety of personnel.

Q 17. Describe your experience with different types of crane control systems.

My experience encompasses various crane control systems, ranging from traditional mechanical systems to modern computerized ones.

Mechanical Controls: These involve levers, cables, and pulleys to control the crane’s functions. While simpler in design, they require significant operator skill and experience for precise control.

Hydraulic Controls: These utilize hydraulic systems for smoother and more precise control. They often provide better load stability than purely mechanical systems.

Electronic Controls: Modern cranes frequently use electronic control systems with computer interfaces and sophisticated safety features, such as load moment indicators (LMIs) that prevent overloading, and anti-two-blocking systems that stop dangerous load movements.

Remote Controls: Some advanced cranes allow for remote operation, allowing the operator to control the crane from a safe distance using a radio control unit, improving safety in hazardous situations.

I’m proficient in working with various control interfaces and am adept at understanding the specifics and limitations of each type. My experience includes troubleshooting malfunctions and ensuring safety protocols are followed across these diverse systems.

Q 18. How do you manage communication between crane operators and ground personnel?

Effective communication between crane operators and ground personnel is paramount for safety. I utilize a multi-faceted approach:

Standard Hand Signals: These are universally recognized signals to communicate instructions clearly and concisely, especially in noisy environments. Regular training and drills ensure everyone understands these signals.

Two-Way Radios: These provide immediate verbal communication, allowing for quick responses and clarifications. This is essential for complex lifts or when hand signals are obscured.

Pre-Lift Briefing: A pre-lift briefing ensures all involved understand the plan, roles, and responsibilities. This session clarifies expectations and addresses potential concerns before the lift commences.

Designated Signal Person: A trained and designated signal person is crucial for directing the crane operator, ensuring clear and unambiguous communication.

Visual Aids: Using visual aids, like lift plans or diagrams, can enhance understanding, particularly during complex lifts.

Example: During a large steel erection, a designated signal person communicates with the crane operator using hand signals and radio communication. The signal person monitors the load’s movement and adjusts instructions as needed, providing critical situational awareness.

Q 19. What are your strategies for ensuring effective crane maintenance scheduling?

Effective crane maintenance scheduling is critical for safety and preventing costly downtime. My strategy involves:

Preventive Maintenance Schedule: This involves a scheduled program of regular inspections and servicing based on the manufacturer’s recommendations and operational hours. This includes lubrication, inspections of critical components, and functional testing.

Predictive Maintenance: Utilizing technologies like vibration analysis and oil analysis allows us to identify potential problems before they lead to failures. This proactive approach minimizes unexpected downtime and enhances overall efficiency.

Detailed Inspection Reports: Thorough records are kept after each inspection, including any identified issues and any corrective actions taken. This documentation provides a history of the crane’s condition, supporting proactive maintenance and compliance with safety regulations.

Compliance with Regulations: Adherence to all applicable safety regulations and standards is paramount. Regular inspections and maintenance ensure compliance and minimize risks.

Training and Competence: Maintenance personnel must be highly trained and competent to carry out repairs and inspections to the required standards.

By adopting this strategy, maintenance schedules are optimized, potential problems are identified early, and the crane’s operational lifespan is extended, enhancing safety and minimizing disruptions.

Q 20. Describe a time you had to solve a critical problem related to crane operation.

During a high-rise construction project, a critical situation arose when a load unexpectedly swung due to a sudden gust of wind. The load, a large concrete panel, was nearing the designated placement point but was threatening to collide with a partially constructed wall.

My immediate response involved:

Immediate Communication: I immediately alerted the crane operator and ground crew through the radio and hand signals to halt the lift.

Risk Assessment: We quickly assessed the situation, focusing on the risk of collision and potential damage or injury. The potential for structural damage to the building was significant.

Controlled Descent: The crane operator slowly and carefully lowered the load, guiding it away from the wall under my supervision.

Re-evaluation: We reevaluated the lift plan, factoring in the increased wind speed. We determined that resuming the lift in the current wind conditions was too dangerous and decided to postpone the lift until conditions improved.

