Cracking a skill-specific interview, like one for Debris Removal and Disposal, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Debris Removal and Disposal Interview

Q 1. Explain the different types of debris encountered in demolition projects.

Demolition projects generate a diverse range of debris. Categorizing it helps with efficient handling and disposal. We typically encounter:

- Concrete and Masonry: This includes bricks, blocks, and concrete chunks, often requiring specialized crushing equipment.

- Wood and Lumber: From framing timbers to smaller scraps, the type and condition of wood determines its disposal route (recycling, landfill, etc.).

- Metals: Steel, iron, aluminum, and other metals can be separated for recycling, a crucial step for environmental responsibility and cost savings.

- Gypsum Board (Drywall): This material often contains hazardous materials, necessitating careful handling and potentially specialized disposal.

- Asphalt and Roofing Materials: These require specialized handling due to their potential for environmental contamination. Asphalt shingles, for instance, often end up in designated recycling facilities.

- Hazardous Waste: This category includes asbestos, lead paint, and other materials requiring special permits and disposal techniques. Identifying and segregating this is paramount for safety and compliance.

- Household Waste: Depending on the demolition project (e.g., residential), leftover appliances, furniture, and other household items might also be present.

Understanding these categories is the first step towards creating a safe and efficient debris removal plan. For example, on a recent school demolition, we encountered asbestos in the ceiling tiles, requiring specialized abatement procedures before any other demolition could commence. This highlights the crucial role of proper identification and risk assessment.

Q 2. Describe your experience with hazardous waste handling procedures.

My experience with hazardous waste handling is extensive. I’ve managed numerous projects involving asbestos abatement, lead paint removal, and handling of other hazardous materials. This includes:

- Strict adherence to OSHA and EPA regulations: This is non-negotiable. We always obtain necessary permits, follow proper procedures for containment, and ensure worker safety through training and protective equipment.

- Detailed site assessments: We thoroughly investigate the site before commencing any work to identify potential hazardous materials and develop a customized handling plan.

- Specialized equipment and personnel: We utilize only trained personnel with the necessary certifications and utilize equipment designed for safe handling and transportation of hazardous waste.

- Proper documentation and reporting: Comprehensive documentation is maintained throughout the process, including manifests for transportation and disposal.

One instance involved a project where we discovered asbestos-containing materials hidden beneath flooring in an older industrial building. We immediately halted work, notified the relevant authorities, and implemented a comprehensive abatement plan in accordance with all regulations. The project took longer, but safety and regulatory compliance were prioritized above schedule.

Q 3. What safety regulations are crucial for debris removal operations?

Safety is paramount in debris removal. Crucial regulations include:

- OSHA (Occupational Safety and Health Administration) regulations: These cover worker protection, personal protective equipment (PPE) requirements (hard hats, safety glasses, high-visibility vests), and safe operating procedures for machinery.

- DOT (Department of Transportation) regulations: These govern the transportation of hazardous and non-hazardous materials, including proper vehicle labeling, secure load fastening, and driver training.

- EPA (Environmental Protection Agency) regulations: These dictate how to handle and dispose of hazardous materials responsibly and minimize environmental impact.

- Local ordinances and permits: Many jurisdictions have specific regulations regarding debris removal and disposal, requiring permits and approvals before work commences.

For instance, ensuring all personnel wear appropriate PPE, including respiratory protection when dealing with dust from demolition activities, prevents health risks. Regular safety briefings and site inspections further enhance safe work practices. Failure to adhere to these regulations leads to potential fines, project delays, and, most importantly, serious injuries.

Q 4. How do you ensure compliance with environmental regulations during debris removal?

Compliance with environmental regulations is a core principle of our operations. We achieve this through:

- Material segregation: Separating recyclable materials (metals, wood, concrete) from non-recyclable waste stream reduces landfill burden and aligns with waste reduction goals.

- Hazardous waste management: Following EPA guidelines for handling and disposal of asbestos, lead paint, and other hazardous materials ensures minimal environmental impact.

- Proper disposal permits and manifests: All waste disposal activities are meticulously documented and carried out with the necessary permits.

- Regular environmental audits: These help identify areas for improvement and ensure ongoing compliance.

- Collaboration with environmental agencies: Maintaining open communication with local and federal agencies ensures that our practices are aligned with the latest standards and guidelines.

A recent project involved a careful management plan for construction and demolition debris (C&D) waste which was meticulously sorted and a large portion diverted from landfills to recycling facilities. This not only met environmental regulations but also resulted in cost savings from reduced disposal fees.

Q 5. What are the different methods for sorting and separating debris?

Debris sorting and separation is critical for efficient recycling, cost reduction, and environmental protection. Methods include:

- Manual sorting: Workers manually separate debris into different categories based on material type (wood, metal, concrete, etc.). This method is effective for smaller projects or for separating specific hazardous materials.

