Unlock your full potential by mastering the most common Creating and Managing Supply Chain interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Creating and Managing Supply Chain Interview

Q 1. Explain the concept of bullwhip effect and how to mitigate it.

The bullwhip effect is a phenomenon in supply chains where demand variability increases as you move upstream in the supply chain. Imagine a whip: a small flick at the end (consumer demand) creates a much larger movement at the handle (supplier). This amplification leads to excess inventory, lost sales, and increased costs.

Mitigation Strategies:

- Improve Information Sharing: Implementing systems like Point-of-Sale (POS) data sharing across the supply chain allows everyone to see real-time demand, reducing forecasting errors. For example, a retailer sharing sales data with its wholesalers and manufacturers prevents overstocking based on inaccurate predictions.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): This collaborative approach involves sharing forecasts and demand plans with suppliers, leading to better alignment and reduced variability. This works best with strong partnerships.

- Reduce Lead Times: Shorter lead times lessen the impact of demand fluctuations because adjustments can be made more quickly. Implementing faster transportation or lean manufacturing can achieve this.

- Use Buffer Stock Strategically: While excessive inventory is detrimental, a carefully planned buffer stock can absorb minor demand fluctuations and prevent overreactions further up the chain.

- Employ Demand-Driven Supply Chains: Focus on producing only what’s needed, when it’s needed, by integrating production and sales information.

- Price Stabilization: Avoid fluctuating prices that may trigger panic buying and stocking in anticipation of price increases further up the chain.

For instance, in the fashion industry, a sudden increase in demand for a particular dress could lead to excessive orders at each level of the supply chain, ultimately resulting in unsold inventory when the trend subsides. Implementing CPFR and reducing lead times via agile manufacturing can mitigate this risk.

Q 2. Describe your experience with different inventory management techniques (e.g., FIFO, LIFO, EOQ).

I have extensive experience with various inventory management techniques. Let’s discuss three common ones:

- FIFO (First-In, First-Out): This method assumes that the oldest inventory is sold first. It’s beneficial for perishable goods and minimizes the risk of obsolescence. Imagine a bakery using FIFO for its bread – older loaves are sold first to avoid spoilage.

- LIFO (Last-In, First-Out): Here, the newest inventory is sold first. This is less common for physical goods due to accounting implications but can be advantageous in certain situations like commodities markets. In times of inflation, LIFO can result in lower reported profits (due to higher cost of goods sold).

- EOQ (Economic Order Quantity): EOQ is a model that calculates the optimal order quantity to minimize total inventory costs (holding costs and ordering costs). This involves balancing the cost of storage against the cost of placing frequent orders. For example, a company manufacturing widgets can use EOQ to determine the ideal number of widgets to order from its supplier at a time to minimize overall expenses. The calculation involves factors such as demand rate, ordering cost, and holding cost.

Beyond these, I’m also familiar with techniques like ABC analysis (prioritizing inventory based on value), just-in-time (JIT) inventory, and vendor-managed inventory (VMI), which I’ve successfully implemented in previous roles. The choice of technique depends heavily on the specifics of the industry, product, and company strategy.

Q 3. How do you measure supply chain efficiency and effectiveness?

Measuring supply chain efficiency and effectiveness requires a holistic approach, focusing on both speed and quality. We can assess efficiency through metrics like:

- Inventory Turnover Rate: How quickly inventory is sold and replenished. A higher rate generally indicates better efficiency.

- Lead Time: The time it takes to fulfill an order, from placement to delivery. Shorter lead times are desirable.

- Order Fulfillment Cycle Time: The time from order placement to customer receipt.

- On-Time Delivery Rate: The percentage of orders delivered on time.

- Perfect Order Rate: The percentage of orders delivered on time, in full, and without errors.

Effectiveness, on the other hand, goes beyond speed and considers the customer experience and overall profitability. Metrics for effectiveness include:

- Customer Satisfaction: High customer satisfaction indicates a well-functioning supply chain that consistently meets customer needs.

- Return on Investment (ROI) of Supply Chain Initiatives: Measuring the financial returns of supply chain improvements.

- Supply Chain Cost as a Percentage of Revenue: A lower percentage shows better efficiency and cost management.

- Fill Rate: Percentage of customer demand met.

By analyzing these metrics together, we gain a comprehensive understanding of the supply chain’s performance.

Q 4. What are the key performance indicators (KPIs) you would track in a supply chain?

The key performance indicators (KPIs) I would track in a supply chain would vary depending on the specific business goals and industry, but some crucial ones include:

- On-Time Delivery Performance: Measures the percentage of orders delivered on or before the scheduled delivery date.

- Inventory Turnover: Shows how efficiently inventory is managed and sold.

- Lead Time: The total time required to fulfill a customer order.

- Order Fulfillment Cycle Time: The time taken from order placement to delivery.

- Perfect Order Rate: Measures the percentage of orders delivered without any errors (on time, in full, damage-free, and correct documentation).

- Customer Satisfaction (CSAT): Measures customer happiness with the delivery process and product quality.

- Supplier Performance: Tracks on-time delivery, quality, and compliance of suppliers.

- Freight Costs: Monitors transportation expenses to optimize logistics.

- Inventory Holding Costs: Measures the costs associated with storing inventory.

- Supply Chain Resilience: Assesses the ability to withstand disruptions and recover quickly.

Regular monitoring and analysis of these KPIs enable proactive adjustments to optimize the supply chain and achieve strategic objectives.

Q 5. Explain your experience with supply chain risk management.

