The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Developing and implementing spray programs interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Developing and implementing spray programs Interview

Q 1. Explain the different types of spray nozzles and their applications.

Spray nozzles are the heart of any spray program, dictating droplet size, distribution, and ultimately, the effectiveness of the application. Different nozzles cater to various needs and target applications.

- Flat Fan Nozzles: These produce a flat, even spray pattern, ideal for row crops and situations requiring uniform coverage over a wide swath. They’re very common in agricultural applications.

- Hollow Cone Nozzles: Creating a donut-shaped spray pattern, these are useful for applying herbicides to foliage, ensuring thorough coverage without excessive waste. The hollow center reduces overlap and waste.

- Full Cone Nozzles: Generating a circular spray pattern, these are suited for spot treatments or applications where a more focused, intense spray is required. You might use these for treating individual trees or localized infestations.

- Air Induction Nozzles: These incorporate air into the spray stream, creating smaller droplets and improving drift reduction. They are excellent for pesticide applications where drift is a major concern.

- Extended Range Nozzles: Designed for high-clearance applications, these nozzles can effectively reach taller plants or crops from a greater distance, reducing the need for multiple passes. These are particularly useful in orchards.

The choice of nozzle depends heavily on factors like target area, spray material, wind conditions, and desired droplet size. For example, using a flat fan nozzle for spot treatments would be inefficient and wasteful, while a full cone nozzle wouldn’t be ideal for wide-acreage spraying.

Q 2. Describe the factors influencing spray droplet size.

Several factors intricately influence spray droplet size, directly impacting application efficacy and environmental impact. Think of it like baking – you need the right ingredients and proportions for the perfect result!

- Nozzle Type and Pressure: Different nozzles generate different droplet sizes. Higher pressure generally results in smaller droplets, but this can also increase drift.

- Fluid Properties: The viscosity (thickness) and surface tension of the spray solution significantly influence droplet formation. Thicker fluids form larger droplets.

- Nozzle Wear and Clogging: Worn or clogged nozzles produce inconsistent droplet sizes, leading to uneven coverage and reduced effectiveness. Regular maintenance is vital!

- Spray Boom Height and Speed: The height of the boom above the target and the speed at which the sprayer is moving affect the spray pattern and droplet size. Too high or too fast can lead to larger droplets and poor coverage.

- Wind Speed and Direction: Wind is a major factor influencing droplet size and drift. High winds can disrupt the spray pattern, leading to uneven coverage and increased environmental impact.

For example, a high wind might cause larger droplets to break up mid-air, resulting in smaller droplets that drift further than intended and potentially cause off-target contamination. Careful consideration of all these factors is essential to optimize droplet size for effective and environmentally responsible spray applications.

Q 3. How do you calibrate a spray boom?

Calibrating a spray boom ensures accurate application of the spray solution, preventing under-application (ineffective treatment) or over-application (waste and potential environmental damage). It’s like adjusting a recipe – you need the right amount of each ingredient for the desired outcome.

- Measure the spray boom width: This is the total width covered by all nozzles on the boom.

- Measure the spray swath: Drive a measured distance, usually 100 feet, and collect the spray from each nozzle in a separate container. This helps to detect any inconsistencies.

- Calculate the area sprayed: Multiply the boom width by the distance traveled (e.g., 20 feet x 100 feet = 2000 square feet).

- Measure the volume sprayed: Add up the volume collected in each container to determine the total volume sprayed over the measured distance.

- Calculate gallons per acre (GPA): Use the following formula:

GPA = (gallons sprayed / area sprayed in acres) * 43560. There are 43,560 square feet in an acre. - Adjust the spray rate: If the GPA is not correct, adjust the pressure or speed of the sprayer to achieve the desired rate.

For example, if you sprayed 2 gallons over 2000 square feet (0.046 acres), your GPA would be: GPA = (2 / 0.046) * 43560 ≈ 189,000 (This is way too high! You’d need to adjust your sprayer to reduce output.)

Q 4. What are the safety precautions for handling pesticides?

Safety is paramount when handling pesticides. These chemicals can be hazardous to human health and the environment if not handled responsibly.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, goggles, respirators (depending on the pesticide), and protective clothing. This is non-negotiable.

- Read and Follow Labels: Carefully read and understand the pesticide label before each application. The label is the law, providing crucial information on safe handling, application rates, and potential hazards.

- Proper Mixing and Application: Mix pesticides in a well-ventilated area, following the instructions on the label precisely. Avoid spraying in windy conditions or when there’s a risk of drift.

