The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Dimension Stone Extraction interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Dimension Stone Extraction Interview

Q 1. Describe the different methods used for dimension stone extraction.

Dimension stone extraction employs several methods, chosen based on factors like stone type, geological conditions, and desired block size. These methods broadly fall under two categories: quarrying and mining.

- Quarrying: This is the most common method for extracting dimension stone. It involves removing the overlying material (overburden) to expose the stone bed. Then, blocks are extracted using various techniques, including drilling and blasting (for harder stones), wire sawing (for softer stones), and channeling machines. Think of it like carefully peeling away layers of earth to reveal a beautiful stone ‘cake’.

- Mining: This approach is used for underground extraction, usually when the stone deposit is located deep beneath the surface or when surface quarrying is impractical. Underground mining involves creating tunnels and shafts to access the stone, then employing methods similar to quarrying to extract blocks. This is akin to creating a subterranean ‘mine’ to reach a valuable stone resource.

- Other methods include using specialized tools such as rock saws and hydraulic splitters for more selective block extraction with minimal damage. The choice depends heavily on the specific stone and site.

Q 2. What are the key geological factors to consider when selecting a dimension stone quarry site?

Selecting a suitable dimension stone quarry site demands careful consideration of several geological factors to ensure efficient and safe extraction of high-quality stone. These factors include:

- Stone Quality and Quantity: The site needs a substantial deposit of dimension stone with consistent quality, color, and texture throughout. Geological mapping and core drilling are crucial to assess this.

- Stone Hardness and Fracturing: The stone’s hardness dictates the extraction methods. Harder stones may require blasting, increasing costs and safety concerns. Pre-existing fractures can reduce block yield and necessitate careful planning.

- Geological Structure: The orientation of bedding planes, joints, and faults significantly impacts block size and extraction feasibility. Favorable geological structures allow for easier extraction of larger, more valuable blocks.

- Overburden Characteristics: The depth and composition of the overburden (soil and rock above the stone) affect the cost and complexity of removal. A thin, easily removable overburden is ideal.

- Hydrogeology: Groundwater presence can affect stability and extraction methods. Water ingress can damage the stone and pose safety hazards. Thorough hydrogeological investigations are essential.

Ignoring these factors can lead to increased costs, extraction difficulties, and potential safety hazards, illustrating the critical role of geological expertise in site selection.

Q 3. Explain the process of drilling and blasting in dimension stone extraction.

Drilling and blasting is a common method for extracting dimension stone, particularly for hard and resistant materials. It involves a series of carefully planned and executed steps:

- Drilling: Holes are drilled into the stone according to a pre-determined pattern. The pattern’s design is crucial in controlling the size and shape of the resulting blocks. Different drill types are used depending on the stone hardness.

- Charging: Explosives are carefully loaded into the drill holes. The amount of explosive used is precisely calculated to achieve controlled fragmentation without excessive damage to the stone blocks.

- Blasting: The explosives are detonated in a controlled sequence, creating fractures within the stone mass and breaking it into manageable blocks. The timing and sequence are critical to the success of the blast.

- Block Recovery: After the blast, the extracted blocks are inspected for damage and sorted according to size and quality. Heavy machinery is typically used to move the blocks.

Safety is paramount throughout this process. Strict adherence to safety regulations, use of appropriate personal protective equipment (PPE), and careful planning are essential to minimize the risk of accidents. Experienced blasters are necessary to handle this process safely and efficiently.

Q 4. How do you ensure the safety of workers during dimension stone extraction operations?

Ensuring worker safety in dimension stone extraction is paramount. A multi-faceted approach is needed, integrating engineering controls, administrative controls, and personal protective equipment (PPE):

- Engineering Controls: This includes implementing safe drilling and blasting procedures, using stable excavation methods to prevent collapses, providing proper ventilation in underground operations, and using machinery with safety features.

- Administrative Controls: This involves implementing a comprehensive safety management system, providing regular safety training to workers, conducting thorough risk assessments, and enforcing strict adherence to safety regulations. This includes clear communication protocols during blasting operations.

- Personal Protective Equipment (PPE): Workers must use appropriate PPE, such as hard hats, safety glasses, hearing protection, and high-visibility clothing. Specialized safety gear is often required for specific tasks like blasting.

- Regular Inspections and Maintenance: Equipment, work areas, and safety systems should be regularly inspected and maintained to prevent accidents.

Safety is not just a responsibility, but a core value in dimension stone extraction. A proactive safety culture minimizes risks and saves lives.

Q 5. What are the common types of equipment used in dimension stone extraction?