Supply chain risk management is critical for business continuity. My experience involves a multi-faceted approach:

- Risk Identification: This starts with identifying potential disruptions, such as natural disasters, supplier failures, geopolitical instability, pandemics, and cyberattacks. Techniques like SWOT analysis and risk assessment matrices are useful.

- Risk Assessment: Analyzing the likelihood and potential impact of each identified risk. This helps prioritize mitigation efforts.

- Risk Mitigation: Developing strategies to reduce the likelihood or impact of identified risks. This might include diversification of suppliers, inventory buffering, robust IT systems, contingency planning, and insurance.

- Risk Monitoring: Continuously monitoring the supply chain environment for emerging threats and changes in risk levels.

- Risk Response: Having pre-defined plans to respond effectively to disruptions, including crisis management protocols and communication strategies.

For example, during a recent project, we identified a reliance on a single supplier as a major risk. We mitigated this by developing relationships with alternative suppliers and strategically building up our inventory of critical components. This proved crucial when unforeseen supply chain disruptions occurred in the global market.

Q 6. Describe a time you had to optimize a supply chain process.

In a previous role, we faced significant delays in our distribution network, leading to increased costs and customer dissatisfaction. To optimize this, I implemented a three-step process:

- Data Analysis: First, we meticulously analyzed delivery data to pinpoint the bottlenecks. This involved mapping the entire distribution process, from warehouse to end customer, identifying delays at various stages.

- Process Re-engineering: We identified inefficient routes and outdated technology. We implemented route optimization software, which significantly reduced travel times. We also upgraded our warehouse management system to improve picking and packing efficiency. We also explored alternative transportation methods to reduce dependency on a single carrier.

- Performance Monitoring: After implementing these changes, we closely monitored key performance indicators such as on-time delivery rates, transportation costs, and customer satisfaction. This allowed us to identify any further inefficiencies and make continuous improvements.

The result was a 20% reduction in delivery times, a 15% decrease in transportation costs, and a significant improvement in customer satisfaction scores. This success showcased the power of data-driven decision-making in supply chain optimization.

Q 7. How do you handle supplier relationship management?

Supplier relationship management (SRM) is crucial for a successful supply chain. My approach focuses on building strong, collaborative partnerships:

- Supplier Selection: Thorough evaluation of potential suppliers based on factors like capacity, quality, reliability, financial stability, and ethical practices. We use a weighted scoring system to objectively compare potential partners.

- Communication and Collaboration: Open and transparent communication is vital. This includes regular meetings, shared performance data, and collaborative problem-solving. We utilize collaborative platforms for efficient information exchange.

- Performance Monitoring and Evaluation: Regularly assessing supplier performance against agreed-upon KPIs to ensure consistent quality and timely delivery. We have a formal supplier performance review process.

- Relationship Building: Cultivating strong relationships built on trust and mutual respect. This may involve joint training programs, shared innovation efforts, and long-term contracts.

- Risk Management: Jointly identifying and mitigating risks within the supplier network. This might include backup suppliers or contingency planning for potential disruptions.

In one instance, a key supplier faced production issues. Through proactive communication and collaboration, we worked together to find alternative solutions, successfully avoiding a major disruption to our production schedule. This highlights the importance of strong supplier relationships in navigating challenging situations.

Q 8. What is your experience with different transportation modes and how do you choose the right one?

Choosing the right transportation mode is crucial for efficient and cost-effective supply chain management. My experience encompasses all major modes: road, rail, sea, and air. The selection process isn’t arbitrary; it’s a strategic decision based on several factors.

- Cost: Road transport is often cheapest for shorter distances, while sea freight is most economical for large volumes over long distances. Air freight is the fastest but most expensive.

- Speed: Air freight offers the fastest delivery, ideal for time-sensitive goods. Sea freight is the slowest, suitable for less urgent shipments.

- Reliability: Each mode has its own reliability factors. Road transport can be affected by traffic congestion, while sea freight is susceptible to weather delays. Air freight generally offers higher reliability, but is more vulnerable to disruptions at airports.

- Capacity: Sea freight handles the largest volumes, while air freight is best for smaller, high-value goods. Road and rail transport fall somewhere in between.

- Product Characteristics: Perishable goods may require temperature-controlled transport, often achievable via road or air. Fragile goods need careful handling, influencing the mode chosen.

For example, I once managed a project where we shifted from road transport to a combined road-rail solution for transporting bulky, low-value components. This reduced costs significantly while maintaining acceptable delivery times. The decision was based on a detailed cost-benefit analysis considering all factors mentioned above.

Q 9. How do you forecast demand and manage fluctuations?

Demand forecasting is essential for optimizing inventory levels and avoiding stockouts or excess inventory. I employ a combination of qualitative and quantitative methods.

- Qualitative Methods: These involve expert opinions, market research, and sales force insights. For example, I’ve used Delphi techniques to gather consensus forecasts from experienced sales managers.

- Quantitative Methods: These utilize historical data and statistical models. Time series analysis (ARIMA, Exponential Smoothing), regression analysis, and causal forecasting models are frequently employed. I have extensive experience using software like SAS and R for sophisticated forecasting.

Managing fluctuations requires agility and responsiveness. Safety stock is crucial to buffer against unexpected surges. Furthermore, I utilize techniques like collaborative planning, forecasting, and replenishment (CPFR) to enhance collaboration with suppliers and improve forecast accuracy. This collaborative approach significantly reduces the bullwhip effect, where demand variations are amplified across the supply chain.

