The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Decorative Concrete Finishing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Decorative Concrete Finishing Interview

Q 1. Describe your experience with different concrete polishing techniques.

Concrete polishing techniques vary depending on the desired finish, from a high-gloss shine to a more matte, honed look. The process generally involves grinding the concrete surface using progressively finer diamond abrasive pads. This removes imperfections and reveals the aggregate.

My experience spans various methods, including:

- Traditional Grinding: This uses multiple passes with different grit diamond tooling, starting with coarse grits to remove major imperfections and finishing with fine grits for the desired level of polish. This is ideal for achieving a high-gloss finish.

- Honing: This technique focuses on creating a smooth, satin-like finish without the intense shine of polishing. It involves fewer grinding steps and often utilizes specific honing pads designed for a less reflective surface.

- Resin Polishing: This advanced technique incorporates the use of densifying resins during the grinding process. These resins fill in small pores in the concrete, leading to a more durable and easier-to-maintain polished floor. This is great for high-traffic areas.

- Metallic Polishing: This is used to highlight metallic aggregates embedded in the concrete, producing a stunning visual effect. It’s a specialized process that requires precise control to avoid damaging the metallic elements.

For instance, I once worked on a project requiring a high-gloss polish for a showroom floor. We employed traditional grinding with multiple passes, resulting in a mirror-like surface that highlighted the beauty of the exposed aggregate. In another project, a client requested a more natural, matte look for a residential patio, and honing was the perfect solution.

Q 2. Explain the process of applying acid stains to concrete.

Acid staining is a chemical process that reacts with the calcium hydroxide in concrete to create a unique, variegated color. The resulting colors are translucent and penetrate the concrete, making them very durable.

The process typically involves these steps:

- Surface Preparation: The concrete surface must be clean, free of contaminants, and properly cured. This often involves pressure washing and thorough cleaning.

- Acid Application: The acid stain is applied evenly to the concrete surface using a brush, roller, or sprayer. It’s crucial to follow the manufacturer’s instructions for application, dilution, and safety precautions.

- Neutralization: After the desired reaction time, the acid stain is neutralized using a neutralizing solution. This stops the staining process and prevents further reactions.

- Cleaning and Sealing: The surface is thoroughly rinsed with clean water to remove any residual chemicals. A concrete sealer is then applied to protect the stain and enhance its longevity.

The beauty of acid staining lies in its unpredictable nature. Each application results in unique color variations, providing a truly one-of-a-kind finish. Consider, for example, a project where we used a combination of iron oxide and acetic acid stains on a large patio to create a beautiful, earthy tone with subtle, mottled effects.

Q 3. What are the different types of concrete sealers and their applications?

Concrete sealers are crucial for protecting decorative concrete finishes from wear, staining, and weathering. There are several types, each with its specific application:

- Acrylic Sealers: These are water-based, easy to apply, and provide good protection against moisture and UV damage. They are suitable for most decorative concrete applications.

- Epoxy Sealers: These are two-part sealers known for their exceptional durability and resistance to chemicals and abrasion. They are ideal for high-traffic areas or industrial settings.

- Penetrating Sealers: These sealers sink into the concrete pores, providing a long-lasting protective layer without changing the appearance of the surface. They enhance the durability of the concrete without creating a film.

- Silane-Siloxane Sealers: These are often used on exterior concrete surfaces. They offer excellent protection against moisture and freeze-thaw cycles.

Choosing the right sealer depends heavily on the project requirements. For instance, an interior polished concrete floor in a commercial building might benefit from an epoxy sealer due to its high durability, while an exterior stamped concrete patio might best be protected with a silane-siloxane sealer to prevent moisture damage. The choice also depends on if you need UV protection, which is crucial for exterior surfaces.

Q 4. How do you prepare a concrete surface for decorative finishes?

Proper surface preparation is the foundation of any successful decorative concrete project. It dictates the adhesion and longevity of the finish.

Preparation typically involves these steps:

- Cleaning: The concrete surface must be thoroughly cleaned to remove dirt, dust, oil, grease, and other contaminants. Pressure washing is often used, followed by a thorough scrubbing and rinsing.

