Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Design of Ergonomic Solutions interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Design of Ergonomic Solutions Interview

Q 1. Define ergonomics and its importance in design.

Ergonomics is the scientific study of people and their working environments. Its core goal is to design workplaces, products, and tasks to fit the capabilities and limitations of the human body. In essence, it’s about creating a comfortable, efficient, and safe environment that minimizes the risk of injury and maximizes productivity. The importance of ergonomics in design is paramount because it directly impacts worker health, safety, and well-being, ultimately leading to increased productivity, reduced absenteeism, and lower healthcare costs. Ignoring ergonomic principles can result in significant financial losses for organizations and considerable suffering for individuals.

For example, poorly designed office chairs can lead to back pain and decreased productivity, while a well-designed workstation can promote better posture, reduce strain, and enhance performance. Ergonomics isn’t just about comfort; it’s about preventing injuries and ensuring long-term health and well-being.

Q 2. Explain the difference between anthropometry and biomechanics.

While both anthropometry and biomechanics are crucial aspects of ergonomics, they focus on different aspects of the human body in relation to its environment. Anthropometry is the measurement of the human body – its dimensions, proportions, and range of motion. This data is essential for designing products and workplaces that fit a wide range of body sizes and shapes. For instance, knowing the average reach of a seated person helps in designing the optimal placement of controls on a machine or dashboard.

Biomechanics, on the other hand, is the study of the forces acting on the body and the body’s response to those forces. This includes analyzing postures, movements, and the stresses placed on muscles, joints, and ligaments during tasks. Understanding biomechanics allows us to identify and mitigate risks of musculoskeletal disorders. For example, biomechanical analysis can reveal the stresses on the spine during lifting tasks, leading to the design of safer lifting techniques or equipment.

Q 3. Describe the key principles of ergonomic workstation design.

Key principles of ergonomic workstation design focus on creating a work environment that supports natural body postures and minimizes physical strain. These principles include:

- Proper Posture: Encouraging neutral postures where the body is naturally aligned, minimizing strain on muscles and joints. This means adjustable chairs, desks, and monitors to allow customization for individual needs.

- Work Surface Height: Ensuring that the work surface is at the correct height to allow for comfortable elbow and wrist angles, preventing strain.

- Monitor Placement: Positioning the monitor at an arm’s length and slightly below eye level to prevent neck strain and eye fatigue.

- Keyboard and Mouse Placement: Placing the keyboard and mouse close to the body, at a height that allows for neutral wrists and forearms. Avoid awkward reaching or twisting.

- Lighting: Providing adequate lighting to reduce eye strain and prevent glare from screens.

- Chair Support: Using adjustable chairs with proper lumbar support to maintain correct spinal alignment.

- Regular Breaks and Movement: Incorporating short breaks throughout the workday to encourage movement and stretch, alleviating stiffness and fatigue. Micro-breaks are crucial for maintaining productivity and preventing discomfort.

Consider a scenario where a worker spends hours at a computer: a poorly designed workstation could cause neck pain, carpal tunnel syndrome, or back problems. By following these principles, we minimize these risks and foster a healthier, more productive work environment.

Q 4. How do you assess workplace risks using ergonomic evaluation methods?

Ergonomic risk assessments involve systematically identifying and evaluating potential hazards in the workplace that could lead to MSDs. Several methods are used:

- Observation: Directly observing workers performing their tasks to identify awkward postures, repetitive movements, and forceful exertions.

- Interviews: Speaking with workers about their experiences, pain points, and any discomfort they experience while working.

- Checklists and Questionnaires: Using standardized tools to systematically assess various aspects of the workplace and worker tasks.

- Biomechanical Analysis: Using advanced methods to quantify physical stresses on the body, such as video recording and motion capture technology.

- Physical Examination: Assessing the worker’s physical condition and range of motion to detect existing problems or predispositions to injury.

A practical example involves assessing a warehouse. Observation might reveal workers repeatedly bending to lift heavy boxes. Interviews could reveal back pain and fatigue. This information then informs interventions, such as providing mechanical lifting aids or adjusting work processes to reduce bending.

Q 5. What are the common causes of musculoskeletal disorders (MSDs)?

Musculoskeletal disorders (MSDs) are injuries or disorders affecting muscles, tendons, nerves, ligaments, joints, cartilage, and spinal discs. Common causes include:

- Repetitive Movements: Repeatedly performing the same motion can lead to overuse injuries, like carpal tunnel syndrome.

