Preparation is the key to success in any interview. In this post, we’ll explore crucial DIN ISO 7083 interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in DIN ISO 7083 Interview

Q 1. Explain the scope and purpose of DIN ISO 7083.

DIN ISO 7083, “Guide to the expression of uncertainty in measurement,” provides a universally accepted framework for evaluating and expressing measurement uncertainty. Its purpose is to ensure consistency and transparency in reporting measurement results, allowing for meaningful comparisons between different measurements and experiments, regardless of the field or technique. The scope encompasses all types of measurements, from simple physical measurements to complex chemical analyses. It doesn’t dictate specific methods but outlines the general principles and procedures for evaluating and expressing uncertainty.

Q 2. Describe the key concepts of measurement uncertainty according to DIN ISO 7083.

Measurement uncertainty, as defined in DIN ISO 7083, quantifies the doubt about the measurement result. It’s not about mistakes or blunders, but rather the unavoidable dispersion of possible values that could reasonably be attributed to the measurand (the quantity being measured). This dispersion arises from various sources, including imperfections in the measurement instruments, limitations in the measurement method, and environmental influences. The key concept is that the uncertainty isn’t a fixed value but rather a statistical estimate reflecting the spread of possible values. DIN ISO 7083 emphasizes the importance of a realistic and defensible assessment of uncertainty, acknowledging that some components of uncertainty are inherently difficult to quantify precisely.

Q 3. How do you determine the combined standard uncertainty?

The combined standard uncertainty (uc) represents the overall uncertainty in the measurement result, considering all identified uncertainty components. It’s calculated by combining the individual standard uncertainties (ui) of each component. If the uncertainty components are uncorrelated, the combined standard uncertainty is calculated using the root-sum-of-squares method:

uc = √(u12 + u22 + ... + un2)

Where u1, u2, … un are the standard uncertainties of the individual components. However, if the components are correlated, their covariances must be included in the calculation, resulting in a more complex formula. This highlights the importance of carefully considering correlations when evaluating measurement uncertainty. For instance, if two measurements rely on the same calibration standard, they are correlated.

Q 4. What are the different types of uncertainty components?

Uncertainty components are categorized based on how their standard uncertainties are evaluated. They can be broadly classified into Type A and Type B components, which are further explained in the next answer. However, beyond this core distinction, components originate from many different sources within the measurement process. Examples include:

- Instrument limitations: Resolution, calibration errors, drift.

- Environmental factors: Temperature, humidity, pressure.

- Method limitations: Approximations in the measurement method, inherent variability of the method.

- Sampling uncertainty: Variability within the sample itself.

- Operator variations: Differences in how different operators perform the measurement.

Identifying all significant components requires a thorough understanding of the measurement process. For instance, a laboratory measuring the concentration of a substance would consider uncertainties from the balance, the volumetric flasks, the reagents, and the analytical method itself.

Q 5. Explain the difference between Type A and Type B uncertainty evaluation.

Type A and Type B uncertainty evaluations distinguish how the standard uncertainties are derived. Type A uses statistical methods, involving multiple repeated measurements. The standard deviation of the mean from these measurements directly provides the standard uncertainty. For example, if we measure the length of a bar ten times and calculate the standard deviation of these measurements, it provides a Type A uncertainty component. Type B evaluations, on the other hand, are based on other available information, not involving repeated measurements. This could include manufacturer specifications, calibration certificates, prior experience, or scientific knowledge. For example, we might obtain the uncertainty from the data sheet of a calibrated instrument. Both types are crucial; Type A captures inherent variability, while Type B accounts for uncertainties that are not readily accessible through direct repeated measurements. Both contribute to the overall uncertainty.

Q 6. How do you express measurement results with uncertainty?

The measurement result is expressed along with its associated uncertainty. The standard form recommended by DIN ISO 7083 is:

Measurand = (Result ± Expanded Uncertainty) Unit

For example, “The mass of the object is (100.0 ± 0.2) g.” The expanded uncertainty is calculated by multiplying the combined standard uncertainty by a coverage factor (k), discussed in the next answer. This expression shows the range within which the true value of the measurand lies with a specified level of confidence. Note that simply stating ‘100.0 g’ is insufficient; it omits the crucial information regarding the uncertainty.