- Repairing: Any cracks, holes, or spalling must be repaired using appropriate patching compounds. The repair must be properly cured before proceeding to the next stage.

- Grinding (if necessary): For polished concrete, grinding is essential to achieve the desired surface smoothness and reveal the aggregate. This step may also be necessary for other finishes to ensure a consistent substrate for better adhesion.

- Priming (if necessary): Some decorative finishes benefit from a primer coat to enhance adhesion and provide a consistent base for the application of the finish.

I remember one project where improper cleaning led to poor adhesion of the stain. We had to spend extra time and effort removing the affected areas and re-preparing the surface before re-applying the stain, which, obviously, added to the project’s cost. Thus, attention to detail during surface prep is crucial to avoid such problems.

Q 5. What are the common problems encountered during concrete polishing and how do you address them?

Concrete polishing can present several challenges:

- Uneven Grinding: This can result from improper technique or using unsuitable tooling. It creates an inconsistent finish. Solution: Use proper techniques, appropriate diamond tooling, and multiple passes with progressively finer grits. Regular calibration of the grinding equipment is also essential.

- Burnishing: This happens when the concrete overheats during polishing, creating a discolored or damaged surface. Solution: Use proper polishing techniques and adequate water lubrication, avoid prolonged grinding in one area, and allow for sufficient cooling time.

- Dust Generation: Polishing generates substantial dust, requiring appropriate dust collection systems. Solution: Use appropriate dust extraction equipment such as vacuums designed for concrete grinding and polishing.

- Lippage: Uneven concrete slabs can lead to lippage which may be revealed after polishing. Solution: Grinding might be able to resolve minor lippage, otherwise, the solution may require grinding down to create a consistent height, or accept the lippage, if acceptable in the design.

Addressing these problems requires experience, attention to detail, and the use of appropriate equipment and techniques. Preventative measures, such as proper preparation and careful execution of the polishing process, are far more effective than trying to remedy the issues after they arise.

Q 6. Explain the process of installing stamped concrete.

Stamped concrete mimics the look of other materials, like brick, stone, or slate, by imprinting patterns into freshly poured concrete. It’s a cost-effective alternative to natural materials.

The process involves:

- Concrete Pouring and Preparation: A standard concrete slab is poured and leveled. A release agent is applied to prevent the stamped mats from sticking.

- Stamping: Specialized stamping mats are pressed into the concrete to create the desired pattern. This is often done in sections to ensure even pressure and prevent cracking.

- Color Hardener Application: A dry-shake color hardener is broadcast onto the surface before stamping or afterwards, depending on the technique. This provides color and enhances durability.

- Sealing: Once the concrete is cured, a sealer is applied to protect the stamped pattern and enhance its longevity. This may require multiple coats, especially for exterior projects.

- Texturing (optional): Texturing tools can further enhance the realism of the stamped pattern, adding depth and definition.

For example, in one project, we used stamped concrete to mimic the look of a cobblestone driveway, creating a cost-effective yet visually appealing solution for the client. The release agent and proper stamping technique ensured a clear and realistic pattern.

Q 7. How do you ensure proper color consistency in decorative concrete projects?

Color consistency is paramount in decorative concrete projects to achieve a uniform and aesthetically pleasing finish. Maintaining consistent color requires meticulous attention throughout the process:

- Using Pre-mixed Pigments: Pre-mixed pigments offer the most reliable way to ensure color consistency. This is particularly important for large projects.

- Accurate Measuring and Mixing: Precisely measure and mix color pigments, ensuring accurate proportions to achieve the desired shade. Use calibrated equipment and follow manufacturer’s instructions.

- Uniform Application: Apply color hardeners, stains, or dyes uniformly to the concrete surface. This often requires overlapping passes to avoid inconsistencies.

- Batching: For large projects, divide the material into smaller, manageable batches to ensure consistent color throughout. Mix the same amount of pigments and additives in each batch.

- Color Samples and Tests: Prepare sample patches on a separate area to test the color and ensure it meets the client’s expectations before proceeding with the main project.

In one case, using pre-mixed pigments for a large commercial project helped us avoid significant color variations across different slabs, providing a professional and visually consistent result. Inconsistent mixing or application could have resulted in noticeable color discrepancies and an unsatisfactory outcome. Thorough testing and attention to detail averted any potential issues.