- Mechanical sorting: Using equipment such as conveyors, crushers, and magnetic separators to automate the sorting process. This increases efficiency and throughput, especially suitable for large-scale projects.

- Optical sorting: Employing advanced sensor technology to identify and separate materials based on their characteristics (e.g., color, shape, density). This is very efficient, particularly for complex mixes of materials.

Imagine sorting a mountain of rubble from a building demolition. Manual sorting would be incredibly slow and inefficient. Using a combination of mechanical conveyors, crushers to reduce the size of concrete, and magnetic separators to extract metal, ensures much greater efficiency and improved safety for our workers.

Q 6. Explain your experience with operating heavy equipment for debris removal.

I have extensive experience operating various heavy equipment used in debris removal, including:

- Excavators: For loading debris into dump trucks and containers.

- Bulldozers: To clear large areas, push debris into piles for easier handling.

- Front-end loaders: For moving and loading bulky debris.

- Crushers: To reduce the volume of concrete and other materials.

My certifications and extensive on-site experience ensure safe and efficient operation of this machinery. Understanding the limitations and capabilities of each piece of equipment is essential for project success and worker safety. For example, choosing the correct size excavator for the job prevents overexertion and potential damage to the machine.

Q 7. How do you manage a large-scale debris removal project effectively?

Managing large-scale debris removal projects effectively requires a structured approach:

- Detailed planning and project scoping: Thoroughly assessing the site, estimating debris volume, and creating a detailed work plan.

- Resource allocation: Determining the appropriate equipment, personnel, and disposal facilities needed.

- Scheduling and logistics: Coordinating transportation, waste disposal, and all on-site activities.

- Safety management: Implementing and enforcing strict safety protocols throughout the project.

- Communication and coordination: Maintaining clear communication among all stakeholders (clients, workers, subcontractors, regulatory agencies).

- Progress tracking and reporting: Regularly monitoring progress against the plan and providing updates to stakeholders.

A recent large-scale demolition project involved coordinating multiple teams, several pieces of heavy equipment, and navigating complex logistical challenges to ensure timely completion while adhering to strict environmental regulations. Effective planning, proactive communication, and a focus on safety were key to its successful completion.

Q 8. Describe your experience with developing and implementing a debris management plan.

Developing and implementing a debris management plan is crucial for efficient and safe removal operations. It involves a systematic approach, starting with a thorough site assessment to determine the type, volume, and location of debris. This assessment informs the selection of appropriate equipment, personnel, and disposal methods. For example, after a hurricane, we’d assess the damage, categorizing debris into vegetative (trees, branches), construction and demolition (C&D) waste, and hazardous materials (asbestos, chemicals).

Next, we establish clear timelines and workflows, outlining the steps involved from initial debris collection to final disposal. This includes designating staging areas, transportation routes, and disposal sites. We also incorporate risk mitigation strategies, addressing potential hazards like unstable structures or contaminated materials. Finally, the plan includes comprehensive documentation, tracking debris removal progress and ensuring compliance with all relevant regulations. One successful project involved a large-scale demolition where we developed a detailed plan that minimized disruption to the surrounding community, resulting in a completed project ahead of schedule and under budget.

Q 9. What are your strategies for minimizing environmental impact during debris removal?

Minimizing environmental impact is paramount. Our strategies focus on several key areas. First, we prioritize recycling and repurposing. For example, clean wood debris is often chipped and used for mulch or biomass energy. Second, we utilize environmentally friendly equipment, such as electric or hybrid vehicles to reduce carbon emissions. We also select disposal sites carefully, choosing facilities that meet rigorous environmental standards. Third, we implement waste reduction strategies, optimizing collection routes to minimize transportation distances and fuel consumption. Finally, we adhere strictly to all environmental regulations, obtaining necessary permits and conducting regular environmental monitoring to ensure our operations don’t negatively impact ecosystems. For instance, during a large-scale cleanup, we diverted over 60% of the debris from landfills through recycling and repurposing initiatives.

Q 10. How do you ensure the safety of your team and the public during debris removal operations?

Safety is our utmost priority. We start with comprehensive training for our team, covering hazard recognition, safe equipment operation, and emergency procedures. Before any operation, we conduct thorough site safety assessments, identifying and mitigating potential hazards such as unstable structures, hazardous materials, and traffic congestion. We utilize appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and high-visibility clothing. Furthermore, we implement traffic control measures, establishing clear work zones and ensuring public safety through signage and flaggers. We also utilize advanced communication technologies for real-time monitoring and coordination. A recent project in a densely populated area involved strict adherence to safety protocols, resulting in a zero-incident record.

Q 11. What is your experience with emergency response protocols in debris removal situations?

