Cracking a skill-specific interview, like one for Die Casting and Molding Processes, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Die Casting and Molding Processes Interview

Q 1. Explain the difference between hot chamber and cold chamber die casting.

The core difference between hot chamber and cold chamber die casting lies in how the molten metal is introduced into the die. Think of it like filling a mold – in hot chamber, the metal is in direct contact with the plunger, which is submerged in a molten metal pool. In cold chamber, the molten metal is ladled into a shot sleeve before being injected.

- Hot Chamber: The plunger is immersed in a molten metal reservoir within the machine. This is suitable for low-viscosity alloys like zinc and tin. Imagine a piston pushing directly from the metal bath, filling the mold rapidly. It’s efficient for high-volume production of smaller parts.

- Cold Chamber: The molten metal is manually or automatically ladled into a shot sleeve separate from the melting unit. This is ideal for higher-viscosity alloys like aluminum and magnesium. It’s like filling a syringe before injecting the molten material. Offers more control over the metal’s temperature and purity.

Choosing between the two depends on the alloy, part size, production volume, and desired level of control. For example, high-volume production of zinc alloy door handles would likely use a hot chamber machine, while the casting of complex aluminum engine parts would opt for cold chamber.

Q 2. Describe the various types of die casting alloys and their applications.

Die casting alloys are chosen based on their mechanical properties, castability, and cost. Common types include:

- Aluminum Alloys: Known for their lightweight and high strength-to-weight ratio, widely used in automotive, aerospace, and electronics. Think of aluminum housings for electronics or components in car engines.

- Zinc Alloys: Offer excellent surface finish and detail reproduction. Cost-effective for intricate parts like decorative items, small housings, and electronic components. They’re readily plated.

- Magnesium Alloys: Even lighter than aluminum, with excellent damping characteristics. Used in applications where weight reduction is critical, such as in laptops, cameras, and automotive parts.

- Copper Alloys (Brass, Bronze): Provide high strength, corrosion resistance, and good electrical conductivity. Used in various applications needing these specific attributes, such as plumbing fittings or electrical connectors.

The selection of the alloy depends on the final application’s requirements. For example, a lightweight laptop would benefit from magnesium, while a high-strength automotive component might use a specialized aluminum alloy.

Q 3. What are the common defects found in die castings and their causes?

Die casting defects can significantly impact part quality and functionality. Some common defects and their causes include:

- Porosity: Caused by trapped air or gases during filling. Think of it as tiny holes in the final casting. This often arises from improper venting or insufficient metal fluidity.

- Cold Shut: Two streams of metal meeting and failing to fuse properly. Happens when the mold isn’t filled sufficiently or the metal is too cold. It’s like two separate pieces fused imperfectly.

- Shrinkage: Occurs due to volume reduction as the metal cools and solidifies. Insufficient metal supply or slow cooling rates contribute to this problem. You see it as voids in the cast piece.

- Surface Defects: Scratches, cracks, or other imperfections on the surface. These are caused by die wear, improper lubrication, or surface contamination during the casting process.

- Misruns: Incomplete filling of the die cavity. This is typically due to insufficient pressure or inadequate fluidity of the molten metal.

Careful process control, proper die design, and meticulous quality checks are crucial to minimize these defects. Analyzing defective parts can pinpoint the root cause and aid in corrective actions.

Q 4. Explain the importance of proper gating and venting in die casting.

Proper gating and venting are crucial for successful die casting. They control metal flow and the escape of gases during the casting process. Think of gating as the pathway for the molten metal and venting as the escape route for trapped gases.

- Gating System: Directs the molten metal into the die cavity efficiently, ensuring complete filling and minimizing turbulence. Improper gating leads to cold shuts, porosity, and incomplete filling.

- Venting System: Allows trapped air and gases to escape, preventing porosity and ensuring a sound casting. Insufficient venting leads to porosity and potentially mold damage.

Design of the gating and venting systems directly impacts the quality of the final product. A well-designed gating system delivers metal smoothly to all sections of the die cavity while a properly designed venting system ensures the smooth evacuation of gases without disruption.

Q 5. How do you determine the optimal casting cycle time?

Optimal casting cycle time is a balance between production rate and part quality. It involves several factors:

- Die Temperature: Higher temperatures generally allow for shorter cycle times but might lead to increased wear and tear on the die.

- Metal Temperature: Proper metal temperature ensures good fluidity and fill, impacting cycle time.