Q 8. What safety precautions do you take when working with concrete chemicals?

Safety is paramount when handling concrete chemicals. These materials can be corrosive, irritating, or even toxic. My standard operating procedure always begins with a thorough review of the Safety Data Sheet (SDS) for each product. This document details the hazards, precautions, and emergency procedures.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses or a face shield, gloves (chemical-resistant nitrile is my preference), a respirator (depending on the chemical and ventilation), and long sleeves and pants.

- Ventilation: Adequate ventilation is crucial to reduce exposure to fumes and dust. This often involves using fans or working outdoors when possible.

- Spill Response: I’m prepared for spills with absorbent materials and neutralizing agents, as specified in the SDS. Spills are contained and cleaned immediately, following the manufacturer’s instructions precisely.

- Waste Disposal: Proper disposal of leftover chemicals and waste materials is vital to protect the environment. I strictly adhere to local regulations and utilize licensed waste disposal services for hazardous materials.

For instance, when working with acid stains, the potential for skin burns and eye damage is significant. Careful application techniques and meticulous PPE usage are non-negotiable in this scenario.

Q 9. Describe your experience with different concrete grinding equipment.

My experience with concrete grinding equipment is extensive, encompassing various types for different applications. I’m proficient with both walk-behind and ride-on grinders, ranging from smaller, hand-held models for detailed work to larger, powerful machines for large-scale projects.

- Walk-behind Grinders: These are versatile and suitable for smaller areas or intricate designs. I’ve used various brands, mastering their nuances and achieving consistent results.

- Ride-on Grinders: For larger projects, ride-on grinders significantly increase efficiency. I’m experienced in operating and maintaining these machines, including understanding diamond blade selection for various concrete types and desired finishes.

- Specialized Equipment: I’ve also worked with specialized equipment like scarifiers for removing old coatings and creating a textured surface, and planetary grinders for precision work and creating decorative patterns.

Choosing the right equipment depends heavily on the project scope and desired outcome. For a small patio renovation, a walk-behind grinder suffices, while a large warehouse floor would necessitate a ride-on grinder. My experience allows me to make informed decisions in this regard.

Q 10. How do you determine the appropriate amount of sealer for a given project?

Determining the appropriate sealer amount involves several factors. It’s not simply a matter of pouring a certain amount; accurate calculation is crucial to avoid over-application (which can lead to a sticky surface) or under-application (leaving the concrete vulnerable).

- Surface Porosity: Highly porous concrete absorbs more sealer than dense concrete. I assess this visually and, if needed, conduct a small test area to determine absorption rates.

- Sealer Type: Different sealers have different application rates specified by the manufacturer on the SDS. I always follow these recommendations carefully.

- Desired Finish: A matte finish requires less sealer than a high-gloss finish, as multiple coats are needed for gloss.

- Square Footage: Accurate measurement of the surface area is essential for a precise calculation. This is done carefully using a measuring wheel or laser measurement tool.

Typically, the manufacturer provides coverage rates per gallon or litre. I use this information and the measured surface area to calculate the required amount. It’s always wise to add a small buffer, around 10-15%, to account for variations and waste.

Q 11. What is your experience with concrete repair and restoration?

Concrete repair and restoration is a significant part of my expertise. I’ve handled everything from minor cracks and chips to extensive damage requiring major structural repairs.

- Crack Repair: I use appropriate patching compounds, ensuring proper surface preparation, and employing techniques to prevent further cracking. This includes using expanding polyurethane foam for larger cracks to fill voids.

- Spalling Repair: Spalling (chipping or flaking of the concrete) requires careful removal of loose material, followed by filling and patching with appropriate materials and ensuring a smooth finish.

- Surface Leveling: Uneven surfaces are addressed through grinding, patching, and the application of self-leveling compounds.

- Structural Repairs: For significant structural damage, I collaborate with structural engineers to ensure the repair is not only cosmetic but also structurally sound.

Recently, I restored a severely damaged driveway using a combination of crack repair, spalling remediation, and an overlay to restore its aesthetic appeal and structural integrity. Each project requires a tailored approach based on the type and extent of damage.

