Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Draping and Tailoring interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Draping and Tailoring Interview

Q 1. Explain the difference between draping and pattern making.

Draping and pattern making are both methods used to create garment patterns, but they differ significantly in their approach. Draping is a three-dimensional process where fabric is manipulated directly on a dress form to create the desired garment shape. It’s a more intuitive, hands-on method, excellent for creating unique and sculptural designs. Pattern making, on the other hand, is a two-dimensional process that uses mathematical calculations and established drafting rules to create flat patterns on paper. It’s a more precise and repeatable method, ideal for mass production and consistent sizing.

Think of it like sculpting versus drawing: draping is like sculpting a clay model – you shape the fabric directly; pattern making is like drawing a blueprint – you create a plan before constructing the final product. Each method has its strengths and weaknesses; often, designers use a combination of both for optimal results.

Q 2. Describe your experience with various draping techniques (e.g., flat pattern draping, 3D draping).

My experience encompasses a wide range of draping techniques. I’m proficient in flat pattern draping, where the fabric is draped on a flat surface before being transferred to a dress form for adjustments. This method is particularly useful for simpler garments and allows for precise control over the pattern pieces. I’m also highly skilled in 3D draping, where the fabric is directly draped on the dress form. This allows for more complex shapes and a greater sense of how the garment will drape on the body. This is perfect for more fitted styles and detailed design features. My experience further includes using both techniques in conjunction; for instance, creating a basic bodice block using flat pattern draping and then using 3D draping to add intricate details like a sculpted neckline or sleeve.

I’ve worked with various fabrics, adjusting my techniques based on the material’s drape and structure. For example, lightweight fabrics like silk chiffon require a gentler approach in 3D draping to avoid distortion, whereas heavier fabrics like wool crepe lend themselves well to both methods.

Q 3. How do you adapt a pattern to accommodate different body types?

Adapting patterns to different body types requires a keen understanding of body measurements and how these variations affect the garment fit. I assess the differences in measurements, focusing on areas like bust, waist, hip circumference, shoulder width, and back length. These differences determine the necessary adjustments.

For example, if a client has a larger bust than the original pattern, I would add width and length to the bust area using darts or princess seams. If the client has a swayback, I would adjust the back waistline to accommodate the curve. For clients with broader shoulders, I would widen the shoulder seam and adjust the neckline accordingly. These adjustments aren’t just about adding or subtracting fabric; they also involve understanding the interplay of different body proportions and maintaining the overall aesthetic balance of the garment. I often create several muslin mockups to fine-tune these adjustments until the fit is perfect.

Q 4. What are your preferred fabrics for draping and why?

My preferred fabrics for draping vary depending on the project, but I generally favor fabrics with a good drape and some body. Muslin is my staple for mockups due to its affordability and ease of manipulation. For final garments, I enjoy working with lightweight wools, silk charmeuse, and cotton poplin. These fabrics provide a good balance between structure and drape, allowing for both precise shaping and beautiful flow.

I avoid fabrics that are excessively stretchy or slippery during the initial draping stages, as these can be difficult to work with and may not hold their shape well. However, understanding how these fabrics behave is crucial, and I’ve developed techniques to manage them effectively in the draping process.

Q 5. Describe your process for creating a muslin mock-up.

Creating a muslin mock-up is a critical step in the design process. It allows me to test the fit and drape of the pattern before using the final fabric. My process starts with selecting a lightweight, inexpensive muslin fabric. I cut out the pattern pieces, adding seam allowances, and carefully sew the pieces together, leaving openings for fitting. The mock-up is then fitted on a dress form or the client, and adjustments are made directly on the muslin using pins. These adjustments are then transferred back to the original pattern pieces for a refined and accurate final garment.

The entire process involves carefully observing the fit – checking for ease of movement, assessing the position of darts and seams, and ensuring the overall silhouette matches the design intent. I often make several iterations of the muslin mock-up, carefully adjusting and refining until the fit is impeccable.

Q 6. Explain your understanding of grainlines and their importance in garment construction.

Grainlines refer to the lengthwise and crosswise yarns in a woven fabric. Understanding grainlines is fundamental to garment construction. The lengthwise grain (warp) runs parallel to the selvage (the finished edge of the fabric) and offers the most stability and least stretch. The crosswise grain (weft) runs perpendicular to the selvage and has more give. The bias is cut at a 45-degree angle to the grain and provides the most stretch.