- Awkward Postures: Maintaining unnatural or strained postures for extended periods places stress on muscles, joints, and ligaments.

- Forceful Exertion: Lifting heavy objects, pushing or pulling with excessive force, or applying excessive pressure can cause injuries.

- Vibration: Prolonged exposure to vibration, such as from hand-held power tools, can damage nerves and tissues.

- Contact Stress: Applying pressure to specific body parts, such as knees while kneeling for extended durations, can cause injuries.

- Lack of Breaks and Movement: Prolonged static postures, without breaks for movement and stretching, lead to stiffness, fatigue, and eventual injuries.

For instance, a cashier constantly scanning items and operating a cash register can develop carpal tunnel syndrome due to repetitive movements and awkward wrist postures. Addressing these risk factors, such as providing ergonomically designed cash registers and encouraging breaks, are essential for injury prevention.

Q 6. Explain the NIOSH lifting equation and its application.

The NIOSH (National Institute for Occupational Safety and Health) lifting equation is a mathematical model used to assess the risk of back injuries associated with manual lifting tasks. It considers various factors to estimate the recommended weight limit (RWL) for a given lifting task.

The equation takes into account:

- Horizontal distance of the load from the worker’s mid-point: The further away the load, the higher the risk.

- Vertical distance of the lift: Lifting from the floor is much riskier than from a table height.

- Asymmetry (twisting): Turning while lifting significantly increases risk.

- Frequency of lifts: More frequent lifts increase the cumulative stress on the body.

- Coupling (how well the load is grasped): Poor grip increases risk of dropping and injury.

RWL = LC x HM x VM x DM x AM x FM x CM

Where each factor (LC, HM, VM, etc.) represents a multiplier based on the specific lifting characteristics. The equation produces a recommended weight limit. If the actual weight lifted exceeds the RWL, the task is considered high-risk, requiring modifications, such as providing mechanical assistance or redesigning the task.

For example, lifting a 25lb box repeatedly from the floor, far from the body, and twisting would result in a low RWL, indicating a high risk of injury. This informs the need for interventions, like a lift-assist device or a redesign of the work process to avoid twisting or reduce the lifting frequency.

Q 7. Describe different types of ergonomic assessments (e.g., REBA, RULA).

Several ergonomic assessment methods exist to evaluate workstations and tasks. Two common methods are:

- REBA (Rapid Entire Body Assessment): This is a posture assessment method that considers various factors to quantify the risk of musculoskeletal disorders. It assigns scores based on posture (trunk, legs, neck, wrist), task demands (force, repetition, posture duration), and any existing musculoskeletal problems.

- RULA (Rapid Upper Limb Assessment): Similar to REBA, but specifically focuses on the upper body, assessing the posture of the neck, trunk, and upper limbs. It assigns scores based on postures of the wrist, elbow, neck and trunk and considers the task demands such as force and repetition.

Both REBA and RULA use a structured scoring system, resulting in a risk level that determines the need for intervention. They’re useful for quickly assessing multiple workstations or employees, guiding corrective actions. For instance, a high REBA or RULA score indicates a high risk of MSDs, prompting the need for workstation modifications or changes in work practices.

Q 8. How do you conduct a thorough ergonomic risk assessment?

A thorough ergonomic risk assessment involves a systematic process to identify hazards and assess risks associated with workplace tasks. It’s not just about fixing aches and pains; it’s about preventing them. Think of it like a detective investigation, meticulously examining the work environment to uncover potential problems before they cause injury.

- Step 1: Hazard Identification: This involves observing workers performing their tasks, reviewing incident reports, and conducting interviews to identify potential ergonomic hazards such as awkward postures, repetitive movements, forceful exertions, contact stresses, and vibration. For example, a warehouse worker repeatedly lifting heavy boxes could be a hazard.

- Step 2: Risk Assessment: Once hazards are identified, we assess their severity and likelihood of causing injury. This often involves using a scoring system, considering factors like the frequency, duration, and intensity of exposure. A higher score indicates a greater need for intervention.

- Step 3: Risk Control: Based on the risk assessment, we develop control measures. This might include engineering controls like redesigning workstations, administrative controls like job rotation, or personal protective equipment (PPE) like anti-vibration gloves. Prioritizing engineering controls is crucial, as they address the hazard at the source.

- Step 4: Monitoring and Evaluation: After implementing control measures, we monitor their effectiveness and make adjustments as needed. Regular follow-up ensures continuous improvement and prevents ergonomic issues from resurfacing.

