The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Design and Simulation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Design and Simulation Interview

Q 1. Explain the difference between FEA and CFD.

FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) are both powerful simulation techniques used in engineering, but they address different physical phenomena. FEA excels at analyzing structural behavior – things like stress, strain, and deformation in solid objects. Think of it as figuring out how a bridge will hold up under weight. CFD, on the other hand, focuses on fluid flow and heat transfer. It’s used to model things like airflow around an airplane wing or water flow through a pipe.

Here’s a simple analogy: Imagine you’re designing a car. FEA would help you analyze the strength of the chassis under crash conditions, ensuring it can withstand impact. CFD would be used to optimize the car’s aerodynamics, minimizing drag and improving fuel efficiency. They often complement each other; for instance, you might use FEA to analyze the stresses on a car’s body caused by aerodynamic forces predicted using CFD.

Q 2. Describe your experience with meshing techniques.

Meshing is a crucial preprocessing step in both FEA and CFD. It involves dividing the geometry of your model into a network of smaller, simpler elements (like triangles or tetrahedra). The accuracy of your simulation is heavily dependent on the quality of your mesh. I have extensive experience with various meshing techniques, including structured, unstructured, and hybrid approaches.

For example, I’ve used structured meshes for modeling simple geometries with predictable flow patterns, like a straight pipe, where uniformity is key. For complex geometries like a car engine, I’d opt for unstructured meshes, offering greater flexibility to adapt to intricate shapes. Hybrid meshes are useful where you want to combine the advantages of both – for example, a structured mesh in areas where high accuracy is needed and an unstructured mesh for more complex details. I am proficient in using mesh refinement techniques, such as local refinement around areas of high stress or gradients, to enhance the accuracy and efficiency of the simulation. My experience also includes mesh independence studies, which are essential to ensure that the simulation results are not significantly affected by the mesh size.

Q 3. What are the limitations of Finite Element Analysis?

While FEA is a powerful tool, it does have limitations. One major limitation is the reliance on simplifying assumptions. We often need to make assumptions about material properties, boundary conditions, and the geometry itself to make the problem solvable. For instance, we might assume a material is perfectly linear elastic, even though it might exhibit non-linear behavior in reality. The accuracy of the results is directly tied to the validity of these assumptions.

- Mesh Dependence: The results can be sensitive to the mesh quality and density. Improper meshing can lead to inaccurate or unreliable results.

- Computational Cost: Analyzing highly complex geometries with fine meshes can be computationally expensive and time-consuming.

- Model Complexity: FEA struggles with highly non-linear phenomena, such as large deformations or material failure, making advanced modeling techniques necessary, which can further increase complexity.

- Accuracy of Input Data: The accuracy of the simulation depends heavily on the accuracy of the input data, including material properties, geometry, and boundary conditions. Inaccurate input data will lead to inaccurate results.

It’s crucial to understand these limitations and carefully consider them when planning and interpreting FEA simulations. Often, validation with experimental data is needed to verify the results.

Q 4. How do you validate your simulation results?

Validating simulation results is paramount. I employ a multi-pronged approach to ensure the accuracy and reliability of my simulations. This typically starts with comparing the simulation results against experimental data, if available. This could involve comparing stress values from FEA with strain gauge measurements on a physical prototype or comparing CFD predicted pressure drops with measured pressure drops in a pipe system.

Beyond experimental validation, I also use several internal checks within the simulation process. These checks include:

- Mesh independence study: Ensuring that the results do not significantly change with mesh refinement.

- Convergence checks: Verifying that the numerical solution has converged to a stable solution.

- Code verification: Utilizing established techniques like unit testing and comparing against analytical solutions where possible.

Discrepancies between simulation and experimental data are carefully analyzed to identify potential sources of error, such as inaccuracies in material properties, boundary conditions, or the simplifying assumptions made in the model.

Q 5. What software packages are you proficient in (e.g., ANSYS, Abaqus, COMSOL)?

I’m proficient in several industry-standard software packages for design and simulation. My expertise includes ANSYS (Mechanical, Fluent, and CFX), Abaqus, and COMSOL Multiphysics. I have extensive experience using these tools for a variety of applications, from structural analysis to fluid dynamics and coupled physics problems. I’m comfortable with pre-processing, solving, and post-processing tasks within these environments, and I’m also proficient in scripting and automation to streamline workflows and increase efficiency.

Q 6. Describe your experience with design optimization techniques.

Design optimization is a core part of my work. I’ve used various optimization techniques to improve designs based on specific criteria, like minimizing weight while maintaining strength or maximizing efficiency. I’m experienced with both gradient-based methods, such as gradient descent, and gradient-free methods, like genetic algorithms. The choice of optimization technique depends on the complexity of the problem and the availability of gradient information.

For instance, in one project involving the design of a lightweight aircraft component, I used topology optimization in ANSYS to remove unnecessary material, leading to a 20% weight reduction while maintaining the required structural integrity. In another project involving pump design, I utilized a genetic algorithm in COMSOL to optimize the impeller geometry for maximum flow rate at a given pressure drop.

Q 7. Explain the concept of boundary conditions in simulation.

Boundary conditions are essentially the constraints and inputs that define the environment of your simulation. They dictate how the model interacts with its surroundings. Without proper boundary conditions, your simulation will lack realism and potentially yield nonsensical results.

These conditions can take many forms, including:

- Fixed Displacement: Specifying the displacement of certain nodes or surfaces, such as fixing one end of a beam.

- Applied Loads: Defining forces or pressures acting on the model, such as a force applied to a lever or pressure inside a pipe.