- Part Geometry: Complex geometries might necessitate longer fill times.

- Solidification Time: Sufficient time is needed for the metal to solidify completely before ejection, preventing warping or cracking.

- Ejection Time: Time needed for the part to be ejected from the die.

Determining the optimal cycle time involves experimentation and data analysis. It’s often achieved through a systematic approach of gradually adjusting parameters, monitoring defects, and measuring production rate until an optimum balance is reached. Software simulations can assist in predicting cycle times and optimizing the process.

Q 6. Describe the process of die design and mold making.

Die design and mold making are intricate processes requiring specialized knowledge. The process usually starts with part design, progresses through die design, and culminates in die construction and testing.

- Part Design: Determining the final part’s shape and dimensions while ensuring manufacturability through die casting.

- Die Design: Creating a three-dimensional model of the die, specifying materials, gating, venting, and cooling systems. Software like CAD/CAM plays a crucial role.

- Mold Making: Fabricating the actual die using machining, EDM (Electrical Discharge Machining), or other methods. High-precision machining is essential for maintaining dimensional accuracy.

- Die Tryout and Refinement: The process of casting test parts to identify and rectify any defects or adjustments needed in the die design.

The entire process requires a close collaboration between designers, engineers, and mold makers. The use of simulation software and advanced machining techniques ensures high quality, durability, and efficiency of the molds.

Q 7. What are the different types of injection molding machines?

Injection molding machines are classified based on several factors, primarily their clamping mechanism and plastic injection method.

- Hydraulic Machines: These use hydraulic cylinders for clamping and injection. They offer high clamping force and are suitable for large molds and thick parts. Think of them as strong, reliable workhorses for substantial projects.

- Electric Machines: Employ electric motors for clamping and injection. They’re energy-efficient, precise, and offer better control over injection parameters. They are ideal for high-precision parts and automation.

- Hybrid Machines: Combine hydraulic and electric systems. They leverage the strengths of both: high clamping force from hydraulics and precise control from electrics. These machines provide a flexible solution to diverse applications.

- Two-Platen Machines: Feature two platens that move independently. They are suitable for specific applications needing more access to the mold or requiring particular ejection systems.

The choice of machine depends on factors like part size, production volume, material properties, and budget considerations. For example, a large automotive component might require a large hydraulic machine, whereas smaller, intricately designed parts could be efficiently produced using an electric machine.

Q 8. Explain the concept of shot size and its impact on product quality.

Shot size in injection molding refers to the amount of molten plastic injected into the mold cavity during a single cycle. Think of it like filling a cup – a larger shot size means more plastic, filling the cup completely. A smaller shot size might leave the cup partially empty. This seemingly simple parameter heavily influences product quality.

A short shot, resulting from insufficient shot size, leads to incomplete filling of the mold cavity, resulting in parts with missing features or insufficient wall thickness. This significantly impacts part strength and functionality. For example, imagine a plastic bottle cap – a short shot would result in a thinner, weaker cap likely to fail under pressure.

Conversely, an overshot (excessive shot size) can cause issues like flashing (excess material squeezed out between the mold halves) and increased internal stresses within the part, potentially leading to warping or cracking. Flashing can affect the part’s aesthetics and can interfere with proper functioning of the part in applications needing precision fit.

Optimizing shot size is crucial for achieving consistent part quality and minimizing waste. Factors to consider include part geometry, material viscosity, melt temperature, and mold temperature. Proper adjustment ensures complete mold filling without excessive material usage.

Q 9. How do you troubleshoot common injection molding problems like short shots or flashing?

Troubleshooting injection molding problems requires a systematic approach. Let’s tackle short shots and flashing:

- Short Shots:

- Insufficient melt volume: Increase the shot size setting on the injection molding machine. Check for blockages in the sprue, runners, or gates.

- High melt viscosity: Increase melt temperature or use a lower viscosity material. This is like trying to pour honey versus water – warmer, less viscous material flows better.

- Molding temperature too low: Increase mold temperature to reduce viscosity near the mold surface and improve flow.

- Gate restriction: Examine gate design for possible restriction; redesign if necessary.

- Flashing:

- Excessive clamping force: Reduce clamping force to prevent plastic from escaping between mold halves.

- Mold temperature too high: Lower mold temperature to increase material viscosity and reduce flow.

- Mold wear or damage: Inspect mold for wear and tear, repair or replace damaged components like parting lines. This is like a worn-out seal on a container leaking its contents.