Correct grain alignment is crucial for a garment’s shape, drape, and fit. Cutting a garment piece on the bias will result in a different drape than cutting on the straight grain. Ignoring grainlines can lead to a garment that looks distorted, twists out of shape, or fits poorly.

For example, cutting a skirt on the bias will provide a beautiful, flowing drape, while cutting it on the straight grain will create a more structured silhouette. Similarly, cutting a collar on the straight grain ensures it lies flat and maintains its shape.

Q 7. How do you identify and correct fitting issues during a draping session?

Identifying and correcting fitting issues during a draping session involves careful observation and a methodical approach. I begin by examining the overall silhouette, checking for any pulling, gaping, or puckering. I then move to specific areas, checking for issues such as:

- Tightness or looseness: I identify areas where the fabric is too tight or too loose by observing the way the fabric drapes on the form and how it interacts with the body.

- Uneven seams: I carefully check for uneven seams, indicating potential pattern issues or errors in cutting.

- Distorted shapes: I look for any distortion in the garment shape, which may result from incorrect grain alignment or inappropriate fabric choice.

Once the issue is identified, I make adjustments by pinning, shifting, or adding/removing fabric directly on the form. For example, if there’s excessive tightness across the bust, I’ll let out the seam using darts or easing techniques. I carefully note all adjustments before removing the draped fabric and transferring them to the flat pattern for precise replication.

Q 8. Describe your experience with different types of sewing machines.

My experience with sewing machines spans a wide range, from basic domestic machines to industrial models. I’m proficient with both mechanical and computerized machines, understanding their nuances and capabilities. For example, I regularly use a Singer 4411 for its robust construction and reliability on heavier fabrics, while a computerized Juki machine allows for precise stitch regulation and intricate embroidery when needed for detail work. Industrial machines are essential for high-volume production and specialized tasks like buttonhole sewing. I understand how stitch length, tension, and feed dogs affect the final product, allowing me to adapt my technique based on the machine and fabric. I’ve also worked with sergers (overlock machines) extensively for professional seam finishes, guaranteeing durability and a clean, finished look.

Q 9. What are your preferred tools and techniques for hand-stitching?

My preferred hand-stitching tools include high-quality needles (sharps, betweens, and embroidery needles depending on the fabric and stitch), fine thread appropriate for the fabric, and thimbles for protection. I value precision and strive for invisible stitches wherever possible. My techniques are focused on efficiency and durability. For example, I frequently employ the backstitch for strength and neatness in seams that require durability like hems and buttonholes. For finer details or decorative elements, I utilize the slip stitch to create nearly invisible seams, crucial when attaching linings or working with delicate fabrics. I’m comfortable with various hand stitches, including running stitches, blanket stitches for decorative edges, and ladder stitches for mending. The key is selecting the appropriate stitch for the specific task and maintaining consistent tension for a professional finish.

Q 10. How do you handle alterations requested by a client?

Handling client alterations involves a structured process. First, I carefully consult with the client to understand their needs and desired outcome. I assess the garment thoroughly, noting any existing damage or alterations. I’ll then discuss the feasibility, potential challenges, and cost of the alteration, offering options where appropriate. For instance, if a client wants to shorten a skirt, I’ll discuss the best approach, considering the hemline style and the available fabric. Once we agree on the plan, I meticulously perform the alteration, focusing on maintaining the garment’s integrity and original design aesthetics. A thorough fitting is always part of the process to ensure the alteration meets the client’s expectations before finalization.

Q 11. How do you maintain quality control throughout the draping and tailoring process?

Maintaining quality control is paramount. It starts with meticulous fabric selection and pre-preparation – checking for flaws and pre-shrinking where necessary. Each stage, from draping (creating the initial pattern on a dress form) to cutting, sewing, and finishing, receives careful attention to detail. I regularly inspect my work for accuracy, checking seams for straightness and evenness, ensuring proper stitch tension, and paying close attention to seam finishes to prevent fraying. I use marking tools precisely to ensure accurate cutting and placement. A final pressing is crucial to enhance the garment’s appearance and structure. I believe that consistent quality control builds a reputation for reliability and client satisfaction. A regular maintenance check on my machines further supports my quality control procedures.

