Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Crop Inspection and Grading interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Crop Inspection and Grading Interview

Q 1. Describe the different methods used for assessing crop maturity.

Assessing crop maturity is crucial for harvesting at the optimal time, maximizing yield and quality. We employ several methods, each with its strengths and weaknesses.

- Visual Inspection: This is the most common method, relying on observable characteristics. For example, in wheat, we look for changes in kernel color, from green to golden brown, and the firmness of the grains. In tomatoes, we check for color changes (from green to red, for example), and the overall firmness of the fruit. This is often combined with the feel and touch of the crop.

- Physiological Measurements: These methods involve quantifiable data. For example, we can measure the moisture content of grains using a moisture meter. In fruits, we might measure sugar content using a refractometer or assess the firmness using a penetrometer. These tools offer objective data beyond visual observation.

- Growth Stage Indicators: This involves observing the plant’s developmental stages. For example, in wheat, we note the flowering stage and the subsequent ripening stages, which provide a timeline for harvest. Using crop calendars and growing degree days are very helpful for planning the harvest date.

- Harvest Aids: Certain chemicals can be used to hasten or synchronize ripening, making harvesting more efficient. This method is used less often due to environmental considerations.

The choice of method often depends on the specific crop, available resources, and the desired level of precision.

Q 2. Explain the process of visually inspecting produce for defects.

Visual inspection for defects is a critical step in ensuring produce quality. It’s a meticulous process requiring trained eyes and a systematic approach.

- Standardized Lighting: Consistent lighting is essential to avoid misjudgments due to shadows or variations in light intensity.

- Systematic Examination: The produce is examined systematically, often moving along a conveyor belt, checking for blemishes, bruises, discoloration, shape irregularities, and signs of disease or pest damage.

- Defect Classification: Defects are categorized into different severity levels, allowing for sorting into different grades or for rejection. For example, a small blemish might be acceptable in a lower grade, while the same blemish would make the produce unacceptable in a higher grade.

- Use of Magnification: Sometimes a magnifying glass or other magnifying tools may be used to more clearly identify minor defects.

- Documentation: It is important to document the types and frequencies of different defects, which provides valuable feedback for quality control throughout the whole process. This information is valuable for analysis and improvement.

Experienced inspectors can quickly identify defects, minimizing handling and maximizing efficiency. This practice requires extensive training and consistent quality control procedures.

Q 3. What are the key quality parameters for evaluating [specific crop, e.g., wheat, apples]?

Let’s consider apples as the specific crop. Key quality parameters for evaluating apples include:

- Size and Shape: Apples should be of uniform size and shape, within the specified grade’s requirements. A significant deviation in size or shape may reduce the grade.

- Color: Color is crucial, depending on the variety. Bright, consistent color within the expected range for the variety is desired. Bruising or discoloration reduces quality.

- Firmness: The firmness of the apple is a significant factor, typically measured using a penetrometer. This indicates the apple’s ripeness and shelf life.

- Taste and Aroma: While subjective, the flavor and aroma are important indicators of quality, checked through sensory analysis.

- External and Internal Defects: The presence of bruises, insect damage, blemishes, or internal defects significantly affects grade. These are visually inspected or detected using automated imaging systems.

- Moisture Content: For storage purposes, the moisture content might be checked to help predict the shelf life.

These parameters are often combined to determine the overall quality and grade of apples. Grading standards may vary by region or market demands.

Q 4. How do you identify and classify common crop diseases and pests?

Identifying and classifying crop diseases and pests requires a combination of knowledge and practical skills.

- Visual Inspection: Examining plants for symptoms like discoloration, wilting, lesions, unusual growths, insect presence (or evidence of insect feeding), or other anomalies is the first step. A thorough examination, including leaves, stems, roots, and fruits, is necessary.

- Laboratory Analysis: When visual inspection is not conclusive, laboratory testing might involve microscopic examination of plant tissues to identify pathogens or pests. This could include DNA analysis for accurate identification.

- Reference Materials: Using field guides, disease identification manuals, and online resources, including image databases, aids in accurate identification.

- Expert Consultation: In cases of uncertainty or complex infestations, consulting with plant pathologists or entomologists is crucial for accurate diagnosis and treatment recommendations.

Accurate identification is crucial for selecting the appropriate control measures, preventing widespread damage, and preserving crop yields.

Q 5. What are the common grading standards used in your region/country for [specific crop]?

Grading standards for apples (as an example) vary by region and market. However, common factors include size, color, shape, and the presence/absence of defects. In many regions, standards are established by agricultural organizations or government bodies. These standards often define specific grades (e.g., Extra Fancy, Fancy, C grade) with clearly defined criteria for each grade. For example, a higher grade like ‘Extra Fancy’ demands very few, if any defects, and specific size and color ranges. A lower grade like ‘C’ allows more defects and wider size variations. These standards ensure fair trade and consumer protection, informing purchasing decisions and pricing structures.

Q 6. Describe your experience with using grading equipment (e.g., scales, sorters).

My experience with grading equipment encompasses a wide range of technologies. I’ve extensively used:

- Scales: Various scales, from simple platform scales for weighing bulk lots to highly precise electronic scales for individual fruit weighing, are common. Accurate weighing ensures correct pricing and adherence to size grading requirements.

- Sorters: Optical sorters use cameras and sensors to identify defects based on color, shape, size, and other criteria. These sorters automatically sort produce into different grades, significantly improving efficiency and consistency.

- Size Graders: These machines sort produce based on size, using rollers, sieves, or other mechanisms. This ensures uniformity in packaging and meets market demands for size ranges.

My experience with calibration and maintenance of these instruments is also significant, guaranteeing accurate and reliable results. Understanding the limitations of each piece of equipment and its appropriate application is also crucial for effective and efficient grading.

Q 7. How do you ensure accurate and consistent grading across multiple batches of produce?