Dimension stone extraction utilizes a variety of equipment, chosen based on the specific operation and stone characteristics. Common types include:

- Drilling Equipment: This includes various types of drills, from hand-held drills for smaller operations to large, crawler-mounted drills for larger-scale quarrying. Diamond core drills are commonly used for precision drilling in hard rock.

- Blasting Equipment: This includes explosives, detonators, and blasting mats for safety. The choice of explosive depends on the rock type and desired fragmentation.

- Excavating Equipment: Excavators, loaders, and bulldozers are crucial for removing overburden and handling extracted blocks. These machines vary in size and capacity depending on the scale of operation.

- Wire Saws: These are used for cutting blocks from the quarry face, offering more precise cuts than blasting. This is particularly useful for softer stone types.

- Block Handling Equipment: Cranes, forklifts, and specialized stone handling equipment are used to lift, transport, and stack blocks safely.

- Cutting and Shaping Equipment: This includes various types of saws, grinders, and polishers used for block processing.

Q 6. Describe the process of block cutting and shaping.

Block cutting and shaping transform raw, extracted blocks into usable dimension stone products. This multi-stage process involves several key steps:

- Primary Cutting: Initial cutting often uses wire saws or gang saws to create slabs of a desired thickness. This stage focuses on efficient extraction of large, usable pieces.

- Secondary Cutting: This involves further processing to create specific shapes and sizes based on customer orders. This may involve using various types of saws, including diamond blade saws, bridge saws and circular saws, for precise cuts.

- Shaping and Finishing: This final step involves shaping and finishing the blocks to meet the desired specifications. Techniques include grinding, polishing, and honing, to achieve a smooth and aesthetically pleasing finish. The choice of finishing method depends heavily on the intended use of the stone.

The process is highly dependent on the type of stone and intended application. For example, granite may require more robust cutting equipment compared to softer stones like marble. Precision and careful handling are critical throughout to prevent damage and maintain the quality of the final product.

Q 7. How do you assess the quality of extracted dimension stone blocks?

Assessing the quality of extracted dimension stone blocks involves a thorough evaluation of several key factors:

- Visual Inspection: This includes checking for color consistency, texture, and the presence of any defects like cracks, fissures, or inclusions. This is often done under natural and artificial light.

- Physical Testing: Tests like compressive strength, flexural strength, and water absorption are performed to determine the stone’s physical properties and durability. This data is critical for structural applications.

- Petrographic Analysis: Microscopic examination of thin sections of the stone reveals its mineral composition, texture, and any potential weaknesses. This allows for a deeper understanding of the stone’s behavior and longevity.

- Durability Tests: Testing for freeze-thaw resistance and stain resistance ensures the stone’s suitability for its intended environment. This is particularly important for exterior applications.

- Dimensional Accuracy: Measurement of the block’s dimensions ensures it meets specifications and avoids waste during processing.

A combination of visual assessment, physical testing, and laboratory analysis ensures that only high-quality blocks are selected for further processing and market use. This comprehensive assessment mitigates risks and guarantees customer satisfaction.

Q 8. Explain the importance of environmental considerations in dimension stone extraction.

Environmental considerations are paramount in dimension stone extraction. Ignoring them leads to significant ecological damage and regulatory issues. Sustainable practices are crucial for long-term viability.

- Minimizing land disturbance: Careful planning and extraction methods reduce the quarry’s footprint and preserve surrounding ecosystems.

- Water management: Controlling water runoff and preventing contamination of nearby water sources is essential. This often involves implementing sediment ponds and managing water usage efficiently.

- Air quality: Dust suppression techniques, such as spraying water during blasting and using dust suppressant chemicals, are critical for maintaining air quality and protecting worker health.

- Biodiversity protection: Protecting and restoring habitats for local flora and fauna is a key aspect of responsible quarrying. This can involve habitat creation or relocation efforts.

- Waste management: Proper management of waste rock and other byproducts minimizes visual impact and potential environmental hazards. Recycling and repurposing waste materials whenever possible is highly beneficial.

For example, in a recent project, we implemented a closed-loop water system that significantly reduced water consumption and prevented contamination of a nearby river.

Q 9. What are the common challenges faced during dimension stone extraction?

Dimension stone extraction presents several challenges. These vary based on the type of stone, geological conditions, and location but generally include:

- Geological complexities: Unexpected geological features like faults, fractures, and variations in stone quality can disrupt operations and increase costs.

- Weather conditions: Extreme weather events can halt operations, damage equipment, and increase safety risks.

- Access and infrastructure: Remote quarry locations may require significant investment in access roads, power lines, and other infrastructure.

