Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Egg production and quality control interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Egg production and quality control Interview

Q 1. Describe the different methods for grading eggs.

Egg grading is crucial for ensuring consistent quality and consumer satisfaction. It’s typically done using a combination of methods focusing on factors like weight, shell quality, and interior quality.

- Weight Grading: Eggs are categorized into different weight classes (e.g., jumbo, extra large, large, medium, small) based on their weight. This ensures consumers receive the quantity they expect. For example, a ‘jumbo’ egg will weigh significantly more than a ‘small’ egg.

- Visual Inspection (Candling): This is a non-destructive method where a light source is shone through the egg to examine the yolk, white, and air cell. A trained grader can identify defects like blood spots, meat spots, or cracked yolks, leading to a better understanding of the egg’s internal quality. A larger air cell usually indicates a less fresh egg.

- Shell Quality Assessment: Inspectors assess the shell for cracks, deformities, or thin spots. Eggs with significant shell damage are usually rejected to prevent breakage and microbial contamination during handling and transport. Think of it like checking for imperfections in a finely crafted ceramic vase.

These grading methods are often combined to assign a quality grade to each egg, ensuring consistent product quality within each grade.

Q 2. Explain the process of pasteurization in egg production.

Pasteurization of liquid eggs (egg whites or yolks) is a heat treatment process that destroys harmful bacteria like Salmonella, extending the shelf life and ensuring food safety. It’s vital for products used in food processing such as mayonnaise, cakes, and other prepared foods.

The process usually involves heating the liquid egg to a specific temperature (typically around 60°C or 140°F) for a set period. This carefully controlled heating process inactivates most pathogenic bacteria without significantly affecting the egg’s functional properties like foaming or whipping capabilities. Think of it like gently steaming the egg to ensure safety without making it overcooked.

Different methods exist, including high-temperature short-time (HTST) and ultra-high-temperature (UHT) pasteurization. The choice of method depends on the desired shelf life and the intended application of the liquid egg product. Post-pasteurization, rapid cooling is crucial to prevent further bacterial growth or quality degradation.

Q 3. What are the common causes of egg shell breakage during handling?

Eggshell breakage during handling is a significant concern in the egg industry, resulting in economic losses and potential contamination issues. Several factors contribute to this:

- Rough Handling: Improper handling during collection, transportation, and processing is a primary cause. Jostling and dropping eggs will undoubtedly cause breakage.

- Shell Quality: Eggs with naturally thin or weak shells are more susceptible to breakage. This can be influenced by factors such as genetics and nutrition of the laying hens.

- Temperature Fluctuations: Sudden changes in temperature can cause the shell to become more fragile. Think of how a rapidly cooled glass can crack.

- High Storage Density: Overcrowding in storage crates can put excessive pressure on the eggs, increasing the risk of breakage.

- Storage time: As eggs age the shells become progressively weaker and more prone to cracking.

Implementing careful handling procedures, proper storage conditions, and selecting high-quality eggs are crucial in minimizing shell breakage.

Q 4. How do you identify and address issues related to Salmonella in egg production?

Salmonella contamination is a serious food safety concern in egg production. It primarily originates from the hen’s reproductive tract. Addressing this requires a multi-pronged approach:

- Vaccination of hens: Vaccinating laying hens against Salmonella is a proactive measure to reduce the incidence of contamination within the flock. This is a critical preventive step.

- Biosecurity Measures: Strict biosecurity protocols, including hygiene practices, rodent and pest control, and controlled access to hen houses, are vital to prevent Salmonella from entering the production environment.

- Sanitation and Cleaning: Thorough cleaning and disinfection of egg handling equipment and facilities are crucial to minimize contamination risk. Regular checks are essential.

- Testing and Monitoring: Regular testing of eggs and flocks for Salmonella helps in early detection and allows for timely interventions to prevent outbreaks.

- Proper Egg Handling and Storage: Maintaining appropriate temperatures and avoiding cross-contamination are vital to prevent post-harvest contamination.

In cases of confirmed Salmonella contamination, thorough investigation, culling affected birds, and implementing stricter control measures are necessary to contain the outbreak.

Q 5. What are the key indicators of egg freshness?