Ensuring accurate and consistent grading across multiple batches requires a multi-faceted approach:

- Calibration and Maintenance: Regular calibration of all grading equipment, including scales and sorters, is essential to minimize errors due to equipment drift or malfunction. Routine maintenance is crucial for equipment reliability.

- Standardized Procedures: Clear, documented grading procedures, including visual inspection protocols and equipment settings, are fundamental for consistency. All personnel should be trained in the same procedures.

- Training and Quality Control: Comprehensive training for inspectors is necessary to ensure uniformity in visual grading. Regular quality checks, including internal audits, are needed to identify and correct inconsistencies.

- Data Management: Maintaining detailed records of each batch’s grading results provides valuable information to track performance, identify trends, and make necessary adjustments to improve grading accuracy.

- Use of Technology: Automated grading systems are useful in minimizing human error, but they also require proper calibration and training to ensure accurate results.

By employing these strategies, we can achieve highly consistent grading results, improving the quality and reliability of the product across all batches.

Q 8. What are the implications of inaccurate crop grading on market value?

Inaccurate crop grading directly impacts market value, often leading to significant financial losses for both producers and buyers. Imagine a farmer meticulously cultivating high-quality apples, only to have them graded incorrectly as a lower grade. This immediately reduces their selling price, resulting in reduced profit margins. Conversely, overgrading can lead to dissatisfied customers who receive subpar produce, damaging reputation and future sales. The implications depend on the severity of the inaccuracy and the type of crop; for example, slight inaccuracies in grading potatoes might have a minor impact, whereas misgrading premium grapes could result in substantial financial losses due to their higher price point. Accurate grading is crucial for fair pricing, ensuring producers are compensated appropriately for their efforts and buyers receive the quality they expect.

For instance, a misclassification of a batch of premium coffee beans as a standard grade could mean a loss of hundreds, even thousands, of dollars depending on the volume. This underscores the importance of meticulous inspection and adherence to established grading standards.

Q 9. How do you handle discrepancies or disagreements regarding crop quality?

Discrepancies in crop quality assessments are handled through a systematic process involving careful review and, if necessary, re-inspection. First, I’d review the initial grading process, examining the methods and criteria used. Were the established standards correctly applied? Were the inspectors adequately trained and experienced? I would then compare the disputed grading with the original samples, taking note of any inconsistencies. If the discrepancy persists, I may employ a second, independent inspection by a qualified expert to provide an unbiased evaluation. Documentation is key; maintaining clear records of each inspection step allows for thorough review and resolution of disputes. In some cases, it may be necessary to involve a third-party arbitrator or rely on established industry guidelines to resolve the issue fairly.

For example, if a disagreement arises concerning the moisture content of a grain shipment, we would re-test the sample using calibrated equipment and compare the results with the original readings. If a significant difference still exists, a neutral third-party laboratory may be employed for arbitration.

Q 10. Explain the importance of maintaining accurate records during crop inspection.

Maintaining accurate records during crop inspection is paramount for several reasons. First, it ensures traceability, allowing us to track the origin, handling, and quality of the produce throughout the entire supply chain. This is crucial for identifying the source of any problems and preventing future occurrences. Second, accurate records are essential for compliance with regulations and industry standards. Many exporting countries have stringent requirements regarding food safety and quality, and comprehensive documentation is needed to meet these requirements. Third, detailed records facilitate analysis, allowing us to identify trends, improve inspection processes, and make informed decisions about resource allocation. Finally, accurate records are essential for resolving disputes and providing evidence in case of legal challenges.

Imagine a situation where a batch of produce is rejected due to a quality issue. Without detailed records, it becomes very difficult to determine the root cause of the problem or to defend against potential claims. Detailed records including date, time, location, inspector’s name, and specific quality metrics are essential for efficient and transparent operations.

Q 11. Describe your experience with different post-harvest handling techniques.

My experience encompasses various post-harvest handling techniques, including proper cleaning, sorting, grading, and storage methods. I’m familiar with different storage technologies, such as controlled atmosphere storage (CAS) for fruits and vegetables, which extends shelf life by regulating oxygen, carbon dioxide, and temperature levels. I’m also experienced with modified atmosphere packaging (MAP) that helps maintain product quality and extend shelf life by modifying the gaseous environment around the produce. Furthermore, I’m knowledgeable about various drying techniques, including sun drying, air drying, and mechanical drying, for different crops. My experience extends to techniques used for minimizing waste and maximizing the value of harvested products, including using byproducts in other applications. For example, I’ve worked with projects where fruit peels and pulp were used to create value-added products such as jams, juices, or even animal feed.

One specific example is my involvement in a project optimizing the post-harvest handling of mangoes. We implemented a combination of improved sorting techniques, refrigerated storage, and modified atmosphere packaging, which resulted in a significant reduction in spoilage and an extension of shelf life by approximately 30%.

Q 12. How do you ensure food safety standards are met during crop inspection?

Ensuring food safety standards are met during crop inspection involves adhering to strict protocols throughout the entire process. This starts with verifying the grower’s practices, including pest and disease management strategies, fertilizer usage, and water quality. During the inspection, I carefully examine the produce for signs of contamination, such as pesticide residues, microbial growth, or physical damage. I’m familiar with relevant food safety regulations like HACCP (Hazard Analysis and Critical Control Points), and my inspections are designed to identify potential hazards at every stage. Laboratory testing may be required to confirm compliance with specific standards for pesticide residues or microbial limits. Accurate record-keeping is essential to trace the origin and handling of any product found to be non-compliant. Collaboration with regulatory agencies and employing certified testing labs are essential to upholding the highest food safety standards.

For example, if a sample tests positive for excessive pesticide residues, we would immediately isolate that batch and initiate a traceback investigation to determine the source and implement corrective actions to prevent future occurrences. This could involve a review of the grower’s practices and implementation of stricter monitoring procedures.

