The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Custom leatherwork interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Custom leatherwork Interview

Q 1. Explain the different types of leather and their suitability for various projects.

Choosing the right leather is crucial for a successful project. Different types of leather offer varying levels of durability, texture, and aesthetic appeal. Here are a few key types:

- Full-grain leather: This is the top layer of the hide, retaining its natural grain and offering superior strength and durability. It’s ideal for high-stress items like belts, bags, and holsters. Scratches and marks add character over time.

- Top-grain leather: The top layer after the full-grain has been sanded to remove imperfections. It’s smoother and more consistent than full-grain but slightly less durable. It’s a good choice for jackets, wallets, and other items where a smoother finish is desired.

- Genuine leather: This is often a split-hide, meaning it’s the lower layer of the hide. It’s less durable than full or top-grain, but more affordable. It’s suitable for less demanding projects.

- Nubuck leather: A type of suede leather, it’s soft, velvety, and has a characteristic nap. However, it’s delicate and needs more care. It’s well-suited to items that aren’t exposed to significant wear and tear, such as decorative accessories.

- Patent leather: Treated with a glossy, resin-coated finish, this leather is waterproof and highly resistant to scratches. It’s often used for formal shoes or accessories, but it’s less breathable than other leathers.

The choice ultimately depends on the project’s demands and the desired aesthetic. For example, I’d never use genuine leather for a heavy-duty work belt, but it’s perfectly suitable for a less demanding item like a small notebook cover.

Q 2. Describe your experience with various leather tooling techniques (e.g., stamping, carving).

My experience with leather tooling is extensive, encompassing a broad range of techniques. I’m proficient in both hand and machine tooling.

- Stamping: I use a variety of stamps to create intricate designs, from simple floral patterns to complex geometric shapes. The depth of the impression can be controlled by the pressure applied and the type of stamp used. I often combine different stamps to build complex imagery.

- Carving: This involves using specialized tools to create three-dimensional relief designs. This process requires precision and patience, and I’ve mastered various carving techniques, from backgrounding to beveling, to achieve depth and shadowing. I’ve carved everything from intricate Celtic knots to realistic animal portraits.

Beyond these core techniques, I’m also skilled in tooling with different materials, like adding inlays of contrasting colored leathers or using metallic tooling for accents. For instance, I recently completed a custom briefcase with deeply carved floral patterns, inlaid with contrasting turquoise leather and finished with antiqued brass hardware.

Q 3. How do you select the appropriate leather for a specific design and its intended use?

Selecting the right leather involves a careful consideration of both the design and the intended use.

- Design Considerations: The design dictates the required texture and thickness. For instance, delicate designs might require thinner, more supple leather, while bolder, embossed designs might need thicker, firmer leather to support the tooling.

- Intended Use: Durability is paramount. A wallet needs a durable leather that can withstand daily wear and tear, while a decorative wall hanging requires a leather that is aesthetically pleasing but may not need exceptional strength. I also consider factors such as water resistance and breathability based on the intended use.

For example, if I’m designing a motorcycle saddlebag, I’ll choose a thick, full-grain leather known for its durability and water resistance. In contrast, for a delicate jewelry pouch, I might select a softer, thinner leather like lambskin or goatskin.

Q 4. What are the common challenges encountered during the leather dyeing process, and how do you address them?

Leather dyeing can be challenging, but with experience, predictable results are achievable. Common challenges include:

- Uneven Color: This can result from inadequate preparation or inconsistent application of dye. I address this by ensuring the leather is properly cleaned and conditioned before dyeing and using a consistent application technique.

- Bleeding: Some dyes bleed into lighter-colored leathers. To avoid this, I use dye fixatives and perform test patches before full application.

- Color variations between batches: Natural variations in hide can impact the way dye is absorbed. Addressing this requires careful selection of hides from the same batch to ensure consistent coloration.

My approach emphasizes careful preparation, consistent application, and the use of high-quality dyes and fixatives. I also utilize various techniques, including hand-dyeing, sponging, and airbrushing, to achieve specific effects.

Q 5. Describe your experience with leather stitching techniques (e.g., saddle stitch, hand stitch).

Stitching is a crucial element in leatherwork, determining both the durability and the aesthetic appeal of the finished product. I’m highly proficient in several stitching techniques.