Several indicators help determine egg freshness:

- Air Cell Size: A small air cell indicates a fresh egg. As eggs age, the air cell expands due to moisture loss.

- Albumen (Egg White) Height: The thicker, higher the egg white, the fresher the egg. The albumen becomes thinner and more watery with age.

- Yolk Appearance: A firm, round yolk suggests freshness. As eggs age, the yolk becomes flatter and more spread out.

- Shell Texture: A fresh egg shell feels rough and slightly chalky. Older shells may feel smoother.

- Float Test: Place the egg in a bowl of water. Fresh eggs will sink and lie flat on their side. Older eggs may float partially, and very old eggs will float completely.

These indicators, especially when assessed together, provide a good indication of egg freshness, though the grading process will typically identify more subtle indicators of quality than a casual assessment.

Q 6. Explain the role of temperature and humidity in egg storage.

Temperature and humidity play critical roles in egg storage, significantly influencing their quality and shelf life. Maintaining optimal conditions slows down the natural deterioration processes within the egg.

Temperature: Eggs should be stored at a relatively low temperature, ideally between 0°C and 4°C (32°F and 39°F). This slows down bacterial growth and reduces the rate of albumen thinning. Storing eggs at room temperature dramatically shortens their shelf life.

Humidity: High humidity helps prevent moisture loss from the egg, maintaining the quality of the egg white. However, excessively high humidity can increase the risk of microbial growth. Optimal humidity levels are generally around 75-85%.

Maintaining consistent temperature and humidity throughout storage is essential to prevent temperature fluctuations, which can compromise shell integrity and accelerate deterioration. Maintaining optimal temperature and humidity is crucial for extending egg freshness and preventing losses due to spoilage.

Q 7. Describe various egg packaging methods and their impact on product quality.

Several methods are used for egg packaging, each affecting product quality and shelf life:

- Cartons: Paperboard cartons are widely used for retail packaging. They provide a degree of protection but offer limited cushioning. Quality cartons are vital to minimize breakage during transit and storage.

- Plastic Trays: Plastic trays provide better cushioning and protection compared to cartons, reducing the risk of shell breakage. They can be used on their own or within cartons for additional protection. Using plastic trays means fewer broken eggs.

- Modified Atmosphere Packaging (MAP): This technique involves altering the gaseous composition within the package to extend shelf life. Reducing oxygen levels and increasing carbon dioxide or nitrogen can inhibit microbial growth and maintain egg quality. MAP eggs often have a longer shelf life.

- Vacuum Packaging: This packaging method removes air from the packaging to extend the shelf life and prevent oxidative damage, particularly for liquid egg products.

The choice of packaging method depends on factors such as egg type (shell eggs vs. liquid eggs), transportation distance, storage conditions, and desired shelf life. Appropriate packaging is essential for minimizing damage, preventing contamination, and maintaining egg quality during distribution and storage.

Q 8. What are the critical control points (CCPs) in egg production for food safety?

Critical Control Points (CCPs) in egg production are steps in the process where hazards can be prevented, eliminated, or reduced to acceptable levels. Think of them as the crucial moments where things can go wrong if not carefully managed. Identifying and controlling these points is essential for ensuring food safety.

- Egg Laying and Collection: Preventing contamination from feces and nesting materials is paramount. This involves regular cleaning of laying nests, prompt collection of eggs, and avoiding cracked or dirty eggs.

- Cleaning and Sanitization: Thorough washing and sanitizing of eggshells is vital to remove surface contaminants. The process needs precise control of water temperature, detergent concentration, and sanitizer efficacy.

- Storage and Temperature Control: Maintaining appropriate temperatures throughout the storage and handling process is crucial. Eggs should be stored at low temperatures to slow down bacterial growth, preventing spoilage.

- Processing (if applicable): In processed egg products like liquid eggs or powdered eggs, steps like pasteurization become CCPs, eliminating potential pathogens like Salmonella.

- Packaging and Transportation: Maintaining the cold chain during transport and storage is vital to avoid temperature abuse. Proper packaging prevents damage and contamination.

Failing to manage any of these CCPs can lead to foodborne illnesses like Salmonella infection, highlighting the critical nature of these control measures.