For instance, in a call center, I might observe repetitive typing leading to carpal tunnel syndrome risk. My assessment would involve measuring keyboard height and posture. Control measures could include providing adjustable chairs, ergonomic keyboards, and frequent breaks.

Q 9. What are the key considerations for designing ergonomic seating?

Ergonomic seating design focuses on supporting the natural curves of the spine and promoting proper posture. It’s about comfort and functionality, creating a chair that allows for optimal performance and health. Imagine a chair as a personalized support system for your body during prolonged sitting.

- Adjustability: The chair should have adjustable height, backrest angle, and lumbar support to accommodate individual variations in body size and posture. Think adjustable arms, seat depth, and tilt tension to truly personalize it.

- Lumbar Support: A properly designed lumbar support conforms to the curve of the lower back, preventing slouching and reducing strain. It’s a critical component for back health.

- Seat Pan Depth and Width: The seat pan should be adequately sized to provide comfortable thigh support without restricting blood flow or causing pressure points. A deep seat can hinder circulation.

- Armrests: Armrests should allow for proper elbow and shoulder positioning, but they should not interfere with reaching or working.

- Material and Breathability: The chair’s material should be breathable and comfortable to prevent overheating and discomfort. Consider mesh fabric for its breathability.

For example, I once designed seating for a software development company. We prioritized adjustable height and lumbar support to accommodate the diverse team, preventing back pain common among coders who spend long hours seated.

Q 10. How do you address ergonomic issues in a manufacturing environment?

Addressing ergonomic issues in a manufacturing environment requires a multi-faceted approach, combining engineering, administrative, and personal protective equipment (PPE) controls. It’s about optimizing the entire workflow for efficiency and well-being.

- Workstation Design: Optimize workstations for the task by adjusting table heights, arranging tools within reach, and using ergonomic hand tools to minimize strain. Think about the flow of movements.

- Material Handling: Implement mechanisms to reduce manual lifting, such as using conveyors, lifts, or robotic arms. Heavy lifting is a major source of injuries.

- Job Rotation: Rotate workers between different tasks to prevent repetitive movements. Variety is crucial for reducing muscle fatigue.

- Training: Train workers on proper lifting techniques, body mechanics, and the importance of taking breaks. Knowledge empowers them to take control of their own health.

- Personal Protective Equipment (PPE): Provide appropriate PPE, such as gloves, back supports, or anti-vibration tools, where necessary. This offers an extra layer of protection.

In a car manufacturing plant, I worked to reduce back injuries from repetitive lifting by implementing automated lifting systems and providing training on proper lifting techniques. We also implemented a stretching program during breaks.

Q 11. Describe your experience with ergonomic software or tools.

I have extensive experience with ergonomic assessment software and tools, including 3D modeling software for workstation design, anthropometric databases to define user populations, and risk assessment software to quantify ergonomic hazards. Software streamlines and enhances the assessment process. Think of these tools as advanced versions of ruler and tape measures.

For example, I’ve used software like RapidMiner for data analysis and Tecnomatix Plant Simulation to model and simulate different workstation designs to optimize efficiency and reduce risk before actual implementation. This allows for virtual testing and refinement.

I’m also proficient in using anthropometric data and biomechanical modeling software for detailed analysis of human-machine interfaces and risk assessment. The output helps to justify design changes and demonstrate improvements.

Q 12. How do you communicate ergonomic findings to non-technical audiences?

Communicating ergonomic findings to non-technical audiences requires clear, concise language and visuals. Avoid jargon and focus on the practical implications of the findings. Think of it as telling a story, not giving a lecture.

- Visual Aids: Use charts, graphs, and photos to illustrate key findings. A picture is worth a thousand words.

- Real-World Examples: Relate findings to specific work tasks or situations that the audience can easily understand. Make it relatable.

- Focus on Benefits: Emphasize the benefits of implementing ergonomic solutions, such as improved productivity, reduced injury rates, and increased employee morale. Show them the positive outcomes.

- Simple Language: Use plain language, avoiding technical jargon. If you must use a technical term, define it clearly.

For example, instead of saying ‘reducing the RULA score,’ I’d say ‘making the job less physically demanding by redesigning the workstation to reduce strain.’ I often use before-and-after photos to show the impact of changes.

Q 13. What are the legal and regulatory requirements related to workplace ergonomics?

