Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Crate Loading interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Crate Loading Interview

Q 1. Explain the importance of proper crate loading techniques.

Proper crate loading is paramount for efficient and safe transportation. It’s not just about fitting as much as possible into a crate; it’s about optimizing weight distribution, preventing damage to goods, and ensuring the safety of workers and transportation vehicles. Improper loading can lead to instability, shifting cargo during transit, damage to goods, and even accidents. Think of it like building a house – a strong foundation and well-planned structure are essential for stability.

For example, imagine loading heavy items at the top of a crate with lighter items at the bottom. This could cause the crate to topple over during transit. Conversely, properly distributing weight ensures stability and reduces the risk of damage or accidents.

Q 2. Describe different crate loading methods and their applications.

Several methods exist, each with its applications.

- Block Stacking: This is the most common method, where items are stacked like building blocks, filling the crate completely and efficiently using the available space. It’s ideal for uniformly sized and weighted items. Imagine stacking bricks – you wouldn’t place small ones on top of large ones, would you?

- Pyramid Stacking: Heavier items form the base, with progressively lighter items stacked on top, forming a pyramid. This is perfect for items with varying weights. Think of a pyramid – the wide base supports the narrower top.

- Combination Stacking: This method combines both block and pyramid stacking, optimizing space and stability for mixed cargo. It’s the most versatile approach for varied goods.

The choice depends on the items being shipped, their size, weight, and fragility. For instance, fragile items would benefit from pyramid stacking or careful cushioning within block stacking.

Q 3. How do you determine the optimal stacking pattern for various crate sizes and weights?

Determining the optimal stacking pattern requires careful consideration of several factors. I use a combination of software simulations and practical experience. We start by inputting the dimensions and weight of each crate and its contents. The software then analyzes different stacking patterns to determine which maximizes stability and minimizes stress points while considering the weight capacity of the transport vehicle. This also accounts for potential shifting during transport.

For example, if we’re loading crates of different sizes, we might use larger crates as a base to stabilize the smaller, lighter ones on top. The software helps to visually represent the potential risks associated with different arrangements and assists in selecting the safest and most efficient configuration.

Q 4. What safety regulations must be followed during crate loading?

Safety regulations are crucial and vary by region and type of transport. However, some common aspects include:

- Weight Limits: Never exceed the weight capacity of the crate or the transportation vehicle.

- Securement: Loads must be properly secured to prevent shifting during transit using appropriate methods like straps, shrink wrap, or bracing.

- OSHA Compliance (or equivalent): Following all relevant occupational safety and health regulations regarding lifting, handling, and securing loads to protect workers from injury.

- Dangerous Goods Regulations: Special regulations apply to the transport of hazardous materials. Labeling, containment, and segregation are critical aspects.

Failure to comply with safety regulations can lead to serious consequences, including accidents, damage to goods, and legal repercussions.

Q 5. How do you prevent damage to goods during crate loading and transport?

Preventing damage requires a multi-pronged approach:

- Proper Cushioning: Using appropriate packing materials (bubble wrap, foam, etc.) to protect fragile items from impact.

- Strategic Placement: Placing heavier items at the bottom, distributing weight evenly, and avoiding sharp corners that could pierce other items.

- Securement: Employing proper load securing methods to minimize movement during transport. Straps and shrink wrap are key here.

- Climate Control: Ensuring appropriate temperature and humidity levels, particularly for temperature-sensitive goods.

- Crate Integrity: Using high-quality crates in good condition to prevent breakage.

Imagine shipping delicate glassware – you wouldn’t just throw them in a box! Careful planning and protective measures are essential for ensuring goods arrive undamaged.

Q 6. Describe your experience with different types of crating materials.

My experience encompasses various crating materials, each with its pros and cons:

- Wood: Durable and relatively inexpensive, but susceptible to moisture damage and pests. Requires proper treatment for international shipping.

- Plywood: Stronger and more resistant to moisture than solid wood, making it ideal for overseas shipments. It’s more expensive than solid wood though.

- Cardboard: Cost-effective for lighter items, but less durable. Offers good protection for some goods but needs additional protection if the goods are fragile.

- Plastic: Lightweight, water-resistant, and reusable, but can be more expensive and less durable in high impact situations.

- Metal: Extremely durable and protective, but heavy and expensive, best suited for extremely heavy or high-value goods that need maximum protection.

The choice depends on factors like cost, weight, durability requirements, and the type of goods being shipped. For example, I’ve used sturdy wooden crates for heavy machinery and lightweight cardboard boxes for smaller, less fragile items.