- Saddle Stitch: This is a strong, durable stitch used for items that experience significant stress, such as belts and bags. It involves using two needles and a single thread, creating a secure, interlocking stitch that is resistant to coming undone.

- Hand Stitch: This encompasses a variety of stitches, each with its own unique characteristics and uses. I utilize different hand stitches based on the desired aesthetic and level of durability needed. Some hand stitches are more decorative and visually appealing, while others are designed for maximum strength.

My stitch work emphasizes even spacing, consistent tension, and the use of appropriate needles and thread for each technique. The choice of stitch greatly impacts the final piece; for instance, a saddle stitch would be unsuitable for fine jewelry work, while a delicate running stitch might be too fragile for a sturdy briefcase.

Q 6. How do you create and use leather patterns?

Creating and using leather patterns is foundational to accurate and efficient leatherwork.

I typically start by sketching the design on paper, then translating it into a pattern using cardboard or a similar material. For more complex projects, I might use computer-aided design (CAD) software for more precise patterns. Once the pattern is created, I cut it out carefully. Next, I trace the pattern onto the leather, using a tracing wheel or chalk. Finally, I cut the leather along the traced lines, ensuring clean and precise cuts to minimize waste and maximize accuracy. Precise patterns are essential, particularly for symmetrical or complex projects. For instance, a mistake in the pattern for a pair of gloves would be immediately noticeable and unacceptable.

Q 7. Explain your process for designing a custom leather product from initial concept to final product.

My design process is iterative and client-focused. It proceeds as follows:

- Initial Consultation: I meet with the client to understand their needs, preferences, and budget. We discuss the design, materials, and functionality of the desired product.

- Design Development: Based on the consultation, I develop sketches and patterns. This might involve several iterations to refine the design to the client’s satisfaction.

- Material Selection: I choose the appropriate leather, thread, and hardware based on the design, intended use, and client preferences.

- Pattern Making: I create precise patterns, ensuring accurate fit and minimizing waste.

- Leather Preparation: I clean, condition, and dye the leather as needed to achieve the desired look and feel.

- Construction: I carefully construct the product, paying close attention to detail and utilizing appropriate stitching and tooling techniques.

- Finishing: The final touches might include edge finishing, polishing, and applying protective treatments.

- Quality Control: I inspect the finished product to ensure it meets the highest standards of quality and craftsmanship.

- Delivery: Once the product is approved, I deliver it to the client. Often, I include a care guide for the longevity of their custom leather item.

For example, recently I designed a custom-tooled leather journal for a writer. We collaborated on the design, choosing a rich brown leather and incorporating subtle tooling based on her favorite flower. The end result was a unique, high-quality journal perfectly suited to her needs and preferences.

Q 8. What software or tools do you use for leather design and pattern making?

For leather design and pattern making, I utilize a combination of digital and traditional methods. My primary digital tool is a vector-based design program like Adobe Illustrator. This allows me to create precise patterns, experiment with different designs, and easily scale them for different projects. For example, I can design a complex embossed pattern in Illustrator, then accurately translate that into a cutting pattern for a custom-made belt. I also utilize specialized software like Pepakura Designer for more complex 3D leather projects, allowing me to create accurate templates from 3D models. Alongside digital tools, I rely heavily on traditional methods. I use a variety of rulers, French curves, and other drafting tools to refine my designs and create precise paper patterns before transferring them to the leather. This allows me to feel the design and assess its feasibility during the creation process.

Q 9. How do you ensure the durability and longevity of your leather products?

Ensuring the durability and longevity of my leather products involves a meticulous approach, starting with material selection. I prioritize high-quality, full-grain leather known for its strength and resilience. Full-grain leather maintains the natural grain of the hide, making it resistant to scratches and abrasions. Beyond the leather itself, strong, durable stitching is paramount. I use a high-quality waxed thread and employ techniques like saddle stitching, a time-tested method that creates incredibly strong and aesthetically pleasing seams. In addition, I pay close attention to edge finishing. Properly finished edges protect the leather from fraying and moisture damage, significantly extending the product’s lifespan. I use a combination of techniques like sanding, applying edge paint, and burnishing to create a smooth, durable, and aesthetically pleasing edge. Finally, I advise my clients on proper care and maintenance of their leather goods, providing detailed instructions on cleaning, conditioning, and storage.