Post-incident Review: After the incident, we conducted a thorough review of our procedures, identifying the need for better real-time wind monitoring and more robust safety protocols to handle unexpected wind gusts. This involved updating our site-specific risk assessment and implementing new emergency response procedures.

This experience highlighted the importance of quick thinking, clear communication, and a thorough understanding of emergency procedures in critical situations.

Q 21. What is your experience with emergency shutdown procedures for cranes?

Emergency shutdown procedures for cranes are critical for preventing accidents and damage. My experience covers various types of emergency situations and procedures.

Operator-Initiated Shutdowns: Crane operators are trained to immediately shut down the crane using the emergency stop button in response to any hazardous situation, such as an uncontrolled load swing, equipment malfunction, or a safety breach.

Ground Crew Intervention: In some cases, the ground crew may need to activate an emergency shutdown, either through a designated emergency stop switch or by alerting the operator of immediate danger.

Automatic Emergency Stops: Modern cranes often have automatic emergency stops activated by sensors that detect overloading, excessive wind speeds, or other critical conditions. These systems play a vital role in enhancing safety.

Post-Shutdown Procedures: Following an emergency shutdown, detailed procedures are in place. This includes securing the load, inspecting the crane for damage, documenting the incident, and determining the cause of the event to prevent future recurrences.

Training on emergency procedures is regularly conducted to ensure all personnel are proficient in their roles and responsibilities during an emergency.

Q 22. How do you handle crane inspections and certification processes?

Crane inspections and certifications are crucial for ensuring safe and efficient operation. My approach involves a multi-stage process, beginning with a thorough visual inspection covering all aspects of the crane – from the boom and hoisting mechanism to the electrical systems and safety devices. This includes checking for wear and tear, loose bolts, damaged cables, and any signs of malfunction. I meticulously document all findings using standardized checklists and digital photography. This is followed by more in-depth checks, which might involve non-destructive testing (NDT) techniques such as ultrasonic testing to detect internal flaws in critical components.

Certification follows a rigorous procedure, adhering to relevant industry standards and regulations (e.g., ASME B30, OSHA). This often involves engaging certified inspection bodies who verify the crane’s compliance, conduct load testing, and issue the necessary certification documentation. I actively participate in this process, providing all necessary information and ensuring the smooth execution of the certification tests. For example, during a recent inspection of a tower crane, a minor crack was detected in a weld on the boom. This led to a targeted NDT inspection and a temporary halt to operations until the repair was completed and re-certified. This proactive approach prevented a potentially catastrophic failure.

Q 23. Describe your experience with different types of crane foundations.

My experience encompasses a wide range of crane foundation types, each suited for different soil conditions and crane capacities. I’ve worked with everything from simple, shallow foundations for smaller mobile cranes to complex, deep foundations for large, heavy-duty tower cranes.

- Shallow Foundations: These are cost-effective and suitable for cranes with relatively low loads and stable soil conditions. They typically involve concrete footings or spread footings.

- Pile Foundations: Used where the soil is weak or the crane load is significant. Piles are driven deep into the ground to transfer the load to a stable stratum. I’ve been involved in projects using both driven and bored piles.

- Caissons: These are large, hollow concrete structures that provide a robust foundation for very heavy cranes in challenging soil conditions. They are often used for offshore cranes or very large land-based cranes.

- Mat Foundations: A large, reinforced concrete slab that distributes the crane’s load over a large area. This is a common choice when the crane is particularly heavy or the soil is very weak.

The selection of the appropriate foundation is critical for crane stability and safety and requires careful consideration of soil mechanics, crane load calculations, and relevant engineering codes.

Q 24. How do weather conditions affect crane operations and what precautions do you take?

Weather significantly impacts crane operations. High winds, heavy rain, snow, and ice can all compromise crane stability and safety. My approach involves a multi-layered safety protocol:

- Wind Speed Monitoring: We use anemometers to continuously monitor wind speed and direction. Operations cease if wind speeds exceed the crane’s operational limits, which are specified in the crane’s manual.

- Rain and Snow: Heavy rain or snow accumulation can increase the crane’s weight and reduce visibility, impacting safe operation. We often suspend operations in such conditions, or implement measures to clear accumulated snow or ice.

