Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Derrick Troubleshooting interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Derrick Troubleshooting Interview

Q 1. Describe your experience troubleshooting Derrick mechanical issues.

My experience with Derrick troubleshooting spans over 10 years, encompassing various rig types and operational environments. I’ve worked extensively on land-based derricks, as well as those used on offshore platforms. My expertise involves diagnosing and rectifying a wide range of mechanical issues, from minor component failures to major structural problems. I’m proficient in using both preventative maintenance schedules and reactive troubleshooting methodologies, focusing on identifying root causes rather than just addressing immediate symptoms. For instance, I once successfully resolved a recurring issue of slow hoisting speeds on an older derrick by identifying worn sheaves and replacing them, preventing a potential catastrophic failure.

I’m experienced in working with various Derrick manufacturers’ equipment and have a strong understanding of their design specifications and operational limits. This allows me to quickly pinpoint malfunctions and recommend effective solutions.

Q 2. Explain the different types of Derrick failures you’ve encountered.

Derrick failures can be broadly classified into several categories: Mechanical failures include issues with the crown block, traveling block, hook, and other moving parts. This can involve broken sheaves, worn wire ropes, or damaged gears. Hydraulic failures are common, involving leaks in hoses, cylinders, or pumps, leading to reduced lifting capacity or complete system failure. Electrical failures can impact the control system, braking mechanisms, or lighting, potentially leading to safety hazards. Finally, structural failures are the most serious, involving damage to the derrick’s main structure, typically due to overloading or inadequate maintenance. For example, I once encountered a failure where a sheave fractured due to fatigue, highlighting the importance of regular inspections. In another case, a hydraulic leak led to a significant loss of lifting capacity requiring prompt attention.

Q 3. How do you diagnose a problem with a Derrick’s braking system?

Diagnosing a Derrick braking system problem is a methodical process. I begin by visually inspecting all brake components for wear, damage, or leaks. This includes checking the brake drums, linings, actuators, and hydraulic lines for any obvious issues. Then, I’ll test the brake system functionality under various load conditions, paying close attention to the response time and stopping power. If the brakes are hydraulic, I’ll check the hydraulic pressure, fluid level, and for any leaks. For air brakes, I’d test the air pressure and check for leaks in the air lines. A systematic approach is crucial; I’ll use diagnostic tools like pressure gauges and multimeters to pinpoint the exact source of the malfunction. I’ll often create a flowchart to trace the system’s operation, helping isolate the problem area. This approach helped me quickly diagnose a faulty brake actuator on a drilling rig which was quickly repaired preventing any further issues.

Q 4. What safety protocols do you follow when troubleshooting a Derrick?

Safety is paramount when troubleshooting a Derrick. Before commencing any work, I ensure a thorough risk assessment is performed and all necessary safety permits are obtained. I always wear appropriate personal protective equipment (PPE), including safety helmets, safety glasses, gloves, and high-visibility clothing. I’ll also establish a clear communication system with the crew to ensure everyone understands the tasks being performed and potential hazards. Lockout/Tagout procedures are strictly followed when working on energized systems. The work area will be secured, preventing unauthorized access. Finally, I always follow the manufacturer’s recommendations and safety guidelines strictly. The systematic adherence to these safety protocols ensures that the work is carried out safely and efficiently. A near miss incident involving a dropped object, taught us the importance of constantly reinforcing safety procedures.

Q 5. Explain the process of inspecting a Derrick for wear and tear.

Inspecting a Derrick for wear and tear requires a detailed and systematic approach. I typically start with a visual inspection, checking all visible components for signs of damage, corrosion, or deformation. This involves closely examining the structural members, wire ropes, sheaves, drums, and all other moving parts. I’ll use calibrated measuring tools to check dimensions, looking for any significant deviations from specifications. I’ll also inspect welds for cracks and other defects. For critical components, non-destructive testing (NDT) methods like ultrasonic testing might be employed to identify internal flaws. Detailed records are kept, noting the condition of each component and any necessary repairs or replacements. Regular inspections and meticulous record-keeping are critical for preventative maintenance and avoiding catastrophic failures. For example, I identified a significant crack in a main structural member during a routine inspection that was addressed proactively.

