Cracking a skill-specific interview, like one for Electrical Rough-In, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Electrical Rough-In Interview

Q 1. Explain the process of bending conduit to meet specific requirements.

Bending conduit is a crucial skill in electrical rough-in, ensuring a neat, efficient, and code-compliant installation. The process involves using various bending tools – hand benders for smaller conduits and hydraulic benders for larger ones – to create precise bends at specific angles and radii. The goal is to avoid kinks, which can damage the wire and impede signal transmission.

First, you need to plan the conduit route, carefully measuring distances and calculating the angles of the bends required to navigate obstructions and reach the desired locations. Then, you carefully mark the conduit at the points where you need to bend it. Using a bender, you apply consistent pressure to create a smooth, uniform curve that conforms to the desired radius. Different types of bends include 90-degree bends, 45-degree bends, and even compound bends (a combination of bends). It’s crucial to avoid over-bending, which can weaken the conduit and potentially cause cracks. Over time and experience, electricians develop a feel for the right amount of pressure to apply. Imagine bending a metal straw – too much force and you’ll crush it, too little, and you won’t get the proper bend. Accurate bending is all about consistent application of pressure and understanding the material’s properties.

For example, on a recent job installing conduit in a home renovation, I had to navigate a series of obstacles in the attic. Using a combination of 45-degree and 90-degree bends with a hydraulic bender, I was able to efficiently snake the conduit through the framing while maintaining a clean and safe installation.

Q 2. Describe your experience with various types of wire and cable.

My experience encompasses a wide range of wire and cable types, from standard copper THHN (Thermoplastic High Heat Resistant Nylon) and THWN (Thermoplastic High Heat Resistant Nylon with Moisture Resistance) wires used in most residential and commercial applications, to specialized cables like armored cable (BX), MC cable (Metal-Clad Cable), and even fiber optic cables.

THHN and THWN wires are common choices for their flexibility, durability, and different temperature ratings. The choice depends on the location (e.g., wet locations vs. dry) and the expected current. Armored cable (BX) provides added protection against physical damage and is often used in exposed locations. MC cable offers a similar advantage, but with a more flexible design. Understanding the ampacity (current-carrying capacity) of each wire type is critical to ensuring safe and code-compliant installations. This involves careful consideration of wire gauge and installation conditions. For instance, bundling wires together decreases the overall ampacity of the individual conductors. Fiber optic cables, on the other hand, are completely different – they transmit data via light pulses, rather than electrical current. I’ve worked with these cables on high-speed data network installations.

I am also proficient in identifying wire types by their markings and color codes, and always ensure that the correct wire type is used for the intended application to ensure both safety and compliance.

Q 3. How do you ensure proper grounding and bonding during rough-in?

Proper grounding and bonding are paramount for electrical safety. Grounding provides a path for fault currents to flow safely to the earth, preventing dangerous electrical shocks and fire hazards. Bonding connects metal components, such as conduit and boxes, to create a continuous low-impedance path for fault currents. In essence, you’re creating a network that safely diverts electricity to the ground in case of a fault.

During rough-in, I start by connecting the grounding electrode conductor (GEC) to the building’s grounding system, typically a ground rod driven into the earth. From there, I ensure that all metal conduit is properly bonded together using grounding connectors or by relying on the conduit’s inherent conductivity. Electrical boxes are then connected to the grounded conduit system. I regularly use a clamp-on ammeter to verify proper bonding and check for continuity between ground points. Testing this ensures the ground path is functioning correctly. It is important to note that plastic boxes, while allowed in specific installations, must be grounded via separate grounding wires.

For instance, I recently discovered a problem with an incomplete ground during an inspection. One of the boxes in a kitchen circuit lacked a proper connection to the grounding path. I immediately rectified this by adding the appropriate grounding wires, preventing a potential electrical hazard. Ignoring this kind of issue could result in significant safety risks and potential legal liabilities.

Q 4. What are the NEC code requirements for installing conduit?

The National Electrical Code (NEC) outlines numerous requirements for conduit installation, emphasizing safety and code compliance. Key aspects include:

- Conduit Type and Size: The NEC specifies the appropriate conduit type (rigid metal conduit (RMC), flexible metal conduit (FMC), electrical metallic tubing (EMT), etc.) based on the application and environmental conditions. The size must be large enough to accommodate the required number of wires and allow for proper bending radius.

- Bending Radius: Bends must meet minimum radius requirements to avoid damage to the conduit and the wires inside. Improper bending can crush or weaken the conduit, creating potential hazards.

- Support and Securing: Conduit must be properly supported and secured at regular intervals to prevent sagging and potential damage. The spacing between supports depends on the conduit type and size.

- Grounding and Bonding: As previously discussed, the conduit must be properly grounded and bonded to ensure a safe path for fault currents.

- Entrance and Exit Points: Conduit entrances and exits from boxes must be properly protected to prevent damage to the wires and ensure a secure installation.

- Specific location restrictions: Conduit placement needs to meet code requirements related to proximity to other services, such as gas lines, and appropriate installation within walls and ceilings.