Q 7. Explain your experience with securing loads using various methods (strapping, shrink wrap, etc.).

I’m proficient in using various load securing methods:

- Strapping: Steel or polypropylene straps provide excellent tensile strength for securing heavy or bulky items within the crate or to the pallet. Proper tension is vital to prevent shifting.

- Shrink Wrap: A cost-effective way to bundle items together and create a waterproof barrier. It’s less effective for heavier items and may require additional bracing. I’ve found it useful for palletized goods.

- Corner Braces: Protect corners from damage and add stability to the entire crate, especially crucial for stacked boxes.

- Edge Protectors: Protect the edges of the crates from damage, making sure the crate structure remains intact during loading and unloading.

The choice depends on the weight, size, and fragility of the goods. For instance, heavy machinery might require steel straps and corner braces, while lighter items could be secured effectively with shrink wrap.

Q 8. How do you handle oversized or oddly shaped items during crate loading?

Handling oversized or oddly shaped items requires careful planning and execution. The key is to maximize space utilization while ensuring stability and safety. We start by assessing the dimensions and weight of the item, then determine the optimal orientation within the crate. This often involves custom bracing or padding. For example, a long, thin pipe might be secured horizontally with foam padding to prevent shifting, while a large, irregularly shaped piece of machinery may require custom-built wooden supports within the crate to cradle it in place.

We also consider the center of gravity. Oddly shaped items can have uneven weight distribution, so we carefully position them to maintain a low center of gravity and prevent tipping. Think of it like balancing a wobbly stack of books – you’d place the heaviest ones at the bottom and center.

Finally, securing the item is paramount. We might use straps, wedges, or custom-made wooden supports, depending on the item’s shape and weight. Thorough documentation of the securing method and the item’s position is crucial for handling and delivery.

Q 9. What are the potential consequences of improper crate loading?

Improper crate loading can have serious consequences, ranging from minor inconveniences to significant financial losses and safety hazards. The most common issues include:

- Damage to goods: Shifting loads can crush or damage items during transit.

- Damage to the crate itself: Overloading or uneven weight distribution can cause the crate to break apart.

- Safety hazards: Unsecured loads can shift during transport, creating risks for drivers and handlers. A dropped crate could cause serious injury or even fatalities.

- Delays and increased costs: Damaged goods or accidents lead to delays, requiring repairs, replacements, and increased handling fees.

- Legal liability: In case of accidents or damage, the shipper can be held legally responsible for any resulting losses.

For instance, I once witnessed a crate of glass bottles collapse due to improper stacking, resulting in thousands of dollars in losses. This emphasizes the importance of following best practices and regulations.

Q 10. How do you ensure that the weight distribution is balanced in a crate?

Balanced weight distribution is essential for safe and efficient crate loading. The goal is to achieve a uniform weight distribution, minimizing stress on any single point within the crate and the vehicle carrying it. We achieve this through careful planning and execution.

First, we assess the total weight and dimensions of all items to be loaded. Then, we strategically place heavier items at the bottom and closer to the crate’s center of gravity. Lighter items are placed on top, filling gaps to prevent shifting.

Visualize it like building a tower of blocks – you wouldn’t put the largest block at the top! We use techniques like interleaving items of different weights and shapes to create stability. For example, we might alternate between heavy boxes and lighter bags, ensuring that no single area is significantly heavier than others. Regularly checking the weight distribution throughout the loading process prevents imbalances.

Q 11. Describe your experience with using load securing devices.

I have extensive experience with various load securing devices, including:

- Strapping: This is a common method used to secure large or heavy items within a crate, preventing shifting. I’m proficient in using different types of straps and tensioning devices. Knowing how to properly secure the straps is crucial to ensure adequate tension without damaging the goods.

- Dunnage: I use wooden blocks, inflatable bags, and other forms of dunnage to fill empty spaces and prevent items from moving within the crate. Properly using dunnage is vital for distributing weight evenly and cushioning fragile items.

- Shrink wrap: This plastic film provides an additional layer of security, especially for smaller items or when combined with other securing devices. It keeps items tightly bound together, preventing movement.

- Edge protection: Using corner protectors, edge boards, and other materials to prevent damage to products during transit.

My experience includes selecting the appropriate securing devices based on the items’ fragility, weight, dimensions, and mode of transport. For instance, we might use a combination of straps and dunnage for a particularly heavy or oddly shaped item to ensure it’s secure during long-distance shipping.

Q 12. How do you handle damaged or defective crates?