For instance, during a recent period of high market volatility, we implemented a more granular forecasting model that segmented demand by region and product type. This allowed us to adjust inventory levels more precisely and mitigate the impact of the fluctuations.

Q 10. Explain your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive, covering implementation, configuration, and optimization. WMS software streamlines warehouse operations, improving efficiency and accuracy. I’ve worked with various systems, including Manhattan Associates, Blue Yonder, and NetSuite WMS.

A key aspect of my work involves configuring these systems to meet specific business requirements. This includes defining warehouse layouts, managing inventory tracking methods (FIFO, LIFO, FEFO), optimizing picking strategies (wave picking, zone picking), and integrating the WMS with other enterprise systems like ERP and TMS. I also have experience with implementing barcode scanning, RFID tracking, and automated guided vehicles (AGVs) to enhance warehouse automation.

In a previous role, I led the implementation of a new WMS that resulted in a 20% reduction in order fulfillment time and a 15% decrease in warehouse operating costs. This involved meticulous planning, thorough user training, and ongoing system optimization. Data analysis played a crucial role in identifying areas for improvement and measuring the impact of the new system.

Q 11. How do you ensure supply chain visibility?

Supply chain visibility is critical for proactive management and responsive decision-making. It involves tracking goods and information throughout the entire supply chain, from origin to end customer. I achieve this through a multi-pronged approach.

- Real-time Tracking: Utilizing GPS tracking on shipments, barcode/RFID scanning at various points in the supply chain, and integrating data from transportation management systems (TMS).

- Data Integration and Analytics: Connecting various systems (ERP, WMS, TMS, and supplier portals) to provide a holistic view of inventory levels, order status, shipment progress, and potential disruptions.

- Supply Chain Visibility Platforms: Leveraging specialized software platforms that provide a centralized dashboard for monitoring key performance indicators (KPIs) and identifying potential bottlenecks or risks.

- Collaboration and Communication: Fostering transparent communication with suppliers, logistics providers, and customers to share information and proactively address any issues.

For example, during a recent project, we implemented a real-time tracking system that enabled us to identify and resolve a transportation delay proactively, preventing a potential stockout and avoiding significant financial losses. The data-driven approach allowed us to make informed decisions and mitigate risk.

Q 12. What is your experience with Lean and Six Sigma methodologies in supply chain?

Lean and Six Sigma methodologies are integral to my approach to supply chain optimization. Lean focuses on eliminating waste (muda) in all its forms, while Six Sigma aims to reduce defects and variability. I’ve applied both extensively.

- Lean: I’ve utilized techniques like value stream mapping to identify and eliminate non-value-added activities. Kaizen events (continuous improvement workshops) are frequently used to drive incremental improvements. 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) is applied to create a more efficient and organized warehouse environment.

- Six Sigma: I use DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify) methodologies to systematically address supply chain problems and improve processes. Statistical tools like control charts and process capability analysis are essential for data-driven decision-making.

In one project, we implemented a Lean initiative that reduced lead times by 25% by optimizing the warehouse layout and improving material handling processes. Another project used Six Sigma to reduce the defect rate in a particular product line by 80%, improving customer satisfaction and reducing costs.

Q 13. Describe your experience with implementing a new supply chain technology.

Implementing new supply chain technology requires careful planning and execution. My experience includes the implementation of a new Transportation Management System (TMS). The process involved several key phases:

- Needs Assessment and Selection: Defining business requirements, evaluating different TMS solutions, and selecting the most suitable software based on functionality, cost, and integration capabilities.

- Project Planning and Resource Allocation: Developing a detailed project plan with timelines, milestones, and resource allocation. This included identifying and training key personnel.

- System Configuration and Customization: Customizing the TMS to match specific business processes, integrating it with existing systems (ERP, WMS), and configuring reporting and analytics dashboards.

- Data Migration and Testing: Migrating existing data into the new system, conducting rigorous testing to ensure accuracy and functionality, and addressing any bugs or issues.

- Training and Go-Live: Providing thorough training to users, managing the go-live process, and providing ongoing support and maintenance.

Post-implementation, ongoing monitoring and optimization are vital. We used key performance indicators (KPIs) like on-time delivery, transportation costs, and customer satisfaction to measure success and identify areas for further improvement. The result was improved transportation efficiency and cost savings.

Q 14. How do you handle supply chain disruptions?

Supply chain disruptions are inevitable. My approach involves a combination of proactive risk mitigation and reactive response strategies.

- Risk Identification and Assessment: Identifying potential disruptions (natural disasters, pandemics, geopolitical instability, supplier issues) and assessing their likelihood and potential impact.

- Risk Mitigation Strategies: Implementing strategies like diversifying suppliers, holding safety stock, building redundant supply routes, and developing contingency plans.

- Real-time Monitoring and Early Warning Systems: Using data analytics and technology to monitor supply chain activities and identify potential disruptions early on.

- Incident Response Plan: Having a well-defined plan for responding to disruptions, including communication protocols, alternative sourcing options, and customer notification procedures.

- Post-Incident Review: Conducting a thorough review of the disruption to identify lessons learned and improve future preparedness.

For instance, during a recent port strike, our pre-emptive measures – including using alternative ports and securing alternative transportation – minimized the impact on our operations. Post-incident analysis led to improvements in our risk management procedures and contingency planning.

Q 15. What are your strategies for cost reduction in the supply chain?