Non-compliance with the NEC can lead to fines, project delays, and, most importantly, safety hazards. A thorough understanding of these codes is essential for any electrician.

Q 5. Explain your understanding of different types of electrical boxes and their applications.

Various types of electrical boxes serve specific purposes and applications. The choice depends on factors like the number of wires, the type of device being installed, the location, and the type of wall construction.

- Metal Boxes: These are common and provide good grounding, often made of steel or aluminum.

- Plastic Boxes: Lightweight and often used in non-metallic sheathed cable installations, they must be specifically grounded.

- Old Work Boxes: Designed for retrofitting in existing walls, they have clamps to secure them in place.

- New Work Boxes: Used during new construction, they are installed within the wall cavities.

- Gang Boxes: Accommodate multiple devices, such as multiple switches or outlets.

- Utility Boxes: Larger boxes designed for outdoor use, providing added weatherproofing.

For example, in a residential setting, I often use gang boxes to install multiple switches in a hallway or multiple receptacles in a kitchen. For outdoor installations, such as lighting fixtures on a porch, utility boxes offer increased protection against weather and physical damage.

Selecting the correct box size is crucial to ensure there’s enough space for wires and devices without overcrowding, which can create heat buildup and fire hazards. This directly relates to the volume of wire within the box – it must be within code-allowed fill levels to ensure adequate space and prevent damage.

Q 6. How do you identify and avoid potential hazards during rough-in?

Identifying and avoiding hazards is a top priority in electrical rough-in. This involves a multi-layered approach. First, proper planning and site assessment are crucial. This includes understanding where gas lines, plumbing, and other utilities are located to avoid accidental damage. I use blueprints and often confirm locations physically before starting any work. Using a stud finder is common practice to avoid puncturing plumbing and gas lines when drilling.

Secondly, following safety protocols is essential. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and work boots. Always using proper tools and equipment is key; never compromise on the condition and suitability of your tools. Thirdly, I am vigilant for potential hazards while working in attics, crawl spaces, or other confined areas where poor air quality or falling debris pose a threat. Always working with a buddy is a good habit. Regularly check for damaged wires or conduit and report them immediately to the supervisor. Finally, maintaining a clean and organized workspace helps to prevent accidents.

For instance, on one job, I noticed a section of conduit running dangerously close to a gas line. I immediately stopped work and alerted the foreman. This early detection prevented a potentially catastrophic situation. Safety checks and attention to detail are not optional; they are paramount.

Q 7. Describe your experience with installing various types of outlets and switches.

My experience includes installing a wide variety of outlets and switches, ranging from standard duplex receptacles and single-pole switches to more specialized devices like GFCI (Ground Fault Circuit Interrupter) outlets, AFCI (Arc Fault Circuit Interrupter) breakers, dimmer switches, and smart switches.

Standard duplex receptacles and single-pole switches are common in most residential and commercial applications. GFCI outlets are essential in areas prone to moisture, such as bathrooms and kitchens, offering protection from electrical shocks. AFCI breakers help protect against arc faults that can cause fires. Dimmer switches allow for adjustable lighting levels, while smart switches offer additional features such as remote control and automation. The correct installation of these devices, ensuring all connections are tight and securely fastened, requires knowledge and care. Testing the functionality of each device after installation is an essential step. The use of correct wire and appropriate grounding to each switch and outlet is paramount.

Recently, I installed a network of smart switches in a new home, integrating them with the home automation system. This required careful planning to ensure compatibility and seamless integration. Each installation type requires a certain level of attention to detail and understanding of the specific device’s features and requirements.

Q 8. How do you manage wire organization and labeling in a complex system?

Wire organization and labeling are crucial for a successful and maintainable electrical system, especially in complex projects. Think of it like a well-organized library – you need a system to find any book (wire) quickly and easily. My approach involves a multi-step process: First, I create a comprehensive wiring diagram before starting the rough-in. This serves as a roadmap, detailing the circuit numbers, wire types, and their destinations. Then, I use color-coded wires whenever possible, adhering to industry standards and local codes. Each wire is meticulously labeled at both ends using heat-shrink labels or professional-grade markers, clearly indicating the circuit number and its function (e.g., ’20-A-Lighting-Kitchen’). For large projects, I also use wire numbering systems that are logical and easy to track. Finally, I maintain a detailed log of all wiring runs, including locations and connections. This ensures future modifications or troubleshooting are simplified. In one recent project, a complex commercial building, this method allowed us to easily identify and fix a faulty circuit within minutes, minimizing downtime and frustration.

Q 9. What are your methods for ensuring the safety of electrical installations?

Safety is paramount in electrical installations. My methods are multi-faceted and focus on adherence to the National Electrical Code (NEC) and all relevant local regulations. Before any work begins, I perform a thorough site survey to identify potential hazards, such as existing gas lines or underground utilities. I always use appropriate personal protective equipment (PPE), including safety glasses, gloves, and arc-flash protective gear where necessary. I rigorously inspect all materials before installation, rejecting anything that appears damaged or substandard. During the installation process, I double-check all connections and ensure proper grounding to prevent electrical shocks and fires. Regular testing with calibrated tools, such as a multimeter, forms a critical part of my process, ensuring circuits are operating correctly and within safe voltage limits. Finally, I maintain detailed records of all safety checks performed. One time, during a residential retrofit, my meticulous inspection revealed a faulty ground connection – a potential fire hazard that was easily resolved, highlighting the critical role of safety protocols.

