Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Develop and Implement Ergonomics Programs interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Develop and Implement Ergonomics Programs Interview

Q 1. Describe your experience in conducting ergonomic assessments.

Ergonomic assessments are the cornerstone of any successful ergonomics program. My experience encompasses a wide range of assessment methods, tailored to the specific needs of the workplace. This includes conducting both qualitative and quantitative assessments. Qualitative assessments involve observing workers, interviewing them about their tasks and any discomfort, and reviewing job descriptions. Quantitative assessments utilize tools like Rapid Upper Limb Assessment (RULA) and Rapid Entire Body Assessment (REBA) to objectively measure postures and movements. For example, in a recent assessment of a manufacturing plant, I used RULA to score the postures of assembly line workers, identifying high-risk tasks involving repetitive reaching and awkward twisting. This led to recommendations for workstation adjustments and task redesign. I also utilized video recording and time-motion studies in another project involving nurses to quantify the repetitive nature of their movements. In each case, the assessment approach was chosen based on the specific hazard being investigated and the resources available.

Q 2. Explain the different types of ergonomic hazards.

Ergonomic hazards are anything in the work environment that can lead to musculoskeletal disorders (MSDs) or other work-related injuries. They can be broadly categorized into:

- Physical Hazards: These include awkward postures (e.g., prolonged bending, twisting, reaching), repetitive movements, forceful exertions, vibration, and contact stress (e.g., pressure points from tools). Think of a cashier constantly reaching across a counter, a construction worker using a jackhammer, or a nurse repeatedly lifting patients.

- Psychosocial Hazards: These are less tangible but equally important. They involve factors like high work demands, low job control, lack of support, and workplace violence. For example, a call center agent dealing with constant pressure to meet targets while lacking autonomy in their work might develop stress-related MSDs.

- Environmental Hazards: This includes factors such as extreme temperatures, poor lighting, and inadequate ventilation which can contribute to fatigue and increase the risk of injury. A poorly lit warehouse might lead to strained eyes and falls.

It’s crucial to remember that these hazards often interact. For instance, repetitive movements combined with forceful exertions and awkward postures create a significantly higher risk of injury than any one factor alone.

Q 3. How do you identify ergonomic risk factors in a workplace?

Identifying ergonomic risk factors involves a systematic approach. I typically begin with a thorough walkthrough of the workplace, observing workers performing their tasks. This observation is supplemented by interviews with workers to understand their experiences, including any pain, discomfort, or fatigue. I also review job descriptions, safety data sheets, incident reports, and medical records. Tools like checklists and questionnaires can help standardize the process and ensure consistency. For instance, a checklist can be used to evaluate workstation design, including chair adjustability, monitor placement, and keyboard positioning. Analyzing existing injury data reveals trends and pinpoints high-risk areas. For example, if a high number of back injuries occur amongst warehouse workers, that’s a strong indicator for investigating lifting techniques and load handling practices. A combination of these methods provides a comprehensive understanding of ergonomic risks.

Q 4. What are the key components of a successful ergonomics program?

A successful ergonomics program is more than just addressing individual problems; it’s a holistic approach. Key components include:

- Management Commitment: Leadership must support the program through resource allocation and clear communication.

- Employee Involvement: Workers should be actively involved in identifying hazards and implementing solutions. Their insights are invaluable.

- Hazard Identification and Risk Assessment: This forms the basis for prioritizing interventions.

- Hazard Control: Implementing engineering controls (e.g., workstation modifications), administrative controls (e.g., job rotation, work-rest schedules), and personal protective equipment (PPE) as needed.

- Training and Education: Workers need to understand proper lifting techniques, workstation adjustments, and the importance of reporting symptoms.

- Monitoring and Evaluation: Regular assessments and feedback loops ensure the program’s effectiveness. This includes tracking injury rates and worker feedback.

Consider it like building a house – you need a solid foundation (management commitment), strong walls (employee involvement), and a sturdy roof (monitoring and evaluation) to create a safe and productive environment.

Q 5. Describe your experience developing and implementing an ergonomics program.

I have extensive experience developing and implementing ergonomics programs across various industries. One notable project involved a call center experiencing high rates of musculoskeletal complaints. We started by conducting thorough ergonomic assessments using questionnaires, observations, and workstation measurements. This revealed that prolonged sitting, repetitive typing, and awkward postures were major contributors. Our implemented program included workstation redesign (adjustable chairs, footrests, keyboard trays), training on proper posture and stretching techniques, and regular microbreaks. We also introduced alternative work arrangements, such as stand-up desks, based on the employees’ preferences. The program was tracked through injury reports and employee feedback surveys. The outcome was a significant reduction in reported musculoskeletal pain and improved worker satisfaction.

Q 6. How do you prioritize ergonomic improvements based on risk assessment?