Emergency response protocols are critical, particularly in disaster scenarios. Our teams are trained to respond swiftly and efficiently to unforeseen circumstances, such as equipment malfunctions, hazardous material spills, or injuries. We have established clear communication channels and escalation procedures to ensure rapid response and coordination with emergency services. Our protocols include procedures for handling medical emergencies, evacuations, and securing the worksite. Regular drills and training sessions keep our team prepared for various scenarios. For instance, during a recent flood, we swiftly mobilized our teams, deployed emergency response equipment, and coordinated with local authorities to ensure swift and safe debris removal from flooded areas.

Q 12. Describe your proficiency in using various debris removal equipment.

Our proficiency with debris removal equipment is extensive. We utilize a variety of machinery, including excavators, loaders, grapple trucks, roll-off containers, and specialized equipment for handling hazardous materials. Our operators are highly skilled and certified, possessing the necessary training and experience to operate these machines safely and efficiently. Regular maintenance and inspection of all equipment is crucial to ensure optimum performance and prevent accidents. We stay updated on the latest technologies and equipment to optimize our operations. For instance, our team has extensive experience operating heavy machinery in challenging terrains, like steep slopes and confined spaces, ensuring effective and safe debris removal in diverse conditions.

Q 13. Explain your knowledge of different disposal methods for various types of debris.

Different debris types require specific disposal methods. Vegetative debris can be chipped, composted, or used for biomass energy. Construction and demolition (C&D) waste often involves sorting and separating recyclable materials like wood, metal, and concrete. Hazardous materials require special handling and disposal in accordance with strict regulations. We are experienced in working with different waste management facilities, choosing the appropriate disposal methods based on the material type, local regulations, and cost-effectiveness. For example, we’ve successfully managed the disposal of asbestos-containing materials, ensuring complete compliance with all environmental regulations and worker safety standards.

Q 14. How do you handle unexpected issues or challenges during a debris removal project?

Unexpected issues are inevitable. Our approach involves proactive risk assessment and contingency planning. When faced with unforeseen challenges, such as discovering unexpected underground utilities or encountering unusually hazardous materials, we have established protocols for immediate response. This includes halting operations, conducting a thorough reassessment, and implementing revised plans to address the new challenges. Clear communication with clients and stakeholders is crucial to keep everyone informed. Our team’s problem-solving skills, combined with our flexible approach, allows us to adapt to changing situations and complete the project successfully. For example, during a recent project, we discovered unexpected asbestos, implementing emergency procedures and coordinating with specialized contractors to safely remove and dispose of the material without any disruptions to the project timeline.

Q 15. What is your experience with asbestos or other hazardous material removal?

Asbestos and other hazardous material removal requires specialized training and adherence to strict safety protocols. My experience encompasses several large-scale projects involving asbestos abatement in commercial buildings and industrial facilities. This involved meticulous planning, including air monitoring, containment, and disposal in accordance with EPA regulations. We used specialized equipment like negative pressure enclosures and HEPA filtered vacuums to prevent fiber release. For example, during a recent renovation of a school, we successfully removed asbestos-containing insulation from pipes without any airborne fiber exceedances, ensuring the safety of workers and occupants. We also have experience handling other hazardous materials such as lead paint, PCB’s and mercury, always prioritizing worker and environmental safety above all else. Each material requires a unique approach, from proper Personal Protective Equipment (PPE) to specialized disposal methods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the volume and weight of debris for transportation and disposal?

Calculating debris volume and weight is crucial for efficient transportation and disposal. We use a combination of methods. For loose materials like soil or rubble, we estimate volume using measurements (length x width x height) of piles or containers. For larger debris, individual item measurements and volume calculations are employed. Weight estimations depend on the material’s density – we often utilize average density values for common materials (e.g., wood, concrete, metal) to estimate total weight. For precise weight determination, particularly with heavier materials, on-site weighing using scales or load cells on trucks is essential. The accuracy of our calculations directly impacts transportation costs and the selection of appropriate disposal facilities. For example, if we miscalculate the weight of debris for a truck, this can lead to overloading or insufficient capacity, both of which have safety and cost implications.

Q 17. How do you track and document debris removal activities to ensure compliance?

Tracking and documenting debris removal activities is critical for compliance and auditing. We maintain detailed records using a combination of paper-based and digital systems. This includes manifests, chain-of-custody documents, and daily logs recording the volume and type of materials removed, the location of disposal, and the personnel involved. Photographs and GPS coordinates are utilized to provide visual and locational context. All documentation adheres to relevant regulations and serves as a verifiable record of our operations. Our digital system allows for real-time updates and easy report generation, streamlining data analysis and compliance auditing. This detailed documentation allows us to readily respond to any audit requests and demonstrate responsible environmental management. For example, a recent project involving the demolition of a multi-story building required meticulous documentation due to the large volume of different waste materials generated.

Q 18. Describe your experience with working with regulatory agencies on waste disposal permits.