- Temperature Conditions: Prescribing temperatures or heat fluxes on surfaces, crucial for thermal simulations.

- Fluid Flow Conditions: Specifying inlet velocity, pressure, or temperature for CFD simulations.

- Symmetry Conditions: Exploiting symmetry in geometry to reduce computational costs.

Accurate and realistic boundary conditions are crucial for accurate and meaningful simulation results. Incorrectly defined boundary conditions can lead to unrealistic results and misinterpretations.

Q 8. How do you handle convergence issues in your simulations?

Convergence issues in simulations arise when the solution doesn’t settle to a stable result, often manifesting as oscillations or non-physical values. Think of it like trying to balance a pencil on its tip – it’s inherently unstable. Handling these requires a multifaceted approach.

Mesh Refinement: A coarse mesh (the digital representation of your physical object) can lead to inaccurate solutions and slow convergence. Refining the mesh, especially in areas of high stress or gradient changes, significantly improves accuracy and stability. Imagine trying to map the terrain of a mountain range – a coarse map will miss details, while a fine map provides a much more accurate picture.

Time Step Control: In transient simulations (those involving time), using excessively large time steps can lead to instability. Reducing the time step allows the simulation to “catch” more details and gradually converge. It’s like taking more frequent pictures of a rapidly changing event – you get a more accurate representation.

Solver Settings: Different solvers (the computational engine behind the simulation) have different convergence properties. Experimenting with solver parameters like tolerances and relaxation factors can be crucial. This is similar to adjusting the settings on a camera to get the best image quality.

Boundary Conditions: Incorrect or unrealistic boundary conditions (how the model interacts with its surroundings) can drastically affect convergence. Ensuring accurate boundary conditions is essential. It’s like setting the correct parameters for a scientific experiment – wrong inputs lead to wrong results.

Model Simplification: Sometimes, the model itself might be too complex, leading to convergence problems. Simplifying the model, if feasible, can improve convergence without significantly sacrificing accuracy. Think of it like breaking a complex problem into smaller, manageable parts.

Q 9. What are your preferred methods for post-processing simulation data?

Post-processing simulation data is critical for extracting meaningful insights. My preferred methods are a blend of visualization and quantitative analysis.

Visualization Software: Tools like ANSYS Workbench, Abaqus CAE, and ParaView allow for creating contour plots, vector plots, and animations to visualize stress, strain, temperature, and fluid flow. This visual representation helps quickly identify critical areas and potential failure points. Imagine viewing a weather map to understand the temperature distribution across a region.

Data Extraction and Analysis: I utilize scripting languages like Python with libraries like NumPy and Pandas for detailed data analysis. This enables calculating statistics (e.g., maximum stress, average temperature), generating reports, and performing custom analyses tailored to specific project needs. This is akin to using statistical tools to analyze survey data.

Data Comparison and Validation: When experimental data is available, I overlay simulation results with experimental measurements to evaluate the accuracy and reliability of the simulation model. This process, called model validation, is crucial for ensuring confidence in the simulation results. It’s like comparing a model airplane to the real thing.

Q 10. Describe a complex simulation project you’ve worked on and your role.

I was involved in simulating the thermal management of a high-power electric vehicle battery pack. My role encompassed the entire process, from model creation to result validation.

Model Creation: I built a detailed 3D CAD model of the battery pack, including individual cells, cooling plates, and the housing. This was a complex task requiring careful consideration of geometric details and material properties.

Meshing: I generated a high-quality mesh, ensuring sufficient refinement in critical areas like cell-to-plate contact interfaces. This step is crucial for accurate thermal simulation.

Simulation Setup: I defined boundary conditions based on realistic operating scenarios, including charging/discharging cycles and ambient temperatures. I also chose an appropriate solver and set convergence criteria.

Results Analysis: After the simulation, I analyzed the temperature distribution within the battery pack, identifying potential hotspots and areas requiring design improvements. This involved creating contour plots and calculating key metrics like maximum cell temperature.

Validation: We compared simulation results with experimental data obtained from testing a prototype battery pack. This validation step ensured that our simulation accurately captured the real-world thermal behavior.

This project highlighted the importance of detailed modeling, meshing strategies, and experimental validation for ensuring the reliability and accuracy of simulation results.

Q 11. How do you ensure the accuracy and reliability of your simulations?

Ensuring the accuracy and reliability of simulations is paramount. It’s achieved through a rigorous and multi-stage process.

Model Verification: This involves checking that the simulation model correctly represents the intended design and that the inputs are accurate. It’s like double-checking your work before submitting a report.

Mesh Convergence Study: Refining the mesh until the results don’t change significantly ensures that the mesh is fine enough to capture all relevant features. This is similar to zooming into a map until the details are clear enough.

Solver Convergence Check: Monitoring the solver’s convergence behavior is crucial to identify any potential issues and ensure stability. It’s like monitoring the progress of a chemical reaction to ensure it proceeds as expected.

Experimental Validation: Comparing simulation results with experimental data from real-world tests is the ultimate validation. This is similar to comparing a prototype with the final product.

Uncertainty Quantification: Accounting for uncertainties in material properties, boundary conditions, and other input parameters provides a realistic assessment of the simulation’s reliability. It’s like acknowledging the margin of error in any measurement.

Q 12. Explain your understanding of different element types in FEA.

Finite Element Analysis (FEA) utilizes different element types to represent the geometry and behavior of structures. The choice of element type significantly impacts accuracy and computational cost.

