Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Drill Cutting Analysis interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Drill Cutting Analysis Interview

Q 1. Explain the importance of drill cuttings analysis in drilling operations.

Drill cuttings analysis is paramount in drilling operations because it provides crucial real-time information about the subsurface formations being penetrated. Think of it as a geologist’s window into the Earth. By analyzing the cuttings, we gain insights into the lithology (rock type), formation properties (porosity, permeability), potential hydrocarbon indicators, and possible drilling hazards. This information directly impacts decisions related to well design, drilling parameters, mud program optimization, and overall wellbore stability, ultimately leading to safer, more efficient, and cost-effective drilling operations. Without it, drilling would be significantly more risky and less productive.

Q 2. Describe the different types of drill cuttings and their significance.

Drill cuttings come in various forms, reflecting the diverse geological formations encountered. We can broadly categorize them as follows:

- Sedimentary Cuttings: These are the most common type, originating from sedimentary rocks like sandstone, shale, limestone, and conglomerate. Their characteristics vary greatly; for example, sandstone cuttings will be relatively hard and gritty, while shale cuttings are often softer and more easily broken.

- Igneous Cuttings: These originate from volcanic rocks like basalt and granite, usually characterized by their crystalline structure and hardness. Identifying igneous rocks requires careful observation of mineral composition and texture.

- Metamorphic Cuttings: Formed by the alteration of pre-existing rocks under heat and pressure, examples include slate, schist, and marble. Identifying them involves recognizing characteristic textures and mineral assemblages indicative of metamorphism.

- Special Cuttings: This group includes unusual cuttings like coal, evaporites (salt, gypsum), and various mineralized zones, providing valuable information about unique subsurface conditions. Coal cuttings, for example, often signal a potential source rock for hydrocarbons.

The significance lies in their direct correlation to the formation’s properties. For instance, the presence of soft shale cuttings might indicate a need for adjustments to the drilling mud to prevent wellbore instability, while hard igneous cuttings may necessitate changes in the drilling bit and parameters.

Q 3. How do you identify and interpret lithology from drill cuttings?

Lithology identification from drill cuttings relies on a systematic approach combining visual observation with basic tests. It’s a bit like a geological detective work! We start with visual examination, noting the color, texture (e.g., granular, crystalline, flaky), hardness, and presence of fossils or other distinctive features. For example, a fine-grained, dark-grey cutting that easily crumbles might indicate shale, while a coarse-grained, light-brown cutting with visible quartz grains is likely sandstone. Further analysis might involve simple tests like acid reaction (to identify carbonates) or streak testing (to determine mineral hardness).

Microscopic analysis can provide more detailed information. Thin sections prepared from the cuttings can be examined under a petrographic microscope, allowing for the identification of individual minerals and their proportions, giving a more precise lithological classification. This detailed analysis is especially critical in complex formations or when subtle differences are crucial for reservoir characterization.

Q 4. Explain the process of drill cuttings sample preparation for analysis.

Proper sample preparation is crucial for accurate analysis. The process typically involves:

- Cleaning: Removing excess drilling mud from the cuttings is the first step to avoid masking the true characteristics of the rock. This is usually done by washing the cuttings with water or a suitable solvent.

- Drying: The cuttings are then dried in an oven at a controlled temperature to prevent alteration of the sample.

- Size Fractionation: Often, the cuttings are sieved into different size fractions (e.g., > 2mm, 2-1mm, 1-0.5mm, <0.5mm) to enhance the analysis of various grain sizes and textures.

- Weighing: Weighing is necessary for certain analyses, particularly when calculating the volume of the different components in the sample.

- Storage: Samples are carefully stored to prevent contamination and degradation. This usually involves storing them in labelled bags or containers.

The degree of preparation depends on the specific analysis to be carried out. For instance, detailed petrographic analysis will require more meticulous preparation compared to a quick visual identification of the lithology.

Q 5. What are the key parameters to be monitored during drill cuttings analysis?

Key parameters monitored during drill cuttings analysis include:

- Lithology: Type of rock (sandstone, shale, limestone, etc.).

- Color: Can indicate the presence of certain minerals or organic matter.

- Texture: Grain size, shape, and sorting (well-sorted vs. poorly-sorted).

- Hardness: An indication of the rock’s strength and potential drilling difficulties.

- Fossil content: Provides biostratigraphic information for age determination and paleoenvironmental reconstruction.

