Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Electrical Drawings interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Electrical Drawings Interview

Q 1. Explain the difference between single-line and three-line electrical diagrams.

The key difference between single-line and three-line electrical diagrams lies in their level of detail and the information they convey. Think of it like comparing a roadmap to a detailed street map. A single-line diagram simplifies a complex electrical system, showing only the main components and their connections using single lines to represent conductors, regardless of the number of phases or wires. It’s ideal for overview and system analysis. For instance, a single-line diagram of a power plant might show the generator, transformer, and transmission lines, but not the individual wires within those lines.

In contrast, a three-line diagram provides a more detailed representation, explicitly showing all three phases (or more, depending on the system) of a three-phase power system. Each phase is represented by a separate line, making it easier to understand phase relationships and individual conductor details. This is crucial for design, installation, and troubleshooting of complex systems. Imagine a three-line diagram showing a motor control center; you’d clearly see the three phases feeding the motors, the control circuits, and the protective devices.

In essence: single-line diagrams are for high-level understanding, while three-line diagrams provide a detailed picture for practical implementation and maintenance.

Q 2. What are the standard symbols used in electrical drawings according to IEEE or IEC standards?

Standard symbols in electrical drawings are defined by widely accepted standards like IEEE (Institute of Electrical and Electronics Engineers) and IEC (International Electrotechnical Commission). While specific symbols may vary slightly between standards and even within different versions of the same standard, the core concepts remain consistent. Many CAD software packages automatically include these symbols in their libraries.

- Power Sources: These symbols typically represent generators, batteries, or utility power supplies. They often include polarity indicators for DC sources.

- Loads: Symbols for loads vary based on the type (motors, lights, heaters, etc.) Each load has a specific symbol to easily identify its function. For example, a light bulb will have a symbol clearly representing a light source.

- Switches and Breakers: Different types of switches (toggle, push button, etc.) and circuit breakers (molded case, air circuit breaker) have distinct symbols to indicate their operational characteristics.

- Protective Devices: Fuses, circuit breakers, and relays all have unique symbols to denote their role in system protection.

- Transformers: The transformer symbol clearly distinguishes between step-up and step-down transformers.

- Wiring: Symbols show different wire types (single-line, multi-conductor cable), and sometimes even specific wire gauges, especially in detailed drawings.

Consistency in symbol usage is crucial for clear communication. Deviation from standard symbols can lead to misunderstandings and potentially dangerous errors during installation or maintenance. Therefore, always refer to the relevant standard when creating electrical drawings.

Q 3. Describe your experience with AutoCAD or other Electrical CAD software.

I’ve been proficient in AutoCAD Electrical for over eight years and have also used EPLAN and Bentley’s MicroStation. My experience spans the entire design process, from initial schematic design to detailed panel layouts and wiring diagrams. I’m adept at creating and managing projects using these software’s libraries of standard electrical symbols and components.

For instance, on a recent project involving a large industrial facility, I used AutoCAD Electrical to design the entire electrical system. This involved creating schematics, panel layouts, wire lists, and other necessary documentation. The software’s automation features, such as automatic wire numbering and bill of materials generation, significantly improved efficiency and accuracy. I also leveraged its capabilities for error checking to ensure compliance with electrical codes and standards.

Furthermore, my experience includes using these tools to collaborate with other engineers and technicians, ensuring seamless data exchange and consistency throughout the project lifecycle. My skills extend beyond basic drafting; I’m comfortable with advanced features like creating custom symbols and managing large, complex projects effectively.

Q 4. How do you ensure accuracy and consistency in your electrical drawings?

Accuracy and consistency are paramount in electrical drawings; errors can have serious consequences. My approach is multifaceted:

- Adherence to Standards: I rigorously follow relevant standards (IEEE, IEC, and local codes) for symbols, labeling conventions, and drawing formats to ensure clarity and prevent misinterpretations.

- Version Control: Using a robust version control system (like those embedded in many CAD software or standalone systems) is essential for tracking revisions and collaborating effectively. This prevents accidental overwrites and ensures everyone is working with the latest version.

- Regular Checks and Reviews: I conduct thorough self-checks and peer reviews at different stages of the drawing process. This involves verifying component selection, wiring connections, and compliance with design specifications.

- Automated Checks: Leveraging the automated error-checking features within the CAD software is critical. These tools often identify potential conflicts or inconsistencies before they become major issues.

- Detailed Documentation: Maintaining clear and comprehensive documentation, including revision logs, design specifications, and component lists, is crucial for traceability and future updates.

