Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Drapery Hardware Installation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Drapery Hardware Installation Interview

Q 1. What types of drapery hardware are you familiar with (e.g., traverse rods, stationary rods, brackets)?

My expertise encompasses a wide range of drapery hardware, from the simplest to the most complex systems. This includes:

- Stationary Rods: These are simple, decorative rods used for curtains that don’t require opening and closing mechanisms. They’re ideal for smaller windows or where a minimalist look is desired.

- Traverse Rods: These rods use a cord and carrier system to open and close curtains smoothly. They’re versatile and suitable for larger windows and heavier curtains.

- Extension Rods: These adjustable rods can expand to fit a variety of window widths, offering convenience and adaptability.

- Brackets: These are essential components that secure the rods to the wall or ceiling. They come in various styles and finishes to complement different decor.

- Finials: Decorative end caps that add a polished look to the rods. The choices are endless, from simple knobs to ornate designs.

- Rings and Carriers: These are the components that connect the curtains to the traverse rod, allowing for smooth operation.

I’m proficient in installing and troubleshooting all these hardware types, ensuring a seamless and aesthetically pleasing result.

Q 2. Describe your experience installing different types of window treatments (e.g., curtains, blinds, shades).

My experience with window treatment installation is extensive. I’ve worked with a variety of materials and styles including:

- Curtains: From sheer voile to heavy velvet, I’ve installed curtains of all weights and fabrics, adapting my techniques to suit each material’s unique properties. I understand the importance of proper pleating and hanging techniques for optimal drape and appearance.

- Blinds: I’m experienced in installing both vertical and horizontal blinds, paying close attention to alignment and functionality. This includes ensuring proper cord tension and smooth operation of the lifting mechanism.

- Shades: I’ve installed various types of shades, including cellular, roller, and Roman shades. Accurate measurements and precise installation are critical to ensure proper fit and function.

I always prioritize a clean, professional finish, paying attention to detail throughout the entire installation process.

Q 3. How do you measure for drapery hardware installation?

Accurate measurements are paramount for successful drapery hardware installation. The process involves several key steps:

- Determine Rod Length: Measure the window width, adding extra length (typically 12-24 inches) on each side for proper fullness and drape. This ensures the curtains extend beyond the window frame.

- Bracket Placement: Measure the distance from the window frame to where you want the rod to hang. This is crucial for ensuring the curtains clear the window sill and frame.

- Height Considerations: Decide on the desired hanging height. Standard practice often places the rod a few inches above the window frame.

- Curtain Length: Measure the desired length of the curtains from the rod to the floor or desired hemline, factoring in any desired pooling or break.

- Consider Obstacles: Account for any existing window trim, molding, or other obstructions that might affect the rod placement and curtain length.

I always double-check my measurements to avoid costly mistakes. Using a measuring tape and a level are crucial for precision.

Q 4. Explain the process of installing a traverse rod system.

Installing a traverse rod system requires precision and attention to detail. Here’s a step-by-step guide:

- Mark Bracket Locations: Use the measurements from the previous step to mark the precise locations for the brackets on the wall or ceiling using a level.

- Install Brackets: Securely attach the brackets to the wall or ceiling using appropriate screws and anchors. Ensure they are level and firmly fixed.

- Install the Rod: Carefully slide the traverse rod into the brackets. Ensure it’s securely seated and level.

- Attach Carriers: Attach the carriers to the curtain headings. The number of carriers will depend on the width and weight of the curtains.

- Thread the Cord: Thread the cord through the carriers and the traverse mechanism, ensuring smooth operation.

- Hang Curtains: Carefully hang the curtains onto the carriers.

- Test Operation: Test the opening and closing mechanism to ensure smooth, easy operation.

Throughout the process, I always check for levelness and proper alignment. A perfectly functioning and visually appealing result is my priority.

Q 5. What safety precautions do you take during drapery hardware installation?

Safety is my top priority during drapery hardware installation. My safety procedures include:

- Proper Ladder Use: When working at heights, I always use a sturdy ladder with a wide base and ensure it’s properly positioned. I never overreach while on a ladder.

- Protective Gear: I wear safety glasses to protect my eyes from debris. I also use work gloves to protect my hands.

- Secure Work Area: I clear the work area of any obstructions that could cause tripping or falling. I use appropriate caution if working near electrical wiring or plumbing.

- Power Tool Safety: If using power tools, I ensure they are in proper working order, and I follow all manufacturer’s safety guidelines.

