Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Distinctive Trimming interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Distinctive Trimming Interview

Q 1. Explain the different types of trimming tools and their applications.

Trimming tools are crucial for achieving precise and aesthetically pleasing finishes in various materials. The choice of tool depends largely on the material being trimmed and the desired outcome. Here are some key types:

- Shears/Scissors: These range from basic fabric shears for general trimming to specialized pinking shears that create a zigzag edge to prevent fraying, and fine detail shears for intricate work. For example, pinking shears are perfect for lightweight fabrics like cotton, while heavy-duty shears are needed for thicker materials like denim.

- Rotary Cutters: These offer speed and precision for trimming large pieces of fabric or other materials. They’re ideal for straight cuts and repetitive trimming tasks, particularly in production environments. I’ve found them invaluable when working with large batches of leather.

- Blades (e.g., craft knives, utility knives): These are incredibly versatile, allowing for detailed cuts and shaping, but require careful handling due to their sharpness. I often use a craft knife for intricate trimming on fur or delicate fabrics.

- Electric Trimmers: These motorized tools are excellent for bulk trimming and offer consistent cuts, especially when dealing with larger volumes or difficult materials. The speed and consistency are unmatched for large-scale leather trimming operations.

The application of each tool is dictated by the project’s requirements. For example, hand-shearing offers great control for complex shapes, while a rotary cutter is best for straight lines on large quantities of material.

Q 2. Describe your experience with various trimming materials (e.g., fabric, leather, fur).

My experience spans a wide range of trimming materials. Each presents unique challenges and necessitates a tailored approach:

- Fabric: I’ve worked extensively with various fabrics, from delicate silks to heavy-duty canvas. Understanding the weave and drape of each fabric is critical for selecting the right tool and technique to achieve a clean, even trim without damage. For instance, a sharp pair of shears is essential for delicate silks to avoid pulling or snagging the threads.

- Leather: Leather trimming demands precision and sharpness to avoid tearing or leaving uneven edges. I often use rotary cutters for straight cuts and sharp blades for intricate details. The type of leather also matters—full-grain leather is more robust and requires a different approach than softer suede.

- Fur: Fur is exceptionally delicate. Trimming requires a light touch and specialized tools to avoid damaging the delicate hairs. Craft knives and fine detail shears are frequently employed, with careful attention paid to the direction of the fur for a natural-looking result.

Adaptability is key. I adjust my technique based on the material’s properties, always prioritizing minimizing damage and ensuring a high-quality finish.

Q 3. How do you ensure consistent trimming quality across large production runs?

Maintaining consistent trimming quality across large production runs hinges on meticulous planning and execution. Several strategies are crucial:

- Standardized Procedures: Detailed written or video instructions outlining every step of the trimming process ensure uniformity across all team members.

- Tool Calibration and Maintenance: Regularly checking and sharpening tools is vital. Dull tools lead to inconsistent cuts and potentially damage materials.

- Quality Control Checks at Each Stage: Implementing frequent spot checks throughout the process allows for the early detection and correction of any inconsistencies.

- Use of Jigs and Templates: These are indispensable for ensuring accurate and repeatable cuts, especially for complex shapes.

- Training and Skill Development: Well-trained staff are essential. Consistent training helps to maintain skill levels and reduce errors.

For example, in a recent large-scale leather goods production, we implemented a rigorous quality control system with checks at three points in the trimming process, which drastically reduced defects and ensured a high level of consistency in our final products.

Q 4. What are the common challenges faced in distinctive trimming, and how do you overcome them?

Distinctive trimming presents unique challenges. Some common issues include:

- Material Variations: Inconsistent material thickness or texture can lead to uneven trimming. Careful pre-trimming inspection and adjustments to the trimming technique are crucial to address this.

- Complex Shapes and Designs: Intricate designs require meticulous hand-trimming or specialized tooling, demanding precision and patience. Templates and jigs are invaluable here.

- Maintaining Sharpness: Dull tools are a significant source of inconsistent trimming and potential damage to the material. Regular sharpening and tool maintenance are non-negotiable.

- Production Speed vs. Quality: Balancing speed with precision is an ongoing challenge, especially in high-volume production. Careful planning and efficient workflow processes help strike this balance.