- Emergency Preparedness: Have a plan in place for emergencies, including knowing where to find safety data sheets (SDS) and having access to emergency medical services.

- Storage and Disposal: Store pesticides securely in a locked, designated area, away from food, children, and pets. Dispose of empty containers and leftover pesticides responsibly, following local regulations.

- Clean-up: Thoroughly clean equipment after each use, following manufacturer guidelines and local regulations.

A simple example: Never mix pesticides near a water source to avoid contamination. Always wash your hands thoroughly after handling pesticides, before eating, drinking, or smoking.

Q 5. What are the environmental considerations in spray program design?

Environmental considerations are integral to effective spray program design. Our goal is to control pests effectively while minimizing negative impacts on the environment.

- Target Specificity: Select pesticides that specifically target the pest of concern, minimizing harm to non-target organisms like beneficial insects and pollinators. Broad-spectrum pesticides should be used cautiously.

- Drift Reduction: Employ techniques and equipment designed to minimize drift, such as using low-drift nozzles, spraying in calm conditions, and applying appropriate buffer zones around sensitive areas. Drift can contaminate water bodies and non-target areas.

- Water Quality Protection: Avoid spraying near water bodies, and select pesticides that are less likely to contaminate water resources. Consider buffer zones and use proper application techniques to prevent runoff.

- Soil Health: Choose pesticides that minimize soil contamination and disruption of soil microbial communities. Consider the impact of repeated applications on soil health.

- Integrated Pest Management (IPM): Incorporate IPM strategies into the spray program, which involve using pesticides as a last resort. IPM combines multiple approaches such as biological control, cultural practices, and monitoring to manage pest populations.

For example, choosing a pesticide with lower toxicity to bees is crucial for protecting pollinators. Using a nozzle with reduced drift prevents contaminating a nearby river or lake.

Q 6. Explain different spray application methods (e.g., aerial, ground).

Spray application methods vary based on factors like the size of the area, type of crop, and terrain. Choosing the right method is crucial for effective and efficient application.

- Ground Application: This is common for smaller areas and involves using equipment like boom sprayers, backpack sprayers, or hand-held sprayers. It’s easier to control and manage on the ground.

- Aerial Application: Used for larger areas, this method involves applying pesticides from aircraft, such as helicopters or airplanes. It’s more efficient for covering vast areas but requires specialized equipment and expertise.

- High-Clearance Sprayers: These are used in orchards and vineyards, applying spray from a raised platform that avoids damaging the plants. This method offers precision.

- Directed Spraying: This technique targets the specific area needing treatment, minimizing waste and reducing environmental impact. It’s commonly used for weed control in row crops.

For example, a large field of corn would benefit from aerial application due to its speed and efficiency. However, a small vegetable garden would be best treated with a backpack sprayer for precise control.

Q 7. How do you calculate the required spray volume for a given area?

Calculating the required spray volume involves determining the area to be sprayed and the desired application rate (GPA). It’s similar to calculating paint needed for a room – you need to know the surface area and the paint coverage per gallon.

- Measure the area: Determine the area to be sprayed in acres (or convert other units, like square feet, to acres).

- Determine the desired application rate (GPA): This depends on the pesticide label and the specific needs of the application. This is the amount of spray mixture needed per acre.

- Calculate the total spray volume: Multiply the area (in acres) by the desired application rate (GPA). This will give you the total volume of spray solution needed in gallons.

Example: You need to spray 10 acres of land with a pesticide that requires an application rate of 2 GPA. The total volume needed is 10 acres * 2 GPA = 20 gallons.

Accurate calculations are crucial to avoid under-application, leading to ineffective pest control, or over-application, causing unnecessary environmental impact and waste.

Q 8. Describe the process of selecting appropriate pesticides for a specific pest.

Selecting the right pesticide is crucial for effective pest control and minimizing environmental impact. It’s a multi-step process that begins with accurate pest identification. You need to know exactly what pest you’re dealing with before choosing a pesticide. Next, you consider the pest’s life cycle and its vulnerability at different stages. Some pesticides are more effective against larvae, while others work better on adults. Then, you evaluate the target location – the type of crop, the surrounding environment, and potential non-target organisms that could be affected. Finally, you select a pesticide with the appropriate mode of action, considering factors like its toxicity, persistence in the environment, and compatibility with other pesticides or adjuvants. For example, if you identify aphids on your roses, you might choose a contact insecticide that directly kills the aphids upon contact, and one with low toxicity to beneficial insects like ladybugs. Always check the pesticide label carefully for specific instructions and safety precautions.