Q 10. Describe your experience with leather finishing techniques (e.g., edge finishing, burnishing).

My experience with leather finishing techniques is extensive. Edge finishing is crucial for both durability and aesthetics. I typically begin by carefully sanding the edges to create a smooth, even surface. Then, I apply several coats of edge paint or sealant, allowing each coat to dry thoroughly before applying the next. The choice of edge paint depends on the leather and the desired aesthetic; some projects call for a more subtle finish, while others benefit from a more vibrant color. Burnishing is the final step, where I use a variety of tools – from slickers to bone folders – to compress and polish the edge, creating a smooth, glossy finish that is both protective and visually appealing. This process can be time-consuming but is essential for creating high-quality, durable leather goods. For example, on a high-end briefcase, I’d spend considerable time perfecting the edge finishing, ensuring a flawless, protective, and aesthetically pleasing result. The contrast between the clean edge and the natural leather adds to the overall quality of the piece.

Q 11. How do you handle customer orders and manage expectations?

Handling customer orders and managing expectations involves clear communication and meticulous record-keeping from the initial consultation to the final delivery. I begin by thoroughly discussing the customer’s vision, including desired materials, design elements, and timeframe. I provide realistic estimates of completion times, considering factors such as complexity and current workload. I use detailed sketches and visual aids to confirm the design and address any questions or concerns. I maintain open communication throughout the process, providing updates on progress and addressing any questions promptly. I also set clear expectations regarding potential delays and any unforeseen issues. If a problem arises, I proactively address it and discuss potential solutions with the customer to ensure a positive outcome. Transparent communication and realistic expectations are key to maintaining strong customer relationships and ensuring client satisfaction.

Q 12. Describe your experience with repairing damaged leather goods.

Repairing damaged leather goods requires a careful assessment of the damage and the use of appropriate techniques. For minor scratches or scuffs, I might use leather conditioners or specialized cleaners to restore the leather’s appearance. More significant damage, like tears or holes, requires more involved repair work. I use techniques like patching, stitching, and applying leather fillers to reconstruct the damaged areas. The goal is to seamlessly blend the repair with the existing leather, minimizing the visibility of the damage. For instance, I recently repaired a vintage leather jacket with a significant tear on the sleeve. I carefully matched the leather, used careful stitching to close the tear, and then used a specialized dye to blend the patch with the original leather, making the repair virtually invisible. The success of such repairs depends heavily on careful planning and precision in the execution.

Q 13. What safety precautions do you take when working with leather and tools?

Safety is paramount in leatherwork. I always use appropriate eye protection, such as safety glasses, when working with cutting tools or sanding leather. Sharp tools, like knives and chisels, should always be stored properly when not in use. I maintain a clean and organized workspace to prevent accidents caused by tripping or clutter. When using chemicals like dyes or finishes, I work in a well-ventilated area, and I always follow the manufacturer’s instructions for safe handling and disposal. Proper hand protection, such as leather gloves, is also essential when working with sharp tools or abrasive materials. I regularly inspect my equipment for damage or wear and replace worn items promptly to ensure safety. Regularly sharpening tools is also critical as dull tools are more likely to slip and cause injury.

Q 14. How do you maintain and care for your leatherworking tools?

Maintaining and caring for my leatherworking tools is crucial for their longevity and performance. After each use, I clean my tools thoroughly to remove any debris or residue. Sharp tools, such as knives and chisels, are regularly sharpened to maintain their sharpness and prevent accidents. I use appropriate lubricants or oils to keep moving parts functioning smoothly and prevent rust or corrosion. I store my tools in a protective case or on a tool rack, ensuring they are properly organized and protected from damage. Leather mallets and other wooden tools are inspected for cracks or damage and are occasionally treated with linseed oil to maintain their condition. Regular maintenance of my tools is not only essential for preserving their quality but also crucial for safety and efficiency when working on leather projects.

Q 15. What are your preferred leather suppliers, and why?