Q 6. How do you identify and address hydraulic leaks in a Derrick system?

Identifying and addressing hydraulic leaks in a Derrick system begins with a visual inspection to locate the source of the leak. I use absorbent materials to pinpoint the precise location. Then, I’ll check the hydraulic pressure and fluid level. Leaks are often caused by damaged hoses, fittings, or seals. I may need to use specialized tools like pressure gauges and leak detectors to locate hidden leaks. Once the source is found, the damaged component needs to be replaced or repaired. The system should then be thoroughly flushed and refilled with the correct hydraulic fluid. I’ll pressure test the system to ensure the repair has been effective. In some cases, this might involve specialized equipment, but meticulous work and a systematic approach always pays off. For example, a small pinhole leak in a high-pressure hose was easily missed initially but was successfully repaired only after carefully examining every fitting.

Q 7. What are the common causes of Derrick malfunctions?

Derrick malfunctions have several common causes. Lack of proper maintenance is a significant contributor, leading to wear and tear on components, resulting in failures. Operator error can also lead to problems. For example, overloading the derrick or improper operation can cause damage. Environmental factors, such as extreme temperatures or corrosive environments, can also accelerate component degradation. Design flaws or manufacturing defects can also contribute to malfunctions. Finally, inadequate lubrication can lead to premature wear and tear. Regular inspections, preventative maintenance schedules, and proper operator training can significantly reduce the occurrence of derrick malfunctions. Understanding these common causes helps in prioritizing preventative maintenance and proactive risk mitigation. A case study of a derrick failure due to inadequate lubrication highlighted the need for detailed maintenance procedures.

Q 8. Describe your experience with Derrick preventative maintenance.

Preventative maintenance on a derrick is crucial for ensuring its longevity and safe operation. My approach focuses on a meticulous, scheduled inspection process, adhering to manufacturer recommendations and best practices. This involves regular visual inspections checking for wear and tear on cables, sheaves, and the mast itself. I also meticulously inspect hydraulic systems for leaks, checking fluid levels and ensuring proper functioning of pumps and valves. Lubrication of moving parts is key, preventing friction and extending component life. I meticulously document all inspections, noting any anomalies or required repairs. For example, I once identified a hairline crack in a sheave during a routine inspection, preventing a potentially catastrophic failure during operation.

- Visual Inspection: Cables, sheaves, mast, hydraulic lines, and structural components.

- Hydraulic System Check: Fluid levels, leaks, pump operation, valve function.

- Lubrication: All moving parts according to manufacturer specifications.

- Documentation: Detailed records of all inspections and findings.

Q 9. How familiar are you with Derrick schematics and manuals?

I’m highly proficient in reading and interpreting derrick schematics and manuals. My experience allows me to quickly locate specific components, understand their functions, and trace electrical pathways. I’m comfortable navigating complex diagrams and cross-referencing information to troubleshoot effectively. I find the detailed exploded views invaluable for identifying parts and understanding assembly. For instance, I recently used a schematic to diagnose a faulty limit switch on a hoisting system, saving significant time compared to trial-and-error troubleshooting.

Q 10. Explain your approach to troubleshooting electrical issues in a Derrick.

Troubleshooting electrical issues in a derrick requires a systematic and safety-conscious approach. My process begins with a thorough visual inspection, checking for damaged wiring, loose connections, and any signs of overheating. I then utilize multimeters and other diagnostic tools to test voltage, current, and continuity. I always prioritize safety by de-energizing the system before performing any tests or repairs. A methodical approach—following the electrical schematics—allows me to isolate the problem area. For example, I once resolved a complete power outage by tracing a faulty connection in the main power distribution panel using a continuity tester.

- Visual Inspection: Check for damaged wiring, loose connections, and overheating.

- Safety First: De-energize the system before any testing or repairs.

- Diagnostic Testing: Use multimeters to test voltage, current, and continuity.

- Schematic Analysis: Trace electrical pathways to identify the problem area.