- Equipment limitations: Specialized equipment is needed for efficient extraction, and its maintenance and repair can be expensive.

- Regulatory compliance: Meeting environmental regulations and obtaining necessary permits can be complex and time-consuming.

- Worker safety: Quarrying is inherently risky, and maintaining a safe working environment requires stringent safety protocols and training.

One memorable challenge involved dealing with an unexpected fault line in a granite quarry. We had to adapt our extraction plan, increasing costs but preventing significant loss of valuable material.

Q 10. How do you manage waste generated during dimension stone extraction?

Waste management is a critical component of responsible dimension stone extraction. We employ a multi-pronged approach:

- Waste minimization: Careful planning and precise cutting techniques reduce the amount of waste generated.

- Reclamation and restoration: We work to restore the quarry site after extraction, often using waste rock for backfilling and landscaping.

- Recycling and repurposing: Suitable waste materials might be crushed and used as aggregate in construction projects.

- Landfill disposal: Only non-recyclable waste is sent to licensed landfills, strictly adhering to regulations.

- Monitoring and reporting: Regular monitoring and reporting ensure compliance with environmental regulations and identify areas for improvement.

For instance, in one project, we successfully repurposed waste marble chips to create decorative aggregates for landscaping projects, reducing landfill waste and generating additional revenue.

Q 11. Describe your experience with different types of dimension stone (e.g., granite, marble, limestone).

My experience encompasses a wide range of dimension stones. Each presents unique challenges and opportunities:

- Granite: Known for its durability and hardness, granite requires specialized equipment and blasting techniques. The extraction process is often more challenging due to its inherent strength.

- Marble: More delicate than granite, marble requires careful handling and extraction to prevent breakage. Its beauty often commands a higher price point.

- Limestone: Limestone is widely used in construction and varies greatly in its properties depending on its formation. Some limestones are easily extracted, while others require more precise methods.

Working with each stone type has broadened my understanding of the nuanced techniques required for efficient and safe extraction.

Q 12. How do you ensure the efficiency and productivity of dimension stone extraction operations?

Ensuring efficiency and productivity in dimension stone extraction involves a holistic approach:

- Optimized quarry layout: A well-planned layout maximizes resource utilization and minimizes transportation costs.

- Advanced equipment: Investing in modern, high-performance equipment, like wire saws and specialized loaders, significantly improves productivity.

- Skilled workforce: Training and retaining skilled workers is crucial for safe and efficient operations. Effective training programs reduce incidents and improve quality.

- Data-driven decision making: Monitoring key performance indicators (KPIs) allows for real-time adjustments and continuous improvement.

- Regular maintenance: Preventative maintenance minimizes downtime and keeps equipment operating at peak efficiency.

For example, we implemented a new quarry management software system, which improved scheduling and optimized equipment usage, leading to a 15% increase in productivity.

Q 13. What are the key performance indicators (KPIs) you use to monitor the performance of a dimension stone quarry?

Key performance indicators (KPIs) are crucial for monitoring quarry performance. We track:

- Production rate (tonnes/day or m³/day): Measures the volume of stone extracted per unit of time.

- Block recovery rate (%): Indicates the proportion of usable blocks extracted from the total extracted material.

- Waste generation rate (%): Tracks the amount of waste generated relative to the usable material.

- Operating costs ($/tonne or $/m³): Analyzes the cost-effectiveness of the extraction process.

- Safety incidents rate (number of incidents/worker-hours): Monitors safety performance and identifies areas for improvement.

- Equipment uptime (%): Measures the percentage of time equipment is operational, highlighting potential maintenance needs.

Regular monitoring of these KPIs helps us identify areas for improvement and optimize resource allocation for maximum efficiency and profitability.

Q 14. Explain your experience with quarry layout and planning.

Quarry layout and planning are fundamental to efficient and sustainable operations. The process typically involves:

- Geological surveys and mapping: Detailed surveys identify the extent and quality of the stone resource and geological complexities.

- Resource modeling: Three-dimensional modeling helps visualize the resource and plan extraction sequences to maximize yield.

- Extraction sequence planning: Developing an efficient extraction plan minimizes waste and environmental impact.

- Infrastructure design: Planning access roads, haul roads, processing facilities, and waste disposal areas is essential.

- Environmental impact assessment: A comprehensive environmental impact assessment is required to identify and mitigate potential environmental risks.

- Regulatory approvals: Obtaining necessary permits and approvals from relevant authorities is crucial before starting operations.