Q 13. What are the key factors to consider when inspecting crops for export?

Inspecting crops for export involves considering several key factors beyond standard quality assessment. First, the produce must meet the specific import regulations of the destination country. These regulations may include phytosanitary requirements (related to plant health) and stipulations concerning pesticide residues, microbial limits, and packaging standards. Second, the crops should be free from pests and diseases to prevent the spread of plant pathogens to new regions. Third, proper packaging and labeling are crucial to ensure the safe transportation and handling of the produce. Finally, documentation is essential; this includes certificates of origin, phytosanitary certificates, and other required documentation to meet customs requirements. Failure to meet any of these requirements can result in rejection of the shipment and significant financial losses.

For example, exporting mangoes to the European Union requires adherence to stringent phytosanitary regulations, including inspections to ensure the absence of specific fruit flies. Non-compliance could lead to the entire shipment being rejected at the border.

Q 14. What are your strategies for managing large volumes of crops during inspection?

Managing large volumes of crops during inspection requires a well-organized and efficient approach. This involves using a combination of technology and systematic procedures. We might employ automated sorting and grading systems to handle large volumes efficiently. Random sampling techniques ensure representative inspection of the entire lot. Clearly defined inspection protocols and checklists help standardize the process and ensure consistency across the team. Efficient logistics, including appropriate storage facilities and transportation, are crucial to prevent spoilage and maintain product quality. Data management systems facilitate the tracking and analysis of inspection results, allowing us to identify potential problems early and make necessary adjustments. Collaboration with other stakeholders, including growers, transporters, and buyers, is crucial for smooth and efficient operations.

For instance, in inspecting a large shipment of potatoes, we might use a combination of automated size-grading equipment and random sampling for quality checks. This approach helps ensure an efficient and comprehensive inspection of a large volume of product while maintaining accuracy and compliance with quality standards.

Q 15. How do you prioritize tasks when faced with multiple simultaneous inspection requests?

Prioritizing multiple inspection requests requires a systematic approach. I utilize a combination of factors to create a prioritized list. First, I consider the urgency of each request; time-sensitive inspections, such as those for perishable goods nearing their expiration date, take precedence. Next, I assess the volume and complexity of each inspection. Larger-scale inspections or those requiring specialized equipment or expertise might necessitate scheduling adjustments. Finally, I factor in contractual obligations and client importance. Clients with ongoing contracts or those who are key partners receive prioritized attention. I use a digital task management system to track deadlines and ensure efficient workflow management, providing regular updates to clients on the progress of their inspections.

For instance, imagine receiving three simultaneous requests: a small, routine inspection for a local farmer, a large-scale inspection for a major exporter with an impending shipment, and an emergency inspection due to a suspected pest infestation. The emergency inspection would be prioritized first due to its urgency. The large-scale export inspection would likely be next, given its volume and the potential financial implications for the client. The smaller, routine inspection would be scheduled thereafter. This system ensures efficient resource allocation and maintains client satisfaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a situation where you had to solve a complex problem related to crop quality.

During a large-scale apple harvest, we encountered unexpectedly high levels of bruising in a particular orchard. Initial assessments pointed towards harvesting techniques, but the severity and pattern of bruising suggested a deeper issue. We investigated several potential causes, including equipment malfunction, insufficient padding during transport, and even environmental factors like sudden temperature fluctuations. Through a meticulous process that involved analyzing samples from different parts of the orchard, reviewing harvesting and transportation logs, and consulting meteorological data, we identified the root cause to be a combination of insufficient orchard floor padding and unusually heavy rainfall shortly before harvest, causing increased fruit weight and susceptibility to damage. Solving this problem involved recommending adjustments to harvesting procedures, introducing better protective measures, and negotiating a price adjustment with the farmer to account for the reduced yield and quality.

Q 17. How familiar are you with various agricultural regulations and certifications?

My familiarity with agricultural regulations and certifications is extensive. I am well-versed in national and international standards such as USDA (United States Department of Agriculture) regulations for organic produce, GAP (Good Agricultural Practices), and GLOBALG.A.P. certifications. I understand the requirements for different produce types and am up to date on the latest revisions and additions. For instance, I’m proficient in interpreting pesticide residue limits, traceability standards, and food safety regulations specific to various crops and markets. My knowledge ensures accurate assessments and the generation of reports that meet regulatory compliance needs.

Q 18. Explain the difference between internal and external crop inspection.

Internal crop inspections are conducted by the producer or organization itself to monitor quality and identify potential issues within their own operations. This can include pre-harvest checks of crops in the field, post-harvest assessments at processing facilities, or regular checks of stored inventory. External crop inspections, on the other hand, are carried out by independent third-party inspectors, often hired by buyers, exporters, or regulatory bodies to verify quality and compliance with specific standards. This provides an unbiased assessment and helps build trust and transparency across the supply chain. The primary difference lies in the objectivity and accountability; internal inspections are inherently less objective, while external inspections offer independent verification.

Q 19. How do environmental factors affect crop quality and inspection processes?

Environmental factors significantly influence crop quality and inspection processes. Adverse weather conditions such as excessive rainfall, droughts, heat waves, or unexpected frosts can directly affect the size, shape, color, and overall quality of crops. For example, excessive rainfall can lead to fungal diseases and increased incidence of bruising, requiring closer scrutiny during inspection. Similarly, prolonged periods of drought can cause stress resulting in smaller yields and reduced quality. These factors must be considered during the inspection as they can impact the final grading and market value of the produce. Additionally, environmental conditions during storage and transportation also play a role; high humidity can encourage mold growth, while extreme temperatures can lead to spoilage.

Q 20. What are the implications of using different storage methods on crop quality?