- Repair and Testing: Repair faulty components and retest the system.

Q 11. How do you ensure the safe operation of a Derrick after repairs?

Ensuring safe operation after repairs is paramount. After completing any repairs, I perform a comprehensive series of tests, verifying the functionality of all systems and safety mechanisms. This includes load testing within safe limits, checking emergency stops, and ensuring all safety interlocks are functioning correctly. I meticulously document all tests and repairs, adhering to all safety regulations and company procedures. A thorough post-repair inspection, often involving multiple team members, guarantees that all systems are operating as designed before returning the derrick to service. Think of it like a thorough pre-flight checklist for an airplane—every detail matters.

Q 12. What is your experience with Derrick load testing and certification?

I possess significant experience in derrick load testing and certification. I’m familiar with various testing methods, including proof loading and non-destructive testing techniques. I understand the importance of adhering to industry standards and regulations during the testing process. I’ve overseen numerous load tests, meticulously documenting the results and ensuring compliance with all safety requirements. Proper documentation is vital for certification, which is a key element of demonstrating the derrick’s safe operating capacity.

Q 13. Describe your experience working with different types of Derrick components.

My experience encompasses a wide range of derrick components, including various types of hoisting mechanisms, hydraulic systems, braking systems, structural elements (mast, boom, etc.), and electrical control systems. I’m comfortable working with different manufacturers’ equipment and can adapt to diverse system designs. I have hands-on experience with both older, more mechanically driven systems and newer, computer-controlled derricks. For instance, I’ve repaired both traditional drum-type hoists and more modern systems that use advanced control algorithms.

Q 14. How do you handle emergency situations involving Derrick malfunctions?

In emergency situations, my primary focus is on safety. My response protocol begins with immediately securing the area, preventing access to potentially hazardous components. Then, I perform a quick risk assessment to identify the immediate danger, and initiate emergency shutdown procedures. Next, I initiate communication with the appropriate personnel (supervisors, safety officers) to report the incident and coordinate a safe response. After the emergency is contained, a thorough investigation is conducted to identify the cause of the malfunction and implement corrective actions to prevent recurrence. A recent emergency involved a sudden hydraulic fluid leak; my swift action to shut down the system prevented further damage.

Q 15. What are the common signs of Derrick structural damage?

Identifying structural damage in a derrick requires a keen eye and a thorough understanding of its mechanics. Common signs include visible cracks or bends in the main mast, boom, or substructure. These can often be found near welds, joints, or areas of high stress. Look for signs of metal fatigue, such as pitting or corrosion, particularly in areas exposed to the elements. Another critical indicator is misalignment—noticeable deviations from the derrick’s planned geometry, which might point to foundation settling or previous impact damage. Sagging or deformation of any structural members should raise immediate concerns. Finally, listen for unusual noises during operation; creaking, groaning, or metallic bangs can signify weakening or impending failure.

Example 1: A crack appearing near the base of the derrick mast, potentially caused by repeated stress from heavy lifting operations.

Example 2: A noticeable bend in the boom, possibly resulting from an accidental collision or overload.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with your team during Derrick troubleshooting?

Effective communication is paramount during derrick troubleshooting. I employ a multi-pronged approach. Firstly, I use clear and concise language, avoiding technical jargon unless absolutely necessary and explaining it clearly if it’s needed. I prioritize face-to-face communication whenever possible, allowing for immediate clarification and visual inspection of the issue. If face-to-face isn’t feasible, I leverage clear, concise written reports supplemented with photos or videos. I believe in fostering a collaborative environment, encouraging team members to voice their concerns and contribute their expertise. Regular briefings keep everyone informed about progress, any identified risks, and planned actions. Critical decisions are discussed transparently, and everyone understands their roles and responsibilities.

Example: During a recent incident involving a malfunctioning hoist, I used a combination of visual aids (photos of the damaged component) and a simple explanation of the likely failure mode to help my team rapidly understand the problem and develop a solution.

Q 17. Describe your experience with Derrick software and control systems.