Cost reduction in the supply chain is a multifaceted challenge requiring a strategic approach. It’s not just about slashing individual costs, but optimizing the entire network for efficiency. My strategies focus on several key areas:

- Inventory Optimization: Implementing just-in-time (JIT) inventory management significantly reduces storage costs and minimizes the risk of obsolescence. For example, in a previous role, we transitioned from a large warehousing system to a JIT model, reducing inventory holding costs by 15% within six months. This involved close collaboration with suppliers to ensure timely deliveries.

- Transportation Management: Negotiating better rates with carriers, optimizing routes using route optimization software (like

Route4Meor similar), and consolidating shipments are crucial. We once successfully reduced transportation costs by 10% by consolidating shipments from multiple suppliers to a central distribution center and using a more efficient carrier. - Supplier Relationship Management (SRM): Developing strong relationships with key suppliers allows for collaborative cost reduction initiatives. This includes negotiating volume discounts, exploring alternative sourcing options, and working together to improve process efficiency. In one project, we collaborated with a supplier to redesign packaging, reducing material costs by 8% without compromising product protection.

- Process Improvement: Identifying and eliminating waste throughout the supply chain using Lean principles (like Kaizen) is vital. This involves analyzing every step of the process to identify inefficiencies and bottlenecks. In a past project, we implemented Lean methodologies to streamline our order fulfillment process, reducing lead times by 20%.

- Technology Adoption: Investing in supply chain management software (like SAP SCM, Oracle SCM Cloud) can automate tasks, improve visibility, and provide data-driven insights for better decision-making. The return on investment (ROI) from such software often outweighs the initial cost.

Ultimately, a successful cost reduction strategy requires a data-driven approach, continuous monitoring, and a commitment to ongoing improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with regulations in the supply chain?

Compliance is paramount in supply chain management. Ensuring adherence to regulations requires a proactive and multi-layered approach:

- Thorough Understanding of Regulations: Staying abreast of all relevant laws and regulations, including those related to import/export, labor practices, environmental protection, and data privacy (like GDPR, CCPA), is critical. We maintain a comprehensive compliance manual that is regularly updated.

- Supplier Audits: Regularly auditing suppliers to ensure they meet our compliance standards and those of relevant governing bodies is essential. This might involve on-site visits or utilizing third-party audit services. This process identifies potential risks early and allows for corrective action.

- Documentation and Traceability: Maintaining detailed records of all transactions and processes is crucial for demonstrating compliance. Utilizing blockchain technology can enhance traceability and transparency within the supply chain, particularly valuable for tracking ethically sourced materials or combating counterfeiting.

- Training and Awareness: Providing ongoing training to employees on compliance policies and procedures ensures everyone understands their roles and responsibilities. Regular workshops and online modules are helpful to reinforce key concepts.

- Continuous Monitoring and Improvement: Regularly review and update compliance procedures to adapt to evolving regulations and industry best practices. We conduct regular internal audits and use external compliance specialists for an independent assessment.

A strong compliance program not only minimizes legal risks but also enhances the company’s reputation and builds trust with customers and stakeholders.

Q 17. Explain your experience with different types of forecasting models.

My experience encompasses a range of forecasting models, each suited to different contexts and data availability.

- Simple Moving Average (SMA): This is a basic model, useful for stable demand patterns with minimal seasonality. It averages past demand data to predict future demand.

SMA = (Sum of demand for n periods) / n - Weighted Moving Average (WMA): Similar to SMA, but assigns different weights to past periods, giving more importance to recent data. This is suitable when more recent data is more indicative of future trends.

- Exponential Smoothing: This model gives exponentially decreasing weights to older data, adapting more quickly to changes in demand. There are different variations like single exponential smoothing, double exponential smoothing (for trend), and triple exponential smoothing (for trend and seasonality).

- ARIMA (Autoregressive Integrated Moving Average): A sophisticated statistical model suitable for time series data with complex patterns, including trend and seasonality. It requires specialized statistical software for analysis.

- Machine Learning Models: Advanced models like neural networks or regression models can be applied to large datasets to uncover complex patterns and relationships, providing more accurate forecasts. This requires significant data processing and modeling expertise.

The choice of model depends heavily on the specific product, market conditions, data quality, and available resources. I typically evaluate the accuracy of different models using metrics like Mean Absolute Error (MAE) and Mean Squared Error (MSE) to select the most appropriate one for the situation.

Q 18. How do you manage inventory levels to minimize costs and avoid stockouts?

Effective inventory management balances the need to meet customer demand with the cost of holding inventory. My approach focuses on:

- Demand Forecasting: Accurate forecasting, as discussed earlier, is the foundation of good inventory management. It allows us to predict future demand and order accordingly.

- Inventory Classification: Categorizing inventory based on demand (A, B, C classification) helps prioritize management efforts. High-demand (A) items require close monitoring and precise forecasting. Low-demand (C) items can be managed with simpler methods.

- Safety Stock Calculation: Maintaining a buffer stock (safety stock) to protect against unexpected demand fluctuations or supply disruptions is essential. The amount of safety stock is determined based on lead times, demand variability, and service level targets.

- Inventory Turnover Analysis: Regularly reviewing inventory turnover rates provides insights into inventory efficiency. High turnover suggests efficient inventory management, while low turnover indicates potential overstocking.

- Technology Utilization: Inventory management systems (IMS) provide real-time visibility into inventory levels, facilitating better decision-making and reducing stockouts. Many systems utilize barcode and RFID technology to track inventory movement automatically.

By combining these methods, we aim for an optimal inventory level that balances the costs of holding inventory with the risks of stockouts, ultimately maximizing profitability.

Q 19. Describe your experience with demand planning and sales forecasting.