By combining these methods, I maintain a high level of accuracy and consistency, minimizing the risk of errors and improving project efficiency.

Q 5. Explain the process of creating an electrical schematic diagram.

Creating an electrical schematic diagram is a systematic process that usually involves these steps:

- Gathering Requirements: The process begins with clearly defining the project’s functional requirements, load calculations, and system specifications. Understanding these needs is crucial for creating an accurate schematic.

- Component Selection: Choose appropriate components (e.g., circuit breakers, relays, motors) based on the requirements and standards. This often involves considering voltage, current ratings, and other critical parameters.

- Schematic Design: Use CAD software to draw the schematic, arranging components logically and ensuring clear labeling. This stage requires a thorough understanding of electrical principles and best practices for diagram readability.

- Wiring and Interconnections: Carefully plan and draw the connections between different components, using standardized symbols for wires and connections. Ensure clear identification of wire sizes and types.

- Verification and Review: Conduct thorough checks to verify the correctness and completeness of the design. This could involve circuit simulations or peer reviews.

- Documentation: Document the schematic thoroughly, including a title block, revision history, and any special notes.

Creating an electrical schematic diagram isn’t just about drawing lines; it’s about designing a safe and efficient electrical system that meets its intended function. Each symbol and connection has significance and impacts the overall system performance.

Q 6. How do you handle revisions and updates to electrical drawings?

Handling revisions and updates efficiently is key to managing electrical drawings. My approach focuses on:

- Version Control: Employing a version control system (such as those integrated within CAD software) allows for tracking revisions and easily reverting to previous versions if needed. It’s a critical part of maintaining project integrity.

- Revision Log: Maintaining a detailed revision log is essential. Each change should be documented with a description of the alteration, date, and author. This creates a clear audit trail.

- Controlled Revisions: Updates should be made through a controlled process. This might involve a formal review and approval process before changes are implemented in the master drawing. This helps to maintain accuracy and prevent accidental errors.

- Notification: All relevant stakeholders should be notified of revisions and updates to ensure everyone is working with the most current version of the drawings.

- Redlining and Markups: Using redlining tools within the CAD software allows for clear communication of changes and simplifies the revision process.

Proper revision management is not just about maintaining accurate drawings, but also about facilitating efficient collaboration and preventing potential safety issues.

Q 7. What are your strategies for managing large and complex electrical drawing projects?

Managing large and complex electrical drawing projects requires a structured approach:

- Project Breakdown: Divide the project into smaller, manageable sections. This makes it easier to track progress, assign tasks, and manage individual components of the system.

- Team Collaboration: Utilize efficient team communication tools and establish clear roles and responsibilities within the team. This fosters better coordination and error detection.

- Data Management: Employ a robust data management system to organize drawings, specifications, and other project documents. This could involve cloud-based storage or a centralized server.

- Automated Tools: Leverage automated features of CAD software like automatic wire numbering, reporting, and cross-referencing, improving accuracy and reducing manual effort.

- Regular Meetings and Progress Tracking: Schedule regular meetings to track progress, address issues, and make decisions. Using project management software can also provide a holistic overview and facilitate better tracking of deliverables.

- Template and Standards: Creating standardized templates and following consistent design practices ensures uniformity throughout the project.

By implementing these strategies, even the most complex projects can be managed effectively, minimizing potential risks and ensuring project success.

Q 8. Describe your experience with electrical drawing standards and codes (e.g., NEC, NFPA).

My experience with electrical drawing standards and codes is extensive, encompassing both the National Electrical Code (NEC) and the National Fire Protection Association (NFPA) standards. I’ve worked extensively with NEC articles covering everything from wiring methods and overcurrent protection to grounding and bonding requirements. Understanding these codes isn’t just about following rules; it’s about ensuring safety and compliance. For instance, I’ve used NEC Article 250 extensively in designing grounding systems, ensuring proper equipment grounding and bonding to protect against electrical shock. Similarly, I’ve applied NFPA 70E, which focuses on electrical safety in the workplace, to design systems that minimize arc flash hazards. This involved calculating arc flash boundaries and specifying appropriate personal protective equipment (PPE) for electricians working on the system. I’m also familiar with other relevant standards depending on the project’s location and specific requirements.

In practice, this involves reviewing the applicable codes at the start of every project, incorporating those requirements into my designs, and meticulously documenting my compliance with the codes in the drawings themselves. For example, I’ll clearly indicate conductor types and sizes according to NEC requirements and clearly mark all grounding and bonding conductors. This ensures that the drawings are not only complete but also serve as a vital safety reference for contractors and electricians during installation and maintenance.

