Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Electrical Diagrams interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Electrical Diagrams Interview

Q 1. Explain the difference between a wiring diagram and a schematic diagram.

Wiring diagrams and schematic diagrams both represent electrical systems, but they differ significantly in their purpose and level of detail. Think of a wiring diagram as a detailed road map showing exactly how wires are routed and connected, while a schematic diagram is a more abstract blueprint illustrating the functional relationships between components.

A wiring diagram focuses on the physical layout of wires, showing the path of each wire from its source to its destination, including wire colors, sizes, and connector types. It’s essential for installers and technicians who need to physically connect components. It often resembles a messy, realistic view of the electrical system.

In contrast, a schematic diagram prioritizes the logical connections between components. It uses standardized symbols to represent various electrical elements (resistors, capacitors, transistors, etc.) and shows how they interact functionally without explicitly detailing the physical wiring path. It is primarily used for design, analysis, and troubleshooting. It’s cleaner and more abstract.

Example: Imagine a simple circuit with a battery, switch, and light bulb. A wiring diagram would show how the wires are routed from the battery terminals, through the switch, to the light bulb terminals, including the wire colors. A schematic diagram, on the other hand, would simply show the battery, switch, and bulb as symbols connected with lines, representing the functional relationship without detailing the physical wire paths.

Q 2. What are the standard symbols used in electrical diagrams?

Standard symbols in electrical diagrams are crucial for clear and unambiguous communication. They are defined by international standards like IEEE and IEC. While variations exist, the core symbols remain consistent across most diagrams.

- Power Sources: Batteries (represented by long and short parallel lines), AC power sources (a circle with a sine wave), and DC power sources (a circle with + and – signs).

- Passive Components: Resistors (zig-zag line), capacitors (two parallel lines), inductors (a coil).

- Switches: Various symbols exist, depending on the type of switch (SPST, SPDT, etc.) Usually a simple line with a break indicating the switching action.

- Semiconductors: Diodes (triangle pointing to the anode), transistors (different shapes depending on the type – NPN, PNP, FET).

- Other Components: Motors (circle with a coil), transformers (two coils), ground (triangle or a grounded connection symbol).

The precise appearance of a symbol may vary slightly depending on the software or standard used, but the core meaning remains the same. This standardization is critical for global collaboration and preventing misinterpretations.

Q 3. How do you interpret a ladder diagram?

Ladder diagrams are commonly used in industrial control systems to represent the logic of programmable logic controllers (PLCs). They depict the relationships between various control elements such as switches, sensors, and actuators.

Imagine two vertical lines representing the power rails – positive and negative. Rungs (horizontal lines) connect between these rails, representing a circuit. Each rung comprises various components represented by symbols. The elements are connected in series along the rung, and each rung represents an independent circuit path.

Interpreting a rung: A typical rung might include a normally open (NO) contact from a push button switch, followed by a normally closed (NC) contact from a limit switch, and finally, a coil representing an actuator (like a solenoid valve). The system activates the coil (the valve opens) only if the push button is pressed and the limit switch is open. This shows the logical AND relationship between the switch contacts.

Ladder diagrams simplify complex logic by using a structured, visual representation that is relatively easy to understand even for individuals without extensive electrical engineering training. The readability makes it suitable for troubleshooting and modification by technicians.

Q 4. Describe your experience with different types of electrical diagrams (e.g., single-line, three-line).

My experience encompasses a broad range of electrical diagrams. I’ve worked extensively with single-line, three-line, and schematic diagrams.

Single-line diagrams are highly simplified representations, primarily used for power system studies. They show major components (generators, transformers, buses, etc.) and their connections without detailed wiring information. These are great for high-level overviews of large systems.

Three-line diagrams provide more detail than single-line, showing three phases of a three-phase system. They are essential for understanding power distribution in industrial and commercial settings. They are more detailed than single-line diagrams but are still simplified relative to schematic diagrams.

Schematic diagrams, as mentioned earlier, are my most frequent work. I’ve used them in various projects, from small-scale electronic circuits to larger industrial control systems. My proficiency includes creating and interpreting schematics for both AC and DC circuits, understanding the relationships between components and their functions.