Demand planning and sales forecasting are critical for aligning supply with demand. My experience involves:

- Data Collection and Analysis: Gathering historical sales data, market research, economic indicators, and competitor information is the first step. This data is then cleaned and analyzed to identify trends and patterns.

- Qualitative and Quantitative Forecasting: I utilize both qualitative methods (like expert opinions, market surveys) and quantitative methods (like time series analysis, regression models) to develop forecasts. Combining these approaches often provides a more accurate and robust prediction.

- Collaboration with Sales and Marketing: Close collaboration with the sales and marketing teams is crucial. They provide valuable insights into upcoming promotions, new product launches, and market dynamics. This ensures that the forecast reflects anticipated changes in demand.

- Continuous Monitoring and Adjustment: Forecasts are not static. Regularly monitoring actual sales data against the forecast allows for prompt adjustments to the plan. This may involve refining forecasting models or adjusting production schedules.

- Scenario Planning: Considering different potential scenarios (e.g., best-case, worst-case) helps prepare for various demand levels. This allows for more flexible planning and reduces the impact of unexpected events.

Accurate demand planning significantly improves supply chain efficiency, reducing costs associated with overstocking or stockouts and enabling better resource allocation.

Q 20. How do you collaborate with different departments within a company to improve the supply chain?

Effective supply chain management requires cross-functional collaboration. My approach involves:

- Open Communication: Establishing clear communication channels between different departments (sales, marketing, production, procurement, finance) is paramount. Regular meetings, shared dashboards, and collaborative platforms facilitate information sharing and alignment.

- Shared Goals and Metrics: Defining common goals and key performance indicators (KPIs) across departments ensures everyone is working towards the same objectives. Examples include on-time delivery, inventory turnover, and customer satisfaction.

- Cross-Functional Teams: Creating cross-functional teams allows for direct collaboration and problem-solving. This fosters a sense of shared ownership and responsibility for supply chain performance.

- Data Sharing and Transparency: Making relevant data accessible to all relevant stakeholders promotes transparency and enables informed decision-making. This may involve implementing a shared data warehouse or using collaborative software.

- Conflict Resolution Mechanisms: Having clear processes for resolving conflicts and disagreements between departments is crucial for maintaining effective collaboration. This might involve mediation or escalation procedures.

By fostering a culture of collaboration and shared responsibility, we can optimize the entire supply chain and achieve greater efficiency and effectiveness.

Q 21. Explain your approach to selecting and evaluating suppliers.

Supplier selection and evaluation is a critical process that significantly impacts supply chain performance. My approach involves a structured process:

- Defining Requirements: Clearly defining the specific requirements for the supplier (quality standards, delivery timelines, pricing, capacity) is the first step. This ensures that the selection process focuses on the most relevant criteria.

- Identifying Potential Suppliers: Researching and identifying potential suppliers through industry directories, online databases, trade shows, and networking is crucial. This involves assessing their capabilities and reputation.

- Supplier Pre-qualification: Screening potential suppliers based on pre-defined criteria (financial stability, certifications, experience) narrows down the field to a select group of qualified candidates.

- Supplier Audits: Conducting thorough audits (on-site or remote) to assess their quality management systems, operational capabilities, and compliance standards is vital. This might involve using standardized audit checklists and templates.

- Negotiation and Contract Management: Negotiating favorable terms with selected suppliers and establishing clear contracts with defined responsibilities and performance metrics is essential. This protects the company’s interests and ensures mutual accountability.

- Performance Monitoring and Evaluation: Regularly monitoring supplier performance against established metrics (on-time delivery, quality, cost) and providing feedback allows for continuous improvement and identification of potential issues early on.

A robust supplier selection and evaluation process ensures we work with reliable and high-performing suppliers, minimizing risks and optimizing supply chain operations.

Q 22. What are your strategies for improving supplier performance?

Improving supplier performance is crucial for a robust supply chain. My strategy is multifaceted, focusing on collaboration, performance measurement, and continuous improvement. I begin by establishing clear, measurable, achievable, relevant, and time-bound (SMART) goals with each supplier, aligning their performance with our overall business objectives. This includes defining key performance indicators (KPIs) such as on-time delivery, quality rates, and cost efficiency.

Regular performance reviews are vital. These aren’t just about identifying shortcomings; they’re opportunities for open dialogue and problem-solving. For example, if a supplier consistently misses deadlines, we’d collaboratively investigate the root cause – maybe it’s capacity constraints, material shortages, or internal process inefficiencies. Once identified, we can implement corrective actions, which might involve providing technical assistance, offering capacity expansion support, or streamlining their processes.

Furthermore, I strongly believe in fostering a collaborative relationship with our suppliers. This includes transparency in our needs and expectations, and a commitment to fair and mutually beneficial partnerships. We actively seek feedback from our suppliers to understand their challenges and continuously work towards optimizing the entire supply chain ecosystem. Incentivizing strong performance through performance-based pricing or other reward systems further motivates suppliers to meet and exceed expectations.

Q 23. Describe your experience with contract negotiations with suppliers.

Contract negotiation is a delicate balance between securing favorable terms and maintaining strong supplier relationships. My approach emphasizes a collaborative and transparent negotiation process. I start by thoroughly understanding the supplier’s capabilities, costs, and market position. This allows me to craft realistic and mutually beneficial terms. I always focus on the long-term relationship, viewing contracts as partnerships rather than simple transactions.