Q 12. Explain the process of applying epoxy coatings to concrete.

Applying epoxy coatings is a multi-step process that demands precision and attention to detail. The surface preparation is critical for a long-lasting, high-quality finish.

- Surface Preparation: Thorough cleaning and grinding are essential to remove any dust, debris, oil, or contaminants. This ensures proper adhesion.

- Priming (if necessary): Depending on the epoxy system and the concrete substrate, a primer may be required to enhance adhesion and improve the final finish.

- Mixing the Epoxy: Epoxies are typically two-part systems that need to be mixed precisely according to the manufacturer’s instructions. Incorrect mixing ratios can compromise the epoxy’s performance and durability.

- Application: The epoxy is applied using appropriate tools, such as rollers, squeegees, or spray equipment, ensuring even coverage and avoiding air bubbles. Multiple coats are often required depending on the desired thickness and finish.

- Curing: The epoxy needs sufficient time to cure properly, usually at least 24 hours, and avoiding foot traffic or exposure to water during that time. Environmental conditions (temperature and humidity) significantly affect curing time.

For instance, I recently applied an epoxy coating to a commercial kitchen floor, ensuring a seamless, hygienic, and durable surface capable of withstanding heavy traffic and frequent cleaning. The quality of the epoxy finish is directly linked to the meticulousness of these steps.

Q 13. How do you handle challenging concrete surfaces, such as uneven or cracked surfaces?

Challenging surfaces like uneven or cracked concrete require a strategic approach to achieve a professional finish. Simply applying a coating over imperfections will only highlight them.

- Uneven Surfaces: Grinding or using self-leveling compounds are often necessary to create a smooth, even base before applying any coatings or overlays. This ensures a uniform finish and prevents stress on the applied materials.

- Cracked Surfaces: Cracks need to be repaired before applying any coatings or overlays. This may involve filling cracks with epoxy or other repair materials and ensuring proper adhesion. Ignoring cracks can lead to the coating cracking as well.

- Surface Preparation: Thorough cleaning is essential to remove any loose debris, dust, or contaminants from the cracks or uneven areas before attempting repair or applying a finish. This ensures proper bonding.

A recent project involved a patio with significant cracking and unevenness. I first repaired the cracks, then ground the surface to create a level base, and finally applied a decorative concrete overlay to achieve a uniform and beautiful finish. Addressing the underlying issues is critical for a long-lasting and aesthetically pleasing outcome.

Q 14. What are the different types of concrete overlays and their applications?

Concrete overlays offer a cost-effective way to renovate and upgrade existing concrete surfaces. Various types exist, each suited for different applications.

- Microtoppings: These thin overlays (1/8” to 1/4”) are ideal for enhancing appearance and providing a durable finish. They’re great for improving existing surfaces without significant changes in height.

- Polymer Modified Overlays: These are more durable and flexible than standard concrete overlays, making them suitable for areas with high traffic or potential for cracking. They are often used in commercial applications.

- Stamped Concrete Overlays: These allow for creating patterns and textures, mimicking natural stone or brick. They’re popular for driveways, patios, and walkways.

- Epoxy Overlays: Providing excellent chemical and abrasion resistance, epoxy overlays are perfect for areas requiring high durability and easy cleaning, such as commercial kitchens or garages.

The choice of overlay depends on the project’s budget, the desired aesthetics, and the level of durability required. For example, a stamped concrete overlay might be perfect for a residential patio, while a polymer-modified overlay would be more appropriate for a busy commercial parking lot.

Q 15. Describe your experience with microtopping applications.

Microtopping is a thin, self-leveling cement overlay that’s incredibly versatile for creating stunning decorative concrete finishes. My experience spans a wide range of applications, from residential floors and countertops to commercial spaces like boutiques and restaurants. I’ve worked with various colors and finishes, achieving everything from sleek, modern aesthetics to more textured, rustic looks. I’m proficient in all aspects of the process, from surface preparation and primer application to the actual microtopping application and final polishing. A recent project involved transforming a dated bathroom floor into a luxurious, polished concrete surface using a warm grey microtopping with a subtle metallic sheen. The client was thrilled with the result, and it showcased the transformative power of this material.