- Identify the pest: Use visual identification guides, entomologists, or diagnostic labs for confirmation.

- Consider the pest’s life cycle: Apply the pesticide when the pest is most vulnerable.

- Evaluate the environment: Choose a pesticide with minimal impact on beneficial insects, pollinators, and the environment.

- Select the appropriate mode of action: Choose a pesticide that effectively targets the pest without causing harm to other organisms or the environment.

Q 9. How do you ensure accurate spray coverage?

Accurate spray coverage is essential for effective pest control. Think of it like painting a wall – you need even coverage to get the best result. Several factors contribute to achieving this. First, proper nozzle selection is vital. Different nozzles create different spray patterns (e.g., flat fan, cone). Choosing the right nozzle for the target area and crop ensures uniform distribution. Second, correct spray pressure is crucial. Too low, and you get insufficient coverage; too high, and you get drift and waste. Third, appropriate spray volume is key; this ensures you apply the correct pesticide concentration while avoiding runoff. Finally, calibration of the spray equipment is paramount. Regular calibration ensures the correct amount of pesticide is applied per unit area, maximizing efficacy and minimizing environmental impact. We use a variety of techniques to check coverage, including visual inspection, dye tracing, and even specialized equipment to measure droplet size and distribution. A common mistake is not properly calibrating the sprayer before each application, leading to either insufficient coverage or excessive pesticide use.

Q 10. What are the common problems encountered in spray application and their solutions?

Spray application often faces challenges. Clogging of nozzles is a frequent problem, often caused by pesticide formulation or impurities in the water. Regular cleaning and filtration prevent this. Drift, where the spray goes beyond the intended target area, is a major concern, especially with windy conditions. Using lower drift nozzles, applying spray during calm conditions, and choosing formulations that minimize drift are crucial solutions. Uneven coverage can result from improper nozzle selection, incorrect pressure, or faulty equipment. Careful calibration and maintenance are essential. Inaccurate application rates, caused by calibration errors, lead to either ineffective pest control or pesticide overuse. Regular calibration is therefore essential. Finally, incorrect mixing of pesticides can result in ineffective treatments or even damage to plants. Following label instructions meticulously is vital. Addressing these issues requires vigilance, proper equipment maintenance, and adherence to best practices.

Q 11. Explain the importance of record-keeping in spray programs.

Record-keeping is crucial for effective spray programs. It’s like keeping a detailed medical history; it allows you to track effectiveness, identify trends, and make informed decisions. Detailed records help monitor pest populations and pesticide efficacy, enabling adjustments in the spray program as needed. They demonstrate compliance with regulations, provide valuable data for future spray programs, and are vital if any issues arise. This documentation includes date, location, pest targeted, pesticide used (including rate, volume and formulation), equipment used, weather conditions, and application method. It also includes observation of pest populations before and after application. This allows for analysis of the program’s success and for making changes to improve efficiency and reduce environmental impact. Imagine trying to manage a large orchard without detailed records – it would be chaos!

Q 12. How do you maintain and calibrate spray equipment?

Maintaining and calibrating spray equipment is vital for accurate and efficient application. Regular cleaning after each use is essential to prevent nozzle clogging and corrosion. This involves rinsing the equipment thoroughly with clean water, followed by a specific cleaning solution if necessary. Inspection for leaks, wear and tear, and any damage is equally crucial. Calibration ensures the correct amount of pesticide is applied per unit area. This typically involves measuring the output of the sprayer over a known distance and time, and adjusting the settings as needed. This process often includes measuring the area covered, time taken and the volume of spray solution used to calculate the application rate. We use precise measuring tools, and follow manufacturer instructions carefully for each piece of equipment. This may seem like a small detail, but it’s the difference between effective pest control and wasted resources.

Q 13. What are the regulations and compliance requirements for spray programs?

Spray programs are subject to numerous regulations and compliance requirements designed to protect human health and the environment. These regulations vary by location but typically involve pesticide registration, licensing of applicators, restricted-use pesticides (RUPs), personal protective equipment (PPE) requirements, and environmental protection measures such as buffer zones and drift mitigation techniques. Compliance requires adhering to pesticide labels, maintaining detailed records of all pesticide applications, and undergoing regular training to stay up-to-date on regulations. Failure to comply can result in substantial fines and legal repercussions. It’s essential to stay abreast of updates in pesticide regulations and ensure all personnel involved are trained and certified to handle and apply pesticides safely and legally.