During negotiations, I leverage data-driven insights to support my arguments. For instance, I’d use historical data on delivery performance or quality metrics to justify specific clauses related to penalties or incentives. I clearly articulate our requirements and expectations while remaining open to exploring alternative solutions that accommodate both parties’ needs. I also ensure the contract includes clear definitions of responsibilities, payment terms, and dispute resolution mechanisms. A well-structured contract mitigates risks and fosters trust, laying the foundation for a successful and enduring partnership.

In one instance, I negotiated a contract with a key supplier who initially proposed high prices. By presenting detailed market analysis demonstrating lower prices from their competitors and by highlighting the long-term volume we could provide, we were able to secure more favorable pricing while still ensuring a strong relationship.

Q 24. How do you ensure the security and integrity of the supply chain?

Supply chain security and integrity are paramount. My approach involves a multi-layered security strategy encompassing risk assessment, vendor vetting, robust processes, and technology. Firstly, I conduct thorough risk assessments to identify potential vulnerabilities across the entire supply chain, from raw material sourcing to product delivery. This includes evaluating geopolitical risks, environmental factors, and cybersecurity threats.

Vendor vetting is a crucial step. We perform due diligence on potential suppliers, assessing their financial stability, ethical practices, and security protocols. We might conduct on-site audits to verify their operations and compliance with our standards. We also integrate robust tracking and tracing systems to monitor the movement of goods throughout the chain. This enables real-time visibility and faster responses to disruptions or potential threats.

Technology plays a significant role. Implementing advanced analytics tools to detect anomalies and potential fraud is critical. Cybersecurity measures, such as secure data storage and access controls, are also implemented to protect sensitive supply chain information. Furthermore, establishing clear protocols for handling incidents and disruptions ensures a swift and effective response to any security breaches.

Q 25. How do you use data analytics to improve supply chain decisions?

Data analytics are transformative for supply chain decision-making. I use data analytics to gain a clear, real-time view of the supply chain’s performance, allowing proactive intervention and optimization. We collect data from various sources, including ERP systems, supplier portals, and transportation management systems (TMS).

This data is analyzed to identify patterns, trends, and anomalies. For instance, we might use predictive analytics to forecast demand fluctuations, enabling better inventory management and preventing stockouts or overstocking. We also use prescriptive analytics to optimize transportation routes, reducing lead times and transportation costs. Real-time dashboards provide a visual representation of key performance indicators (KPIs), enabling immediate identification of potential issues.

For example, by analyzing historical sales data and external economic indicators, we accurately predicted a surge in demand for a particular product during a holiday season. This allowed us to proactively increase inventory levels, ensuring we met customer demand without experiencing stockouts. This proactive approach minimized lost sales and maintained customer satisfaction.

Q 26. What software or tools are you proficient in for supply chain management?

My proficiency spans several software and tools crucial for effective supply chain management. I’m highly experienced in Enterprise Resource Planning (ERP) systems such as SAP and Oracle, which are essential for integrating various aspects of the supply chain, from procurement to logistics. I’m also adept at using Supply Chain Planning (SCP) software, which supports demand forecasting, inventory optimization, and production planning.

Furthermore, I’m proficient in Transportation Management Systems (TMS) for optimizing logistics, managing carrier relationships, and tracking shipments. My expertise extends to Business Intelligence (BI) tools like Tableau and Power BI, which are critical for data visualization and analysis. I’m familiar with Warehouse Management Systems (WMS) and have experience with various collaborative platforms for communication and data exchange with suppliers.

Proficiency in these tools allows me to effectively manage all aspects of the supply chain, from procurement to delivery, and to make data-driven decisions to optimize performance.

Q 27. Describe a challenging supply chain problem you solved and how you approached it.

One particularly challenging situation involved a major supplier experiencing a significant production disruption due to a natural disaster. This directly impacted our production schedule and threatened to cause significant delays in fulfilling customer orders. My approach was systematic and involved several key steps.

Firstly, I immediately established a cross-functional team to assess the situation. We contacted the supplier to understand the extent of the damage and projected recovery timelines. Secondly, we leveraged our network of alternative suppliers to source the affected components, although finding suitable replacements with similar quality and specifications at short notice was demanding. Thirdly, we implemented a prioritization strategy, focusing on fulfilling orders for our most critical customers first.

Finally, we leveraged our data analytics capabilities to model different scenarios and optimize the allocation of available resources. Through transparent communication with customers, we managed their expectations effectively. By employing a collaborative, data-driven approach, we mitigated the impact of the disruption, minimizing the negative consequences for both our company and our customers. This experience highlighted the importance of maintaining diverse supplier relationships and having robust contingency plans in place.

Q 28. What are your future goals in supply chain management?

My future goals in supply chain management center around leveraging technology to create truly resilient and sustainable supply chains. I’m particularly interested in exploring the potential of artificial intelligence (AI) and machine learning (ML) for predictive maintenance, demand forecasting, and risk mitigation. I also want to champion the adoption of sustainable practices throughout the supply chain, focusing on reducing carbon emissions and promoting ethical sourcing.

Specifically, I aim to lead initiatives that integrate blockchain technology to enhance transparency and traceability across the supply chain, ensuring greater accountability and reducing fraud. I also aspire to mentor and develop future supply chain professionals, sharing my knowledge and expertise to build a more skilled and innovative workforce. Ultimately, I want to contribute to building supply chains that are not only efficient and profitable but also socially and environmentally responsible.

Key Topics to Learn for Creating and Managing Supply Chain Interview

- Supply Chain Design & Strategy: Understanding different supply chain models (e.g., agile, lean), network design optimization, and the impact of globalization.

- Procurement & Sourcing: Negotiating contracts, supplier relationship management, risk mitigation strategies, and exploring sustainable sourcing practices.