I also have experience with other specialized diagrams like wiring diagrams and P&ID (Piping and Instrumentation Diagrams) when they are integrated with the electrical components of larger systems.

Q 5. How do you ensure accuracy and consistency in your electrical diagrams?

Accuracy and consistency are paramount in electrical diagrams. Errors can have serious consequences, ranging from equipment malfunction to safety hazards. My approach to ensuring accuracy involves several key steps:

- Reference Documentation: I always refer to project specifications, manufacturer datasheets, and relevant standards (like IEC or IEEE) to ensure that all components and symbols are accurately represented.

- Component Verification: I meticulously verify each component’s specifications, ratings, and connection points before including it in the diagram. This minimizes errors related to component selection and connections.

- Cross-Checking: I perform rigorous cross-checking of the diagrams, often with a colleague, to identify and correct any inconsistencies or potential errors. A second pair of eyes is invaluable.

- Version Control: I use software with version control features to manage revisions and track changes. This ensures that the latest version is always available and that previous versions are easily accessible if needed.

- Standard Symbol Usage: I strictly adhere to standardized symbols and notations, ensuring that the diagrams are easily understood by others. Consistency in presentation is very important.

Furthermore, clear labeling and annotation are essential for both accuracy and clarity. Detailed annotations make the diagram much easier to understand.

Q 6. What software are you proficient in for creating and editing electrical diagrams?

I am proficient in several software packages for creating and editing electrical diagrams. My primary tools include:

- AutoCAD Electrical: This is a powerful software for creating detailed and comprehensive electrical diagrams, particularly useful for larger projects.

- EPLAN Electric P8: A widely used software known for its robust features, standardization, and data management capabilities.

- SolidWorks Electrical: Seamless integration with SolidWorks’ 3D modeling capabilities makes this ideal for projects involving physical component placement and routing.

I am also comfortable using other drawing software like Visio and even specialized scripting environments to automate certain repetitive tasks in diagram creation.

Q 7. Explain the process of creating an electrical diagram from a project specification.

Creating an electrical diagram from a project specification is a multi-stage process requiring careful planning and execution:

- Requirements Gathering: The first step is to thoroughly review the project specification document, understanding the system’s functional requirements, load calculations, and any relevant safety standards.

- Component Selection: Based on the requirements, I select appropriate components, referring to manufacturer datasheets to confirm specifications and ratings.

- Diagram Planning: I then plan the layout of the diagram, considering factors like clarity, readability, and adherence to standards. This includes choosing a suitable scale and organization method.

- Symbol Placement: I place the chosen components as symbols on the diagram, accurately representing the system’s physical layout or logical connections (schematic vs. wiring).

- Wiring/Connection Definition: I carefully define the connections between components, ensuring that all power supply, control signals, and data paths are correctly shown.

- Review and Verification: I conduct thorough review to ensure accuracy and consistency. This includes cross-referencing with the specification and comparing against known standards. A peer review is highly recommended.

- Documentation: Finally, I provide proper documentation including a revision history, component list, and any relevant notes or annotations.

Throughout this process, clear communication with engineers and stakeholders is critical to ensure that the diagram accurately reflects project requirements and is suitable for its intended purpose.

Q 8. How do you handle revisions and updates to existing electrical diagrams?

Managing revisions in electrical diagrams is crucial for accuracy and safety. We employ a version control system, often integrated with CAD software. Each revision is clearly documented with a revision number, date, description of changes, and the initials of the person making the changes. This ensures traceability and allows us to easily revert to previous versions if needed. For instance, if a component is replaced, the diagram is updated to reflect the new part number, specifications, and any relevant wiring changes. A change log meticulously tracks all modifications, preventing confusion and ensuring everyone is working from the latest, approved version.

Furthermore, we utilize a robust review process before implementing any changes. Senior engineers or project leads review the proposed changes to ensure they meet safety regulations and design specifications. This multi-layered approach minimizes errors and guarantees the integrity of the electrical diagrams throughout the project lifecycle.

Q 9. Describe your experience with electrical code standards (e.g., NEC).