Damaged or defective crates are a significant concern. We inspect each crate before loading. Any crate with significant damage, like cracks, splits, or loose boards, is immediately rejected. If minor damage is found (e.g., a small dent), we assess its impact on structural integrity. If the crate’s structural integrity is compromised, we replace it. A weakened crate poses serious risks during transit.

If damage occurs during the loading process, it’s thoroughly documented, and corrective actions are taken. This might involve reinforcing the crate, using additional securing devices, or even replacing it entirely, depending on the severity of the damage. Record-keeping is key to tracing any issues back to their source and preventing recurrence.

Q 13. How do you identify potential hazards during the crate loading process?

Identifying potential hazards during crate loading involves a multi-step process. It begins with a thorough risk assessment, considering the specific items being loaded, their weight, dimensions, and fragility. We also assess the environment – ensuring there is sufficient space, lighting, and equipment to perform the job safely.

We look for potential hazards like:

- Uneven surfaces: These can lead to instability and tipping.

- Obstructions: These can impede safe movement and handling.

- Damaged equipment: Using faulty equipment is unsafe and should never be done.

- Improper lifting techniques: This can lead to injuries.

Throughout the process, we employ a systematic approach, carefully checking for any hazards and taking appropriate precautions. This might involve using lifting equipment, employing additional personnel, or adjusting the loading plan. Regular safety checks and training are crucial for minimizing risks.

Q 14. What is your experience with inventory management related to crate loading?

Inventory management is integral to efficient crate loading. It starts with accurate inventory tracking of goods before loading. We use barcodes, RFID tags, or similar technologies to track individual items. This allows for quick verification of quantity and condition, preventing discrepancies and errors.

Real-time inventory updates are crucial for optimizing crate loading. We often utilize software systems that integrate with our loading procedures. These systems allow us to plan crate configuration based on available space and item dimensions, maximizing efficiency and minimizing waste. This approach ensures that we use our resources efficiently, reduce handling times, and improve overall logistics.

Accurate post-loading inventory checks help prevent losses and ensure that shipments reach their destination completely and undamaged.

Q 15. Explain your experience using inventory management software in relation to crate loading

Inventory management software is crucial for efficient crate loading. It allows for real-time tracking of stock levels, optimizing space utilization and preventing overstocking or shortages. My experience includes using systems like [mention a specific software, e.g., SAP WM, Fishbowl Inventory] to manage warehouse inventory, integrating directly with crate loading processes. For example, before loading a crate for a specific order, I would use the system to verify the items’ availability, their dimensions, and weight. The software would then suggest an optimal loading plan based on predefined crate specifications and weight limits, minimizing wasted space and ensuring efficient transport.

This integration helps prevent errors. Imagine trying to load a crate without knowing the exact weight and dimensions of each item – it’s like building a house without blueprints! The software serves as that blueprint, providing real-time data to guide the loading process and prevent costly mistakes like overloading or damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage your time effectively during peak crate loading periods?

Peak crate loading periods demand meticulous time management. My approach revolves around prioritization, planning, and effective communication. I begin by analyzing the workload, identifying urgent orders and prioritizing them based on delivery deadlines and product sensitivity. I then create a detailed schedule, allocating specific time slots for different tasks, like receiving inventory, preparing crates, and loading trucks. This schedule is shared with the team for transparency and coordination.

Furthermore, I utilize lean principles to streamline the process. This involves eliminating unnecessary steps and optimizing workflows to reduce loading times. For instance, pre-sorting items based on their destination and crate allocation significantly accelerates the loading process. Regular briefings with the team maintain momentum and proactively address any potential bottlenecks or unexpected issues.

Q 17. Describe a time you had to solve a complex crate loading problem.

We once faced a challenging situation involving an unusually large and oddly shaped order. We had to load a variety of oversized, fragile, and heavy equipment into standard crates for international shipping. The initial loading plan resulted in unstable stacks and risked damaging the equipment. To solve this, I collaborated with the engineering team to design custom crate inserts and implement a modified loading sequence.

We utilized 3D modeling software to simulate different loading configurations, testing weight distribution and stability under various conditions. The custom inserts provided crucial support for fragile items, preventing shifting during transit. The revised loading sequence, which prioritized heavier items at the bottom and strategically placed the inserts, ensured a stable and secure load. The successful completion of this project highlighted the importance of adaptability and creative problem-solving in crate loading.

Q 18. How do you prioritize tasks during crate loading operations?

Task prioritization during crate loading is based on several key factors: order urgency, product fragility, delivery deadlines, and space constraints. I employ a weighted prioritization system, assigning scores to each task based on these factors. Urgent, time-sensitive orders with fragile items receive the highest priority. Tasks that maximize space utilization are also given higher priority to ensure efficient truck loading.