- Mineral composition: Determined through microscopic analysis, X-ray diffraction, or other techniques.

- Porosity and Permeability (indirectly): These are inferred from the cuttings’ texture and visual characteristics.

- Hydrocarbon indicators: Presence of oil stains, gas bubbles, or fluorescence can suggest potential hydrocarbon reservoirs.

- Presence of potential hazards: This includes highly reactive shales, unstable formations, lost circulation zones, high-pressure zones.

Q 6. How do you determine the formation porosity from drill cuttings?

Directly determining formation porosity from drill cuttings is challenging because the cuttings are fragmented and often altered during the drilling process. However, we can make indirect estimations. Visual examination of the cuttings’ texture, particularly the grain size, packing density, and presence of pore spaces, can provide a qualitative assessment of porosity. For a more quantitative estimation, we often rely on other measurements obtained during drilling, such as the formation density log (from wireline logging) which can provide more reliable porosity data. It’s important to understand the limitations of estimating porosity from cuttings alone; it’s rarely accurate.

Q 7. Explain how drill cuttings analysis helps in identifying potential hazards.

Drill cuttings analysis is vital for identifying potential hazards during drilling operations. For example:

- Unstable formations: The presence of highly fractured or clay-rich shales can signal potential wellbore instability, necessitating adjustments to the drilling mud or wellbore design to prevent collapses or wellbore swelling.

- High-pressure zones: Unusual fluid pressures and the presence of fractured rocks in cuttings might warn of abnormally pressured formations that could lead to a blowout if not managed properly.

- Lost circulation zones: The presence of highly permeable or fractured formations can indicate potential for fluid loss during drilling, requiring the use of special drilling muds or techniques.

- Presence of reactive minerals: Some minerals react with the drilling mud (e.g., anhydrite and gypsum), causing problems with mud properties and wellbore stability. Identification of these minerals from cuttings allows for proactive management.

- Toxic or hazardous materials: Drill cuttings can sometimes contain hazardous substances, like hydrogen sulfide (H2S) or radioactive materials. Early detection via cuttings analysis allows for appropriate safety precautions to be put in place.

Identifying these hazards beforehand allows for proactive mitigation strategies, improving safety and operational efficiency.

Q 8. Describe the role of drill cuttings analysis in wellbore stability.

Drill cuttings analysis plays a crucial role in maintaining wellbore stability. By examining the cuttings – the small pieces of rock brought to the surface during drilling – we gain valuable insights into the formation’s properties. This information is critical because unstable formations can lead to wellbore collapse, stuck pipe, and ultimately, costly drilling delays and potential hazards. For instance, if the analysis reveals the presence of highly fractured or shale formations susceptible to swelling when exposed to drilling fluids, we can adjust the drilling mud properties (e.g., increase density, modify chemical composition) to mitigate the risk of instability and maintain a stable wellbore throughout the drilling operation.

Imagine building a tall tower – you wouldn’t start building without analyzing the soil’s stability, right? Similarly, understanding the formation’s characteristics through cuttings analysis is paramount to ensuring a stable and safe wellbore.

Q 9. How does drill cuttings analysis assist in optimizing drilling parameters?

Drill cuttings analysis directly influences the optimization of drilling parameters. Analyzing cuttings helps determine the optimal drilling rate, weight on bit (WOB), and rotary speed (RPM). If the analysis shows a particularly hard formation, we might increase WOB and RPM (within safe limits) to maximize penetration rate. Conversely, if the cuttings indicate a soft, potentially unstable formation, we would reduce WOB and RPM to avoid hole instability or formation damage. This iterative process, guided by cuttings analysis, ensures efficient and safe drilling while preventing costly complications.

For example, if cuttings consistently show signs of significant fracturing under the current drilling parameters, we would likely adjust to a lower WOB to minimize further fracturing and reduce the risk of stuck pipe.

Q 10. Explain the use of drill cuttings analysis in formation evaluation.

Drill cuttings analysis provides a valuable, albeit indirect, method of formation evaluation. While not as detailed as wireline logging, cuttings analysis offers crucial preliminary information on lithology (rock type), porosity, and potential presence of hydrocarbons. The size, shape, and color of the cuttings provide clues about the formation’s hardness and composition. Furthermore, the presence of certain minerals, fossils, or hydrocarbon indicators (e.g., oil staining) can provide valuable information about the formation’s potential reservoir characteristics. This initial information guides subsequent, more sophisticated evaluation techniques.