My experience with the National Electrical Code (NEC) and other relevant standards is extensive. I’m proficient in interpreting and applying the code’s provisions for various electrical systems, from residential wiring to complex industrial installations. I understand the importance of adhering to articles pertaining to grounding, overcurrent protection, wiring methods, and other crucial safety aspects. For example, I’ve worked on projects requiring specific grounding techniques for sensitive equipment, ensuring compliance with NEC Article 250. I also regularly incorporate arc flash hazard analysis and mitigation strategies, based on the latest NEC requirements, into my work. This ensures that the diagrams reflect safe and code-compliant designs. Staying updated with the latest code revisions and amendments is a continuous part of my professional development.

Q 10. How do you ensure your diagrams comply with relevant safety regulations?

Compliance with safety regulations is paramount in electrical diagram creation. We incorporate several strategies to ensure this. Firstly, we meticulously follow relevant electrical codes, like the NEC, as already mentioned. Secondly, we use standardized symbols and notations consistent with industry best practices to avoid ambiguity and misinterpretations that could lead to accidents. Thirdly, we conduct thorough design reviews, scrutinizing aspects like overcurrent protection, grounding, and isolation techniques. For instance, we carefully consider the use of appropriate circuit breakers and fuses, ensuring that they are sized correctly to protect against overloads and short circuits. We also perform arc flash studies for high-voltage systems to determine the necessary personal protective equipment (PPE) and safe working procedures. Lastly, detailed safety notes are often included directly on the diagrams to highlight potential hazards and recommended precautions.

Q 11. Explain the importance of proper documentation in electrical diagrams.

Proper documentation is the cornerstone of safe and efficient electrical systems. Well-documented diagrams act as a comprehensive guide for installation, maintenance, and troubleshooting. This includes detailed component specifications, wiring schedules, panel schedules, and clear labeling. Think of it like a detailed recipe: without precise instructions and measurements, you can’t replicate the dish successfully. Similarly, without clear documentation, it’s extremely difficult to understand, maintain, or modify an electrical system. We maintain a revision history, as mentioned earlier, along with detailed descriptions of any special considerations or non-standard components. This ensures the diagrams are easily understood by anyone working with the system, regardless of their familiarity with the project.

Q 12. How do you troubleshoot problems identified in electrical diagrams?

Troubleshooting problems identified in electrical diagrams often involves a systematic approach. I begin by reviewing the relevant sections of the diagrams, cross-referencing with the actual physical installation whenever possible. If a problem is indicated, I’ll first check for obvious errors like incorrect wiring connections or component mismatches. Next, I utilize testing instruments such as multimeters and clamp meters to verify voltages, currents, and continuity. I carefully document my findings, noting any discrepancies between the diagram and the physical system. If the problem persists, I may resort to simulating the circuit using specialized software to isolate the root cause. This might involve running simulations to identify potential voltage drops, power imbalances, or other anomalies. A thorough analysis, combining visual inspection and testing, leads to efficient problem resolution.

Q 13. Describe your experience working with different types of electrical components.

My experience spans a wide range of electrical components, including but not limited to: various types of circuit breakers (molded case, thermal magnetic), contactors, relays (solid-state, electromechanical), transformers (power, isolation), motors (AC, DC), sensors, programmable logic controllers (PLCs), and various types of wiring and cabling (e.g., shielded, armored). I have worked with both low-voltage and high-voltage systems, understanding the unique challenges and safety considerations associated with each. For example, I have extensive experience integrating motor control centers (MCCs) into industrial automation systems, requiring a detailed understanding of the interaction between various components. My knowledge also extends to understanding the behavior and application of different types of semiconductor devices within the circuit.

Q 14. How do you manage large and complex electrical diagrams?

Managing large and complex electrical diagrams requires a structured approach. I utilize CAD software with features designed for managing large projects, allowing for hierarchical diagrams, layer management, and easy navigation. This software enables breakdown of complex systems into smaller, more manageable sections, improving organization and collaboration. We employ a modular design approach, breaking down the system into functional blocks, simplifying the creation and understanding of individual sections. Each block is carefully documented, and cross-referencing between modules ensures a consistent and well-defined overall system. Clear naming conventions, detailed legends, and comprehensive revision control all play a crucial role in managing the complexity and maintaining the integrity of these extensive diagrams. Furthermore, regular review meetings with the team help identify potential issues and ensure consistency across the entire project.