My experience encompasses a broad range of derrick software and control systems. I’m proficient in using various types of Programmable Logic Controllers (PLCs) for monitoring and controlling derrick functions such as hoisting, swinging, and luffing. I’m familiar with troubleshooting PLC programs using diagnostic tools and ladder logic diagrams, addressing issues like faulty sensors, actuator malfunctions, and software bugs. I have hands-on experience with various Human-Machine Interfaces (HMIs) used to monitor and control derrick operations. I understand the importance of data logging and its role in preventative maintenance. Furthermore, I’m experienced with modern data acquisition systems which can provide real-time feedback and aid in predictive maintenance analysis. This ensures optimal performance and prevents unexpected downtime.

Example: In a previous role, I successfully diagnosed and resolved a critical issue caused by a software glitch in the derrick’s control system by analyzing the PLC’s diagnostic logs and modifying the relevant ladder logic code.

Q 18. Explain your understanding of Derrick safety regulations and compliance.

Derrick safety regulations and compliance are of utmost importance. My understanding includes a thorough knowledge of OSHA (Occupational Safety and Health Administration) standards, or equivalent international regulations, specifically relating to derrick operation, maintenance, and inspection. This includes understanding the requirements for regular inspections, operator training, load capacity limitations, and emergency procedures. I’m familiar with the documentation required for compliance, such as inspection reports, maintenance logs, and operator certification records. I believe in a proactive approach to safety; implementing regular safety audits, enforcing safe work practices, and providing ongoing training to ensure continuous compliance.

Example: I’ve actively participated in developing and implementing site-specific safety procedures based on relevant regulations to ensure the safe operation of derricks across multiple projects.

Q 19. How do you prioritize repairs when multiple Derrick issues exist?

Prioritizing repairs when multiple derrick issues exist requires a systematic approach. My strategy centers on assessing the severity and potential impact of each issue. Safety-critical problems, such as structural damage or hydraulic leaks, always take precedence. Issues posing an immediate safety risk or causing significant downtime are addressed before less critical ones. I use a risk matrix that considers the likelihood and consequence of each issue, assigning priorities accordingly. This ensures that resources are allocated efficiently and that the most critical problems are tackled first.

Example: If a derrick has both a minor electrical fault and a significant hydraulic leak, I would prioritize fixing the hydraulic leak first, as it poses a much greater safety risk and potential for significant damage.

Q 20. What tools and equipment are essential for Derrick troubleshooting?

The essential tools and equipment for derrick troubleshooting vary depending on the specific issue, but a core set includes:

- Diagnostic tools: Multimeters, oscilloscopes, and PLC programming software for electrical and control system diagnostics.

- Measuring instruments: Levels, plumb bobs, and tape measures for checking alignment and dimensions.

- Specialized tools: Wrenches, sockets, and torque wrenches for mechanical repairs.

- Hydraulic tools: Pressure gauges, hydraulic pumps, and leak detection equipment for hydraulic systems.

- Safety equipment: Hard hats, safety glasses, harnesses, and fall protection equipment.

- Documentation: Derrick operation manuals, schematics, and maintenance logs.

Beyond this, specialized tools like ultrasonic flaw detectors for non-destructive testing of structural components might be needed for more complex issues.

Q 21. Describe your problem-solving skills in a Derrick troubleshooting scenario.

My problem-solving approach during derrick troubleshooting follows a structured methodology. It begins with a thorough assessment of the problem, gathering data through observation, inspection, and interviews with operators. I then develop a hypothesis about the root cause, using my understanding of derrick mechanics, control systems, and potential failure modes. This hypothesis is then tested through systematic troubleshooting steps, verifying or refuting its validity. Once the root cause is identified, I develop a repair plan, ensuring it addresses the problem completely and minimizes the risk of recurrence. Finally, I document the problem, the troubleshooting steps, and the solution for future reference. Throughout the entire process, I prioritize safety and compliance with all relevant regulations.

Example: During a recent derrick malfunction characterized by erratic hoisting, I systematically checked the electrical system, hydraulics, and control software, ultimately identifying a faulty sensor causing incorrect feedback to the control system. The problem was quickly resolved by replacing the faulty sensor.

