Preparation is the key to success in any interview. In this post, we’ll explore crucial Dust Sampling interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Dust Sampling Interview

Q 1. Describe the different types of dust sampling methods.

Dust sampling methods are categorized based on the type of information they provide and the sampling strategy employed. Broadly, we have:

- Gravimetric Sampling: This is the most common method, measuring the weight of dust collected on a filter. It provides a mass concentration of respirable or inhalable dust.

- Direct-Reading Instruments: These devices provide immediate measurements of dust concentration in the air, useful for real-time monitoring and quick assessments. Examples include light scattering instruments (photometers) and optical particle counters.

- Personal Air Sampling: A type of gravimetric sampling where the sampler is worn by the worker, measuring their personal exposure to dust. This is crucial for assessing occupational health risks.

- Area Sampling: This involves collecting samples from a specific area to represent the general dust level, rather than individual exposure. It’s useful for assessing overall workplace conditions.

- Source Sampling: This focuses on identifying and quantifying dust emissions from specific sources like machinery or processes, helping pinpoint areas for control measures.

The choice of method depends on the specific objective of the sampling exercise. For example, a construction site might use area sampling to assess general air quality, while a mining operation might utilize personal air sampling to monitor worker exposure to respirable silica.

Q 2. Explain the principle behind gravimetric dust sampling.

Gravimetric dust sampling relies on the basic principle of weighing. A known volume of air is drawn through a filter, which traps the dust particles. The filter is then weighed before and after sampling. The difference in weight represents the mass of dust collected. By knowing the volume of air sampled, we can calculate the dust concentration in the air, typically expressed as milligrams per cubic meter (mg/m³).

Imagine a sieve separating sand from water. The filter acts as the sieve, trapping the dust (sand) while the air (water) passes through. By weighing the sand before and after filtering the water, we can determine how much sand was present in the water.

Q 3. What are the limitations of personal air sampling?

While personal air sampling offers valuable insights into individual worker exposure, it has limitations:

- Representativeness: The sample reflects only the worker’s exposure during the sampling period and may not represent their exposure over a longer time or across different tasks.

- Worker Behavior: The worker’s movements and activities can influence the sample, potentially leading to underestimation or overestimation of actual exposure if the worker is not properly trained or behaving naturally.

- Sampler Interference: The sampling device itself might interfere with the worker’s tasks or comfort, altering their behavior and potentially affecting the accuracy of the measurement.

- Cost and Complexity: Setting up and managing personal sampling campaigns for large numbers of workers can be time-consuming and expensive.

For instance, a welder might have a very different exposure during welding compared to other tasks, and a single personal air sample might not capture this variability.

Q 4. How do you select the appropriate sampling method for a given situation?

Selecting the appropriate sampling method requires careful consideration of several factors:

- Objective of the sampling: Is the goal to assess worker exposure, general air quality, or source emissions?

- Type of dust: Respirable, inhalable, or total dust fractions require different sampling methods and equipment.

- Workplace conditions: Factors like air velocity, temperature, and humidity can influence sampling performance.

- Available resources: Budget, personnel, and equipment availability will constrain options.

- Regulatory requirements: Compliance with OSHA, NIOSH, or other relevant standards is crucial in many situations.

A methodical approach, involving a preliminary site survey and consultation with a qualified industrial hygienist, is essential for selecting the most suitable and effective dust sampling method.

Q 5. What are the common standards and regulations related to dust sampling (e.g., OSHA, NIOSH)?

Several standards and regulations govern dust sampling, aiming to ensure consistency, accuracy, and worker protection. Key examples include:

- OSHA (Occupational Safety and Health Administration): OSHA sets permissible exposure limits (PELs) for various dusts and mandates appropriate sampling and monitoring procedures in workplaces.

- NIOSH (National Institute for Occupational Safety and Health): NIOSH conducts research and provides recommendations for occupational safety and health, including best practices for dust sampling. Their methods are often considered the gold standard.

- ACGIH (American Conference of Governmental Industrial Hygienists): ACGIH publishes Threshold Limit Values (TLVs®), which are guidelines for workplace exposure limits to chemical substances and physical agents, including dust.