Q 9. How do you ensure compliance with safety regulations in your electrical drawings?

Ensuring compliance with safety regulations is paramount in electrical design. It’s not just about ticking boxes; it’s about safeguarding lives and preventing costly accidents. My approach involves a multi-layered strategy:

- Strict adherence to codes and standards: As mentioned previously, I diligently follow NEC and NFPA standards, ensuring that every aspect of the design, from wire sizing to grounding methods, complies with the relevant regulations.

- Arc flash hazard analysis: For high-voltage systems, I conduct thorough arc flash hazard analyses to determine the potential energy levels and identify appropriate PPE. The results of this analysis are incorporated directly into the drawings, clearly indicating arc flash boundaries and the required PPE.

- Grounding and bonding strategies: I employ robust grounding and bonding strategies to minimize the risk of electrical shock and equipment damage. These are clearly detailed on the drawings, showing the location of grounding electrodes, grounding conductors, and bonding jumpers.

- Coordination with other disciplines: Effective communication with other disciplines, such as mechanical and structural engineering, is crucial to avoid conflicts that could compromise safety. For example, ensuring adequate clearance between electrical conduits and other systems prevents damage and potential hazards.

- Regular reviews and checks: Throughout the design process, I perform regular reviews and checks to ensure that all safety measures are in place. This includes peer reviews and potentially even third-party safety audits, especially on large and complex projects.

Think of it like building a house – you wouldn’t leave out crucial structural elements for safety. Similarly, leaving out vital safety measures in an electrical drawing is unacceptable and could have severe consequences.

Q 10. Explain the importance of proper labeling and annotation in electrical drawings.

Proper labeling and annotation are essential for clear communication and efficient project execution. They are the bridge between the designer’s intent and the installer’s understanding. Imagine trying to build something from an instruction manual with missing or unclear steps – that’s what an improperly labeled electrical drawing is like.

- Clear identification of components: Every component, from circuit breakers to switches and receptacles, must be clearly identified with appropriate symbols and labels. Using standardized symbols is crucial for unambiguous communication. For example,

●might represent a receptacle, while□could signify a lighting fixture. - Wiring designations and tagging: Each wire must have a consistent and easily traceable designation, including wire type and size. This ensures that installers know exactly what each wire is for and how it connects to other parts of the system. For example, using a numbering system, such as ‘R1’, ‘R2’, etc., for red wires and consistently labelling the size and type, prevents confusion.

- Panel schedules and device listings: Panel schedules and detailed device listings provide a comprehensive overview of all components and their locations, assisting installers and maintenance personnel in understanding the entire system.

- Notes and specifications: Clear and concise notes are essential to convey any special instructions, clarifications, or design considerations. For example, specifying the type of conduit to be used or any special grounding requirements should be clearly stated.

In summary, meticulous labeling and annotation create drawings that are easy to understand, error-free and facilitate a safe and efficient installation. It’s about clear communication and preventing costly mistakes and potential hazards down the line.

Q 11. Describe your experience with creating electrical panel schedules.

Creating electrical panel schedules is a critical part of my work. A well-structured panel schedule acts as a comprehensive inventory, providing detailed information on each panel’s contents and functionality. I’ve created numerous panel schedules for projects ranging from small residential buildings to large industrial facilities. My approach ensures clarity and accuracy, which is vital for both the installation process and future maintenance.

The process typically involves:

- Gathering data: This involves collecting information on the load requirements for each circuit and choosing the appropriate circuit breakers and other devices.

- Creating the schedule: Using software like AutoCAD Electrical or similar, I meticulously document each circuit, including the circuit number, breaker size, load description, and any special requirements.

- Organizing the information: The schedule is arranged logically and clearly, with columns for circuit number, breaker size, device type, load description, and any notes. This format ensures the data is easy to read and understand.

- Verifying accuracy: Before finalizing the schedule, I conduct thorough checks to ensure that the information is accurate, complete, and aligns with the other drawings and calculations.

A well-organized panel schedule saves time, reduces errors during construction, and facilitates smooth and efficient troubleshooting down the line. It’s essentially a roadmap for the electrical system, ensuring everyone involved is on the same page.

Q 12. How do you coordinate electrical drawings with other disciplines (e.g., mechanical, architectural)?

Coordination with other disciplines is crucial for a successful project. Electrical systems don’t exist in isolation; they must integrate seamlessly with mechanical, architectural, and structural systems. Ignoring this coordination can lead to costly clashes, delays, and safety issues.