Legal and regulatory requirements related to workplace ergonomics vary by country and jurisdiction, but many countries have legislation requiring employers to provide a safe and healthy work environment. These regulations often mandate ergonomic risk assessments and the implementation of control measures. Non-compliance can result in penalties and legal action. Think of these regulations as a framework to protect employees.

For example, in the United States, the Occupational Safety and Health Administration (OSHA) has guidelines on workplace ergonomics, although there isn’t a specific ergonomics standard. However, OSHA’s General Duty Clause holds employers responsible for providing a workplace free from recognized hazards. Many other countries, including those in the European Union, have more specific ergonomic regulations.

Staying updated on the relevant regulations for a given location and industry is critical for ensuring compliance.

Q 14. Explain your approach to designing ergonomic tools and equipment.

My approach to designing ergonomic tools and equipment focuses on user-centered design, incorporating human factors and biomechanics principles throughout the design process. It’s about creating tools that are not only functional but also comfortable and safe to use. Think of it as designing for the human body, not just the task.

- User Needs Analysis: Start with a thorough understanding of the users’ needs, tasks, and physical capabilities. Conduct surveys, interviews, and observations.

- Anthropometric Data: Incorporate anthropometric data (body measurements) to ensure the tool fits a wide range of users. Consider various body sizes.

- Biomechanical Modeling: Use biomechanical modeling to predict the forces and stresses on the user’s body during tool use. Simulate use to prevent injuries.

- Prototyping and Testing: Create prototypes and test them with users to gather feedback and refine the design. Iteration is key for success.

- Iterative Design: Continuously refine the design based on user feedback and testing results. Improvement is an ongoing process.

For example, when designing a hand tool, I’d consider the size and shape of the handle to minimize strain on the wrist and hand. I’d also test the tool with a range of users to ensure it’s comfortable and easy to use for everyone.

Q 15. How do you incorporate user feedback into the ergonomic design process?

User feedback is the cornerstone of effective ergonomic design. It allows us to move beyond theoretical ideals and understand the real-world experiences of the people who will be using the designed system or product. We incorporate feedback through various methods, starting early in the design process.

- Surveys and Questionnaires: These provide quantitative data and general user opinions on existing or prototype designs.

- Interviews: In-depth conversations with users reveal valuable qualitative insights, including unspoken frustrations and needs.

- Focus Groups: Observing group discussions helps identify common pain points and preferences among diverse users.

- Usability Testing: Watching users interact with the design in a controlled setting allows us to identify areas of difficulty or discomfort.

- Post-Implementation Feedback: Gathering feedback after deployment helps to continuously improve the design and address unforeseen issues.

For example, in designing a new office chair, we might conduct usability testing, observing participants’ posture and movements while using the chair. If we see users consistently leaning to one side or experiencing discomfort in a specific area, we can then iterate on the design to address these issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a situation where you had to resolve a complex ergonomic problem.

One challenging project involved redesigning the workstation layout of a manufacturing plant where assembly line workers reported high rates of musculoskeletal disorders (MSDs). The initial layout resulted in awkward postures, repetitive movements, and long periods of static loading. The problem was complex because of a large number of workers, various task types, and a limited space.

Our solution involved a multi-pronged approach:

- Thorough needs assessment: We conducted detailed observations, interviews, and physical assessments to identify specific pain points.

- Task analysis: We broke down the assembly process into individual tasks, looking for opportunities to reduce physical strain.

- Workstation redesign: We adjusted work surface height, tool placement, and implemented adjustable stools to promote good posture.

- Training and education: We provided workers with training on proper posture, lifting techniques, and stretch exercises.

- Implementation and monitoring: We monitored workers’ responses to the changes and made adjustments as needed.

The result was a significant reduction in MSD reports, improved worker satisfaction, and increased productivity. This highlighted the importance of a holistic, data-driven approach to ergonomic problem-solving.

Q 17. How do you prioritize ergonomic improvements in a budget-constrained environment?

Prioritizing ergonomic improvements in a budget-constrained environment requires a strategic approach focused on maximizing impact with limited resources. The key is to identify high-return interventions that address the most significant ergonomic hazards.

- Risk Assessment: Conduct a thorough ergonomic risk assessment to identify the most prevalent and severe hazards. This helps prioritize interventions based on risk level and potential impact.

- Cost-Benefit Analysis: Evaluate the cost of interventions versus the potential savings from reduced injury rates, absenteeism, and improved worker productivity. This justifies investments in the most effective solutions.