These standards often specify acceptable sampling methods, equipment, and analytical procedures. Compliance is critical to prevent health problems and avoid legal penalties.

Q 6. Explain the importance of proper sample chain of custody.

Maintaining a proper chain of custody (COC) for dust samples is essential to ensure the integrity and legal admissibility of the results. The COC documents the handling, storage, and analysis of the sample from collection to final reporting. This minimizes the risk of sample contamination, loss, or tampering, ensuring that the results are reliable and trustworthy.

Think of it like a package being shipped across the country – each step in its journey is tracked and documented. Similarly, each person handling the sample, from the sampler to the laboratory analyst, signs and dates a COC form, thereby maintaining a complete record of the sample’s handling.

A well-maintained COC is crucial for investigations, litigation, and regulatory compliance. It provides evidence that the results reflect the actual dust levels and weren’t compromised during the process.

Q 7. How do you calibrate and maintain dust sampling equipment?

Calibration and maintenance are crucial for accurate and reliable dust sampling. The specific procedures depend on the type of equipment used.

- Flow Rate Calibration: For gravimetric samplers, the flow rate – the volume of air sampled per unit of time – must be accurately calibrated using a primary flow calibrator, usually a rotameter or critical orifice. Regular calibration ensures the sample volume is correctly determined.

- Leak Checks: Regular leak checks of the sampling system are essential to ensure that the measured airflow is accurately reflecting the air volume sampled and not leaking around seals.

- Filter Integrity: The integrity of the filter needs to be checked before and after sampling to ensure that no dust escapes during the sampling process.

- Instrument Maintenance: For direct-reading instruments, manufacturer’s instructions for cleaning, maintenance and calibration must be followed. This includes replacing filters, cleaning optical components, and performing calibration checks.

Regular calibration and maintenance schedules should be established and meticulously followed to guarantee the accuracy and reliability of the sampling data. Records of these activities must be meticulously maintained.

Q 8. Describe the process of preparing samples for laboratory analysis.

Preparing dust samples for lab analysis is crucial for accurate results. It involves several key steps, starting with proper sample collection using appropriate methods (e.g., using personal air samplers or bulk sampling). Once collected, the samples need to be carefully preserved to prevent contamination or loss of analytes. This often involves storing them in airtight, labeled containers at a stable temperature.

For example, a sample collected on a filter needs to be carefully transferred into a clean container to prevent any fibers from being lost or damaged.

Next, the sample might require pre-treatment depending on the analytical techniques to be employed. This could include drying, weighing, digestion, or extraction procedures, all aimed at preparing the sample for analysis while minimizing bias. Proper documentation throughout the process is paramount for maintaining sample chain of custody and ensuring the integrity of results. Failure to properly prepare samples can lead to inaccurate results and flawed conclusions.

Q 9. What are the different types of dust analysis performed in a laboratory?

Dust analysis in a laboratory is diverse, catering to various needs and applications. Common types include:

- Gravimetric Analysis: This is the most basic method, determining the total dust mass collected. It’s particularly useful for assessing general dust levels and compliance with regulations.

- Microscopic Analysis: Examines dust particles under a microscope to identify their composition (e.g., minerals, fibers, organic matter). This helps determine potential health risks associated with specific dust types. For example, we might identify asbestos fibers, silica particles, or pollen.

- Chemical Analysis: Identifies the chemical composition of the dust, determining the presence of specific elements or compounds (e.g., heavy metals, silica). This is vital for understanding toxicity and potential health impacts.

- Particle Size Analysis: Determines the distribution of particle sizes in the dust sample. This is important because smaller particles can penetrate deeper into the lungs, posing greater health risks. This is often done using techniques like laser diffraction or sieving.

- X-ray Diffraction (XRD): Used to identify crystalline materials within the dust sample, providing information about the mineralogical composition.

The specific analysis methods used depend heavily on the suspected dust composition, the objective of the sampling, and the client’s needs. A comprehensive analysis may involve a combination of these methods.

Q 10. How do you interpret the results of a dust sampling analysis?

Interpreting dust sampling results requires a holistic approach, considering the type of analysis performed and the context of the sample collection. The results are often compared against relevant standards and regulations (e.g., Occupational Safety and Health Administration (OSHA) Permissible Exposure Limits (PELs)).