My approach to coordination involves:

- Regular meetings and communication: I participate actively in design coordination meetings with architects, mechanical engineers, and other relevant disciplines. This allows for proactive identification and resolution of potential conflicts.

- Model review and clash detection: Using BIM software (as discussed below), I regularly review the model for any clashes between electrical systems and other building elements. Clash detection software helps pinpoint and address potential issues before construction begins.

- Clear communication of requirements: I clearly communicate the space requirements for electrical systems, including conduits, equipment locations, and clearances needed for safe access and maintenance. This communication usually involves providing detailed drawings and specifications to other team members.

- Marked-up drawings and revisions: I use marked-up drawings to track changes and revisions made during the coordination process. This ensures that everyone is working from the same up-to-date information.

Coordination is a collaborative process. It’s not just about avoiding clashes but also about optimizing the design for efficiency and safety. The result is a more integrated and streamlined process that produces a better final product.

Q 13. What is your experience with BIM (Building Information Modeling) in electrical design?

My experience with Building Information Modeling (BIM) in electrical design is significant. I’ve worked extensively with software such as Revit and AutoCAD Electrical, leveraging BIM’s capabilities to create intelligent and coordinated electrical models. BIM is not just about creating 3D models; it’s about creating a digital twin of the building’s electrical system.

The benefits of using BIM include:

- Improved coordination: BIM facilitates seamless coordination with other disciplines by providing a central platform for all building information. This reduces clashes and improves the overall efficiency of the design process.

- Clash detection: BIM software allows for automated clash detection, identifying potential conflicts between electrical systems and other building components before construction starts, which reduces costly rework during construction.

- Enhanced visualization: BIM provides excellent visualization capabilities, allowing for better communication and understanding of the electrical system’s design.

- Quantity take-off and cost estimation: BIM software can automatically generate quantity take-offs, making it easier to accurately estimate the cost of materials and labor.

- Improved documentation: BIM generates comprehensive documentation, including detailed drawings, schedules, and reports, ensuring clarity and accuracy in construction and maintenance.

In short, BIM transforms the design and construction process, making it more efficient, accurate, and less prone to errors. It’s a crucial tool in modern electrical design, and I’m proficient in its use.

Q 14. Describe your experience with using electrical calculation software.

I have extensive experience using various electrical calculation software packages. These tools are indispensable for ensuring accurate and efficient design. They handle complex calculations quickly and accurately, reducing the risk of human error. I’m proficient in software like ETAP, SKM PowerTools, and EasyPower, which are commonly used for various tasks.

My typical use cases include:

- Short circuit calculations: Determining fault currents is crucial for selecting appropriate protective devices. Software like ETAP allows for precise calculation of short circuit currents under various fault conditions, ensuring that the protection system is adequately sized.

- Voltage drop calculations: Excessive voltage drop can affect equipment performance and efficiency. Software helps accurately predict voltage drop in different parts of the system, allowing for appropriate conductor sizing and equipment placement.

- Load flow analysis: Understanding how power flows through the electrical system is critical for efficient design and operation. Software performs load flow studies, identifying potential bottlenecks and optimizing system design.

- Protective relay coordination studies: Ensuring proper coordination between protective relays is essential for reliable system operation. Software helps in coordinating protective relays to ensure selective tripping during faults.

These software tools are not just about crunching numbers; they enhance the design process, allowing for rapid analysis of different design options and leading to more efficient and reliable electrical systems. They are integral to my design workflow, boosting both efficiency and accuracy.

Q 15. How do you handle discrepancies or errors discovered in electrical drawings?

Discovering discrepancies or errors in electrical drawings is a critical part of the design process. My approach is systematic and involves several steps. First, I meticulously compare the drawings against the project specifications and relevant codes (like NEC in the US or IEC internationally). Any deviation is flagged immediately. Next, I verify the calculations, checking for consistency in power ratings, voltage drops, and short-circuit currents. I utilize software to assist with these calculations to minimize human error. Third, I cross-reference the drawings with other disciplines’ drawings, such as architectural and structural, to identify potential clashes or conflicts. For instance, a conduit might be routed through a structural beam, which is a problem. Finally, I document all discrepancies in a clear and concise report, detailing the nature of the error, its potential impact, and the proposed solutions. I always communicate these findings to the design team and the client promptly. A recent project involved discovering a mismatch between the panel schedule and the actual wiring diagram. This was caught during review, preventing a potentially expensive rework on-site.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of different types of electrical load calculations.