I’m also experienced in troubleshooting common issues such as pinholes, cracking, and uneven curing. My approach emphasizes meticulous preparation and attention to detail at every stage to ensure a flawless finish.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage timelines and budgets on decorative concrete projects?

Managing timelines and budgets on decorative concrete projects requires a strategic approach. I begin by thoroughly understanding the client’s vision and then develop a detailed project plan that outlines all tasks, materials, and labor costs. This plan includes realistic timelines, factoring in potential delays and unforeseen circumstances. For example, unexpected weather conditions can impact curing time, so I always build in buffer time. I use project management software to track progress, manage resources, and communicate effectively with the client. Regular communication is key—I provide updates, discuss potential changes, and address concerns promptly.

Budget management involves careful material selection and sourcing, negotiating favorable rates with suppliers, and efficiently managing labor costs. I always present the client with a detailed, transparent breakdown of all expenses and maintain accurate records throughout the project. In situations where budget constraints arise, we collaborate to find cost-effective solutions without compromising the quality of the final product; this might involve adjusting the scope of work or exploring alternative materials.

Q 17. What software or tools do you use for design or estimating?

For design and estimating, I utilize a combination of software and tools. I use SketchUp for creating 3D models and visualizations that help clients visualize the final product and make informed design choices. For estimating, I rely on spreadsheets to calculate material quantities, labor costs, and overall project expenses. I also incorporate specialized concrete estimating software that helps to accurately predict the amount of material required and accounts for waste. This ensures accurate bidding and helps to avoid costly overruns. Finally, I use digital photography and photo editing software to document the progress of projects and create before-and-after presentations for clients. These tools work in conjunction to provide a seamless process from conception to completion.

Q 18. Explain your experience with different types of concrete pigments.

My experience encompasses a variety of concrete pigments, including integral, surface, and powdered pigments. Integral pigments are added to the concrete mix before pouring, resulting in a consistent color throughout the entire slab. These are great for large, uniform areas. Surface pigments, on the other hand, are applied to the surface after the concrete has cured, offering more flexibility in design and allowing for unique patterns and effects. Powdered pigments offer a wide range of colors and can be mixed to create custom shades. I’m well-versed in understanding the properties of each type, knowing how they interact with different concrete mixes, and how to achieve the desired color intensity and uniformity. For example, I recently used a combination of integral and surface pigments to create a two-toned effect on a patio—a dark base with lighter, swirling accents.

Choosing the right pigment depends heavily on the project’s requirements and desired aesthetic, including considerations for UV resistance and fade resistance over time.

Q 19. How do you ensure the longevity and durability of your decorative concrete work?

Ensuring the longevity and durability of decorative concrete requires meticulous attention to detail at every stage of the process. This starts with proper substrate preparation – a clean, sound base is crucial for a lasting finish. I carefully select high-quality materials, including concrete mixes formulated for durability and resilience. The application process itself must be precise, following the manufacturer’s instructions for proper mixing ratios, curing times, and sealing techniques. Appropriate sealing is paramount; I use high-quality sealants that protect the concrete from water damage, staining, and UV degradation. The choice of sealant depends on the specific application and the desired level of protection.

I also advise clients on proper maintenance, providing clear instructions on cleaning methods and recommending regular inspections to catch any potential issues early. This proactive approach ensures that their decorative concrete investment remains beautiful and functional for years to come.

Q 20. Describe a time you had to troubleshoot a problem on a concrete project.

On a recent project involving a large exposed aggregate patio, we encountered unexpected issues with the aggregate settling unevenly during the curing process. This resulted in a slightly uneven surface. To troubleshoot this, I first analyzed the cause – the mix design wasn’t quite right, leading to premature setting time. My solution involved carefully removing the affected sections and re-pouring them with a modified mix design, paying close attention to the water-cement ratio and using a vibration technique to ensure proper compaction. We also adjusted our timeline to accommodate this unexpected delay and kept the client updated at every step. Ultimately, we corrected the unevenness and delivered a finished product that met the client’s expectations.

Q 21. What are your preferred methods for cleaning and maintaining decorative concrete?