Different storage methods have substantial implications on crop quality and longevity. Proper storage is crucial for maintaining freshness, minimizing spoilage, and preserving nutritional value. For instance, storing produce at optimal temperature and humidity levels is essential. Controlled atmosphere storage (CAS) significantly extends the shelf life of many fruits and vegetables by modifying the atmosphere within the storage facility. Conversely, inadequate storage conditions—such as improper ventilation, fluctuating temperatures, or high humidity—can accelerate decay, promote pest infestations, and result in significant quality loss, leading to substantial economic losses. Factors such as the type of crop, maturity stage at harvest, and intended shelf life all influence the choice of storage method.

Q 21. What are your skills in data analysis and reporting related to crop inspection?

I possess strong data analysis and reporting skills. I’m proficient in using statistical software (e.g., R, SPSS) to analyze inspection data, identify trends, and generate insightful reports. I can use various techniques to assess quality parameters, detect outliers, and track changes over time. This allows me to create visualizations, such as charts and graphs, illustrating quality trends and helping identify areas for improvement in production or handling practices. My reports typically include summary statistics, quality indices, compliance indicators, and recommendations based on the data analysis. For example, I can analyze data from multiple inspections to determine the overall quality of a particular batch or to identify specific issues that might affect the whole supply chain. Furthermore, I’m skilled in creating customized reports tailored to client needs, adhering to industry best practices and regulatory requirements.

Q 22. How do you communicate your findings to growers and other stakeholders?

Communicating inspection findings effectively is crucial for building trust and ensuring growers understand the implications of the assessment. My approach involves a multi-faceted strategy, combining clear written reports with concise verbal explanations.

Written Reports: I generate detailed reports that include:

- Clear and concise summary of the overall crop condition.

- Detailed descriptions of any defects, including type, severity, and percentage of affected produce.

- High-quality photographs illustrating the damage or imperfections observed.

- Recommendations for improving crop quality or addressing identified issues, such as adjusting irrigation practices or implementing pest management strategies.

- Grading information conforming to relevant industry standards (e.g., USDA standards).

Verbal Communication: I prioritize direct communication with growers. I explain the report’s findings in plain language, avoiding jargon, and answer their questions patiently. I ensure growers understand the context of the assessment and how the results might affect their yields and marketability.

Stakeholder Communication: When necessary, I communicate with other stakeholders, such as buyers or processors, adapting the level of detail to their needs and expertise. This may involve providing a summary report or participating in conference calls to discuss findings and next steps.

Q 23. Describe your experience with using specific software or technology for crop inspection.

Throughout my career, I’ve utilized several software and technologies to streamline and enhance crop inspections. This includes:

- Image analysis software: I have extensive experience using programs that allow for the automated detection and classification of defects in images captured during inspections. For example, I’ve used software that can identify bruising or discoloration on apples with remarkable accuracy, quantifying the extent of the damage in a fraction of the time it would take manually.

- Drone technology: I’m proficient in operating and analyzing data from drones equipped with high-resolution cameras and multispectral sensors. This technology allows for efficient large-scale assessments, particularly useful for identifying variations in crop health across fields. For instance, I’ve used drone imagery to detect nutrient deficiencies in large-scale corn fields before they become noticeable to the naked eye.

- GIS (Geographic Information Systems): I integrate inspection data with GIS platforms to spatially map crop health and damage. This allows for the identification of patterns and trends, potentially linked to environmental factors or cultivation practices. This detailed analysis helps identify at-risk areas or trends which might help to address future crop issues more effectively.

- Data Management Systems: I’m adept at using dedicated software for recording, storing, and analyzing inspection data, ensuring data integrity and allowing for trend analysis over time.

Q 24. How do you stay up-to-date with the latest advancements in crop inspection techniques?

Staying current in the rapidly evolving field of crop inspection requires a proactive approach. I regularly engage in several activities to maintain my expertise:

- Professional Development: I actively participate in industry conferences, workshops, and webinars to learn about the newest technologies, methodologies, and best practices. These events often showcase the latest research and innovative solutions in crop inspection.

- Scientific Publications: I read peer-reviewed journals and scientific literature to stay abreast of research findings on disease detection, pest management, and advanced imaging techniques.

- Online Resources: I utilize online platforms and resources that offer tutorials, webinars, and training materials on cutting-edge techniques. This allows for continuous learning at my own pace.

- Networking: I actively participate in professional organizations and engage with other experts in the field through online forums and discussions. This fosters collaboration and allows for the exchange of knowledge and insights.

- Industry Collaboration: I engage with agricultural universities and research institutions to remain updated on technological advancements and research findings.

Q 25. Explain your experience with different types of crop damage and their causes.

My experience encompasses a wide range of crop damage types and their underlying causes. I can identify and differentiate between various forms of damage, including:

- Physiological disorders: These are often caused by environmental stresses like drought, nutrient deficiencies, or extreme temperatures. For instance, blossom-end rot in tomatoes results from calcium deficiency, while sunscald in apples is caused by excessive sunlight exposure.

- Pest damage: Insects, mites, and other pests cause significant damage to crops. Identifying the specific pest is crucial for effective management. For example, I’ve assessed corn crops damaged by corn borers and developed recommendations for appropriate pest control measures.

- Disease damage: Fungal, bacterial, and viral diseases can dramatically affect crop yields and quality. I have experience identifying various diseases, such as late blight in potatoes or powdery mildew in grapes, and recommending appropriate disease management strategies.

- Mechanical damage: This can occur during harvesting, handling, or transportation. Bruising, cuts, and other physical injuries reduce the marketability of produce. My assessments often include recommendations for improved handling practices to minimize these types of losses.

- Hail damage: Hailstorms can inflict significant damage to crops, causing bruising and other physical injuries. The extent of the damage can vary widely based on hail size and storm intensity. My experience includes evaluating the impact of hail on various crops, including vineyards and orchards.