To overcome these, I emphasize thorough preparation, including material pre-checks and tool maintenance. I also utilize a combination of hand and machine trimming techniques to optimize both speed and accuracy, selecting the most appropriate method for each task. For example, I might use a machine for straight cuts on large pieces of fabric but switch to hand trimming for more intricate details.

Q 5. Explain your understanding of different trimming techniques (e.g., hand trimming, machine trimming).

Different trimming techniques offer distinct advantages:

- Hand Trimming: This provides maximum control and precision, making it ideal for intricate details and complex shapes. It demands skill and patience but offers unparalleled accuracy. For example, hand trimming is essential for creating clean, precise edges on delicate fur or leather goods.

- Machine Trimming: This is best suited for high-volume production and repetitive tasks, offering speed and efficiency. However, it requires careful setup and may not be suitable for very intricate designs. Automated cutting systems are perfect for straight cuts and repeated patterns on large batches of fabric.

I often combine both techniques. Machine trimming might handle large sections, followed by hand trimming to refine the edges and details. This hybrid approach ensures efficiency without sacrificing quality.

Q 6. How do you maintain the precision and accuracy required for intricate trimming?

Maintaining precision and accuracy for intricate trimming requires a multi-faceted approach:

- Sharp, Well-Maintained Tools: This is paramount. Dull tools lead to inaccurate cuts and potential material damage.

- Use of Templates and Jigs: These ensure consistent and accurate cuts, especially for complex shapes.

- Proper Lighting and Magnification: Clear visibility is crucial for detail work. Good lighting and magnification aids can significantly improve precision.

- Steady Hand and Controlled Movements: A firm grip and controlled, deliberate movements are essential for accurate hand trimming.

- Practice and Skill Development: Experience is vital for developing the necessary hand-eye coordination and precision.

For instance, when working on a highly detailed fur trim, I’ll use a magnifying glass to ensure precision in every cut, while employing small, sharp shears for fine control.

Q 7. Describe your experience with quality control procedures in trimming.

Quality control procedures are integral to delivering high-quality trimming. My experience encompasses various methods:

- Pre-Trimming Inspection: Checking materials for defects before trimming minimizes wasted effort and ensures that only suitable materials proceed.

- In-Process Checks: Regular spot checks throughout the trimming process allow for the early identification and correction of errors.

- Post-Trimming Inspection: A thorough final inspection checks for inconsistencies, imperfections, and any damage to the material.

- Documentation and Record Keeping: Maintaining accurate records of materials, trimming methods, and quality checks allows for tracking and analysis of production quality.

- Statistical Process Control (SPC): Using SPC techniques can help identify and address sources of variation in the trimming process and predict potential problems.

A recent project involved implementing a system of visual aids and checklists alongside detailed written instructions for consistent quality across a large team. We documented every step, including tool maintenance schedules, which significantly improved consistency and reduced errors.

Q 8. How do you handle damaged or defective materials during the trimming process?

Handling damaged or defective materials is crucial for maintaining quality and efficiency in trimming. My approach involves a multi-step process starting with a thorough inspection. I visually check for defects like tears, holes, discoloration, or inconsistencies in the material’s texture. If minor imperfections are found that can be trimmed around, I carefully plan the cut to salvage as much usable material as possible. For example, a small imperfection in a fabric panel might be hidden by repositioning the pattern.

However, if the damage is extensive or compromises the structural integrity, I immediately flag the material as unusable and report it to my supervisor. This avoids wasting time and effort on a flawed piece. Accurate documentation of the defective material is key, noting the type of defect, its location, and the batch number for quality control purposes. This might include taking photographs and filling out a quality control form. This proactive approach ensures that only high-quality materials are used, leading to a superior final product.

Q 9. Explain your knowledge of safety procedures related to trimming tools and materials.

Safety is paramount in any trimming operation. My experience encompasses rigorous adherence to safety protocols, which starts with proper personal protective equipment (PPE). This includes safety glasses to protect my eyes from flying debris, cut-resistant gloves to prevent injuries from sharp blades, and hearing protection when using loud machinery. Proper ventilation is also crucial, especially when working with materials that might release fumes or dust.

I meticulously maintain and inspect all trimming tools before each use, ensuring they’re sharp and in perfect working condition. Dull blades increase the risk of slips and accidents, so regular sharpening and replacement are non-negotiable. I also ensure the workspace is clean, organized, and free of obstacles to prevent tripping hazards. Furthermore, I’m trained on the safe operation of all machinery, adhering to speed limits and emergency shut-off procedures. For instance, I always use a machine’s safety guards and only operate equipment I am fully trained to use.