My experience working with regulatory agencies like the EPA and local environmental protection departments involves securing waste disposal permits, filing reports, and maintaining compliance with all applicable regulations. This includes submitting detailed waste characterization reports and ensuring the selected disposal facilities are licensed to receive the specific types of waste we are handling. We proactively engage with agencies, providing regular updates and responding promptly to any inquiries. Building strong relationships with regulators is crucial to ensure smooth operations and avoid potential penalties. For instance, in a recent project involving contaminated soil, we successfully navigated the permitting process by engaging with the state environmental agency early in the project planning stage. This collaborative approach enabled us to meet all regulatory requirements efficiently.

Q 19. What is your understanding of the lifecycle assessment of different waste materials?

Understanding the lifecycle assessment (LCA) of different waste materials is paramount for sustainable waste management. An LCA evaluates the environmental impact of a material throughout its entire life cycle, from raw material extraction to disposal. This includes energy consumption, greenhouse gas emissions, water usage, and potential pollution. Knowing the LCA of materials informs our recycling and disposal strategies, enabling us to prioritize environmentally friendly options. For example, choosing to recycle concrete rather than sending it to a landfill significantly reduces the carbon footprint associated with the material’s disposal. We carefully consider factors such as the recyclability, energy required for processing, and potential environmental impacts of various disposal pathways when managing waste streams.

Q 20. How do you maintain accurate records of waste disposal and transportation?

Maintaining accurate records of waste disposal and transportation is essential for compliance, auditing, and efficient operations. We utilize a combination of digital and physical record-keeping, with all documentation cross-referenced and readily accessible. This includes manifests, disposal tickets, and GPS tracking data for transportation vehicles. The system is designed to ensure data integrity and prevent errors. Our digital system generates detailed reports, providing readily accessible information on waste volumes, disposal locations, and transportation routes. This level of meticulous record-keeping allows for thorough tracking, quick retrieval of information, and seamless compliance auditing. For example, we can quickly identify the disposal location for a specific batch of waste if necessary.

Q 21. Describe your experience in waste recycling and diversion strategies.

Waste recycling and diversion strategies are integral to our operations. We actively seek opportunities to maximize recycling and reduce the amount of waste sent to landfills. This involves separating different waste streams – recyclable materials such as metals, plastics, and wood are segregated from non-recyclable waste. We work with licensed recycling facilities to ensure proper processing and responsible management of recycled materials. We employ innovative strategies such as pre-sorting materials on-site to improve recycling rates and reduce disposal costs. For instance, on a recent construction project, we implemented a comprehensive waste management plan that achieved a 75% diversion rate, significantly reducing landfill waste and promoting sustainable practices. These strategies are not just environmentally beneficial; they often provide cost savings by reducing disposal fees.

Q 22. How do you manage and mitigate risks related to debris removal operations?

Risk management in debris removal is paramount. It’s not just about clearing the debris; it’s about doing it safely and responsibly. We employ a multi-layered approach. First, a thorough site assessment identifies potential hazards – asbestos, hazardous materials, unstable structures, underground utilities. This assessment informs our safety plan, which includes:

- Personal Protective Equipment (PPE): Ensuring all personnel have and use appropriate PPE like hard hats, safety glasses, gloves, and high-visibility clothing.

- Traffic Control: Implementing traffic management plans, including signage and flaggers, to prevent accidents involving vehicles and pedestrians.

- Emergency Procedures: Establishing clear communication protocols and emergency response plans in case of accidents or unexpected events, including readily available first aid kits and contact information for emergency services.

- Regular Safety Briefings: Conducting pre-job briefings to ensure all team members are aware of the risks and safety procedures.

- Equipment Maintenance: Regularly inspecting and maintaining all equipment to prevent malfunctions and accidents.

For example, during a demolition project, we might discover asbestos-containing materials. Our response would immediately involve halting work, contacting specialized asbestos abatement contractors, and implementing strict containment protocols before resuming debris removal. This proactive approach minimizes risks and ensures worker safety.

Q 23. What are your strategies for cost-effective and environmentally sound waste management?

Cost-effective and environmentally sound waste management is a core principle of our operations. We achieve this through a combination of strategies:

- Waste Stream Diversification: We prioritize separating materials at the source (e.g., separating wood, metal, concrete, etc.) for recycling and reuse. This reduces landfill disposal, lowering costs and environmental impact.

- Negotiating with Recycling and Disposal Facilities: We build strong relationships with facilities to secure competitive pricing and efficient waste processing. This might involve negotiating volume discounts or exploring alternative disposal options.

- Utilizing Sustainable Technologies: We explore and adopt technologies that minimize waste and enhance efficiency. For example, using crushers to reduce the volume of concrete waste or utilizing mobile processing units on-site to reduce transportation costs.

- Proper Documentation and Reporting: Maintaining meticulous records of waste generation, processing, and disposal allows for accurate reporting and demonstrates compliance with environmental regulations. This also helps us track our progress towards sustainability goals and identify areas for improvement.

For instance, in a post-hurricane cleanup, we would carefully sort debris, separating recyclable materials like metal and wood from non-recyclable waste. This not only reduces landfill space but also generates revenue from the sale of scrap metal, further offsetting project costs.