For example, if gravimetric analysis shows total dust levels exceeding the PEL for respirable dust in a workplace, this indicates potential exposure risks for workers. Similarly, identification of asbestos fibers during microscopic analysis necessitates urgent action to mitigate exposure and protect workers’ health. If chemical analysis reveals the presence of significant levels of silica, the risk of silicosis needs to be considered. It’s crucial to understand that results aren’t interpreted in isolation but within the broader context of the work environment, employee activities, and control measures in place.

A qualified professional, often an industrial hygienist, is necessary to interpret the results accurately and make appropriate recommendations for mitigating risks.

Q 11. What are the health hazards associated with exposure to different types of dust?

Exposure to different types of dust presents diverse health hazards, ranging from minor irritation to severe, life-threatening diseases. Some examples include:

- Silica Dust: Can cause silicosis, a debilitating lung disease.

- Asbestos Fibers: Linked to asbestosis, lung cancer, and mesothelioma.

- Coal Dust: Associated with coal worker’s pneumoconiosis (black lung disease).

- Wood Dust: Can cause allergic reactions, asthma, and even nasal and sinus cancers.

- Metal Dust (e.g., aluminum, beryllium): Can cause various respiratory and systemic diseases.

- Organic Dust (e.g., grain dust, cotton dust): Can trigger allergic alveolitis (hypersensitivity pneumonitis) and other respiratory illnesses.

The severity of the health hazard depends on factors like the type of dust, particle size, concentration, duration of exposure, and individual susceptibility. It’s vital to understand that the cumulative effect of long-term exposure to even seemingly harmless dust can have significant health consequences.

Q 12. Explain the concept of permissible exposure limits (PELs).

Permissible Exposure Limits (PELs) are legally mandated limits for airborne concentrations of specific hazardous substances, including dusts, in the workplace. These limits are established by regulatory bodies like OSHA in the United States and are designed to protect workers’ health by minimizing their exposure to harmful substances. PELs are typically expressed in terms of milligrams or micrograms of dust per cubic meter of air (mg/m³ or µg/m³) averaged over an eight-hour workday.

For instance, the OSHA PEL for respirable silica dust is 50 µg/m³. This means that the average airborne concentration of respirable silica in a workplace should not exceed this limit over an eight-hour workday. Exceeding PELs can lead to significant penalties for employers and increased health risks for workers. The specific PELs vary depending on the type of dust and its toxicity.

Q 13. How do you control dust emissions in an industrial setting?

Controlling dust emissions in an industrial setting is crucial for both environmental protection and worker safety. A multi-faceted approach is often necessary, involving a hierarchy of control measures:

- Engineering Controls: These are the most effective methods, aiming to reduce dust generation at the source. Examples include:

- Enclosure/Containment: Enclosing processes that generate dust to prevent its release into the air.

- Local Exhaust Ventilation (LEV): Capturing dust at its source using hoods and ductwork connected to a filtration system.

- Process Modification: Altering the process to reduce dust generation (e.g., using wet methods instead of dry methods).

- Administrative Controls: These involve managing work practices to minimize exposure. Examples include:

- Work Rotation: Limiting the duration of exposure for individual workers.

- Training and Education: Educating workers about dust hazards and proper safety procedures.

- Housekeeping Practices: Implementing regular cleaning procedures to minimize dust accumulation.

- Personal Protective Equipment (PPE): This should be considered as a last resort and used in conjunction with engineering and administrative controls. Examples include:

- Respirators: Providing workers with respirators to filter out dust particles.

An effective dust control program often combines these measures to achieve optimal protection.

Q 14. Describe the various types of dust control equipment.

Various dust control equipment is available, each suited for specific applications and dust characteristics. Some examples include:

- Dust Collectors (e.g., baghouses, cyclones, electrostatic precipitators): These are used to remove dust from the exhaust air of industrial processes.

- Scrubbers: Use liquid to remove dust from the air stream.

- Filters (e.g., HEPA filters, cartridge filters): Employ filter media to trap dust particles.

- Vacuum Cleaners (Industrial): Used for cleaning up dust in the workplace.