Electrical load calculations are essential to ensure the electrical system is adequately sized and safe. There are several types, each serving a specific purpose:

- Demand Load Calculation: This determines the maximum expected electrical load on a system at any given time. It considers the diversity factor, which accounts for the fact that not all loads operate simultaneously. For example, not every light or appliance in a building is on at once. This calculation is crucial for selecting appropriate transformers, switchgear, and other equipment.

- Branch Circuit Load Calculation: This involves determining the load on individual circuits within the system. It’s based on the connected loads (e.g., lighting fixtures, receptacles) and the associated load factors, ensuring that each circuit doesn’t exceed its capacity. Overloading a circuit is a fire hazard.

- Motor Load Calculation: This focuses on the starting and running currents of motors, which can be significantly higher than their rated power. It considers the motor’s full-load current, starting torque, and the appropriate motor starting methods (like across-the-line starters or reduced-voltage starters) to ensure safe operation.

- Short-Circuit Current Calculation: This assesses the magnitude of fault currents that could occur in the event of a short circuit. This calculation is essential for coordinating protective devices (fuses and circuit breakers) to effectively clear the fault while minimizing damage to the system.

Software tools significantly aid in these calculations, providing accuracy and efficiency.

Q 17. How do you ensure the readability and clarity of your electrical drawings?

Readability and clarity are paramount in electrical drawings. I ensure this through several strategies. First, I utilize standard symbols and conventions according to industry standards (IEEE, ANSI, etc.). Consistency is key; using the same symbol for the same element across all drawings avoids confusion. Next, I employ a clear and logical layout, organizing the information logically. This might involve using different sheets for different sections of the project, with clear labeling and cross-referencing. I also prioritize proper scaling and appropriate annotation. Dimensions, wire sizes, equipment specifications, and other critical information must be easily identifiable. Furthermore, I use color-coding strategically to highlight different voltage levels, circuits, or systems. For instance, red might be used for high voltage, blue for low voltage, and so on. Finally, I always review the drawings from a fresh perspective – almost as if I were a contractor unfamiliar with the project – to identify any potential ambiguities.

Q 18. Explain your process for reviewing and approving electrical drawings.

My review and approval process is a multi-step procedure. It starts with a self-check to ensure accuracy and completeness before sharing with the team. Then, a peer review follows. Other engineers on the team review the drawings, focusing on different aspects of the design—one might review the power system calculations, while another examines the grounding scheme. This cross-checking helps to catch errors that might be missed by a single reviewer. After peer review, the drawings are reviewed by a senior engineer for final verification and approval. This person has extensive experience and can provide guidance on areas needing improvement. Finally, client review and approval, if needed, are obtained. This entire process is documented and includes a signed-off document to establish accountability and prevent mistakes from reaching the construction stage.

Q 19. What is your experience with creating and interpreting one-line diagrams?

I have extensive experience creating and interpreting one-line diagrams. These simplified diagrams show the main components of an electrical power system using single lines to represent buses, transformers, generators, and protective devices. They are invaluable for understanding the overall system configuration and for performing load flow and fault studies. Creating a one-line diagram involves understanding the complete system architecture, selecting appropriate symbols, and arranging them logically to reflect the power flow. Interpreting them involves identifying key elements, understanding the power flow path, and extracting critical information, such as transformer ratings and protective device settings. For example, I recently used a one-line diagram to quickly identify a potential overload on a transformer during a capacity upgrade project, allowing us to proactively address the issue.

Q 20. How do you manage revisions and version control for electrical drawings?

Managing revisions and version control is critical for maintaining the integrity and accuracy of electrical drawings throughout a project’s lifecycle. I utilize a version control system, such as a cloud-based platform or dedicated CAD software with revision control features. Every revision is assigned a unique revision number or identifier. Changes are meticulously documented, including a description of the modifications made and the date/author. This helps to track changes and easily revert to previous versions if needed. The system ensures that everyone on the team is working with the most up-to-date version of the drawing, reducing the likelihood of conflicts and errors. A clear revision history is maintained, serving as an audit trail for any changes made to the drawings.

Q 21. Describe your experience with generating reports from electrical design software.

I am proficient in generating reports from various electrical design software packages. This involves using the software’s reporting capabilities to extract data and present it in a clear and organized format. These reports typically include schedules of equipment (e.g., panel schedules, lighting schedules), cable schedules, load summaries, and other relevant information. The specific types of reports vary depending on the project’s requirements. For instance, I have generated reports showing voltage drop calculations for a large commercial building, ensuring compliance with voltage limits. The software also assists in generating reports to comply with building codes and regulatory requirements, ensuring proper documentation. The ability to generate these reports saves considerable time and effort compared to manual methods and ensures consistency and accuracy.