In one project, we used advanced 3D modeling software to simulate different extraction sequences, optimizing the layout to reduce waste by 10% and improve overall efficiency.

Q 15. How do you handle unexpected geological challenges during extraction?

Unexpected geological challenges are a common reality in dimension stone extraction. These can range from encountering unforeseen faults and fissures in the rock to discovering areas with unexpectedly weak or unstable strata. My approach involves a multi-pronged strategy. First, thorough pre-extraction geological surveys are crucial. These involve detailed mapping, core drilling, and geophysical studies to identify potential problem areas before significant extraction begins. This minimizes surprises. However, even the best surveys can’t predict everything. When unexpected challenges arise, I implement the following steps:

- Immediate Halt and Assessment: Extraction is immediately stopped in the affected area. A team of geologists and experienced quarry personnel assesses the situation, identifying the nature and extent of the problem.

- Revised Extraction Plan: Based on the assessment, a revised extraction plan is developed. This might involve adjusting blasting patterns, modifying extraction techniques (e.g., switching from blasting to wire sawing), or even completely bypassing the problematic area.

- Support Systems: In cases of unstable strata, we may need to implement rock bolting or other support systems to ensure the safety of personnel and equipment.

- Documentation and Analysis: Every incident is meticulously documented, including the nature of the problem, the corrective actions taken, and lessons learned. This information feeds back into future planning and risk mitigation strategies.

For example, during a project in Vermont, we encountered an unexpected fault line deeper than anticipated. Instead of continuing with the original plan which risked collapse, we used advanced wire sawing techniques to carefully extract blocks around the fault, minimizing waste and maximizing safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your knowledge of relevant safety regulations and compliance standards in dimension stone extraction.

Safety is paramount in dimension stone extraction. My understanding of relevant regulations and standards is extensive, covering both federal and state laws, as well as industry best practices. This includes, but isn’t limited to:

- OSHA Regulations (Occupational Safety and Health Administration): I’m intimately familiar with OSHA’s requirements concerning fall protection, blasting safety, heavy equipment operation, personal protective equipment (PPE), and emergency response planning. This includes regular safety training for all personnel.

- MSHA Regulations (Mine Safety and Health Administration): Where applicable, we strictly adhere to MSHA guidelines for surface mining operations, including ventilation, dust control, and noise reduction.

- State-Specific Regulations: Every state has its own specific regulations related to dimension stone extraction. I make sure our operations comply fully with all applicable local rules and permits.

- Industry Best Practices: We go beyond minimum compliance by adopting industry best practices for risk management, hazard identification, and incident reporting. This includes regular safety audits and inspections.

For instance, our quarry utilizes a comprehensive PPE program including hard hats, safety glasses, steel-toed boots, and hearing protection, along with regular safety meetings to address potential hazards and best practices. We also conduct regular safety training, including emergency procedures and first aid, to ensure everyone is well prepared to handle any situation.

Q 17. How do you maintain and repair extraction equipment?

Maintaining and repairing extraction equipment is crucial for operational efficiency and safety. Our strategy relies on a preventative maintenance schedule combined with prompt repairs when needed. This involves:

- Preventative Maintenance Schedule: We follow a rigorous preventative maintenance schedule for all equipment, including excavators, loaders, bulldozers, and rock cutting machines. This schedule includes regular inspections, lubrication, and component replacements to prevent breakdowns.

- Qualified Technicians: We employ or contract with highly qualified and experienced technicians to perform maintenance and repairs. These technicians are familiar with the specific requirements of the machinery used in dimension stone extraction.

- Spare Parts Inventory: Maintaining a sufficient inventory of spare parts for common repairs minimizes downtime. This is especially crucial for equipment parts prone to wear and tear.

- Record Keeping: All maintenance and repairs are meticulously documented, allowing us to track equipment performance and identify recurring problems.

A practical example is our system for monitoring hydraulic systems on our excavators. Regular fluid sampling, pressure checks, and filter changes prevent costly hydraulic failures and potential safety incidents. This preventative maintenance is far more cost-effective than emergency repairs.

Q 18. What is your experience with inventory management of dimension stone blocks?

Effective inventory management of dimension stone blocks is essential for optimizing profitability and meeting customer demands. Our system integrates several key aspects:

- Block Grading and Classification: Each extracted block is carefully graded and classified based on size, quality, and type of stone. This allows us to match blocks to specific customer orders and optimize inventory.

- Inventory Tracking System: We use a computerized inventory management system to track the location, quantity, and quality of each block. This system allows for real-time monitoring of inventory levels and assists in order fulfillment.