Q 15. What are some common errors to avoid when creating electrical diagrams?

Creating accurate and unambiguous electrical diagrams is crucial for safety and efficient troubleshooting. Common errors stem from carelessness and a lack of standardization. Here are some key pitfalls to avoid:

- Missing or Incorrect Labels: Every component should be clearly labeled with its designation, rating (voltage, amperage, etc.), and function. Ambiguous labels or missing labels lead to confusion and potential hazards.

- Improper Wiring Representation: Lines must clearly show the connection points between components, avoiding ambiguity. Incorrectly representing wire sizes or types can lead to miscalculations and potential overloads.

- Inconsistent Symbol Usage: Adhere strictly to recognized standards (like IEC or ANSI) for symbols. Using inconsistent or self-defined symbols hinders understanding and interoperability.

- Lack of Revision Control: Electrical diagrams often evolve. Implementing a revision control system, including version numbers and change logs, is vital to avoid confusion and errors.

- Ignoring Safety Conventions: Always represent safety features like fuses, circuit breakers, and grounding symbols correctly and prominently.

- Scale and Clarity Issues: Diagrams should be drawn to scale, and labels and lines should be large enough to be easily legible. A cluttered diagram is hard to interpret.

For example, a missing label on a high-voltage component could lead to a dangerous shock. Similarly, an inaccurate representation of wiring could result in overheating or a system failure. Preventing these errors requires meticulous attention to detail, adherence to standards, and regular verification.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the use of different line types and weights in electrical diagrams.

Line types and weights in electrical diagrams are not just aesthetic choices; they convey critical information about the electrical components and their interconnections. Different line types and weights represent different aspects of the circuit.

- Line Weight: Thicker lines typically represent power lines carrying larger currents. Thinner lines might represent control signals or low-current circuits. This visual distinction helps in understanding the relative importance and capacity of different parts of the circuit.

- Line Types:

- Solid Lines: Generally used for normal connections.

- Dashed Lines: Often signify control signals, or connections that are intermittent or not always active.

- Dotted Lines: Frequently represent connections that are conceptually linked but physically separated (like a signal routed through several devices).

- Double Lines: Can indicate bus bars or high-voltage lines.

For instance, a thick solid line might represent a 480V power line feeding a motor, while a thin dashed line could represent a low-voltage signal from a sensor to a PLC. This visual distinction enhances the readability and understanding of the diagram.

Q 17. How do you incorporate symbols for different types of power sources in your diagrams?

Electrical diagrams employ standardized symbols for various power sources to ensure clarity and consistency. The choice of symbol depends on the type of source.

- Batteries: Represented by a pair of parallel lines of unequal length, indicating the positive and negative terminals.

- AC Sources: Usually depicted by a circle with a sine wave inside, representing alternating current.

- DC Sources: Often shown as a circle with a plus (+) and minus (-) symbol, representing direct current.

- Solar Panels: Represented by a series of interconnected rectangles, symbolizing the photovoltaic cells.

- Generators: Usually shown as a circle with a stylized alternator symbol or a specific designation (like an uppercase ‘G’).

For example, in a diagram of a solar-powered system, you would see the solar panel symbol (multiple interconnected rectangles) connected to a battery symbol (parallel unequal lines) and then to the load. The use of these standardized symbols makes it instantly clear what the power source is and how it feeds into the circuit.

Q 18. What are your strategies for ensuring clarity and readability in electrical diagrams?

Clarity and readability are paramount in electrical diagrams. Strategies to achieve this include:

- Logical Arrangement: Organize components logically, often following a flow diagram (left-to-right, top-to-bottom). This makes it easier to trace the flow of power and signals.

- Strategic Use of White Space: Avoid overcrowding. Adequate white space improves readability and reduces visual clutter.

- Consistent Labeling and Numbering: Use a systematic approach for numbering components and wires, ensuring consistency throughout the diagram.