Q 12. Describe your experience with various types of closures (e.g., zippers, buttons, hooks and eyes).

I have extensive experience with various closures. I’m proficient with inserting zippers (both invisible and conventional), attaching buttons (with appropriate shank buttons for better fabric flow), and installing hooks and eyes. My selection of the right closure depends heavily on the garment’s style and fabric. For instance, an invisible zipper is ideal for a sleek, refined look on a tailored dress, while a sturdy metal zipper is more suitable for outerwear. My skill extends to creating decorative buttonholes and securing closures securely to ensure longevity and ease of use. I even utilize specialized techniques for closures like snap fasteners and decorative buckles. Choosing the appropriate closure and method of attachment is essential for ensuring both functionality and aesthetic appeal.

Q 13. Explain your understanding of different seam finishes and their applications.

Understanding seam finishes is crucial for garment durability and appearance. Different finishes are selected based on fabric type and garment construction. Common finishes include serging (overlocking), which prevents fraying; pinking, which creates a decorative edge; French seams, providing a clean, elegant finish for sheer fabrics; Hong Kong finishes, offering a professional, clean edge; and zigzag stitching, a simple yet effective way to prevent fraying. I often combine techniques, for example, using a serger to finish a seam and then enclosing it within a French seam for extra reinforcement in high-stress areas like shoulder seams. The choice of seam finish directly impacts the garment’s longevity, making it a critical aspect of the tailoring process.

Q 14. How do you interpret a technical design specification?

Interpreting technical design specifications requires careful attention to detail and a thorough understanding of garment construction. I start by thoroughly reviewing the specifications, paying attention to every aspect, including fabric type, measurements, construction details (seam allowances, closures, linings, etc.), and any specific design features. I may create a sample muslin (a test garment from a less expensive fabric) to check the fit and adjust the pattern before proceeding with the final fabric. I also look for potential challenges or inconsistencies within the specifications and make notes. Communication with the designer is essential to clarify any ambiguities or potential issues before starting the actual tailoring process. The goal is to accurately recreate the designer’s vision while ensuring a perfectly fitting and well-constructed garment. For instance, if the specs call for a specific interfacing, I’ll ensure I use the correct type to provide the exact support and drape intended by the designer.

Q 15. Describe your experience with industrial sewing equipment.

My experience with industrial sewing equipment is extensive, encompassing a wide range of machines including single-needle and double-needle lockstitch machines, overlock (serger) machines, coverstitch machines, and industrial buttonhole machines. I’m proficient in operating and maintaining these machines, understanding their specific functionalities and limitations. For example, I’ve worked extensively with Juki and Brother industrial machines, understanding the nuances of adjusting stitch length, tension, and presser foot pressure to achieve optimal results depending on the fabric type. I’m also familiar with troubleshooting common mechanical issues, such as needle breakage, tension problems, and bobbin malfunctions. My experience extends to high-speed production environments, requiring efficient machine operation and preventative maintenance to maximize productivity.

I’m also comfortable using specialized equipment like computer-aided design (CAD) cutting systems for efficient pattern cutting from large fabric rolls. Understanding the workings and capabilities of diverse industrial sewing equipment is crucial for efficient and high-quality garment construction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your approach to troubleshooting technical issues during garment construction?

My approach to troubleshooting technical issues during garment construction is systematic and methodical. It starts with careful observation and identification of the problem. I begin by examining the garment for visible flaws, such as skipped stitches, broken threads, or uneven seams. I then consider the type of machine used, the fabric properties, and the specific sewing technique employed.

For example, if I encounter skipped stitches, I’ll check the needle, thread tension, and presser foot pressure. If the problem persists, I might investigate the bobbin case and timing mechanism of the sewing machine. My troubleshooting process involves a logical progression of steps, starting with the most likely causes and systematically eliminating them until the root cause is identified and corrected. I also keep detailed notes documenting the problem, the steps taken to diagnose it, and the solution, allowing me to quickly resolve similar issues in the future. Documentation is key to continuous improvement.

Q 17. How familiar are you with CAD pattern design software?