Q 22. How do you ensure the drawings are suitable for construction and installation?

Ensuring electrical drawings are suitable for construction and installation involves a multi-faceted approach. It’s not just about creating visually appealing diagrams; it’s about creating a precise and unambiguous set of instructions. This requires meticulous attention to detail and adherence to industry standards.

- Comprehensive Detailing: The drawings must include all necessary information, such as equipment specifications (manufacturer, model number, ratings), cable sizing and routing, termination points, panel schedules, and device locations. Ambiguity is the enemy of efficient construction. For example, a vague notation about ‘running conduit’ needs to specify conduit type, size, and routing.

- Clear and Consistent Labeling: Every component, wire, and conduit should be clearly labeled with its designation. Consistent labeling schemes across the entire project are crucial. Imagine the chaos if two different systems were used for numbering conduits on the same site!

- Adherence to Codes and Standards: The drawings must comply with all relevant electrical codes and standards (e.g., NEC in the US, BS 7671 in the UK). This ensures safety and legality. A simple oversight, like improper grounding, can lead to serious consequences.

- Revision Control: A robust revision control system is mandatory. Any changes must be clearly documented and communicated to all stakeholders. Imagine the frustration of working from an outdated drawing!

- Coordination with other Disciplines: Electrical drawings must be coordinated with architectural, structural, and mechanical drawings to avoid conflicts and ensure proper integration. For instance, ensuring electrical conduit doesn’t interfere with HVAC ductwork is crucial.

By adhering to these principles, I ensure the drawings are not only accurate but also readily usable by contractors and installers, leading to efficient and safe project completion.

Q 23. Explain your understanding of grounding and bonding in electrical systems.

Grounding and bonding are crucial for safety in electrical systems. Grounding connects non-current-carrying metal parts of equipment to the earth, providing a low-impedance path for fault currents. Bonding connects non-current-carrying metal parts of the system together, equalizing their electrical potential. Think of it like this: grounding is the safety net, and bonding is the interconnected safety net, minimizing voltage differences and preventing hazardous situations.

Grounding diverts fault currents to the earth, preventing dangerous voltage buildup on exposed metal parts. A short circuit to a metal enclosure, for instance, would be safely routed to earth through the grounding system, tripping a breaker and preventing electrocution.

Bonding prevents voltage differentials between metal enclosures. If two metal enclosures are bonded, a fault on one will not create a dangerous voltage difference between the two.

Effective grounding and bonding require careful design and execution. The size and type of grounding conductors, the location of grounding electrodes, and the bonding methods must all be carefully chosen according to applicable codes and standards. I use appropriate grounding and bonding methods and materials in all my designs.

Q 24. How familiar are you with various types of electrical protection devices?

I’m very familiar with various electrical protection devices. These devices are crucial for preventing damage to equipment and ensuring personnel safety. My experience encompasses a wide range of devices, including:

- Circuit Breakers: These automatically interrupt the circuit in case of overcurrent or short circuit conditions. I’m proficient in selecting appropriate types and ratings based on load calculations and system requirements.

- Fuses: Similar to circuit breakers, fuses offer overcurrent protection but are designed to be replaced after operation.

- Ground Fault Circuit Interrupters (GFCIs): These devices detect ground faults and instantly shut off the power, preventing electric shock. They are crucial in areas with potential water contact.

- Arc Fault Circuit Interrupters (AFCIs): AFCIs detect arcing faults, which can lead to fires, and quickly interrupt the circuit.

- Surge Protective Devices (SPDs): SPDs protect sensitive equipment from voltage surges and spikes caused by lightning strikes or power grid fluctuations.

- Motor Protection Relays: These relays protect motors from various faults, such as overcurrent, overheating, and phase imbalance.

Choosing the right protection device for a specific application requires understanding the load characteristics, environmental factors, and relevant safety regulations. I ensure my designs incorporate appropriate protection, taking into account the potential risks involved.

Q 25. Describe your experience with short circuit and arc flash calculations.

I have extensive experience in short circuit and arc flash calculations. These calculations are essential for ensuring the safety of personnel working on electrical systems and for selecting appropriate protective devices.

Short circuit calculations determine the maximum current that could flow during a short circuit. This information is critical for selecting circuit breakers and other protective devices with sufficient interrupting capacity. Software like SKM Power*Tools is commonly used for these calculations, often incorporating load flow analysis to determine fault current contributions from various sources.