- Improper mold closure: Ensure proper mold alignment and closing mechanisms are working correctly.

Remember, careful observation, precise measurements, and systematic troubleshooting are key to resolving these issues. Often, it’s a combination of factors that contribute to the problem.

Q 10. What are the different types of plastics used in injection molding?

The world of plastics used in injection molding is vast. They’re classified based on their chemical structure and properties. Here are some key examples:

- Thermoplastics: These materials soften when heated and harden when cooled, allowing for repeated melting and molding. Common examples include:

- Polyethylene (PE): Excellent flexibility and chemical resistance; used in films, bottles, and containers.

- Polypropylene (PP): Strong and impact-resistant; used in automotive parts, packaging, and appliances.

- Polyvinyl Chloride (PVC): Stiff and durable, often used for pipes, window frames, and flooring.

- Polystyrene (PS): Inexpensive and readily moldable; used in disposable cups, packaging, and insulation.

- Acrylonitrile Butadiene Styrene (ABS): Tough, impact-resistant, and durable; often used in automotive parts and electronics.

- Polyethylene Terephthalate (PET): A strong and lightweight material used in beverage bottles and packaging.

- Thermosets: These materials undergo an irreversible chemical change upon curing, permanently setting their shape. They are generally stronger and more heat-resistant than thermoplastics, but can only be molded once. Examples include epoxy and phenolic resins.

The choice of plastic depends heavily on the application requirements, considering factors like strength, durability, heat resistance, chemical resistance, and cost.

Q 11. Explain the role of mold temperature control in injection molding.

Mold temperature control is absolutely crucial in injection molding for several reasons. Think of it as controlling the environment for your plastic to ‘settle’ into the shape of the mold.

Impact on Part Quality: A properly controlled mold temperature ensures consistent part quality by influencing:

- Part surface finish: Too low a temperature can lead to rough surfaces or sink marks. Too high can lead to sticking.

- Part shrinkage and warpage: Maintaining a consistent mold temperature minimizes uneven cooling and reduces dimensional variation.

- Cycle time: Proper temperature management optimizes cooling, allowing for faster cycle times and increased production rates.

- Stress and warpage: Efficient heat dissipation helps minimize internal stress, reducing warpage and cracking.

Control Mechanisms: Mold temperature is controlled using various methods like circulating heated or chilled water or oil through channels within the mold. Sophisticated systems can maintain specific temperatures in different mold zones.

Real-World Example: In the manufacture of precision plastic housings for electronics, precise mold temperature control is essential for ensuring consistent dimensions and a smooth surface finish. Even slight deviations can result in parts that don’t fit correctly.

Q 12. Describe the different types of mold materials and their properties.

Mold materials are selected based on their mechanical properties, thermal properties, and cost. Here are some common types:

- Tool Steel: A durable and heat-resistant material commonly used for high-volume production runs. Different grades offer varying levels of hardness and wear resistance.

- Aluminum: Lighter and less expensive than steel; often used for prototyping and lower-volume production. Offers good thermal conductivity and machining ease but lower wear resistance.

- Beryllium Copper: Offers high strength, excellent thermal conductivity, and resistance to wear. Primarily used for molds requiring high precision and durability.

- Maraging Steel: Provides high strength and dimensional stability at high temperatures, suitable for demanding applications.

Material selection involves a trade-off between cost, durability, and performance. For instance, while tool steel is expensive, its exceptional wear resistance justifies its use in large-scale production of demanding parts.

Q 13. How do you ensure dimensional accuracy in die casting and injection molding?

Ensuring dimensional accuracy in die casting and injection molding is critical for functionality and interchangeability. Several techniques contribute:

- Precise Mold Design: CAD/CAM technology enables precise mold design, incorporating allowances for material shrinkage and warpage. This is akin to creating a tailor-made pattern, accounting for the final garment’s shrinkage after washing.

- Mold Temperature Control: Consistent mold temperature minimizes variations in cooling rates, resulting in uniform shrinkage and reduced warpage.

- Material Selection: Choosing a material with low shrinkage is crucial; different plastics possess different shrinkage rates.

- Injection Parameters: Precise control of injection pressure, speed, and hold time ensures consistent filling of the mold cavity.

- Regular Mold Maintenance: Wear and tear on the mold can affect dimensional accuracy. Regular inspection, cleaning, and repair are essential.