Q 10. Explain your experience with installing raceways and cable trays.

I have extensive experience installing a variety of raceways and cable trays, selecting the appropriate type based on the specific project needs and environmental considerations. For example, I regularly use EMT (electrical metallic tubing) for its versatility and cost-effectiveness in residential and light commercial applications. In more demanding situations, such as those involving harsh environments or high voltage, I prefer rigid conduit for its superior protection. For larger projects that require organized cable management, I utilize cable trays, properly securing them to structural members according to load capacity calculations. I am proficient in all aspects of raceway installation, including bending, threading, connecting, and grounding. I’m also skilled in using various tools such as a bender, threader, and knockout punch to ensure clean and accurate installations. One particularly challenging project involved navigating a tight, existing space in an older building while adhering to strict regulations. Through precise planning and execution, we successfully installed a new electrical system using EMT and strategically-placed cable trays, demonstrating my ability to work within constraints.

Q 11. How do you handle unexpected issues or changes during a rough-in project?

Unexpected issues are inevitable in construction. My approach involves proactive planning, open communication, and problem-solving skills. First, I thoroughly review blueprints and specifications to anticipate potential problems. However, if unexpected changes occur, I immediately document the situation, photograph it, and consult with the project supervisor or engineer. We discuss possible solutions, prioritizing safety and compliance. If significant design changes are needed, I collaborate on updating the plans and make the necessary modifications. For example, in one project, we discovered an unforeseen obstruction during conduit installation. By quickly adapting our strategy and using a different routing, we avoided major delays and kept the project on schedule. This highlights the importance of adaptability and strong communication within the team.

Q 12. Describe your experience with different types of termination devices.

My experience encompasses a wide range of termination devices, tailored to specific applications. I am proficient in using various types of connectors, including wire nuts, crimp connectors, and terminal blocks for low-voltage applications. For higher voltage systems, I utilize specialized connectors and lugs, ensuring secure and reliable connections. I also have experience with different types of receptacles and switches, from standard household outlets to heavy-duty industrial options. My knowledge extends to specialized termination methods such as compression connectors for grounding wires and properly installing disconnects and circuit breakers. Regularly, I’m involved in ensuring proper torque is applied to ensure consistent and secure connections. I recently completed a project requiring specialized high-amperage connectors for a large industrial machine; my expertise in this area prevented any potential downtime or safety issues.

Q 13. What are the common causes of electrical faults, and how do you troubleshoot them?

Common electrical faults can stem from several sources. Loose connections, damaged wiring, faulty switches or receptacles, and overloaded circuits are frequently encountered. Troubleshooting begins with a visual inspection, carefully examining wires, connections, and equipment for any signs of damage or overheating. Then, I use a multimeter to test for voltage, continuity, and resistance. Identifying the location of the fault is key, and often this is done through systematically checking circuits and components. For example, a tripped breaker might indicate an overloaded circuit, while a flickering light could point to a loose connection or faulty wiring. Understanding the principles of electricity, and how each component functions, is crucial for effective troubleshooting. In one instance, a mysterious power outage was traced to a corroded neutral connection in the main panel – a problem quickly solved once properly identified.

Q 14. Explain your understanding of voltage drop calculations.

Voltage drop calculations are essential to ensure sufficient voltage reaches the end of a circuit, preventing underperformance and potential damage to equipment. These calculations consider the length of the wire, the wire’s gauge (size), and the current (amperage) it carries. A larger voltage drop means more energy is lost as heat in the wires. This is crucial for proper circuit operation. Using online calculators or industry standard formulas, I determine the appropriate wire gauge to minimize voltage drop and comply with NEC guidelines. Improperly sized wires can lead to inefficient operation, and ultimately, equipment failure and potential fire hazards. For example, in a large commercial project, accurate voltage drop calculations ensured we specified the correct wire size for long runs, delivering sufficient power to all endpoints without issues.

Q 15. How do you ensure compliance with local electrical codes?

Ensuring compliance with local electrical codes is paramount for safety and legality. My approach involves a multi-step process. First, I meticulously review the project’s specifications and obtain the relevant local electrical code books (like the National Electrical Code (NEC) and any local amendments). I then cross-reference these codes with the project blueprints and specifications throughout the entire rough-in process. This proactive approach prevents costly rework and ensures the installation meets all legal requirements.

For instance, when working on a residential project, I carefully check the requirements for grounding, circuit breaker sizing, and the proper spacing of outlets as specified in the NEC. I document every step of the process, maintaining detailed records of materials used, inspections conducted, and any deviations from the plan (always justified and approved).

Regular communication with the inspector is crucial. I schedule pre-inspections to address potential concerns before they become major issues. This proactive approach avoids delays and ensures a smooth final inspection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret electrical drawings and blueprints?