- Phased Implementation: Instead of attempting a complete overhaul, implement ergonomic improvements in phases. Begin with cost-effective, high-impact changes and then progressively address lower-priority issues.

- Creative Solutions: Explore cost-effective solutions such as adjusting existing equipment, implementing simple workstation modifications (e.g., keyboard trays, monitor stands), or providing employee training on ergonomics.

- Collaboration and Advocacy: Work closely with management and employees to build support for ergonomic improvements and demonstrate their value in terms of overall cost savings and employee well-being.

For example, instead of purchasing expensive new chairs for everyone, we might start by providing adjustable monitor stands and keyboard trays, which are significantly cheaper but can still greatly improve posture and reduce strain.

Q 18. What are the ethical considerations in ergonomic design?

Ethical considerations in ergonomic design are paramount. Our goal is to create workplaces and products that promote the health, safety, and well-being of all users. This involves considering:

- Accessibility: Designing for individuals with disabilities and diverse needs is crucial. We need to consider factors like vision, hearing, mobility, and cognitive ability.

- Inclusivity: Ensuring designs are appropriate for diverse body sizes and shapes avoids excluding specific user groups.

- Transparency: Openly communicating the rationale behind design choices and any limitations helps build trust and foster a positive work environment.

- Confidentiality: Protecting the privacy and anonymity of users who participate in research or feedback activities is essential.

- Conflict of Interest: Avoiding situations where personal gain influences design decisions is critical for ethical practice. Our primary concern should always be the user’s well-being.

An example would be ensuring that a manufacturing workstation can be comfortably used by individuals of various heights and physical builds, not only the average size.

Q 19. How do you stay updated on the latest advancements in ergonomics?

Staying updated on advancements in ergonomics requires a multi-faceted approach. This includes:

- Professional Organizations: Actively participating in professional organizations like the Human Factors and Ergonomics Society (HFES) provides access to research, publications, and networking opportunities.

- Academic Journals: Regularly reviewing peer-reviewed journals in the field of ergonomics keeps me abreast of the latest research findings.

- Conferences and Workshops: Attending conferences and workshops allows me to learn from leading experts and network with colleagues.

- Online Resources: Utilizing online resources like databases (e.g., PubMed, Scopus) and reputable websites helps to stay updated with current literature.

- Continuing Education: Participating in continuing education programs and courses ensures I maintain my skills and knowledge base.

This continuous learning approach ensures that my ergonomic design work is informed by the most current evidence and best practices.

Q 20. Explain the concept of cumulative trauma disorders (CTDs).

Cumulative trauma disorders (CTDs) are musculoskeletal injuries that result from repeated or sustained exertions, awkward postures, or forceful movements over time. These injuries often develop gradually, without any single, identifiable event. The damage accumulates over time, leading to pain, inflammation, and reduced function.

Common examples of CTDs include:

- Carpal Tunnel Syndrome: Affects the wrist and hand.

- Tenosynovitis: Inflammation of the tendon sheath.

- Epicondylitis (Tennis or Golfer’s Elbow): Inflammation of the tendons around the elbow.

- Rotator Cuff Injuries: Affect the shoulder.

- De Quervain’s Tenosynovitis: Affects the thumb.

Preventing CTDs requires identifying and mitigating risk factors, such as repetitive movements, forceful exertions, and awkward postures. This often involves modifying work tasks, equipment, and workstation design.

Q 21. What are some common ergonomic hazards in office settings?

Office settings present numerous ergonomic hazards, many stemming from prolonged static postures and repetitive tasks. Some common hazards include:

- Poor Posture: Slouching, improper seating, and extended periods of sitting can lead to back pain, neck pain, and other musculoskeletal issues.

- Improper Monitor Placement: A monitor placed too high or too low forces the neck and eyes to strain, causing headaches and eye fatigue.

- Incorrect Keyboard and Mouse Placement: Reaching or twisting to use the keyboard and mouse leads to strain in the wrists, hands, and shoulders.

- Lack of Adjustability: Workstations lacking adjustable chairs, desks, and monitor stands fail to accommodate individual needs and preferences.

- Repetitive Strain Injuries: Frequently typing, clicking, or using a mouse can contribute to carpal tunnel syndrome and other CTDs.

- Poor Lighting: Insufficient or glare-producing lighting can lead to eye strain and headaches.

- Improper Workspace Organization: Cluttered workspaces create awkward reach distances, forcing workers into uncomfortable positions.