Think of it as a reconnaissance mission: cuttings analysis gives you a preliminary map of the territory before you embark on more detailed surveys. It allows for preliminary decisions on the next steps in formation evaluation, potentially saving time and resources.

Q 11. Describe the challenges associated with drill cuttings analysis in complex formations.

Analyzing cuttings from complex formations presents several challenges. These formations, often characterized by high heterogeneity (variations in properties), extreme temperatures, or high pressures, can lead to altered or fragmented cuttings, making accurate interpretation difficult. The cuttings may be severely broken up during drilling and transportation, losing their original context and shape. Additionally, the effects of drilling fluids on the cuttings can further complicate interpretation. Furthermore, contamination from older cuttings or from the drilling process itself can lead to inaccurate results.

Dealing with highly fractured shale formations, for instance, can be particularly challenging because the original formation properties can be masked by the fracturing, potentially leading to incorrect assessments of wellbore stability or reservoir quality.

Q 12. How do you handle and analyze cuttings from different drilling environments?

Handling and analyzing cuttings from diverse drilling environments requires a systematic approach. The procedure begins with proper sample collection at the shale shaker, where careful segregation of cuttings by depth intervals is crucial. Cuttings should then be preserved appropriately (discussed in the next answer) to minimize alteration. Laboratory analysis typically involves visual examination, sieve analysis (to determine grain size distribution), and potentially more sophisticated techniques like XRD (X-ray diffraction) or thin-section analysis for detailed mineralogical and petrophysical characterization. The analysis methods and interpretation are tailored to the specific challenges of each environment, taking into account factors like temperature, pressure, and formation type.

In a high-pressure, high-temperature environment, for instance, we would need to prioritize rapid processing and analysis to avoid alteration of the cuttings due to prolonged exposure to atmospheric conditions.

Q 13. What are the limitations of drill cuttings analysis?

Drill cuttings analysis has limitations. The most significant limitation is the potential for sample bias. Cuttings may not be representative of the entire formation due to the selective nature of the drilling process. Furthermore, the size and condition of the cuttings can be severely affected by drilling parameters, mud properties, and transportation to the surface, leading to inaccurate representation of the formation’s properties. The analysis is also limited by the resolution; detailed information about the formation (e.g., detailed porosity profiles) cannot be obtained through cuttings analysis alone. It provides a valuable overview but often needs to be complemented by other formation evaluation methods for a more comprehensive understanding.

Imagine trying to understand the landscape of a country based solely on a handful of rocks picked up at random locations. You’d have some idea, but certainly not a detailed picture.

Q 14. What are the different methods used for preserving drill cuttings samples?

Several methods are used to preserve drill cuttings samples, all aimed at minimizing alteration and maximizing the accuracy of subsequent analyses. The most common method is immediate refrigeration, which helps to slow down or prevent chemical and physical changes. Another common approach involves the use of preservatives, such as alcohol or other stabilizing chemicals, to reduce oxidation and prevent sample degradation. Proper labeling and documentation, including depth interval, date, and time of collection, are vital to maintaining the integrity and context of the samples. Proper storage in sealed containers is necessary to prevent contamination and further degradation. In some cases, specialized preservation techniques, such as freezing, may be employed for particularly sensitive samples.

Think of it like preserving a historical artifact; careful handling and preservation are essential to ensure its value and accuracy for future study.

Q 15. How do you ensure accurate and reliable data from drill cuttings analysis?

Ensuring accurate and reliable data from drill cuttings analysis hinges on meticulous sample handling and a robust analytical process. Think of it like baking a cake – if your ingredients (samples) are compromised or your recipe (analysis method) is flawed, the final product (data) will be unreliable.

- Representative Sampling: We need to ensure the cuttings are truly representative of the formation being drilled. This means minimizing contamination, maintaining consistent sample collection intervals (e.g., every 5-10 feet), and carefully logging the drilling parameters (e.g., rate of penetration, weight on bit) which can affect cutting size and shape.

- Proper Preservation: Cuttings are prone to alteration – moisture loss, oxidation, etc. – so prompt processing is crucial. This often involves immediate labeling, secure storage, and potentially the use of preservatives depending on the geological formation and planned analyses (e.g., preventing oxidation in sulfide-rich formations).