- Load Capacity Awareness: When installing rods and brackets, I ensure that they are appropriately sized and rated to support the weight of the curtains.

By adhering to these safety measures, I ensure a safe and efficient installation process for both myself and my clients.

Q 6. How do you handle difficult installations (e.g., uneven walls, complex window shapes)?

Difficult installations require creative problem-solving and adaptability. For uneven walls, I use shims to level the brackets. This ensures that the rod hangs straight and the curtains drape properly. For complex window shapes (e.g., arched windows, bay windows), I’ll often use multiple rods or custom-cut brackets to achieve the desired look and functionality. In some cases, this might require a more detailed plan beforehand involving accurate measurements and potential custom solutions. I never hesitate to consult with the client if a custom approach is needed to ensure the final product meets their expectations.

Q 7. What tools and equipment are essential for drapery hardware installation?

The essential tools for drapery hardware installation are:

- Measuring Tape: For accurate measurements of window widths and curtain lengths.

- Level: To ensure that the rod and brackets are installed level.

- Drill with appropriate drill bits: For drilling pilot holes and securing brackets.

- Screwdriver (or drill with screwdriver bits): To secure the brackets and rods.

- Stud Finder: To locate wall studs for secure bracket attachment.

- Shims: To correct for uneven walls.

- Safety Glasses: To protect eyes from debris.

- Work Gloves: To protect hands.

- Ladder (if needed): For reaching high windows.

Having the right tools ensures a smooth, efficient, and safe installation process. I always ensure my tools are in good working order before starting any project.

Q 8. How do you determine the appropriate weight capacity for drapery hardware?

Determining the appropriate weight capacity for drapery hardware is crucial for safe and effective installation. It prevents damage to the hardware, walls, and the drapery itself. This involves considering several factors:

- Drapery Weight: This is the most critical factor. Weigh the fabric panels, including lining and any interlining. Heavier fabrics, such as velvet or brocade, require stronger hardware.

- Hardware Material: Different materials have varying strength levels. For example, sturdy metal rods generally support heavier drapes compared to lightweight plastic rods. The manufacturer’s specifications should always be checked.

- Rod Length and Mounting Type: Longer rods experience greater stress, necessitating stronger hardware. The type of mounting (e.g., ceiling mount versus wall mount) also affects weight capacity. Ceiling mounts generally offer superior stability.

- Number of Carriers: The weight is distributed across the carriers (the rings or glides that hold the drapes). More carriers mean less weight on each individual carrier. Using the correct number and distributing weight evenly is essential for prevention of sagging.

Example: For heavy velvet drapes on a 10-foot rod, I’d select a heavy-duty metal rod with a weight capacity significantly exceeding the total weight of the panels, and use more carriers than the minimum required by the manufacturer’s instruction.

Q 9. Describe your experience working with different materials (e.g., wood, metal, plastic).

I have extensive experience working with various drapery hardware materials. Each material presents unique challenges and advantages:

- Wood: Offers a classic and elegant look. Wood rods need careful consideration of weight capacity as they can be prone to warping or breaking under excessive weight. Regular maintenance, such as polishing and occasional oiling, extends lifespan.

- Metal: Provides excellent strength and durability, especially suitable for heavier drapes. Metals like steel or brass offer different aesthetic choices. Metal can corrode in high-humidity environments, requiring careful material selection and potential protective coatings.

- Plastic: Lightweight and budget-friendly, plastic is best suited for lighter drapes. It’s less durable and might not be suitable for heavier fabrics or large windows. They are susceptible to damage from harsh chemicals and direct sunlight.

I choose the material based on the client’s budget, aesthetic preferences, and the weight of the drapery. For instance, I’d recommend metal hardware for heavy drapes in a high-traffic area, while plastic might be suitable for lightweight curtains in a child’s bedroom.

Q 10. What is your experience with installing motorized drapery systems?

My experience with motorized drapery systems includes installation, programming, and troubleshooting. I’m proficient with various brands and control systems, including those utilizing smartphone apps or integrated home automation systems.

Installation involves careful wiring and integration with the power supply, ensuring correct operation and safety. Programming the motorized systems usually requires understanding the manufacturer’s specific protocols and software. Troubleshooting includes addressing issues with power, connectivity, and motor functionality. I’ve had to diagnose problems ranging from faulty wiring to software glitches, often involving contacting the manufacturer for technical support.

Example: Recently I installed a Lutron motorized system in a high-end home. The initial setup involved calibrating the motors and synchronizing them to ensure seamless operation across multiple windows. Later, I diagnosed a minor software bug by updating the system’s firmware.