Prioritizing ergonomic improvements is crucial, especially when resources are limited. I typically use a risk matrix that considers both the likelihood and severity of potential injuries. This involves assigning scores to each identified risk factor based on its probability of occurrence and the potential consequences. For example, a high-likelihood, high-severity risk (such as repetitive lifting of heavy objects) would receive a higher priority than a low-likelihood, low-severity risk (such as occasional awkward reaching). This data-driven approach ensures that resources are focused on addressing the most significant hazards first, maximizing the impact of interventions. A simple color-coded system (red, amber, green) can be visually helpful for communicating risk levels to management and workers.

Q 7. What methods do you use for data collection in ergonomic assessments?

Data collection in ergonomic assessments is multifaceted. I employ various methods depending on the specific situation. These include:

- Direct Observation: Observing workers performing their tasks to identify postures, movements, and environmental factors.

- Interviews: Gathering subjective information from workers about their experiences, including pain, discomfort, and fatigue.

- Questionnaires: Standardizing data collection with structured questionnaires assessing workstation design, work practices, and health status.

- Measurements: Using tools like tape measures, inclinometers, and goniometers to quantify postures, reach distances, and forces.

- Video Recording and Time-Motion Studies: Providing objective records of worker movements and task durations.

- Review of Medical Records and Incident Reports: Identifying trends in injuries and illnesses to highlight areas of concern.

The combination of these methods offers a holistic understanding of the ergonomic risks present in the workplace. Choosing the right combination depends on budget, time constraints, and the complexity of the tasks.

Q 8. How do you analyze ergonomic data to identify solutions?

Analyzing ergonomic data to identify solutions involves a systematic approach. It begins with data collection, which might include observation of workers, questionnaires, interviews, and measurements of workstation parameters like posture, reach, and force exertion. Then, we use this data to pinpoint risk factors contributing to musculoskeletal disorders (MSDs). For example, if we consistently observe workers reaching overhead for extended periods, this suggests a potential risk factor.

Next, we analyze the data using various methods. This can involve simple descriptive statistics (e.g., calculating the average reach distance) or more sophisticated statistical techniques (e.g., regression analysis to determine the relationship between reach distance and the incidence of shoulder pain). The goal is to identify patterns and trends in the data that help us understand the root causes of ergonomic problems.

Finally, we translate these findings into specific, actionable solutions. For instance, if the analysis shows a strong link between overhead reaching and shoulder pain, we might recommend adjusting workstation heights, using assistive devices, or redesigning the work process to minimize overhead reaching. Throughout the process, we use established ergonomic standards and guidelines (e.g., NIOSH lifting equation) to benchmark and validate our findings and proposed solutions.

Q 9. Explain your experience with ergonomic design principles.

My experience with ergonomic design principles is extensive. I’ve applied principles of anthropometry (measurement of human body dimensions) to ensure workstations accommodate the physical variations in workers. This includes designing chairs with adjustable heights and lumbar support, and workstations with adjustable keyboard trays and monitor heights. I’ve also incorporated biomechanics principles, understanding how forces act on the body during work tasks. This informs design decisions regarding tool weight, handle design, and work postures to minimize strain.

Further, I consider the principles of workplace layout and workflow design. Efficient layouts reduce unnecessary movement and strain, while well-designed workflows can minimize repetitive tasks and awkward postures. For example, I once redesigned a packaging line to reduce repetitive bending and twisting, significantly decreasing reported back pain among employees. My focus is always on creating a balanced and adaptable work environment that promotes well-being.

Q 10. What software or tools do you use for ergonomic evaluations?

I utilize a range of software and tools for ergonomic evaluations. These include 3D modeling software (e.g., SolidWorks, AutoCAD) to create virtual models of workstations and assess reach distances, postures, and other key factors. We also use anthropometric software that can simulate worker populations and ensure workstation designs accommodate various body sizes and shapes. Additionally, I employ software for quantitative risk assessments, allowing for objective scoring and prioritization of ergonomic hazards.

Besides software, I use various measurement tools: inclinometers for measuring angles, tape measures for distances, force gauges for measuring grip strength, and electromyography (EMG) to assess muscle activity. These tools are essential for gathering comprehensive data, accurately identifying ergonomic hazards, and validating the effectiveness of implemented solutions.

Q 11. How do you communicate ergonomic findings and recommendations to management?

Communicating ergonomic findings and recommendations effectively is crucial. I approach this by preparing clear, concise reports that summarize the findings, identify priority risks, and propose tailored solutions. These reports are visually appealing, using charts, graphs, and pictures to illustrate key findings and make the data more accessible.

I present these findings during management meetings, using plain language, avoiding jargon, and highlighting the potential costs and benefits of implementation (e.g., reduced worker’s compensation claims, increased productivity). I also actively engage management in discussions, answering their questions, and tailoring recommendations to align with their priorities and budgetary constraints. A cost-benefit analysis is frequently a part of my presentation to emphasize the return on investment of ergonomic improvements. Finally, ongoing communication through follow-up meetings and progress reports ensures management’s continued involvement and commitment.

Q 12. How do you ensure employee participation in an ergonomics program?