- Standardized Procedures: Following standardized operating procedures (SOPs) for every step, from sample retrieval to analysis, is vital for consistency and repeatability. This eliminates variability introduced by different technicians and techniques.

- Quality Control: Implementing quality control measures, such as running duplicate analyses or using reference samples, helps identify potential errors and ensures the data’s reliability. We can also use blind samples or proficiency testing to evaluate the accuracy of our methods.

For example, on one project, we noticed inconsistencies in lithology descriptions between different shifts. By implementing a stricter SOP and conducting training, we dramatically improved the data consistency and accuracy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of integrating drill cuttings analysis with other logging data.

Integrating drill cuttings analysis with other logging data, such as wireline logs (gamma ray, resistivity, density), is crucial for a comprehensive understanding of the subsurface. It’s like having two pieces of a puzzle – each provides a different perspective, but together they reveal a clearer picture.

- Lithological Correlation: Cuttings provide direct visual observation of lithology, which can be correlated with wireline log responses to confirm formations and identify changes.

- Porosity and Permeability Estimation: While cuttings don’t directly measure porosity and permeability, their visual characteristics (grain size, sorting, cementation) can inform initial estimates, which are then refined using wireline logs.

- Fluid Identification: Cuttings can reveal the presence of hydrocarbons or formation water, but wireline logs (e.g., NMR, density) provide more quantitative information on fluid saturation and type.

- Improved Formation Evaluation: The combination of direct observations (cuttings) and indirect measurements (logs) allows for a more robust and complete formation evaluation, leading to better reservoir characterization and well planning decisions.

In one instance, cuttings analysis indicated the presence of unusual amounts of clays in a specific zone. By integrating this with the gamma ray log, we confirmed a significant clay-rich layer that wasn’t initially obvious, improving our understanding of the reservoir’s sealing potential.

Q 17. Describe your experience with different types of drill cutting analysis equipment.

My experience encompasses a variety of drill cuttings analysis equipment, each with its strengths and limitations. The selection depends on the specific analysis needs and project requirements.

- Microscope: A fundamental tool for examining cuttings’ mineralogy, texture, and the presence of fossils. I have extensive experience with both optical and petrographic microscopes, using various magnification levels to identify different features.

- Sieve Shakers and Sieve Sets: Used to determine the grain size distribution, which helps characterize the formation’s permeability and texture. I’m proficient in using different sieve sizes and interpreting the resulting grain size curves.

- X-Ray Diffraction (XRD): Used for quantitative mineralogical analysis, providing more precise information about the mineral composition of the cuttings than visual inspection alone. I have practical experience in sample preparation, running the analysis, and interpreting the XRD patterns.

- X-Ray Fluorescence (XRF): Provides elemental composition, which is valuable for identifying specific minerals and potentially detecting the presence of hydrocarbons based on their elemental signature. I’m familiar with both handheld and laboratory-based XRF instruments.

On a recent project involving a complex carbonate reservoir, the integration of XRD and petrographic microscopy was particularly valuable in characterizing the different carbonate fabrics and their diagenetic history, leading to a better understanding of porosity and permeability variations.

Q 18. How do you interpret changes in cuttings properties throughout a wellbore?

Interpreting changes in cuttings properties throughout a wellbore is a crucial aspect of formation evaluation. These changes often indicate transitions between different geological formations, potential reservoir boundaries, or changes in subsurface conditions.

- Lithological Changes: Variations in grain size, color, mineralogy, and fossil content directly reflect changes in lithology. For example, a transition from sandstone cuttings to shale cuttings indicates a change in formation type.

- Fluid Indications: The presence of hydrocarbons or water in cuttings can indicate permeable zones. Hydrocarbon staining, for example, could suggest the presence of oil or gas, while water-saturated cuttings would suggest a different reservoir potential.

- Fracturing and Alteration: The presence of fractures, veins, or alteration minerals in cuttings can suggest the impact of tectonic stress or diagenetic processes on the formation, potentially affecting reservoir properties.

- Correlation with Other Data: Changes in cuttings characteristics are best interpreted when considered in conjunction with other well data, such as wireline logs and drilling parameters.

For example, a sudden increase in shale cuttings accompanied by a decrease in grain size in a sandstone formation might suggest a fault zone that could impede fluid flow.

Q 19. Explain how you would troubleshoot inconsistencies in drill cuttings analysis results.