- High-pressure water jets: Effective for removing dust from surfaces.

The choice of equipment depends on factors such as the type and amount of dust generated, the desired level of dust control, and the available budget and space. Proper maintenance and regular inspection of dust control equipment are essential to ensure its effectiveness and prevent unexpected failures.

Q 15. What are the safety precautions for conducting dust sampling?

Safety is paramount in dust sampling. Before you even think about collecting a sample, a thorough risk assessment is crucial. This involves identifying potential hazards, such as exposure to hazardous dusts (e.g., silica, asbestos), confined spaces, and working at heights. Based on this assessment, we implement appropriate control measures. This could include wearing appropriate personal protective equipment (PPE), such as respirators (selected based on the type of dust), safety glasses, gloves, and high-visibility clothing. Proper ventilation is also essential to minimize dust clouds during sampling. In addition, we follow all relevant health and safety regulations and company procedures. For example, if working near heavy machinery, lockout/tagout procedures must be followed rigorously. Finally, appropriate first-aid measures and emergency procedures must be in place and understood by all personnel involved. We wouldn’t start a sampling campaign without conducting a thorough safety briefing covering all these aspects.

Career Expert Tips:

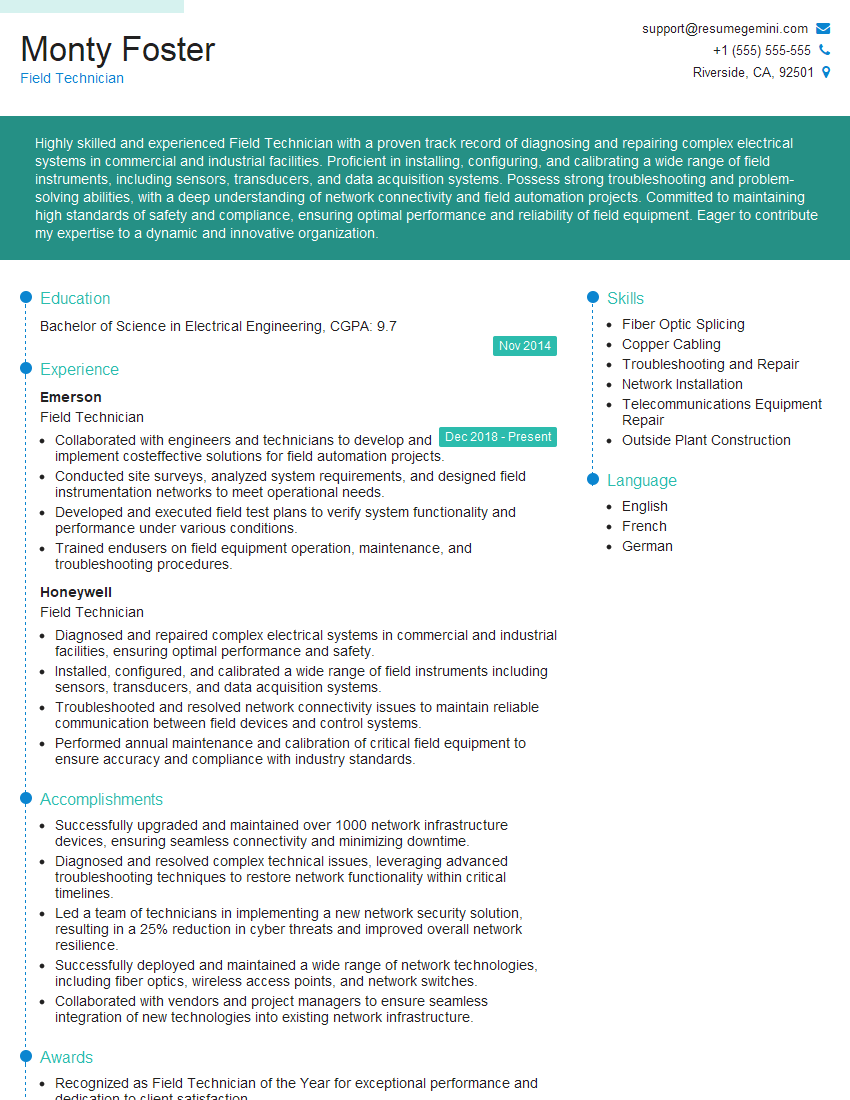

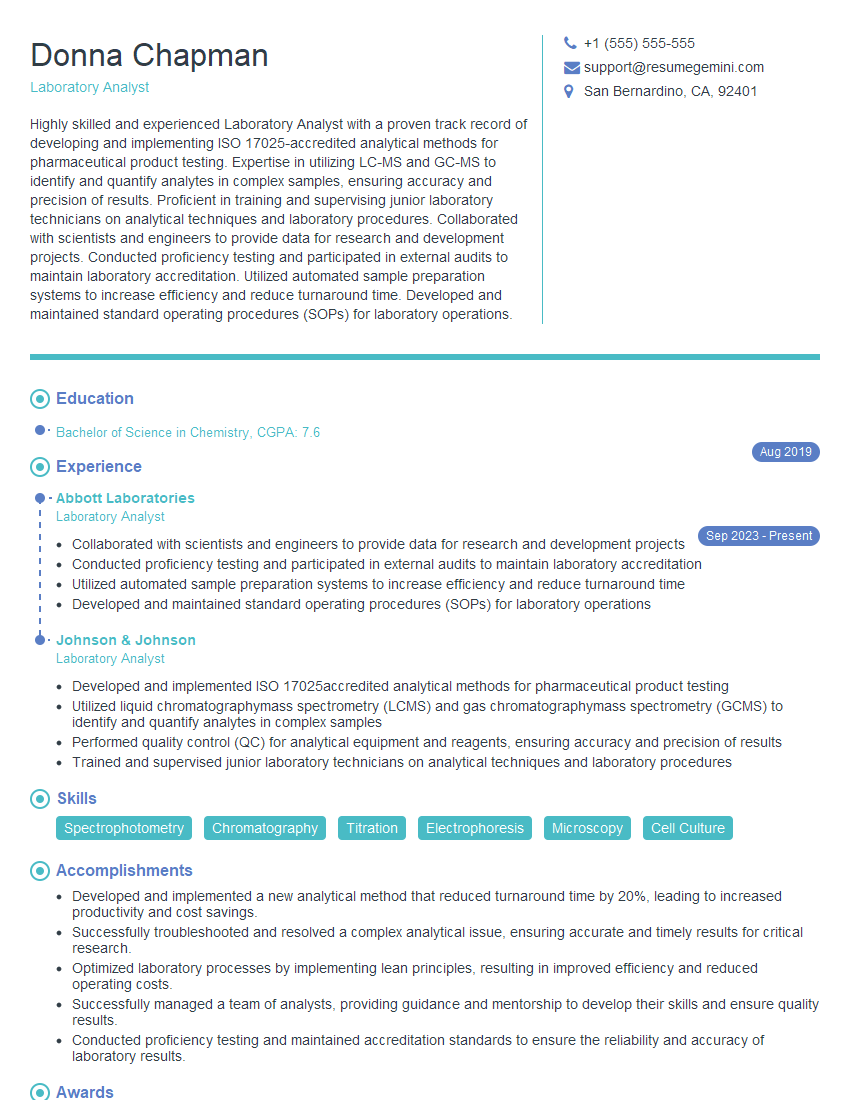

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and reliability of dust sampling results?

Ensuring accurate and reliable dust sampling hinges on meticulous attention to detail across the entire process. Firstly, selecting the appropriate sampling method is critical. This depends heavily on the type of dust, its concentration, the sampling location, and the objective of the study. For instance, using a cyclone for respirable dust measurement is preferred over using a high-volume sampler for assessing total dust concentration. Secondly, proper calibration and maintenance of sampling instruments are non-negotiable. Before each sampling event, instruments are calibrated against certified standards, ensuring accurate readings. Regular maintenance, as specified by the manufacturer, prolongs their lifespan and maintains accuracy. Thirdly, sample handling and analysis are equally important. Samples must be properly labeled, stored, and transported to prevent contamination or loss. The laboratory analysis follows standardized procedures using accredited methods, and results are reviewed for consistency and outliers. Finally, adhering to established quality control protocols, including blank samples and duplicate analyses, enables us to assess method performance and identify potential errors.