Q 24. How do you communicate effectively with clients, stakeholders and regulatory bodies?

Effective communication is the cornerstone of successful debris removal projects. We maintain open lines of communication with clients, stakeholders, and regulatory bodies through various channels:

- Regular Project Updates: We provide clients with regular progress reports, addressing concerns and answering questions promptly.

- Transparent Reporting: Detailed reports, including waste manifests and disposal records, ensure transparency and accountability.

- Stakeholder Meetings: We engage in proactive meetings with stakeholders, such as community members or local businesses, to address their concerns and provide updates.

- Compliance with Regulatory Requirements: We meticulously adhere to all relevant local, state, and federal regulations, submitting necessary permits and reports in a timely manner.

- Utilizing Different Communication Tools: We adapt our communication methods depending on the audience, using email, phone calls, in-person meetings, and even social media platforms when appropriate.

For example, during a large-scale demolition project, we would schedule regular meetings with the client, contractors, and local authorities to discuss safety protocols, waste management plans, and address any concerns.

Q 25. Explain your experience with the transportation and disposal of different waste types.

We have extensive experience handling diverse waste types, each requiring specialized transportation and disposal methods:

- Construction and Demolition Debris (C&D): This includes wood, concrete, metal, drywall, etc., often requiring specialized containers and transportation for efficient handling and sorting for recycling or disposal in designated landfills.

- Hazardous Waste: Materials like asbestos, lead paint, and chemicals require strict adherence to regulations, specialized handling, and transportation in approved containers with proper labeling and documentation. We use licensed hazardous waste transporters and disposal facilities.

- Municipal Solid Waste (MSW): This involves household garbage, requiring proper sorting and transportation to landfills or waste-to-energy facilities. We adhere to local regulations for waste collection and disposal.

- Medical Waste: This necessitates rigorous adherence to safety and biohazard protocols, using specialized containers and transportation to ensure safe and environmentally sound disposal in accordance with all relevant health regulations.

We have a fleet of vehicles equipped to handle various waste types, ranging from roll-off containers for C&D debris to specialized trucks for hazardous materials. Each vehicle is maintained regularly and operated by trained professionals.

Q 26. Describe your knowledge of various waste disposal facilities and their capabilities.

My knowledge of waste disposal facilities encompasses a wide range of options, each with its capabilities and limitations:

- Landfills: These are the most common disposal sites, accepting various waste types, but often have capacity limitations and environmental concerns. Different landfills specialize in different waste types (e.g., hazardous waste landfills).

- Recycling Centers: These facilities process recyclable materials like paper, plastic, metal, and glass, diverting them from landfills and conserving resources.

- Waste-to-Energy Plants: These facilities use waste as fuel to generate electricity, reducing landfill burden and providing a renewable energy source.

- Transfer Stations: These act as intermediate points, consolidating waste from various sources before transporting it to larger disposal facilities. This enhances efficiency and reduces transportation costs.

- Specialized Hazardous Waste Facilities: These handle hazardous materials, requiring specific permits, safety measures, and treatment processes.

Selecting the appropriate facility is crucial and depends on factors such as waste type, volume, regulatory requirements, and cost-effectiveness. We thoroughly vet facilities to ensure they meet our standards for safety and environmental responsibility.

Q 27. How do you ensure the proper labeling and packaging of hazardous waste materials?

Proper labeling and packaging of hazardous waste is crucial for safety and compliance. We adhere to a strict protocol:

- Using Approved Containers: We use only containers designed and approved for hazardous waste, ensuring they are leak-proof and properly sealed.

- Accurate Labeling: Each container is clearly labeled with the hazardous waste’s identity, including its chemical name, hazard class, and any necessary precautions.

- Detailed Manifests: We meticulously prepare waste manifests detailing the type and quantity of hazardous waste, the generator’s information, and the transporter and disposal facility’s information. These documents are essential for tracking and ensuring proper disposal.

- Employee Training: Our team receives comprehensive training on hazardous waste handling, including safe practices for labeling, packaging, and transportation.

- Compliance with Regulations: We strictly adhere to all relevant regulations, including those defined by OSHA, EPA, and local authorities.

Failure to properly label and package hazardous waste can have severe consequences, including fines, environmental damage, and potential harm to human health. Our commitment to accurate labeling and documentation ensures compliance and minimizes risks.

Q 28. What are the ethical considerations involved in debris removal and disposal?

Ethical considerations are central to our operations. We prioritize:

- Environmental Responsibility: Minimizing environmental impact through waste reduction, recycling, and responsible disposal methods. This includes selecting environmentally sound disposal facilities and adhering to all environmental regulations.

- Worker Safety: Prioritizing the health and safety of our employees through comprehensive safety training, adequate PPE, and strict adherence to safety protocols.