This system allows for a dynamic approach to task management, enabling me to adapt to unexpected changes or delays. For example, if a shipment faces a last-minute delay, I can quickly adjust the priority list, ensuring that the most time-sensitive orders remain on schedule. Regular progress reviews help ensure that we are sticking to the prioritized schedule and efficiently utilize resources.

Q 19. How familiar are you with different types of forklifts used in crate loading?

My familiarity with forklifts extends to various types, including counterbalanced forklifts, reach trucks, order pickers, and narrow aisle forklifts. I understand their operational characteristics, safety protocols, and limitations. For example, I know that counterbalanced forklifts are ideal for handling heavy pallets in open spaces, while reach trucks are better suited for high-bay storage and narrow aisle forklifts are essential for maximizing space utilization in dense warehousing environments.

I’m adept at selecting the appropriate forklift for a given task, considering factors such as crate weight, dimensions, and warehouse layout. Safety is paramount; I always ensure operators are properly trained and adhere to safety regulations. Furthermore, I’m familiar with forklift maintenance procedures, enabling me to quickly identify and report any potential mechanical issues.

Q 20. Explain your experience with using handheld scanners for inventory tracking during crate loading.

Handheld scanners are indispensable for inventory tracking during crate loading. I have extensive experience using scanners to verify items against packing lists and update inventory databases in real-time. This ensures accuracy and minimizes errors. For example, as each item is loaded into a crate, I scan its barcode, confirming its presence and quantity against the order details. This information is instantly reflected in the inventory management system, providing an accurate record of what’s been loaded and what remains.

The data collected by the scanners contributes to comprehensive reporting and analysis, enabling continuous improvement of our loading processes. The reduction of manual data entry also decreases the risk of human error, while providing near real-time visibility into inventory status. The accuracy provided by handheld scanners ensures that the loading process is both efficient and accurate.

Q 21. What are your preferred methods for documenting crate loading procedures?

Documentation is crucial for maintaining accuracy, traceability, and compliance. My preferred methods include a combination of digital and physical documentation. I utilize inventory management software to digitally record loading details such as crate IDs, item quantities, weights, and timestamps. This data can be easily accessed, analyzed, and shared. In addition, I maintain physical copies of packing lists, delivery notes, and inspection reports. These serve as backup documentation and are especially useful when dealing with any potential discrepancies or audits.

For visually documenting the loading process, I use photographs or videos to showcase the arrangement of items within the crate, especially for fragile or complex shipments. This pictorial record adds another layer of verification and helps in addressing any post-loading issues. The combined approach ensures comprehensive documentation and compliance with industry standards and best practices.

Q 22. Describe your experience with load planning software.

My experience with load planning software encompasses several leading platforms, including [Software Name 1], [Software Name 2], and [Software Name 3]. I’m proficient in utilizing these tools to optimize crate loading, considering factors like weight distribution, center of gravity, and the dimensions of both the crates and the transportation vehicle. For instance, in a recent project involving the shipment of delicate electronics, I used [Software Name 1]’s 3D modeling capabilities to visually plan the crate arrangement, ensuring optimal space utilization and minimizing the risk of damage during transit. This software allowed me to generate reports detailing the weight distribution and stability analysis for each load, ensuring compliance with safety regulations. I’m also familiar with software that integrates with warehouse management systems (WMS) for seamless data flow and inventory tracking.

Beyond the specific software, my expertise includes understanding the underlying algorithms and principles behind load optimization. I’m comfortable adjusting parameters within the software to adapt to unique project requirements and constraints, such as handling oddly shaped items or incorporating specific customer requests. My experience allows me to confidently select the most appropriate software for a given task and effectively utilize its features to achieve optimal results.

Q 23. How do you ensure compliance with relevant regulations and standards (e.g., OSHA)?

Ensuring compliance with regulations like OSHA is paramount in crate loading. My approach is multifaceted. Firstly, I am thoroughly familiar with the specific OSHA standards relevant to material handling, including those related to weight limits, safe lifting techniques, and hazard communication. I consistently incorporate these standards into my load planning and execution. This includes using proper lifting equipment when necessary, ensuring adequate training for all team members, and clearly marking hazardous materials.

Secondly, I maintain detailed records of all loading operations, including weight measurements, load configurations, and any safety incidents. These records serve as a crucial audit trail demonstrating compliance. Finally, I actively participate in safety training and stay updated on any changes or revisions to relevant regulations. I view safety not just as a set of rules, but as a core responsibility, making continuous improvements a priority. For example, if a new regulation is announced, I immediately update my procedures to incorporate it.