- Color-Coding (Where Appropriate): Using different colors for different voltage levels or signal types can improve comprehension but should be used cautiously to avoid visual overload.

- Clear Annotation: Add brief, descriptive notes to clarify complex parts of the circuit or explain specific functions.

- Appropriate Scale: Choose a scale that allows all components and labels to be clearly visible without unnecessary magnification or reduction.

- Use of Layers (in CAD Software): This allows for organizing different aspects of the circuit (power, control, communication) into separate layers for better management and clarity.

Think of it like reading a well-written book—clear structure, logical flow, and appropriate use of whitespace make all the difference. Similarly, a well-organized electrical diagram is easily understood and safer to work with.

Q 19. How do you utilize layering techniques in CAD software for electrical diagrams?

Layering in CAD software is a crucial technique for managing the complexity of electrical diagrams. Each layer represents a distinct aspect of the design, facilitating organization and selective visibility.

- Power System Layer: Contains high-voltage lines, transformers, circuit breakers, and other power-related components.

- Control System Layer: Includes PLCs, sensors, actuators, and other control-related components.

- Communication Layer: Shows network interfaces, communication cables, and other network infrastructure.

- Grounding Layer: Represents grounding conductors and connections.

- Annotation Layer: Used for adding labels, notes, and other annotations.

By organizing elements into different layers, you can easily turn specific layers on or off for focusing on specific aspects of the diagram. For example, while troubleshooting a control issue, I might hide the power system layer to focus solely on the control circuits. This layered approach significantly enhances the efficiency and clarity of the design process.

Q 20. Describe your experience with creating and interpreting control system diagrams.

I have extensive experience creating and interpreting control system diagrams, including ladder logic diagrams, function block diagrams (FBDs), and sequential function charts (SFCs). My experience encompasses various industrial automation applications.

In a recent project involving a robotic arm control system, I created FBDs to model the logic for different robotic movements. Each block represented a specific function, like motor speed control or position feedback. These diagrams allowed for a clear and modular representation of the control system logic. I also employed ladder logic for simpler aspects of the control system, where the sequential nature of the logic was readily apparent.

Interpreting these diagrams involves understanding the underlying logic, identifying potential bottlenecks, and tracing signals through the system. My experience allows me to quickly diagnose issues and propose solutions based on the control system diagrams.

Q 21. How do you ensure consistency in numbering and labeling within an electrical diagram?

Consistency in numbering and labeling is essential for maintaining clarity and traceability in electrical diagrams. My strategies include:

- Predefined Numbering Schemes: I utilize a systematic approach, like sequential numbering (e.g., starting with ‘1’ for each component type) or a hierarchical scheme (e.g., using prefixes for panel designations or circuit locations). This avoids ambiguity and ensures unique identification for each component.

- Automated Numbering Tools (in CAD software): Most CAD software offers automated numbering features, which can help manage and maintain consistency. This ensures accuracy and efficiency.

- Cross-Referencing: Components or wires are often referenced in multiple places (e.g., in a parts list, bill of materials, or schematic). Ensuring consistent naming across all documents helps maintain traceability and prevents errors.

- Regular Verification: Before finalizing a diagram, I always verify the numbering and labeling for consistency and correctness. This step helps catch any inadvertent inconsistencies.

For instance, in a large industrial control system, consistent numbering and labeling allows for accurate tracking of signals throughout the system. It helps in efficient troubleshooting and minimizes the risk of misinterpretations that could lead to costly downtime or equipment damage.

Q 22. Explain your experience using cross-referencing in complex electrical diagrams.

Cross-referencing in complex electrical diagrams is crucial for maintaining clarity and traceability. It involves establishing links between different parts of the diagram, ensuring that all components and their connections are properly identified and documented. This avoids ambiguity and facilitates troubleshooting and modifications.

In practice, this often involves using unique identifiers (e.g., component numbers, wire numbers) that are consistently used throughout the diagram set and associated documentation. For example, a particular motor might be labeled ‘M1’ on the main power distribution diagram and then referenced again with the same label ‘M1’ in a detailed schematic of its control circuit. Furthermore, a parts list would cross-reference ‘M1’ to the specific motor model and its manufacturer. Software tools often assist with this, automatically updating cross-references when components are moved or renamed. I’ve used this technique extensively in projects involving large industrial control systems, reducing errors and improving overall maintainability.