Q 7. What is the significance of coverage factor (k) in expressing expanded uncertainty?

The coverage factor (k) is a numerical value used to multiply the combined standard uncertainty (uc) to obtain the expanded uncertainty (U):

U = k * uc

The expanded uncertainty (U) defines an interval around the measurement result within which the true value of the measurand is expected to lie with a stated level of confidence. The most commonly used value for k is 2, corresponding to approximately a 95% confidence level for a normal distribution. However, the choice of k depends on the desired level of confidence and the distribution of the uncertainty components. A larger k increases the confidence level but also widens the uncertainty interval, providing a more conservative estimate. It’s crucial to explicitly state the chosen k value and the associated confidence level when reporting the results to ensure transparency and reproducibility.

Q 8. Describe the process of calibrating a measuring instrument according to DIN ISO 7083.

Calibrating a measuring instrument according to DIN ISO 7083 involves a systematic process to determine its accuracy and ensure it conforms to predefined standards. It’s like taking your car for a tune-up – you’re verifying its performance against known, reliable values.

The process typically includes:

- Preparation: Thoroughly cleaning the instrument, reviewing its operating manual, and ensuring environmental conditions (temperature, humidity) are suitable and stable.

- Comparison: Comparing the instrument’s readings against a traceable standard of known accuracy. This often involves using a higher-accuracy reference instrument or a calibrated standard artifact.

- Measurement: Taking multiple readings at various points across the instrument’s measurement range, allowing for statistical analysis.

- Analysis: Analyzing the collected data to determine the instrument’s deviation from the standard, calculating uncertainties, and identifying any systematic errors.

- Documentation: Recording all measurements, calculations, and observations in a comprehensive calibration certificate.

- Adjustment (optional): If the instrument’s deviation exceeds specified tolerance limits, adjustment might be necessary, followed by recalibration.

For example, calibrating a digital thermometer involves comparing its readings against a calibrated liquid-in-glass thermometer or a traceable temperature bath across a range of temperatures. Any deviation is then documented in the certificate.

Q 9. What are the essential elements of a calibration certificate?

A calibration certificate is a crucial document that provides evidence of a measuring instrument’s accuracy. Think of it as a report card for your measuring device. Essential elements include:

- Unique Identification: A unique number or identifier for the certificate and the instrument.

- Instrument Description: Complete details about the instrument, including model, serial number, and manufacturer.

- Calibration Date: The date the calibration was performed.

- Calibration Method: A description of the methods and standards used.

- Calibration Results: Numerical data summarizing the calibration, including measured values, deviations from the standard, and uncertainties.

- Traceability Statement: A statement confirming the traceability of the calibration to national or international standards.

- Uncertainty Statement: A statement specifying the measurement uncertainties associated with the calibration results.

- Expiry Date: The date when the calibration is no longer considered valid.

- Accreditor details (if applicable): Information about the accrediting body, showing the calibration laboratory’s competency.

- Calibration Laboratory Information: Details of the laboratory that performed the calibration, including address and contact information.

- Signatures and Approvals: Signatures of authorized personnel confirming the validity of the calibration.

Q 10. Explain the concept of traceability in calibration.

Traceability in calibration is the ability to demonstrate an unbroken chain of comparisons linking a measurement result to national or international standards. It’s like a family tree for your measurements – showing how they’re related to the most reliable source. This ensures consistent and reliable measurement results worldwide. Imagine trying to compare weights using different, unverified scales – unreliable and incomparable! Traceability solves this problem.

Achieving traceability involves a hierarchy of standards. A calibrated instrument is traceable if its calibration was performed using an instrument calibrated against a higher-level standard, and so on up the chain to a national metrology institute (NMI), whose standards are usually linked to international standards.

Q 11. How do you assess the validity of a calibration certificate?

Assessing the validity of a calibration certificate requires careful review of several aspects:

- Check the Expiry Date: Ensure the certificate is still valid. Calibration certificates have a limited lifespan.

- Verify the Laboratory Accreditation (if needed): If the application requires accredited calibration, check for the accrediting body’s logo and accreditation number. This ensures the lab meets high quality standards.