Q 11. How do you ensure the proper alignment and functionality of drapery hardware?

Ensuring proper alignment and functionality of drapery hardware is paramount for aesthetics and operation. My process involves:

- Precise Measurements: Accurate measurements of window dimensions and drapery lengths are essential for correct rod placement. Using a level ensures the rod is perfectly horizontal.

- Secure Mounting: Using appropriate anchors and screws for the wall or ceiling material is crucial. This prevents sagging and ensures the hardware can support the drapery weight.

- Even Distribution: Drapery should hang evenly. Adjusting carrier spacing and ensuring the rod is properly centered will prevent unevenness. If the weight is unevenly distributed, I’ll adjust the placement of the drapery fabric on the rod.

- Functional Testing: After installation, I always test the drapery mechanism to ensure smooth operation of opening and closing. This includes adjusting the carriers and checking for any snags or binding.

Example: I recently installed a traverse rod system. To ensure precise alignment, I used laser levels to mark the bracket locations, meticulously checked the levelness of the rod and the smooth travel of the drapery panels along the traverse track. I addressed the slight snag by adjusting the carrier spacing and gently lubricating the track.

Q 12. How do you troubleshoot common issues with drapery hardware installation?

Troubleshooting common issues is a regular part of the job. Here are some common problems and solutions:

- Sagging Drapes: Often caused by insufficient weight capacity, uneven weight distribution or faulty hardware. Solutions include using stronger hardware, redistributing weight, tightening screws, or replacing damaged carriers.

- Binding or Sticking Drapes: Often caused by obstructions, debris, or lack of lubrication in the tracks or carriers. Solutions include cleaning the tracks, lubricating with appropriate lubricant, and removing obstructions.

- Uneven Drapery Hanging: Can be caused by improper rod placement or uneven weight distribution. Solutions include re-leveling the rod, readjusting the carriers or using weights to balance the drapery panels.

- Motorized System Malfunctions: Problems can range from power issues to software glitches. Solutions include checking power supply, troubleshooting wiring connections, updating firmware, or contacting the manufacturer for support.

Systematic troubleshooting involves checking the simplest solutions first, progressing to more complex issues. Careful examination of the hardware and its components is crucial.

Q 13. How do you handle customer complaints or installation problems?

Handling customer complaints or installation problems requires professionalism and a solution-oriented approach. My steps are:

- Active Listening: I carefully listen to the customer’s concerns, ensuring I understand the issue fully. I ask clarifying questions to pinpoint the exact problem.

- Thorough Inspection: I conduct a thorough inspection to identify the root cause of the problem, taking photos or videos if necessary.

- Proposed Solutions: I propose feasible and cost-effective solutions, discussing options with the customer before proceeding.

- Prompt Action: I strive to resolve the issue promptly, making necessary repairs or replacements.

- Follow-up: I always follow up to ensure the customer is satisfied with the solution.

Building trust and transparency is essential. I maintain open communication with the customer throughout the process. I may offer a partial refund or other accommodations depending on the severity and nature of the issue.

Q 14. Describe your experience working independently and as part of a team.

I’m comfortable working both independently and as part of a team. Independent work requires self-motivation, organization, and problem-solving skills – all crucial for meeting deadlines and ensuring quality work. I’m adept at managing my time and resources effectively, often working on multiple projects concurrently.

Teamwork necessitates strong communication and collaboration skills. I’ve worked on large-scale projects requiring coordination with other tradespeople, such as electricians and painters. Effective teamwork involves clear communication, understanding individual roles, and a shared commitment to project success. I can adapt to various team dynamics and contribute effectively in collaborative settings. I contribute positively by assisting others on my team when needed.

Q 15. What is your experience with various types of curtain headings (e.g., grommets, pleats)?

My experience encompasses a wide range of curtain headings, each requiring a unique approach to installation. Grommet headings, for instance, are relatively straightforward – the grommets themselves provide the hanging points, so installation focuses on ensuring even spacing and proper rod selection for the weight of the curtains. Pleated headings, however, offer more complexity. I’m proficient with various pleat styles including pinch pleats, box pleats, and goblet pleats, each demanding specific techniques and measurements for accurate and aesthetically pleasing results. For example, achieving crisp, uniform pinch pleats requires precise measuring and the use of appropriate tools like a pleat maker. I also have extensive experience with other headings like tab-top, rod pocket, and ripplefold, adapting my methods according to the specific design and fabric.