Arc flash calculations estimate the energy released during an arc flash event. This energy can cause severe burns and other injuries. The results of these calculations are used to determine the appropriate personal protective equipment (PPE) required for working on energized equipment. Software packages like ETAP or EasyPower are used for this purpose, and the calculations often involve sophisticated modelling techniques to accurately estimate arc flash hazards.

I’m proficient in using both software and manual calculation methods, ensuring accuracy and thoroughness in my analysis. Understanding these calculations helps me design safe and compliant electrical systems.

Q 26. How do you utilize symbols and annotations to effectively communicate electrical information?

Effective communication in electrical drawings relies heavily on the proper use of symbols and annotations. These serve as a visual language, conveying complex information concisely and unambiguously. I adhere to industry standards (like IEEE and ANSI) for symbols to ensure clarity and understanding.

Symbols: Standardized symbols for components (e.g., motors, transformers, circuit breakers) ensure everyone understands the diagram. For example, a simple square with a circle inside instantly represents a motor, eliminating lengthy written descriptions.

Annotations: Annotations provide additional detail, clarify symbol meanings, and supply critical information such as wire sizes, ratings, equipment specifications, and notes about installation requirements. Well-placed and clearly written annotations are essential to guide installers.

Example: Instead of drawing a lengthy description of a conduit run, I would use standardized symbols for the conduit type, size, and bending radii, supplemented by annotations indicating the starting and ending points, the total length, and any special requirements.

Clarity and consistency are paramount. My drawings prioritize ease of interpretation, minimizing the potential for errors during construction and installation.

Q 27. What software and tools are you proficient in for electrical drawing creation and management?

I’m proficient in several software packages and tools for electrical drawing creation and management. My expertise includes:

- AutoCAD: A versatile tool for creating detailed 2D drawings, offering precision and the ability to incorporate symbols and annotations.

- Revit: Powerful BIM (Building Information Modeling) software, enabling collaborative design and coordination with other disciplines. This is particularly useful for larger projects.

- ETAP and SKM Power*Tools: Software packages for electrical system analysis, including short circuit, arc flash, and load flow studies. This directly impacts the design process, ensuring safety and efficiency.

- EasyPower: Another powerful software suite for power system analysis, often preferred for its user interface and specific features.

- Microsoft Office Suite (Word, Excel, PowerPoint): Essential for creating project documentation, reports, and presentations.

My proficiency in these tools allows me to create comprehensive, accurate, and well-documented electrical drawings and perform the necessary calculations to ensure a safe and efficient design. I can adapt my approach based on the project’s complexity and client’s preferences.

Q 28. Explain how you would approach troubleshooting inconsistencies between electrical drawings and specifications.

Troubleshooting inconsistencies between electrical drawings and specifications requires a systematic approach. Such inconsistencies can lead to costly delays and safety issues if not addressed promptly and thoroughly.

- Document Review: Begin by meticulously reviewing both the drawings and specifications, identifying all discrepancies. This might include comparing equipment lists, cable schedules, and panel schedules.

- Cross-referencing: Ensure that all references in the drawings match the specifications and vice versa. This process is often aided by using the drawing revision history and comparing against earlier versions.

- Clarification with Stakeholders: Contact the relevant engineers, designers, or contractors involved in the project to clarify the discrepancies. Perhaps an oversight or change was made without updating all relevant documents.

- Prioritize Discrepancies: Categorize the inconsistencies based on their severity and potential impact on the project. Critical discrepancies related to safety must be addressed immediately.

- Issue Resolution and Documentation: Formalize the resolution of each discrepancy, documenting the changes made in both the drawings and specifications. This helps maintain a consistent and accurate record of the project. Often this involves issuing a formal revision to the drawings.

- Verification: Once corrections are made, re-check the drawings and specifications to ensure consistency. This ensures no new errors were introduced.

A systematic approach to this process minimizes errors and ensures that the final product is safe, accurate, and aligns with the original intent and specifications. I have experience managing this process in several projects, including complex industrial installations.

Key Topics to Learn for Electrical Drawings Interview

- Schematic Diagrams: Understanding symbols, components, and their interconnections. Practical application: Interpreting a schematic to troubleshoot a malfunctioning circuit.

- Wiring Diagrams: Identifying wire types, sizes, routing, and termination methods. Practical application: Planning and executing a safe and efficient wiring installation.