I am highly familiar with CAD pattern design software, specifically with industry-standard software like Gerber Accumark and Lectra Modaris. I’m proficient in creating and manipulating patterns, grading sizes, and generating marker plans for efficient fabric utilization. My skills extend to using the software’s advanced features, such as creating notches, manipulating grainlines, and generating various reports. This allows me to efficiently create precise and accurate patterns, reducing waste and improving the overall garment construction process. I also have experience using CAD to create 3D simulations of garments, allowing for visualization and identification of potential fit issues before actual production. Using CAD allows for quick alterations and iterations, saving time and resources.

Q 18. Describe your experience working with different textile types (e.g., woven, knit, leather).

My experience encompasses working with a diverse range of textile types including woven, knit, and leather fabrics. Understanding the unique properties of each fabric type is crucial for selecting appropriate sewing techniques, needle sizes, and stitch types. For woven fabrics such as cotton, silk, or linen, I carefully consider the weave structure and thread count when choosing seam finishes and pressing techniques. Knits, on the other hand, require specialized overlock or coverstitch machines to prevent unraveling and ensure a clean finish. Working with leather necessitates different tools and techniques to prevent damage and ensure durability. I am familiar with adjusting the machine pressure and stitch length to accommodate different thickness and textures. Experience has taught me the importance of selecting the right needle for each fabric to prevent snags and ensure high-quality stitching.

Q 19. How do you determine appropriate seam allowances for various garments?

Determining appropriate seam allowances depends on several factors, including the garment type, fabric weight, and desired style. Generally, seam allowances range from 1⁄4 inch to 1 inch. For example, a tailored garment might use a 5⁄8 inch seam allowance for precision and stability, while a more casual garment could use a 1⁄2 inch seam allowance. Heavier fabrics often require larger seam allowances for strength and durability. I consider the design’s aesthetic requirements as well; for example, exposed seams might necessitate a slightly larger seam allowance to visually enhance the design. There’s no one-size-fits-all answer; my experience allows me to make informed decisions based on the specific project’s demands.

Q 20. Explain your understanding of balance and proportion in garment design.

Balance and proportion are fundamental to garment design, ensuring a flattering and aesthetically pleasing silhouette. Balance refers to the visual equilibrium of the garment, achieved by distributing visual weight evenly. This can involve the placement of design elements such as pockets, darts, or embellishments. Proportion refers to the harmonious relationship between different parts of the garment, such as the sleeve length relative to the torso length or the width of the shoulders relative to the waist. Understanding body proportions is critical. A garment that is well-balanced and proportionally correct will flatter the wearer’s body shape, enhancing their figure. For instance, a garment with a lower neckline needs to balance out with the right skirt or pants design and proportion to the upper body. Achieving proper balance and proportion involves careful consideration of design principles and a thorough understanding of the human form.

Q 21. How do you ensure the structural integrity of a garment?

Ensuring structural integrity is paramount. This involves several key steps. First, selecting appropriate fabrics and interfacings is crucial. Interfacing provides support and stability, preventing stretching and sagging. Second, careful pattern construction and precise cutting are essential for creating a garment that fits well and holds its shape. Third, using the correct sewing techniques, such as reinforcing stress points with additional stitching, prevents seams from failing under stress. Fourth, proper pressing and finishing techniques maintain the garment’s structure and prevent distortion. For example, using appropriate interfacing on collars and lapels provides support and prevents them from flopping open. My attention to detail throughout the entire process guarantees a durable and well-constructed garment capable of withstanding wear and tear.

Q 22. How do you approach creating a tailored garment from scratch?

Creating a tailored garment from scratch is a meticulous process that begins long before the first stitch. It’s a journey that blends artistic vision with precise technical execution. I start with a deep understanding of the client’s needs – their body type, desired style, and the occasion for the garment. This informs my choice of fabric and the initial design concept, which I often sketch to visualize the final product.

Next, I’ll usually create a draping muslin. Draping is where I manipulate fabric directly on a dress form to achieve the desired shape and silhouette. This allows for immediate adjustments and experimentation with design details. Once the drape is perfected, I’ll take careful measurements and create a pattern. This pattern, a two-dimensional representation of the three-dimensional drape, is crucial for accurate garment construction.