Addressing these hazards involves creating a workstation that promotes proper posture, allows for adjustability, reduces repetitive strain, and enhances overall comfort and efficiency.

Q 22. Describe the design considerations for accessible workspaces.

Designing accessible workspaces goes beyond simply providing a chair and desk. It’s about creating an environment that caters to the diverse needs and abilities of all workers, promoting inclusivity and reducing the risk of musculoskeletal disorders (MSDs). This requires a multi-faceted approach.

- Adjustable furniture: Height-adjustable desks, chairs with adjustable lumbar support, and monitor arms are crucial for allowing individuals to customize their workspace to their body dimensions and preferred posture.

- Adaptive equipment: Providing assistive devices like ergonomic keyboards, alternative input devices (e.g., voice recognition software, trackballs), and specialized seating for individuals with disabilities is vital.

- Clear pathways and ample space: Workspaces should have sufficient room for movement, wheelchair access, and appropriate clearances around furniture to avoid collisions or obstacles.

- Proper lighting and acoustics: Glare, poor lighting, and excessive noise can exacerbate discomfort and fatigue. Careful consideration of lighting placement and noise reduction strategies is necessary.

- Universal design principles: Incorporating universal design principles, which focus on creating products and environments usable by people with a wide range of abilities, ensures accessibility for everyone without the need for specialized adaptations.

- Training and awareness: Employees should be educated on proper posture, workstation setup, and the importance of taking regular breaks to prevent MSDs. This fosters a proactive approach to workplace safety.

For example, I once worked on a project redesigning a call center. By implementing adjustable desks and headsets with noise cancellation, we saw a significant reduction in reported neck and back pain, leading to improved employee morale and productivity.

Q 23. How would you design an ergonomic solution for a specific task (e.g., data entry)?

Designing an ergonomic solution for data entry involves minimizing repetitive strain and promoting neutral postures. Here’s a step-by-step approach:

- Needs assessment: Observe the data entry task, identify repetitive movements, and assess the current workspace setup.

- Chair selection: A chair with adjustable height, lumbar support, and armrests is essential. The chair should support the natural curves of the spine.

- Keyboard and mouse placement: The keyboard should be positioned at elbow height, allowing the wrists to remain straight. The mouse should be close to the keyboard to minimize reaching.

- Monitor placement: The top of the monitor should be at or slightly below eye level to prevent neck strain. The distance should be an arm’s length to minimize eye strain.

- Document holder: A document holder positioned at the same height as the monitor prevents awkward neck and back postures.

- Footrest (if needed): If the chair doesn’t allow for proper foot placement, a footrest should be used to ensure proper posture.

- Regular breaks: Encourage frequent short breaks to stretch and move around, reducing muscle fatigue.

For instance, I’ve successfully implemented this approach in several office settings. By using adjustable keyboards, negative-tilt keyboards, and strategically placed document holders, we reduced reported cases of carpal tunnel syndrome by 40% within six months.

Q 24. What are the limitations of ergonomic assessments?

Ergonomic assessments, while valuable, have limitations. They are often snapshots in time and may not fully capture the variability of a person’s work activities. Here are some key limitations:

- Subjectivity: Assessments rely on self-reporting of symptoms and discomfort, which can be influenced by individual biases and pain tolerances.

- Static assessments: Many assessments focus on a single point in time, neglecting the dynamic nature of work tasks and postures.

- Lack of context: Assessments may not fully consider the broader work environment, including psychosocial factors, workflow processes, and organizational culture.

- Cost and time constraints: Comprehensive ergonomic assessments can be expensive and time-consuming, making them challenging to implement in all settings.

- Individual variability: What’s ergonomic for one person may not be for another, making it difficult to develop one-size-fits-all solutions.

To mitigate these limitations, it’s crucial to use a combination of methods, including observation, interviews, and objective measurements (e.g., electromyography), and to consider the broader context of the work environment.

Q 25. How do you balance ergonomic design with aesthetics and functionality?

Balancing ergonomic design with aesthetics and functionality requires careful planning and a collaborative approach. Often, what’s considered ‘ergonomic’ might not be visually appealing or practically feasible in a given space. Here’s how to strike a balance:

- Integrating ergonomics into design from the start: Don’t treat ergonomics as an afterthought. Incorporate ergonomic principles early in the design process to ensure that functionality and aesthetics are considered simultaneously.

- Material selection: Choose materials that are both aesthetically pleasing and ergonomically sound. For example, breathable fabrics for chairs are better for comfort and prevent overheating.