Q 24. What is your experience with hazardous materials handling during crate loading?

My experience with hazardous materials handling is extensive. I’m trained and certified in handling various classes of hazardous materials, adhering strictly to all relevant regulations (e.g., DOT, IATA). This includes understanding the proper labeling, segregation, and packaging requirements for these materials. For example, when loading corrosive chemicals, I ensure they are packaged in compatible containers, separated from incompatible materials, and secured to prevent shifting during transport. The use of absorbent materials and secondary containment is routinely incorporated into plans.

I also have experience using specialized equipment and procedures designed for safe handling, such as using spill containment pallets or utilizing specialized lifting gear. Detailed documentation, including Safety Data Sheets (SDS) review and emergency response plans, are always meticulously followed. Communication with the transportation team is critical to ensure the safe delivery and handling of these materials throughout the entire shipping process.

Q 25. How would you handle a situation where a crate is overloaded?

An overloaded crate is a serious safety hazard. My immediate response would be to stop the loading process immediately. Under no circumstances would I allow an overloaded crate to be moved. The first step involves verifying the weight using accurate scales to confirm the overload. Then, I’d carefully determine the cause of the overload – was it due to incorrect weight estimation, improper packing, or a miscalculation in the load plan?

Depending on the cause, the solution might involve removing items from the crate, repackaging the contents more efficiently, or using a different, stronger crate. In certain instances, it might necessitate splitting the contents across multiple crates. Thorough documentation of the incident, corrective actions taken, and any potential contributing factors is essential. We’d also conduct a review of our procedures to prevent similar incidents in the future, potentially involving additional training or updates to our load planning software.

Q 26. How do you maintain a safe and organized work environment during crate loading?

Maintaining a safe and organized work environment is critical. This starts with clear pathways, proper storage of materials, and well-maintained equipment. I ensure that all loading areas are well-lit and free from obstructions. Appropriate signage, clearly indicating weight limits, hazard zones, and emergency exits, is crucial. We utilize color-coding systems for different material types to improve organization and reduce the risk of mixing incompatible materials.

Regular housekeeping is a priority, removing debris and ensuring a clean workspace. The proper use of personal protective equipment (PPE), such as safety shoes, gloves, and eye protection, is strictly enforced. Regular safety meetings and training sessions address potential hazards and reinforce safe work practices. A well-maintained work environment improves efficiency and minimizes accidents.

Q 27. How do you communicate effectively with colleagues and supervisors during crate loading?

Effective communication is fundamental. I consistently use clear and concise language to avoid misunderstandings. Before starting any loading operation, I conduct a thorough briefing with the team, clarifying the load plan, potential hazards, and safety procedures. Throughout the process, I provide regular updates to the supervisor, highlighting any unexpected issues or challenges. I actively encourage feedback from my colleagues, valuing their input and experience.

In case of emergencies, established communication protocols are followed. We have designated communication channels for reporting incidents and coordinating responses. Open and honest communication fosters a collaborative environment, improving safety and efficiency. For instance, if a team member spots a potential hazard, open communication ensures immediate rectification.

Q 28. Describe your experience with different types of packaging materials used in crate loading.

My experience encompasses a wide range of packaging materials used in crate loading, from basic corrugated cardboard to specialized materials designed for specific product requirements. I’m familiar with various types of wood, including plywood and oriented strand board (OSB), and their suitability for different applications. I have experience working with plastic crates, both reusable and single-use, and understand their strengths and limitations. For products requiring enhanced protection, I’ve used specialized cushioning materials like foam, bubble wrap, and air pillows.

Material selection is based on several factors including product fragility, weight, environmental conditions during transport, and cost-effectiveness. For instance, when shipping fragile glassware, I’d opt for customized foam inserts to provide optimal cushioning. For heavier goods, sturdy wooden crates with appropriate bracing might be preferred. Knowledge of material properties and their interaction with the product is key to effective crate loading and prevents damage during transit.

Key Topics to Learn for Crate Loading Interview

- Space Optimization: Understanding different crate dimensions and maximizing space utilization within a container or truck. This includes applying geometrical principles and considering weight distribution.

- Weight Distribution and Center of Gravity: Learning how to balance weight evenly to prevent shifting during transport, ensuring safety and structural integrity. Practical application involves calculating weight ratios and strategically placing heavier items.

- Load Stability and Securing Techniques: Mastering the use of appropriate bracing, straps, and other securing materials to prevent damage and shifting during transport. This includes understanding different types of cargo and their specific securing needs.