- Storage and Handling: Blocks are stored strategically to minimize damage and maximize space utilization. Careful handling during transport and storage prevents breakage and maintains the quality of the stone.

- Sales Forecasting: Accurate sales forecasting helps anticipate demand and optimize inventory levels, minimizing both overstocking and stockouts.

Imagine we’re working with a particularly rare type of marble. Using our system, we can not only track its exact location within the yard but also allocate specific blocks to fulfill pending orders, ensuring efficient use of this high-value material. This prevents losses due to misallocation or damage.

Q 19. Explain your understanding of different sawing techniques used in dimension stone processing.

Dimension stone processing utilizes a variety of sawing techniques, each with its own advantages and limitations. The choice of technique depends on factors such as the type of stone, desired block size, and surface finish. Some common techniques include:

- Gang Sawing: This technique uses multiple saw blades to cut multiple slabs simultaneously, resulting in high production rates. It’s efficient for large-scale production of standard-sized slabs.

- Wire Sawing: Wire sawing employs a continuous loop of steel wire impregnated with diamond grit to cut blocks. It’s particularly effective for cutting very large blocks or hard stones where gang sawing might be less efficient or cause damage.

- Multi-Blade Sawing: Similar to gang sawing but utilizes fewer blades, often with variable spacing between blades, providing more flexibility in slab size.

- Water Jet Cutting: A high-pressure water jet, often with an abrasive added, is used for cutting. This technique is precise, but slower than other methods, and better suited for intricate cuts or softer stones.

For example, a particularly hard granite might require wire sawing due to its resistance to traditional gang saw blades, while a softer limestone might be efficiently processed using a multi-blade saw. Choosing the right technique is crucial for efficiency, minimizing material waste, and achieving the desired finished product.

Q 20. How do you manage and resolve conflicts within a quarry team?

Conflict resolution is a vital skill in managing a quarry team. My approach prioritizes open communication, clear expectations, and fair resolution. I utilize the following strategies:

- Proactive Communication: Regular team meetings and open-door policies encourage communication and prevent minor issues from escalating.

- Conflict Identification: I actively identify and address potential sources of conflict, such as workload imbalances, unclear roles, or personality clashes.

- Mediation and Facilitation: When conflicts arise, I act as a mediator, facilitating open discussion between the involved parties and helping them reach a mutually agreeable solution.

- Fair and Consistent Application of Rules: Maintaining consistency in applying company policies and procedures ensures fairness and prevents favoritism, which can be a major source of conflict.

- Training and Development: Providing training on conflict resolution techniques and teamwork skills equips employees to manage disagreements effectively.

For example, a disagreement between the blasting crew and the extraction team regarding the size of blasted blocks was resolved by initiating a joint problem-solving session where both teams worked together to create a revised blasting plan that satisfied both groups’ needs. This collaborative approach fostered better teamwork.

Q 21. Describe your experience with budgeting and cost control in dimension stone extraction.

Budgeting and cost control are critical for the financial health of any dimension stone extraction operation. My approach involves a multi-stage process:

- Detailed Budgeting: We begin with a comprehensive budget that includes all anticipated costs, from extraction and processing to transportation and administration. The budget should be broken down into detailed line items.

- Cost Tracking and Monitoring: Regular monitoring of actual costs against the budget is crucial to identify potential cost overruns early on. This includes tracking expenses related to labor, materials, equipment, and energy.

- Variance Analysis: Regular variance analysis helps pinpoint the reasons for any discrepancies between actual and budgeted costs. This allows for prompt corrective actions.

- Efficiency Improvements: Continuously identifying and implementing efficiency improvements is key to reducing costs. This might involve optimizing extraction methods, improving equipment utilization, or streamlining processes.

- Pricing Strategies: Understanding market dynamics and implementing appropriate pricing strategies is crucial for maximizing profitability.

In a recent project, we identified an opportunity to reduce transportation costs by negotiating better rates with a trucking company and optimizing the loading and unloading process. These changes resulted in significant cost savings without compromising on the quality or timeliness of delivery.

Q 22. How do you ensure the quality and consistency of extracted dimension stone?

Ensuring quality and consistency in dimension stone extraction is paramount. It’s a multi-stage process starting even before the first blast. We begin with thorough geological surveys to identify the highest quality zones within the quarry. This involves detailed mapping of the stone’s structure, analyzing its mineral composition for strength and durability, and identifying potential flaws or weaknesses.