Imagine a large factory; cross-referencing is like having a detailed map showing not only each building but also specific rooms, equipment within those rooms, and their interconnections. Without it, finding a specific wire or component amidst the complexity would be a nightmare.

Q 23. How do you handle conflicting information in electrical documentation?

Conflicting information in electrical documentation is a serious issue that can lead to costly errors or safety hazards. My approach to handling this involves a structured, multi-step process:

- Identify and Document: First, meticulously identify all instances of conflicting information, noting the source of each discrepancy. This might involve comparing different revisions of diagrams, specifications, or BOMs.

- Trace the Origin: Determine the root cause of the conflict. Is it due to a design error, an outdated document, or a transcription mistake? This step is critical in understanding the extent of the problem.

- Verify with Engineering: Consult with the design engineers to resolve the conflicts based on engineering principles and design intent. This often involves reviewing calculations, simulations, and other supporting documentation.

- Update and Control: Once the conflicts are resolved, update the affected documents with the verified information. Implement rigorous version control to prevent future conflicts, as explained further in the next question.

- Documentation: Maintain a clear record of the conflict resolution process, including dates, individuals involved, and the final decisions made. This creates an audit trail to prevent future issues.

For instance, if one document specifies a 10A fuse while another shows a 5A fuse for the same circuit, it’s crucial to resolve this discrepancy through engineering review to determine the correct rating to ensure system safety.

Q 24. What are your techniques for managing version control for electrical diagrams?

Effective version control for electrical diagrams is essential for maintaining accuracy and preventing confusion. My preferred approach involves using dedicated software for electronic document management, ideally integrated with a version control system like Git or SVN. These systems provide features such as:

- Revision History: Tracking all changes made to the diagrams, allowing for easy rollback to previous versions if necessary.

- Change Logs: Maintaining a detailed record of each revision, including the date, author, and a description of the changes made.

- Branching and Merging: Facilitating parallel development of diagrams without overwriting each other’s work.

- Access Control: Managing user permissions to restrict access to sensitive diagrams and prevent unauthorized modifications.

In practical terms, this means that every modification to a diagram generates a new revision with a unique identifier. If an error is found in a later revision, we can easily revert to a previous, known-good version. This method is much more reliable and efficient than relying on file version numbering or manual tracking. In my previous role, we used a combination of a dedicated CAD software and a cloud-based version control system to maintain version control of hundreds of electrical diagrams across multiple projects.

Q 25. How do you interpret and utilize bill of materials (BOM) data with electrical diagrams?

The Bill of Materials (BOM) is intrinsically linked to electrical diagrams; it provides a comprehensive list of all components used in a system. Effective utilization of BOM data with electrical diagrams ensures consistency and facilitates procurement, assembly, and maintenance.

My typical workflow involves ensuring that every component in the electrical diagram has a corresponding entry in the BOM. This includes the component’s unique identifier (matching the diagram’s numbering system), part number, manufacturer, quantity, and any other relevant specifications. Software tools often facilitate this integration, allowing for automatic updates to the BOM based on changes in the diagram. Discrepancies between the diagram and the BOM are immediately flagged, ensuring accuracy. For example, if a resistor is added to the diagram but not included in the BOM, the system will highlight this inconsistency. This helps prevent errors during the procurement and assembly phases.

Imagine building a complex device: the BOM is like a shopping list, meticulously listing every part needed. The diagram shows how these parts are connected, creating a blueprint that complements the shopping list. Together, both are indispensable for successful completion.

Q 26. Describe your experience with creating electrical diagrams for industrial automation systems.

I have extensive experience creating electrical diagrams for industrial automation systems, ranging from simple PLC (Programmable Logic Controller) control panels to complex SCADA (Supervisory Control and Data Acquisition) systems. This often involves using specialized CAD software with libraries of pre-defined symbols for industrial components such as PLCs, sensors, actuators, and motor drives.