Linear Elements: These are the simplest elements, approximating the behavior with straight lines or planes. They are computationally efficient but may not accurately represent complex geometries or behavior.

Quadratic Elements: These use curved lines or surfaces, providing higher accuracy for complex geometries and stress distributions. They are more computationally expensive than linear elements.

Tetrahedral Elements: These 3D elements are versatile for complex geometries, but their accuracy might be lower compared to hexahedral elements.

Hexahedral Elements: These 3D elements offer higher accuracy than tetrahedral elements, especially for stress analysis, but can be challenging to generate for complex shapes.

Shell Elements: These elements are used to model thin structures like plates and shells, efficiently capturing bending and membrane behavior.

Beam Elements: These elements are used to model slender structures such as beams and columns, capturing bending, shear, and axial effects.

The selection of element types is a crucial decision that must consider the accuracy requirements, computational resources, and geometry complexity.

Q 13. What is your experience with experimental validation of simulation results?

Experimental validation is an essential step in verifying the accuracy of simulation results. It involves comparing simulation predictions with experimentally measured data. I have extensive experience in this area.

Experimental Design: Working closely with experimentalists to design appropriate experiments that accurately capture the relevant parameters. This includes defining test setups, instrumentation, and measurement techniques.

Data Acquisition and Processing: Gathering and processing experimental data, accounting for measurement uncertainties and errors. This often involves using data acquisition systems and signal processing techniques.

Comparison and Analysis: Comparing simulation predictions with experimental results, quantifying discrepancies, and identifying areas of agreement and disagreement.

Model Refinement: Using the comparison to refine the simulation model and improve its accuracy. This might involve adjusting material properties, boundary conditions, or even the simulation methodology.

A recent project involved validating a CFD (Computational Fluid Dynamics) simulation of airflow around a wind turbine. The comparison between simulation and wind tunnel measurements showed good agreement, validating the accuracy of the simulation model and providing confidence in the design.

Q 14. How do you manage large datasets generated from simulations?

Managing large datasets from simulations requires efficient strategies for storage, processing, and analysis. I typically employ these techniques:

High-Performance Computing (HPC): Utilizing HPC clusters for running simulations and storing large datasets. This approach is essential for managing extremely large datasets and computationally intensive analyses.

Database Management Systems (DBMS): Employing database systems like SQL or NoSQL to organize and manage simulation data efficiently. This approach allows for structured data storage, retrieval, and querying.

Data Compression Techniques: Using appropriate data compression methods to reduce storage space and improve data transfer speeds. This is crucial when dealing with massive datasets.

Cloud Storage: Utilizing cloud storage solutions like AWS S3 or Azure Blob Storage to manage and share large simulation datasets. This provides scalable and cost-effective storage.

Data Visualization and Reduction Techniques: Employing techniques to reduce the size of datasets by focusing on key features or regions of interest, without losing critical information. This involves techniques like proper meshing and selecting key output variables for post processing.

By implementing a combination of these strategies, I ensure efficient management of simulation data, enabling seamless analysis and interpretation of results.

Q 15. Describe your experience with scripting or automation in simulation software.

Scripting and automation are crucial for efficiency and repeatability in simulation. My experience spans several languages, primarily Python and MATLAB, within various simulation platforms like ANSYS, Abaqus, and COMSOL. I’ve used scripting to automate mesh generation, pre-processing tasks like defining boundary conditions and material properties, running simulations in batches, and post-processing results, including data extraction and visualization. For instance, I automated a fatigue analysis workflow for a turbine blade, reducing the time required from days to hours. This involved writing a Python script that iterated through different load cases, ran the simulations, and extracted the relevant stress data for fatigue life prediction. Another example involved creating a MATLAB script to optimize the design parameters of a heat sink by automating multiple simulation runs and using an optimization algorithm to find the best configuration.

Specific examples of tasks automated include:

- Batch processing of numerous simulation runs with varying input parameters.

- Automatic generation of reports and visualizations from simulation outputs.

- Customizing post-processing to extract specific data of interest.

- Integrating simulations with other tools for broader system analysis.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of solvers used in simulation?

Simulation solvers are the mathematical engines that solve the governing equations of a physical system. The choice of solver depends heavily on the problem’s nature and complexity. Broadly, we can categorize them as follows:

- Finite Element Method (FEM): This is the most prevalent solver, particularly for structural mechanics, heat transfer, and fluid dynamics. FEM divides the problem domain into smaller elements, solving the equations within each element and assembling the results. It’s highly versatile and handles complex geometries effectively.

- Finite Difference Method (FDM): FDM uses a grid to approximate derivatives, making it computationally efficient for problems with simple geometries. It’s often used in fluid dynamics and heat transfer.

- Finite Volume Method (FVM): FVM is commonly used in computational fluid dynamics (CFD) and conserves quantities like mass and momentum, making it suitable for fluid flow simulations. It discretizes the governing equations into control volumes and solves for average values within each volume.

- Boundary Element Method (BEM): BEM focuses on the boundaries of the domain, making it efficient for problems with infinite or semi-infinite domains. It’s often used in acoustics and electromagnetics.

Beyond these core methods, there are specialized solvers for specific applications, such as particle-based methods for granular materials or spectral methods for solving certain types of partial differential equations.

Q 17. Explain the concept of model order reduction.

Model Order Reduction (MOR) is a technique used to simplify complex models, reducing their computational cost without significantly sacrificing accuracy. Imagine trying to simulate a car crash – modeling every atom would be computationally impossible! MOR addresses this by approximating the original high-dimensional model with a much lower-dimensional surrogate model that captures the essential dynamics. This is particularly valuable when many simulations are needed, such as in optimization or uncertainty quantification. Methods include:

- Proper Orthogonal Decomposition (POD): POD identifies dominant modes of variation in the system’s behavior from a set of full-order simulations, creating a reduced basis for approximation.