- Lighting: Poor visibility due to fog or darkness requires adequate lighting to ensure the safety of both the crane operator and ground personnel.

- Thunderstorms: Operations are halted during thunderstorms due to the risk of lightning strikes.

We adhere to strict weather-related operational guidelines that are detailed in our safety plans. For instance, during a recent project, unexpectedly high winds forced us to temporarily halt operations, preventing potential accidents.

Q 25. Explain your understanding of the different types of crane hook blocks.

Crane hook blocks are essential components of the hoisting system. They consist of sheaves (pulleys), a hook, and a frame. Different types exist to handle diverse lifting requirements.

- Single Sheave Blocks: The simplest type, with a single sheave for changing the direction of the load line.

- Multiple Sheave Blocks (Block and Tackle): These utilize multiple sheaves to achieve mechanical advantage, allowing the crane to lift heavier loads with less effort. The number of sheaves determines the mechanical advantage. For example, a three-sheave block would provide a 3:1 mechanical advantage.

- Swivel Blocks: Incorporate a swivel mechanism that allows the hook to rotate freely, preventing twisting of the load line.

- Heavy-Duty Blocks: Designed for lifting extremely heavy loads, often constructed from high-strength materials such as forged steel.

Selecting the correct hook block depends on the load capacity, lifting height, and the specific requirements of the lifting operation. Incorrect selection can lead to equipment failure or accidents.

Q 26. What is your experience with using different types of crane slings?

My experience with crane slings encompasses a wide variety of types, each with its own strengths and limitations. Proper sling selection is paramount to safety and efficiency.

- Wire Rope Slings: These are robust and durable but are subject to wear and tear and require regular inspection for broken wires or kinks.

- Synthetic Webbing Slings: Lighter and more flexible than wire rope slings, offering better shock absorption. They’re susceptible to cuts and abrasions and require careful handling.

- Chain Slings: Strong and durable, resistant to cuts and abrasions. They can be vulnerable to elongation or distortion over time.

I emphasize proper sling selection based on factors such as load capacity, sling angle, and the type of material being lifted. I always ensure slings are inspected before each use, rejecting any showing signs of damage. For instance, during a recent lift of a heavy transformer, we opted for a four-leg chain sling to distribute the load evenly and to maintain a safe sling angle.

Q 27. Describe your experience with troubleshooting crane electrical systems.

Troubleshooting crane electrical systems requires a methodical approach and a strong understanding of electrical principles. My experience involves diagnosing and resolving a range of electrical issues, including:

- Motor Problems: Diagnosing issues such as motor overheating, bearing failure, or winding problems often requires testing with multimeters and specialized electrical equipment.

- Wiring Faults: Locating short circuits, open circuits, or loose connections requires careful tracing of wiring diagrams and the use of continuity testers.

- Control System Issues: Troubleshooting problems with limit switches, contactors, relays, and Programmable Logic Controllers (PLCs) might necessitate using specialized diagnostic tools and software.

- Power Supply Issues: Identifying problems with the crane’s power supply, including voltage drops, incorrect phasing, or insufficient power, requires thorough testing of the power source and the crane’s electrical components.

I employ a systematic approach, starting with a visual inspection, followed by more in-depth testing using appropriate equipment. Thorough documentation of the troubleshooting process is essential for future reference. For instance, during a recent incident, a faulty contactor was identified as the cause of a crane’s hoisting mechanism malfunction, a problem that was quickly resolved after its replacement.

Q 28. What are your strategies for training and mentoring crane operators?

Training and mentoring crane operators is a vital aspect of ensuring safe crane operation. My strategy involves a multi-faceted approach:

- Classroom Instruction: Providing theoretical knowledge on crane mechanics, operation procedures, safety regulations, and emergency response.

- Hands-on Training: Practical training on the specific crane models the operators will be using, under the supervision of experienced instructors.

- Simulator Training: Using crane simulators to provide a safe environment for operators to practice different scenarios and hone their skills.

- On-the-job Mentoring: Experienced operators mentoring new recruits, providing guidance and feedback during actual operations.