Cleaning and maintaining decorative concrete depends largely on the type of finish and the sealant used. Generally, regular sweeping or vacuuming is sufficient to remove loose debris. For more thorough cleaning, I recommend using a pH-neutral cleaner and a soft-bristled brush. Avoid abrasive cleaners or harsh chemicals that can damage the surface. For tougher stains, I often use a specialized concrete cleaner, always testing it in an inconspicuous area first. A high-quality sealant will significantly reduce the need for frequent cleaning and will also protect the concrete from stains and moisture damage. Regular sealing, typically every 2-3 years depending on the conditions, is a vital part of long-term maintenance.

I always provide clients with detailed maintenance instructions tailored to their specific project, ensuring they have the knowledge and resources to keep their decorative concrete looking its best for years to come.

Q 22. What are the different types of decorative concrete finishes you’re familiar with?

Decorative concrete finishes offer a wide array of aesthetic possibilities. My expertise spans many popular techniques, including:

- Stamped Concrete: This involves imprinting patterns onto freshly poured concrete, mimicking materials like brick, stone, or wood. It’s incredibly versatile and cost-effective for achieving a high-end look.

- Stained Concrete: Acid stains penetrate the concrete, creating unique, translucent colors that highlight the aggregate. This results in a naturally varied and beautiful finish, perfect for adding character to patios and floors.

- Stenciled Concrete: Similar to stamping, but stencils are used for more intricate designs, allowing for customized logos or patterns.

- Exposed Aggregate: This technique involves washing away the cement paste from the surface, exposing the decorative aggregate (stones, pebbles) beneath. The result is a rugged, textured look ideal for driveways or walkways.

- Polished Concrete: Grinding and polishing the concrete surface to a high gloss reveals the inherent beauty of the material. This creates a sleek, modern look often seen in commercial and residential interiors.

- Microtopping: A thin, self-leveling overlay that can be applied to existing concrete or other substrates, offering a smooth, seamless finish with vibrant color options. This is often utilized for repairs and renovations.

Each technique requires specialized skills and materials, and the best choice depends heavily on the client’s vision, budget, and the intended use of the concrete surface.

Q 23. Explain your understanding of concrete curing processes.

Concrete curing is crucial for achieving the desired strength and durability. It’s the process where the concrete hardens through a chemical reaction called hydration. This involves the cement reacting with water to form a solid mass. Improper curing can lead to cracking, reduced strength, and an overall poor-quality finish.

My approach to curing includes:

- Maintaining Moisture: Keeping the concrete moist for a specific duration is essential. This is often done by using curing compounds, plastic sheeting, or continuous misting. The duration depends on the concrete mix, environmental conditions (temperature and humidity), and the specific project requirements.

- Protecting from Extreme Temperatures: Direct sunlight and high temperatures can cause rapid evaporation of water, hindering hydration. Conversely, freezing temperatures can damage the concrete. Appropriate shading or temperature control is essential.

- Monitoring Curing Time: I carefully monitor the curing process, checking for proper moisture retention and surface condition. This ensures that the concrete reaches its optimal strength before any decorative finishing techniques are applied.

For example, I once worked on a large patio project during a particularly hot summer. To prevent premature drying, we used a combination of plastic sheeting and regular misting to keep the concrete moist for an extended period, resulting in a superior, crack-free finish.

Q 24. How do you ensure the proper mixing ratios for concrete and additives?

Accurate mixing ratios are paramount for achieving the desired concrete properties. I always adhere to the manufacturer’s specifications for both the cement and any admixtures (additives). This includes carefully measuring the water-cement ratio, which significantly impacts the strength, workability, and setting time of the concrete.

My process typically involves:

- Using calibrated equipment: I use calibrated scales and measuring tools to ensure precise measurements of cement, aggregates (sand, gravel), water, and any admixtures, such as pigments, accelerators, or retarders.

- Following batching procedures: I meticulously follow established batching procedures to ensure consistency in the mix across the entire project. This typically includes mixing the dry ingredients first, then gradually adding the water while continuously mixing.

- Testing the mix: Prior to pouring, I often test the slump of the concrete to assess its workability. The slump test measures the consistency of the mix, ensuring it’s suitable for the intended application and chosen finishing technique.

Deviation from the specified ratios can lead to issues such as excessive shrinkage, cracking, reduced strength, or even a complete failure of the concrete. Precision is key in this process.