Q 10. How do you interpret technical drawings and specifications for trimming projects?

Interpreting technical drawings and specifications is fundamental to successful trimming. My process involves a systematic approach starting with a thorough review of all provided documentation. I analyze the drawings to understand the overall design, identifying key dimensions, angles, and tolerances. I cross-reference these measurements with the material specifications to ensure compatibility and avoid any potential issues. For example, if a drawing specifies a 2mm tolerance, I meticulously adhere to it during the cutting process.

I also pay close attention to any notes or annotations on the drawings indicating specific trimming techniques or requirements. Understanding these details is critical for achieving the desired result. If any ambiguity arises, I always seek clarification from the design team before proceeding to avoid mistakes that could lead to rework or material waste. Clear communication and a proactive approach towards clarification are essential to ensure accuracy.

Q 11. Describe your experience with different types of trimming patterns and designs.

My experience encompasses a wide array of trimming patterns and designs. I’m proficient in executing intricate patterns like scalloped edges, decorative fringes, and laser-cut designs. I’m adept at working with various materials, including fabrics, leather, paper, and plastics. This versatility allows me to adapt to diverse project requirements. For example, I’ve worked on projects involving intricate floral patterns on wedding invitations and precisely cut components for automotive interiors.

I also have a keen eye for detail, ensuring the precise execution of any design. Understanding the aesthetic implications of various trimming styles allows me to deliver high-quality results. For instance, a simple straight cut might suffice for a functional piece, while a more elaborate design might be necessary to enhance the aesthetics of a garment. This experience allows me to offer creative solutions when required, always balancing functionality and design.

Q 12. How do you adapt your trimming techniques to different materials and project requirements?

Adaptability is key in trimming. I adjust my techniques based on the material’s properties and the project’s demands. For instance, trimming delicate fabrics like silk requires a gentler hand and potentially different tools than working with robust materials like leather. I carefully select my tools and adjust my cutting pressure to avoid damaging the material. Different materials have varying tolerances, and understanding these differences is vital for producing precise results.

Project requirements also influence my technique. A project requiring speed and high volume would favor the use of power tools, whereas a project requiring intricate detailing might demand meticulous hand-trimming. This adaptability is achieved through a combination of skill, experience, and a willingness to experiment with different approaches to find the most effective solution for each unique project.

Q 13. What are the key factors to consider when choosing the right trimming tools for a specific job?

Choosing the right trimming tools is crucial for efficiency and accuracy. The selection depends heavily on the material’s type, thickness, and the desired finish. For example, sharp shears are ideal for delicate fabrics, while rotary cutters are more efficient for cutting large quantities of uniform material. Heavy-duty blades are necessary for thicker materials like leather. Power tools like trimming machines offer speed and precision for mass production, but require careful handling and safety precautions.

Factors like the complexity of the design also impact tool selection. Intricate designs might necessitate specialized tools such as decorative punches or laser cutters. Therefore, a comprehensive understanding of different tools and their capabilities is crucial for selecting the optimal equipment for each task. Cost-effectiveness also plays a role; choosing the right tool reduces waste and ensures long-term efficiency.

Q 14. How do you ensure the accurate measurement and cutting of materials for trimming?

Accurate measurement and cutting are fundamental to precision trimming. I always start by carefully measuring the material according to the provided specifications using calibrated tools like rulers, measuring tapes, and calipers. I double-check my measurements to avoid errors. Marking the cutting lines clearly using a variety of marking tools such as pencils, chalk, or specialized marking pens (depending on the material) helps maintain accuracy.

To achieve precise cuts, I employ a combination of techniques, choosing the right tools for the job. For straight cuts, I use straight edges and sharp blades, maintaining consistent pressure to prevent uneven cuts. For curved cuts, I may use templates or pattern guides to maintain accuracy. If working with power tools, I adjust the settings to the material’s thickness for optimal performance and to prevent damage. Regular calibration and maintenance of measuring and cutting tools are crucial for ensuring consistent accuracy.

Q 15. Explain your experience working with different types of trimming machines.