- Review the Certificate’s Completeness: Ensure all the essential elements mentioned earlier are present and clearly stated.

- Assess the Uncertainty Statement: A high uncertainty value might indicate potential problems with the calibration. Consider whether this uncertainty is acceptable for your application.

- Examine the Measurement Results: Check if the deviations from the standard are within acceptable tolerances for your specific application.

- Check for Signs of Tampering: Look for any signs that the certificate might have been altered.

If any doubts arise, contact the calibration laboratory for clarification.

Q 12. How do you manage and control measurement uncertainties in a production environment?

Managing and controlling measurement uncertainties in a production environment is crucial for maintaining product quality and consistency. It involves a multi-faceted approach:

- Regular Calibration: Implement a structured calibration program for all measuring instruments, ensuring they’re calibrated at appropriate intervals.

- Proper Instrument Selection: Choose instruments with measurement uncertainties suitable for the application’s requirements.

- Environmental Control: Maintain a stable environment (temperature, humidity) to minimize the influence of environmental factors on measurement accuracy.

- Operator Training: Train operators on the proper use and handling of measuring instruments.

- Statistical Process Control (SPC): Use statistical methods to monitor the process and detect deviations from specified limits. This allows for early identification of issues.

- Uncertainty Budget: Calculate and document the uncertainty budget for each measurement process, identifying major contributors to the overall uncertainty.

- Traceability Management: Ensure traceability of all calibrations to national standards.

For example, in a pharmaceutical production environment, precise measurements of ingredients are crucial. Managing uncertainty through regular calibration, environmental control and robust processes is vital for medication safety and efficacy.

Q 13. What is the role of a calibration laboratory in ensuring measurement quality?

Calibration laboratories play a vital role in ensuring measurement quality by providing reliable and traceable calibration services. They act as the guardians of measurement accuracy.

Their roles include:

- Providing Traceable Calibrations: Linking instrument calibrations to national and international standards, ensuring consistency and reliability.

- Maintaining Calibration Standards: Possessing and maintaining high-accuracy reference standards and equipment.

- Implementing Quality Systems: Following strict quality management systems (e.g., ISO/IEC 17025) to guarantee the accuracy and reliability of their services.

- Issuing Calibration Certificates: Providing comprehensive and verifiable calibration certificates.

- Offering Technical Expertise: Providing expertise on measurement techniques, uncertainty analysis, and quality management.

In essence, calibration laboratories are the backbone of a robust measurement system. They build trust and confidence in the reliability of measurements, which impacts everything from product quality to scientific research.

Q 14. What are the potential sources of measurement uncertainty in your field of expertise?

Potential sources of measurement uncertainty in the field of calibration are numerous and can be broadly classified into:

- Instrument limitations: Resolution, linearity, hysteresis, drift, and repeatability of the measuring instrument itself.

- Environmental factors: Temperature variations, humidity, pressure, and electromagnetic interference affecting instrument performance.

- Operator influence: Human errors in reading instruments, setting parameters, and following procedures.

- Method uncertainty: Limitations and uncertainties inherent in the calibration method used.

- Standard uncertainty: The uncertainty associated with the reference standards used in the calibration process.

- Data analysis uncertainty: Errors or uncertainties in data processing and analysis methods.

For example, calibrating a pressure gauge might be influenced by ambient temperature changes, causing the gauge’s readings to deviate slightly from the actual pressure. Understanding and mitigating these sources through thorough process control is key.

Q 15. How would you handle a situation where measurement uncertainty exceeds the acceptable limits?

If measurement uncertainty exceeds acceptable limits, it indicates a problem with the measurement process. The first step is to investigate the source of the excessive uncertainty. This involves a thorough review of the measurement process, including the equipment, methods, and personnel involved. DIN ISO 7083 guides this process by emphasizing a systematic approach to uncertainty analysis. We might use a cause-and-effect diagram (Ishikawa diagram) to identify potential sources. For example, if we’re measuring the length of a metal rod and the uncertainty is high, the reasons might include poorly calibrated measuring instruments, operator error, variations in temperature affecting the rod’s length, or even vibrations in the environment.