Interpreting electrical drawings and blueprints requires a keen eye for detail and a solid understanding of electrical symbols and conventions. I begin by carefully reviewing the legend to familiarize myself with the symbols used. Then, I systematically trace each circuit from the panel to the various outlets, switches, and fixtures. I look for details like wire sizes, conduit types, and grounding requirements. The information is vital for proper material selection and accurate installation.

For example, a drawing might show a 20-amp circuit running to a kitchen outlet bank. This tells me I need to use 12-gauge wire (as per NEC guidelines for 20-amp circuits) and a 20-amp breaker in the panel. I also check for specific notes or annotations on the drawings which might include details such as special grounding requirements or cable routing.

Beyond the technical aspects, I consider the practical implications. I look for potential clashes between different systems (e.g., plumbing and electrical), and identify areas where I might need to coordinate with other trades. This holistic view ensures a smooth installation process.

Q 17. Explain your experience with working at heights and in confined spaces.

I have extensive experience working at heights and in confined spaces, always prioritizing safety. When working at heights, I strictly adhere to fall protection protocols. This includes using appropriate harnesses, lanyards, and fall arrest systems, always ensuring they are correctly anchored to a secure point. I also make sure the work area is free from obstructions and that I am adequately trained on the use of the equipment.

In confined spaces, such as crawlspaces or attics, I employ proper ventilation to ensure sufficient oxygen and to minimize the risk of hazardous gas buildup. I also use a buddy system – always having a second person present to monitor and assist, and to ensure someone is available to get help if an emergency arises. I never enter a confined space without a pre-entry checklist and proper respiratory protection if needed.

For instance, while working in an attic to run wiring for new recessed lighting, I utilized a harness attached to the roof trusses, ensuring my safety. Another instance involved working within a small utility closet to install wiring for a new outlet; ensuring proper ventilation and working with a colleague significantly reduced the risk.

Q 18. Describe your experience using different types of hand tools and power tools.

My tool proficiency encompasses a wide range of hand and power tools commonly used in electrical rough-in. I’m experienced with hand tools like wire strippers, fish tapes, voltage testers, and various screwdrivers. Proficiency with these tools is crucial for precise and efficient work, from stripping wire ends and connecting them to terminations to preparing and securing conduit.

Power tools I regularly utilize include drills, reciprocating saws, and hole saws for precise cutting and drilling into various materials including wood, metal studs, and drywall. Safety is paramount when using power tools – I always use appropriate personal protective equipment (PPE), such as safety glasses and hearing protection, and I understand the capabilities and limitations of each tool to prevent damage to materials or injury to myself or others.

For example, I recently used a reciprocating saw to carefully cut a section of drywall to install a new junction box, ensuring I didn’t damage any existing wires or plumbing. Another example involves using a specialized drill bit to cut a precise hole in a metal electrical box to accommodate a cable.

Q 19. What is your experience with installing and testing lighting fixtures?

I’m experienced in installing and testing a variety of lighting fixtures, from simple recessed lights to complex chandeliers. The process starts with verifying the fixture’s voltage and amperage requirements against the circuit specifications. I then carefully install the fixture according to the manufacturer’s instructions, paying close attention to proper grounding and wiring connections. I always use the correct size wire and connectors to ensure proper performance and safety. Testing is crucial, and involves verifying that the fixture is properly grounded, receiving the correct voltage, and functioning without any issues.

Testing involves using a voltage tester to confirm that power is correctly reaching the fixture and then switching on the light to check its operational state. I pay close attention to the operational state of the fixture, checking for any flickering or unusual behaviour which may indicate a problem. Thorough testing helps avoid callbacks and ensures customer satisfaction.

A recent project involved installing a series of LED recessed lights. After wiring and securing each fixture, I carefully tested each one individually to ensure proper operation before moving on to the next.

Q 20. How do you maintain a safe and organized work environment?

Maintaining a safe and organized work environment is non-negotiable. My approach involves several key practices. First, I always keep the work area clean and free of debris, ensuring proper pathways and avoiding tripping hazards. Tools are organized and stored securely, ensuring easy access but minimizing the risk of accidental injury. I clearly mark potential hazards, using caution tape to indicate areas with exposed wiring or other dangers.

Second, I adhere strictly to all safety regulations, including the use of PPE such as safety glasses, work gloves, and steel-toed boots. I regularly check my tools to ensure they are in good working order. Moreover, I understand and follow all relevant lockout/tagout procedures when working on live circuits.

For example, I recently completed a remodel job where safety was paramount. We had a system for marking and securing all circuits before opening up walls, clearly labeling each wire for easy identification and ensuring a well-organized process. Our organized approach significantly reduced the risk of errors and enhanced overall efficiency.

Q 21. Describe your experience with different types of conduit materials.

My experience encompasses several conduit materials, each with its own strengths and applications. I’m proficient in working with metallic conduit (such as steel and aluminum), which provides superior protection against physical damage and offers excellent grounding capabilities. However, it can be more challenging to bend and install compared to other materials.