Q 22. How do you document your Derrick troubleshooting procedures?

Derrick troubleshooting procedures are meticulously documented to ensure consistent and safe operation. My documentation follows a standardized format, combining written descriptions with visual aids like photographs and diagrams. This approach facilitates effective communication and knowledge transfer within the team and across different projects.

- Problem Description: A detailed account of the malfunction, including observed symptoms and any error codes.

- Troubleshooting Steps: A chronological list of steps taken, including diagnostic checks, component inspections, and corrective actions. This section highlights successful and unsuccessful approaches to aid future troubleshooting efforts.

- Root Cause Analysis: Identification of the underlying cause of the problem and a rationale for the determined solution.

- Corrective Actions: Specific steps taken to rectify the issue, including parts replaced, settings adjusted, or software updates implemented. This section meticulously documents the repair process.

- Preventative Measures: Recommendations to prevent the recurrence of the problem, including maintenance schedules, operator training, or design modifications.

- Supporting Documentation: Inclusion of relevant data, schematics, and other related documents for comprehensive understanding.

For example, documenting a derrick hoist malfunction might include images of the faulty component, a record of the hydraulic pressure readings, and a detailed account of the replacement procedure, coupled with recommendations for regular lubrication schedules.

Q 23. How do you stay up-to-date with the latest Derrick technology and safety standards?

Staying current in Derrick technology and safety standards is paramount. I achieve this through a multi-pronged approach:

- Industry Publications and Journals: Regularly reviewing trade publications, journals, and online resources dedicated to oil and gas drilling, lifting equipment, and safety standards.

- Professional Development Courses and Conferences: Attending workshops, seminars, and conferences hosted by industry experts to gain insights into emerging technologies and best practices.

- Manufacturer Training and Documentation: Actively seeking out and participating in training programs provided by Derrick manufacturers, ensuring thorough familiarity with the specific equipment used in my operations.

- Networking with Industry Professionals: Engaging with colleagues and experts through professional organizations and online forums to exchange knowledge, discuss challenges, and learn from others’ experiences.

- Regulatory Updates and Compliance: Regularly monitoring and complying with all relevant safety regulations and industry standards issued by governmental bodies and regulatory agencies.

This consistent effort helps me anticipate potential issues, optimize derrick performance, and ensure the safety of all personnel involved in derrick operations.

Q 24. What are the key performance indicators for Derrick efficiency and uptime?

Key Performance Indicators (KPIs) for Derrick efficiency and uptime are crucial for optimizing operations and minimizing downtime. Some critical KPIs include:

- Uptime Percentage: The percentage of time the derrick is operational and available for work. A high uptime percentage indicates excellent operational efficiency.

- Mean Time Between Failures (MTBF): The average time between successive failures of the derrick system. A higher MTBF suggests improved reliability and reduced maintenance needs.

- Mean Time To Repair (MTTR): The average time required to repair a derrick system failure. Lower MTTR indicates a more efficient repair process.

- Cycle Time: The time it takes to complete a single lifting operation. Reducing cycle time improves productivity.

- Safety Incidents: Number of safety incidents related to derrick operations. A low number reflects a strong safety culture and effective risk management.

- Maintenance Costs: Costs incurred for routine and corrective maintenance. Lower costs indicate efficient maintenance practices.

Tracking these KPIs allows for continuous improvement and proactive maintenance strategies, leading to increased profitability and safety.

Q 25. Explain your experience with remote troubleshooting of Derrick systems.

My experience with remote troubleshooting of Derrick systems involves utilizing a combination of technologies and techniques to diagnose and resolve issues from a distance. This often involves leveraging:

- Remote Diagnostics Software: Accessing real-time data from the derrick’s control system through specialized software, allowing for the analysis of operational parameters and identification of potential problems.

- Video Conferencing: Using video conferencing tools to visually inspect the derrick, allowing for a remote assessment of the physical condition of components and systems.

- Data Logging and Analysis: Reviewing historical data logs from the derrick’s sensors and actuators to identify patterns and trends that may indicate developing faults.