- Statistical Process Control (SPC): Monitoring key process parameters throughout production and applying statistical analysis can reveal trends and anomalies that affect dimensional accuracy. This provides a systematic way to track and improve performance.

- In-Process Inspection: Regular in-process inspection (using methods like CMMs – Coordinate Measuring Machines) ensures dimensions remain within tolerances.

A coordinated effort between mold design, material selection, processing parameters, and quality control procedures is necessary to guarantee accurate final dimensions.

Q 14. What are the safety precautions you would take while operating die casting and injection molding machinery?

Safety is paramount when operating die casting and injection molding machinery. Here’s a summary of precautions:

- Lockout/Tagout Procedures: Always follow proper lockout/tagout procedures before performing any maintenance or repair work. This prevents accidental activation of the machinery.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, hearing protection, gloves, and heat-resistant clothing.

- Emergency Stop Buttons: Know the location and operation of emergency stop buttons and ensure they’re readily accessible.

- Machine Guards: Never operate the machine with guards removed or bypassed. These guards shield operators from moving parts.

- Hot Surfaces: Be aware of hot surfaces and use appropriate handling tools.

- Ejection Mechanisms: Exercise caution around ejection mechanisms to avoid injuries.

- Material Handling: Follow safe procedures for handling raw materials and finished parts.

- Regular Machine Inspections: Regularly inspect the machinery for potential hazards and report any issues immediately.

- Training: Ensure thorough training on proper operating procedures and safety protocols before working with the machinery.

Safe operation requires discipline, attention to detail, and adherence to established safety procedures. Never compromise on safety – it is always the top priority.

Q 15. Explain the importance of quality control in die casting and molding processes.

Quality control in die casting and molding is paramount; it ensures consistent part quality, minimizes defects, and ultimately, reduces costs. Think of it as a rigorous system of checks and balances throughout the entire process, from raw material inspection to the final product. Poor quality control leads to scrap, rework, customer dissatisfaction, and potential safety hazards.

A comprehensive QC program involves:

- Incoming Material Inspection: Checking the chemical composition and physical properties of raw materials (e.g., alloys for die casting, polymers for injection molding) to ensure they meet specifications.

- Process Monitoring: Continuously monitoring key process parameters like temperature, pressure, and injection speed to maintain consistency. This often involves using sensors and data acquisition systems.

- In-Process Inspection: Regularly inspecting parts during production using methods like dimensional checks, visual inspection, and destructive or non-destructive testing.

- Final Product Inspection: Thorough inspection of finished parts to detect surface defects, dimensional inaccuracies, and internal flaws. This might include visual checks, CMM measurements, and X-ray inspection.

- Statistical Process Control (SPC): Using statistical methods to monitor process variation and identify trends that could lead to defects. Control charts are a key tool in SPC.

For example, in a die casting operation, if the melt temperature is consistently too low, it can lead to incomplete filling of the die cavity, resulting in porous castings. Regular monitoring and adjustment of the temperature prevent this problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform dimensional inspection on die castings?

Dimensional inspection on die castings verifies that the produced parts conform to the design specifications. This is crucial for functionality and interchangeability. Several methods are employed:

- Coordinate Measuring Machine (CMM): A highly accurate device that uses probes to measure the dimensions of the part. CMMs offer high precision and can measure complex geometries. Imagine it as a sophisticated 3D ruler capable of incredibly fine measurements.

- Optical Comparators: These project an enlarged image of the part onto a screen, allowing for visual comparison against a master drawing or template. They are useful for quickly checking critical dimensions and surface features.

- Calipers and Micrometers: Handheld tools used for basic linear measurements. While less accurate than CMMs, they provide rapid checks on simple dimensions.

- Go/No-Go Gauges: Simple, inexpensive gauges that check if a dimension falls within a specified tolerance range. These are ideal for high-volume production where speed is important.

For instance, a crucial dimension in a car engine component might be checked using a CMM to ensure it meets tight tolerances. Go/No-Go gauges might be used for checking the diameter of a simple shaft.

Q 17. What are the different types of surface finishing techniques used for die castings?

Die castings often require surface finishing to improve aesthetics, corrosion resistance, or functional properties. Several techniques exist:

- Polishing: Mechanical abrasion to create a smooth, shiny surface. Think of it like buffing a car to a high gloss.

- Tumbling: Parts are rotated in a container with abrasive media to smooth surfaces and remove burrs. It’s like a gentler, automated version of hand polishing.