I also have experience with non-metallic conduit (such as PVC), often preferred for its ease of installation and lower cost. PVC is a good choice for many residential applications, but its protective capabilities are less robust than metal conduit. Choosing the right conduit is essential for meeting local code requirements and ensuring both the electrical system’s safety and longevity.

The selection of conduit material depends heavily on the project’s location and requirements; for example, in areas with high risks of physical damage, metal conduit may be necessary. In less demanding environments, non-metallic conduit is often adequate and cost-effective. Understanding the properties of different conduit types is essential for making informed decisions and ensures compliance.

Q 22. Explain your understanding of circuit breaker sizing and selection.

Circuit breaker sizing is crucial for safety and efficiency. It’s all about matching the breaker’s amperage rating to the wire gauge and the expected load of the circuit. A breaker that’s too small will trip frequently, while one that’s too large could lead to overheating, fire hazards, and damage to equipment.

We calculate the load by adding up the wattage of all appliances and lights on a circuit, then divide by the voltage (typically 120V or 240V) to get the amperage. For example, if a circuit has a total load of 1800W on a 120V system, the required amperage is 1800W / 120V = 15A. In this case, a 15-amp breaker would be appropriate. However, we always consider a safety factor and often round up to the nearest standard breaker size (15A, 20A, 30A, etc.). We also need to ensure the wire gauge is sufficient to handle the amperage safely. This is referenced in the NEC (National Electrical Code).

Selecting the right breaker is a critical safety measure. I’ve personally seen instances where an incorrectly sized breaker led to a fire, reinforcing the importance of accurate calculation and adherence to the NEC.

Q 23. How do you ensure proper ventilation in electrical enclosures?

Proper ventilation in electrical enclosures is paramount to prevent overheating and ensure the longevity of the equipment. Heat buildup can significantly reduce the lifespan of components and even pose a fire risk.

Several methods ensure adequate ventilation: sufficient free air space around components within the enclosure, using appropriately sized and positioned vents or louvers for airflow, and ensuring the enclosure itself isn’t blocked or obstructed. We often utilize fans for larger enclosures or those with high heat loads. For example, in a server room, I would always incorporate fans and ensure ample spacing to allow for convection cooling. Another important aspect is to ensure that any ventilation openings aren’t obstructed by debris or other materials.

I always prioritize proper ventilation – it’s a simple yet effective way to avoid major problems down the line.

Q 24. Explain your experience with various grounding methods.

Grounding is fundamental to electrical safety. It provides a low-resistance path for fault currents to flow back to the source, preventing dangerous voltage buildup and protecting people and equipment.

- Grounding Rod System: This involves driving a grounding rod into the earth and connecting it to the electrical system’s grounding electrode. This is a common method for residential and smaller commercial buildings.

- Grounding Electrode System: This involves connecting the system to metal water pipes, or other metallic underground structures that provide a low-impedance path to earth. This method requires careful inspection to ensure proper connection and conductivity.

- Plate Grounding: Used in situations where grounding rods are impractical, such as areas with rocky soil. This utilizes large metal plates buried in the ground.

The choice of grounding method depends on factors like soil conductivity, the size of the electrical system, and local codes. In my experience, I’ve worked with all three methods and always prioritize proper testing to ensure the ground resistance is within acceptable limits. Poor grounding can lead to serious safety risks, so careful planning and execution are essential.

Q 25. Describe your experience with working with other trades on a construction site.

Collaboration with other trades is vital on any construction site. Effective communication and coordination are key to a successful project and preventing conflicts.

I’ve worked closely with framers, drywallers, plumbers, and HVAC technicians. For example, I’ve coordinated with framers to ensure proper placement of electrical boxes before drywall installation. With plumbers, we coordinate the routing of pipes and electrical conduits to avoid conflicts and ensure safety. Clear communication, regular meetings, and respect for each trade’s expertise are fundamental to a smooth workflow. Building strong relationships with other trades ensures that problems are identified and solved efficiently.

Q 26. What are your preferred methods for calculating material requirements?

Accurate material calculation is essential for efficient project management and cost control. My preferred methods are based on a detailed plan review, utilizing software for quantity take-off, and leveraging my experience to account for potential waste or unforeseen needs.

I start by thoroughly reviewing the architectural and electrical plans to identify all the components needed. Then, I input the data into software (like Bluebeam or similar) to generate a detailed list of materials. This includes the number of conduits, wires, boxes, breakers, and other equipment. I always factor in a percentage for waste and potential changes during construction. My experience allows me to anticipate potential issues and account for them in my calculations, preventing delays and cost overruns.

Q 27. How do you prioritize tasks and manage time effectively on a construction site?

Effective task prioritization and time management on a construction site are crucial for meeting deadlines and staying within budget.

I use a combination of techniques, including creating detailed schedules, breaking down larger tasks into smaller, manageable steps, and prioritizing critical path items. For example, I would prioritize rough-in wiring to accommodate other trades’ schedules. Using a project management software or a simple spreadsheet helps maintain schedules and track progress. Regular site meetings with the superintendent and other trades help to identify any potential delays and allow for proactive problem-solving.