Employee participation is essential to the success of any ergonomics program. I foster this participation by involving employees in all stages of the process. This includes conducting interviews and surveys to understand their experiences and perspectives, observing them in their work environments, and using their feedback to identify potential hazards.

I establish a collaborative approach, where employees are not merely passive recipients of ergonomic solutions, but active partners in the improvement process. For instance, I encourage the formation of employee ergonomics committees, allowing them to voice their concerns, participate in problem-solving, and contribute to the selection of ergonomic interventions. This not only increases buy-in and ownership of the program, but also taps into the invaluable knowledge of employees about their work tasks and challenges.

Q 13. Describe your experience with ergonomic training programs.

I have extensive experience in designing and delivering ergonomic training programs. These programs range from short, targeted workshops on specific hazards (e.g., proper lifting techniques) to more comprehensive training modules covering a wide range of ergonomic principles. I tailor my training approaches to the specific needs and knowledge levels of the audience.

My training programs incorporate various methods, including interactive lectures, hands-on exercises, and case studies. I emphasize the practical application of ergonomic principles, providing workers with the knowledge and skills to assess and address ergonomic hazards in their own work environments. For example, one successful program I developed included a ‘mock’ workstation setup exercise where employees identified potential hazards and then worked together to find solutions, creating a fun and practical learning experience. Post-training assessments and follow-up sessions ensure knowledge retention and provide opportunities to address ongoing questions or concerns.

Q 14. How do you measure the effectiveness of an ergonomics program?

Measuring the effectiveness of an ergonomics program requires a multi-faceted approach. It’s not enough to simply implement interventions and assume they’re working. We need to track key metrics to demonstrate the impact of our efforts. This includes measuring the incidence rate of MSDs (e.g., back pain, carpal tunnel syndrome) before and after implementing interventions.

We also track lost-time injuries, worker’s compensation claims, and employee absenteeism rates. Furthermore, we may gather data on productivity measures, such as units produced per hour or task completion times. A reduction in these negative metrics and an increase in productivity metrics would suggest a positive impact of the ergonomics program. Finally, employee surveys and feedback are important to assess worker satisfaction and perceived improvements in their work environment. By combining quantitative data (e.g., injury rates) with qualitative data (e.g., employee feedback), we obtain a holistic understanding of the effectiveness of the ergonomics program and identify areas for continuous improvement.

Q 15. What are the common ergonomic problems associated with computer workstations?

Common ergonomic problems at computer workstations often stem from prolonged static postures and repetitive movements. Think about spending hours hunched over a keyboard, rarely changing position. This can lead to a cascade of issues.

- Musculoskeletal Disorders (MSDs): These are the most prevalent, encompassing conditions like carpal tunnel syndrome (wrist pain and numbness), tendonitis (inflammation of tendons), and neck/back pain (from poor posture).

- Eye Strain: Improper monitor placement (too high, too low, or too far) and inadequate lighting contribute significantly to eye fatigue and headaches.

- Repetitive Strain Injuries (RSIs): Repeated actions like typing or clicking a mouse can inflame muscles, tendons, and nerves in the hands, wrists, arms, and shoulders.

- Poor Posture: Slouching, lack of lumbar support, and improper chair height lead to back pain, neck stiffness, and even rounded shoulders.

For example, I once worked with a graphic designer experiencing severe wrist pain. After an assessment, we discovered her keyboard was positioned too high, forcing her wrists into an unnatural angle. Adjusting the keyboard height and introducing wrist rests dramatically improved her condition.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you address ergonomic issues related to manual material handling?

Addressing ergonomic issues in manual material handling requires a multi-pronged approach focused on reducing the risk of injury from lifting, carrying, pushing, and pulling heavy objects. It’s not just about the weight; factors like posture, frequency, and awkward movements all play a crucial role.

- Job Hazard Analysis (JHA): We begin with a thorough JHA to identify tasks posing the greatest risk. This involves observing workers, analyzing the physical demands of each task, and documenting potential hazards.

- Engineering Controls: These are the preferred method. We aim to eliminate or reduce the risk at the source, for example, using automated lifting devices, conveyors, or redesigning workstations to minimize lifting height and distance.

- Administrative Controls: If engineering controls aren’t feasible, administrative measures come into play. This includes limiting the weight lifted by a single person, implementing team lifting techniques, and providing adequate rest breaks.

- Personal Protective Equipment (PPE): While PPE like back belts might provide some support, it’s crucial to remember that it’s a last resort, not a primary solution. It should be used in conjunction with engineering and administrative controls.

In one project, we redesigned a warehouse layout to optimize workflow and reduce the need for excessive lifting. By implementing a new system with conveyors and lower shelving, we significantly reduced MSDs among workers.

Q 17. Describe your experience with designing ergonomic workstations.

My experience in designing ergonomic workstations spans various industries, from offices to healthcare settings. A well-designed workstation considers the individual’s needs and the specific tasks performed.

The process usually starts with a needs assessment—interviewing the user to understand their work tasks, preferred working styles, and any pre-existing conditions. Then, I assess the physical environment, including available space and lighting. The goal is to create a setup that promotes neutral postures, reduces repetitive strain, and provides comfort.