- Krylov subspace methods: These methods project the system’s dynamics onto a lower-dimensional subspace that captures the most important information for a given frequency range.

The benefits include faster simulations, reduced memory requirements, and enabling real-time analysis or optimization tasks that would otherwise be infeasible. For example, in designing a microchip, MOR allows engineers to quickly simulate the thermal behavior of the chip under various operating conditions, optimizing the cooling system design without lengthy simulations.

Q 18. How do you handle uncertainties and variability in your simulations?

Handling uncertainties and variability is critical for robust design. My approach involves techniques such as:

- Monte Carlo Simulation: This involves running many simulations with randomly sampled input parameters, representing the uncertainty in material properties, geometry, loads, etc. The results provide a statistical distribution of the output quantities, allowing us to quantify the range of possible outcomes.

- Sensitivity analysis: This method assesses how variations in input parameters affect the outputs. It helps identify the most critical parameters to focus on when reducing uncertainties.

- Design for Six Sigma (DFSS): This methodology utilizes statistical tools to understand and minimize the impact of variation on product quality and performance, which often incorporates simulation for predicting outcomes.

- Probabilistic finite element analysis (PFEM): This integrates probabilistic models directly into the finite element simulation, allowing for a more direct quantification of uncertainty propagation.

For example, in designing a bridge, I would use Monte Carlo simulation to account for variations in material strength, load distributions, and environmental factors, providing a more realistic assessment of the bridge’s safety and reliability.

Q 19. What are your experience with different types of material models?

My experience encompasses a wide range of material models, including:

- Linear elastic materials: These are suitable for materials that deform proportionally to the applied load, within their elastic limit (e.g., steel, aluminum under small loads).

- Nonlinear elastic materials: These materials exhibit nonlinear stress-strain relationships, common in rubber or certain polymers.

- Plasticity models (e.g., J2 plasticity, von Mises yield criterion): These describe permanent deformation behavior after yielding, essential for metal forming simulations or crashworthiness analysis.

- Viscoelastic models: These account for time-dependent material behavior, crucial for polymers or biological tissues that exhibit both viscous and elastic characteristics.

- Hyperelastic models (e.g., Mooney-Rivlin, Ogden): Used for materials undergoing large deformations, such as rubber or biological tissues.

- Damage and failure models: These models predict material degradation and ultimate failure, critical for fatigue analysis or impact simulations.

Selecting the appropriate material model is crucial for accurate simulation results. Mismatches can lead to significant errors in predictions. For instance, using a linear elastic model for a highly nonlinear material like rubber would grossly underestimate the deformation under load.

Q 20. Describe your experience with multiphysics simulations.

Multiphysics simulations involve solving coupled physical phenomena simultaneously. My experience includes coupling various physics, such as:

- Fluid-structure interaction (FSI): This involves the interaction between a fluid flow and a deformable structure (e.g., blood flow in arteries, wind loading on a bridge).

- Thermo-mechanical coupling: This accounts for the interplay between temperature changes and mechanical deformation (e.g., thermal stress in a turbine blade).

- Electro-mechanical coupling: This considers the interaction between electrical fields and mechanical deformation (e.g., piezoelectric actuators).

- Fluid-thermal coupling: This is essential for analyzing heat transfer in fluid flows (e.g., cooling systems, electronic component cooling).

These simulations require sophisticated software and a deep understanding of the underlying physics. For example, simulating the performance of a fuel cell involves coupling electrochemical reactions, fluid flow, and heat transfer simultaneously.

Q 21. Explain your understanding of design of experiments (DOE).

Design of Experiments (DOE) is a statistical method used to efficiently explore the design space and identify optimal parameter settings. Instead of running simulations one-by-one, DOE uses carefully chosen combinations of input parameters to understand their impact on outputs. This reduces the number of simulations required, saving time and resources. Common DOE approaches include:

- Full factorial designs: Every possible combination of input parameters is tested.

- Fractional factorial designs: A subset of the full factorial design is selected, efficiently exploring the most influential parameters.

- Central composite designs (CCD): These designs are used to create a response surface model, approximating the relationship between inputs and outputs.

- Taguchi methods: These orthogonal array-based methods are efficient in exploring the design space with fewer experimental runs.

For example, in optimizing the design of an antenna, I would use a DOE approach to systematically vary antenna parameters (e.g., length, width, material) and evaluate their impact on radiation performance. This allows me to identify the optimal parameter combination for maximum efficiency and minimal side lobes, minimizing the overall number of simulations needed.

Q 22. How do you balance simulation accuracy with computational cost?

Balancing simulation accuracy and computational cost is a crucial aspect of effective design and simulation. It’s essentially an optimization problem: you want the most accurate results possible, but simulations can become incredibly computationally expensive, especially with complex models and high resolutions. The key is to find the sweet spot where the accuracy is sufficient for your design goals without exceeding acceptable computational time and resource limitations.

This balance often involves making strategic choices. For example:

- Model simplification: Instead of modeling every tiny detail of a system, you might use simplified representations or reduce the level of detail in certain areas. This could involve using analytical approximations instead of full-scale numerical simulations where appropriate. For example, you might approximate the heat transfer in a component using simplified equations instead of computationally intensive finite element analysis (FEA).