From the pattern, I cut the chosen fabric, paying close attention to the grain and minimizing waste. Then, it’s on to construction: assembling the garment piece by piece, meticulously stitching, pressing, and finishing each seam. The process is iterative, with multiple fittings throughout to ensure a perfect fit. Finally, the garment undergoes a final pressing and inspection before being presented to the client.

For example, I once created a bespoke wedding gown. The initial draping involved numerous iterations to achieve the client’s vision of a flowing A-line silhouette with intricate pleating at the bodice. The final product was a testament to the power of careful draping and precise tailoring.

Q 23. How do you manage your time effectively when working on multiple projects simultaneously?

Managing multiple projects effectively requires a structured approach. I use a project management system, either digital or a well-organized physical planner, to track deadlines and prioritize tasks. Each project gets a dedicated timeline, broken down into smaller, manageable steps. This allows me to realistically assess my workload and allocate time appropriately. For instance, I might schedule draping sessions for one project on Mondays and Wednesdays, focusing on tailoring for another project on Tuesdays and Thursdays. This prevents task overlap and maintains focus.

Prioritization is key. I tackle the most urgent or complex tasks first, reserving less time-sensitive tasks for when my energy levels are lower. Regular breaks are also crucial to avoid burnout and maintain productivity. Effective communication with clients is equally important to manage expectations and avoid delays. This proactive approach to project management helps ensure timely completion of all projects while maintaining high-quality workmanship.

Q 24. Describe your experience with grading patterns.

Grading patterns is a fundamental skill in tailoring. It’s the process of adjusting a base pattern to accommodate different sizes. My experience with grading encompasses both manual and digital methods. Manually, I use precise measurements and mathematical calculations to increase or decrease pattern pieces proportionally. This requires a deep understanding of body proportions and how alterations affect the overall garment fit.

I’m also proficient in using digital pattern-making software, which streamlines the grading process significantly. These programs allow for quick and accurate scaling of patterns across a range of sizes, reducing the potential for errors. Regardless of the method, accuracy is paramount. A poorly graded pattern can result in a garment that is ill-fitting and compromises the intended design. I always double-check my calculations and test graded patterns on a muslin before cutting into expensive fabrics. For example, in a recent project, I graded a pattern for a women’s blazer across 6 sizes (from XS to XXL) ensuring consistent style and fit across each size.

Q 25. What are your strategies for identifying and resolving fitting problems on a completed garment?

Identifying and resolving fitting problems requires a keen eye for detail and a systematic approach. First, I carefully examine the completed garment, noting any areas of tightness, looseness, or distortion. I then analyze the fit against the client’s body to determine the cause of the problem – is it related to the pattern, the cutting, or the construction? Sometimes, simple adjustments like letting out a seam or taking in a dart can resolve the issue.

For more complex problems, I may need to adjust the pattern itself. This might involve altering the seam lines, adding or removing darts, or even redrawing certain sections. I always prioritize minimal alterations to preserve the design integrity of the garment. In some cases, a new muslin fitting might be required to test corrections before adjusting the final garment. Client communication is key throughout this process. I thoroughly explain the adjustments, showing examples and providing options where necessary to ensure their satisfaction. For example, I once had to adjust the sleeve cap of a jacket to resolve a fitting issue that was causing pulling at the shoulders. A quick alteration to the pattern and a re-stitching of the sleeve resolved the problem seamlessly.

Q 26. How do you stay updated with the latest trends and techniques in draping and tailoring?

Staying updated in the dynamic field of draping and tailoring requires continuous learning. I regularly attend industry workshops and seminars to learn about new techniques and technologies. I also subscribe to trade publications and follow influential designers and tailors on social media platforms. These sources provide insights into current trends, emerging innovations, and best practices. Furthermore, I actively participate in online forums and communities dedicated to tailoring and garment construction. This allows me to engage with other professionals, exchange ideas, and learn from their experiences.

Beyond formal learning, I seek inspiration from diverse sources – observing street style, visiting museums, and exploring different cultures. This broad exposure helps me understand evolving aesthetics and incorporate unique elements into my designs. Continuous learning ensures that my skillset remains relevant and allows me to adapt to the ever-changing landscape of fashion. For example, recently I participated in a workshop on using 3D printing technologies to create unique pattern pieces that push the boundaries of traditional tailoring.

Q 27. Describe your experience working collaboratively within a design team.