- Inventory Management: Applying inventory control techniques (e.g., EOQ, ABC analysis), forecasting demand, and optimizing inventory levels to minimize costs and prevent stockouts.

- Logistics & Transportation: Selecting appropriate transportation modes, route optimization, warehouse management, and understanding the impact of logistics on overall supply chain efficiency.

- Demand Planning & Forecasting: Utilizing forecasting methods (e.g., time series analysis, causal forecasting) to predict future demand and align supply with market needs.

- Supply Chain Technology & Analytics: Understanding the role of ERP systems, data analytics, and supply chain visibility tools in improving decision-making.

- Risk Management & Resilience: Identifying and mitigating potential disruptions (e.g., natural disasters, geopolitical events, supplier failures) and building a resilient supply chain.

- Performance Measurement & Improvement: Using key performance indicators (KPIs) to track supply chain performance, identify areas for improvement, and implement continuous improvement methodologies (e.g., Lean, Six Sigma).

- Ethical and Sustainable Practices: Integrating ethical sourcing, environmental sustainability, and social responsibility into supply chain operations.

- Problem-Solving & Case Studies: Developing the ability to analyze complex supply chain scenarios, identify root causes of problems, and propose effective solutions. Prepare to discuss how you’ve tackled challenges in previous roles, focusing on your problem-solving approach.