Q 9. How do you maintain accurate records and traceability in egg production?

Maintaining accurate records and traceability is fundamental to food safety and quality control. It’s like having a detailed diary for every egg, from farm to table. This enables rapid identification of the source of any contamination, should a problem occur.

This is achieved through:

- Farm Records: Detailed records on flock health, feed, medication, and egg production are essential. Each flock should have unique identification.

- Egg Tracking Systems: Each batch of eggs should have a unique identifier (lot number, date, etc.) that is traceable back to its origin. This information is recorded at every stage of handling.

- Temperature Monitoring: Continuous temperature recording during storage and transportation is crucial. Data loggers are often used for this, providing objective evidence of compliance with temperature regulations.

- Processing Records: Detailed records on egg processing techniques, including pasteurization parameters (time and temperature), are mandatory for processed egg products.

- Inventory Management: A clear inventory system helps to track the movement of eggs and ensures that older eggs are used first (FIFO – First In, First Out).

Investing in traceability software can automate much of this, ensuring data accuracy and easy retrieval. This technology is a game-changer in today’s egg production.

Q 10. Explain the role of HACCP in egg production and quality control.

Hazard Analysis and Critical Control Points (HACCP) is a preventative food safety management system. Imagine it as a proactive strategy instead of a reactive one. It’s a systematic approach to identify and control potential hazards that could compromise the safety and quality of eggs.

In egg production, HACCP involves:

- Hazard Analysis: Identifying biological, chemical, and physical hazards, such as Salmonella, pesticide residues, or shell fragments.

- CCP Identification: Determining the critical control points in the production process where these hazards can be effectively controlled.

- Critical Limits: Setting measurable limits for each CCP (e.g., maximum temperature for storage).

- Monitoring: Regularly monitoring CCPs to ensure that critical limits are met.

- Corrective Actions: Establishing procedures to take corrective action if a critical limit is not met.

- Record Keeping: Maintaining detailed records of all HACCP activities, including monitoring data and corrective actions.

- Verification: Regularly verifying that the HACCP plan is effective.

Implementing HACCP ensures that food safety is built into the production process, minimizing the risk of contamination and improving consumer confidence.

Q 11. What are the common spoilage organisms found in eggs, and how are they controlled?

Several spoilage organisms can affect eggs, leading to off-flavors, odors, and potential health risks. The most significant are bacteria, primarily Salmonella Enteritidis, and molds.

- Salmonella Enteritidis: This bacterium is a major concern, often found inside the egg, posing a significant health risk. Controlling Salmonella requires strict hygiene practices in the laying house, thorough cleaning and sanitation of eggshells, and, for liquid eggs, pasteurization.

- Other Bacteria: Pseudomonas, Proteus, and Alcaligenes species are common spoilage bacteria, often entering through the shell pores. Maintaining low storage temperatures and good sanitation minimizes their growth.

- Molds: Molds can grow on the eggshell surface, especially under conditions of high humidity. Proper storage conditions, including low humidity and temperature, help prevent mold growth.

Controlling spoilage organisms involves a combination of preventative measures and good manufacturing practices. Regular cleaning and disinfection, appropriate storage temperatures, and prompt processing (pasteurization for liquid eggs) are crucial strategies.

Q 12. Describe different egg processing techniques used to enhance shelf life.

Various egg processing techniques extend shelf life by reducing microbial load and inhibiting spoilage. These methods often involve heat treatment or other preservation techniques.

- Pasteurization: Heat treatment that kills harmful bacteria, like Salmonella. Liquid eggs are typically pasteurized, ensuring safety and extended shelf life.

- Drying: Eggs can be dried into powder, significantly reducing water activity and inhibiting microbial growth. This leads to a very long shelf life.

- Freezing: Freezing slows down microbial growth and enzymatic reactions, preserving egg quality for extended periods. Rapid freezing methods are preferred to maintain quality.

- Irradiation: A less common method, but irradiation can reduce bacterial contamination. It’s crucial to adhere to legal limits and ensure that the process does not alter egg quality.