- Safety Regulations and Procedures: Familiarity with industry standards, regulations, and best practices related to safe crate loading. This involves understanding potential hazards and implementing preventive measures.

- Inventory Management and Tracking: Understanding how crate loading integrates with inventory control systems and the importance of accurate documentation. This includes efficient methods for tracking loaded items and ensuring accuracy.

- Problem-Solving and Adaptability: Developing the ability to handle unexpected challenges, such as irregularly shaped items or last-minute changes in the shipment plan. This might involve creative problem-solving and efficient resource allocation.

- Types of Crates and Packaging: Understanding the different materials and construction of crates, as well as their suitability for various cargo types. This includes recognizing potential weaknesses and choosing appropriate packaging.

Next Steps

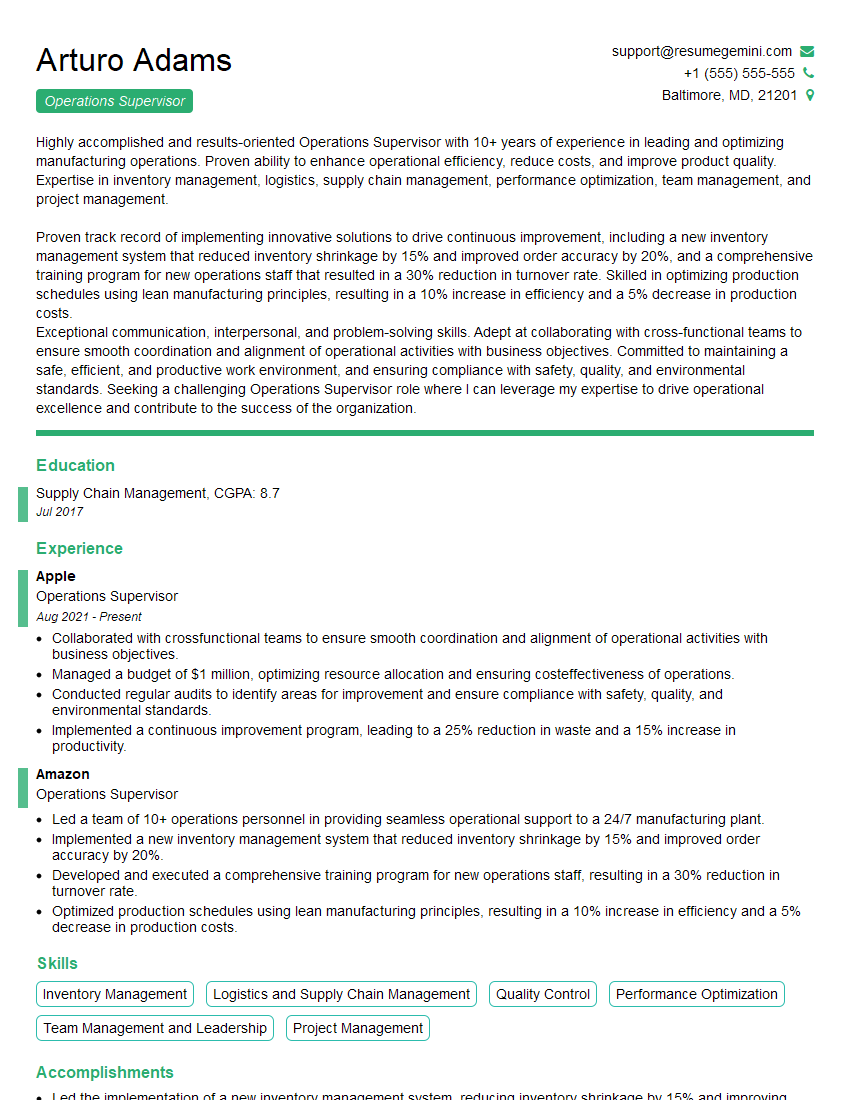

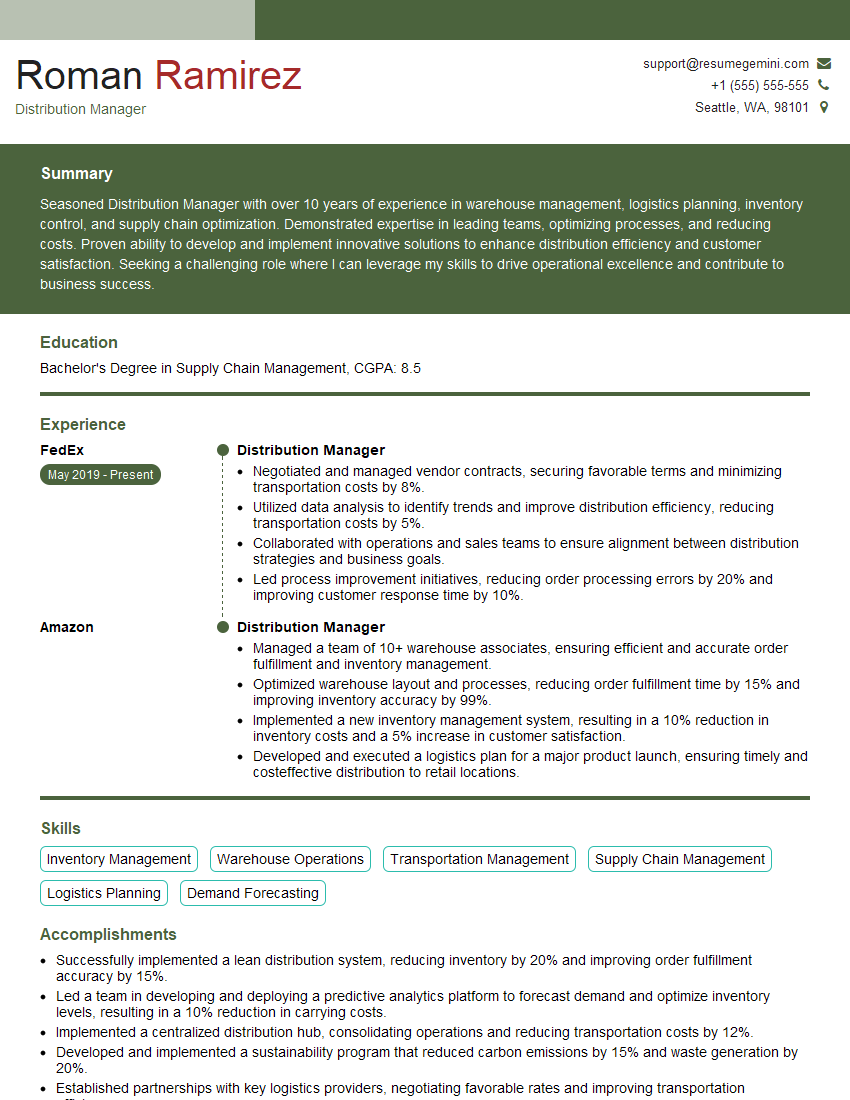

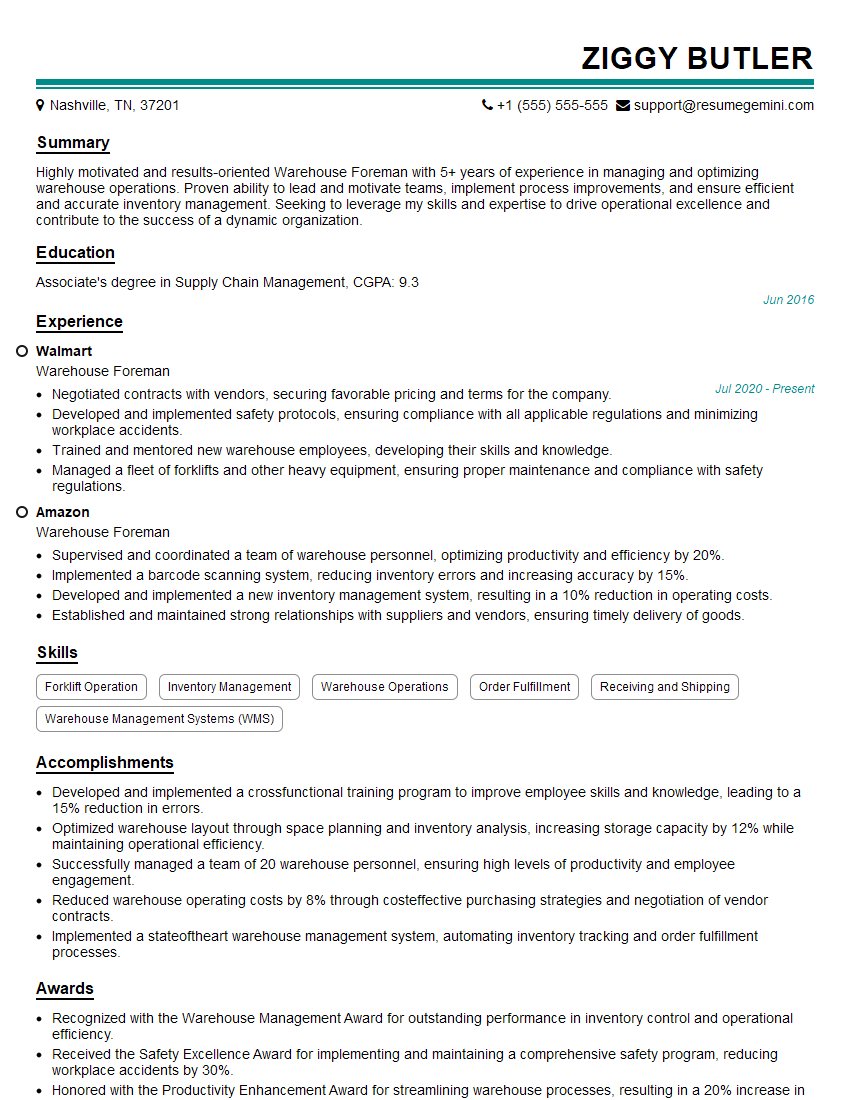