Q 17. How do you handle potential sampling errors and biases?

Sampling errors and biases are inevitable, but we strive to minimize their impact through careful planning and execution. Potential errors include improper sampling technique (e.g., incorrect sampling flow rate, insufficient sampling time), equipment malfunctions, and human error (e.g., mislabeling samples, incorrect data recording). We account for these through meticulous record-keeping, including instrument readings, environmental conditions, and sampling procedures. For instance, we always collect duplicate samples at key locations. Discrepancies between these samples highlight potential problems. Furthermore, blank samples (samples collected in a dust-free environment) are included to detect background contamination. In addition, we use statistical methods, such as ANOVA, to evaluate the variability in the data and assess the significance of observed differences. We also consider possible biases, like non-representative sampling locations, and adjust our procedures accordingly. If significant errors are detected, the sampling process might have to be repeated, and a thorough investigation is carried out to identify the root cause and prevent recurrence.

Q 18. What is the role of quality control in dust sampling?

Quality control (QC) is the backbone of reliable dust sampling. It involves a systematic approach to ensure the accuracy, precision, and reliability of the results. This starts with the pre-sampling phase, encompassing instrument calibration, and selection of appropriate sampling strategies, and extends to the post-sampling phase, including sample handling, laboratory analysis, and data interpretation. QC procedures include checking equipment calibration regularly, using certified reference materials for laboratory analysis, conducting blind analyses (where samples are analyzed without disclosing their origins) to assess analyst proficiency and performing regular inter-laboratory comparisons to ensure results are consistent across different laboratories. We also maintain detailed chain-of-custody records to track samples from collection to analysis, preventing any potential confusion or errors. Maintaining comprehensive documentation that follows a clear and consistent format is essential for both internal auditing and external accreditation purposes.

Q 19. How do you deal with unexpected issues during dust sampling?

Unexpected issues can arise in dust sampling, and preparedness is key. For instance, equipment malfunction during sampling is a common challenge. We always carry spare equipment and parts, enabling us to quickly replace faulty components. Severe weather conditions can also disrupt sampling. In such situations, we postpone the sampling activity until conditions improve, ensuring the safety of personnel and the integrity of the samples. Unexpectedly high dust concentrations could also exceed the sampling instrument’s capacity. If this occurs, we need to adjust the sampling parameters (e.g., reduce sampling time, use a more suitable instrument) or conduct further investigation to determine the source of the unexpectedly high concentration. We always have a contingency plan in place for unforeseen circumstances and promptly document any deviations from the sampling protocol. This ensures transparency and allows us to assess the impact of these deviations on the results and adjust accordingly.

Q 20. Describe your experience with different dust sampling instruments.

My experience encompasses a wide range of dust sampling instruments, including personal sampling pumps for measuring respirable dust (e.g., using IOM samplers and filters), high-volume samplers for total dust measurement, and real-time dust monitors which provide immediate concentration readings. I’ve worked with different types of cyclones to separate respirable fractions, and I’m also familiar with static dust samplers for surface dust. For example, I was involved in a project requiring monitoring asbestos fibers in a demolition site. Here, using a specialized pump with a membrane filter and a specific filter cassette was critical to ensure accurate fiber counts and the safety of the sampling team. In other projects, real-time dust monitors were deployed to monitor dust levels continuously, enabling prompt intervention if threshold limits were exceeded. Each instrument has its strengths and weaknesses, and the choice depends on the specific needs of the project.

Q 21. Explain your understanding of respirable dust.

Respirable dust refers to airborne particulate matter that can penetrate deep into the lungs and reach the alveoli (tiny air sacs). These particles, typically less than 4 µm (micrometers) in aerodynamic diameter, are considered the most hazardous because they can cause serious respiratory health problems, such as silicosis, asbestosis, and lung cancer. The respirable fraction is a critical aspect of dust sampling because these are the particles most likely to cause health issues. Different standards and regulations exist defining the respirable fraction, often using cyclones or impactors as size-selective samplers to collect only the particles within this specific size range. The size-selective collection is necessary because the larger particles are often trapped in the upper respiratory tract and are not as harmful. Understanding the definition and measurement of respirable dust is crucial for accurate risk assessment and implementing appropriate control measures to protect workers’ health.