Inconsistencies in drill cuttings analysis results require systematic troubleshooting. This involves reviewing each step of the process, identifying potential sources of error, and implementing corrective actions.

- Sample Handling Issues: Check for contamination, improper preservation, or inadequate sample representation. Were SOPs followed consistently? Were the samples properly labeled and stored?

- Analytical Errors: Review the analytical methods used. Were the correct procedures followed? Were calibrations checked? Did duplicate analyses show consistency? Were there any equipment malfunctions?

- Interpretation Errors: Ensure the interpretation of cuttings data is consistent with other geological and well data. Were all available data sources considered? Does the interpretation make geological sense?

- Data Reconciliation: If inconsistencies persist, compare the results with other available data (wireline logs, core data) to identify potential discrepancies and refine the interpretation.

In one case, inconsistent grain size distributions were traced back to a faulty sieve shaker. Calibration and maintenance resolved the problem, leading to much more consistent data.

Q 20. How do you communicate your findings from drill cuttings analysis effectively to a team?

Effective communication of drill cuttings analysis findings is essential for informed decision-making. I employ a multi-faceted approach to convey information clearly and concisely.

- Clear and Concise Reports: I generate detailed reports that summarize the key findings, including tables, figures, and interpretations. I avoid technical jargon where possible and explain complex concepts in simple terms.

- Visualizations: I use charts and graphs to illustrate trends and patterns in the data, making it easier for team members to understand the information.

- Presentations: I present my findings in meetings, tailoring my presentation to the audience’s level of technical expertise. I encourage questions and discussions to ensure everyone understands the implications of the data.

- Collaboration: I actively collaborate with geologists, engineers, and other team members to integrate drill cuttings data with other data sources, ensuring a holistic interpretation.

In a recent project, a clear visual representation of lithological changes throughout the wellbore helped the drilling team make informed decisions regarding the optimal drilling parameters and well completion strategy.

Q 21. Describe your experience working with different drilling fluids and their impact on cuttings.

Different drilling fluids significantly impact the condition and properties of drill cuttings, influencing the reliability of the analysis. Understanding these impacts is crucial for accurate interpretation.

- Water-Based Mud: Generally causes minimal alteration to cuttings, making interpretation relatively straightforward. However, water can cause swelling or dispersion in clay-rich formations.

- Oil-Based Mud: Can coat cuttings, making visual identification and mineralogical analysis more challenging. The oil can also mask the presence of hydrocarbons.

- Polymer-Based Mud: Can affect the physical properties of cuttings, potentially causing them to stick together or lose their original texture. Polymer residues can obscure features during microscopic examination.

- Impact on Interpretation: The type of drilling fluid used must be considered during interpretation. For example, cuttings from oil-based mud may require additional cleaning or processing before analysis to ensure accurate results.

In one project, we had to account for the significant impact of a polymer-based mud on the cuttings’ grain size distribution, using specialized cleaning techniques and carefully considering the potential effects on the calculated permeability.

Q 22. Explain how environmental conditions affect the analysis and interpretation of cuttings.

Environmental conditions significantly impact drill cuttings analysis. Factors like temperature, pressure, and the presence of fluids (e.g., drilling mud) can alter the cuttings’ physical and chemical properties. For instance, high temperatures can cause thermal alteration of organic matter, making it difficult to accurately assess the source rock’s maturity. Similarly, the type and properties of drilling mud can mask the inherent characteristics of the cuttings, leading to misinterpretations. We need to carefully consider these factors.

For example, if cuttings are exposed to oxygen after retrieval, oxidation can occur, affecting the color and potentially the assessment of hydrocarbon presence. Therefore, proper preservation techniques are crucial, including immediate sealing of samples in airtight containers to minimize alteration.

Another significant aspect is the influence of pressure. Changes in pressure during the ascent of cuttings from the wellbore to the surface can cause fracturing or alteration of fragile cuttings. This impacts the accurate representation of the formation’s natural state.

Q 23. What software or tools do you use for drill cuttings analysis?

My experience spans a wide range of software and tools utilized in drill cuttings analysis. We routinely employ petrographic microscopes for detailed visual examination of cuttings, identifying minerals, fossils, and textures. Software like GeoMark and Petrel assist in log correlation and interpretation, allowing us to integrate cutting data with wireline logs and seismic data for a more comprehensive understanding of the subsurface. Specialized image analysis software aids in quantifying certain features like grain size distribution and porosity.