My preferred leather suppliers are a blend of established tanneries and smaller, specialized businesses. For large-scale projects requiring consistent quality and volume, I rely on established tanneries like Wickett & Craig, known for their exceptional full-grain leathers. Their hides are durable, have beautiful natural markings, and age gracefully. For more unique leathers, like exotic skins or specially treated hides, I source from smaller artisans. One such supplier is a family-run operation specializing in Horween leather, renowned for its exceptional quality and rich history. The decision depends on the specific project and the client’s needs; selecting the right supplier is crucial for achieving the desired look, feel, and durability of the final product.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your process for pricing your custom leatherwork.

Pricing my custom leatherwork is a multifaceted process. It begins with a detailed consultation with the client to understand their vision, specifications, and desired outcome. Then, I meticulously break down the project into its constituent elements: material costs (leather type and quantity, hardware, thread), labor hours (design, cutting, stitching, finishing, etc.), and any additional services like design revisions or expedited delivery. I use a combination of hourly rates and material cost markups to determine a fair price. For example, a simple leather wallet might involve a few hours of labor and relatively inexpensive materials, resulting in a lower price point, while a bespoke motorcycle saddle might require dozens of hours and premium leathers, leading to a significantly higher price. Transparency is key; I always provide clients with a detailed breakdown of the pricing to ensure complete understanding and agreement before commencing the project.

Q 17. How do you handle customer requests for modifications or alterations?

I embrace modifications and alterations as opportunities to refine the design and better meet the client’s expectations. The process begins with a thorough discussion of the requested changes, exploring their feasibility and potential impact on the timeline and budget. Minor alterations, such as adjusting pocket placement or adding stitching details, are often easily incorporated. More significant modifications, such as changing the leather type or adding complex features, require a reassessment of the project’s scope and may involve adjusted pricing and delivery timelines. I always maintain open communication with the client, providing regular updates and seeking their approval before proceeding with any changes. My goal is to ensure complete client satisfaction through a collaborative and transparent modification process.

Q 18. Describe a time you had to troubleshoot a problem during a leatherworking project.

During a recent project involving a custom-made leather briefcase, I encountered a challenge with the stitching. I was using a particularly thick, densely woven leather which proved difficult to stitch cleanly with my usual needle. The stitches were bunching and causing uneven tension. To troubleshoot this, I systematically investigated different needle types and thread weights. After several experiments, I found a solution using a heavier-duty needle and a waxed linen thread, enabling me to achieve the desired clean, even stitch. This experience reinforced the importance of meticulous planning, careful material selection, and the willingness to experiment to overcome unforeseen challenges. It also highlighted the value of a well-stocked workshop with a variety of tools and materials to address potential problems effectively.

Q 19. What are your strengths and weaknesses as a leatherworker?

My strengths lie in my meticulous attention to detail, my proficiency in various leatherworking techniques, and my ability to translate a client’s vision into a tangible, high-quality product. I possess strong problem-solving skills, as demonstrated in the briefcase example. A weakness, though I’m working on it, is sometimes overcommitting to projects. I’m learning to better manage my workload and prioritize tasks more effectively to ensure timely delivery without compromising quality.

Q 20. How do you stay updated on new trends and techniques in the leather industry?

Staying updated in the leather industry is a continuous process. I regularly subscribe to industry publications like Leather Craftsman magazine and follow influential leatherworkers and tanneries on social media platforms like Instagram. I also actively participate in online forums and attend workshops and trade shows to learn new techniques and discover innovative materials. This proactive approach ensures I remain at the forefront of trends and best practices, enriching my skillset and offering clients the latest advancements in leather craftsmanship.

Q 21. Describe your experience working with different types of hardware (e.g., buckles, zippers).

My experience with different types of hardware is extensive, encompassing various buckles (roller buckles, side-release buckles, etc.), zippers (YKK, Opti, etc.), and other components like rivets, snaps, and D-rings. I understand the importance of selecting hardware that complements the leather and the overall design aesthetic. The material and finish of the hardware must align with the leather’s quality and character; for example, using inexpensive hardware with high-end leather would detract from the overall piece. I carefully consider durability and functionality when choosing hardware, ensuring it is robust enough to withstand daily wear and tear. I’m proficient in installing hardware using appropriate tools and techniques, guaranteeing a secure and professional finish. Selecting the right hardware is a critical aspect of creating a durable and aesthetically pleasing final product.