Q 14. Describe your experience with GPS-guided spraying.

My experience with GPS-guided spraying has been transformative. It allows for precise application of pesticides, minimizing overlap and reducing pesticide use and drift. GPS technology maps the area to be sprayed and guides the sprayer along pre-programmed paths, ensuring even coverage and avoiding missed spots. This is especially advantageous in large fields or areas with complex topography. Using GPS-guided spraying has improved the efficiency and precision of my applications, resulting in reduced pesticide use and increased yields. This technology also allows for the creation of variable rate application maps, enabling different pesticide rates to be applied to different areas within a field based on specific needs, furthering both efficiency and minimizing environmental impact. For example, higher rates could be targeted to areas with higher pest pressure.

Q 15. How do you manage spray drift and minimize environmental impact?

Managing spray drift and minimizing environmental impact is crucial for responsible pesticide application. Spray drift is the movement of pesticide droplets from the target area to non-target areas, potentially harming beneficial insects, wildlife, water sources, and even human health. Minimizing it requires a multi-pronged approach.

- Proper Nozzle Selection: Using low-drift nozzles that produce larger droplets reduces the potential for drift. Different nozzles are designed for various applications and wind conditions. For example, air-induction nozzles create larger droplets with less drift potential compared to standard flat-fan nozzles.

- Weather Conditions: Spraying should only be done under favorable weather conditions. This means low wind speed (ideally less than 10 mph), calm air, and no temperature inversions. Temperature inversions, where warmer air sits above cooler air, can trap spray droplets near the ground and increase drift.

- Boom Height Adjustment: Maintaining the correct boom height ensures even coverage and reduces drift. Too low and you risk excessive runoff; too high and you lose effectiveness and increase drift.

- Buffer Zones: Establishing buffer zones around sensitive areas such as water bodies, beehives, or residential areas further mitigates drift. The width of the buffer zone depends on the specific pesticide and environmental conditions.

- Application Techniques: Employing proper application techniques like maintaining a consistent spray pressure and speed further contributes to reducing drift. Overlapping swaths carefully also ensures complete coverage without excessive application.

- Adjuvants: Using adjuvants can improve spray droplet size and adhesion, which decreases drift and improves efficacy. These are added to the spray tank to enhance pesticide performance.

For instance, during a recent project involving spraying a sensitive riparian area, we meticulously monitored wind speed using an anemometer and implemented a buffer zone of 50 feet around the creek. We selected low-drift nozzles and adjusted our boom height to ensure effective application while minimizing environmental impact.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of spray equipment used in various industries?

The choice of spray equipment depends heavily on the application’s scale, the target area, and the type of pesticide being used. Various industries employ different equipment, each with its own advantages and disadvantages.

- Handheld Sprayers: Ideal for small-scale applications in gardens or greenhouses. These can range from simple hand-pump sprayers to more sophisticated battery-powered models.

- Knapsack Sprayers: Used for slightly larger areas, these are worn on the back and are suitable for applications in orchards, vineyards, or along fence lines.

- Boom Sprayers: Mounted on tractors or ATVs, these are highly efficient for large-scale agricultural applications. They have a boom with multiple nozzles to provide uniform coverage across wider areas.

- Airblast Sprayers: Commonly used in orchards, these utilize high-velocity air to distribute the pesticide droplets, ensuring thorough coverage even within dense canopies. These are more expensive to operate and maintain.

- Aerial Sprayers: Used for extremely large areas such as forests or expansive fields. These utilize planes or helicopters to apply pesticides quickly and efficiently, often over uneven terrain.

- Electrostatic Sprayers: These use an electrical charge to attract pesticide droplets to the target surface, increasing efficiency and reducing drift, particularly useful in enclosed environments.

For example, in large-scale agricultural settings, boom sprayers are the standard, while for treating individual trees in an orchard, airblast sprayers might be preferred. The selection of equipment is a crucial decision influenced by numerous factors.

Q 17. Explain the concept of pesticide resistance and how to mitigate it.

Pesticide resistance occurs when a pest population develops the ability to survive exposure to a pesticide that was previously effective. This happens when a small percentage of the pest population possesses a natural resistance, and repeated applications of the same pesticide allow these resistant individuals to thrive and reproduce, eventually dominating the population.