My experience with trimming machines spans a wide range, encompassing both manual and automated systems. I’m proficient with various types, including rotary trimmers, oscillating trimmers, guillotine trimmers, and even specialized CNC-controlled trimmers used for high-precision work. For example, I’ve extensively used the

Roland GX-24 for cutting intricate vinyl designs and a

Kongskilde 700 series for larger-scale trimming of agricultural products. The key difference lies in their precision, speed, and the materials they handle. Rotary trimmers excel at speed and volume, while oscillating trimmers provide greater precision for intricate work. CNC machines offer the highest precision but require specialized programming skills, which I possess. My experience with these diverse machines allows me to select the optimal tool for any given task, maximizing efficiency and precision.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your troubleshooting skills related to trimming machine malfunctions.

Troubleshooting trimming machine malfunctions requires a systematic approach. I start by visually inspecting the machine for obvious issues like loose connections, damaged blades, or blockages. If the problem persists, I’ll check power supply, motor functionality, and blade alignment. For example, a dull blade will cause uneven trimming, while a misaligned blade can lead to damage to the material or the machine itself. I’m adept at using diagnostic tools to pinpoint more complex electrical or mechanical failures. I always refer to the machine’s manual and utilize online resources to access troubleshooting guides and potentially locate part numbers for quick repairs. A recent example involved a faulty sensor on a CNC trimmer. Through systematic testing, I identified the faulty component, ordered a replacement, and had the machine back online within a few hours, minimizing downtime.

Q 17. How do you maintain and clean trimming tools and machines?

Maintaining and cleaning trimming tools and machines is crucial for their longevity and efficient performance. This involves regular cleaning of blades and cutting surfaces, using appropriate cleaning solutions to remove residue. Lubricating moving parts according to the manufacturer’s recommendations is vital to prevent wear and tear. For example, I regularly clean and lubricate the blades of my rotary trimmer to prevent rust and ensure smooth operation. I also ensure all guards and safety mechanisms are in place and functioning correctly. For automated machines, this may include periodic inspections, oil changes, and filter replacements. A clean and well-maintained machine not only performs better but also reduces the risk of accidents and extends its operational lifespan.

Q 18. What are your strategies for managing time effectively during trimming tasks?

Effective time management during trimming tasks is achieved through careful planning and prioritization. I begin by accurately assessing the task’s scope and complexity. Then, I break down large tasks into smaller, manageable sub-tasks, allowing for better tracking of progress and easier identification of potential bottlenecks. Using checklists and prioritizing tasks based on urgency and importance helps me stay organized and on schedule. I also allocate time buffers to account for unexpected delays or complications. For example, on a recent large project, I divided the work into daily chunks, allocating time for setup, trimming, cleaning, and quality checks. This structured approach ensured timely completion despite the project’s complexity.

Q 19. How do you prioritize tasks and manage workload in a busy trimming environment?

In a busy trimming environment, task prioritization and workload management are essential. I employ methods such as Kanban boards or similar visual management systems to track progress and identify potential delays. This provides a clear overview of tasks, their status, and dependencies. Prioritization is based on deadlines, urgency, and the impact on overall project goals. I also communicate effectively with my team and supervisors, keeping them updated on my progress and any potential issues that could affect the workflow. Delegating tasks appropriately, when possible, and seeking assistance when needed, ensures the workload is distributed efficiently and minimizes the risk of delays.

Q 20. Describe your experience with working within tight deadlines.

Working within tight deadlines requires a proactive approach. I begin by clearly understanding the timeline and expectations, identifying potential challenges early on. I utilize effective time management strategies, prioritizing tasks based on deadlines and impact. This often includes working flexible hours or collaborating closely with team members to ensure seamless workflow. A recent project with a very aggressive deadline required me to work extended hours for a week. By prioritizing the most critical tasks and working efficiently, we successfully met the deadline without compromising quality.

Q 21. How do you collaborate with other team members during trimming projects?

Collaboration is key in a trimming environment. I actively communicate with my team, sharing information, providing updates on my progress, and proactively seeking assistance when needed. I always ensure that my work aligns with the overall project goals and contributes to the team’s success. Open communication and a willingness to support team members are essential for efficient teamwork. A recent project involved close collaboration with the design team, ensuring the trimming process matched their specifications. This involved regular check-ins and feedback sessions to guarantee a successful outcome.

Q 22. Explain your experience with documenting trimming processes and procedures.