- Chair Selection: Proper lumbar support, adjustable height, and armrests are essential.

- Monitor Placement: The top of the monitor should be at or slightly below eye level to prevent neck strain.

- Keyboard and Mouse Placement: These should be positioned to allow for neutral wrist postures, minimizing bending or reaching.

- Document Holders: These help maintain a straight posture and reduce neck strain from constantly looking down.

For instance, I recently designed workstations for a call center. By adjusting chair heights, repositioning monitors, and providing footrests, we reduced reported back pain by over 60% within six months.

Q 18. How do you evaluate the effectiveness of ergonomic interventions?

Evaluating the effectiveness of ergonomic interventions requires a combination of quantitative and qualitative data. Simply asking employees if they feel better isn’t enough; we need objective measures.

- Pre- and Post-Intervention Assessments: We compare measures of musculoskeletal discomfort (using standardized questionnaires like the Nordic Musculoskeletal Questionnaire), lost workdays due to injury, and worker productivity before and after implementing changes.

- Biomechanical Assessments: This involves using motion capture or other technologies to objectively measure posture and movement during work tasks.

- Worker Feedback: Collecting feedback through surveys and interviews provides valuable insights into the user experience and identifies any remaining issues.

- Incident Reporting: Tracking the number and type of work-related injuries helps determine whether the interventions have reduced workplace hazards.

For example, when implementing new chairs in an office, we tracked the number of reported back pain cases before and after. We also surveyed employees to assess their satisfaction with the new chairs and overall comfort levels. The decrease in reported cases and positive feedback confirmed the success of our intervention.

Q 19. What are some common ergonomic interventions for reducing musculoskeletal disorders?

Many ergonomic interventions aim to reduce musculoskeletal disorders (MSDs). These interventions often focus on altering the work environment, the work process, or worker behavior.

- Workstation Adjustments: As discussed previously, this involves optimizing chair height, monitor placement, keyboard and mouse positioning, and using document holders.

- Job Rotation: Varying tasks to prevent prolonged static postures and repetitive movements.

- Stretching and Exercise Breaks: Encouraging regular breaks for stretching and light exercises to alleviate muscle tension and improve blood circulation.

- Training Programs: Educating employees about proper lifting techniques, body mechanics, and workplace ergonomics.

- Ergonomic Equipment: Providing equipment like adjustable keyboards, ergonomic mice, and footrests can significantly improve comfort and reduce strain.

In a manufacturing setting, we implemented job rotation to reduce repetitive strain injuries. Workers now switch between different tasks throughout the day, leading to a significant reduction in reported musculoskeletal issues.

Q 20. How do you stay up-to-date on the latest ergonomic research and best practices?

Staying current in ergonomics requires a continuous learning approach. I actively engage in several strategies to stay informed.

- Professional Organizations: Membership in organizations like the Human Factors and Ergonomics Society (HFES) provides access to journals, conferences, and networking opportunities.

- Peer-Reviewed Journals: Regularly reviewing publications like the Applied Ergonomics journal keeps me updated on the latest research findings.

- Conferences and Workshops: Attending conferences and workshops allows me to learn about new technologies and best practices from experts in the field.

- Online Resources: Utilizing reputable online resources like government websites (e.g., OSHA) and university research centers provides valuable information.

I also actively participate in online forums and communities dedicated to ergonomics, exchanging knowledge and insights with other professionals.

Q 21. How do you handle resistance to ergonomic changes from employees or management?

Resistance to ergonomic changes can come from various sources—employees may be resistant to new procedures, while management might be hesitant due to cost considerations. Addressing this requires a thoughtful and collaborative approach.

- Education and Communication: Clearly explaining the benefits of ergonomic improvements, such as reduced injuries, increased productivity, and improved employee morale, is crucial. Presenting data on the cost of not implementing changes (e.g., lost productivity, workers’ compensation claims) can sway management.

- Pilot Programs: Implementing ergonomic changes on a smaller scale before a full rollout allows for testing, feedback collection, and adjustments to address concerns proactively.

- Employee Involvement: Actively involving employees in the process, such as seeking their input and feedback, enhances buy-in and reduces resistance.

- Gradual Implementation: Introducing changes incrementally allows employees time to adapt to new procedures and equipment, minimizing disruption and promoting smoother transitions.

In one case, management initially resisted investing in new chairs, citing cost concerns. By demonstrating a return on investment through reduced lost-time injuries and increased productivity, I secured funding for the ergonomic upgrades.

Q 22. Describe your experience with ergonomic standards and regulations.

My experience encompasses a broad understanding of ergonomic standards and regulations, including OSHA guidelines in the US, ISO standards internationally, and relevant legislation specific to various industries. I’m familiar with regulations concerning workplace hazards like repetitive strain injuries (RSI), musculoskeletal disorders (MSDs), and the proper use of personal protective equipment (PPE). This understanding extends to both the legal requirements and the best practices that go beyond mere compliance. For example, I’ve worked on projects requiring adherence to specific standards for workstation setup, screen placement, and equipment design, ensuring alignment with both national and international guidelines.