- Electroplating: Applying a thin layer of metal (e.g., chrome, nickel) to enhance corrosion resistance, appearance, or wear resistance. This is like giving the part a protective metallic coat.

- Powder Coating: Applying a dry powder coating that’s then cured to form a durable, protective layer. This is a very common method to enhance corrosion resistance and color.

- Painting: Applying liquid paint to achieve a specific color and finish. This is a more decorative process compared to the others.

- Anodizing (for aluminum): An electrochemical process that creates a thicker, more durable oxide layer on aluminum die castings. This dramatically enhances corrosion resistance.

The choice of finishing technique depends on factors such as the part’s application, the desired surface finish, and cost considerations. For example, a highly polished chrome finish might be ideal for a luxury car part, while a powder coating might suffice for a less demanding application.

Q 18. How do you calculate the required clamping force for an injection molding machine?

Calculating the required clamping force for an injection molding machine is crucial to prevent mold opening during injection, ensuring a complete and defect-free part. There’s no single formula; the calculation involves multiple factors:

- Projected area of the mold: The total surface area of the mold projected onto a plane perpendicular to the clamping force. This is the area the clamping force needs to hold together.

- Injection pressure: The pressure exerted by the molten polymer during injection. Higher injection pressure demands higher clamping force.

- Material properties: The viscosity and pressure-volume-temperature (PVT) behavior of the polymer being molded affects the required clamping force.

- Mold design: Factors like the number of cavities, parting line design, and ejector pin system will influence the required clamping force.

- Safety Factor: A factor (typically 1.5-2.0) added to account for unexpected pressure surges or variations in material properties.

The calculation is usually done using empirical formulas or computer simulations, and many injection molding machine manufacturers provide guidelines or software to assist in this calculation. A simplified (and approximate) approach might involve multiplying the projected area by the injection pressure and the safety factor. However, this is just a very rough approximation and expert knowledge and software simulations are generally necessary for precise determination.

Q 19. Describe the process of mold maintenance and repair.

Mold maintenance and repair are essential to maintain production efficiency and part quality. Neglecting this can lead to significant downtime, defects, and ultimately, increased costs.

The process includes:

- Regular Cleaning: Cleaning the mold after each production run to remove residual material and prevent build-up. This might involve using solvents, compressed air, or specialized cleaning equipment.

- Inspection: Regular visual inspection for wear, erosion, or damage to the mold surfaces, cavities, and other components. This can identify potential problems before they become major issues.

- Polishing and Repair: Minor scratches or imperfections on the mold surface can be repaired by polishing. More significant damage might require specialized repair techniques such as welding or EDM (electrical discharge machining).

- Component Replacement: Worn-out or damaged components (e.g., ejector pins, bushings, guide pins) should be replaced to maintain mold functionality. Preventative replacement is also common to avoid catastrophic failure.

- Storage: Proper storage of molds when not in use, protecting them from corrosion, dust, and damage.

For example, a worn ejector pin can lead to difficulty removing parts from the mold, causing damage or defects. Regular inspection and timely replacement prevent this issue. Mold maintenance should follow a planned schedule, often using a Computerized Maintenance Management System (CMMS) to track tasks and ensure that maintenance is performed effectively.

Q 20. Explain the concept of melt flow index (MFI) and its significance.

Melt Flow Index (MFI) is a measure of the ease with which a thermoplastic polymer melts and flows. It’s determined by measuring the amount of molten polymer that extrudes through a standardized die under specific temperature and pressure conditions. It’s essentially an indicator of the polymer’s viscosity.

Significance:

- Processability: MFI helps determine the suitability of a polymer for different molding processes. A high MFI indicates low viscosity, making the polymer easier to process in injection molding, extrusion, or other melt processing methods.

- Quality Control: Monitoring MFI during polymer production and processing is critical for ensuring consistency. Variations in MFI could indicate changes in polymer properties or degradation.

- Part Properties: The MFI can influence the final properties of the molded part, such as strength, stiffness, and surface finish. A polymer with too high an MFI might produce a weaker part, while one with too low an MFI might be difficult to mold completely.

Imagine trying to squeeze toothpaste out of the tube. A low-MFI polymer is like very thick toothpaste; it’s hard to squeeze out. A high-MFI polymer is like thin toothpaste; it flows easily. Choosing the right MFI is essential for achieving desired processing and part properties.

Q 21. What is the role of a sprue, runner, and gate in the molding process?