- Regular Refresher Courses: Ensuring that operators’ skills and knowledge are up-to-date by providing regular refresher training courses.

- Performance Evaluation: Regularly assessing operator performance through observation and evaluation to identify areas for improvement.

I believe in a supportive learning environment that emphasizes safety and continuous improvement. Through proper training, I aim to instill in operators a strong safety culture and a deep understanding of responsible crane operation.

Key Topics to Learn for Crane Management Interview

- Crane Types and Operations: Understanding the different types of cranes (tower, mobile, overhead, etc.), their functionalities, and safe operating procedures.

- Load Capacity and Stability Calculations: Applying theoretical knowledge to calculate safe working loads, considering factors like wind speed, ground conditions, and crane configurations. Practical application involves real-world scenario analysis to prevent accidents.

- Rigging and Signaling: Mastering proper rigging techniques, understanding the importance of clear communication with crane operators via hand signals and radio communication.

- Safety Regulations and Compliance: Familiarity with relevant safety standards, regulations, and best practices to ensure a safe working environment. This includes understanding risk assessments and mitigation strategies.

- Maintenance and Inspection Procedures: Knowledge of routine maintenance checks, inspection schedules, and identifying potential issues to prevent malfunctions and downtime. Practical application includes documenting maintenance records and reporting issues.

- Troubleshooting and Problem-Solving: Developing the ability to diagnose and resolve common crane operational problems efficiently and safely. This includes understanding the cause and effect of potential issues.

- Project Planning and Management: Understanding how crane operations integrate into larger construction projects, including scheduling, resource allocation, and coordination with other trades.