Flexibility is key. Construction sites are dynamic environments, so I remain adaptable to changing priorities and unforeseen circumstances.

Q 28. Describe your experience with troubleshooting electrical problems post-rough-in

Troubleshooting electrical problems post-rough-in requires a systematic approach and a thorough understanding of electrical systems.

My approach starts with a visual inspection, followed by using testing equipment like multimeters and voltage testers to pinpoint the issue. This could involve checking for loose connections, faulty wiring, or malfunctioning devices. I’ve encountered situations involving incorrect wiring, grounded circuits, and faulty breakers during post-rough-in inspections. These were solved by retracing the wiring, checking ground connections, and replacing faulty components. Detailed documentation is crucial during troubleshooting to ensure a clear understanding of the problem and the solution implemented. I also focus on preventing similar problems in future projects by learning from past experiences.

Key Topics to Learn for Electrical Rough-In Interview

- Blueprint Reading and Interpretation: Understanding electrical schematics, symbols, and specifications to accurately plan installations.

- Wiring Methods and Techniques: Proficiency in various wiring methods (e.g., Romex, conduit bending, pulling wire) and adherence to safety regulations.

- Electrical Code Compliance (NEC): Demonstrate thorough knowledge of relevant National Electrical Code articles and their practical application in rough-in work.

- Planning and Layout: Efficiently planning and executing the electrical layout within a structure, considering load calculations and future needs.

- Box and Fixture Installation: Proper installation of electrical boxes, ensuring secure mounting and adherence to code requirements for various fixture types.

- Grounding and Bonding: Understanding the importance and procedures for proper grounding and bonding to ensure safety and code compliance.

- Troubleshooting Basic Electrical Issues: Demonstrating the ability to identify and address common problems encountered during the rough-in process.

- Safety Procedures and Practices: Highlighting a strong commitment to safety regulations, including proper use of PPE and lockout/tagout procedures.

- Tools and Equipment Familiarity: Demonstrating knowledge of various hand and power tools used in electrical rough-in, including their safe and efficient operation.

- Communication and Teamwork: Emphasize effective communication with other tradespeople and the ability to work collaboratively on a construction site.