Q 22. How do you ensure the consistency of your leatherwork?

Consistency in leatherwork is paramount. It’s achieved through a meticulous approach that begins with material selection and extends to every stage of the process. I start by sourcing high-quality, consistently tanned hides from reputable suppliers. This minimizes variations in thickness, texture, and color. Then, I utilize precise cutting techniques, employing patterns and templates to ensure uniformity in pieces. My stitching is consistent in tension and spacing, using a reliable machine and maintaining a steady hand. Finally, I implement rigorous quality control checks at each step, identifying and addressing any inconsistencies before moving to the next phase. For instance, if I notice a slight variation in the thickness of a piece of leather, I’ll carefully plan my stitching or tooling to compensate, ensuring a perfectly finished product.

Q 23. What are your goals for your career in custom leatherwork?

My career goals in custom leatherwork extend beyond simple craftsmanship. I aim to build a reputation for creating heirloom-quality pieces—items that not only function impeccably but also tell a story. I want to explore innovative design approaches, perhaps incorporating sustainable materials or exploring new leather finishing techniques. Beyond the creative aspect, I aspire to mentor aspiring leatherworkers, sharing my knowledge and passion for this art form. Ultimately, I envision a future where my work is recognized for its exceptional quality, unique designs, and lasting impact on the field of custom leatherwork.

Q 24. How do you handle difficult or demanding clients?

Handling demanding clients requires patience, clear communication, and a commitment to understanding their needs. First, I actively listen to their requests, clarifying any ambiguities upfront. I then present realistic options, explaining the technical limitations or potential challenges involved. If adjustments are needed, I present them as collaborative solutions, discussing the pros and cons of each approach. Transparency is key; I keep clients updated on the project’s progress, informing them of any delays or unexpected issues. Maintaining a professional yet personable demeanor throughout the process is essential in managing expectations and building trust, even with the most challenging clients. For example, once, a client wanted an impossibly intricate design on a particularly stiff leather. I explained the limitations and offered alternative designs that achieved the client’s vision while maintaining structural integrity.

Q 25. Describe your experience with different types of leather adhesives and their applications.

My experience with leather adhesives is extensive. I’ve worked with a range of options, each suited to different applications. For instance, contact cement is excellent for bonding large surfaces, like in the construction of bags or saddlebags, providing a strong, durable bond. However, it requires precise application and a short open time. For smaller, more delicate projects, I often prefer a water-based adhesive, as it’s less aggressive and allows for easier repositioning of pieces before they fully cure. Finally, for very fine leatherwork or repairs, I use specialized, low-viscosity glues that offer incredible precision and flexibility. The choice always depends on the specific project’s demands and the types of leather involved; understanding their individual properties is crucial for successful adhesion.

Q 26. What is your preferred method for cleaning and conditioning leather?

My preferred method for cleaning and conditioning leather involves a gentle approach. First, I use a soft, dry brush to remove loose dirt and debris. Then, I apply a specialized leather cleaner, carefully following the manufacturer’s instructions. I avoid harsh chemicals or excessive moisture, as they can damage the leather’s natural oils and structure. After cleaning, I apply a high-quality leather conditioner, working it into the leather using a circular motion. This replenishes the leather’s natural oils, keeping it supple and preventing cracking or drying. I focus on proper ventilation to ensure the leather dries naturally and avoids becoming excessively brittle. The choice of cleaner and conditioner depends on the type of leather; for example, delicate suede requires a much more gentle approach than robust full-grain leather.

Q 27. How do you manage your time and workflow effectively when working on multiple projects?

Managing multiple projects effectively requires a structured approach. I use a project management system, either digital or physical, to track deadlines, material needs, and the current status of each project. I prioritize tasks based on deadlines and complexity, often tackling the most demanding projects first when my energy levels are highest. I also break down large projects into smaller, manageable tasks, allowing for better focus and progress tracking. Time blocking is another crucial strategy – dedicating specific time slots for particular tasks. This structured approach ensures that all projects progress smoothly and meet their respective deadlines, maintaining quality and client satisfaction.

Q 28. What are some common mistakes to avoid in custom leatherwork?