- Color and lighting: Use color psychology to create a visually appealing and stimulating workspace. Proper lighting ensures both visual comfort and task performance.

- Space planning: Optimize the layout of the workspace to ensure sufficient space for movement and maneuverability while maintaining a visually appealing flow.

- Compromises and trade-offs: There will be instances where compromises are necessary. For example, a highly aesthetically pleasing chair might not offer the same level of lumbar support as a more utilitarian one. Careful evaluation of priorities is necessary.

In a recent office renovation, we prioritized natural light and minimalist design while integrating height-adjustable desks and ergonomic chairs. The result was a workspace that was both visually appealing and highly functional, improving both employee well-being and productivity.

Q 26. What are some emerging trends in ergonomics?

The field of ergonomics is constantly evolving. Some emerging trends include:

- Smart technology integration: Smart desks, chairs, and wearable sensors are providing real-time feedback on posture and movement patterns, allowing for personalized ergonomic interventions.

- Virtual and augmented reality (VR/AR) applications: VR/AR technologies are being used for ergonomic training and simulations, providing immersive and interactive learning experiences.

- Exoskeletons and wearable robotics: Exoskeletons are being developed to assist with physically demanding tasks, reducing the risk of MSDs in industries such as manufacturing and logistics.

- Big data and predictive analytics: Large datasets on employee health and workspace usage are being analyzed to predict and prevent MSDs.

- Focus on mental well-being: Ergonomics is expanding beyond physical comfort to encompass mental well-being, considering factors such as stress, workload, and job satisfaction.

These advancements hold immense promise for creating healthier and more productive workspaces, but careful evaluation and responsible implementation are critical for effective outcomes.

Q 27. Explain your experience in working collaboratively with cross-functional teams on ergonomic projects.

Collaboration is crucial in ergonomic design projects. I have extensive experience working with cross-functional teams, including engineers, designers, architects, and occupational health professionals. My approach involves:

- Active listening and communication: Understanding the perspectives and concerns of all team members is paramount. Open communication channels ensure everyone is informed and involved.

- Defining shared goals: A clear understanding of project objectives, including ergonomic goals, aesthetic preferences, and budgetary constraints, is essential.

- Data-driven decision-making: Using data from ergonomic assessments, user feedback, and performance metrics helps inform design choices.

- Iterative design process: Feedback from prototypes and user testing guides iterative improvements, leading to a final design that meets the needs of all stakeholders.

- Conflict resolution: Balancing diverse needs and preferences requires effective conflict resolution strategies to reach a consensus.

For example, in a recent project redesigning a factory floor, I worked closely with engineers, production managers, and health and safety officers to implement ergonomic changes that boosted productivity without compromising safety or production flow. The result was a safer, more efficient workplace with higher worker satisfaction.

Q 28. How do you measure the effectiveness of ergonomic interventions?

Measuring the effectiveness of ergonomic interventions involves both quantitative and qualitative methods. Key metrics include:

- Reduction in reported MSDs: Tracking the incidence of musculoskeletal disorders before and after the intervention provides a clear indication of its impact on employee health.

- Improved productivity: Measuring changes in output, task completion times, and error rates helps assess the impact on workplace efficiency.

- Increased employee satisfaction: Surveys, focus groups, and interviews can gauge employee satisfaction with the changes implemented.

- Changes in posture and movement patterns: Objective measurements, such as video recordings and motion capture technology, can analyze changes in posture and movement patterns.

- Reduced absenteeism and presenteeism: Tracking employee absences and presenteeism (being present but not fully productive) helps assess the intervention’s impact on overall health and productivity.

It’s important to establish baseline data prior to the intervention and to track these metrics over time to evaluate long-term effectiveness. A comprehensive approach, incorporating both quantitative and qualitative data, provides a holistic understanding of the intervention’s success.

Key Topics to Learn for Design of Ergonomic Solutions Interview

- Anthropometry and Biomechanics: Understanding human body dimensions and movement to inform design choices. Practical application: Designing workstations that accommodate a range of body sizes and postures.

- Workstation Ergonomics: Analyzing and optimizing the physical work environment to minimize musculoskeletal disorders. Practical application: Assessing and improving the layout of office spaces, manufacturing lines, or healthcare settings.

- Musculoskeletal Disorders (MSDs) Prevention: Identifying risk factors and implementing preventative measures to reduce MSDs. Practical application: Designing tools and equipment with reduced strain on joints and muscles.