- Modified Atmosphere Packaging (MAP): Packaging eggs in an atmosphere with reduced oxygen and increased carbon dioxide can slow down microbial growth and extend shelf life. This is particularly useful for extending the life of fresh eggs.

The choice of processing technique depends on the desired product characteristics and shelf life requirements. Each method has its advantages and disadvantages concerning cost, quality retention, and safety.

Q 13. How do you ensure the proper sanitation and hygiene protocols are followed in egg production?

Sanitation and hygiene are the cornerstones of safe egg production. Think of it as maintaining a spotless environment throughout the entire process. This minimizes the risk of contamination and ensures that eggs reach consumers in optimal condition.

This involves:

- Laying House Hygiene: Regular cleaning and disinfection of the hen house, including removal of manure, are crucial to reduce bacterial load and minimize the risk of Salmonella contamination.

- Egg Handling Hygiene: Employees should wear clean clothing, gloves, and protective gear during egg collection and processing. Hand washing is paramount.

- Equipment Sanitation: Egg washing machines, grading equipment, and other processing equipment need regular cleaning and sanitizing to prevent cross-contamination.

- Water Quality: The water used in egg washing should be of high quality and free from contaminants. Sanitizers need to be properly used and monitored.

- Pest Control: Implementing an effective pest control program is crucial to minimize insects and rodents, which can carry pathogens and contaminate eggs.

Regular audits and training programs are essential to ensure that sanitation protocols are consistently followed. A culture of hygiene within the facility is critical for success.

Q 14. What are the legal regulations and standards concerning egg production and sales?

Legal regulations and standards governing egg production and sales vary by country and region, but they typically address food safety, animal welfare, and labeling. These regulations are designed to protect consumers and ensure fair trade practices.

- Food Safety Regulations: Regulations typically mandate adherence to HACCP principles, specific sanitation practices, and maximum residue limits for pesticides and other chemicals. They often specify acceptable levels of bacterial contamination.

- Animal Welfare Standards: Regulations may define acceptable housing conditions for laying hens, specifying cage size, stocking density, and enrichment provisions. These are increasingly stringent across the globe.

- Labeling Requirements: Regulations mandate clear and accurate labeling, including information on weight, grade, production date, and handling instructions.

- Traceability Requirements: Regulations often stipulate the need for robust traceability systems, enabling quick identification of the source of contamination should an issue arise.

- Salmonella Control Programs: Many jurisdictions have implemented programs focusing on reducing Salmonella contamination in eggs. These might involve on-farm testing and control measures.

Staying informed about the latest regulations and standards is essential for all egg producers and sellers to ensure compliance and maintain consumer trust. Industry associations and government agencies provide up-to-date information on the relevant legal frameworks.

Q 15. How do you manage and resolve customer complaints related to egg quality?

Managing customer complaints about egg quality starts with a robust system for receiving and categorizing complaints. We use a dedicated email address and phone line, ensuring quick response times. Each complaint is logged, detailing the issue (e.g., cracked shells, blood spots, off-flavor), the batch number (crucial for traceability), and customer contact information. We then investigate systematically. For instance, a complaint about cracked shells might lead us to check the handling processes during collection and packaging. If a specific batch shows a high rate of complaints, we conduct a thorough investigation of that batch’s entire production cycle, starting from the hen house. This might involve reviewing hen health records, feed quality, and equipment maintenance logs. Depending on the nature and severity of the complaint, we may offer a refund, replacement products, or a discount on future purchases. Open and honest communication with the customer is crucial throughout the process; we aim to resolve the issue quickly and fairly, turning a negative experience into an opportunity to demonstrate our commitment to quality.

For example, one time we received numerous complaints about a subtle off-flavor in our eggs. Tracing the issue back, we discovered a new batch of feed contained a slightly higher-than-usual level of a specific spice used in the hen feed. Switching feed suppliers solved the problem, and we implemented a stricter quality control check on incoming feed ingredients to prevent recurrence.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of egg defects, and how are they identified?

Egg defects can range from minor cosmetic issues to significant quality problems. They are broadly categorized into shell defects, white defects, and yolk defects.

- Shell defects: These include cracks, checks (fine hairline cracks), misshapen shells, shell discoloration, and weak shells. We identify these visually during grading and packing.