- Mesh refinement: In simulations like Finite Element Analysis (FEA), the mesh resolution significantly impacts accuracy. A finer mesh leads to higher accuracy but dramatically increases computational time. Adaptive mesh refinement techniques can help by automatically focusing computational resources on areas where higher accuracy is needed, while maintaining coarser meshes in areas where it’s less critical.

- Solver selection: Different solvers have varying accuracy and computational efficiency. Choosing the right solver for your specific problem is crucial. Implicit solvers are often more stable but slower, while explicit solvers are faster but can be less stable. A careful assessment of the problem and its requirements is necessary to make an informed choice.

- Dimensionality reduction: If appropriate, reduce the dimensionality of your model. For example, using a 2D model instead of a 3D model can significantly reduce computation time, while maintaining acceptable accuracy in specific scenarios.

Ultimately, the optimal balance is determined by the specific project requirements, available computational resources, and the acceptable level of uncertainty in the results. Often, a series of simulations with varying levels of detail are conducted to evaluate the trade-offs.

Q 23. Describe your experience with parallel computing in simulation.

My experience with parallel computing in simulation is extensive. I’ve used it extensively to accelerate computationally intensive simulations, especially those involving large datasets or complex geometries. Parallel computing allows us to break down a large simulation problem into smaller subproblems that can be solved concurrently on multiple processors or cores. This drastically reduces the overall simulation time.

I’m proficient in several parallel computing frameworks, including:

- MPI (Message Passing Interface): I’ve used MPI to distribute the computational load across multiple machines in a cluster, enabling the simulation of extremely large models that would be intractable on a single machine. For example, I used MPI to simulate the fluid dynamics of a complete aircraft during take-off, a task requiring significant computational power.

- OpenMP (Open Multi-Processing): I’ve utilized OpenMP for shared-memory parallel programming, effectively parallelizing loops and other computationally intensive sections of code within a single machine. This approach is excellent for optimizing simulations running on multi-core processors.

A crucial aspect of successful parallel computing is understanding the workload distribution and communication overhead. Poorly designed parallel code can lead to performance degradation due to excessive communication between processors. I have significant experience optimizing parallel code to minimize this overhead and achieve near-linear speedups.

Q 24. What is your experience with high-performance computing (HPC)?

My experience with High-Performance Computing (HPC) spans several years, encompassing the use of large-scale computing clusters and specialized hardware to solve computationally demanding simulation problems. I am comfortable working with queuing systems like SLURM or PBS to submit and manage large simulation jobs.

I’ve utilized HPC resources for simulations in various domains, including:

- Computational Fluid Dynamics (CFD): Simulating complex airflow patterns around aircraft or within industrial processes, often requiring massively parallel computations.

- Finite Element Analysis (FEA): Modeling the structural behavior of large and complex structures, such as bridges or buildings, requiring high-resolution meshes and sophisticated solvers.

- Molecular Dynamics (MD): Simulating the behavior of molecules at the atomic level, a computationally intensive task requiring specialized hardware and algorithms.

Beyond simply running simulations on HPC systems, I understand the importance of optimizing code for HPC environments. This involves understanding memory management, data transfer optimization, and the efficient use of parallel computing techniques. I am also experienced in profiling and debugging code to identify performance bottlenecks and improve efficiency in these complex computing environments. For instance, I once optimized a CFD simulation on a large HPC cluster, reducing its runtime by over 40% by identifying and resolving I/O bottlenecks.

Q 25. How do you ensure the robustness of your simulation models?

Ensuring the robustness of simulation models is critical for reliable results. Robustness refers to the ability of a model to produce accurate and meaningful results even under variations in input parameters, initial conditions, or numerical methods.

My approach to ensuring robustness includes:

- Sensitivity analysis: I systematically vary input parameters to determine their influence on the simulation output. This helps to identify parameters that significantly impact the results and prioritize their accuracy.

- Verification and validation: Verification confirms that the simulation code correctly implements the intended mathematical model. This is often done through unit tests and code reviews. Validation compares the simulation results with experimental data or other reliable sources to ensure that the model accurately represents the real-world phenomenon.

- Mesh convergence studies (for FEA): For simulations employing mesh-based methods (such as FEA), I perform mesh convergence studies to ensure that the results are independent of the mesh resolution. By progressively refining the mesh, I demonstrate that the solution has converged to a stable value.

- Code review and testing: Rigorous code reviews and unit testing are crucial to identify and rectify errors in the code early on. Automated testing is invaluable in this regard.

- Uncertainty quantification: I often incorporate techniques for quantifying the uncertainty in the simulation results, arising from uncertainties in input parameters or model assumptions. This can be done through methods like Monte Carlo simulations.

By systematically addressing these aspects, I aim to create robust simulation models that are reliable and can be used with confidence to inform design decisions.

Q 26. How do you communicate complex technical information to non-technical audiences?

Communicating complex technical information to non-technical audiences requires a clear and concise approach that avoids jargon and focuses on the essential insights. My strategy involves:

- Analogies and metaphors: I use relatable analogies to explain complex concepts. For example, when explaining finite element analysis, I might compare it to dividing a problem into many smaller, manageable pieces like assembling a jigsaw puzzle.

- Visual aids: Charts, graphs, and diagrams are invaluable tools for conveying complex data visually. A well-designed chart can communicate information far more effectively than a lengthy verbal explanation.

- Storytelling: Framing the technical information within a narrative can make it more engaging and easier to remember. I might present the technical details as a part of the bigger story of the project or design process.

- Focus on the ‘So What?’: Always explain the practical implications of the results for the non-technical audience. Why should they care about these simulations? What are the potential benefits or consequences?