- Integrated Pest Management (IPM): This holistic approach prioritizes preventing pest problems using methods such as crop rotation, resistant cultivars, and biological control before resorting to chemical control. It reduces reliance on a single pesticide, limiting the development of resistance.

- Pesticide Rotation: Alternating between different classes of pesticides with different modes of action prevents the selection of resistant individuals. The idea is to use a variety of tools to manage the pest population.

- Refugia Strategy: This involves leaving a portion of the field untreated to allow the survival of susceptible insects, which helps maintain a diverse population and reduces selection pressure for resistance.

- Resistance Monitoring: Regular monitoring of pest populations for resistance development is essential. This can involve bioassays, where the pesticide’s effectiveness is tested on representative samples of the pest population.

- Use of lower application rates and proper application technique: Applying pesticides at the correct rate, according to label instructions, and using proper equipment and technique minimizes selection pressure and reduces the risk of resistance.

I’ve seen firsthand how IPM strategies implemented in a large vineyard significantly reduced the reliance on pesticides and slowed the development of resistance to a previously effective insecticide.

Q 18. How do you assess the effectiveness of a spray program?

Assessing the effectiveness of a spray program involves a combination of methods to measure both immediate and long-term impacts.

- Visual Inspections: Direct observation of the target area to assess the reduction in pest numbers or disease symptoms post-application.

- Sampling and Counts: Collecting samples of pests or disease-affected plants before and after application to quantify the reduction in pest populations.

- Yield Monitoring: Measuring crop yield after the spray program to determine the effect on productivity.

- Statistical Analysis: Analyzing data collected through sampling and yield monitoring to determine the statistical significance of the program’s effectiveness. Paired t-tests are commonly used.

- Economic Analysis: Evaluating the cost-effectiveness of the spray program by comparing the cost of application to the increase in yield or reduction in losses due to pests or diseases.

For example, in a recent project involving control of potato blight, we conducted visual inspections, collected leaf samples to measure disease severity, and monitored yields at harvest to assess the effectiveness of the spray regimen. Our statistical analysis confirmed a significant decrease in disease incidence and a considerable improvement in yield.

Q 19. How do you handle emergency situations related to spray application?

Handling emergency situations related to spray application requires a prepared and swift response, prioritizing safety and environmental protection.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, goggles, and respirators, to prevent exposure to pesticides in any situation.

- Spill Response Plan: Having a well-defined spill response plan, including the appropriate absorbent materials and procedures for cleanup. This plan should include details on contacting relevant authorities (like the Environmental Protection Agency (EPA)) in case of large scale incidents.

- First Aid Procedures: Being aware of and readily equipped to address potential exposure incidents. This includes having readily available first aid kits and knowledge of emergency response protocols.

- Emergency Contact Information: Maintaining readily accessible emergency contact information for relevant authorities, medical personnel, and the pesticide manufacturer or supplier.

- Communication: In case of a major incident, communicating quickly and effectively with concerned parties, including the public, emergency responders, and regulatory bodies.

For example, during a minor sprayer malfunction resulting in a small pesticide spill, we immediately deployed our spill response kit, contacted our supervisor, and followed the established cleanup procedures. No harm to personnel or environment resulted.

Q 20. Describe your experience with different spray formulations (e.g., emulsifiable concentrates, wettable powders).

Experience with different spray formulations is crucial for effective and safe pesticide application. Each formulation has unique characteristics that influence its handling, application, and efficacy.

- Emulsifiable Concentrates (ECs): These are soluble in water, often requiring agitation during mixing to prevent settling. They are easy to handle and measure, but can be more phytotoxic (harmful to plants) than some other formulations if not used carefully. They can also be more prone to drift.

- Wettable Powders (WPs): These are finely ground solids that are dispersed in water. They require thorough mixing and agitation to create a homogenous suspension. They tend to be less prone to drift than ECs but may be more difficult to handle and can clog nozzles if not mixed properly.

- Suspension Concentrates (SCs): These are finely ground solids suspended in a liquid carrier. They are typically easier to handle than WPs and less prone to clogging.

- Soluble Powders (SPs): These dissolve completely in water and are ideal for situations requiring precise application of specific amounts of active ingredient.

I have extensive experience with all these formulations. For example, during a large-scale application of a fungicide on a wheat field, we utilized a suspension concentrate due to its ease of handling and less potential for nozzle clogging compared to wettable powders given the large volume needed.

Q 21. How do you determine the appropriate application rate for pesticides?