- White defects: These affect the egg white (albumen) and can include blood spots, meat spots (small pieces of tissue), off-odors, and abnormal consistency (thin, watery, or too thick).

- Yolk defects: Yolk defects involve issues with the yolk, such as double yolks, blood rings (rings of blood around the yolk), and discoloration (off-color yolks). These are detected visually during candling, a process where eggs are illuminated with a strong light to examine their internal structure.

Visual inspection, often combined with candling, forms the primary method of identifying defects. We utilize automated grading systems that can quickly and efficiently detect shell cracks and size inconsistencies, improving detection speed and consistency compared to manual inspection alone. Further analysis might involve laboratory tests for off-flavors or bacterial contamination, particularly if a batch shows a high level of defects.

Q 17. Describe your experience in troubleshooting egg production challenges.

Troubleshooting egg production challenges is a multifaceted process, demanding a systematic approach. I’ve encountered various issues, such as reduced egg production, increased egg breakage, and changes in egg quality. For example, a sudden drop in egg production could be attributed to several factors, including disease outbreaks in the flock, poor feed quality, stress on the hens due to environmental changes (temperature fluctuations, excessive noise), or inadequate lighting.

My approach involves a detailed analysis of all aspects of the production process. We start by reviewing production records, analyzing egg quality parameters over time, and examining hen health records. Laboratory tests might be employed to rule out infectious diseases or nutritional deficiencies. Environmental factors are also meticulously assessed: ventilation, temperature, humidity, lighting schedules, and nest box design are all carefully reviewed. We look for correlations between these factors and the observed issues. The solution might involve adjusting the hens’ diet, improving their living environment, implementing stricter biosecurity measures, or upgrading equipment. Sometimes, the solution requires a multi-pronged approach, addressing several contributing factors concurrently.

Q 18. Explain how you’d handle a sudden surge in egg production demand.

Handling a sudden surge in egg production demand requires a well-defined plan, anticipating potential bottlenecks and vulnerabilities. Our response involves several key steps:

- Inventory Assessment: We assess current egg stock and storage capacity to gauge the immediate response needed.

- Production Adjustment: If possible, we carefully increase production, monitoring hen welfare closely. Overloading hens can negatively impact future production and egg quality.

- Workforce Management: We evaluate staffing levels to ensure sufficient personnel for grading, packing, and distribution. Overtime or temporary workers may be considered.

- Logistics Optimization: We coordinate with transport companies to schedule additional deliveries and ensure timely distribution to retail outlets.

- Communication: Clear communication with customers, suppliers, and distributors is crucial during this period to manage expectations and ensure smooth operations.

A proactive approach is essential. Regular monitoring of market trends and demand patterns allows us to anticipate and plan for potential surges. Building strong relationships with key suppliers and distributors ensures a smoother response to unexpected events. For example, when a major regional event caused a spike in demand, we utilized our existing network of distributors and employed overtime to meet the increased demand without compromising quality.

Q 19. How do you implement and monitor quality control measures throughout the production process?

Quality control is implemented throughout the entire egg production process, from the hen house to the consumer’s table. We employ a multi-layered approach:

- Hen Health and Nutrition: Regular health checks, vaccination programs, and optimized feeding regimes ensure healthy hens, which are key to producing high-quality eggs.

- Egg Collection and Handling: Careful egg collection procedures, minimizing damage during collection and transportation, are essential.

- Grading and Candling: Eggs are meticulously graded based on size, weight, and shell quality. Candling helps identify internal defects.

- Cleaning and Sanitization: Strict sanitation protocols are followed throughout the facility to prevent bacterial contamination.

- Packaging and Storage: Eggs are carefully packed and stored under optimal temperature and humidity conditions to maintain freshness and quality.

- Traceability: A robust traceability system allows us to track eggs throughout the entire process, identifying the source of any potential problems.

We continuously monitor quality parameters, employing statistical process control (SPC) techniques to identify trends and deviations from established standards. Regular internal audits ensure adherence to quality standards. Any deviations are promptly investigated and corrective actions implemented. We utilize data analysis to continuously improve our processes, reducing waste and improving overall efficiency.