- Active listening and feedback: I encourage questions and feedback to gauge understanding and adjust my communication style accordingly.

Ultimately, the goal is to make the information accessible and relevant to the audience, fostering a better understanding of the work done and its implications.

Q 27. Describe your experience with different types of simulation results visualization.

My experience with simulation results visualization spans various methods, each suited for different types of data and audiences. I use a combination of techniques to present the data effectively.

- 2D and 3D plots: Standard plotting libraries are used to visualize data such as stress distributions, temperature fields, or velocity profiles. Tools like Matplotlib, ParaView, and Tecplot provide flexibility and power for this purpose.

- Contour plots and surface plots: These are especially useful for visualizing scalar fields, such as temperature or pressure, across a domain. They allow for quick identification of regions of high and low values.

- Vector plots: Used to display vector fields such as velocity or magnetic fields, providing a visual representation of both magnitude and direction.

- Animation: Animating simulation results over time can be very powerful for understanding dynamic phenomena, like fluid flow or structural vibrations.

- Interactive visualizations: Using tools that allow exploration of the data through zooming, panning, and slicing can significantly enhance understanding.

The choice of visualization method depends heavily on the type of data and the audience. For example, while detailed contour plots might be suitable for a technical report, a simpler animation might be more effective for a presentation to stakeholders.

Q 28. Explain your process for debugging and troubleshooting simulation errors.

Debugging and troubleshooting simulation errors is a systematic process requiring careful attention to detail. My approach typically involves:

- Error messages: Carefully examine any error messages generated by the simulation software or code. These messages often provide valuable clues about the nature and location of the problem.

- Code review: Systematically review the code for logical errors, syntax errors, or incorrect implementation of algorithms. This step frequently reveals errors that are not immediately apparent from the error messages.

- Data validation: Check the input data for inconsistencies, errors, or missing values. Incorrect or incomplete input data can often lead to unexpected simulation results.

- Step-by-step debugging: Use debugging tools to step through the code line by line, examining variables and their values to track down the source of the error. This is especially useful for identifying subtle logical errors.

- Simplification: If the problem is complex, simplify the model to isolate the source of the error. For example, consider running a smaller, simpler version of the simulation to pinpoint the problem area.

- Consultation with colleagues: Discuss the problem with colleagues or experts in the field. A fresh perspective can often help identify solutions that weren’t apparent before.

In many cases, simulation errors are not caused by a single issue but rather a combination of factors. A systematic and methodical approach is essential to isolate and resolve these problems effectively.

Key Topics to Learn for Design and Simulation Interview

- Fundamentals of Modeling: Understanding different modeling techniques (e.g., finite element analysis, computational fluid dynamics) and their applications in various engineering disciplines.

- Software Proficiency: Demonstrating practical experience with industry-standard simulation software (e.g., ANSYS, Abaqus, COMSOL) and showcasing your ability to solve real-world problems using these tools.

- Design Optimization: Exploring methods for optimizing designs based on simulation results, including sensitivity analysis and design of experiments.

- Data Analysis and Interpretation: Highlighting your skills in interpreting simulation data, identifying trends, and drawing meaningful conclusions to inform design decisions.

- Validation and Verification: Understanding the importance of validating simulation results against experimental data and verifying the accuracy of the simulation models.

- Material Properties and Behavior: Demonstrating knowledge of how material properties influence simulation outcomes and the ability to select appropriate material models for different applications.

- Computational Methods: Familiarizing yourself with the underlying numerical methods used in simulation software, such as solving systems of equations or implementing iterative solvers.

- Problem-Solving and Critical Thinking: Highlight your ability to approach complex design challenges systematically, identify key assumptions, and troubleshoot simulation issues effectively.

- Communication and Teamwork: Emphasize your ability to clearly communicate technical information to both technical and non-technical audiences and to collaborate effectively within a team environment.