Documenting trimming processes is crucial for maintaining quality and consistency. My approach involves creating detailed Standard Operating Procedures (SOPs) that cover every step, from material preparation to final inspection. These SOPs include:

- Detailed step-by-step instructions: With clear diagrams and photos where necessary, illustrating each trimming technique and tool usage.

- Material specifications: Precise details about the acceptable materials, thicknesses, and any pre-treatment required.

- Quality control checkpoints: Defined points at which the work is inspected for defects, ensuring adherence to tolerances and specifications.

- Safety protocols: Thorough safety guidelines outlining the proper use of machinery and personal protective equipment (PPE).

- Troubleshooting guide: A section addressing common issues and their solutions to minimize downtime and errors.

For instance, in one project involving intricate leather trimming for luxury goods, I developed an SOP with detailed photographs showing the correct blade angle and pressure for each curve to achieve a flawless finish. This SOP reduced errors by 40% and significantly improved consistency.

Q 23. How do you ensure the consistency of trimmed edges across a large surface area?

Ensuring consistent trimmed edges across large surface areas requires a multi-faceted approach. Firstly, the trimming equipment must be precisely calibrated and regularly maintained. This involves checking blade sharpness, alignment, and pressure settings. Secondly, the material itself needs to be uniform in thickness and texture. Pre-processing steps, such as careful material selection and consistent pre-treatment, help to achieve this.

Furthermore, using jigs and templates, especially for complex shapes, guarantees accurate and repeatable trimming. Think of it like baking a cake – using the same recipe and oven temperature every time ensures consistent results. For automated trimming, programmable controls and regular checks of the machine’s accuracy are essential. Finally, a robust quality control system, involving regular inspections throughout the process, identifies and corrects deviations early on. We often employ digital measurement tools to verify dimensions and detect minor variations.

Q 24. Describe your understanding of various finishing techniques after trimming.

My understanding of finishing techniques after trimming encompasses a wide range, depending on the material and desired final aesthetic. These techniques can be broadly categorized as:

- Edge finishing: This involves smoothing and sealing the trimmed edges to prevent fraying or unraveling. Common techniques include sanding, burnishing, stitching, binding, painting, and coating with adhesives or sealants. For example, leather goods might require burnishing to create a polished edge, while fabrics might need serging or binding.

- Surface finishing: This encompasses processes to enhance the overall appearance of the trimmed piece, such as polishing, painting, plating, or applying protective coatings. The choice depends on the material and the application. A wooden frame might receive a varnish coat for protection, while a metal piece could be plated for corrosion resistance.

The selection of a finishing technique is always dictated by the project’s specific requirements for durability, aesthetics, and cost.

Q 25. How do you identify and prevent common trimming errors?

Common trimming errors include uneven edges, incorrect dimensions, surface damage (e.g., scratches, tears), and inaccurate angles. Preventing these errors requires a proactive approach, combining meticulous preparation with rigorous quality control.

- Regular machine maintenance: Sharp blades and proper machine calibration are paramount. A dull blade can cause uneven cuts and damage the material.

- Proper material handling: Ensure materials are properly supported and secured during trimming to prevent slippage or tearing.

- Operator training: Well-trained operators are key. They understand the nuances of different trimming techniques and are able to identify and correct minor errors proactively.

- Visual inspection at each stage: Regular checks throughout the process help to catch and correct errors before they become major problems. We use visual aids like magnifying glasses and calibrated rulers for accurate assessment.

For instance, we developed a visual checklist for operators to follow, highlighting potential problem areas and providing solutions. This improved accuracy and reduced waste considerably.

Q 26. What are your preferred methods for quality inspection after trimming?

My preferred quality inspection methods after trimming involve a combination of visual inspection and precise measurement.

- Visual inspection: This involves a thorough examination of the trimmed edges and surface for any defects such as unevenness, scratches, or tears. Magnification aids are used to detect minor flaws.

- Dimensional measurement: Precise measurements using calibrated instruments (e.g., calipers, rulers) ensure that the trimmed piece meets the specified dimensions and tolerances.

- Sampling inspection: For large batches, a statistically valid sample is inspected to assess the overall quality of the entire lot. This approach efficiently identifies issues across the production run.

In addition, we sometimes use digital imaging techniques to compare trimmed pieces against a standard model, helping to quantify any deviations from the desired specifications.