Q 20. What are your strategies for minimizing egg waste during processing and storage?

Minimizing egg waste requires a strategic approach addressing each stage of the process.

- Efficient Egg Collection: Proper nest design and regular collection minimize broken eggs.

- Careful Handling: Training staff on proper handling techniques reduces breakage during transportation and processing.

- Improved Grading: Using advanced grading technologies improves the accuracy of sorting, reducing waste from misclassifications.

- Waste Recycling: Broken eggs and waste products are processed and reused as animal feed, reducing environmental impact.

- Storage Optimization: Maintaining optimal storage conditions extends shelf life and reduces spoilage.

- Inventory Management: Efficient inventory management prevents excess stock from spoiling.

For example, we introduced automated egg collection systems to reduce breakage. By implementing these strategies, we reduced our overall egg waste by 15% within a year, a significant improvement in both efficiency and profitability. Regular reviews of our waste streams help us identify areas for further improvement and optimize our processes continuously.

Q 21. How do you ensure the efficient use of resources (energy, water) in egg production?

Efficient resource utilization is critical for sustainable egg production. Our strategies focus on several key areas:

- Energy Efficiency: We use energy-efficient lighting systems, automated climate control, and optimized ventilation to reduce energy consumption. Regular maintenance of equipment ensures optimal performance.

- Water Conservation: Water-efficient cleaning systems and recycling programs help conserve water. We monitor water usage closely and implement strategies to reduce consumption.

- Waste Management: Implementing a robust waste management system, including composting and recycling programs, minimizes environmental impact and reduces disposal costs.

- Renewable Energy: Exploring the use of renewable energy sources, such as solar power, can further reduce our carbon footprint and operational costs.

- Continuous Improvement: Regular monitoring and analysis of resource consumption help us identify areas for improvement and implement new technologies and best practices.

For example, installing LED lighting reduced our energy consumption by 30% compared to traditional lighting, resulting in significant cost savings and environmental benefits. We regularly review our energy and water consumption data, and adapt our strategies based on those findings to ensure long-term sustainability.

Q 22. Describe your experience with egg quality analysis techniques (e.g., Haugh unit measurement).

Egg quality analysis is crucial for maintaining consistent product quality and consumer satisfaction. One of the most common techniques is measuring the Haugh unit, which reflects the albumen’s (egg white’s) thickness and therefore, the egg’s overall freshness. A higher Haugh unit score indicates a fresher, higher-quality egg.

My experience involves using a Haugh unit meter, a device that measures the height of the albumen after the egg is cracked onto a flat surface. The formula, which considers both albumen height and egg weight, calculates the Haugh unit score. For example, an egg weighing 60 grams with an albumen height of 7 mm would have a higher Haugh unit score than an egg of the same weight with an albumen height of 4 mm. This data is then used to assess the overall quality of the eggs within a batch and identify any inconsistencies in production or storage. Beyond Haugh units, I’m also experienced in analyzing other quality indicators like yolk color, shell strength (using a compression tester), and shell thickness (using a micrometer). These assessments provide a comprehensive picture of egg quality, allowing for early detection of potential issues.

Q 23. How do you stay updated on the latest advancements and best practices in egg production and food safety?

Staying current in egg production and food safety is paramount. I achieve this through multiple avenues. I actively subscribe to and read leading industry journals such as Poultry Science and World’s Poultry Science Journal. I also regularly attend industry conferences and workshops, both nationally and internationally, where leading researchers and practitioners share their latest findings and best practices. Furthermore, I’m involved in professional organizations like the American Egg Board, which provide updates on regulations and emerging technologies. Finally, I maintain a strong network of colleagues within the industry, exchanging information and insights on a regular basis. This multi-faceted approach ensures that my knowledge base remains both up-to-date and relevant to the ever-evolving landscape of egg production.

Q 24. What are the different types of egg-laying hens and their characteristics?

Several types of egg-laying hens are used commercially, each with its own characteristics. Leghorns are known for their high egg production, producing predominantly white eggs, and their relatively small body size. They are often preferred for large-scale commercial operations due to their efficiency. Rhode Island Reds, on the other hand, are known for their brown eggs and are favored by consumers who prefer that color. They are considered dual-purpose breeds, meaning they are decent layers and also provide a reasonable amount of meat. Australorps are another popular breed, laying large, brown eggs, and are known for their docility and adaptability. The choice of breed depends on market demands, desired egg color, climate, and overall production goals. Each breed has specific nutritional needs and sensitivities which need to be factored into their management.