Next Steps

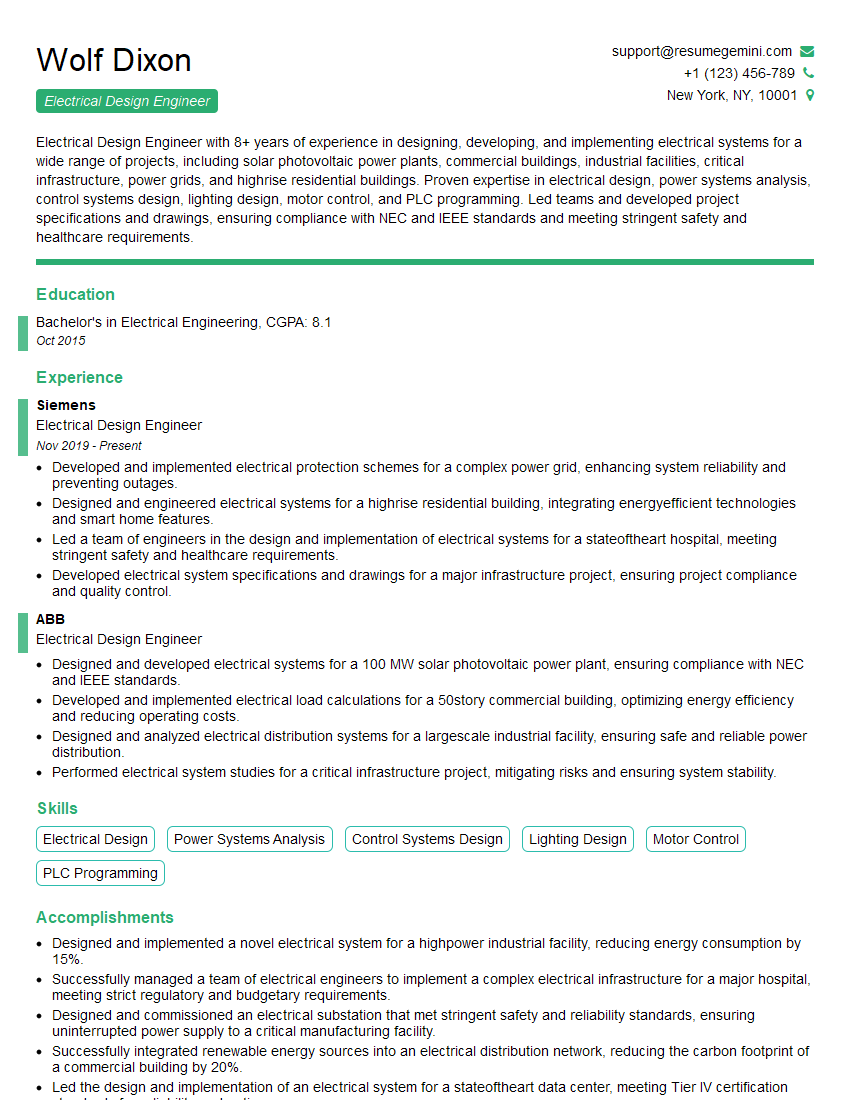

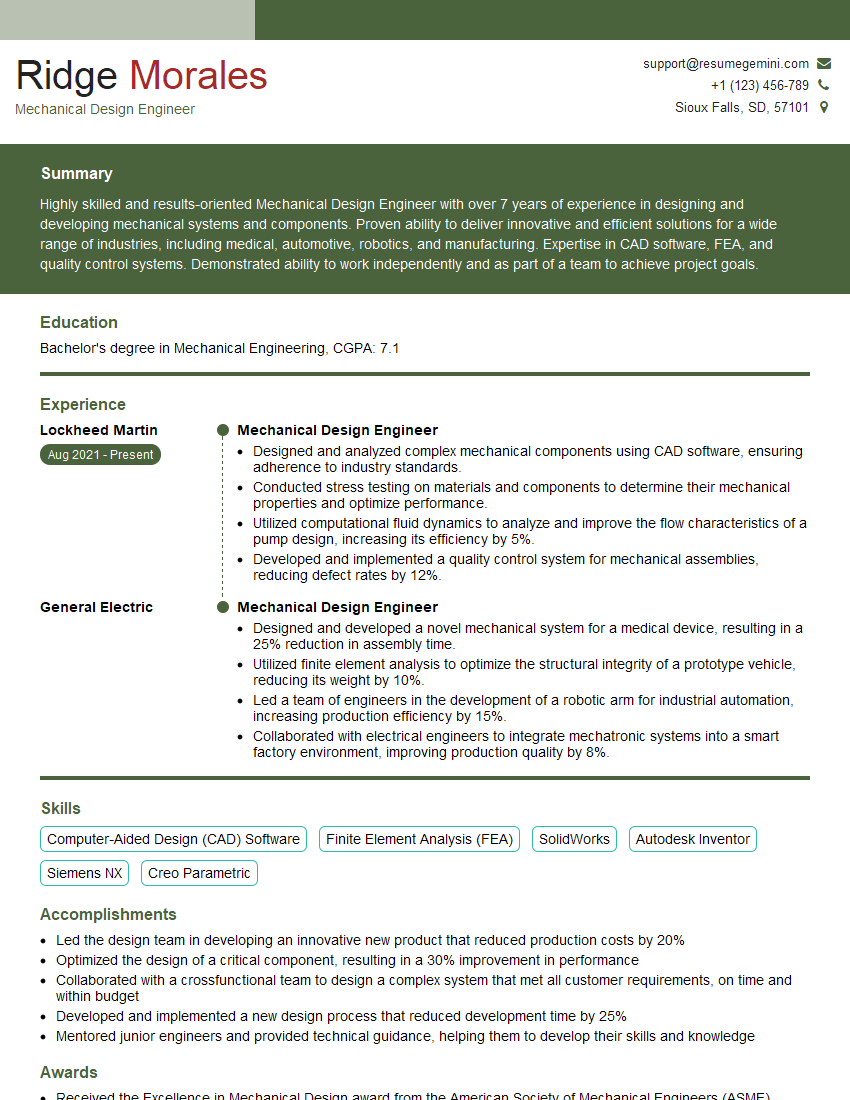

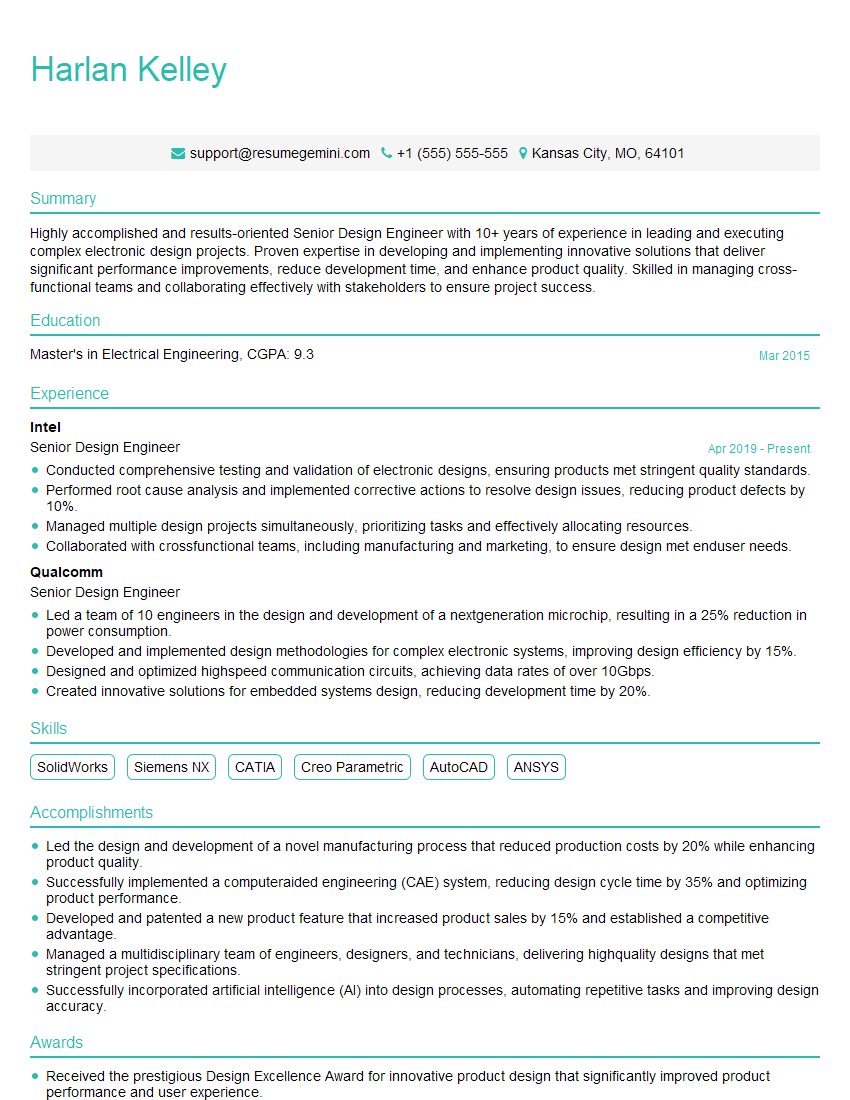

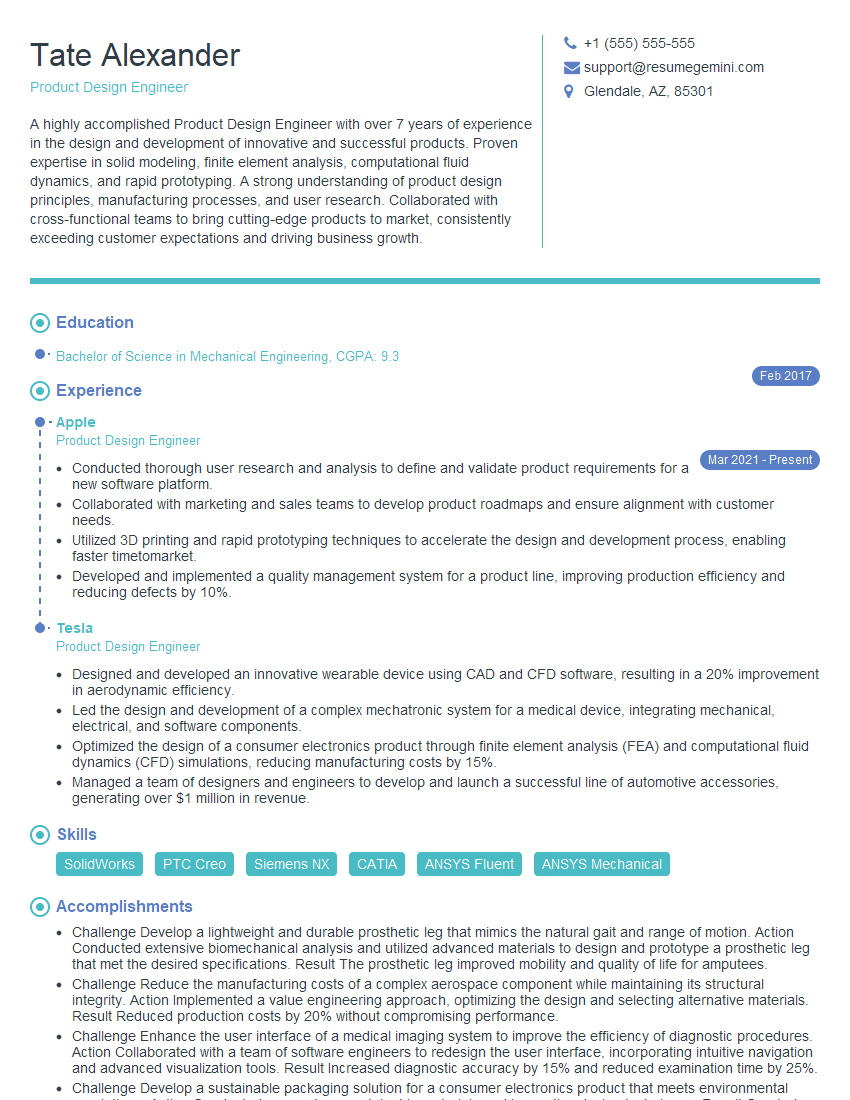

Mastering Design and Simulation opens doors to exciting and challenging careers in various industries. A strong foundation in these areas significantly enhances your problem-solving abilities and positions you for leadership roles. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the Design and Simulation field. We provide examples of resumes specifically designed for this industry to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good