Next Steps

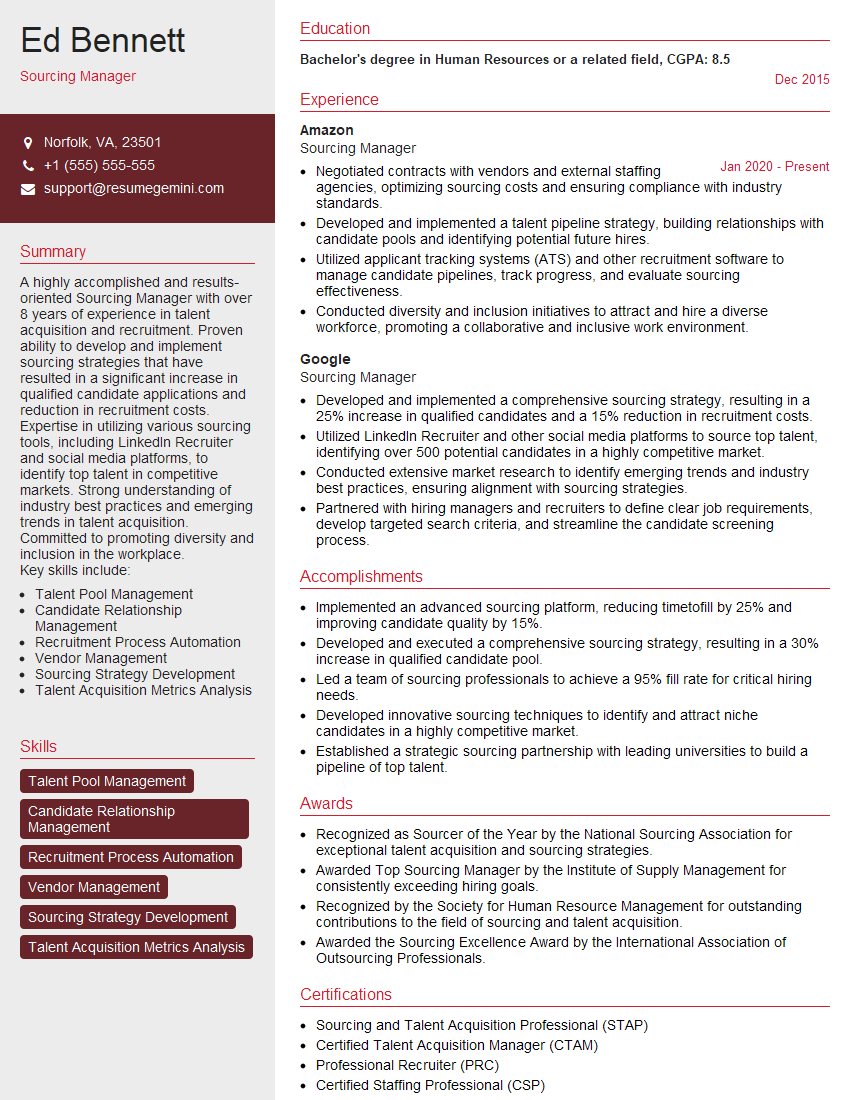

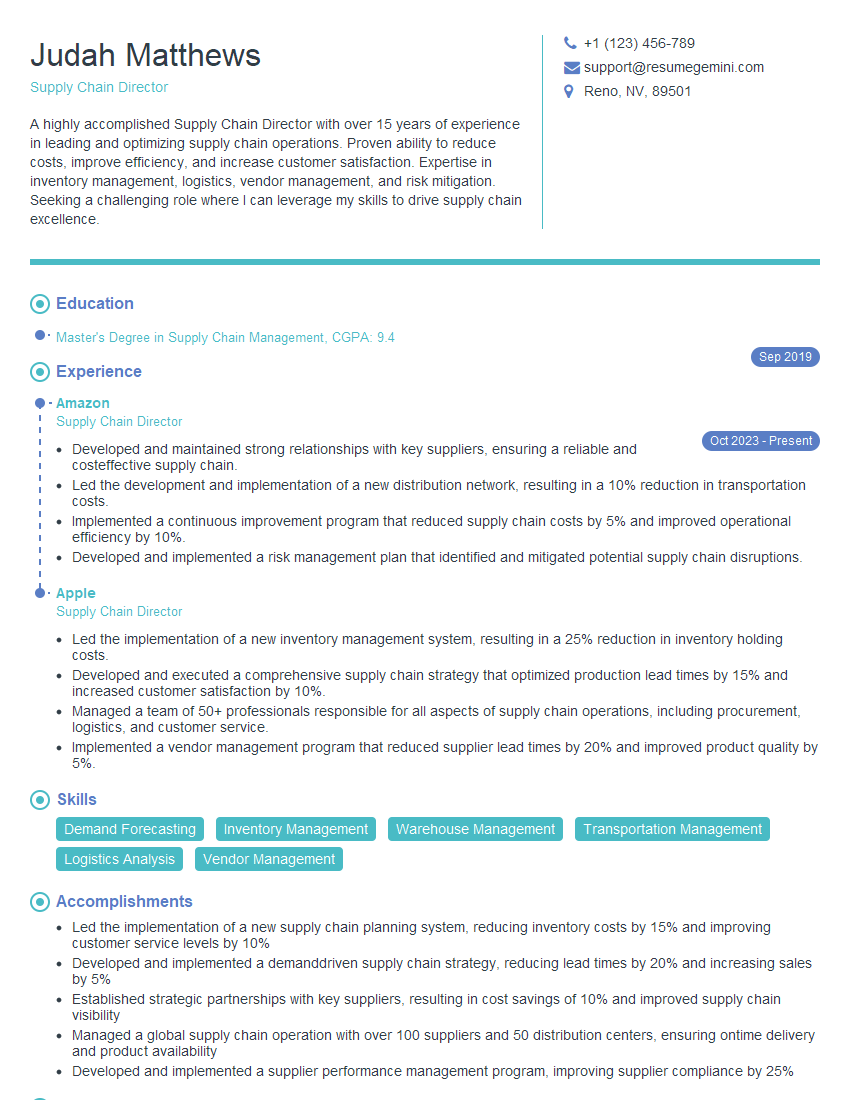

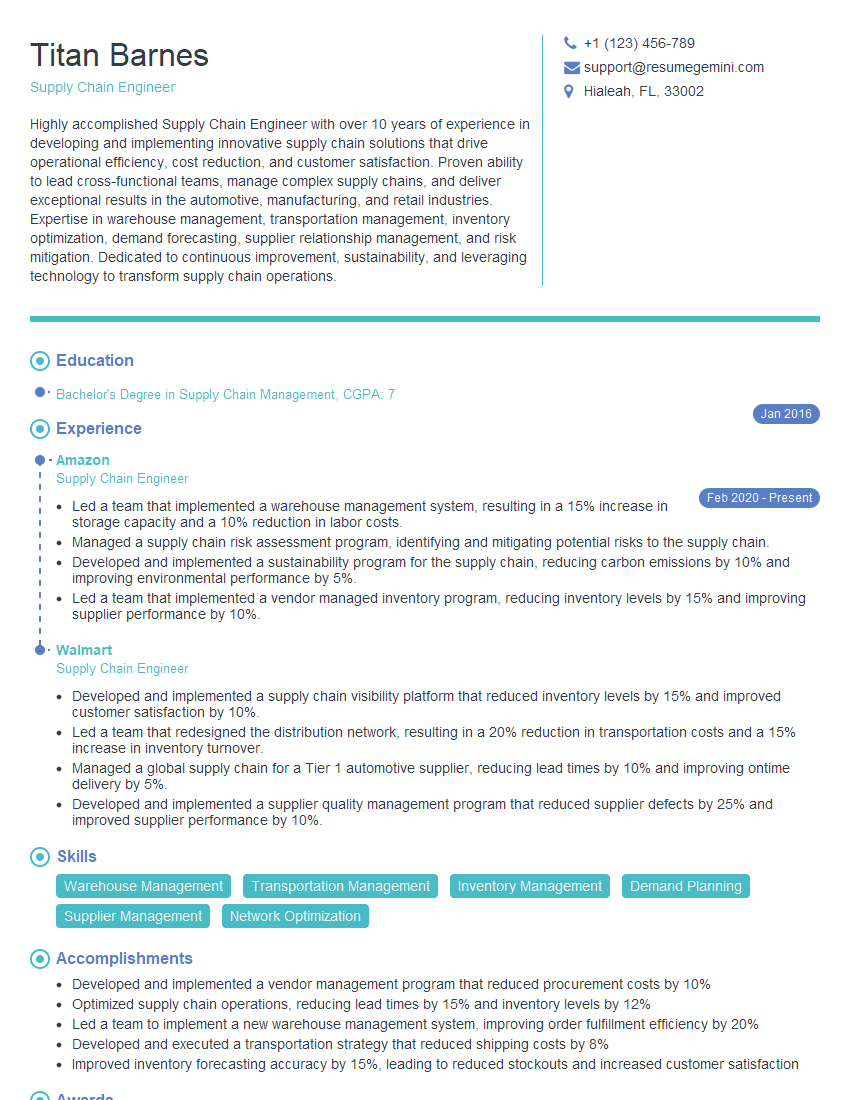

Mastering the creation and management of efficient and resilient supply chains is crucial for career advancement in today’s dynamic business environment. This expertise opens doors to leadership roles, higher earning potential, and the opportunity to make a significant impact on organizational success. To maximize your job prospects, it’s vital to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your supply chain expertise. Examples of resumes specifically designed for Creating and Managing Supply Chain roles are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good