Q 25. What is your experience with working with different types of concrete (e.g., colored, stamped)?

My experience encompasses a wide range of concrete types. I’ve worked extensively with colored concrete, achieved through the use of integral pigments mixed directly into the concrete before pouring, and surface stains applied afterwards for varied effects. I’m also highly proficient in stamped concrete, where specialized stamps are used to create realistic impressions of natural stone, brick, or wood.

Working with colored concrete requires careful consideration of pigment selection and dosage to achieve the desired shade and avoid issues like color fading or uneven coloration. With stamped concrete, the timing and technique of applying the stamps are crucial to ensure clear, well-defined impressions. Achieving a seamless, natural look demands both precision and artistry.

For example, a recent project involved creating a stamped concrete patio with a rustic stone effect. This required careful selection of a suitable stamp, precise application techniques, and the use of release agents to prevent the concrete from sticking to the stamp.

Q 26. Describe your experience working with different types of tools and equipment in decorative concrete finishing.

Proficiency with various tools and equipment is essential in decorative concrete finishing. My experience covers a wide array, including:

- Power Trowels: For achieving a smooth, level surface.

- Concrete Stamps: For creating patterns and textures.

- Grinders and Polishers: For polishing concrete to a high sheen.

- Edgers and Groovers: For creating defined edges and joints.

- Power Washers: For cleaning and preparing surfaces.

- Various hand tools: Floats, bull floats, trowels, brushes, and sponges, all of which are used for achieving specific textures and finishes.

Beyond the tools themselves, understanding their proper operation and maintenance is crucial for efficient and safe work. Regular maintenance and calibration ensure optimal performance and longevity of equipment, minimizing downtime and maximizing project efficiency.

Q 27. How do you manage and communicate with clients during a project?

Clear and consistent communication is paramount. From the initial consultation to project completion, I prioritize open communication with my clients. This begins with a thorough understanding of their needs, preferences, and budget.

My approach includes:

- Detailed consultations: I conduct comprehensive consultations to discuss project scope, materials, design options, and timelines.

- Regular updates: I provide regular updates throughout the project, keeping clients informed of progress and addressing any concerns promptly.

- Visual aids: I utilize sketches, samples, and digital renderings to illustrate design concepts and manage expectations.

- Open communication channels: I maintain open communication channels, whether via email, phone, or in-person meetings, ensuring easy access for client inquiries.

Effective communication ensures that the final product aligns perfectly with the client’s vision, fostering client satisfaction and building trust.

Q 28. How do you stay current with the latest trends and technologies in decorative concrete finishing?

Staying current is crucial in this rapidly evolving field. I actively engage in several strategies to stay informed about the latest trends and technologies:

- Industry publications and websites: I regularly read industry publications and visit websites dedicated to decorative concrete finishing.

- Trade shows and conferences: Attending trade shows and conferences allows me to learn about new products, techniques, and industry best practices.

- Networking with other professionals: Connecting with other professionals in the field provides valuable insights and opportunities for collaboration.

- Continuing education courses: I actively pursue continuing education courses and workshops to enhance my skills and knowledge base.

For example, I recently completed a workshop on using new, environmentally friendly concrete sealers, significantly improving the sustainability of my projects and meeting growing client demands for eco-conscious solutions.

Key Topics to Learn for Your Decorative Concrete Finishing Interview

- Surface Preparation: Understanding different substrate types (concrete, existing coatings), proper cleaning methods, crack repair techniques, and the importance of achieving a suitable profile for optimal adhesion.

- Stain Application Techniques: Mastering various staining methods (acid, water-based, integral), color mixing and blending, achieving consistent color application across large areas, and troubleshooting common staining issues like blotchiness or uneven color.

- Sealer Selection and Application: Knowledge of different sealer types (penetrating, topical, acrylic, epoxy), understanding their respective properties and applications, proper application techniques to ensure durability and longevity, and addressing issues like bubbling or hazing.

- Stamping and Texturing: Familiarity with various stamping techniques and tools, creating realistic textures (stone, brick, wood), understanding release agent application and its impact on the final finish, and troubleshooting problems like incomplete impressions or damaged stamps.