- Community Well-being: Minimizing disruption to the community during operations, ensuring transparency and communicating effectively with residents and stakeholders.

- Transparency and Accountability: Maintaining accurate records and transparent reporting to clients, stakeholders, and regulatory agencies.

- Fair and Ethical Business Practices: Ensuring fair pricing, honest communication, and ethical relationships with all our partners.

For example, when working in a residential area, we take extra precautions to minimize noise and dust pollution, using quiet equipment and implementing dust suppression techniques. Our commitment to ethical practices builds trust with our clients and the community, and ensures long-term sustainability.

Key Topics to Learn for Debris Removal and Disposal Interview

- Safety Procedures and Regulations: Understanding OSHA guidelines, hazard communication, and proper use of personal protective equipment (PPE) is crucial for safe and compliant operations.

- Debris Classification and Handling: Learn to identify different types of debris (hazardous vs. non-hazardous, construction waste, etc.) and apply appropriate handling and disposal methods.

- Equipment Operation and Maintenance: Familiarity with various equipment used in debris removal (e.g., excavators, loaders, roll-off containers) and their maintenance is vital. Demonstrate understanding of preventative maintenance schedules and troubleshooting.

- Environmental Regulations and Compliance: Knowledge of environmental laws and regulations regarding waste disposal, recycling, and landfill procedures is essential. Be prepared to discuss sustainable practices.

- Site Assessment and Planning: Explain your approach to assessing a debris removal site, including safety considerations, logistical planning (access, transport), and resource allocation.

- Waste Management Strategies: Discuss different waste management strategies, including recycling, reuse, and disposal options, and how to select the most appropriate method for a given situation.

- Project Management and Teamwork: Highlight your experience in managing debris removal projects, coordinating teams, and meeting deadlines effectively.

- Emergency Response and Disaster Relief: If applicable, showcase experience in debris removal following natural disasters or other emergencies. Emphasize efficient and safe operation under pressure.