Collaborative work is integral to the design process. I value open communication and active listening in team settings. My experience working in design teams involves actively contributing ideas, sharing technical expertise, and supporting my colleagues. I find that a strong team dynamic fosters creativity and allows for a more holistic design outcome. I’m adept at translating design concepts into technical specifications, ensuring a smooth transition between design and production.

In a collaborative environment, I’m comfortable taking direction, but also equally capable of offering constructive feedback and suggestions. I believe in a respectful and supportive work environment where everyone’s contributions are valued. A recent project involved collaborating with a designer on a ready-to-wear collection. My role was crucial in refining the designs from a technical perspective, ensuring the garment prototypes met the production standards and fit requirements. This included optimizing the patterns, suggesting suitable fabrics and providing guidance on the construction process.

Q 28. How do you handle client feedback and revisions?

Handling client feedback and revisions is a crucial aspect of my work. I welcome feedback as an opportunity to improve and meet client expectations. I actively listen to client concerns, asking clarifying questions to ensure a thorough understanding of their perspective. I approach revisions systematically. I document all feedback and discuss the proposed changes with the client to agree on the best approach. This collaborative process ensures that the revisions align with both the client’s vision and the technical capabilities of the garment.

For example, a client once requested a change in the neckline of a dress after the initial fitting. Instead of simply implementing the change, I discussed the implications of the alteration, offering different options to achieve the desired effect while preserving the overall balance and aesthetics of the dress. Through clear communication and a collaborative approach, we were able to successfully incorporate the change, resulting in a garment that perfectly met the client’s needs and exceeded their expectations.

Key Topics to Learn for Your Draping and Tailoring Interview

- Fabric Selection and Drape: Understanding fabric properties (weight, drape, stretch) and their impact on garment design and construction. Practical application: Explaining how different fabrics drape on various body types and how this influences pattern design choices.

- Pattern Making Techniques: Mastering both flat pattern drafting and draping techniques, including basic bodice, skirt, and sleeve construction. Practical application: Describing your experience with different pattern-making methods and your ability to adapt patterns to various styles and sizes.

- Draping on the Stand: Proficiency in manipulating fabric on a dress form to create unique shapes and silhouettes. Practical application: Detailing your process for creating a draped garment, from initial muslin to final fitting.

- Sewing Techniques and Construction: Expertise in various sewing techniques relevant to tailoring, including seam finishes, darts, zippers, and buttonholes. Practical application: Explaining your preferred methods for achieving clean and professional finishes.

- Fitting and Alterations: Understanding the importance of fitting and making adjustments to ensure a perfect fit. Practical application: Describing your approach to fitting garments on different body types and resolving common fitting issues.

- Design Principles and Aesthetics: Knowledge of design principles (balance, proportion, silhouette) and the ability to apply them to create aesthetically pleasing garments. Practical application: Analyzing the design elements of existing garments and explaining your design choices.

- Advanced Techniques (Optional): Explore techniques like couture sewing, pattern grading, and specialized draping methods, depending on the job requirements. Practical application: Showcase any advanced skills you possess and their relevance to the position.