Common mistakes in custom leatherwork often stem from a lack of planning or inadequate understanding of leather properties. One frequent error is using the wrong type of leather for a given project—choosing a delicate leather for a high-stress application will lead to early wear and tear. Another common mistake is neglecting proper preparation. This includes insufficient pattern making and cutting, leading to ill-fitting pieces, or failing to pre-condition the leather, which can make stitching or tooling difficult and uneven. Finally, rushing the process can lead to inconsistencies in stitching, tooling, or finishing, impacting the overall quality and appearance of the finished piece. Thorough planning, preparation, and patience are key to avoiding these issues and ensuring a high-quality result.

Key Topics to Learn for Custom Leatherwork Interview

- Leather Selection & Properties: Understanding different types of leather (e.g., full-grain, top-grain, suede), their characteristics, and suitability for various projects. Practical application: Explaining the trade-offs between durability, aesthetics, and cost for a specific project.

- Leatherworking Techniques: Mastering fundamental skills like stitching (hand and machine), cutting, shaping, tooling, dyeing, and finishing. Practical application: Describing your experience with different stitching methods and their advantages in different contexts.

- Pattern Making & Design: Creating accurate patterns, adapting existing designs, and understanding ergonomic considerations for custom pieces. Practical application: Explaining your process for translating a client’s vision into a functional and aesthetically pleasing design.

- Tools & Equipment: Familiarity with essential leatherworking tools (e.g., knives, mallets, stamps, sewing machines) and their proper use and maintenance. Practical application: Demonstrating knowledge of safety procedures and preventative maintenance for equipment.

- Project Management & Client Communication: Managing project timelines, budgets, and client expectations effectively. Practical application: Describing your approach to handling client revisions or unexpected challenges.

- Repair & Restoration: Understanding techniques for repairing damaged leather goods and restoring vintage pieces. Practical application: Explaining your problem-solving approach to addressing unique repair challenges.

- Business Acumen (for advanced roles): Understanding pricing strategies, marketing, and customer relationship management within a custom leatherwork business.