- Overlayments: Knowledge of different overlayment types and their applications, understanding the process of mixing and placing overlayments, achieving a smooth and level surface, and addressing common challenges like cracking or delamination.

- Safety Procedures and Regulations: Understanding and adhering to relevant safety protocols for working with chemicals and equipment, proper handling and disposal of materials, and complying with OSHA and other industry regulations.

- Project Management & Cost Estimation: Ability to estimate material quantities and labor costs, manage project timelines effectively, and communicate clearly with clients and colleagues.

- Troubleshooting and Problem-Solving: Identifying and addressing common issues encountered during the decorative concrete finishing process, such as uneven color, cracking, poor adhesion, and how to adapt techniques based on specific job site conditions.

Next Steps: Unlock Your Career Potential

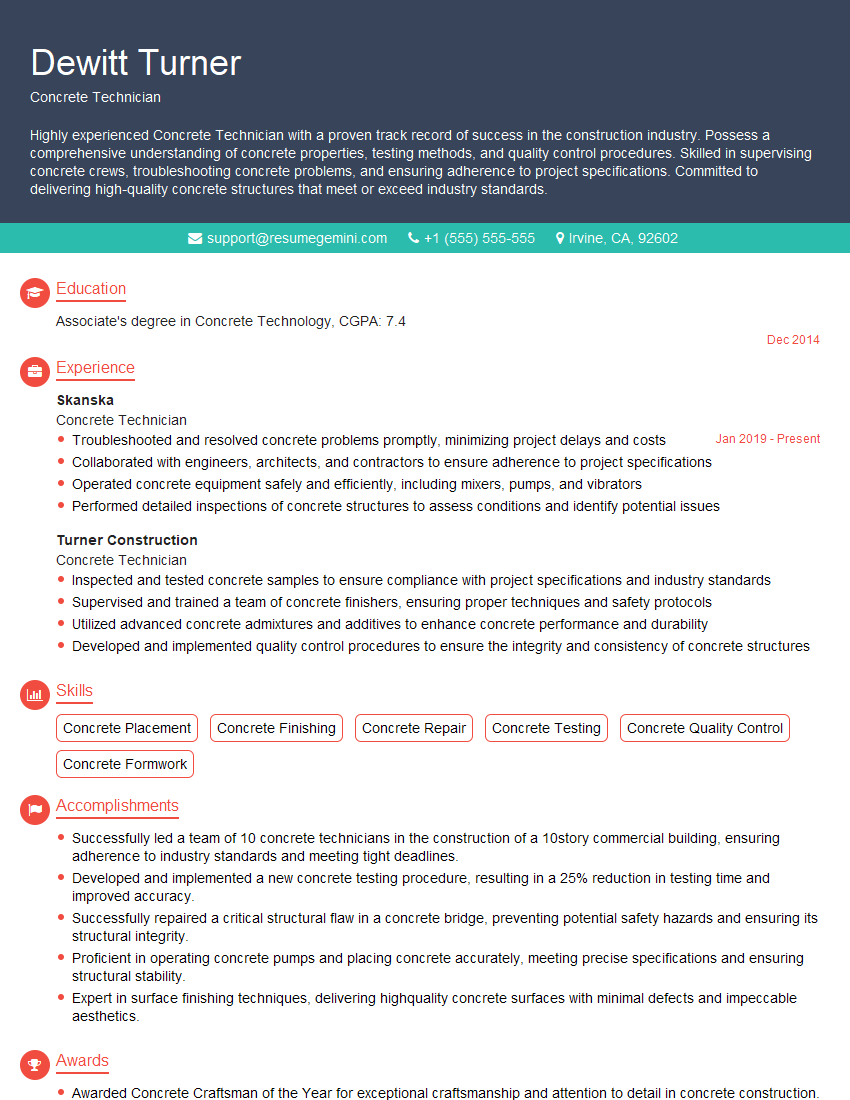

Mastering decorative concrete finishing opens doors to a rewarding career with diverse opportunities for growth. To stand out from the competition, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. They offer examples of resumes specifically tailored to the decorative concrete finishing field, providing you with the best possible chance to land your dream job. Invest in your future – build a compelling resume that showcases your expertise and secures your next interview!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good