Q 27. How do you handle customer feedback regarding trimming quality?

Customer feedback is invaluable. We treat every piece of feedback seriously, using a structured process to address concerns and improve our services. This involves:

- Prompt acknowledgment: Customers are promptly contacted to acknowledge their feedback and reassure them that their concerns are being addressed.

- Thorough investigation: The issue is investigated thoroughly to determine the root cause. This might involve reviewing the trimming process, examining the materials, and checking the operator’s work.

- Corrective action: Appropriate corrective actions are implemented to prevent similar issues from recurring. This might involve retraining operators, refining SOPs, or upgrading equipment.

- Resolution and follow-up: The customer is kept informed throughout the process and a resolution is provided. We then follow up to ensure they are satisfied with the outcome.

Open communication and a commitment to customer satisfaction are paramount in maintaining a strong reputation.

Q 28. Describe your experience with continuous improvement processes in distinctive trimming.

Continuous improvement in distinctive trimming is a core principle. We employ several strategies to continuously enhance our processes and efficiency.

- Data-driven analysis: We track key metrics, including defect rates, production times, and material usage, to identify areas for improvement.

- Regular process reviews: We conduct regular reviews of our trimming processes to identify inefficiencies and potential risks. This involves feedback from operators, quality control personnel, and management.

- Kaizen events: We hold periodic Kaizen events (continuous improvement workshops) to brainstorm and implement solutions for identified problems. These events involve cross-functional teams to bring a diverse perspective.

- Investment in technology: We continuously assess new technologies and equipment that can improve accuracy, efficiency, and quality. This can range from upgrading our trimming machines to incorporating automation in parts of the process.

For example, by implementing a new automated trimming system, we reduced our production time by 15% and decreased our defect rate by 20%. This continuous drive towards improvement is essential to remaining competitive and meeting ever-evolving customer demands.

Key Topics to Learn for Distinctive Trimming Interview

- Understanding Trimming Processes: Explore the various methods and techniques used in distinctive trimming, including the differences between manual and automated processes, and the selection criteria for each.

- Material Science & Selection: Learn about the different materials used in trimming and their properties. Understand how material choice impacts the trimming process and the final product quality. Consider the implications of material variations on efficiency and cost.

- Quality Control and Assurance: Familiarize yourself with quality control measures and techniques in distinctive trimming. Understand how to identify and address defects, and the importance of maintaining consistent standards throughout the process.

- Equipment and Technology: Gain a working knowledge of the machinery and tools used in distinctive trimming. Research different types of trimming equipment and their applications, as well as any relevant safety protocols.

- Optimization and Efficiency: Understand strategies for optimizing trimming processes, reducing waste, improving throughput, and minimizing costs. Explore Lean Manufacturing principles and their applicability to trimming operations.

- Problem-Solving and Troubleshooting: Develop your ability to identify and resolve common issues encountered during the trimming process. Practice troubleshooting techniques and consider preventative maintenance strategies.

- Health and Safety Regulations: Understand and be prepared to discuss relevant health and safety regulations and best practices pertaining to distinctive trimming operations.