My approach emphasizes clarity, accuracy, and adherence to industry standards such as IEC 61346 or ISA standards. Key aspects include:

- Clear Labeling: Using consistent and descriptive labels for all components and wires, ensuring easy understanding of the system.

- Logical Organization: Structuring the diagrams logically to reflect the functional blocks of the system, which improves readability and comprehension.

- Schematic Capture: Employing schematic capture tools to simplify design and documentation.

- Simulation: Utilizing simulation software to validate the design before implementation, reducing risks of errors and rework.

One memorable project involved designing the electrical system for a large automated packaging line. This required intricate coordination of various subsystems, including sensor networks, robotic arms, conveyors, and control panels. The use of well-organized diagrams was essential for effective communication amongst the project team and successful commissioning of the system.

Q 27. Explain your knowledge of different types of connectors and their representation in diagrams.

Understanding different types of connectors and their proper representation in electrical diagrams is crucial for clear communication and accurate documentation. This includes mechanical specifications as well as electrical characteristics.

Common connector types and their representations include:

- Terminal Blocks: Often represented by a rectangular symbol with numbered terminals, indicating wire connections.

- Circular Connectors: Depicted with a circular symbol showing the number of pins and their arrangement. Specific connector types like DB9, or industrial connectors like M12, are often shown with their specific symbol or a text annotation.

- Ribbon Connectors: Represented by a rectangular symbol with multiple lines representing the individual conductors.

- Screw Terminals: Illustrated with a symbol representing the screw terminals on the device for connecting the wires.

- Quick Disconnect Connectors: Represented with symbols that indicate a quick-connect mechanism such as a latching system.

In diagrams, it’s vital to clearly indicate connector pinouts and wire assignments, often using tables or detailed annotations. This ensures that components can be correctly connected and maintained. I frequently utilize industry-standard symbols and consistently apply the same conventions in my diagrams, which leads to better communication and troubleshooting.

Q 28. How would you approach updating legacy electrical diagrams to current standards?

Updating legacy electrical diagrams to current standards is a common but challenging task. It requires a systematic and careful approach to ensure accuracy and maintain system integrity. My strategy includes the following steps:

- Assessment: First, thoroughly assess the legacy diagrams to identify areas that don’t conform to current standards (e.g., outdated symbols, missing information, unclear labeling).

- Documentation Review: Simultaneously examine all supporting documentation, including original design specifications and previous modifications. This provides valuable context and helps in understanding the system’s functionality.

- Standardization: Choose the appropriate current standards to align with (e.g., IEC 61346, IEEE standards). This is critical for maintaining consistency and facilitating easy understanding of the diagrams.

- Redesign (If Necessary): For complex or poorly documented systems, redesign might be required to meet current standards. This may involve updating symbols, creating new sheets, or restructuring the diagrams to improve clarity.

- Version Control: Implement a robust version control system to track changes made during the updating process. This maintains history and allows for rollback to previous versions, if needed.

- Verification: After updating the diagrams, thoroughly verify their accuracy by comparing them to the existing system, checking for inconsistencies and potential errors.

For example, a legacy diagram might use outdated symbols for relays. Updating these to current symbols, while retaining the core functionality, improves the diagram’s clarity and allows for easier comprehension by engineers familiar with modern standards. This process, while time-consuming, is crucial for the safe and reliable operation of electrical systems.

Key Topics to Learn for Electrical Diagrams Interview

- Schematic Diagrams: Understanding the symbols, conventions, and interpretation of various schematic diagrams including single-line, ladder, and wiring diagrams. Practice drawing and interpreting these diagrams for different electrical systems.

- Wiring Diagrams: Mastering the ability to read and understand wiring diagrams to trace circuits, identify components, and troubleshoot potential problems. Consider practicing fault finding exercises.

- One-Line Diagrams: Learn to interpret power system one-line diagrams, focusing on understanding power flow, protection schemes, and equipment representation. This is crucial for larger-scale systems.

- PLC and Control Systems Diagrams: Familiarize yourself with ladder logic diagrams used in programmable logic controllers (PLCs) and their role in automation and control systems. Practice analyzing simple PLC programs.