During extraction, we employ precise blasting techniques and careful block cutting to minimize damage. Experienced quarry workers assess each block visually, and often utilize non-destructive testing methods like ultrasonic testing to detect internal flaws before the block is even moved. This allows for informed decisions on the block’s suitability for specific applications. Finally, meticulous record-keeping tracks the origin and characteristics of each block, establishing a clear chain of custody that supports quality control throughout the entire process. Think of it like making a fine wine – careful selection of the grapes (stone), controlled fermentation (extraction), and precise aging (finishing) are all critical to the final product’s excellence.

Q 23. Explain your knowledge of different stone finishing techniques (e.g., polishing, honing).

Stone finishing is an art and science. It transforms raw blocks into beautiful and functional products. Polishing, for instance, uses progressively finer abrasives to achieve a high-gloss sheen. This process removes microscopic surface irregularities, revealing the stone’s inherent beauty and enhancing its color and pattern. Honing, on the other hand, produces a smoother, matte finish by using coarser abrasives than polishing. Other techniques include flamed finishing (creating a textured surface using high-temperature flames), sandblasting (creating a uniform, slightly textured finish), and bush-hammering (producing a rough, anti-slip surface). The choice of finish depends entirely on the intended application; a polished granite countertop requires a different finish than a flamed granite paving stone.

For example, a project requiring high durability and slip resistance might opt for honed or flamed finishes, while projects needing elegance and reflective qualities would use a high-polish finish. The selection process always balances aesthetics with the practical demands of the finished product’s use case.

Q 24. Describe your experience with transportation and logistics of dimension stone blocks.

Transporting dimension stone blocks is a significant logistical challenge. These blocks can weigh tons and require specialized handling equipment. We start by selecting the appropriate transportation method, considering factors like distance, block size and weight, and road accessibility. This often involves large, specialized trailers or even heavy-lift cranes for loading and unloading.

Careful planning of the route is crucial to prevent damage during transit. This means avoiding sharp turns and low bridges and ensuring the route is suitable for the weight and dimensions of the transported blocks. Proper securing of the blocks to the transport vehicles is also paramount to avoid shifting and potential accidents. GPS tracking and real-time monitoring are becoming increasingly important in ensuring on-time delivery and tracking the condition of the cargo throughout the journey. In one instance, we had to utilize a barge and specialized lifting equipment to transport exceptionally large blocks across a waterway to avoid severely constraining road transport limitations.

Q 25. How do you plan for and manage the long-term sustainability of a dimension stone quarry?

Long-term sustainability in dimension stone quarrying is crucial. Our approach incorporates several key strategies. First, we prioritize responsible resource management. This means meticulous planning of extraction to minimize waste and maximize the yield of high-quality blocks. Second, we implement strict environmental protection measures. This includes minimizing water usage, controlling dust emissions, and rehabilitating the quarry site after extraction is complete. This involves restoring the land to its natural state or adapting it for other beneficial uses.

Third, we focus on energy efficiency. We continually look for ways to optimize our operations, reducing energy consumption by using more fuel-efficient equipment and improving operational techniques. Finally, we engage with local communities and stakeholders, ensuring transparency and addressing their concerns. Long-term sustainability is not just environmentally responsible but also economically viable. A responsible quarry can operate successfully for generations, providing employment and resources while minimizing its environmental footprint. We view this as a holistic responsibility extending beyond our immediate operations.

Q 26. How do you utilize technology to improve efficiency and safety in dimension stone extraction?

Technology plays a vital role in enhancing efficiency and safety in dimension stone extraction. We use computer-aided design (CAD) software for precise quarry planning and block design, optimizing the extraction process and minimizing waste. GPS-guided machinery ensures precise cutting and reduces the risk of human error. 3D laser scanning provides detailed digital models of the quarry face, helping us to identify the best blocks for extraction.

Remote-controlled machinery reduces the need for workers to be in close proximity to hazardous areas. Real-time monitoring systems help us track equipment performance and detect potential problems early on. Drones are used for aerial surveys of the quarry, providing valuable data for planning and monitoring. Investing in technology not only boosts productivity but, perhaps more importantly, safeguards the wellbeing of our workforce, improving overall safety on-site.

Q 27. Describe your experience with various types of explosives and blasting techniques.

The choice of explosives and blasting techniques depends greatly on the specific characteristics of the stone and the desired block size. We typically use a variety of explosives, from emulsion explosives to ANFO (ammonium nitrate fuel oil), selecting the type that best suits the geological conditions and the target fragmentation pattern.

Blasting techniques range from conventional techniques employing strategically placed boreholes to more advanced techniques like precision blasting, which uses smaller charges and more sophisticated initiation systems to achieve finer control over fragmentation. Safety is paramount, and we adhere to strict safety protocols and regulations throughout the blasting process, including pre-blast surveys, careful charge placement and initiation, and post-blast inspections. Proper training and certification of our blasting crews are essential to minimizing risk and ensuring environmental protection.