I’ve also stayed current with evolving regulations and technological advancements impacting workplace ergonomics. This includes understanding the impact of new technologies on worker health, such as the increase in remote work and the associated challenges with home office setups. This allows me to offer solutions that are not only legally compliant but also proactively prevent injuries and promote a healthy work environment.

Q 23. How do you integrate ergonomics into the design of new processes or equipment?

Integrating ergonomics into new processes and equipment design is crucial for preventing future problems. My approach involves a proactive, participatory design process. This starts with a thorough job hazard analysis identifying potential ergonomic risks early in the development stage. We then use this analysis to inform the design, incorporating principles of anthropometry (measuring human body dimensions), biomechanics (study of human movement), and human factors (understanding human capabilities and limitations).

For example, in designing a new assembly line, we’d consider factors like the height and reach of workstations, tool weight and design, and the frequency and duration of repetitive movements. We’d use ergonomic principles to optimize tool placement, introduce adjustable work surfaces, and incorporate strategies for reducing strain, such as automation where appropriate. Mockups and prototypes are frequently utilized to allow for iterative adjustments based on real-world testing and feedback from simulated users.

Q 24. What is your experience with different ergonomic assessment methods (e.g., RULA, REBA)?

I’m proficient in various ergonomic assessment methods, including RULA (Rapid Upper Limb Assessment) and REBA (Rapid Entire Body Assessment). RULA focuses on the upper body, evaluating postures and movements of the neck, trunk, and arms. REBA expands this to the entire body, considering more factors including leg posture and force exertion. I also utilize other assessment tools tailored to the specific task and environment, such as OWAS (Ovako Working Posture Assessment System) and NIOSH lifting equation. The choice of method depends on the complexity of the job and the level of detail required.

For example, in a manufacturing setting, I might use RULA to quickly screen workstations for potential problems, then follow up with a more detailed REBA assessment if needed. Beyond these structured assessments, I also conduct observational assessments, where I directly observe workers performing their tasks to identify potential ergonomic hazards. This direct observation often leads to valuable insights not captured by standardized questionnaires or checklists.

Q 25. How do you prioritize ergonomic improvements when resources are limited?

Prioritizing ergonomic improvements with limited resources requires a strategic approach. I use a risk-based prioritization system. This involves identifying high-risk tasks, those with a high probability of injury and high severity of potential consequences. We quantify these risks using data from incident reports, injury statistics, and ergonomic assessments. This allows us to focus resources where they will have the greatest impact.

For example, if we find that a particular task leads to frequent back injuries, we’d prioritize implementing improvements to that workstation even if other areas might also benefit from changes. This may involve simpler and cost-effective solutions such as adjusting workstation height or providing better tool support before investing in major equipment upgrades. We also consider the return on investment (ROI) of different interventions, aiming for cost-effective solutions that deliver significant improvements in worker health and safety.

Q 26. Explain your experience with developing ergonomic guidelines for a specific industry.

I developed ergonomic guidelines for the healthcare industry, specifically focusing on reducing musculoskeletal injuries among nurses. This involved a thorough review of existing literature and best practices, combined with on-site assessments of different hospital units. We identified common risk factors such as patient handling, repetitive movements, and prolonged standing. The guidelines included recommendations for proper lifting techniques, the use of assistive devices, workstation design, and training programs.

The guidelines were developed in collaboration with healthcare professionals, including nurses, physical therapists, and occupational health specialists. The feedback loop ensured that the guidelines were practical, feasible, and readily adopted by the workforce. We also included metrics to track compliance and the effectiveness of the guidelines in reducing injuries. The success of this initiative was measured by a noticeable decrease in reported musculoskeletal injuries among nursing staff post-implementation of the guidelines.

Q 27. How do you create a culture of safety and ergonomics within a workplace?

Creating a culture of safety and ergonomics requires a multifaceted approach, going beyond simply implementing rules. It’s about fostering a collaborative environment where employees feel empowered to report concerns and actively participate in improving their workspaces. This starts with leadership commitment—visible support from upper management is essential.

Key elements include comprehensive training programs covering ergonomic principles, safe work practices, and hazard recognition. Regular communication, including newsletters, meetings, and feedback sessions, keeps employees engaged and informed about new initiatives and improvements. Incentivizing participation, recognizing employees who contribute to safety improvements, and creating a blame-free reporting culture where near misses are viewed as learning opportunities are all critical. Encouraging teamwork, establishing ergonomic committees, and offering ergonomic champions within teams can also make a significant contribution to the building of a safe and productive workplace.

Q 28. Describe a situation where you had to troubleshoot an ergonomic problem. What was your solution?

I encountered a situation where a high rate of carpal tunnel syndrome was reported among data entry clerks. Initial assessments using RULA revealed repetitive wrist extension and flexion during typing. The workstations lacked adjustable keyboard trays, and the monitors were positioned poorly.