- Expert Consultation: Collaborating with remote experts specializing in derrick systems to gain insights and leverage their experience.

For instance, I once remotely diagnosed a faulty hydraulic pressure sensor on a derrick using remote diagnostics software. By analyzing pressure readings, I was able to confirm the sensor malfunction and guide the on-site team to replace the faulty sensor. The entire process was completed efficiently and minimized downtime.

Q 26. How do you contribute to a safe and efficient work environment during Derrick maintenance?

Contributing to a safe and efficient work environment during Derrick maintenance involves adhering to strict safety protocols and fostering a collaborative approach.

- Risk Assessment and Mitigation: Conducting thorough risk assessments to identify potential hazards and implementing appropriate control measures, including lockout/tagout procedures, personal protective equipment (PPE), and safe work practices.

- Clear Communication and Teamwork: Maintaining open and clear communication with all team members, including precise instructions, regular updates, and prompt response to any concerns.

- Proper Tool and Equipment Usage: Ensuring all tools and equipment are properly inspected, maintained, and used according to manufacturers’ instructions to prevent accidents.

- Adherence to Safety Standards: Strict adherence to all relevant safety regulations and company policies, emphasizing safe work practices and promoting a culture of safety.

- Training and Competency: Ensuring that all personnel involved in derrick maintenance have the necessary training, skills, and competencies to perform their tasks safely and effectively.

My proactive approach to safety ensures all maintenance activities are executed with minimal risk, preventing accidents and maximizing efficiency.

Q 27. Describe a time you successfully troubleshooted a complex Derrick problem.

During a particularly challenging offshore operation, we experienced a complete failure of the main hoisting system on our derrick. The initial diagnosis pointed to a possible motor failure, but after a thorough inspection, we discovered that the issue stemmed from a combination of problems:

- Worn sheaves and drums: The sheaves and drums exhibited significant wear, causing slippage and reduced hoisting capacity.

- Hydraulic leak in the main control valve: A slow leak within the main control valve resulted in insufficient hydraulic pressure to fully power the hoisting system.

- Contaminated hydraulic fluid: The hydraulic fluid was contaminated with debris, further contributing to the hydraulic system malfunction.

Troubleshooting involved systematically addressing each issue: We replaced the worn sheaves and drums, repaired the hydraulic leak in the valve, and thoroughly flushed and replaced the contaminated hydraulic fluid. Following these steps, the hoisting system was restored to full functionality. The incident highlighted the importance of preventative maintenance and thorough root cause analysis to avoid future occurrences.

Q 28. What is your experience with different types of Derrick designs and configurations?

My experience encompasses a wide range of Derrick designs and configurations, including:

- Conventional Derrick Systems: Familiar with various configurations of conventional derricks, understanding their mechanical components, hydraulic systems, and operational characteristics.

- Top Drive Systems: Experienced in troubleshooting and maintaining top drive systems, including the control systems, rotating mechanisms, and associated equipment.

- Mast Type Derricks: Proficient in handling various mast-type derrick designs, from smaller mobile units to larger, fixed structures commonly found in onshore and offshore drilling operations.

- Subsea Derrick Systems: Possess a working knowledge of subsea derrick configurations and the unique challenges related to their maintenance and repair in harsh underwater environments.

This broad experience allows me to adapt my troubleshooting skills to a wide variety of Derrick designs, maximizing efficiency and safety regardless of the specific configuration.

Key Topics to Learn for Derrick Troubleshooting Interview

- Derrick Structure and Components: Understanding the mechanical, hydraulic, and electrical systems of a derrick, including crown blocks, traveling blocks, and drawworks.

- Rig-Up and Rig-Down Procedures: Mastering the safe and efficient assembly and disassembly of a derrick, adhering to industry best practices and safety regulations.

- Troubleshooting Common Issues: Identifying and resolving problems related to hoisting systems, braking systems, and power sources. This includes diagnosing mechanical failures, hydraulic leaks, and electrical malfunctions.

- Preventive Maintenance: Understanding the importance of regular inspections, lubrication, and component replacement to prevent breakdowns and maximize derrick lifespan.