Determining the appropriate application rate for pesticides is critical for effective pest control while minimizing environmental impact. The rate is not arbitrary; it is carefully calculated based on several factors.

- Pesticide Label Instructions: The pesticide label is the primary source of information. It provides recommended rates based on the target pest, crop type, and environmental conditions. Always follow label instructions meticulously.

- Pest Population Density: The severity of the pest infestation dictates the application rate. Higher pest densities necessitate higher rates, within the label’s recommendations.

- Crop Stage: The sensitivity of the crop to the pesticide can vary at different growth stages. Younger or more susceptible crops may require lower rates.

- Weather Conditions: Temperature, humidity, and rainfall can influence pesticide effectiveness and decomposition. Adjustments may be necessary based on these conditions to prevent runoff.

- Calibration of Spray Equipment: Accurate calibration of spray equipment is essential to ensure consistent application rates. Inaccurate calibration can result in either under-application (ineffective pest control) or over-application (increased environmental impact).

For instance, in managing a corn borer infestation, we first carefully assessed the pest population density using sampling techniques. Considering the crop stage, label recommendations, and weather conditions, we adjusted the application rate accordingly, ensuring optimal pest control while staying within the label’s recommendations. Calibration was confirmed by measuring the output per unit area of the equipment prior to the application.

Q 22. Explain the principles of integrated pest management (IPM).

Integrated Pest Management (IPM) is a sustainable approach to pest control that aims to minimize pesticide use while maximizing effectiveness. It’s like being a detective, carefully investigating the problem before resorting to drastic measures. Instead of immediately spraying, IPM uses a holistic strategy that considers several factors.

- Monitoring: Regularly checking for pests and assessing their impact on the crop.

- Identification: Accurately identifying the pest to determine the best control method. Misidentification can lead to ineffective treatments and environmental damage.

- Prevention: Implementing cultural practices like crop rotation, proper sanitation, and choosing pest-resistant varieties to prevent pest infestations.

- Biological Control: Introducing natural enemies like beneficial insects or nematodes to control pest populations. This is like using nature’s own pest control service!

- Chemical Control: Using pesticides only as a last resort, and only when necessary and appropriate. Even then, we select the least toxic option and use it judiciously.

For example, in managing aphids on roses, IPM might start with monitoring aphid numbers and identifying the specific species. If numbers are low, simply removing them by hand might be sufficient. If numbers are high, introducing ladybugs (a natural predator) would be the next step. Chemical pesticides would only be used if other methods fail and the infestation poses a significant threat to the roses.

Q 23. What are the various methods of spray application for different crop types?

Spray application methods vary depending on the crop type, the pest, and the pesticide. We need to ensure optimal coverage while minimizing drift and runoff. Different techniques are required for different situations.

- Ground Spraying: This is common for many crops, using boom sprayers, handheld sprayers, or knapsack sprayers. Boom sprayers are ideal for large fields, while handheld sprayers are better for smaller areas or orchards.

- Aerial Spraying: Used for large-scale applications, particularly in crops like cotton or corn. It’s efficient but requires careful consideration of wind speed and direction to avoid drift.

- High-Volume Spraying: This method uses a large volume of spray solution to ensure thorough coverage, often suitable for crops with dense foliage.

- Low-Volume Spraying: This method utilizes less spray solution, reducing costs and environmental impact but requiring precise application.

- Drip/fertigation: Certain pesticides can be applied through irrigation systems, targeting the roots. This is suitable for soil-borne pests and reduces environmental impact.

For example, a low-volume sprayer might be suitable for applying herbicides to a field of soybeans, while a high-volume sprayer would be better suited for applying insecticides to a dense orchard.

Q 24. How do you monitor and evaluate the effectiveness of different spray techniques?

Monitoring and evaluating spray effectiveness involve a multi-pronged approach to ensure the treatment was successful and didn’t cause unintended consequences.

- Pre-treatment Assessment: Counting pest populations or assessing disease severity before spraying to establish a baseline.

- Post-treatment Assessment: Repeat the assessment after a suitable period. The interval depends on the pest’s life cycle and the pesticide’s residual activity. Counting surviving pests allows us to determine treatment efficacy.

- Visual Inspection: Observing the crop for signs of pest damage or disease after treatment.

- Sampling: Taking samples of plants or soil to assess the level of pest control achieved.

- Data Analysis: Comparing pre- and post-treatment data to determine the effectiveness of the spray program.