My solution involved a multi-pronged approach: We first implemented adjustable keyboard trays and footrests to improve posture and reduce strain. Second, we adjusted monitor height and position to maintain a neutral wrist position. Third, we provided training on proper typing techniques, emphasizing breaks and stretches. Finally, we introduced ergonomic mouse designs and encouraged the use of voice recognition software to reduce repetitive strain. After implementing these solutions, we monitored injury rates, demonstrating a significant reduction in reported cases of carpal tunnel syndrome. This success highlighted the effectiveness of a holistic ergonomic approach addressing both the workstation design and employee behavior.

Key Topics to Learn for Develop and Implement Ergonomics Programs Interview

- Needs Assessment & Risk Identification: Understanding how to conduct thorough workplace assessments to identify ergonomic risks and prioritize areas for improvement. This includes utilizing observation techniques, interviews, and data analysis.

- Ergonomic Design Principles: Applying principles of anthropometry, biomechanics, and workplace design to create safer and more efficient workspaces. Practical application involves recommending workstation adjustments, tool modifications, and work process changes.

- Implementation Strategies: Developing and implementing effective ergonomics programs, including training, communication, and ongoing monitoring. This involves creating and delivering training materials and tracking the effectiveness of implemented changes.

- Musculoskeletal Disorders (MSDs) Prevention: Deep understanding of common MSDs, their causes, and preventative measures. This includes knowledge of risk factors and effective interventions.

- Legislation and Compliance: Familiarity with relevant health and safety regulations and standards related to ergonomics. This involves understanding reporting requirements and ensuring compliance.

- Data Analysis and Reporting: Collecting and analyzing data to demonstrate the effectiveness of ergonomic interventions. This involves using metrics to track injury rates and demonstrate ROI.

- Program Evaluation and Improvement: Continuously evaluating the ergonomics program’s effectiveness and making necessary adjustments. This includes using feedback mechanisms and data to refine strategies.

- Communication and Collaboration: Effectively communicating ergonomic principles and recommendations to management, workers, and other stakeholders. This involves building consensus and fostering a safety culture.