Q 22. How do you determine the appropriate sampling duration?

Determining the appropriate sampling duration is crucial for accurate dust concentration measurement. It depends on several factors, including the variability of the dust concentration, the desired level of precision, and the sampling method used. Imagine trying to measure the average temperature of a day – a single reading wouldn’t be sufficient; you need multiple readings throughout the day to get a representative average.

For instance, in a relatively stable environment like a controlled manufacturing process, a shorter sampling duration might suffice. However, in a highly variable environment like a construction site with fluctuating dust levels, a longer duration – perhaps involving multiple shorter samples at different times – would be necessary to capture representative data. We often use statistical methods to determine the minimum sampling time needed to achieve a pre-defined level of confidence in our results. This might involve pilot studies to assess the variability of dust concentrations at the site before implementing the full sampling campaign.

In practice, we might employ a combination of methods. For example, we could use a short initial sampling period to establish the baseline variability, then calculate the necessary sampling duration to achieve the desired precision based on the calculated standard deviation. This ensures efficient resource allocation while maintaining data quality.

Q 23. What are the different types of filters used in dust sampling?

Several filter types are employed in dust sampling, each with specific advantages and disadvantages. The choice depends on the type of dust being sampled, the particle size range of interest, and the subsequent analysis techniques.

- Membrane filters (e.g., polycarbonate, cellulose esters): These are widely used due to their high efficiency in collecting fine particles, uniform pore size, and low background mass. They’re ideal for gravimetric analysis (measuring dust mass) and microscopic examination.

- Fiber filters (e.g., glass fiber, quartz fiber): These are typically less expensive than membrane filters and are suitable for collecting larger particles. However, they have higher background mass and can be less efficient for very fine particles. They’re often used when larger sample volumes are required.

- Mixed cellulose ester filters: These offer a good balance of efficiency and cost-effectiveness, suitable for a broad range of applications.

For example, when analyzing asbestos fibers, we might prefer a membrane filter with a very fine pore size to capture even the smallest fibers effectively. In other applications, like collecting larger dust particles in a foundry, a glass fiber filter might be more appropriate.

Q 24. Explain the concept of particle size distribution and its importance in dust sampling.

Particle size distribution refers to the relative abundance of particles of different sizes within a dust sample. This is incredibly important because particle size significantly impacts the health effects of dust inhalation and the efficiency of dust control measures. Fine particles (e.g., PM2.5) are more easily inhaled and can penetrate deep into the lungs, posing a greater health risk than larger particles. Understanding the size distribution helps us determine the potential health hazards and design appropriate control strategies.

Imagine comparing two dust samples with the same total mass but different size distributions. One might have mostly large particles, while the other might be dominated by fine particles. The latter sample would present a much greater respiratory hazard despite having the same total mass. We often use techniques like laser diffraction or microscopic analysis to determine the particle size distribution. This data is crucial for regulatory compliance and risk assessment.

Q 25. How do you manage and store dust samples?

Proper management and storage of dust samples are crucial to prevent contamination and sample degradation. The goal is to maintain sample integrity from the moment of collection until analysis. This involves several key steps:

- Immediate sealing: Once the sampling is complete, the filter is carefully removed from the sampler and sealed in an airtight container to prevent loss or contamination.

- Labeling: Each sample must be clearly labeled with the date, time, location, sampling method, and any other relevant information. This is essential for traceability.

- Storage conditions: Samples are stored in a cool, dry, and dark place to minimize degradation. Temperature and humidity fluctuations can alter the sample mass and composition.

- Chain of custody: A detailed record of who handled the sample and when is crucial, especially in legal contexts, to ensure the sample’s integrity hasn’t been compromised.

For example, if we suspect that a sample might contain volatile organic compounds, we would need to take additional precautions, such as storing it in a freezer or using specialized containers.

Q 26. What software or tools do you use for data analysis in dust sampling?

Data analysis in dust sampling involves a variety of software and tools depending on the type of analysis performed. Gravimetric analysis, for example, is relatively straightforward, but more complex analysis techniques require specialized software.