For instance, if we’re targeting potato blight, we would photograph the affected areas beforehand. Following treatment, we would revisit those areas after a week or two and retake photos, measuring the reduction in blight severity. This data allows us to see which treatment (if multiple were used) was the most effective.

Q 25. Describe your experience with using different types of spray adjuvant.

Adjuvants are substances added to pesticides to improve their effectiveness. Think of them as ‘helpers’ that enhance the pesticide’s performance. My experience encompasses a wide range of adjuvants.

- Spreaders and Stickers: These improve the distribution of pesticides and help them adhere to plant surfaces, enhancing coverage and preventing runoff. I’ve used these extensively in applying fungicides to grapevines.

- Penetrants: These enhance the absorption of pesticides into plant tissues, particularly for systemic pesticides. This is essential for certain herbicides or insecticides.

- Buffers: These help to maintain the pH of the spray solution, ensuring the pesticide remains stable and effective.

- Drift Reduction Agents: These help to minimize the drift of pesticides during spraying, reducing environmental impact. Crucial for aerial applications or spraying near sensitive areas.

In one project, we used a spreader-sticker adjuvant to improve the efficacy of a fungicide on a potato crop. The addition of this adjuvant significantly reduced the amount of fungicide needed to achieve the desired level of disease control. Proper adjuvant selection is crucial for cost-effectiveness and environmental protection.

Q 26. What are the potential health hazards associated with spray application, and how are they mitigated?

Pesticide exposure can pose several health hazards, ranging from mild skin irritation to more severe effects like organ damage. It’s crucial to always prioritize safety.

- Acute Toxicity: Immediate health effects such as skin irritation, eye irritation, nausea, and vomiting. This requires immediate first aid and medical attention if needed.

- Chronic Toxicity: Long-term health effects including neurological problems, reproductive issues, and cancer. This highlights the importance of regular medical checkups and adhering to safety guidelines.

- Exposure Routes: Pesticides can be absorbed through the skin, inhaled, or ingested, making proper PPE vital.

Mitigation strategies include using the least toxic pesticides available, following label instructions carefully, and implementing thorough safety protocols. This includes regular equipment maintenance and ensuring the proper disposal of empty containers. Worker training is absolutely critical to minimize risks.

Q 27. Explain the importance of proper personal protective equipment (PPE) in spray application.

Personal Protective Equipment (PPE) is non-negotiable for anyone handling pesticides. It’s the first line of defense against exposure and potential health risks. The type of PPE required depends on the pesticide and the application method, but a standard set includes:

- Coveralls: To protect skin from pesticide contact.

- Gloves: Chemical-resistant gloves are crucial to protect the hands.

- Respirator: Protects the respiratory system from inhaling pesticide particles or vapors.

- Eye protection: Safety goggles or a face shield prevents pesticide from entering the eyes.

- Footwear: Waterproof boots to protect feet and ankles.

I always emphasize the importance of PPE training and ensuring that workers understand how to properly don, doff, and maintain their PPE. Regular inspections of PPE are necessary to ensure effectiveness. Neglecting PPE is simply not an option.

Q 28. Describe your experience with using precision spraying technologies to reduce pesticide usage.

Precision spraying technologies are revolutionizing pesticide application, allowing us to target pesticides more effectively and significantly reduce pesticide usage.

- GPS Guidance Systems: These help to ensure uniform coverage and prevent overlapping or missed areas, reducing pesticide waste.

- Variable Rate Technology (VRT): Allows for applying different rates of pesticide based on the specific needs of the area, optimizing application and minimizing environmental impact.

- Sensor-Based Spraying: Using sensors to identify areas where pests or diseases are present and applying pesticide only to those areas. This technology dramatically reduces the amount of pesticide needed.

- Drone Technology: Drones equipped with precision spraying systems can apply pesticides with greater accuracy and efficiency in various terrains.

I’ve had considerable experience using GPS guidance systems and VRT to optimize pesticide application in vineyards. We saw a significant reduction in pesticide usage while maintaining effective pest control. The adoption of these technologies offers a sustainable and cost-effective approach to pest management.

Key Topics to Learn for Developing and Implementing Spray Programs Interview

- Spray Program Design & Planning: Understanding application methods, target areas, and environmental factors influencing spray program effectiveness. This includes selecting appropriate equipment and calculating application rates.

- Formulation and Mixing: Knowledge of different spray formulations (e.g., emulsions, suspensions), understanding the importance of accurate mixing ratios, and ensuring the stability and efficacy of the final spray mixture.