For data management and analysis workflows, we utilize various databases and spreadsheets (e.g., Excel, Access) to organize and track the vast amounts of data generated during a project. This ensures efficient data handling and facilitates effective communication and collaboration among team members.

Q 24. How do you handle and interpret abnormal cuttings observations?

Abnormal cuttings observations require a systematic approach. The first step involves meticulous documentation – noting the deviation from expected cuttings characteristics, including lithology, color, texture, and presence of unusual materials. Then, a thorough review of the drilling parameters (e.g., rate of penetration, weight on bit) and mud properties is conducted to identify potential causes.

For instance, encountering unexpected high concentrations of shale in a sandstone formation might suggest a fault or a change in stratigraphic unit. The presence of unusual minerals could indicate hydrothermal alteration or a specific geochemical environment. We always consider multiple scenarios before reaching conclusions and often discuss findings with senior geologists and engineers to gain diverse perspectives.

If the cause remains unclear, further investigation may involve detailed petrographic analysis, geochemical testing, and potentially revisiting the well logs to verify interpretations. Ultimately, our goal is to understand the reasons for the anomalies and accurately incorporate them into the geological model.

Q 25. Describe your experience with quantitative analysis of drill cuttings.

My experience with quantitative analysis of drill cuttings focuses on generating data-driven insights. This involves the use of image analysis software to quantify parameters like grain size distribution, porosity estimates from thin sections, and the quantification of specific minerals using point counting methods. This allows us to move beyond simple visual descriptions and generate objective, numerical data that can be statistically analyzed and integrated into reservoir models.

For example, in one project, we used image analysis to quantify the percentage of calcite cement within a sandstone reservoir, a critical parameter for reservoir quality assessment. This quantitative data, alongside other formation evaluation data, enabled us to build a more robust reservoir model leading to more accurate reserves estimations.

I’m also experienced in utilizing geochemical data from cuttings analysis, such as TOC (total organic carbon) content and biomarker analysis, to assess the hydrocarbon potential of source rocks and mature formations. This provides critical input for exploration and production decisions.

Q 26. Explain your understanding of the relationship between drilling parameters and cuttings properties.

Drilling parameters and cuttings properties are intimately linked. The rate of penetration (ROP), weight on bit (WOB), and rotary speed directly influence the size, shape, and degree of fracturing in the cuttings. High ROP, for instance, often results in finer cuttings and increased fracturing, indicating a softer or more easily-broken formation. Conversely, low ROP might suggest harder rock or issues with the drilling bit.

The type of drilling mud also plays a significant role. Some mud types can cause cuttings to swell, alter their color, or mask their true properties. Understanding the effects of the drilling mud on the cuttings is crucial for accurate interpretation. We often analyze mud properties alongside cuttings data to gain a complete picture of the formation being drilled.

Imagine drilling through a shale formation with high WOB and slow ROP: the cuttings will likely be larger, angular, and potentially show significant fracturing, indicative of a relatively hard and brittle shale. In contrast, drilling through the same formation with low WOB and high ROP might produce finer, more rounded cuttings, suggesting easier drilling and potentially a softer or more fractured shale.

Q 27. How do you ensure quality control and quality assurance in drill cuttings analysis?

Quality control and quality assurance (QC/QA) are paramount in drill cuttings analysis. We employ various techniques to ensure data accuracy and reliability. This includes rigorous sampling procedures, ensuring representative samples are collected at regular intervals and properly documented. All samples are meticulously labelled, catalogued, and stored according to strict protocols to avoid contamination and misidentification.

Blind samples are regularly sent to independent labs for analysis, comparing their findings with our lab results. We use this method to assess the consistency and accuracy of our methodologies. Internal quality control checks are performed at various stages of the analysis workflow, involving visual inspection, measurement verification, and cross-checking of data. Regular calibration and maintenance of equipment (e.g., microscopes) are essential to maintain the highest standards of accuracy.

Regular training sessions ensure that personnel consistently follow standardized operating procedures (SOPs), which is a key element of our QA protocols.

Q 28. Describe your experience with health and safety procedures during drill cuttings analysis.