Recently, I worked on a project involving intricate box pleats on heavy velvet curtains. The challenge was to maintain consistent pleat depth and prevent sagging. My solution involved using a heavier-duty curtain rod and additional support brackets to distribute the weight evenly. The end result was stunning, testament to the importance of understanding the nuances of different heading styles.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper tension and operation of curtain cords and mechanisms?

Proper tension and operation of curtain cords and mechanisms are critical for smooth, reliable function and longevity. It starts with selecting the correct mechanisms for the weight and style of the curtains. For example, lightweight curtains might work well with a simple cord-and-pulley system, while heavier curtains would require a more robust system, perhaps incorporating a chain mechanism or even a motorized system.

Once installed, I meticulously check for proper tension. This involves ensuring the cords run smoothly through the pulleys, there’s no binding, and the curtains open and close evenly without any resistance. If there’s an imbalance, I adjust the cords accordingly, sometimes involving recalibrating the weights or adjusting the mechanism itself. I always test the operation multiple times to confirm flawless function, and I instruct clients on the proper usage and maintenance of the system to prevent future problems.

Q 17. What are your experience with different wall anchoring methods (e.g., drywall anchors, screws)?

My experience with wall anchoring methods is comprehensive, encompassing various materials and techniques. Drywall anchors are frequently used, but the selection depends on the weight of the hardware. For lighter curtain rods, simple plastic anchors suffice. However, heavier rods or drapes necessitate stronger anchors like molly bolts or even toggle bolts for more secure fixing in hollow walls. For solid walls, screws are the preferred method, ensuring a robust and reliable hold.

I always assess the wall type before selecting the appropriate anchor. Misjudging this can lead to the rod falling, which can be damaging and dangerous. For instance, when working with older houses featuring plaster walls, I use specialized anchors designed for these types of surfaces. My approach prioritizes safety and reliability, using appropriate anchors for every situation to prevent damage or accidents.

Q 18. Explain your understanding of building codes related to window treatments.

Understanding building codes related to window treatments is crucial for ensuring safety and compliance. Key considerations include fire safety regulations, especially concerning the flammability of curtain fabrics. Many codes specify the required fire retardant treatments or the acceptable fabric types. Furthermore, I’m familiar with codes relating to cord safety, particularly for those in reach of children. These codes often require specific mechanisms to prevent strangulation hazards. Also, accessibility regulations might dictate the ease of operating window treatments for individuals with disabilities.

In practice, I always research the relevant local and national building codes before starting a project. This might involve contacting the local building authority for clarification or referring to industry standards. Compliance with these codes isn’t just a legal requirement; it prioritizes the safety and well-being of my clients.

Q 19. How do you handle changes or revisions to an installation project?

Handling changes or revisions is a common occurrence in installation projects. My approach is collaborative and transparent. Firstly, I thoroughly document all changes, ensuring everyone is informed. This involves creating updated plans or sketches, and clearly communicating the implications of the changes, such as cost adjustments or timeline impacts.

For example, if a client decides to change the curtain fabric after the hardware has been installed, we’ll discuss the implications of changing to a heavier fabric, potentially requiring a stronger rod or additional support brackets. This proactive communication prevents surprises and allows for seamless integration of changes, ensuring a smooth and satisfactory outcome for the client.

Q 20. Describe your experience with working from blueprints or installation drawings.

Working from blueprints or installation drawings is a standard procedure for many projects. My proficiency includes interpreting detailed drawings to understand the specifications of the hardware, the curtain dimensions, and the desired placement of the rods. I use this information to accurately measure, cut, and install the hardware, ensuring it aligns perfectly with the overall design and building layout.

I recall a recent project where the blueprints specified a complex, multi-layered window treatment system. By carefully analyzing the drawings and cross-referencing measurements, I was able to successfully install the system as planned, showcasing the efficiency and precision afforded by following detailed installation drawings.

Q 21. What is your experience with maintaining and repairing existing drapery hardware?

Maintaining and repairing existing drapery hardware is a significant part of my services. Common issues include malfunctioning cords, loose brackets, or damaged pulleys. My expertise extends to identifying the problem, sourcing replacement parts, and performing the necessary repairs efficiently and cost-effectively.

For example, recently I repaired a set of curtains where the cord had become frayed and was no longer operating smoothly. Instead of replacing the entire system, I carefully replaced the damaged section of the cord, saving the client both time and money. This demonstrates my ability to provide cost effective solutions while prolonging the lifespan of their existing drapery hardware.