- Calibration and Maintenance of Spray Equipment: Mastering the techniques for calibrating spray equipment to ensure consistent application rates. Understanding routine maintenance procedures and troubleshooting common equipment malfunctions.

- Safety Procedures and Regulations: Familiarity with relevant safety regulations and personal protective equipment (PPE) requirements. Developing and implementing safe work practices for spray program execution.

- Data Collection and Analysis: Understanding the importance of accurate data recording during spray applications. Analyzing collected data to assess program efficacy and identify areas for improvement.

- Environmental Impact Assessment: Considering the potential environmental impact of spray programs and implementing strategies for minimizing negative consequences. Understanding environmentally friendly practices.

- Pest Biology and Behavior: Understanding the target pest’s life cycle, behavior, and susceptibility to different control methods. This is vital for developing effective spray programs.

- Problem-Solving and Troubleshooting: Ability to diagnose and solve problems related to spray application, equipment malfunction, or unexpected results. This includes adapting the spray program based on field observations.

Next Steps

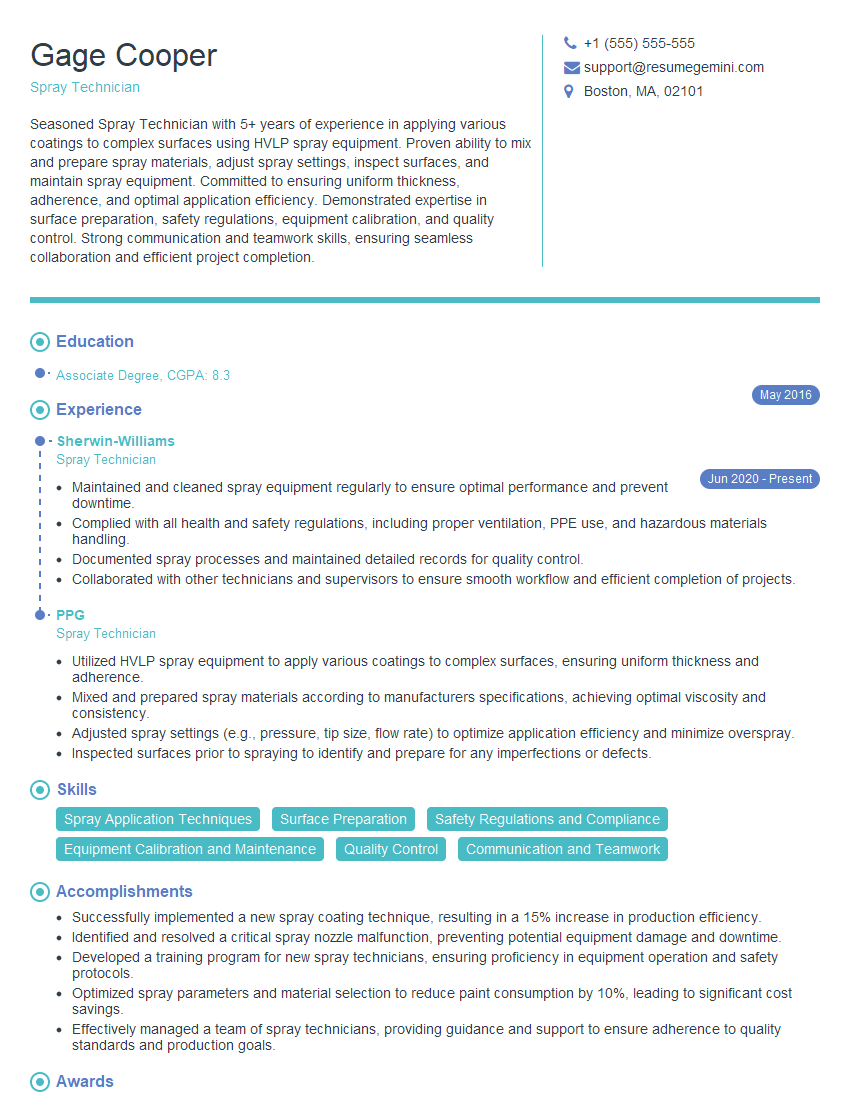

Mastering the development and implementation of spray programs is crucial for career advancement in many fields, including agriculture, pest control, and public health. A strong understanding of these principles demonstrates a high level of competence and problem-solving skills, making you a valuable asset to any team. To maximize your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Developing and implementing spray programs are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good