Understanding the causes of damage is crucial for developing effective preventative measures and minimizing future losses. I always incorporate my understanding of these causes into my assessment reports and recommendations.

Q 26. How do you maintain objectivity and impartiality during crop inspection?

Maintaining objectivity and impartiality is paramount in crop inspection. My commitment to fairness is reflected in several key aspects of my work:

- Adherence to Standards: I strictly follow established grading standards and guidelines. This ensures consistent and unbiased evaluations across different crops and locations.

- Detailed Documentation: I meticulously document all observations and measurements. Detailed records minimize subjective interpretations and provide a transparent audit trail of the inspection process.

- Calibration and Verification: When using instruments or technology, I ensure proper calibration to guarantee accuracy and reliability of measurements. Regular verification of equipment helps reduce potential bias.

- Transparency and Openness: I am always transparent with my methods and findings, readily addressing any questions or concerns from growers or other stakeholders. Open communication builds trust and minimizes suspicion of bias.

- Continuous Professional Development: Staying updated on the latest methodologies and technologies helps minimize biases stemming from outdated practices or a lack of knowledge.

My reputation rests on the integrity of my assessments, and I rigorously maintain impartiality in all aspects of my work.

Q 27. Describe a time you had to deal with a difficult or challenging inspection situation.

One challenging situation involved a large-scale dispute over the quality of a grape harvest. A significant portion of the crop showed signs of sunburn, with both the grower and the buyer disagreeing on the extent of the damage and its impact on marketability. The grower claimed the damage was minimal and primarily cosmetic, whereas the buyer argued it rendered a significant portion of the harvest unsellable.

To address the issue, I employed a multi-pronged approach:

- Thorough Field Inspection: I conducted a comprehensive on-site inspection, systematically sampling various sections of the vineyard and carefully documenting the severity and extent of sunburn damage.

- Objective Data Collection: I utilized digital imagery and advanced image analysis software to quantify the damaged area accurately. This provided unbiased data to support my assessment.

- Industry Standards: I referred to the established grading standards for grapes to determine the classification of damaged fruit based on objectively measured parameters, avoiding subjective interpretations.

- Clear and Concise Report: I prepared a detailed report summarizing my findings and explaining my rationale, using clear language that both the grower and buyer could understand.

- Mediation: I acted as a neutral party, mediating discussions between the grower and buyer to reach a mutually acceptable solution based on the factual evidence presented in my report.

Ultimately, my objective assessment, supported by data and clear communication, helped resolve the dispute amicably. This experience highlighted the importance of impartiality, detailed documentation, and effective communication in resolving complex situations in crop inspection.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and expertise in crop inspection and grading, as well as the responsibilities of this role and the prevailing market rates for similar positions. Based on my qualifications and the details of this position, I am seeking a salary in the range of [Insert Salary Range]. I am open to discussing this further and am confident we can reach an agreement that is mutually beneficial.

Key Topics to Learn for Crop Inspection and Grading Interview

- Crop Physiology and Development: Understanding plant growth stages, identifying healthy vs. unhealthy development, and recognizing the impact of environmental factors on crop quality.

- Quality Standards and Grading Systems: Familiarizing yourself with industry-specific grading standards (e.g., USDA, international standards), understanding grading criteria for different crops, and applying these standards consistently.

- Pest and Disease Identification: Mastering the identification of common crop pests and diseases, understanding their impact on crop quality, and applying appropriate control measures.

- Post-Harvest Handling and Storage: Understanding the principles of proper post-harvest handling, including techniques for minimizing damage and spoilage during transportation and storage.

- Sensory Evaluation Techniques: Developing skills in visually inspecting crops for defects, assessing texture, and evaluating aroma and flavor (where applicable).

- Technological Applications: Exploring the use of technology in crop inspection, such as imaging systems, sensors, and automated grading equipment.

- Data Analysis and Reporting: Understanding how to collect, analyze, and report inspection data effectively, using data to identify trends and improve quality control processes.

- Compliance and Regulations: Familiarizing yourself with relevant food safety regulations and industry best practices related to crop inspection and grading.

- Problem-solving and Decision-making: Developing the ability to identify and resolve issues related to crop quality, applying critical thinking skills to make informed decisions.