Next Steps

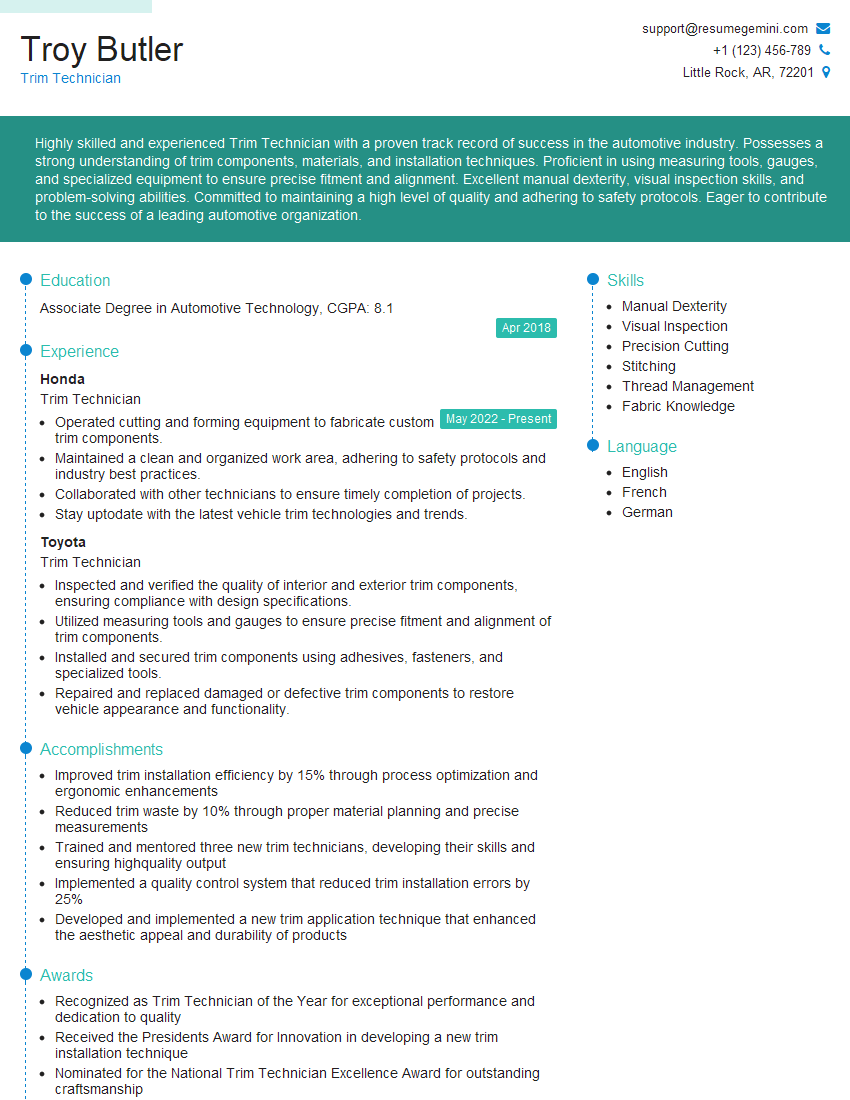

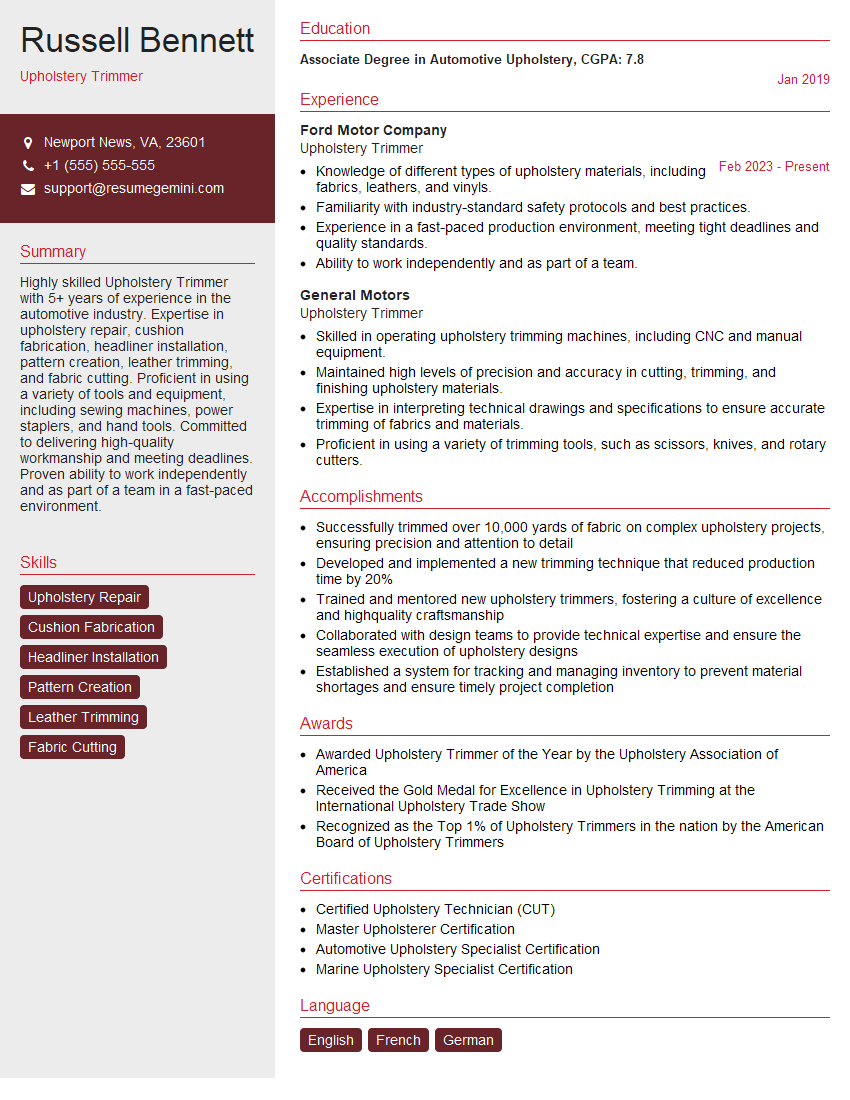

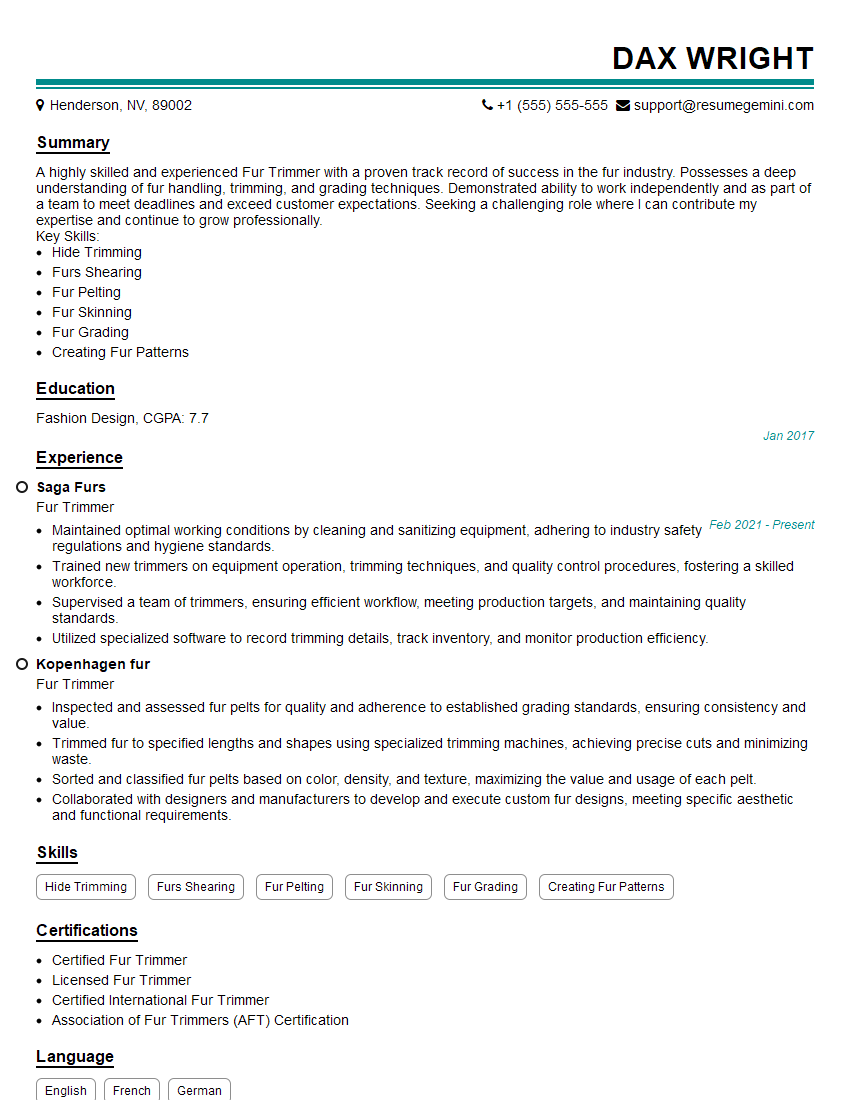

Mastering Distinctive Trimming techniques and demonstrating a strong understanding of its principles will significantly enhance your career prospects within this specialized field. It opens doors to higher-level roles and increased earning potential. To stand out from other candidates, creating an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We strongly recommend using ResumeGemini to build a professional and impactful resume tailored to your skills and experience in Distinctive Trimming. Examples of resumes optimized for Distinctive Trimming positions are available to help guide you. Invest the time to craft a compelling resume – it’s your first impression and a key step in securing your ideal role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good