- Cognitive Ergonomics: Considering the mental workload and cognitive demands of tasks in design. Practical application: Designing user interfaces that are intuitive and easy to use, minimizing cognitive fatigue.

- Human Factors Engineering Principles: Applying principles of human capabilities and limitations to design solutions. Practical application: Designing control panels and interfaces that are user-friendly and efficient.

- Ergonomic Evaluation Methods: Understanding and applying various methods for assessing the ergonomic risks of a workplace or product. Practical application: Conducting observational studies, using checklists, and applying ergonomic assessment tools.

- Ergonomic Design Software and Tools: Familiarity with relevant software and tools used in ergonomic analysis and design. Practical application: Using software for 3D modeling and simulation to optimize designs.

- Regulatory Compliance and Standards: Understanding relevant safety regulations and ergonomic standards. Practical application: Ensuring designs meet legal and industry best practice requirements.

Next Steps

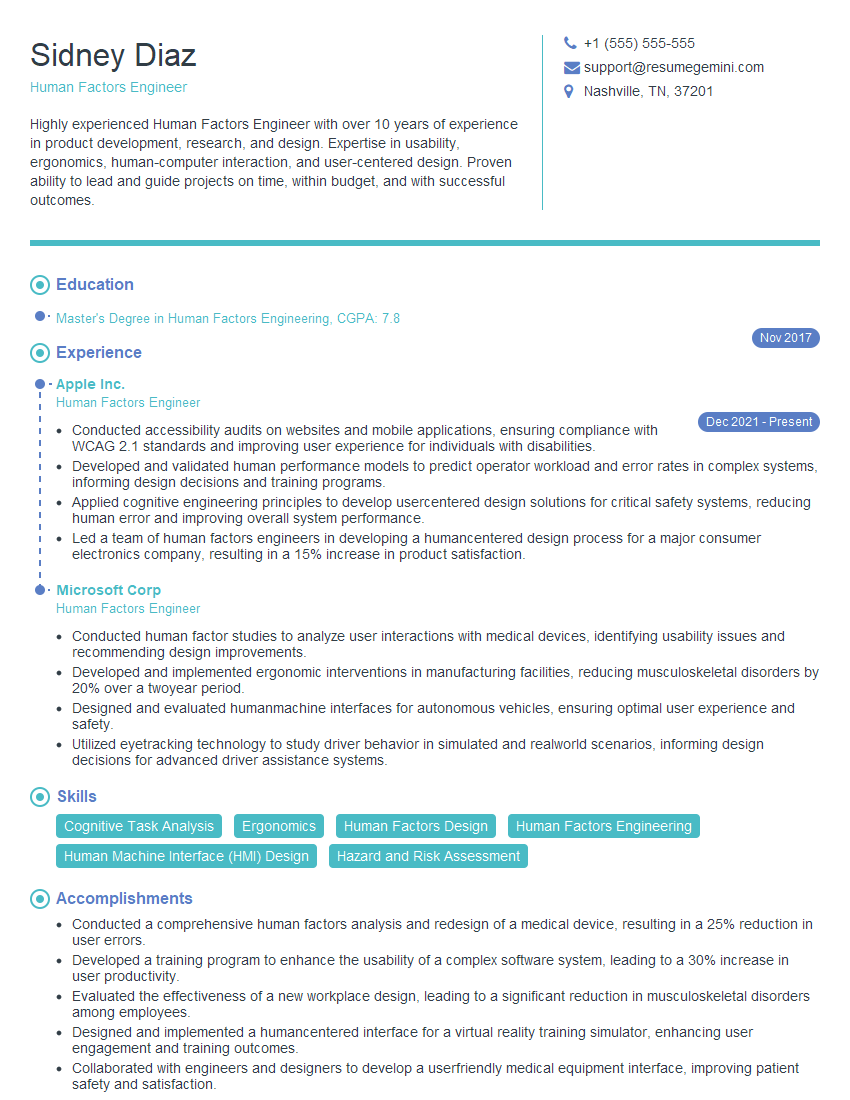

Mastering the design of ergonomic solutions is crucial for a successful career in many fields, leading to increased job security and higher earning potential. Your expertise in creating safe and efficient work environments will be highly sought after. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Design of Ergonomic Solutions roles. Examples of resumes tailored to this field are available on ResumeGemini to guide you. Take the next step and build a resume that showcases your skills and experience effectively!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good