Next Steps

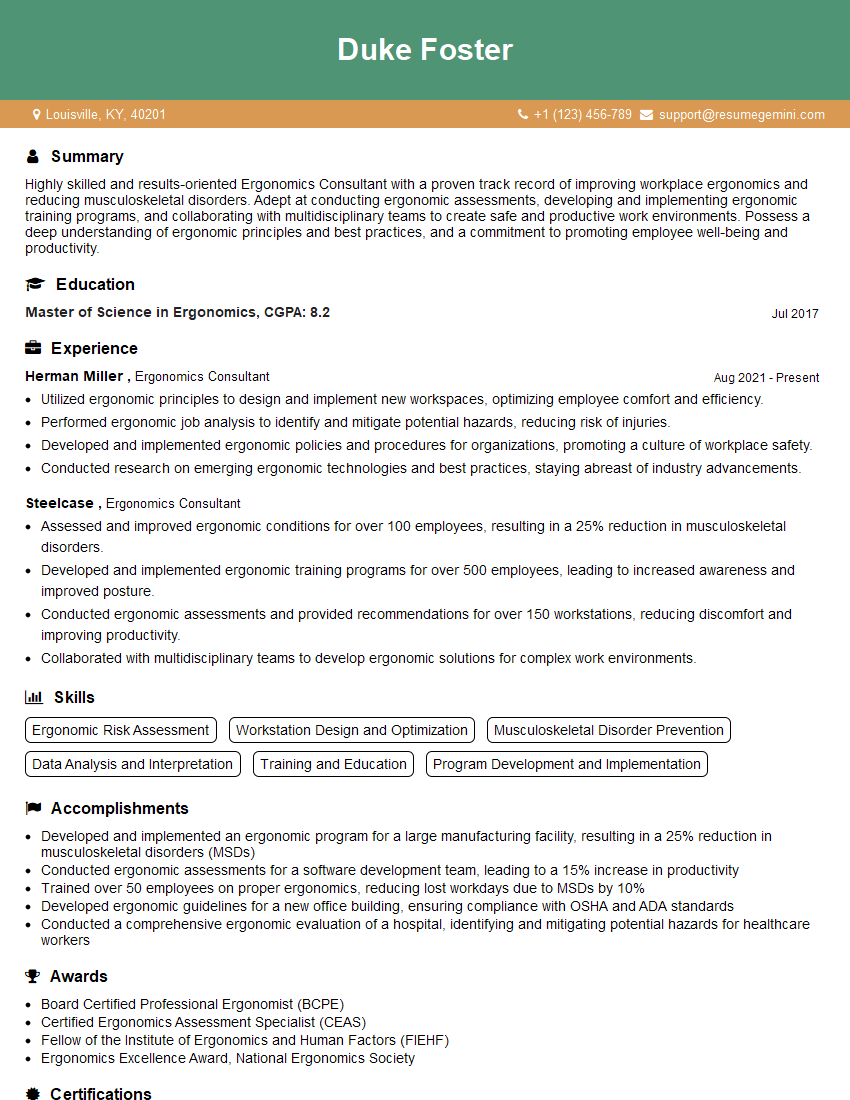

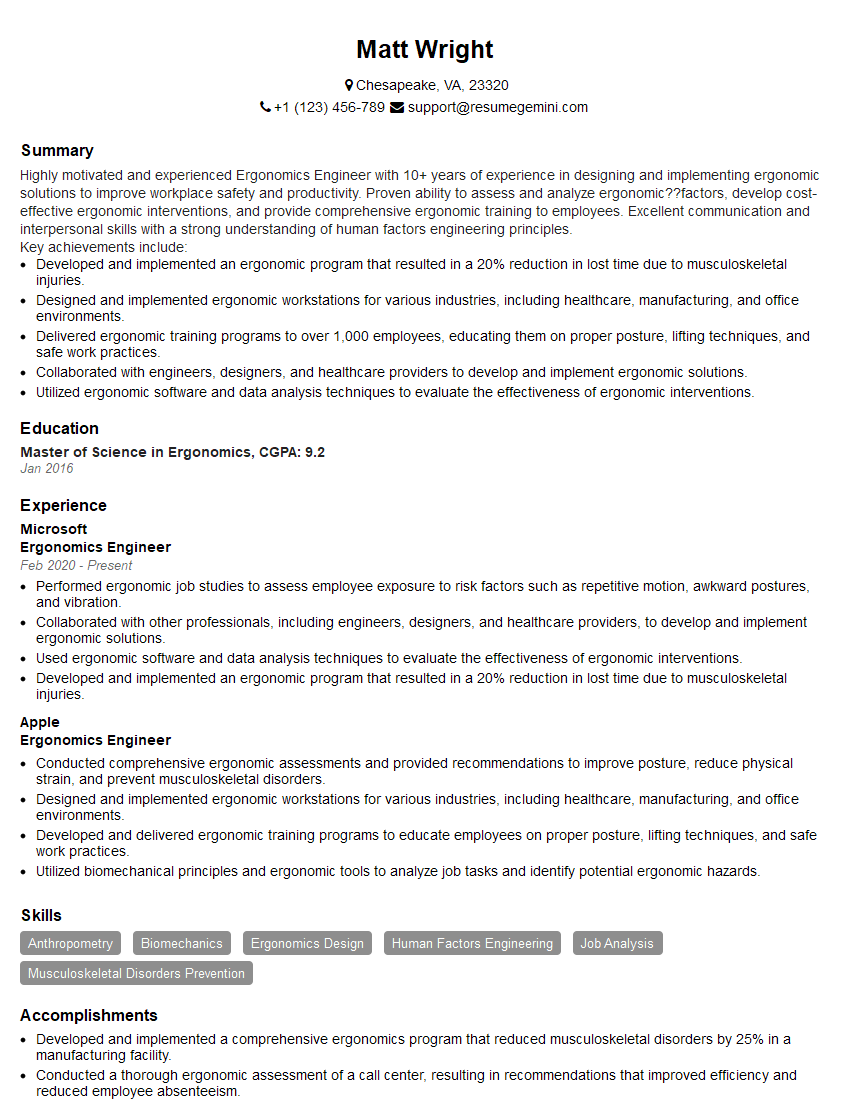

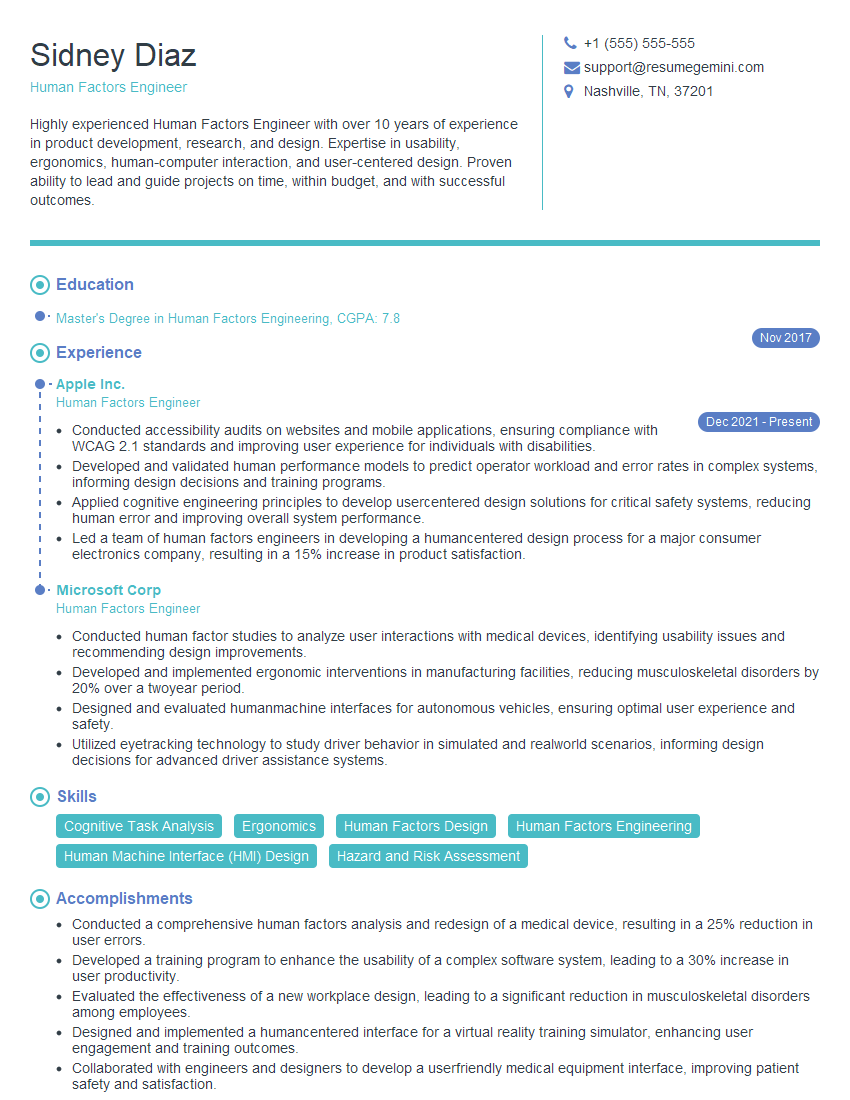

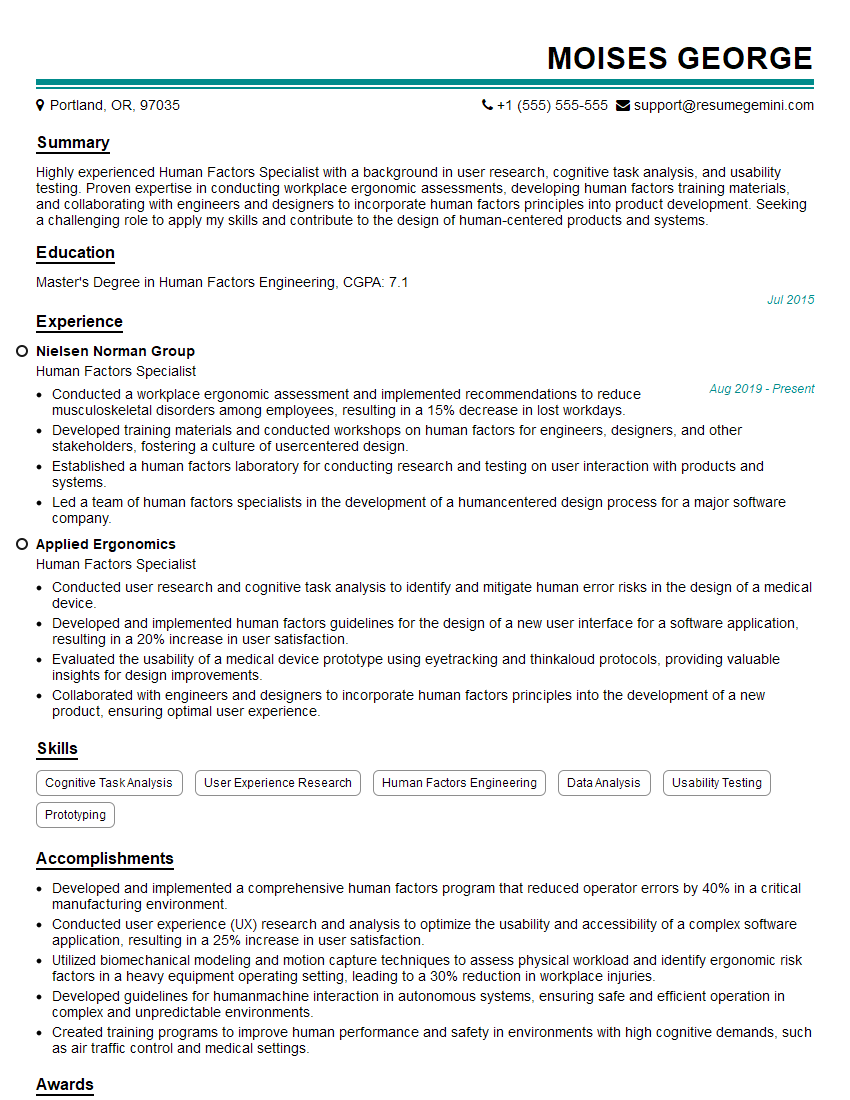

Mastering the development and implementation of ergonomics programs is crucial for a successful career in occupational health and safety. It demonstrates a commitment to employee well-being and a proactive approach to risk management, highly valued by employers. To significantly boost your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that effectively highlights your qualifications. Examples of resumes tailored to Develop and Implement Ergonomics Programs are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good