Next Steps

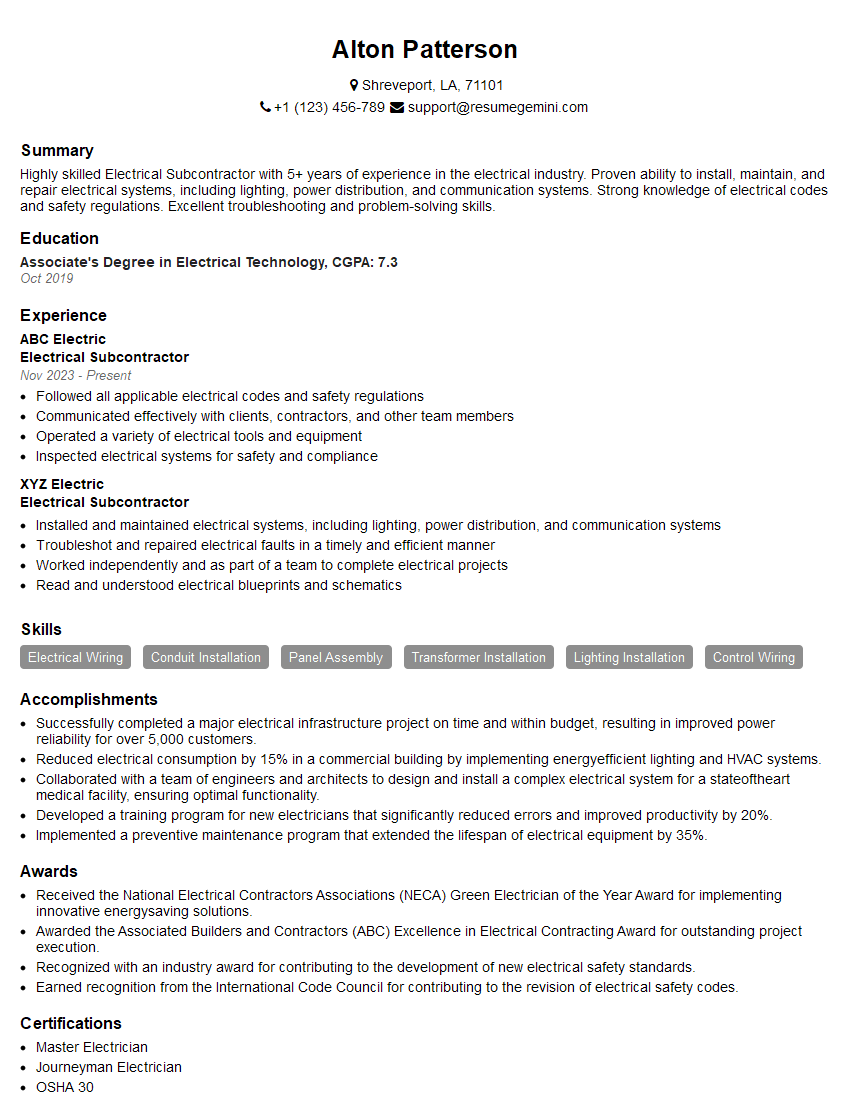

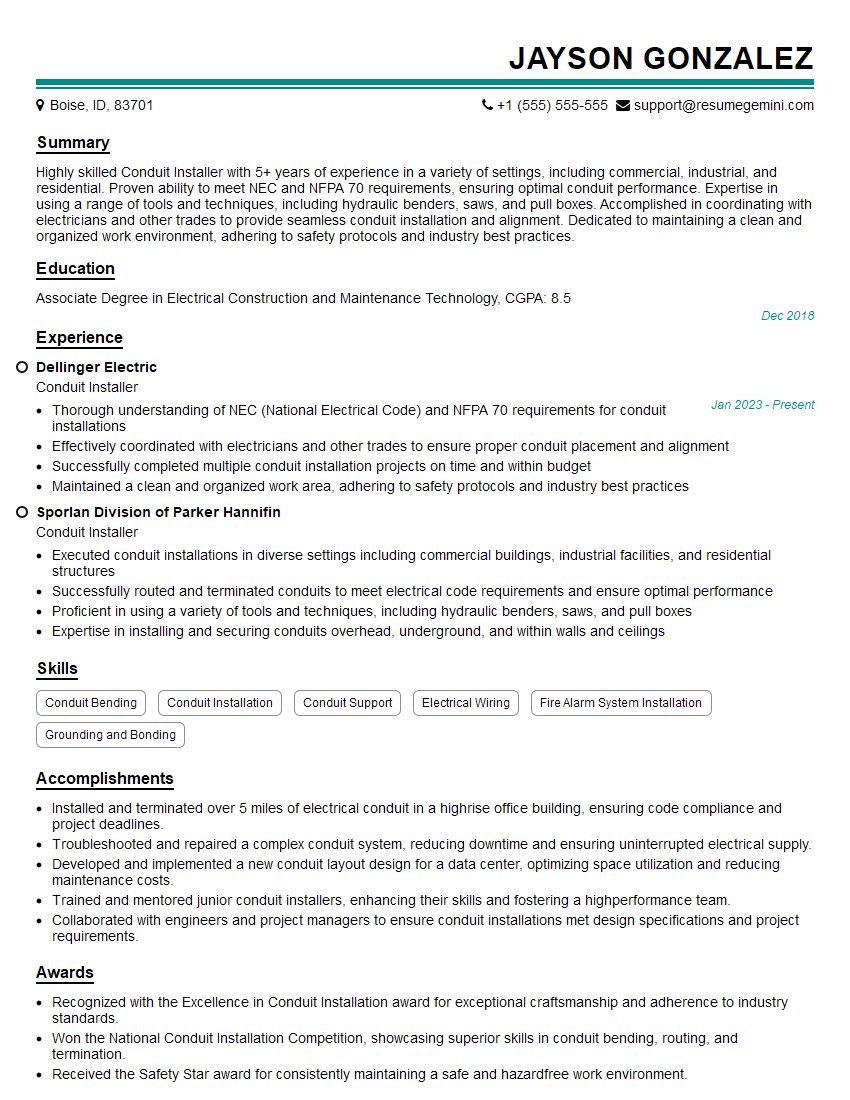

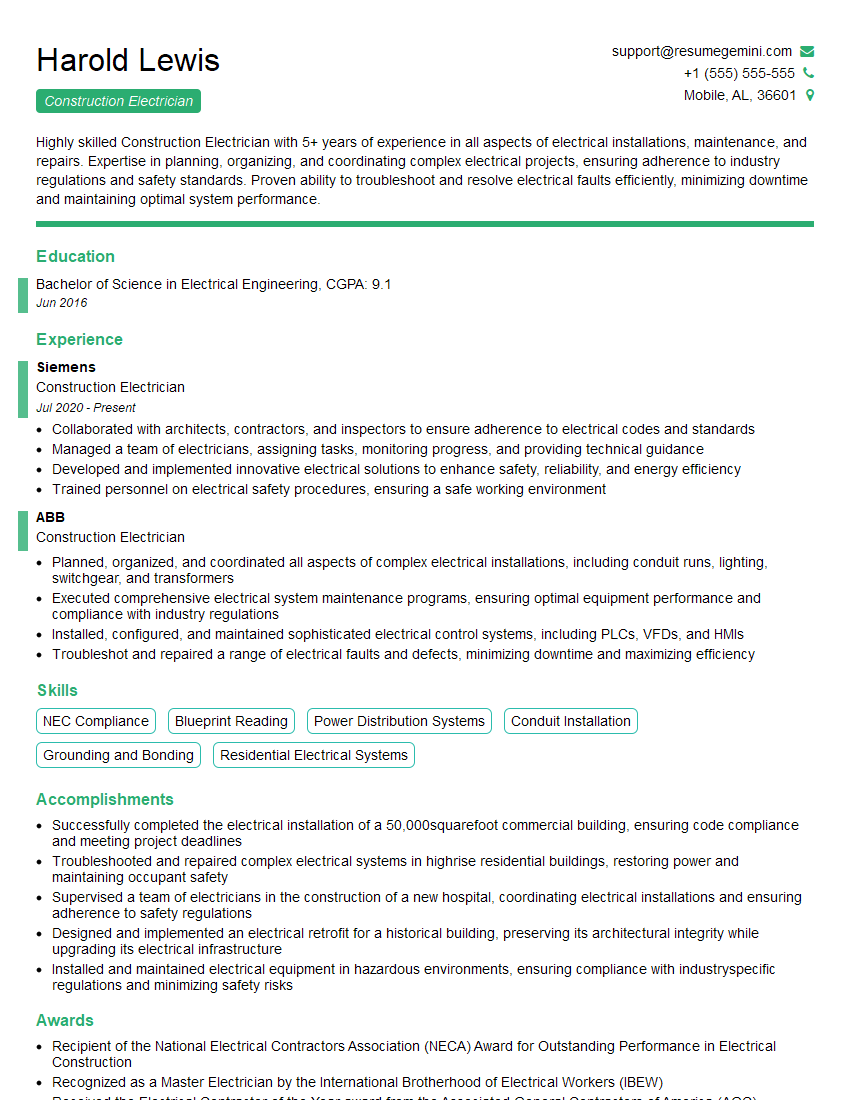

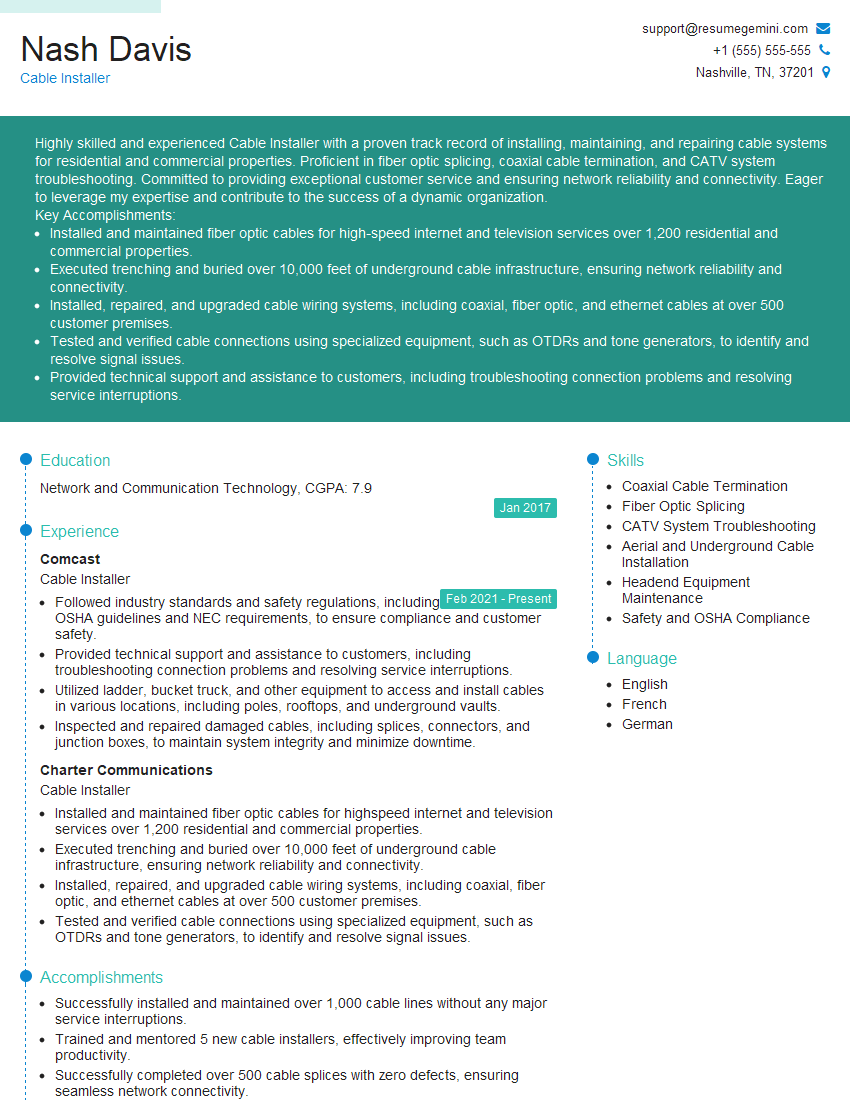

Mastering Electrical Rough-In is crucial for career advancement in the construction industry, opening doors to higher-paying roles and increased responsibility. A well-crafted resume is your key to unlocking these opportunities. To maximize your chances of landing your dream job, create an ATS-friendly resume that highlights your skills and experience effectively. We recommend using ResumeGemini, a trusted resource for building professional resumes that get noticed. ResumeGemini provides examples of resumes tailored to Electrical Rough-In, ensuring your application stands out from the competition. Invest the time to build a strong resume; it’s an investment in your future.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good