In the molding process, the sprue, runner, and gate are critical components that control the flow of molten material into the mold cavity.

- Sprue: The main channel through which the molten material enters the mold from the injection nozzle. It’s like the main pipeline delivering the material.

- Runner: The channel that distributes the molten material from the sprue to individual mold cavities. It’s like a branching network that distributes water from the main pipe.

- Gate: The small opening that allows molten material to flow from the runner into the mold cavity. It’s like a valve that controls the flow of material into the individual rooms (cavities).

The design of the sprue, runner, and gate system is crucial for ensuring complete and uniform filling of the mold cavity, minimizing defects like short shots or air entrapment. Poorly designed gating can lead to weld lines, sink marks, or other defects in the final part. The design considerations include the material flow characteristics, cavity geometry, and required injection pressure. The entire system, including runners and sprues, is usually removed from the molded part after cooling.

Q 22. Explain the concept of back pressure in injection molding.

Back pressure in injection molding refers to the pressure applied to the molten polymer in the barrel before it’s injected into the mold cavity. It’s not the injection pressure itself, but rather a counter-pressure that helps control various aspects of the molding process.

Think of it like this: imagine squeezing toothpaste from a tube. If the tube is completely open at the end, the toothpaste comes out quickly and might splatter. Back pressure is like partially closing the end of the tube – it controls the flow rate and prevents premature material degradation.

- Improved Melt Homogeneity: Back pressure ensures better mixing of the polymer melt, leading to a more consistent product.

- Reduced Degradation: By controlling the flow, back pressure reduces shear forces, minimizing material degradation and improving part quality.

- Better Fill Control: It aids in achieving a more complete and uniform fill of the mold cavity, especially in complex parts.

- Decreased Flow Rate: The pressure resists the forward flow, reducing the velocity of the melt and improving control.

In practice, adjusting back pressure is critical for optimizing the molding parameters. Too much back pressure can lead to increased cycle time and potential screw damage. Too little will result in inconsistent parts and increased material degradation.

Q 23. What is the difference between a two-plate and a three-plate mold?

The primary difference between two-plate and three-plate molds lies in their core configuration and how they handle the molding process. A two-plate mold has all the core pins and cavities housed within the two main mold halves. A three-plate mold, on the other hand, separates the core pins into a dedicated core plate, positioned between the two main mold halves (the cavity and ejector plates).

- Two-Plate Molds: Simpler in design and less expensive to manufacture. They are suitable for simpler parts where core pull-out is straightforward. However, they might be limited in their ability to handle intricate core designs or complex undercuts.

- Three-Plate Molds: Allow for more complex core movements and features like undercuts. The separate core plate facilitates more intricate core pull-out mechanisms, offering greater design flexibility. However, they are more expensive and complex to build and maintain.

Imagine a simple key. A two-plate mold might suffice. But if you have a key with complex indentations or features on both sides, a three-plate mold offering more precise and independent control over core movements would be necessary.

Q 24. Describe your experience with different types of ejection systems.

My experience encompasses a wide range of ejection systems, each with its strengths and limitations. I’ve worked with:

- Hydraulic Ejection: Using hydraulic cylinders to push the parts out of the mold. This is a robust system, ideal for high-volume production and larger parts. However, it can be more expensive to implement.

- Mechanical Ejection: Employing springs, cams, or other mechanical mechanisms to eject parts. This approach is cost-effective and simple for smaller parts but might lack the power of hydraulic systems.

- Pneumatic Ejection: Utilizing compressed air to eject parts. This method is versatile, offering adjustable ejection force and suitability for different part sizes. However, the air pressure needs to be precisely controlled.

- Stripper Plates: These plates work in conjunction with ejection systems to remove parts that are sticking or require delicate handling.

- Combination Systems: Many advanced molds use hybrid systems combining elements of hydraulic, pneumatic, and mechanical ejection for optimal performance based on part geometry and material properties.

Choosing the right system depends on factors like part complexity, production volume, material properties, and budget. For example, delicate electronics might demand pneumatic or a combination system, while sturdy automotive parts could benefit from hydraulic ejection.

Q 25. How do you handle material degradation during the molding process?

Material degradation during molding can manifest in several ways, leading to defects such as discoloration, reduced mechanical strength, and inconsistent part properties. My approach to handling this involves a multi-pronged strategy:

- Material Selection: Choosing the right resin is crucial. Resins with higher thermal stability are less prone to degradation. Understanding the material’s melt flow index (MFI) and its behavior under shear stress is critical.