Q 25. What are your skills in using data analysis to optimize egg production efficiency?

Data analysis plays a critical role in optimizing egg production efficiency. My skills encompass collecting and analyzing data from various sources, including egg production records, feed consumption data, mortality rates, and environmental parameters like temperature and humidity. I utilize statistical software like R and SPSS to identify trends, correlations, and outliers that can improve farm operations. For example, analyzing historical data on feed conversion ratios (FCR) – the amount of feed consumed per unit of eggs produced – can help refine feeding strategies to reduce costs and improve efficiency. Similarly, analyzing mortality data can help us identify and address factors that negatively impact hen health and egg production. By using data-driven decision making, we can minimize waste, improve resource allocation, and ultimately maximize the profitability of the egg production system.

Q 26. Explain your understanding of the impact of feed formulation on egg quality.

Feed formulation directly impacts egg quality in several ways. The nutritional content of the feed dictates the egg’s nutritional profile, including the levels of vitamins, minerals, and fatty acids. For instance, diets deficient in omega-3 fatty acids will result in eggs with lower omega-3 content. The quality of ingredients also matters; using high-quality ingredients ensures optimal nutrient absorption and ultimately leads to better egg quality. A balanced diet, including adequate levels of protein, calcium (for shell strength), and essential amino acids (for albumen and yolk quality), is crucial for producing high-quality eggs. For example, a diet lacking in calcium will result in eggs with thin and weak shells, making them prone to breakage. In contrast, a well-formulated diet will improve egg size, yolk color, and shell quality, contributing to improved overall egg quality and consumer acceptance.

Q 27. How do you ensure the welfare of laying hens in your egg production system?

Ensuring the welfare of laying hens is a top priority, ethically and from a production perspective. We implement several strategies to promote their well-being. This includes providing ample space, allowing for natural behaviors like dust bathing, and maintaining a clean, comfortable environment. We monitor their health closely, preventing and managing diseases promptly. We provide balanced and nutritious feed and fresh water at all times. Our housing systems are designed to minimize stress and promote social interaction among the birds. We adhere to strict biosecurity protocols to prevent disease outbreaks. Regular inspections and auditing processes ensure that these standards are consistently maintained, reflecting our commitment to ethical and humane egg production. Our practices exceed industry standards, and we are actively involved in continuously improving our hen welfare protocols.

Q 28. Describe your experience with different types of egg processing equipment.

My experience encompasses various egg processing equipment, ranging from automated egg grading and washing machines to egg-breaking and pasteurization systems for liquid egg products. I’m familiar with different types of egg washers – from simple brush washers to more advanced systems using ozonated water for sanitization. I understand the functionality of egg graders, which use optical sensors and weighing mechanisms to classify eggs by size and weight. In liquid egg processing, I have experience with breaking machines, homogenizers, and pasteurization units, ensuring the safety and quality of liquid egg products. I am also proficient in operating and maintaining equipment for packaging, ensuring that eggs reach the consumer in optimal condition. Understanding the capabilities and limitations of each piece of equipment is vital for efficient and safe egg processing.

Key Topics to Learn for Egg Production and Quality Control Interview

- Hen Housing and Management: Understanding different housing systems (cage, aviary, free-range), their impact on egg quality and bird welfare, and best practices for flock health and productivity.

- Egg Formation and Physiology: Knowing the biological processes involved in egg formation, factors influencing egg size and shell quality, and common physiological problems affecting egg production.

- Egg Grading and Classification: Familiarizing yourself with industry standards for grading eggs based on size, weight, shell condition, and interior quality. Understanding the practical application of these standards in a commercial setting.

- Quality Control Procedures: Mastering techniques for detecting and managing egg defects (cracks, blood spots, meat spots), implementing sanitation protocols to minimize contamination, and understanding traceability systems.