Q 22. How do you manage your time effectively during installation projects?

Effective time management is crucial for successful drapery hardware installation. My approach involves a three-step process: planning, execution, and review. Planning begins with a thorough site visit, carefully assessing the job’s scope and potential challenges. This allows me to create a detailed timeline, factoring in travel time, material acquisition, and the complexity of the installation. Execution involves adhering to this schedule, prioritizing tasks efficiently and proactively addressing any unexpected issues that may arise. For example, if I encounter a wall that requires extra bracing for heavy drapes, I adjust the timeline accordingly but communicate this to the client immediately. Review involves assessing the efficiency of my process for future projects. This allows me to continuously refine my time management and improve my overall productivity.

Q 23. What methods do you use to keep your tools and equipment organized?

Maintaining organized tools and equipment is paramount for efficiency and safety. I utilize a system that combines dedicated tool bags, labelled storage containers, and a rolling toolbox. Each bag is designated for a specific task—one for measuring tools, another for drilling and fastening equipment, and a third for smaller components like screws and brackets. My rolling toolbox contains larger power tools and accessories. This system allows for quick access to any tool I need, preventing delays and ensuring workplace safety. I also religiously clean and maintain my tools after each project, storing them in designated locations. Think of it like a well-organized kitchen—knowing where everything is makes the process smoother and less stressful.

Q 24. Describe your process for cleaning up after an installation project.

Cleaning up after a project is as important as the installation itself. It reflects professionalism and respect for the client’s home. My cleanup process involves several steps: first, I carefully remove all debris, including packaging materials, excess screws, and any dust or shavings. Then, I vacuum the area thoroughly, paying special attention to hard-to-reach places. Finally, I double-check the installation area for any loose items or potential hazards. I treat the client’s home as if it were my own, leaving the space cleaner than I found it. This level of attention to detail reinforces trust and satisfaction.

Q 25. How do you maintain a professional demeanor while working in clients’ homes?

Maintaining a professional demeanor in a client’s home requires a combination of respectful communication, meticulous work habits, and mindful behavior. I always arrive on time, dressed appropriately, and introduce myself politely. I protect the client’s floors and furniture with drop cloths, and I always keep the work area tidy. Open communication is key; I inform clients of any potential issues or delays promptly and keep them updated on progress. It’s about treating their home with the respect it deserves and demonstrating professionalism in every aspect of my work.

Q 26. What is your experience with installing different types of brackets and supports?

I have extensive experience installing various brackets and supports, including traditional single and double brackets, decorative brackets (like those with finials), ceiling mounts, and more specialized systems like traverse rods. My experience extends to different materials, too, such as wood, metal, and plastic. For instance, I know the best techniques for anchoring brackets into different wall types (drywall, brick, concrete) and how to adjust installation methods based on the weight and type of drapery. I also have experience with installing extensions and corner brackets for larger windows or unusual configurations. Choosing the right bracket is critical for both the aesthetics and structural integrity of the drapery system.

Q 27. Describe your experience with measuring and cutting curtain rods to size.

Precise measuring and cutting are essential for a flawless installation. My process begins with meticulous measurements of the window or area where the rod will be installed, accounting for overlap and desired extension beyond the window frame. I use a measuring tape and level to ensure accuracy. After calculating the needed rod length, I use a hacksaw or rod cutter (depending on the material) to cut the rod to the precise measurement. I always make test cuts on scrap material first, to ensure I have the right technique and avoid mistakes with the actual rod. A properly sized rod guarantees a professional finish and optimal functionality. I also carefully deburr the cut ends for safety and a cleaner look.

Q 28. How do you communicate effectively with clients and colleagues about installation progress?

Clear and consistent communication is vital. I communicate with clients before, during, and after the installation. Before the job, I confirm the details and answer any questions. During the installation, I keep clients updated on progress, addressing any concerns they may have. If unexpected issues arise, I explain them clearly and offer solutions. After completion, I provide a walkthrough, confirming their satisfaction. With colleagues, I maintain open lines of communication, sharing information about project timelines and potential challenges. Prompt and effective communication helps to ensure the success of every project and maintains positive working relationships.

Key Topics to Learn for Drapery Hardware Installation Interview

- Understanding Drapery Hardware Types: Familiarize yourself with various hardware components like rods, brackets, finials, rings, carriers, and tracks. Know their different materials (wood, metal, plastic) and applications.

- Measurement and Calculation: Master accurate measuring techniques for window dimensions and drapery lengths. Understand how to calculate the necessary hardware quantities and adjust for different drapery styles (e.g., grommets, pleats).