Next Steps

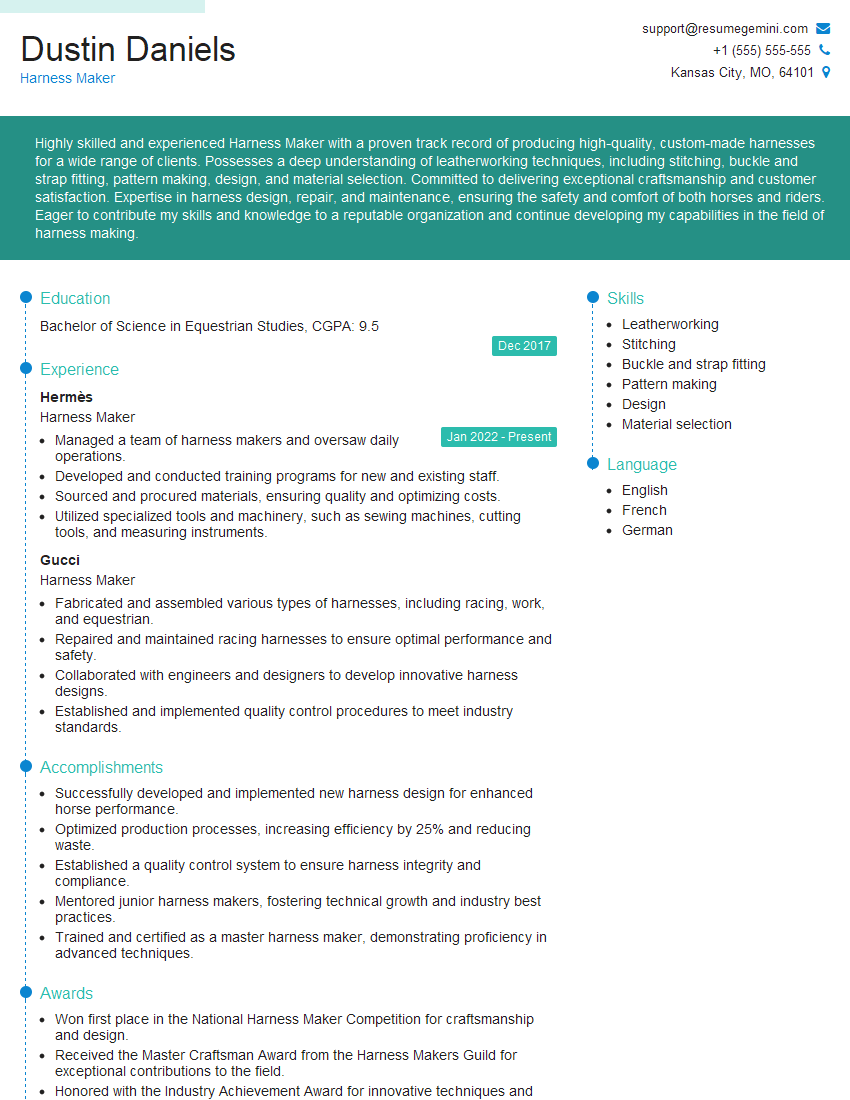

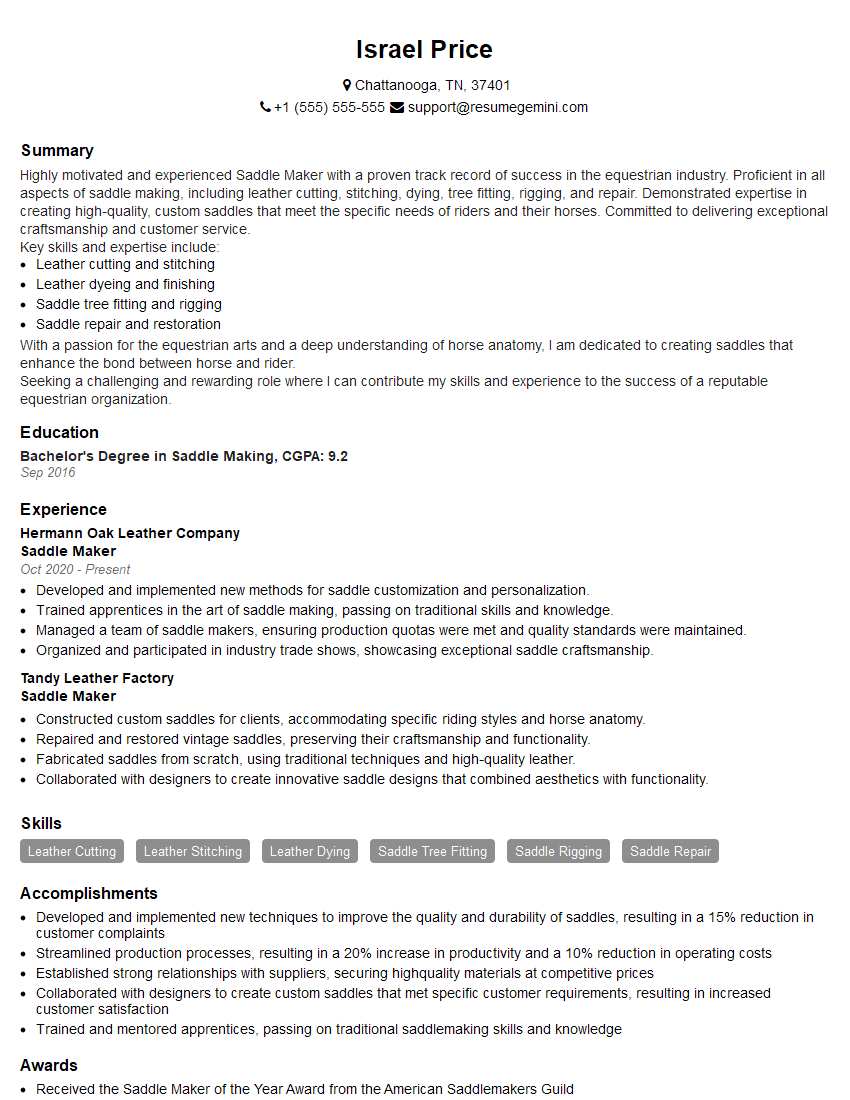

Mastering custom leatherwork opens doors to a rewarding career with diverse opportunities, from independent artisanship to roles in high-end fashion and bespoke design. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, designed to highlight your skills and experience effectively. Examples of resumes tailored to the custom leatherwork industry are available to help guide your creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good