- Safety Protocols and Emergency Procedures: Demonstrating knowledge of emergency shutdown procedures, load capacity limitations, and safety regulations relevant to derrick operation.

- Hydraulic Systems Diagnostics: Understanding pressure readings, flow rates, and identifying potential leaks or malfunctions within the derrick’s hydraulic system.

- Electrical Systems Diagnostics: Troubleshooting electrical faults, understanding wiring diagrams, and ensuring safe electrical practices while working with the derrick.

- Communication and Teamwork: Highlighting the importance of effective communication with the drilling crew during troubleshooting and maintenance activities.

Next Steps

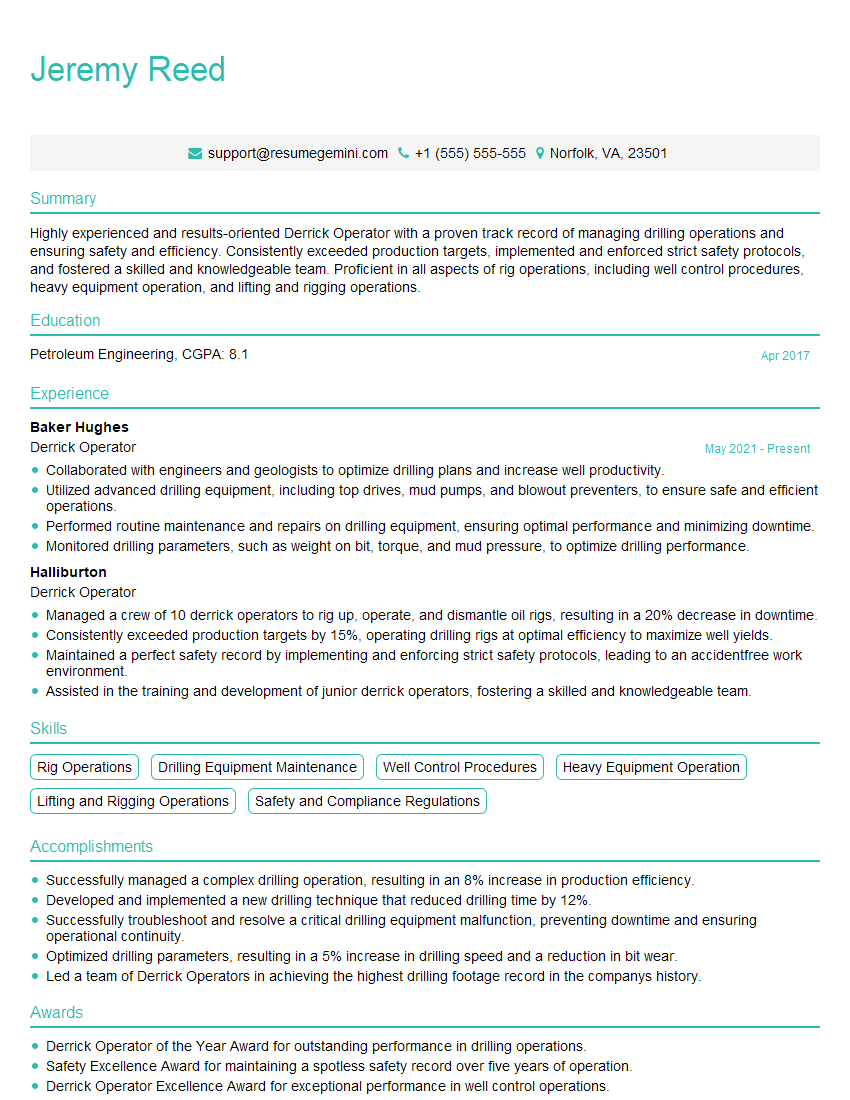

Mastering Derrick Troubleshooting is crucial for career advancement in the oil and gas industry, opening doors to higher-paying roles and increased responsibility. A strong understanding of these critical systems demonstrates valuable expertise and commitment to safety. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your skills and experience. Examples of resumes tailored to Derrick Troubleshooting are provided to guide you. Use this opportunity to showcase your expertise and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good