- Installation Techniques: Learn proper installation methods for different hardware types and window configurations. This includes drilling, screwing, anchoring, and leveling techniques. Practice safe handling of tools.

- Troubleshooting Common Issues: Prepare to discuss common problems encountered during installation, such as uneven hanging, hardware malfunctions, and wall type considerations (drywall, plaster, brick). Know how to resolve these effectively.

- Safety Procedures and Best Practices: Understand and be able to articulate safety procedures related to working at heights, using power tools, and handling materials. Familiarize yourself with industry best practices for efficient and quality installations.

- Different Drapery Styles and their Hardware Requirements: Gain knowledge of how different drapery styles (e.g., pinch pleats, grommets, inverted pleats) influence the choice and installation of appropriate hardware.

- Working with Various Materials: Be prepared to discuss experience working with different window treatments and the associated hardware, considering materials like wood, metal, and fabric.

Next Steps

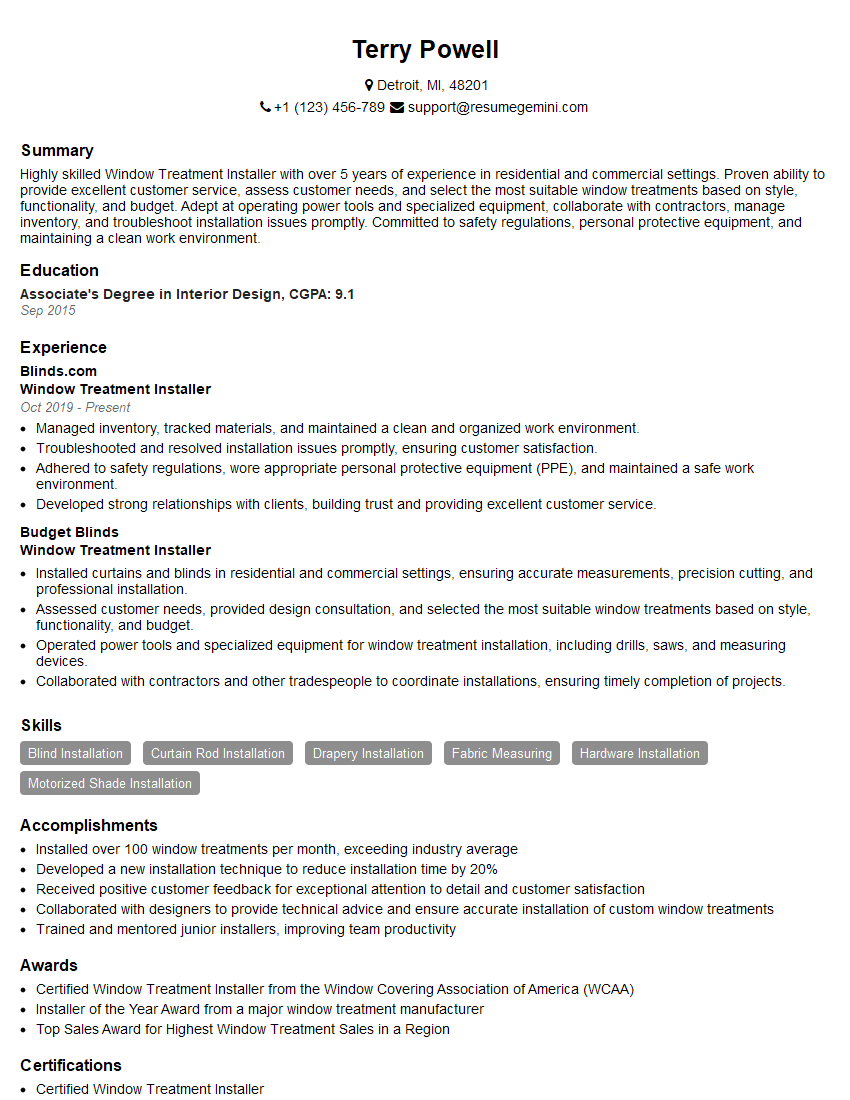

Mastering drapery hardware installation opens doors to exciting career opportunities in interior design, home improvement, and related fields. A strong understanding of these skills demonstrates professionalism, attention to detail, and practical expertise highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that showcases your abilities effectively. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers examples of resumes tailored to Drapery Hardware Installation to help you present your skills in the best possible light. Take the next step towards your dream job – create your winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good