Once the source is identified, corrective actions are implemented. These actions could include recalibrating the measuring instrument to a higher standard, improving the measurement technique (e.g., using a more stable measuring environment, a more precise instrument), providing additional training to personnel, or improving the instrument’s environmental control. After implementing corrections, the measurement uncertainty analysis needs to be repeated to verify that the uncertainty is now within acceptable limits. If it remains high, the cycle of investigation, correction, and verification needs to be repeated until the issue is resolved. Failing to address high uncertainty can lead to incorrect decisions and costly consequences, impacting product quality and potentially safety.

Career Expert Tips:

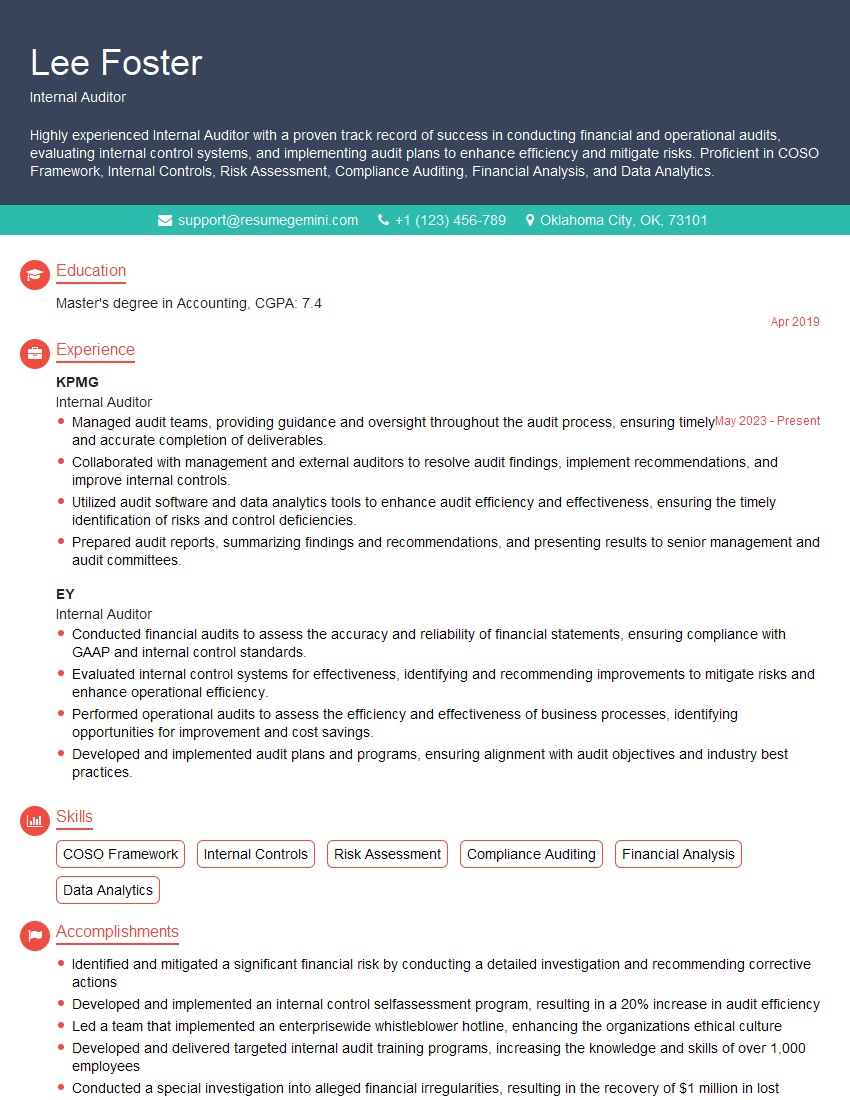

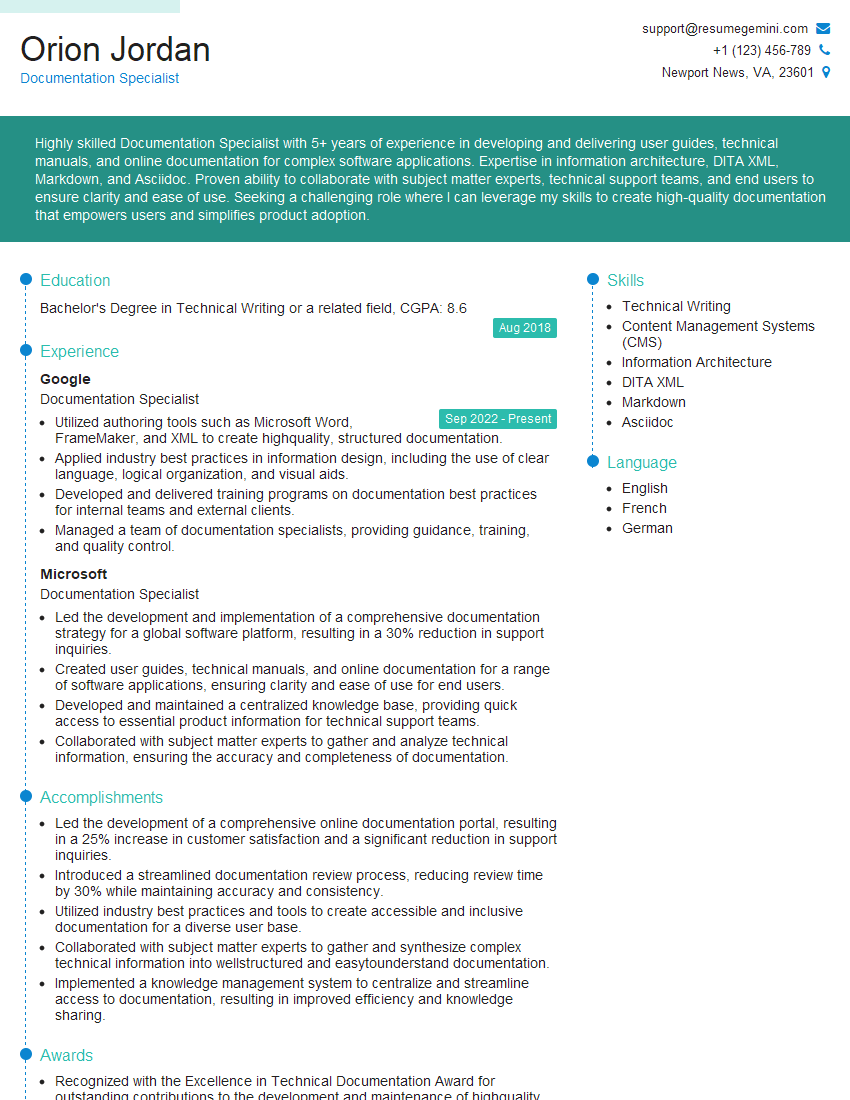

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with statistical methods used in uncertainty analysis.

My experience with statistical methods in uncertainty analysis is extensive. I’m proficient in using various methods as outlined in DIN ISO 7083, including the ‘Guide to the Expression of Uncertainty in Measurement’ (GUM). This includes calculating uncertainty components from various sources like calibration certificates, repeatability and reproducibility studies, and environmental factors. I routinely employ techniques like the law of propagation of uncertainty to combine these components into a final uncertainty estimate. This often involves using statistical distributions (like normal, rectangular, triangular, or others as appropriate) to model the uncertainty components and account for their potential correlation.

I have practical experience using software packages like [mention specific software you are familiar with e.g., MATLAB, R, or specialized metrology software] to perform these calculations efficiently and accurately. For example, in a recent project involving the calibration of a pressure sensor, I used a Monte Carlo simulation to estimate the combined uncertainty, accounting for the various contributing factors. This allowed for a robust and realistic representation of the overall uncertainty.

Q 17. How do you ensure the competence of personnel involved in calibration activities?

Ensuring personnel competence is paramount in calibration activities. DIN ISO 7083 emphasizes the importance of training and qualification. We follow a multi-faceted approach:

- Initial Training: All personnel are provided with comprehensive training on the relevant calibration procedures, the use of measuring equipment, and the importance of accurate record-keeping. This training is tailored to the specific equipment and methods employed.

- Ongoing Professional Development: We have a continuous professional development program with regular updates and refresher courses to keep personnel abreast of the latest techniques and standards. This helps address changes in technology and best practices.