Health and safety are paramount in our operations. We adhere to strict safety protocols to prevent accidents and exposure to hazardous materials. This includes the use of personal protective equipment (PPE) such as gloves, safety glasses, and lab coats when handling cuttings and chemicals. Proper ventilation is maintained in the lab to minimize exposure to potentially harmful gases or dusts generated during the analysis.

All samples are handled and disposed of according to industry best practices and regulations, including minimizing waste, proper segregation of hazardous materials, and adherence to local environmental regulations. We conduct regular safety training sessions to ensure that all personnel are aware of and can implement safety protocols. Emergency procedures are clearly defined and regularly practiced.

Specific procedures are in place to handle potentially hazardous materials such as radioactive or toxic substances, ensuring their safe handling, storage, and disposal. Our commitment to health and safety is integrated into every aspect of the drill cuttings analysis process.

Key Topics to Learn for Drill Cutting Analysis Interview

- Rock Mechanics and Formation Evaluation: Understanding the relationship between rock properties, drilling parameters, and cutting characteristics. This includes knowledge of different rock types and their influence on cutting analysis.

- Drilling Fluid Dynamics: Analyzing the impact of drilling fluid properties (rheology, density, etc.) on bit performance and cutting transport. Practical application involves interpreting mud logs and identifying potential issues.

- Bit Mechanics and Selection: Understanding the different types of drill bits, their mechanisms of action, and how to select the appropriate bit for various geological formations. This includes analyzing bit wear and performance.

- Cutting Size and Shape Analysis: Interpreting the size, shape, and distribution of drill cuttings to infer formation properties, potential drilling problems (e.g., unexpected formations, wellbore instability), and optimize drilling parameters.

- Data Acquisition and Interpretation: Gathering and analyzing data from various sources (e.g., mud logs, drilling reports, downhole sensors) to understand cutting characteristics and their implications for drilling operations. This includes proficiency in relevant software.

- Advanced Techniques: Exploring advanced techniques like image analysis of drill cuttings, statistical analysis for pattern recognition, and integration with other drilling data for comprehensive wellbore analysis.

- Problem-Solving and Decision Making: Demonstrating the ability to analyze cutting data, identify potential problems, propose solutions, and make informed decisions regarding drilling optimization.