- Process Parameter Optimization: Careful control of injection speed, temperature, pressure, and back pressure is essential. Reducing shear forces by optimizing injection speed and avoiding excessive melt temperatures minimizes degradation.

- Regular Material Testing: Implementing regular testing of the raw materials and finished products ensures quality consistency and allows for early detection of degradation. Methods include tensile testing, melt flow rate analysis, and visual inspection.

- Mold Design and Maintenance: Proper mold design reduces shear forces. Regular mold maintenance and cleaning help prevent contamination and degradation that could be caused by build-up on the mold surface.

- Drying Procedures: If using hygroscopic materials, employing proper drying procedures before molding is crucial to minimize degradation caused by moisture.

For instance, in a project involving a high-performance polymer, we discovered degradation was happening due to excessive shear in the mold’s narrow flow channels. By redesigning the gate and modifying the injection parameters, we resolved this issue and produced parts meeting the specified quality standards.

Q 26. Explain your experience with statistical process control (SPC) in a die casting or molding environment.

Statistical Process Control (SPC) is integral to maintaining consistent quality and efficiency in molding and die-casting. I have extensive experience using SPC charts (e.g., control charts, histograms, capability analysis) to monitor various parameters.

In previous roles, we used SPC to track:

- Dimensional Accuracy: Monitoring critical dimensions of parts to ensure they’re within the specified tolerance range.

- Cycle Time: Tracking cycle times to identify variations and potential bottlenecks in the process.

- Material Properties: Monitoring parameters like MFI to ensure consistent material quality.

- Defect Rates: Using control charts to identify trends in common defects and proactively address the root causes.

Data collected through SPC tools allows us to perform capability analysis, determining the process capability index (Cpk) to assess how well the process meets the specified tolerances and to identify areas for improvement. We employed control charts to track key metrics continuously. If a point fell outside the control limits, it triggered a thorough investigation to identify and correct the issue.

The use of SPC wasn’t just about reacting to problems, but rather anticipating them. Through careful monitoring and analysis, we consistently improved our process and reduced variability, resulting in higher yields and better-quality parts.

Q 27. What software are you proficient in for CAD/CAM or process simulation?

My proficiency in CAD/CAM and process simulation software includes:

- Autodesk Moldflow: For simulating the injection molding process, predicting filling patterns, pressure distribution, and potential defects. This allows for design optimization before manufacturing.

- SolidWorks: For 3D CAD modeling, creating and modifying mold designs, and generating necessary manufacturing drawings.

- Mastercam: For CAM programming to generate toolpaths for CNC machining of mold components.

- Autodesk Inventor: For 3D modeling and design, creating detailed assembly models and simulations.

I’m also familiar with various analysis tools integrated within these software packages, such as finite element analysis (FEA) for mold strength and stress analysis and computational fluid dynamics (CFD) for melt flow analysis. This allows for comprehensive analysis and optimized mold design.

Q 28. Describe a time you had to troubleshoot a complex problem in a die casting or molding process.

In a previous project involving zinc die casting, we experienced recurring cracking issues in a particular area of the part. Initial troubleshooting focused on material properties and injection parameters, but the problem persisted.

Using a structured approach, we:

- Thoroughly documented the problem: We meticulously documented the occurrence, location, and severity of the cracks.

- Gathered data: We collected data on injection pressure, temperature profiles, cycle time, and material properties.

- Analyzed the mold: We examined the mold for potential defects, wear, or erosion.

- Performed finite element analysis (FEA): FEA analysis pinpointed areas of high stress concentration in the part’s design.

- Redesigned the part: Based on the FEA analysis, we redesigned the problematic area to reduce stress concentration. We also implemented minor mold modifications to improve cooling.

By systematically investigating every potential factor and employing advanced simulation tools, we successfully identified and resolved the root cause. The redesign significantly reduced the cracking issue and ensured production of high-quality parts.

Key Topics to Learn for Die Casting and Molding Processes Interview

- Die Casting Processes: Understanding the different types (high-pressure, low-pressure, squeeze casting), their advantages and limitations, and material selection criteria.

- Molding Processes: Familiarize yourself with various molding techniques (e.g., sand casting, investment casting, shell molding) and their respective applications in different industries.

- Material Properties and Selection: Know how material properties (strength, fluidity, thermal conductivity) influence the selection of appropriate alloys and casting methods.