- Competency Assessment: Regular competency assessments, including practical exercises and theoretical tests, are conducted to evaluate personnel’s understanding and skills. This ensures that personnel consistently meet the required levels of competency and helps to pinpoint areas where additional training might be needed.

- Documentation: A complete record of training, qualification, and competency assessments is maintained for each individual involved in calibration activities. This documentation forms part of the quality management system and demonstrates our commitment to compliance with DIN ISO 7083.

By implementing these measures, we ensure that our personnel are consistently competent and capable of performing accurate and reliable calibration work, contributing significantly to reduced measurement uncertainty.

Q 18. Explain the importance of maintaining calibration records and documentation.

Maintaining accurate and complete calibration records and documentation is critical for several reasons:

- Traceability: Calibration records provide traceability to national or international standards, ensuring that the measurements are reliable and comparable across different laboratories or organizations. This is essential for demonstrating compliance with regulations and quality standards.

- Verification: Records allow for verification of the accuracy and validity of measurements over time. If discrepancies arise, the records can help identify the source of the problem.

- Legal and Regulatory Compliance: Many industries have regulations and standards requiring meticulous calibration records. Maintaining these records ensures compliance and avoids potential legal issues.

- Continuous Improvement: Analysis of calibration records helps to identify trends and patterns, which can be used for continuous improvement of the calibration process. This could lead to identifying issues in the measurement process and improving accuracy.

- Auditing: Calibration records are crucial for internal and external audits to demonstrate compliance with relevant standards and regulatory requirements.

In essence, these records serve as a critical component of the quality management system, demonstrating our commitment to accurate and reliable measurement and ensuring the integrity of our calibration services.

Q 19. How do you interpret the results of a measurement uncertainty analysis?

Interpreting the results of a measurement uncertainty analysis involves understanding the meaning of the uncertainty value obtained. It’s not just a number; it’s a statement about the quality of the measurement. The uncertainty value, typically expressed with a confidence level (e.g., 95%), represents the range within which the true value of the measurand is likely to lie. For example, if a measurement of a voltage is 10V ± 0.2V (k=2, 95% confidence level), it means we are 95% confident that the true voltage lies between 9.8V and 10.2V.

The interpretation also depends on the context. A small uncertainty might be acceptable in some situations, but unacceptable in others depending on the application. For example, a small uncertainty might be acceptable for measuring the length of a piece of wood for a general purpose but not acceptable for measuring the dimensions of a critical component for aerospace applications. Therefore, the analysis needs to be compared with the requirements or specifications of the measurement process. If the uncertainty is too high, it indicates a need to improve the measurement process, as discussed in previous answers.

Q 20. What are the key differences between accuracy and precision?

Accuracy and precision are often confused, but they represent different aspects of measurement quality.

- Accuracy refers to how close a measurement is to the true value. A highly accurate measurement is one that is very close to the actual value of the measurand.

- Precision refers to how close repeated measurements of the same quantity are to each other. High precision means that the measurements are highly reproducible.

Imagine hitting a target with darts. High accuracy means all darts are clustered around the bullseye (close to the true value), while high precision means that all darts are clustered closely together regardless of whether they are near the bullseye. You could have high precision but low accuracy (all darts close together but far from the bullseye) or low precision but high accuracy (darts spread out but their average is near the bullseye). Both are important for reliable measurement; ideally, you’ll want both high accuracy and high precision.

Q 21. What are the different methods for reducing measurement uncertainty?

Reducing measurement uncertainty requires a systematic approach, focusing on various aspects of the measurement process. Several methods can be implemented:

- Improve the Measurement Equipment: Using more precise and accurate instruments, with lower uncertainties stated on their calibration certificates, is a direct way to reduce uncertainty.

- Enhance Measurement Techniques: Refining the measurement procedure, controlling environmental factors (temperature, humidity, vibration), and using appropriate calibration techniques can minimize uncertainty contributions from the method.

- Increase the Number of Measurements: Taking multiple measurements and performing statistical analysis can help reduce the uncertainty associated with random errors. This applies to situations where variability is a key part of the measurement uncertainty.