Next Steps

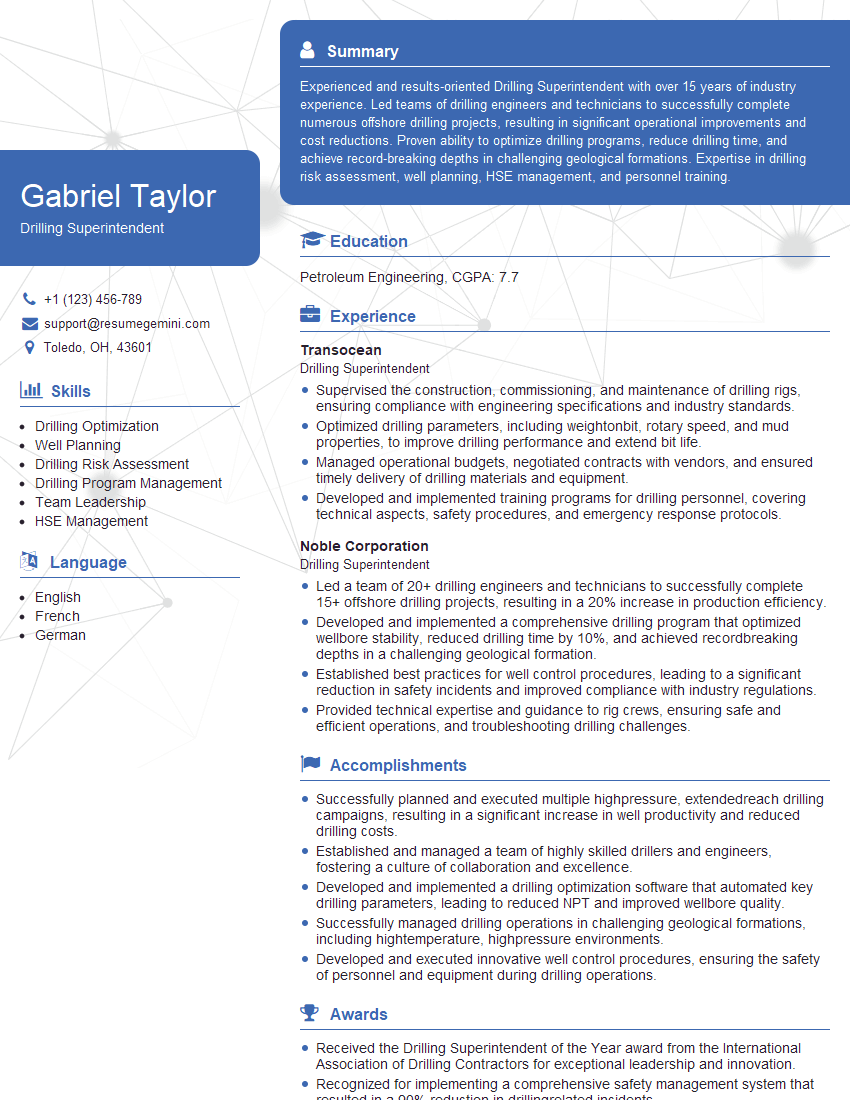

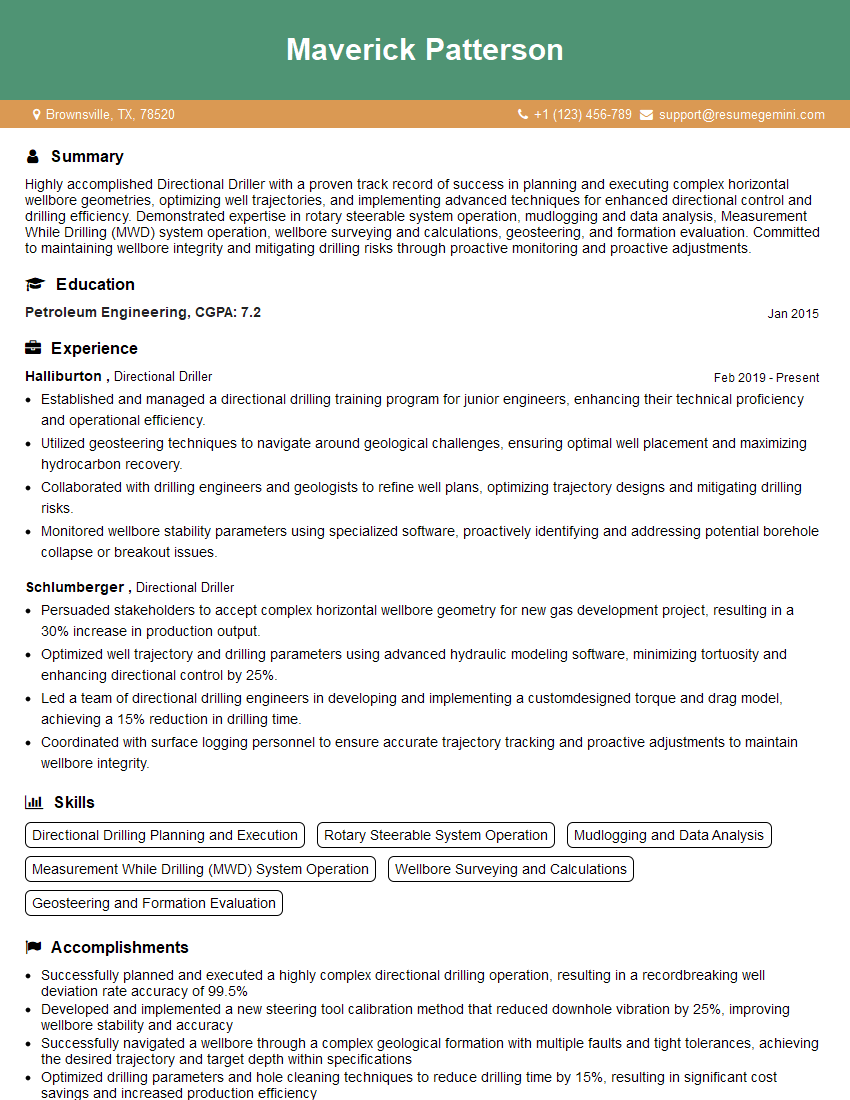

Mastering Drill Cutting Analysis is crucial for career advancement in the oil and gas, geothermal, or mining industries. A strong understanding of this field allows for improved drilling efficiency, cost reduction, and enhanced wellbore stability. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of Drill Cutting Analysis roles. Examples of resumes specifically tailored to this field are available through ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good