- Panel Schedules and Layouts: Interpreting panel information to understand circuit breakers, fuses, and load distribution. Practical application: Designing and implementing a safe and effective electrical panel.

- One-Line Diagrams: Understanding the simplified representation of a power system. Practical application: Analyzing power flow and potential system faults.

- Electrical Codes and Standards (NEC, IEC): Familiarity with relevant safety regulations and best practices. Practical application: Ensuring compliance and safety in all electrical designs and installations.

- Blueprint Reading and Interpretation: Understanding architectural drawings and integrating them with electrical designs. Practical application: Coordinating electrical work with other trades during construction.

- Calculations (Voltage Drop, Load Calculations): Performing necessary calculations to ensure proper system design. Practical application: Designing a system that meets the needs of the load while adhering to safety regulations.

- Troubleshooting Techniques: Developing systematic approaches for identifying and resolving electrical problems. Practical application: Efficiently diagnosing and repairing faulty circuits.

- Software Proficiency (AutoCAD, Revit, etc.): Demonstrating experience with industry-standard electrical design software. Practical application: Creating accurate and professional electrical drawings.

Next Steps

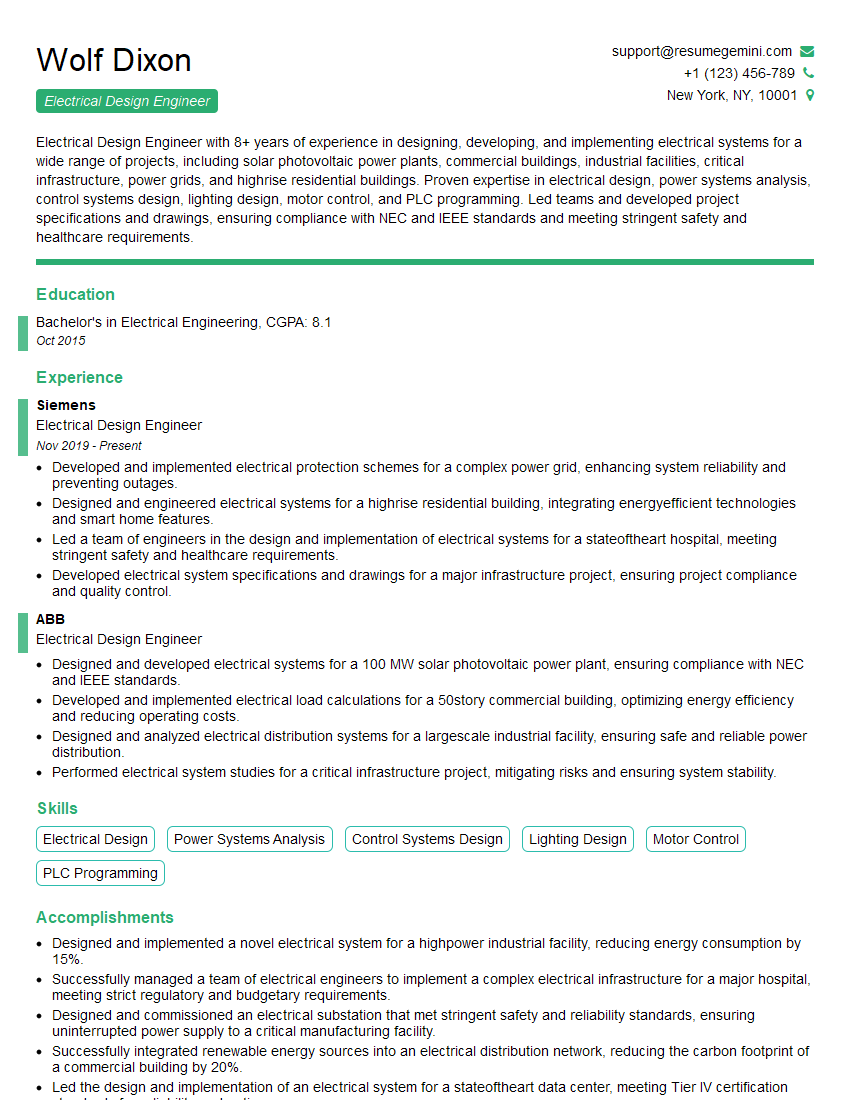

Mastering electrical drawings is crucial for career advancement in the electrical field, opening doors to higher-level positions and more challenging projects. To enhance your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource for building professional resumes that highlight your skills and experience effectively. Examples of resumes tailored specifically to Electrical Drawings professionals are available to help you showcase your expertise and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good