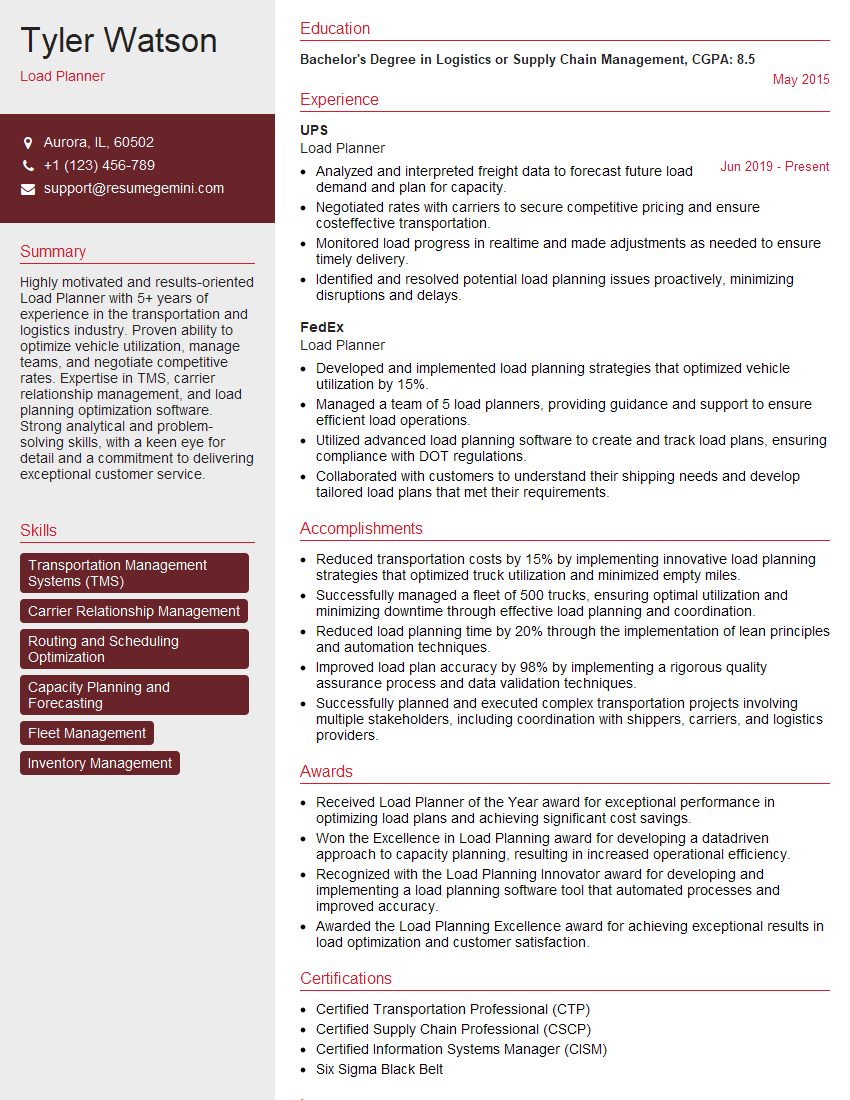

Mastering crate loading techniques opens doors to rewarding careers in logistics, warehousing, and transportation. A strong understanding of these principles demonstrates your commitment to efficiency, safety, and problem-solving – highly valued attributes in today’s competitive job market. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. Examples of resumes tailored to Crate Loading are available for your review to guide you in showcasing your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good