- Gating and Riser Design: Learn the principles behind designing effective gating systems and risers to ensure complete mold filling and minimize defects.

- Casting Defects and Troubleshooting: Be prepared to discuss common casting defects (porosity, shrinkage, cold shuts) and strategies for prevention and remediation.

- Mold Design and Manufacturing: Understand the process of designing and manufacturing molds, including considerations for material selection, cooling systems, and ejection mechanisms.

- Quality Control and Inspection: Familiarize yourself with various quality control techniques used in die casting and molding, including visual inspection, dimensional measurement, and destructive/non-destructive testing.

- Safety Procedures and Regulations: Demonstrate awareness of safety protocols and industry regulations relevant to die casting and molding operations.

- Automation and Robotics: Understand the role of automation and robotics in modern die casting and molding processes, including their benefits and challenges.

- Process Optimization and Cost Reduction: Be prepared to discuss strategies for optimizing casting processes to improve efficiency and reduce production costs.

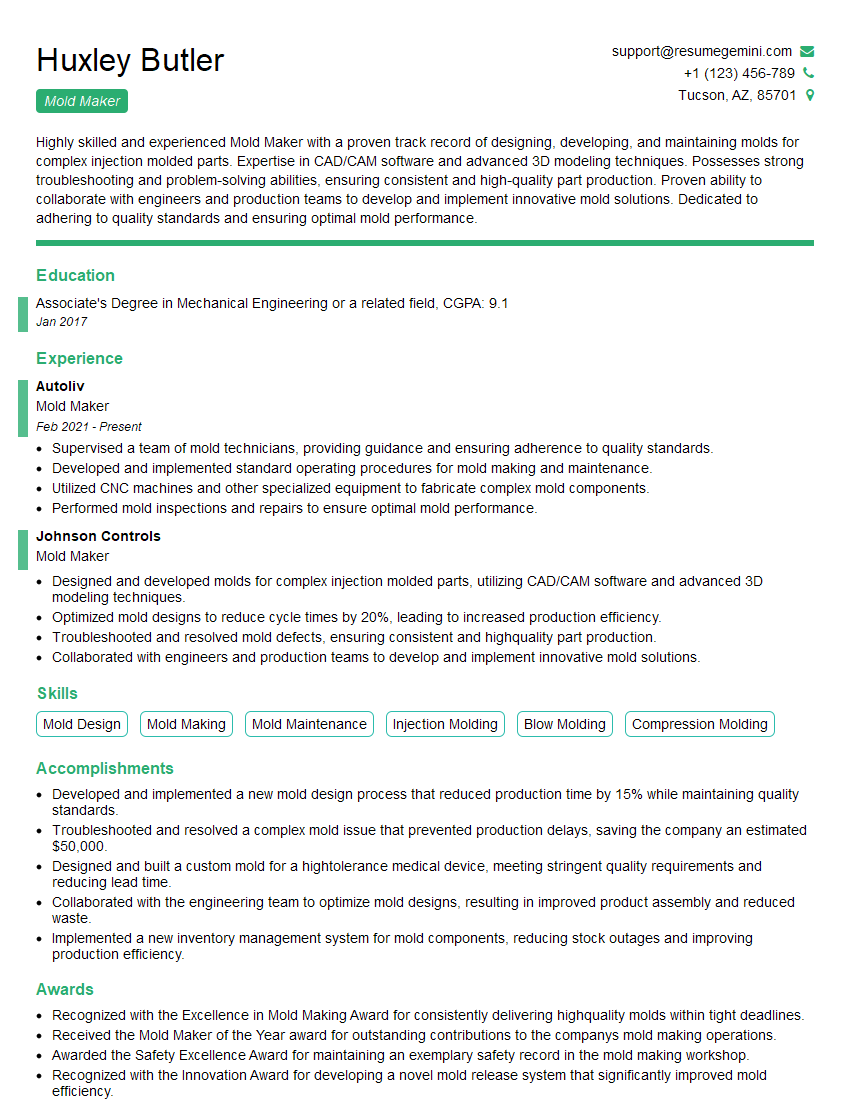

Next Steps

Mastering Die Casting and Molding Processes opens doors to exciting career opportunities in manufacturing, automotive, aerospace, and many other industries. A strong understanding of these processes is highly valued by employers. To increase your chances of landing your dream job, focus on creating an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to the Die Casting and Molding Processes industry to guide you through the process. Take the next step towards your successful career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good