Next Steps

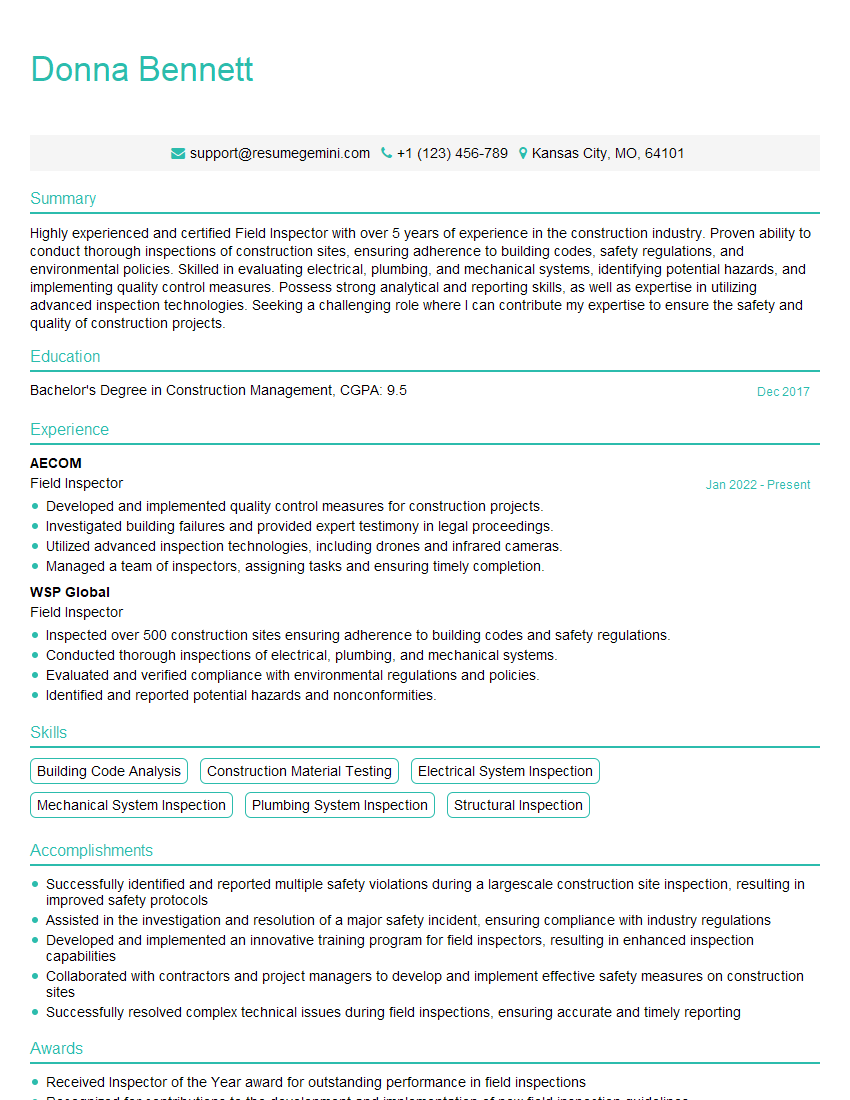

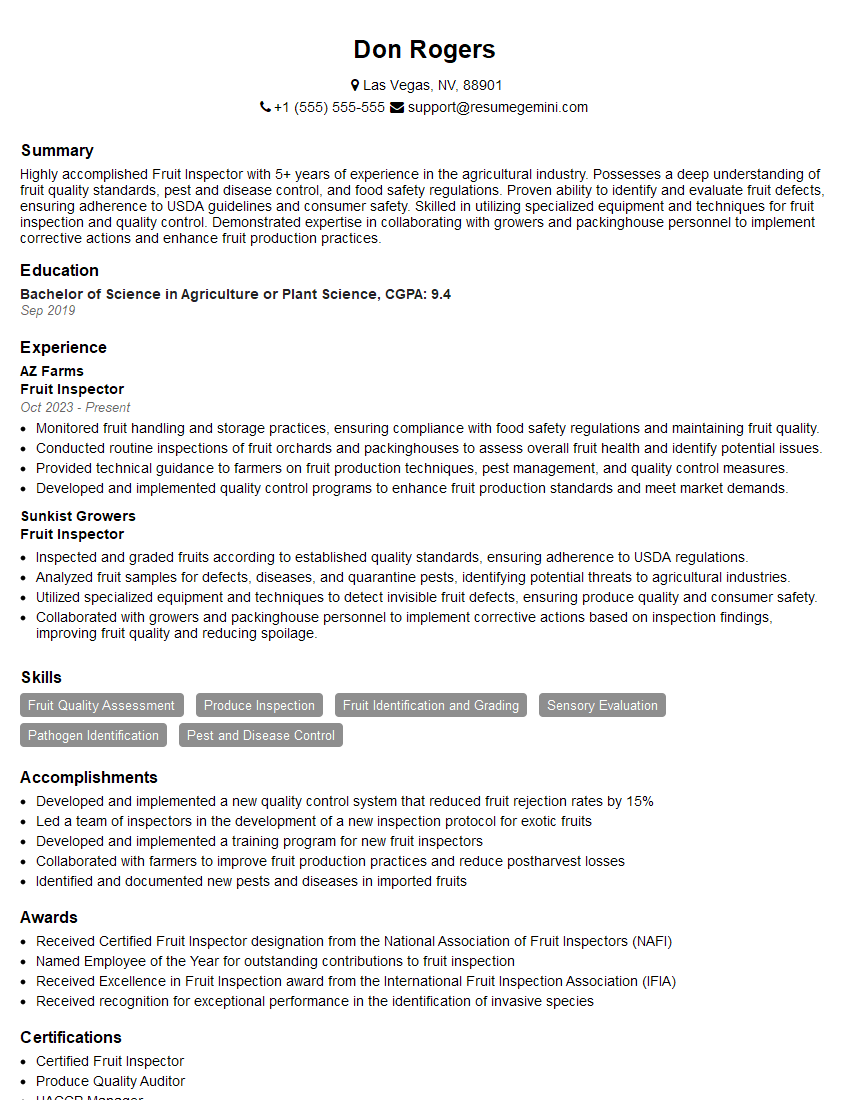

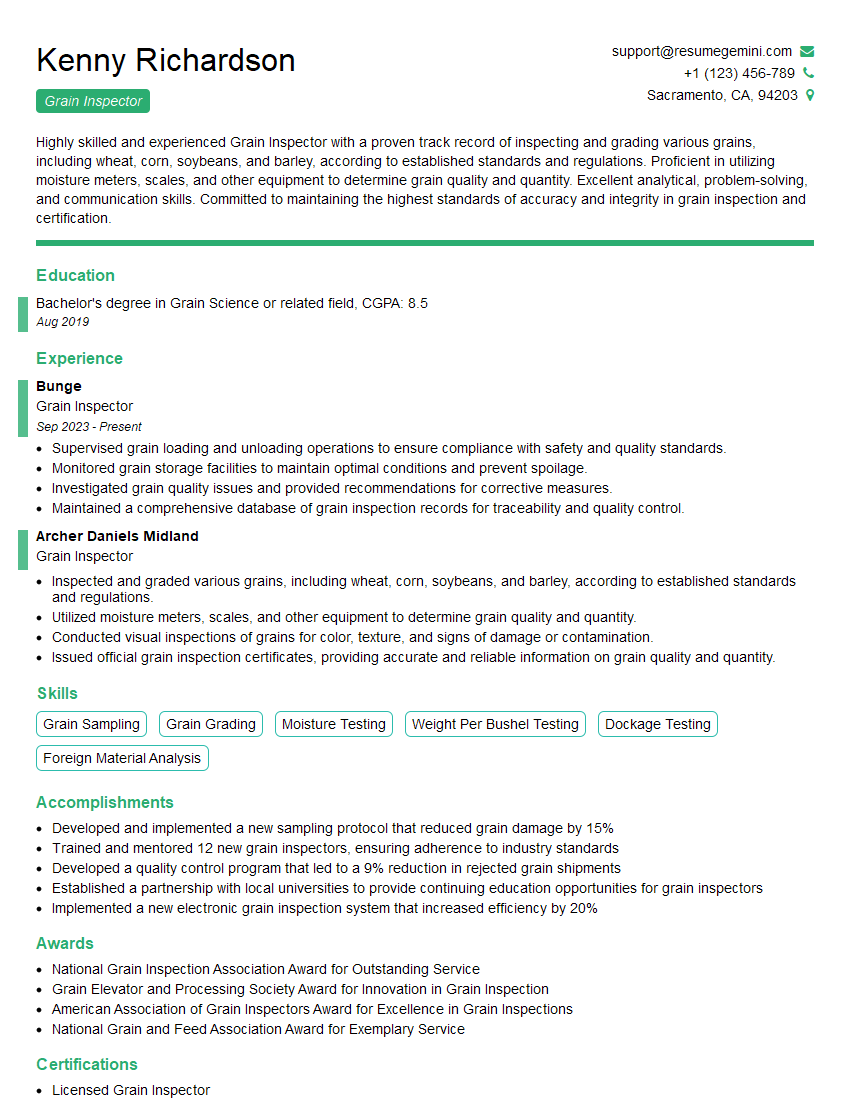

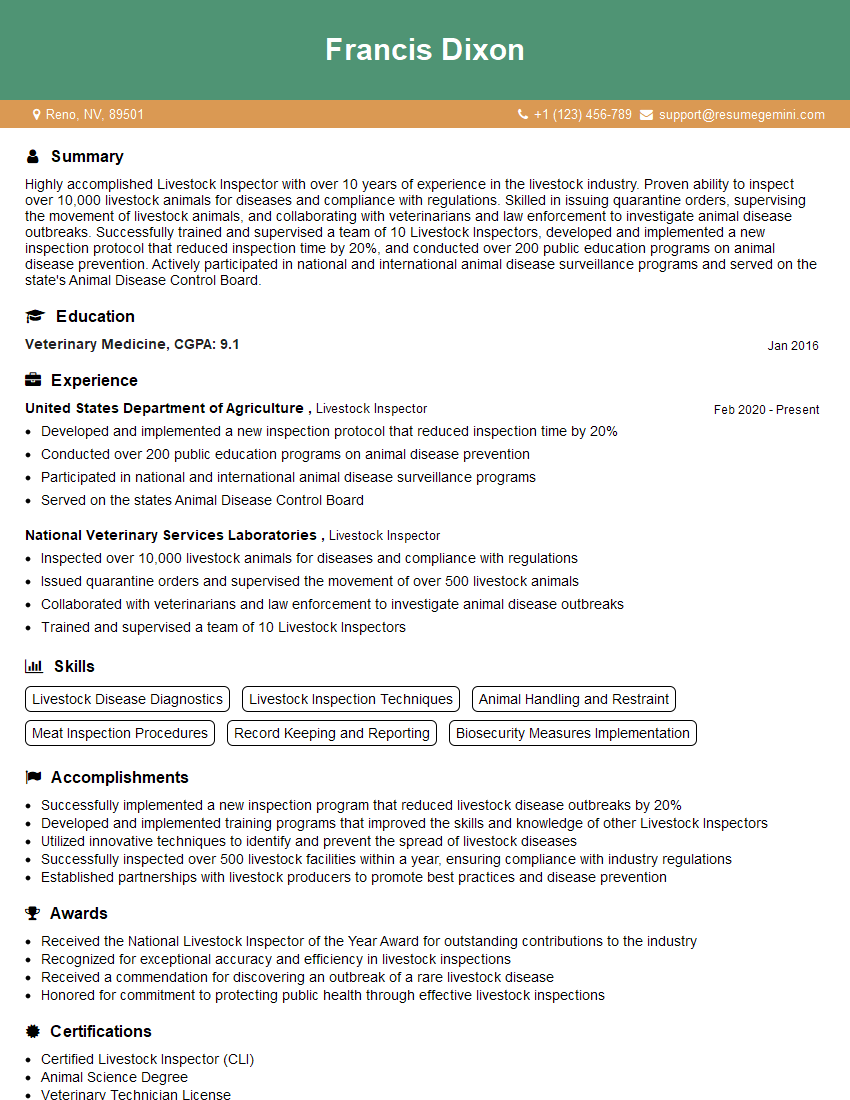

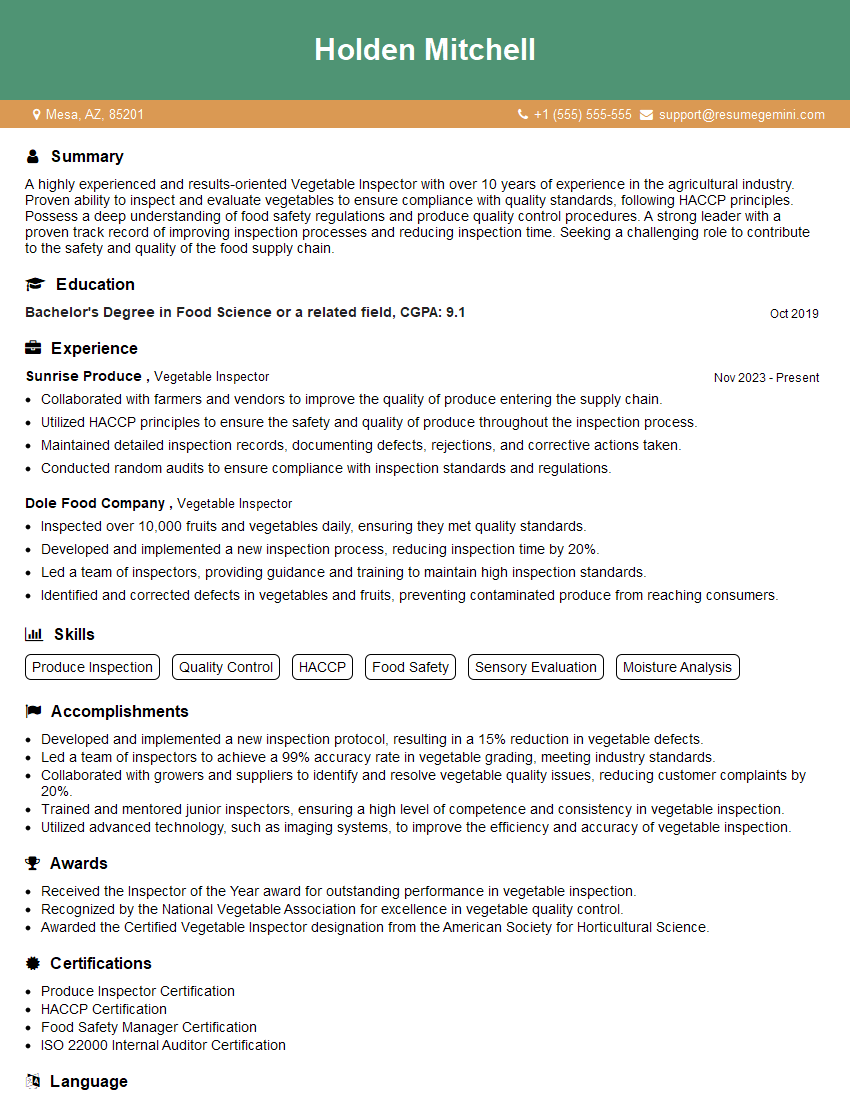

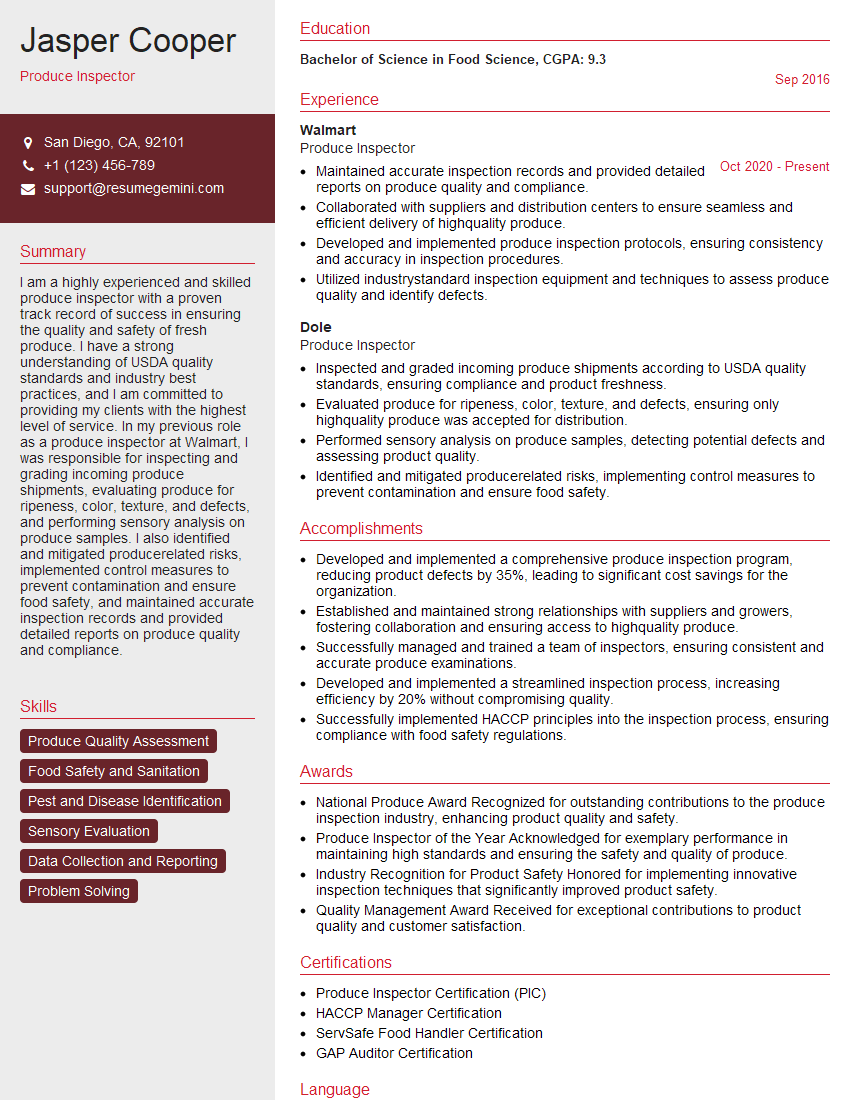

Mastering Crop Inspection and Grading opens doors to a rewarding career with opportunities for growth and specialization. A strong understanding of these principles will make you a highly competitive candidate. To maximize your chances of securing your dream role, create a professional and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a compelling resume that showcases your qualifications effectively. Examples of resumes tailored specifically to Crop Inspection and Grading are available to help guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good