- Electrical Symbols and Standards: Thorough understanding of industry standard symbols and their correct application. Be familiar with relevant standards like ANSI/IEEE.

- Troubleshooting and Problem Solving: Develop your ability to analyze electrical diagrams to identify faults, predict system behavior, and propose effective solutions. This is a highly valued skill.

- Safety Regulations and Practices: Demonstrate knowledge of relevant safety regulations and practices related to working with electrical diagrams and systems. Safety is paramount.

- Practical Applications: Relate your theoretical knowledge to real-world applications in various industries, such as power generation, industrial automation, building management, etc.

Next Steps

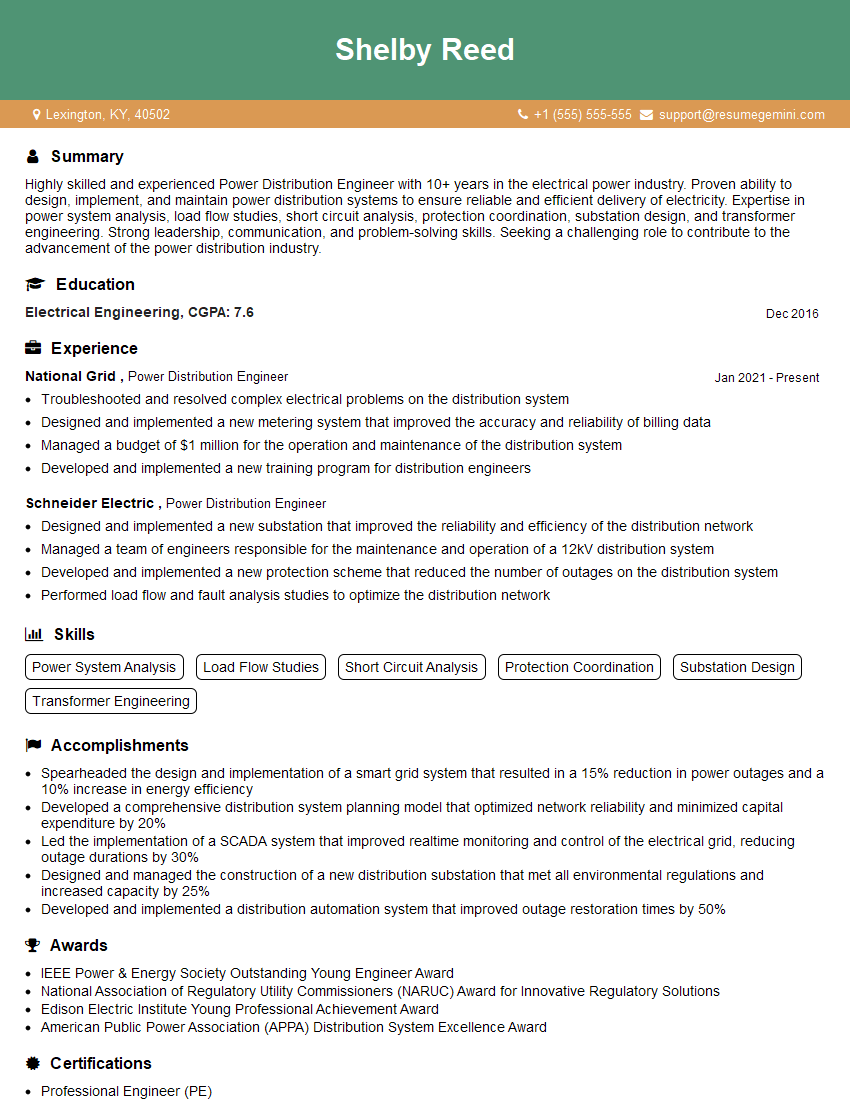

Mastering electrical diagrams is crucial for career advancement in various electrical engineering fields, opening doors to exciting opportunities and higher-level roles. To maximize your job prospects, it’s essential to create a professional and ATS-friendly resume that showcases your skills effectively. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the electrical engineering industry. Examples of resumes specifically designed for candidates with expertise in Electrical Diagrams are available to guide you. Invest time in crafting a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good