Q 28. What are your strategies for optimizing yield and minimizing waste in dimension stone extraction?

Optimizing yield and minimizing waste are key goals. We achieve this through careful quarry planning, utilizing advanced block design software, and employing precise extraction techniques. Block design software helps us to determine the optimal size and shape of blocks to maximize their yield, minimizing waste by creating the most saleable pieces possible.

Careful planning and efficient use of machinery ensures minimal damage to the extracted blocks and limits the amount of material requiring discarding. Recycling of waste material, such as smaller fragments, for use in other applications, such as aggregate for construction, further contributes to waste reduction and contributes to overall operational sustainability. We regularly review our extraction procedures to identify areas for improvement in yield and waste reduction, ensuring continuous enhancement of our efficiency and environmental responsibility.

Key Topics to Learn for Your Dimension Stone Extraction Interview

- Geological Survey and Site Assessment: Understanding geological formations, identifying suitable stone deposits, and conducting site surveys to determine extraction feasibility.

- Extraction Methods and Techniques: Familiarity with various extraction techniques like drilling, blasting, sawing, and wire sawing, including their advantages and limitations in different geological contexts. Practical application includes understanding the selection criteria based on stone type, location, and environmental considerations.

- Equipment and Machinery: Knowledge of heavy machinery used in extraction (e.g., excavators, loaders, cranes, specialized cutting equipment), their maintenance, and safety protocols.

- Block Handling and Processing: Understanding the procedures for handling extracted blocks, minimizing damage, and transporting them safely to processing facilities. This includes considerations for size, weight, and fragility.

- Health and Safety Regulations: Deep understanding of relevant safety regulations, risk assessment procedures, and best practices to ensure a safe working environment.

- Environmental Impact and Sustainability: Knowledge of environmental regulations, minimizing the ecological footprint of extraction activities, and implementing sustainable practices.

- Quality Control and Assurance: Understanding procedures for ensuring the quality of extracted stone, identifying defects, and meeting customer specifications. This includes knowledge of different grading systems.

- Project Management and Cost Estimation: Ability to plan and manage extraction projects effectively, including cost estimation, resource allocation, and scheduling.

- Problem-solving and Troubleshooting: Demonstrating the ability to analyze and solve problems encountered during the extraction process, such as equipment malfunctions, geological challenges, or safety incidents.