- Improve Calibration Procedures: Using a more traceable calibration standard or a more frequent calibration schedule can contribute to lowering the measurement uncertainty.

- Reduce Operator Error: Providing additional training to personnel, developing clear and detailed instructions, and utilizing quality control measures can minimise uncertainty due to human error.

- Environmental Control: Ensuring a stable and controlled environment can minimize the influence of environmental factors on measurement uncertainty.

The choice of method depends on the specific source of uncertainty identified during the uncertainty analysis. Often a combination of techniques are necessary for a significant reduction in the overall uncertainty. It is important to systematically assess and address all significant contributions of uncertainty to obtain the most reliable result.

Q 22. Describe a situation where you had to troubleshoot a measurement problem.

During a project involving the verification of dimensional tolerances on precision-machined parts, we encountered a significant discrepancy between our measurements and the design specifications. The measurements were consistently outside the tolerance limits, suggesting a potential issue with our measuring instrument, the environmental conditions, or even the measurement process itself.

Our troubleshooting process began with a careful review of the measurement procedure. We checked for operator errors, ensuring consistent handling of the parts and instrument. We then investigated the environmental factors, verifying the temperature and humidity were within the acceptable range specified by DIN ISO 7083 and the instrument’s operational limits. This involved using calibrated environmental monitoring devices. Next, we calibrated the measuring instrument against a traceable standard, following the procedures outlined in ISO 17025. We discovered a slight drift in the measuring instrument’s calibration, sufficient to explain the observed discrepancies. Recalibration resolved the problem, and subsequent measurements were well within the required tolerances. This experience underscored the importance of regular calibration and the need for a systematic troubleshooting approach.

Q 23. How familiar are you with different calibration methods (e.g., direct comparison, substitution)?

I’m very familiar with various calibration methods, as described in DIN ISO 7083. The choice of method depends heavily on the type of measuring instrument and its intended application.

- Direct Comparison: This method involves comparing the output of the instrument under calibration to a known standard. For example, comparing a calibrated pressure gauge directly to a master pressure gauge.

- Substitution: In substitution calibration, the instrument under test replaces a known standard in a measurement setup. The differences in readings reveal any discrepancies in the instrument being calibrated. This is commonly used for weighing instruments.

- Calibration using a certified reference material: This method involves using a certified reference material (CRM) with known properties to check the accuracy of instruments such as spectrophotometers or pH meters.

Understanding the strengths and weaknesses of each method is vital. For instance, direct comparison is straightforward but susceptible to errors in the reading process. Substitution minimizes these reading errors, offering higher accuracy.

Q 24. Explain your understanding of the influence of environmental conditions on measurement uncertainty.

Environmental conditions significantly affect measurement uncertainty. DIN ISO 7083 emphasizes this, detailing how temperature, humidity, pressure, and even vibrations can influence the accuracy of measurements. Consider a length measurement using a steel measuring tape: temperature changes alter the tape’s length due to thermal expansion, introducing error. Similarly, high humidity can affect the accuracy of electronic instruments.

To account for this, we need to:

- Control the environment: Ideally, measurements should be conducted in a controlled environment with stable temperature, humidity, and pressure. This minimizes environmental influences on the readings.

- Measure environmental parameters: Record temperature, humidity, and pressure during the measurement. This data allows for environmental corrections, minimizing uncertainty based on these variables, or the estimation of the impact of the uncertainty in environmental parameters on the result.

- Use appropriate instrumentation: Select instruments with low sensitivity to environmental changes or instruments equipped with automatic compensation.

- Include environmental uncertainty in the final uncertainty budget: Quantify the impact of environmental variability on the overall measurement uncertainty, accurately reflecting the uncertainty.

Ignoring environmental influences can lead to significant errors. A comprehensive understanding and management of environmental factors are essential for achieving reliable and accurate measurements, in compliance with DIN ISO 7083.

Q 25. How do you select appropriate measurement instruments based on required uncertainty levels?

Selecting the right measurement instrument is critical for achieving the desired uncertainty level. The process involves:

- Defining required uncertainty: Begin by clearly defining the acceptable level of uncertainty for the measurement application. This is often dictated by specifications or standards.