Next Steps

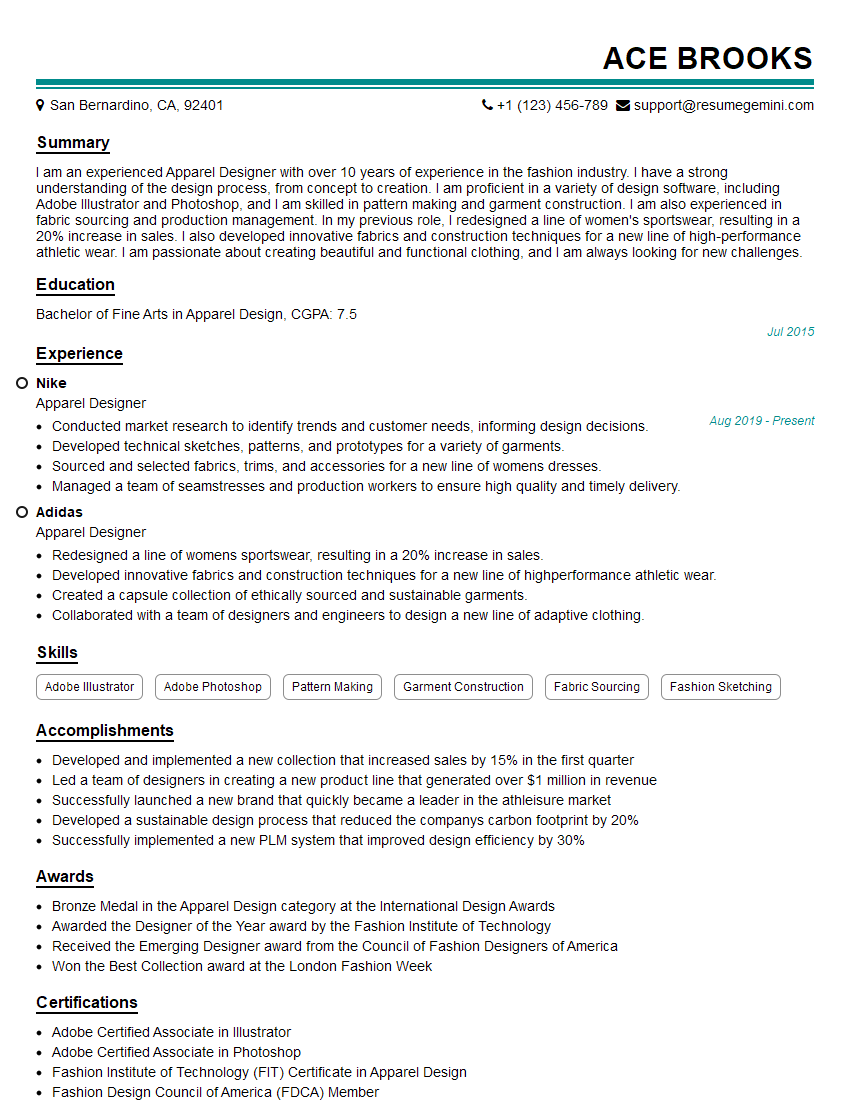

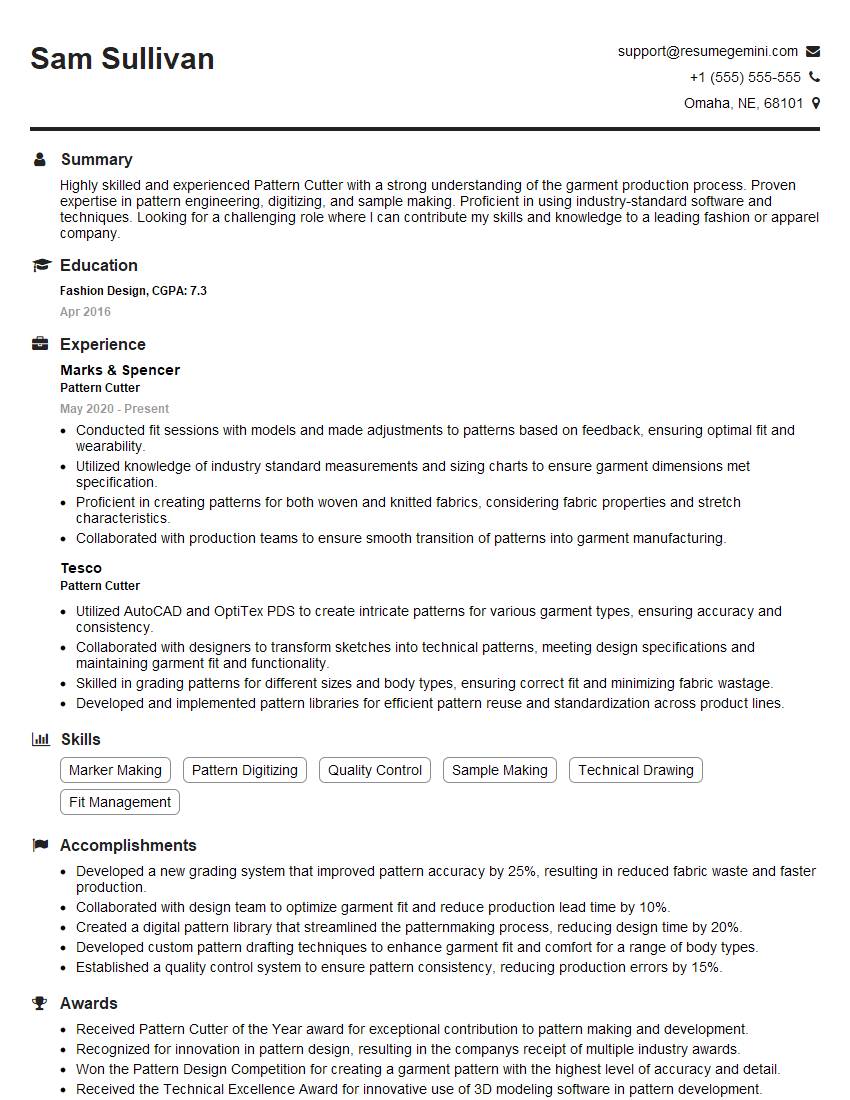

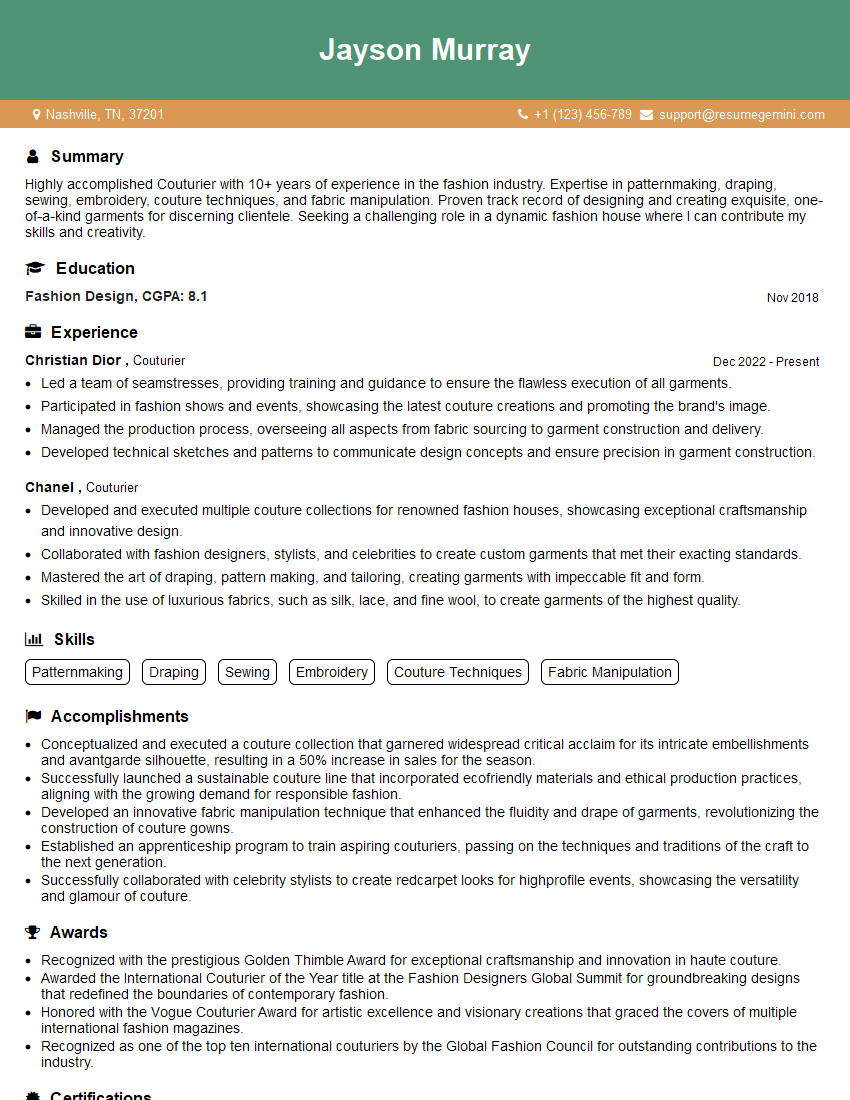

Mastering draping and tailoring opens doors to exciting careers in fashion design, bespoke tailoring, and costume creation. To stand out, a strong and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. They offer examples of resumes tailored specifically to the draping and tailoring field, ensuring you present your qualifications in the best possible light. Take the next step in your career journey and craft a resume that truly reflects your talent and expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good