Next Steps

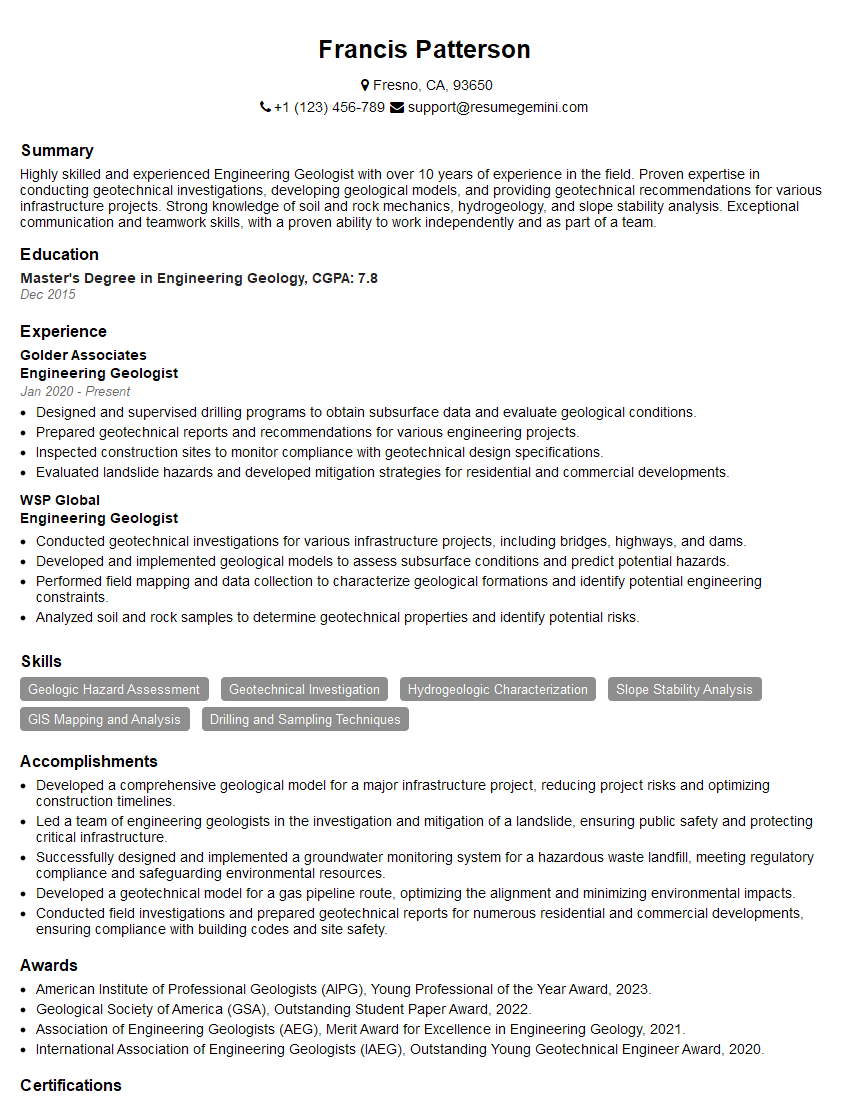

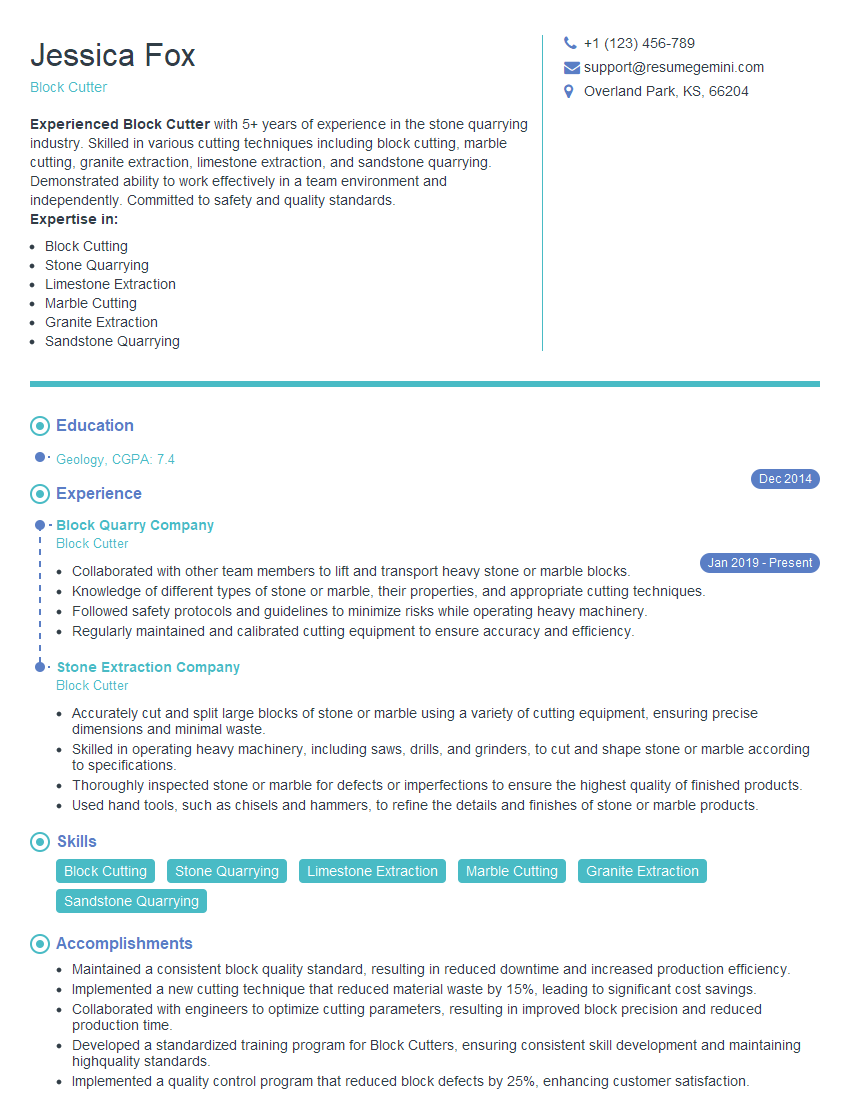

Mastering Dimension Stone Extraction opens doors to exciting career opportunities in a growing industry. To maximize your chances of securing your dream role, a strong and ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. They provide examples of resumes tailored to the Dimension Stone Extraction industry, ensuring your application stands out. Invest time in crafting a compelling resume – it’s your first impression and a key step towards a successful career.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good