- Egg Storage and Handling: Learning about proper storage conditions (temperature, humidity) to maintain egg quality, understanding the impact of storage time on egg characteristics, and best practices for minimizing post-harvest losses.

- Food Safety Regulations and Compliance: Understanding relevant food safety regulations (e.g., HACCP principles) and their application to egg production and handling. Knowing how to maintain documentation and ensure compliance.

- Egg Processing and Packaging: Familiarizing yourself with different egg processing methods (washing, sanitizing, grading), packaging techniques, and the importance of maintaining hygiene throughout the process.

- Troubleshooting and Problem-Solving: Developing skills in identifying and resolving issues related to egg production, quality, and processing. This includes analyzing data, identifying root causes, and implementing corrective actions.

- Data Analysis and Record Keeping: Understanding the importance of accurate data collection and analysis to monitor production performance, identify trends, and make informed decisions regarding quality control.

Next Steps

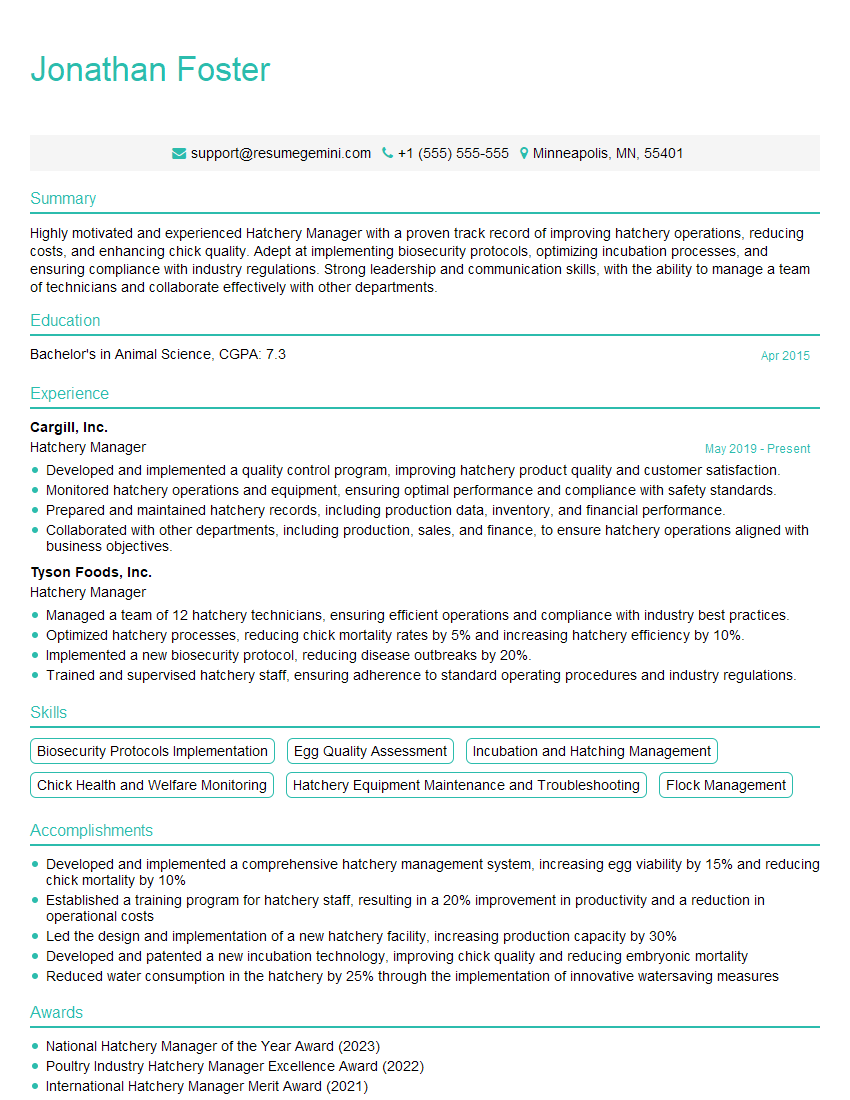

Mastering egg production and quality control opens doors to rewarding careers in the food industry, offering opportunities for advancement and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to egg production and quality control are available to help you craft a compelling application that showcases your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good