- Instrument specifications: Review the technical specifications of potential instruments, focusing on stated uncertainty. Look for instruments whose stated uncertainty is less than the required uncertainty.

- Calibration certificate: Ensure that the instrument’s calibration certificate confirms compliance with the required uncertainty.

- Traceability: The calibration certificate must demonstrate traceability to national or international standards.

- Instrument suitability: Consider factors beyond accuracy, such as the instrument’s range, resolution, robustness, and ease of use.

For instance, if measuring a very small dimension with high precision, you would need a highly accurate instrument like a calibrated micrometer, not a general-purpose ruler. By carefully considering these factors, you can select an instrument appropriate for meeting the required uncertainty levels.

Q 26. How do you ensure the accuracy and reliability of measurement data in a quality management system?

Ensuring accurate and reliable measurement data within a quality management system (QMS) requires a multi-faceted approach, heavily influenced by DIN ISO 7083’s principles. This involves:

- Calibration program: Implement a comprehensive calibration program for all measuring instruments, with regular calibration intervals based on instrument usage and stability.

- Traceable standards: Use calibration standards traceable to national or international standards to ensure the accuracy of the calibration process.

- Calibration records: Maintain detailed records of all calibrations, including instrument identification, calibration date, results, and any necessary corrections.

- Competent personnel: Ensure that personnel performing measurements and calibrations are adequately trained and competent.

- Measurement procedures: Define and document clear measurement procedures to minimize errors and ensure consistency.

- Environmental control: Control and monitor environmental conditions to minimize their impact on measurements.

- Regular audits: Conduct regular audits to verify compliance with calibration procedures and the overall measurement system.

Properly implemented, this system ensures data integrity, traceability, and ultimately, the reliability and quality of the final product or service.

Q 27. Describe your experience with different types of measuring instruments and their calibration procedures.

My experience encompasses a wide range of measuring instruments, including:

- Dimensional measurement instruments: Calipers, micrometers, dial indicators, optical comparators; calibration procedures involve comparison to master gauges and traceable standards.

- Weight measurement instruments: Balances (analytical and general purpose); calibration uses calibrated weights traceable to national standards, and regular testing of linearity and repeatability.

- Pressure measurement instruments: Pressure gauges and transducers; calibration involves comparison to deadweight testers or other calibrated pressure sources.

- Temperature measurement instruments: Thermometers, thermocouples, and RTDs; calibration involves comparison to calibrated temperature baths or reference thermometers.

Each instrument type has its unique calibration procedure. The procedures are always documented, and the calibration process follows recognized standards like ISO 17025 and DIN ISO 7083, ensuring traceability and accuracy. The calibration history is diligently tracked and forms an integral part of our quality control system.

Key Topics to Learn for DIN ISO 7083 Interview

- Understanding the Standard: A thorough grasp of the core principles and objectives outlined in DIN ISO 7083. Focus on its purpose and the problems it solves.

- Data Integrity and Security: Explore the methods and techniques used to ensure data integrity and security within the framework of DIN ISO 7083. Consider practical scenarios where these measures are crucial.

- Implementation and Testing: Learn about the practical implementation of DIN ISO 7083 in different systems and environments. Understand the various testing methodologies employed to validate compliance.

- Risk Management and Mitigation: Analyze potential risks associated with non-compliance and explore strategies for effective risk mitigation within the context of the standard.

- Interoperability and Compatibility: Examine how DIN ISO 7083 ensures interoperability and compatibility between different systems and platforms. Understand the challenges and solutions involved.

- Case Studies and Best Practices: Research real-world examples of successful DIN ISO 7083 implementations. Identify common challenges and best practices for optimal outcomes.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and resolve issues related to DIN ISO 7083 compliance. Practice identifying and resolving potential conflicts.

Next Steps

Mastering DIN ISO 7083 opens doors to exciting career opportunities in data management, security, and compliance. A strong understanding of this standard is highly valued by employers seeking professionals who can ensure data integrity and security within their organizations. To maximize your job prospects, create an ATS-friendly resume that clearly highlights your skills and experience related to DIN ISO 7083. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to DIN ISO 7083 are available through ResumeGemini to provide inspiration and guidance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good