- Spreadsheet software (e.g., Microsoft Excel): Used for basic calculations like average dust concentrations, standard deviations, and data summarization.

- Statistical software (e.g., SPSS, R): Utilized for more advanced statistical analysis to assess data normality, perform hypothesis testing, and generate confidence intervals.

- Image analysis software (e.g., ImageJ): Used for analyzing microscopic images to determine particle size distribution, morphology, and identification of specific particles (e.g., asbestos fibers).

- Specialized dust sampling software: Several software packages are specifically designed for analyzing dust sampling data, often incorporating features for data management, quality control, and reporting.

For instance, I frequently use R for statistical modeling of dust concentration data and ImageJ to analyze microscopic images of filter samples. The choice of software depends on the complexity of the data and the questions being asked.

Q 27. Describe your experience with reporting and documenting dust sampling results.

Reporting and documenting dust sampling results requires clear, concise communication of the findings in a standardized format. This often involves generating detailed reports that include information on the sampling methodology, data analysis, and interpretations.

My reports typically include a description of the sampling site, the sampling methods used, the number of samples collected, the duration of sampling, the analytical techniques employed, and the results (e.g., dust concentration, particle size distribution). I also include an assessment of the data quality, identification of potential sources of error, and recommendations based on the findings. These reports might be used to evaluate exposure levels, design engineering controls, or inform regulatory agencies. Furthermore, I adhere to relevant standards and guidelines, ensuring compliance and consistency. For instance, the format and content of my reports often align with regulatory requirements and established industry best practices.

Q 28. How do you stay updated on the latest advancements and best practices in dust sampling?

Staying updated in the field of dust sampling requires a proactive approach. The field is constantly evolving, with new sampling techniques, analytical methods, and regulatory guidelines emerging regularly.

- Professional organizations: I actively participate in professional organizations like the American Industrial Hygiene Association (AIHA) and attend conferences and workshops to learn about the latest advancements.

- Peer-reviewed publications: I regularly read peer-reviewed journals and scientific literature to stay abreast of new research and developments.

- Industry standards and guidelines: I regularly review and update my knowledge of relevant industry standards and guidelines issued by organizations like OSHA and NIOSH.

- Continuing education courses: I regularly engage in continuing education courses to enhance my skills and knowledge.

Attending conferences and reading journals allows me to not only learn about new techniques but also to network with other experts, sharing best practices and discussing challenges in the field. This ensures I’m equipped to handle diverse sampling situations and utilize the most effective and accurate methods.

Key Topics to Learn for Dust Sampling Interview

- Sampling Methods: Understand various dust sampling techniques (e.g., gravimetric, optical, personal air sampling) and their applications in different industries and environments. Consider the advantages and disadvantages of each method.

- Instrumentation and Calibration: Become familiar with the equipment used in dust sampling, including pumps, filters, and analyzers. Master the principles of calibration and its importance in ensuring accurate results.

- Data Analysis and Interpretation: Learn how to process and interpret dust sampling data. Understand the calculation of dust concentrations and the significance of different exposure limits.

- Health and Safety Regulations: Familiarize yourself with relevant health and safety regulations and standards pertaining to dust exposure (e.g., OSHA, NIOSH guidelines). Understand safe work practices and personal protective equipment (PPE) requirements.

- Sample Handling and Chain of Custody: Learn best practices for handling and transporting dust samples to maintain sample integrity and ensure accurate results. Understand the importance of documentation and chain of custody.

- Quality Control and Quality Assurance (QA/QC): Grasp the importance of QA/QC procedures in dust sampling to ensure the reliability and validity of results. Understand how to identify and address potential sources of error.

- Specific Industry Applications: Explore the unique challenges and applications of dust sampling in various industries like mining, construction, manufacturing, and agriculture. Be prepared to discuss relevant case studies.

- Problem-Solving Scenarios: Practice identifying and troubleshooting potential issues encountered during dust sampling, such as equipment malfunctions, sample contamination, or inaccurate readings.

Next Steps

Mastering dust sampling techniques opens doors to exciting career opportunities in environmental health and safety, industrial hygiene, and related fields. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes specifically designed for Dust Sampling professionals are available to guide you. Invest time in creating a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good