Next Steps

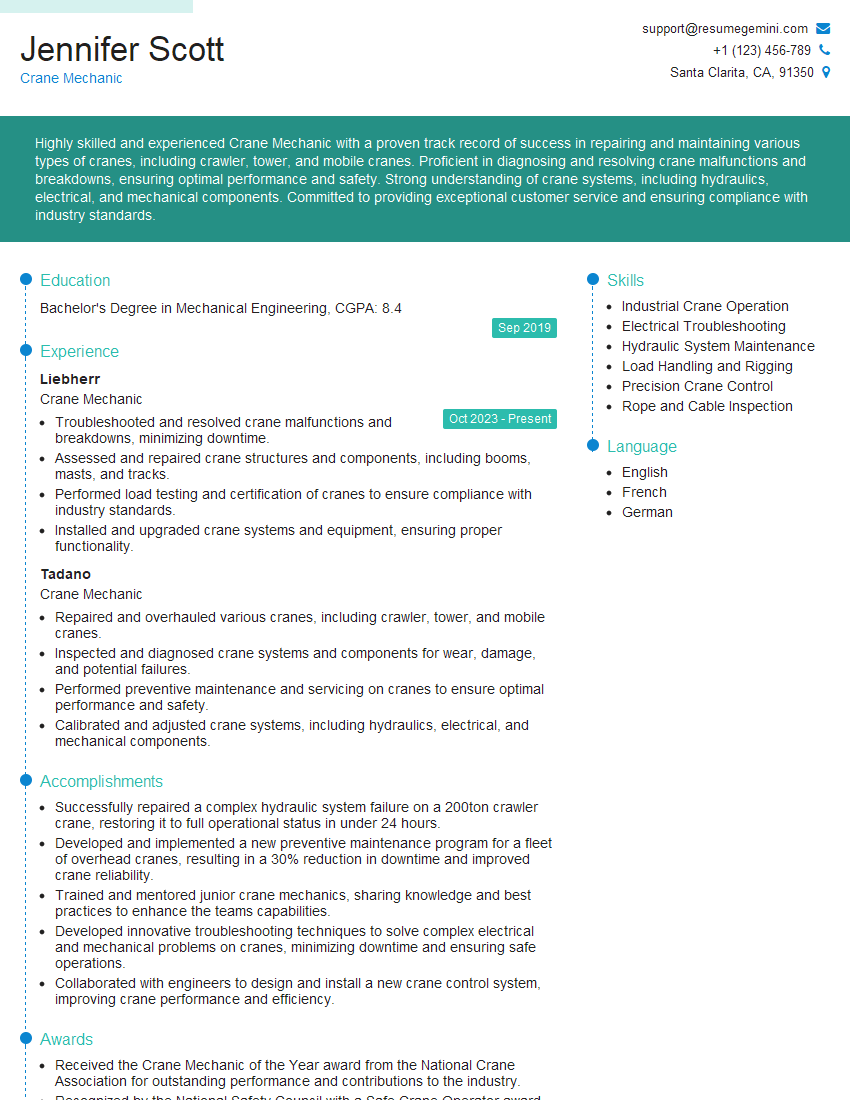

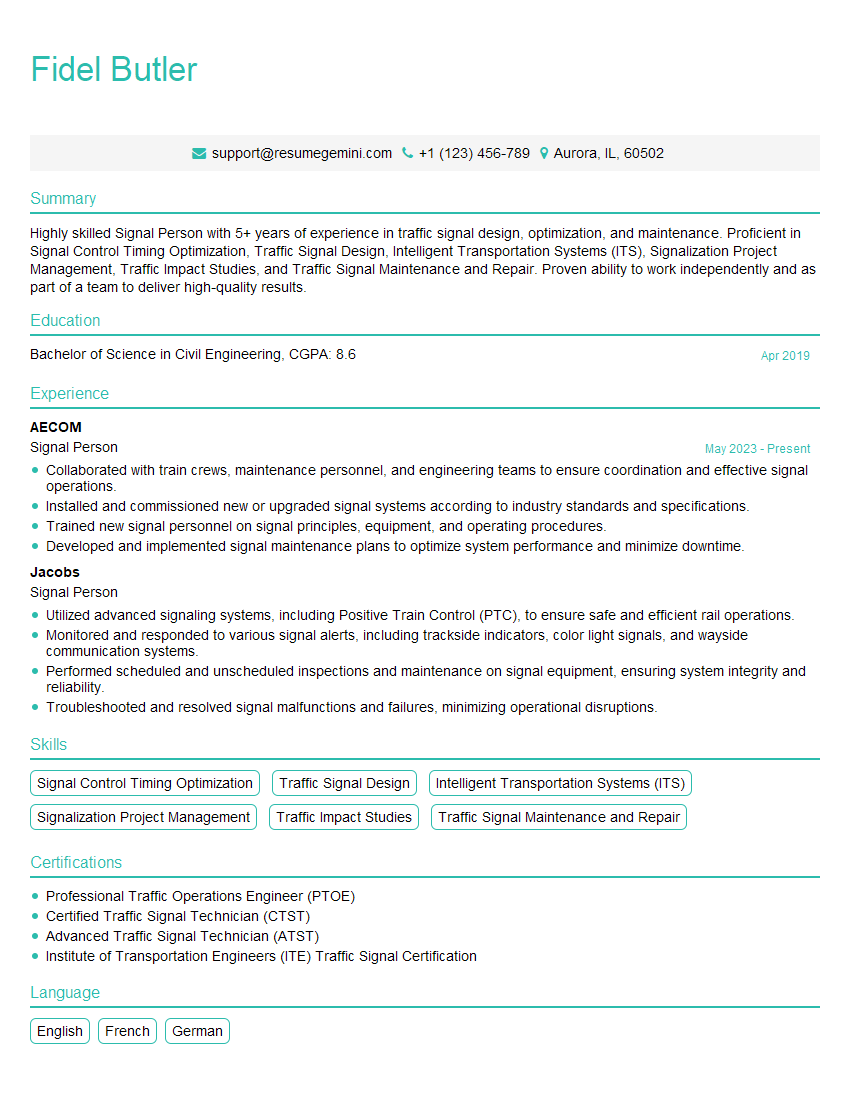

Mastering Crane Management opens doors to exciting career opportunities with increased responsibility and earning potential. A strong foundation in this field is highly sought after in the construction and heavy lifting industries. To maximize your job prospects, it’s crucial to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional, impactful resumes. We provide examples of resumes tailored to Crane Management to help you showcase your qualifications and land your dream job. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good