Next Steps

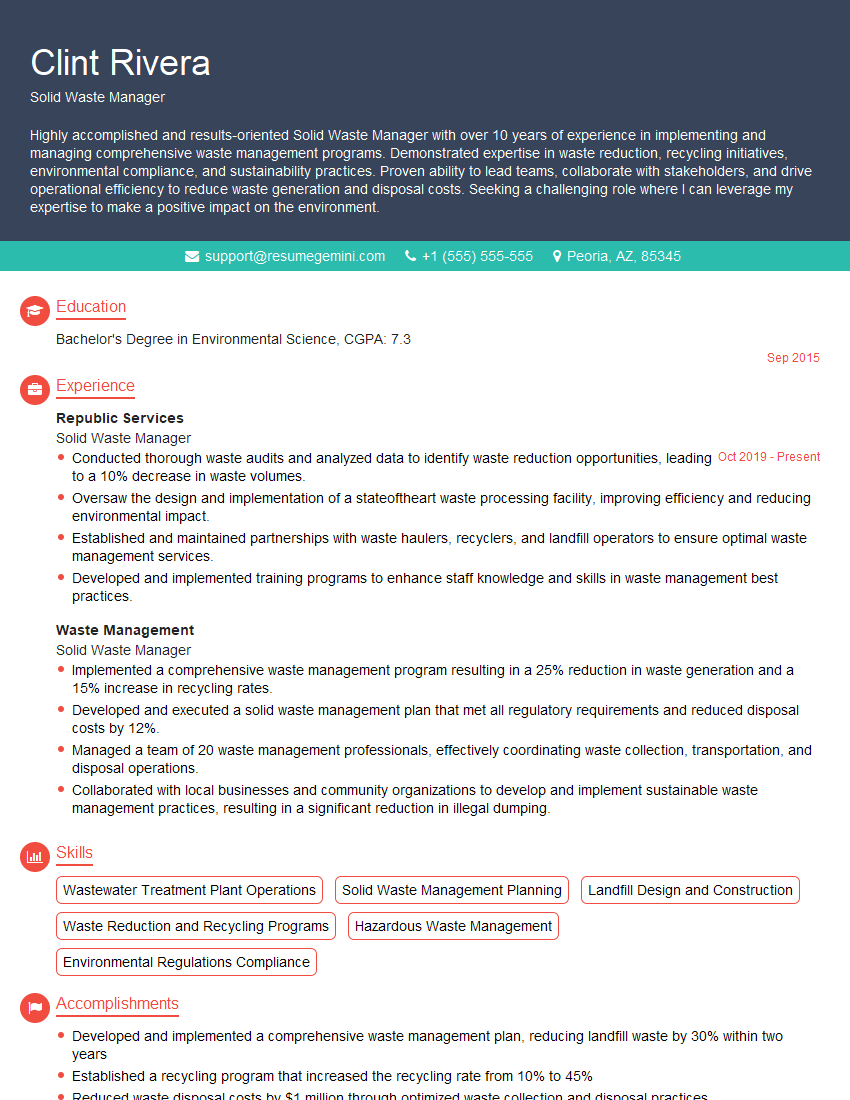

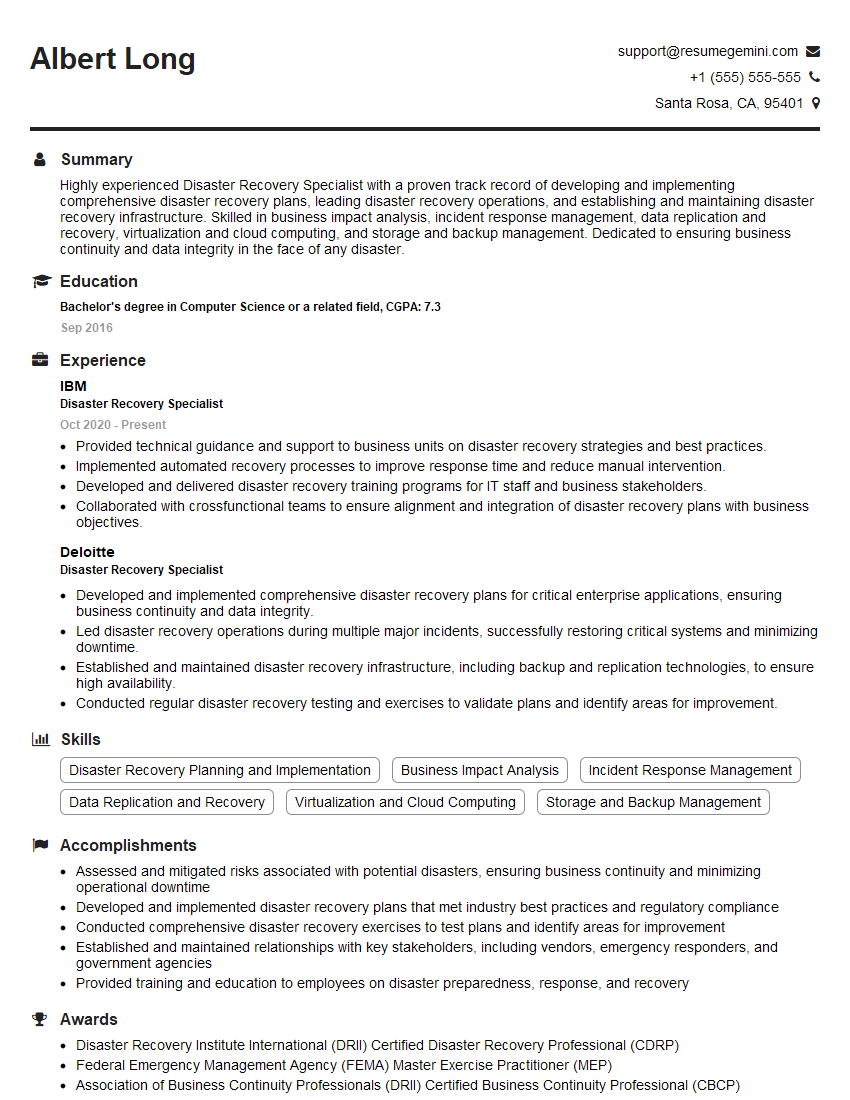

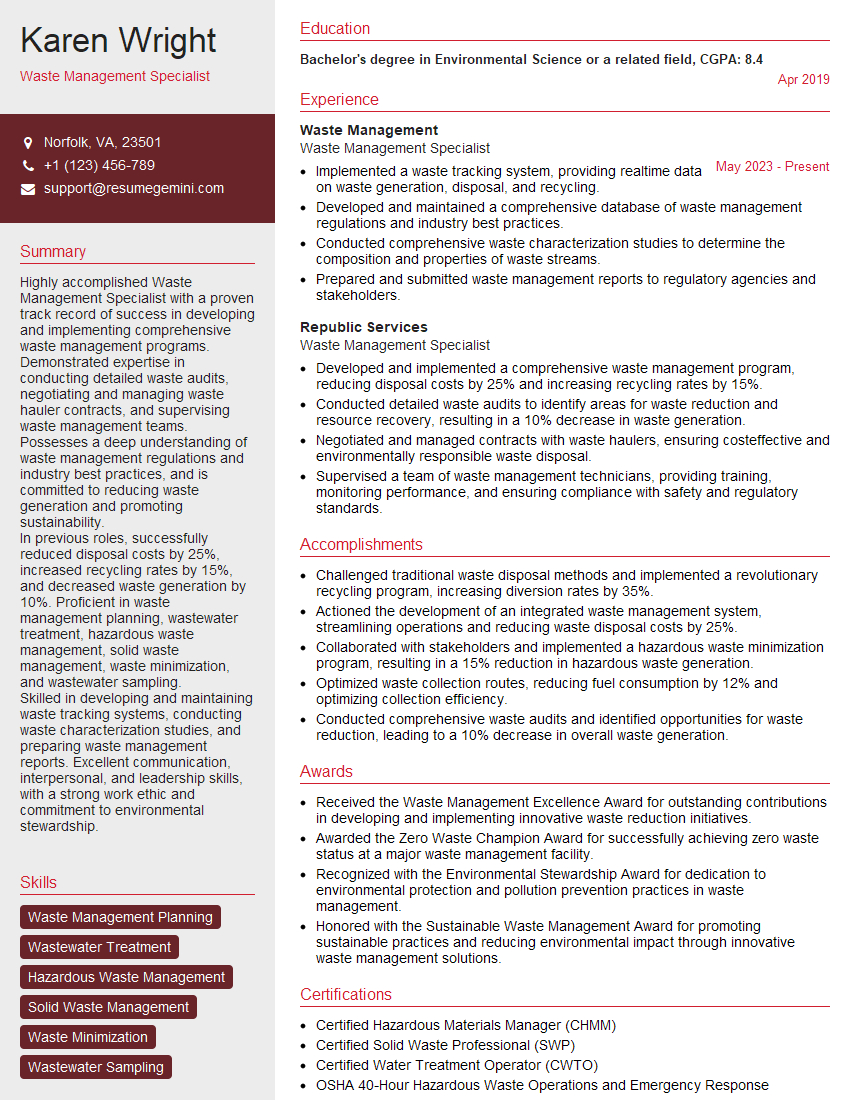

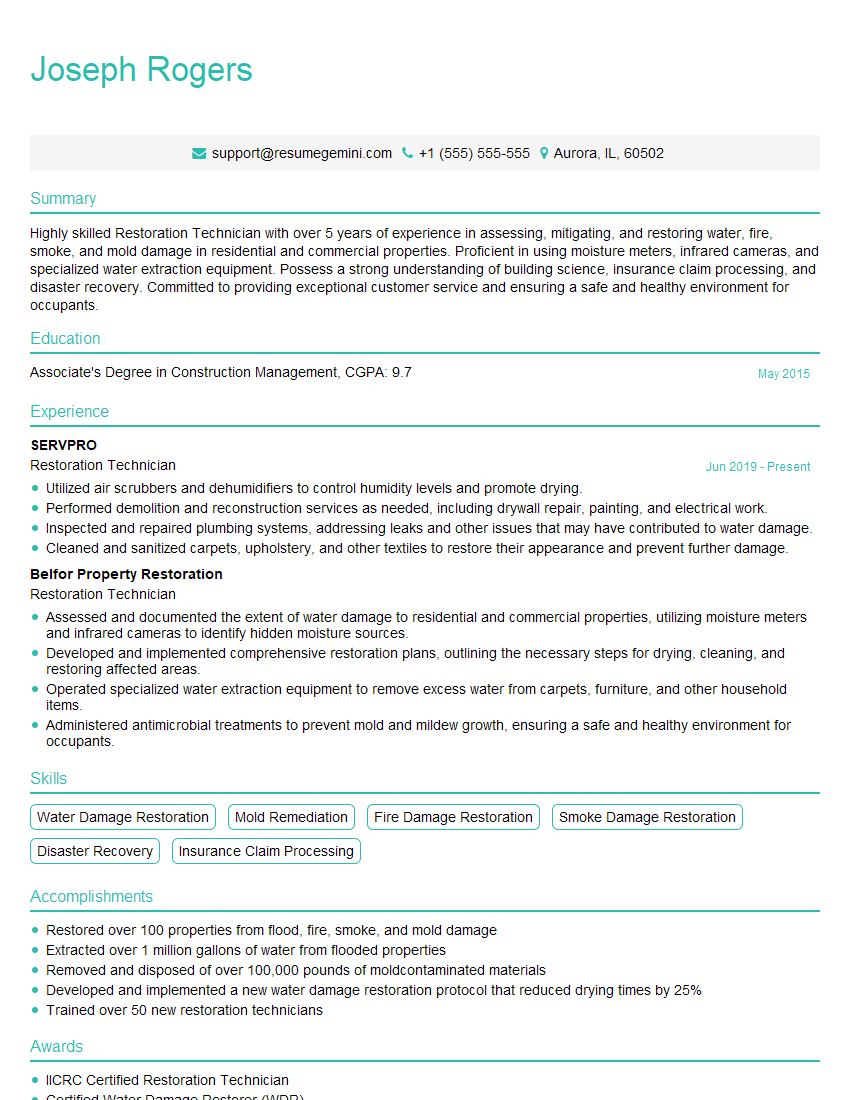

Mastering Debris Removal and Disposal opens doors to a rewarding career with strong growth potential in a vital industry. Your expertise in safe and efficient waste management will be highly sought after. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. They offer examples of resumes tailored specifically to the Debris Removal and Disposal field to guide you in crafting your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good